wheel AUDI A4 1998 B5 / 1.G Suspension Front Axle Components Workshop Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 1998, Model line: A4, Model: AUDI A4 1998 B5 / 1.GPages: 26, PDF Size: 0.33 MB

Page 1 of 26

40-17

Front drive axles, removing

and installing

WARNING!

Do not re-use any fasteners that are worn or

deformed in normal use.

Some fasteners are designed to be used only

once, and are unreliable and may fail if used

a second time. This includes, but is not

limited to, nuts, bolts, washers, circlips and

cotter pins. Always follow the

recommendations in this manual-replace

these fasteners with new parts where

indicated, and any other time it is deemed

necessary by inspection.

Removing

- Remove wheel trim.

On light-alloy wheels use puller in vehicle tool kit

to remove trim cap

- Remove collar bolt for drive axle.

WARNING!

The vehicle must be standing on its wheels

Pa

ge 1 of 26 Front drive axles, removin

g and installin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.SU01.40.3

Page 2 of 26

when loosening or tightening the collar bolt

for the drive axle (item - 17 -, page Page 40

-

4 ). Otherwise the risk of an accident exists.

- Remove wheel.

Pa

ge 2 of 26 Front drive axles, removin

g and installin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.SU01.40.3

Page 3 of 26

40-18

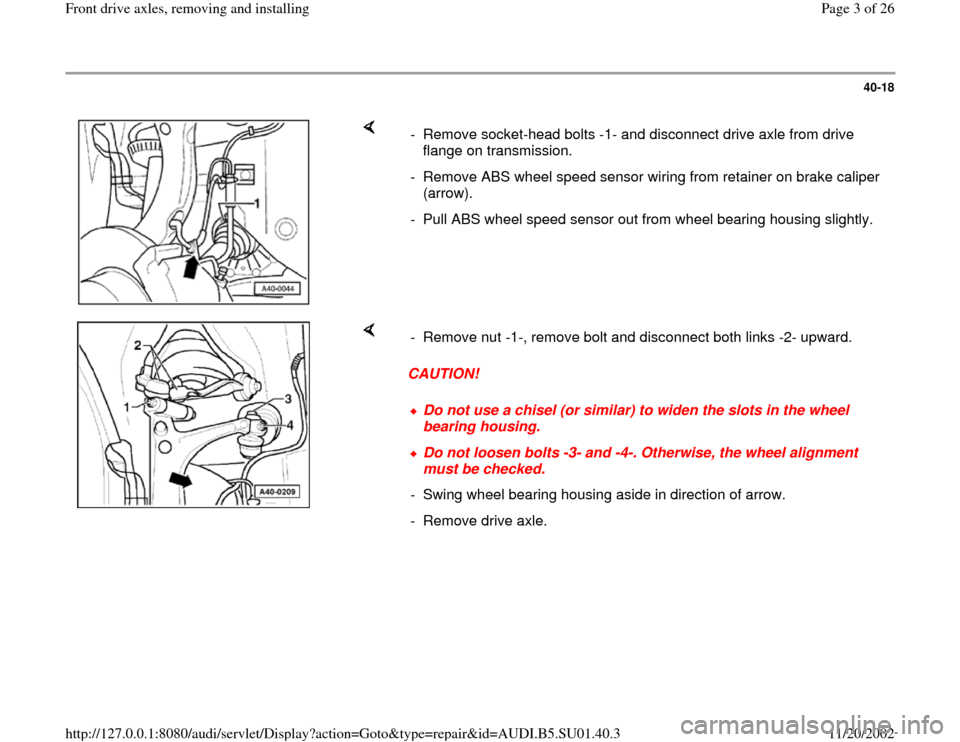

- Remove socket-head bolts -1- and disconnect drive axle from drive

flange on transmission.

- Remove ABS wheel speed sensor wiring from retainer on brake caliper

(arrow).

- Pull ABS wheel speed sensor out from wheel bearing housing slightly.

CAUTION! - Remove nut -1-, remove bolt and disconnect both links -2- upward.

Do not use a chisel (or similar) to widen the slots in the wheel

bearing housing. Do not loosen bolts -3- and -4-. Otherwise, the wheel alignment

must be checked.

- Swing wheel bearing housing aside in direction of arrow.

- Remove drive axle.

Pa

ge 3 of 26 Front drive axles, removin

g and installin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.SU01.40.3

Page 4 of 26

40-19

Installing

- Install drive axle into wheel bearing housing and

bolt it to drive flange on transmission.

- Install both upper links and tighten nut to 40 Nm

(30 ft lb).

When tightening, press upper links downward as

far as possible

- Fully tighten bolts connecting drive axle to drive

flange on transmission.

M8 bolts: 40 Nm (30 ft lb)

M10 bolts: 80 Nm (59 ft lb)

- Push ABS wheel speed sensor into wheel

bearing housing up to stop and insert sensor

wiring into retainer on brake caliper.

- Install wheel.

- Install and tighten new bolt for drive axle.

