AUDI A4 1999 B5 / 1.G AEB ATW Engines Lubrication System Components User Guide

Manufacturer: AUDI, Model Year: 1999,

Model line: A4,

Model: AUDI A4 1999 B5 / 1.G

Pages: 33, PDF Size: 0.6 MB

AUDI A4 1999 B5 / 1.G AEB ATW Engines Lubrication System Components User Guide

A4 1999 B5 / 1.G

AUDI

AUDI

https://www.carmanualsonline.info/img/6/953/w960_953-0.png

AUDI A4 1999 B5 / 1.G AEB ATW Engines Lubrication System Components User Guide

Trending: oil level, oil temperature, oil capacity, low oil pressure, sensor, drain bolt, oil filter

Page 11 of 33

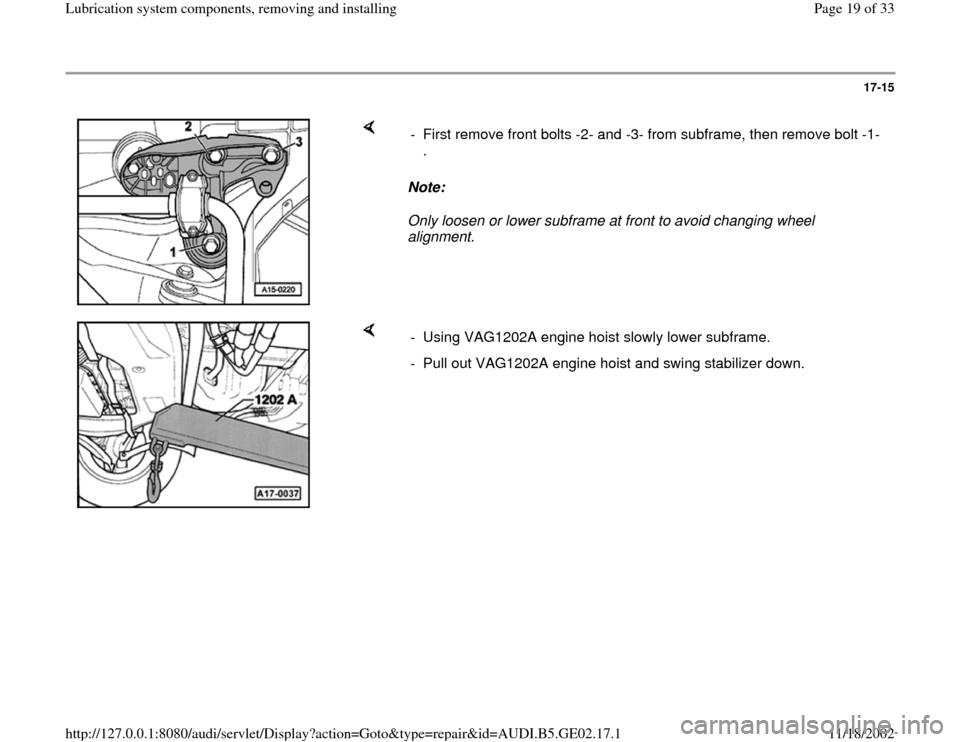

17-7

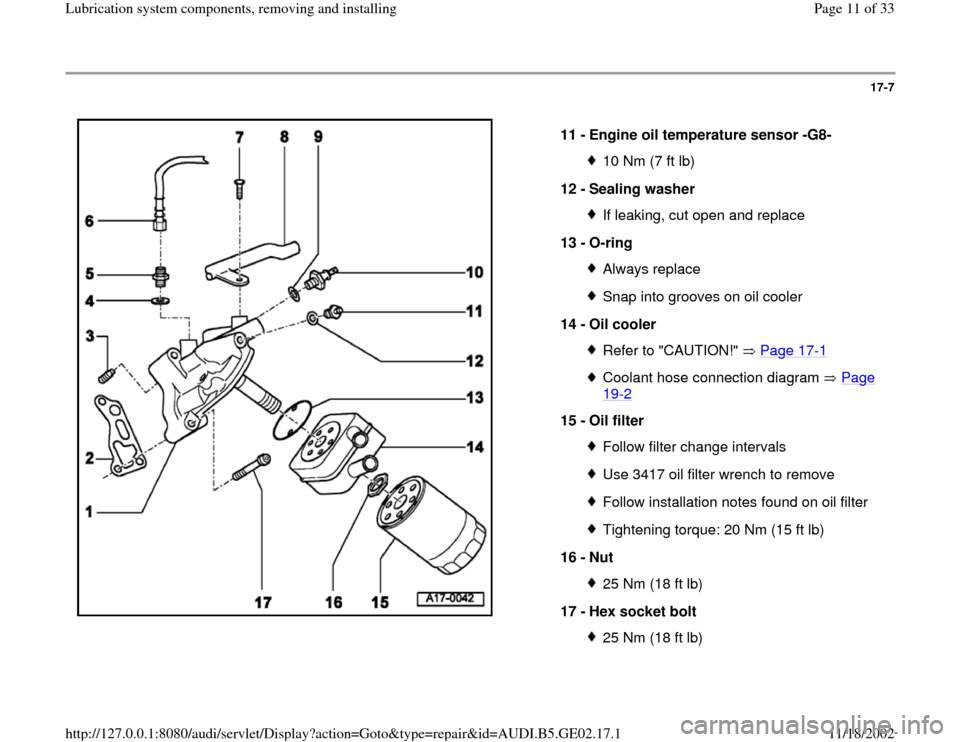

11 -

Engine oil temperature sensor -G8-

10 Nm (7 ft lb)

12 -

Sealing washer If leaking, cut open and replace

13 -

O-ring Always replaceSnap into grooves on oil cooler

14 -

Oil cooler Refer to "CAUTION!" Page 17

-1

Coolant hose connection diagram Page 19

-2

15 -

Oil filter

Follow filter change intervalsUse 3417 oil filter wrench to removeFollow installation notes found on oil filterTightening torque: 20 Nm (15 ft lb)

16 -

Nut 25 Nm (18 ft lb)

17 -

Hex socket bolt 25 Nm (18 ft lb)

Pa

ge 11 of 33 Lubrication s

ystem com

ponents, removin

g and installin

g

11/18/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE02.17.1

Page 12 of 33

17-8

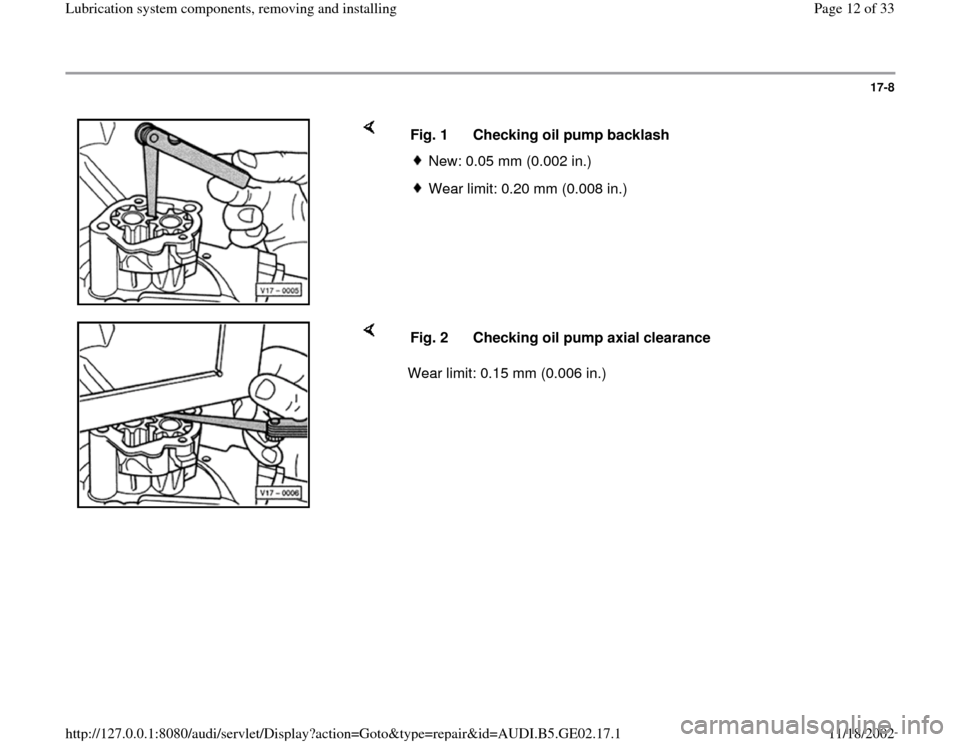

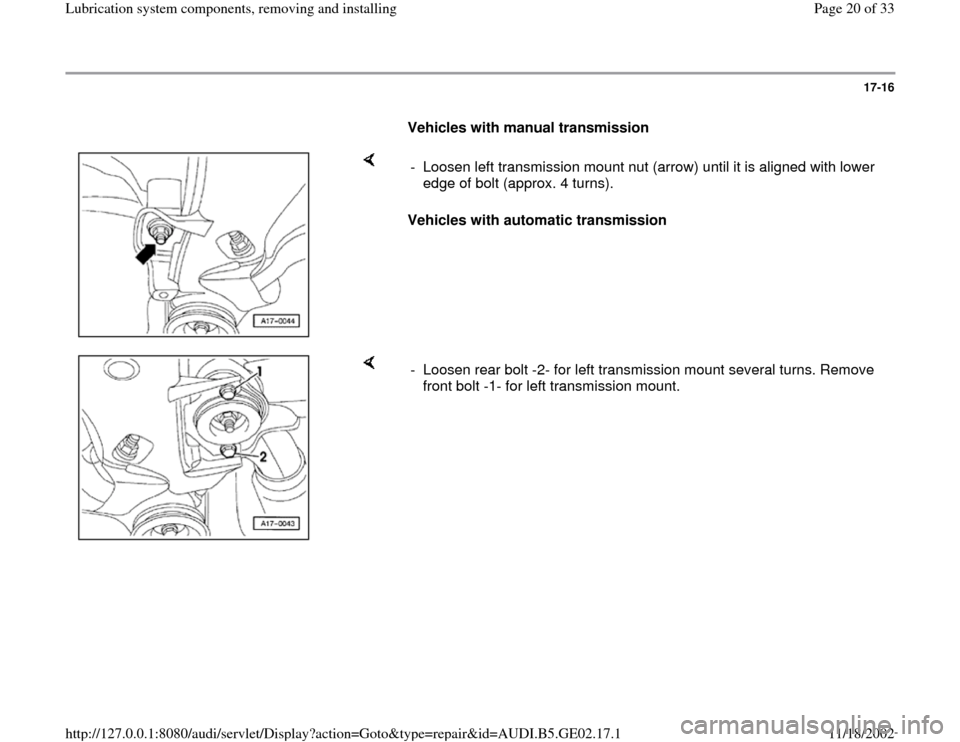

Fig. 1 Checking oil pump backlash

New: 0.05 mm (0.002 in.) Wear limit: 0.20 mm (0.008 in.)