M14 bolt: 115 Nm (85 ft lb) + 1/2-turn (180

Pa

ge 4 of 26 Front drive axles, removin

g and installin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.SU01.40.3

Page 5 of 26

(180 )

M16 bolt: 190 Nm (140 ft lb) + 1/2-turn

(180 )

WARNING!

The vehicle must be standing on its wheels

when loosening or tightening the collar bolt

for the drive axle (item - 17 -, page Page 40

-

4 ). Otherwise the risk of an accident exists.

Pa

ge 5 of 26 Front drive axles, removin

g and installin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.SU01.40.3

Page 11 of 26

40-24

Plastic CV joint boots

Special tools, test equipment and auxiliary

items

VAG1275 3207 VW411

VW401/402 VW412 VW522

40-204 A VAG1682 3340

On the Audi A4, new plastic CV joint boots are

installed on the 88 mm outer joint (wheel end) of

the front axle.

The plastic boots can be identified because they

are made out of a harder material than the

rubber boots.

The harder plastic boots necessitates the use of

stainless steel clamps for attaching the boots.

Pa

ge 11 of 26 Front drive axles, removin

g and installin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.SU01.40.3

Page 18 of 26

40-31

4 -

Clamps

Always replaceTightening Fig.1

5 -

Boot for outer constant velocity joint

Check for splits and abrasionsBefore tightening clamp, briefly lift end of

boot to equalize pressure (ventilate) Fig. 3 As of chassis no. 8DTA 279 794, new

boots were introduced for 88 mm outer

joint (wheel end) Fig. 1

6 -

Clamp

Always replaceTightening Fig. 1

7 -

Spring washer

Installation position Fig. 5

Pa

ge 18 of 26 Front drive axles, removin

g and installin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.SU01.40.3

Page 25 of 26

40-38

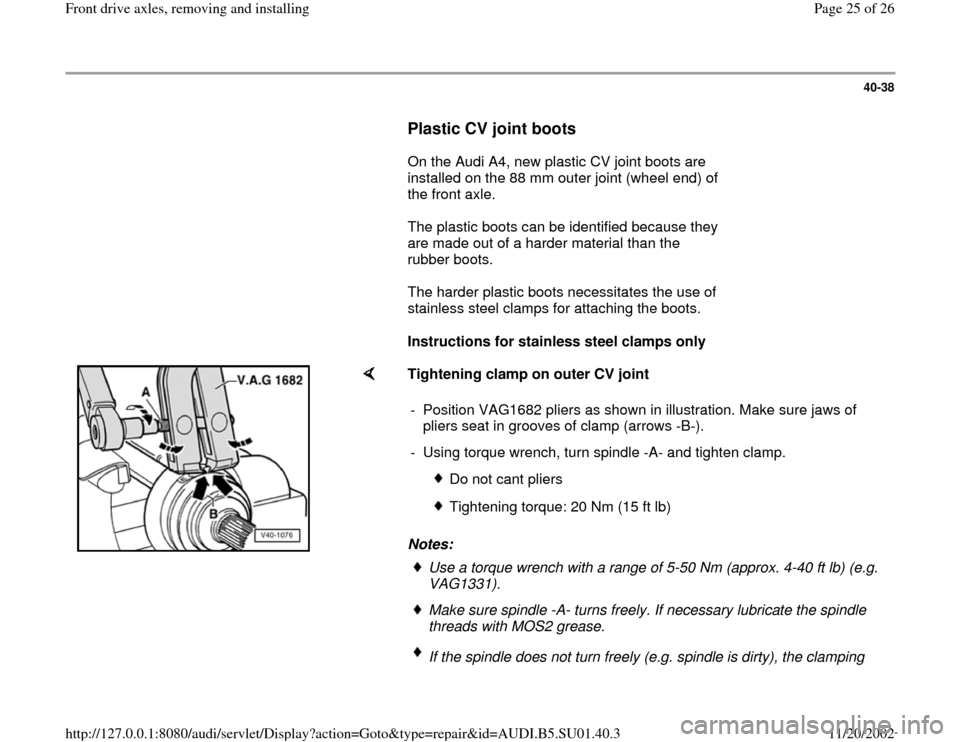

Plastic CV joint boots

On the Audi A4, new plastic CV joint boots are

installed on the 88 mm outer joint (wheel end) of

the front axle.

The plastic boots can be identified because they

are made out of a harder material than the

rubber boots.

The harder plastic boots necessitates the use of

stainless steel clamps for attaching the boots.

Instructions for stainless steel clamps only

Tightening clamp on outer CV joint

Notes: - Position VAG1682 pliers as shown in illustration. Make sure jaws of

pliers seat in grooves of clamp (arrows -B-).

- Using torque wrench, turn spindle -A- and tighten clamp.

Do not cant pliers

Tightening torque: 20 Nm (15 ft lb)

Use a torque wrench with a range of 5-50 Nm (approx. 4-40 ft lb) (e.g.

VAG1331). Make sure spindle -A- turns freely. If necessary lubricate the spindle

threads with MOS2 grease. If the spindle does not turn freely (e.g. spindle is dirty), the clamping

Pa

ge 25 of 26 Front drive axles, removin

g and installin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.SU01.40.3