Wear limit: 0.15 mm (0.006 in.) Fig. 2 Checking oil pump axial clearance

Pa

ge 12 of 33 Lubrication s

ystem com

ponents, removin

g and installin

g

11/18/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE02.17.1

Page 13 of 33

17-9

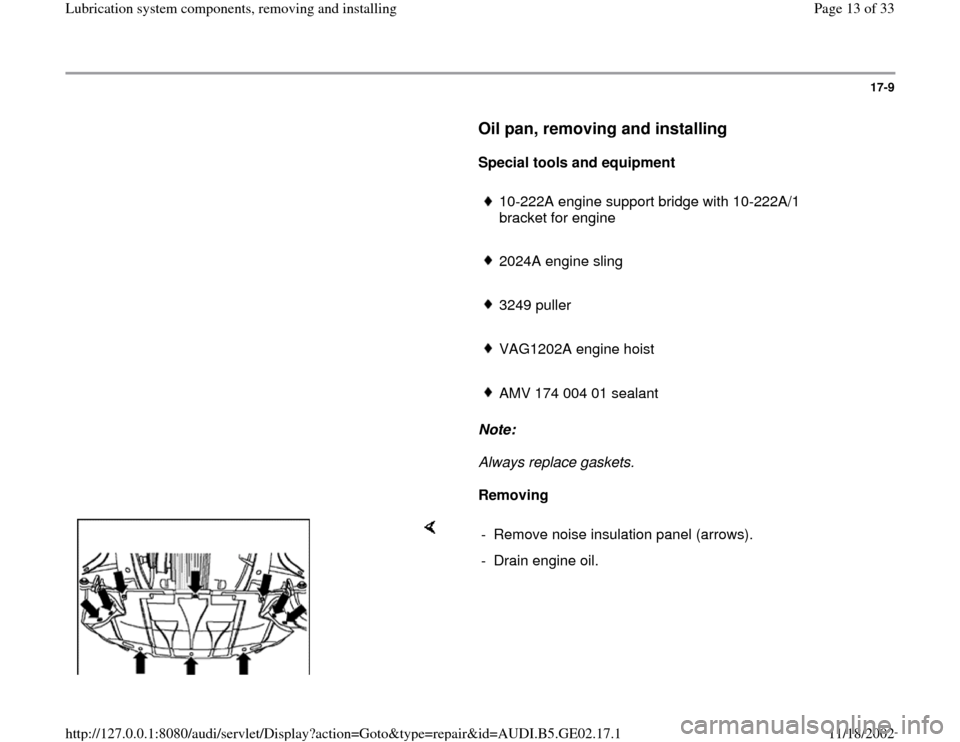

Oil pan, removing and installing

Special tools and equipment

10-222A engine support bridge with 10-222A/1

bracket for engine

2024A engine sling

3249 puller

VAG1202A engine hoist

AMV 174 004 01 sealant

Note:

Always replace gaskets.

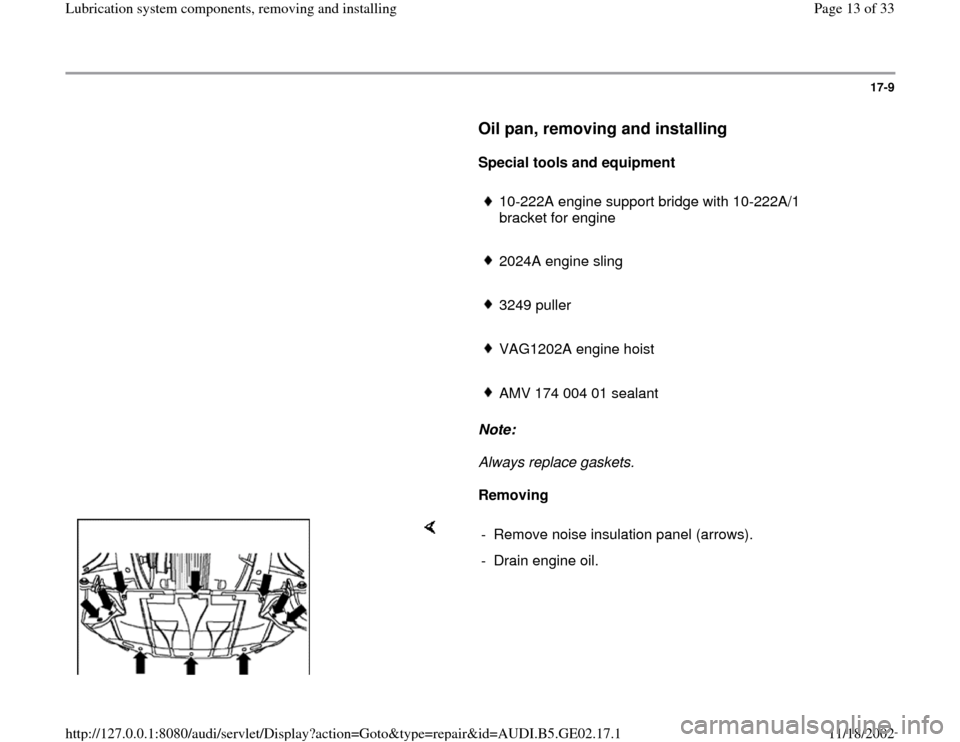

Removing

- Remove noise insulation panel (arrows).

- Drain engine oil.

Pa

ge 13 of 33 Lubrication s

ystem com

ponents, removin

g and installin

g

11/18/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE02.17.1

Page 14 of 33

17-10

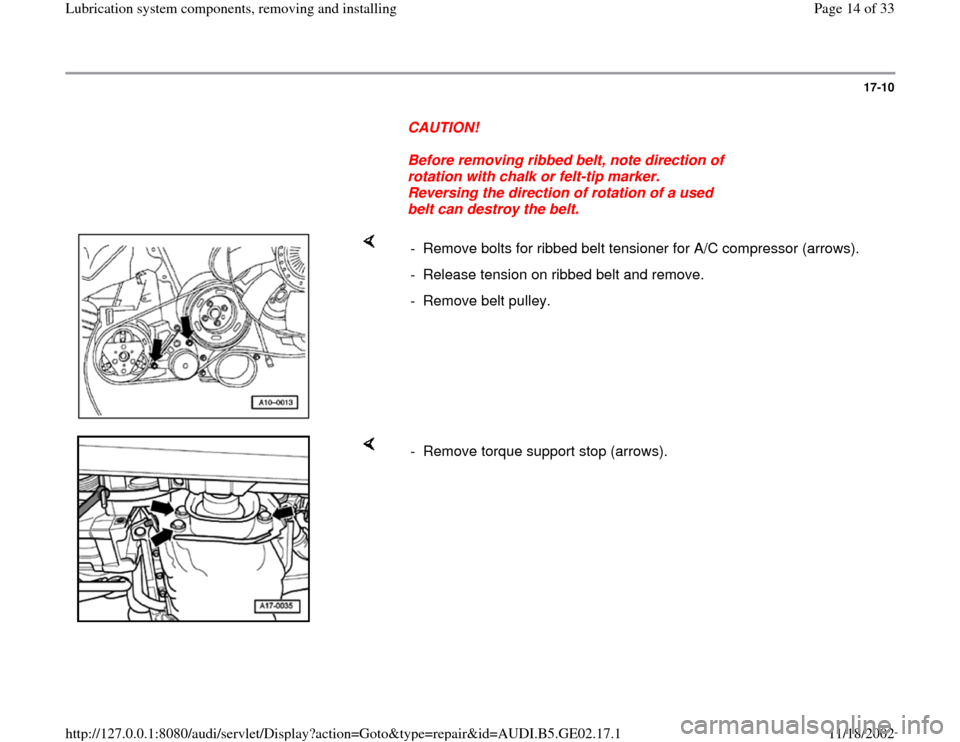

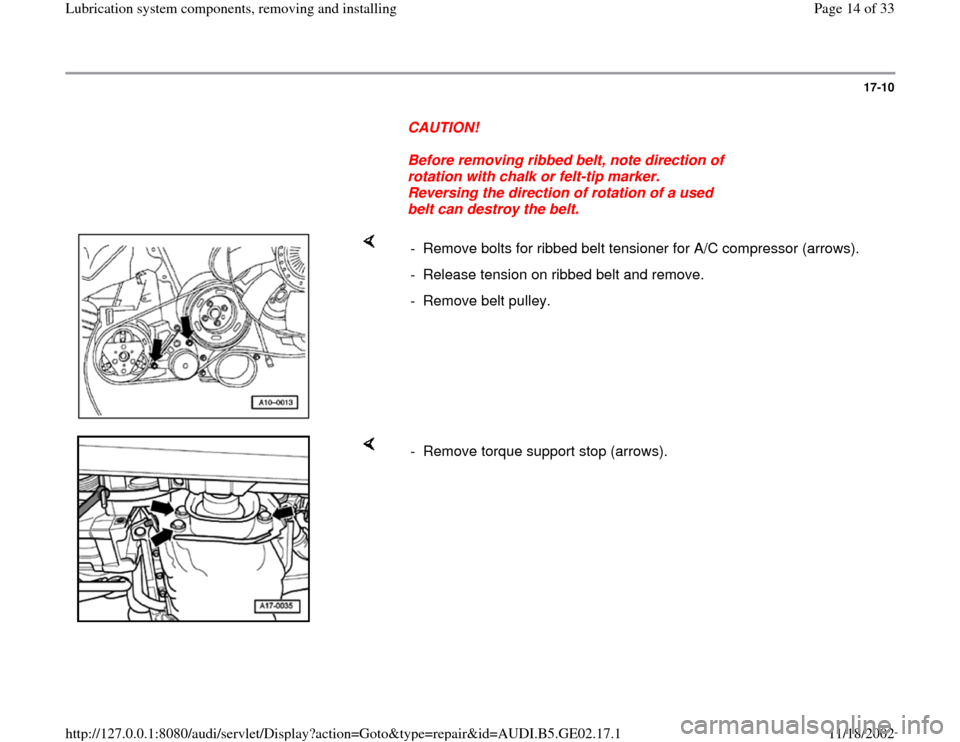

CAUTION!

Before removing ribbed belt, note direction of

rotation with chalk or felt-tip marker.

Reversing the direction of rotation of a used

belt can destroy the belt.

- Remove bolts for ribbed belt tensioner for A/C compressor (arrows).

- Release tension on ribbed belt and remove.

- Remove belt pulley.

- Remove torque support stop (arrows).

Pa

ge 14 of 33 Lubrication s

ystem com

ponents, removin

g and installin

g

11/18/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE02.17.1

Page 15 of 33

17-11

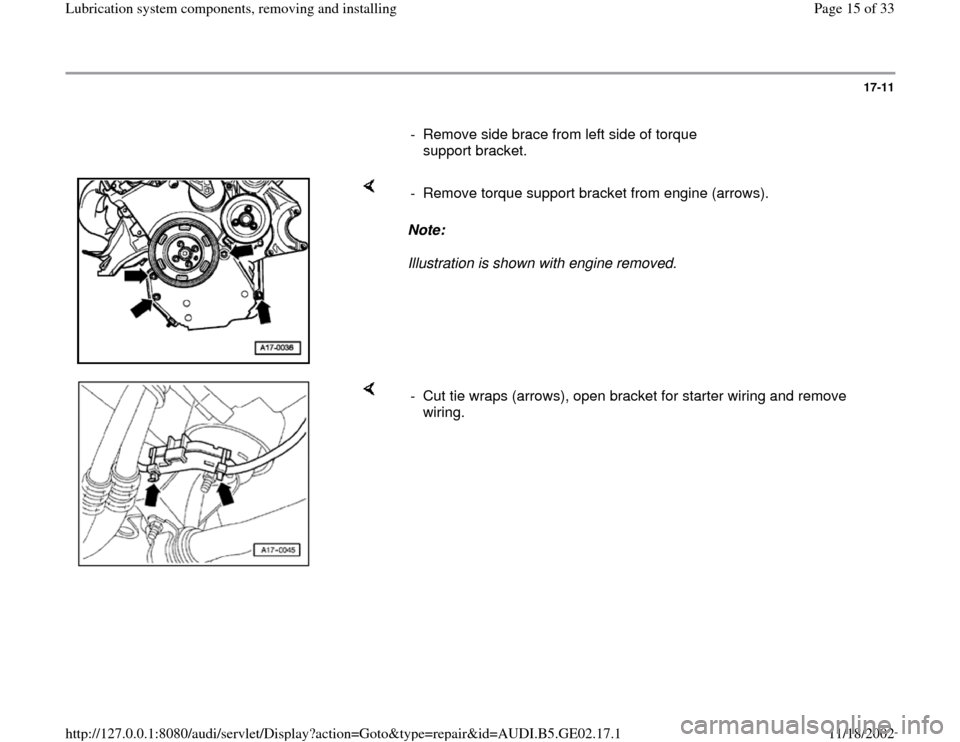

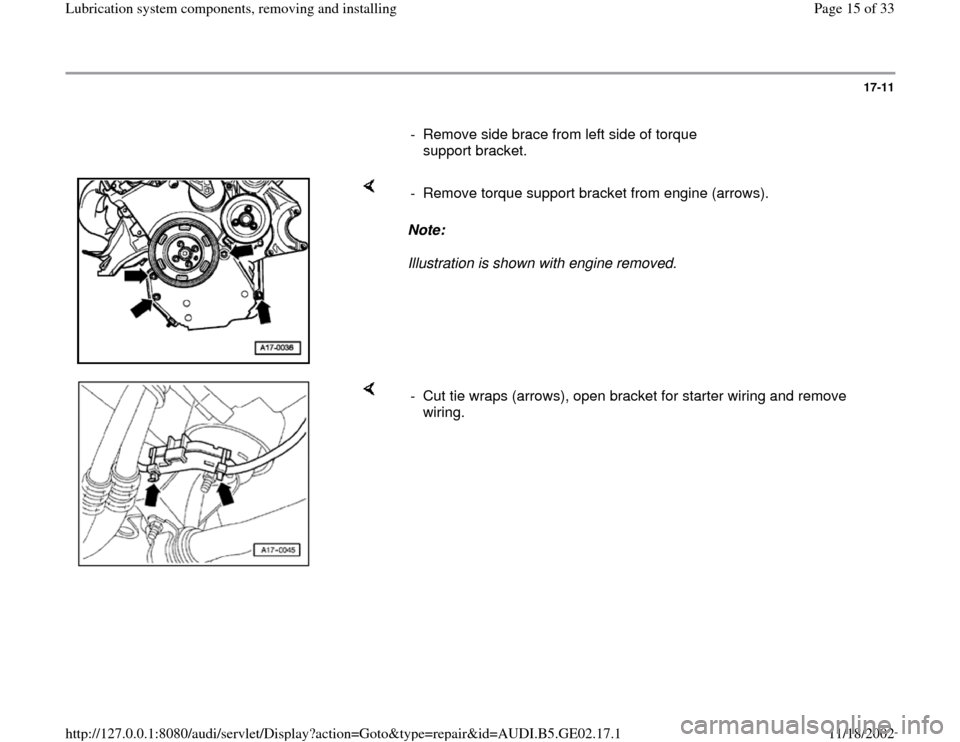

- Remove side brace from left side of torque

support bracket.

Note:

Illustration is shown with engine removed. - Remove torque support bracket from engine (arrows).

- Cut tie wraps (arrows), open bracket for starter wiring and remove

wiring.

Pa

ge 15 of 33 Lubrication s

ystem com

ponents, removin

g and installin

g

11/18/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE02.17.1

Page 16 of 33

17-12

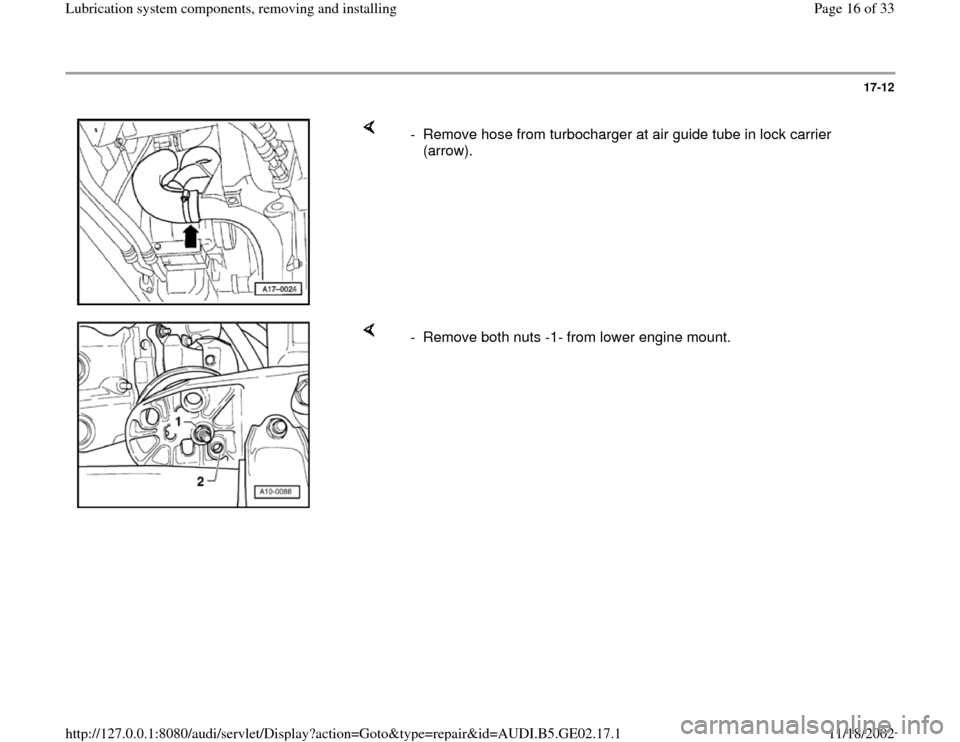

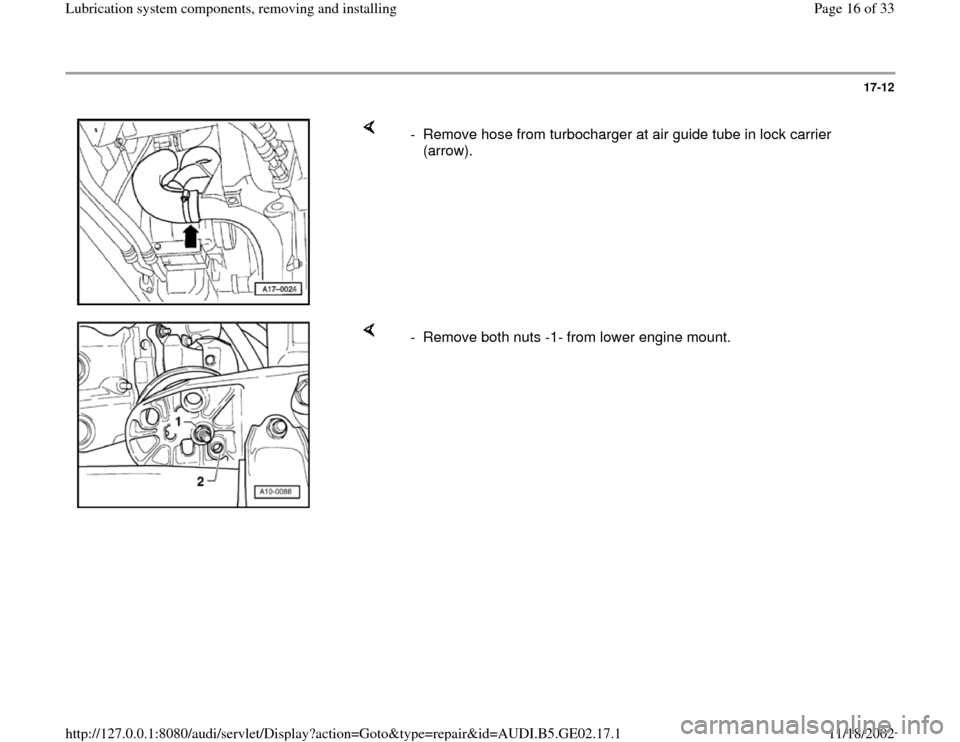

- Remove hose from turbocharger at air guide tube in lock carrier

(arrow).

- Remove both nuts -1- from lower engine mount.

Pa

ge 16 of 33 Lubrication s

ystem com

ponents, removin

g and installin

g

11/18/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE02.17.1

Page 17 of 33

17-13

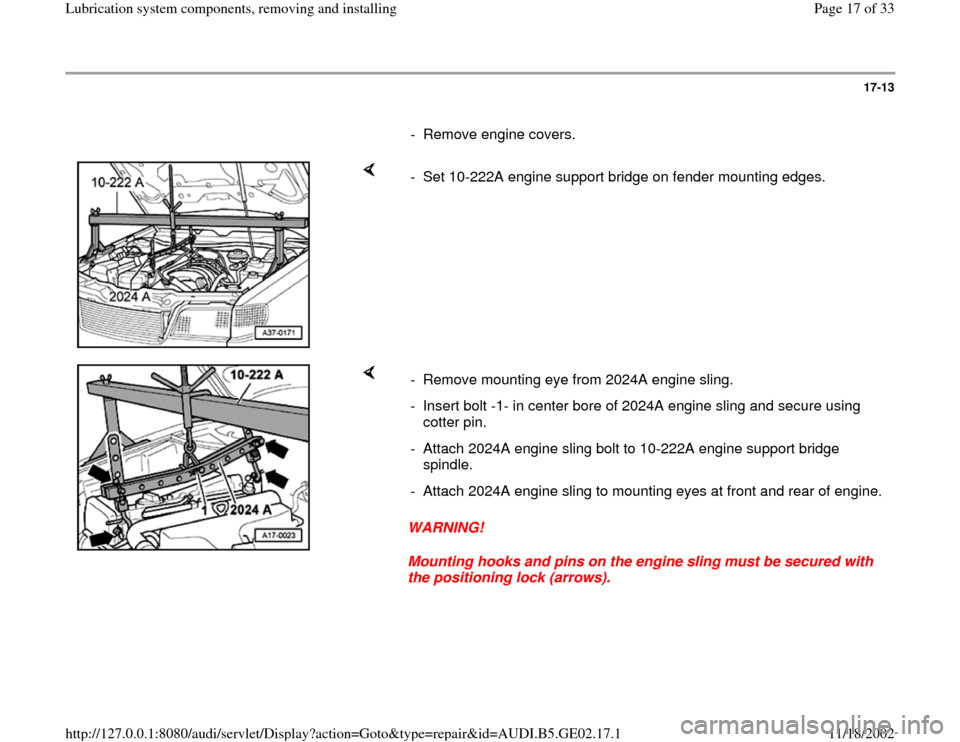

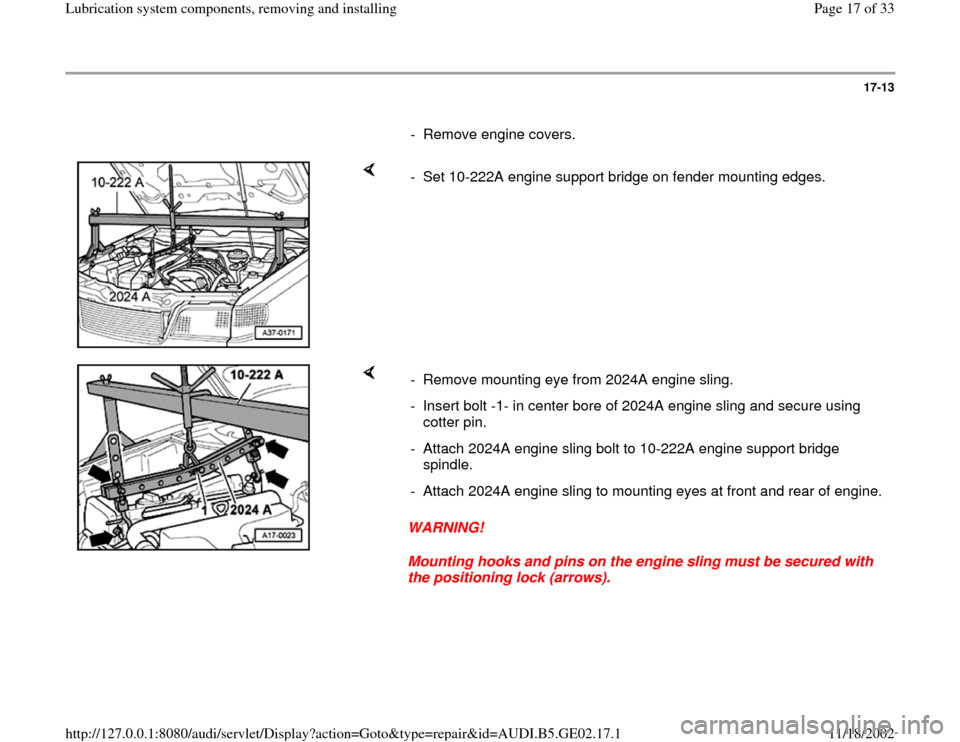

- Remove engine covers.

- Set 10-222A engine support bridge on fender mounting edges.

WARNING!

Mounting hooks and pins on the engine sling must be secured with

the positioning lock (arrows). - Remove mounting eye from 2024A engine sling.

- Insert bolt -1- in center bore of 2024A engine sling and secure using

cotter pin.

- Attach 2024A engine sling bolt to 10-222A engine support bridge

spindle.

- Attach 2024A engine sling to mounting eyes at front and rear of engine.

Pa

ge 17 of 33 Lubrication s

ystem com

ponents, removin

g and installin

g

11/18/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE02.17.1

Page 18 of 33

17-14

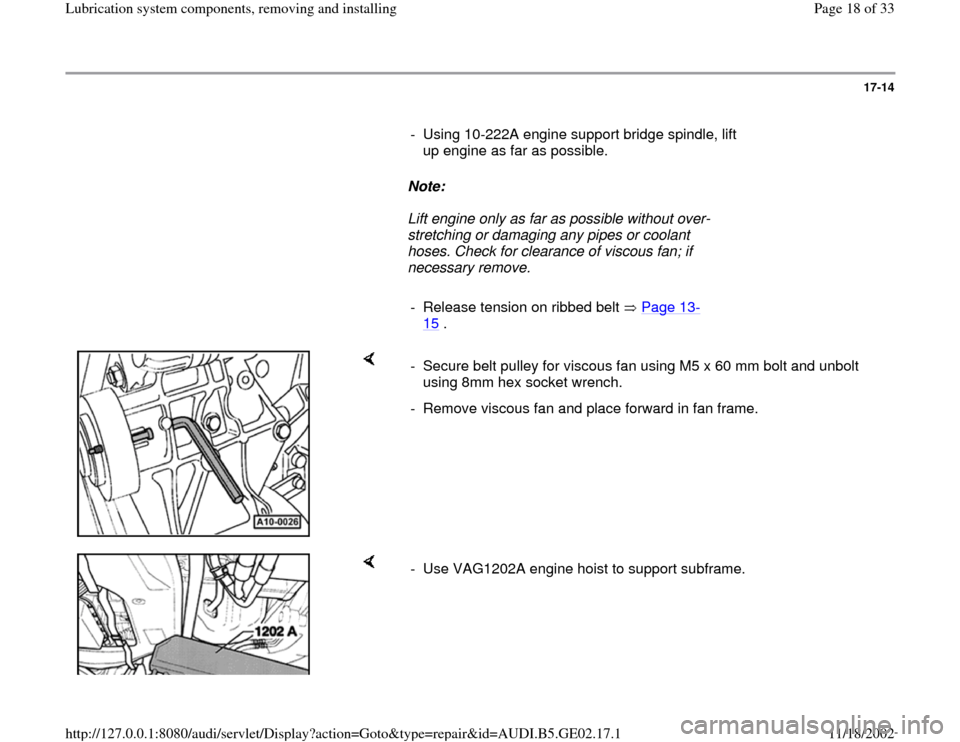

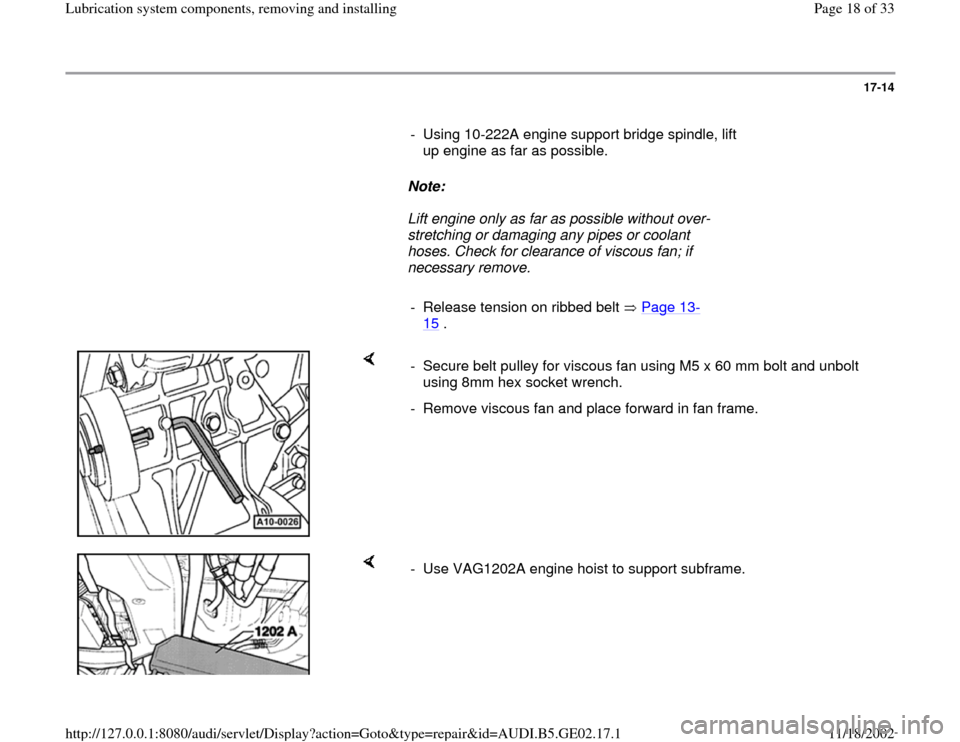

- Using 10-222A engine support bridge spindle, lift

up engine as far as possible.

Note:

Lift engine only as far as possible without over-

stretching or damaging any pipes or coolant

hoses. Check for clearance of viscous fan; if

necessary remove.

- Release tension on ribbed belt Page 13

-

15

.

- Secure belt pulley for viscous fan using M5 x 60 mm bolt and unbolt

using 8mm hex socket wrench.

- Remove viscous fan and place forward in fan frame.

- Use VAG1202A engine hoist to support subframe.

Pa

ge 18 of 33 Lubrication s

ystem com

ponents, removin

g and installin

g

11/18/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE02.17.1

Page 19 of 33

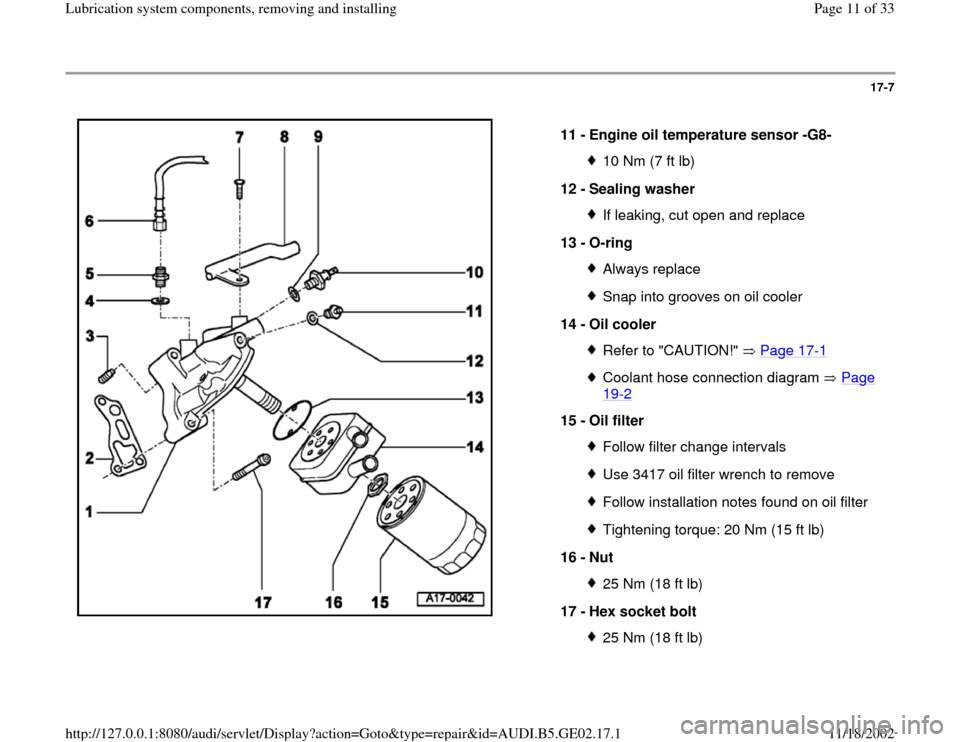

17-15

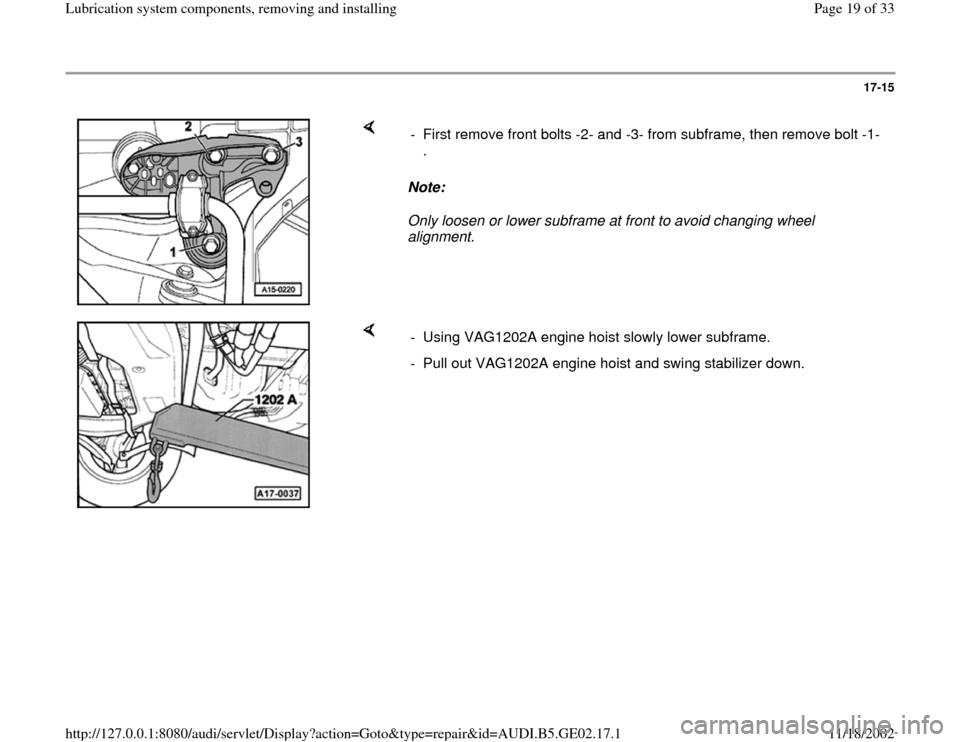

Note:

Only loosen or lower subframe at front to avoid changing wheel

alignment. - First remove front bolts -2- and -3- from subframe, then remove bolt -1-

.

- Using VAG1202A engine hoist slowly lower subframe.

- Pull out VAG1202A engine hoist and swing stabilizer down.

Pa

ge 19 of 33 Lubrication s

ystem com

ponents, removin

g and installin

g

11/18/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE02.17.1

Page 20 of 33

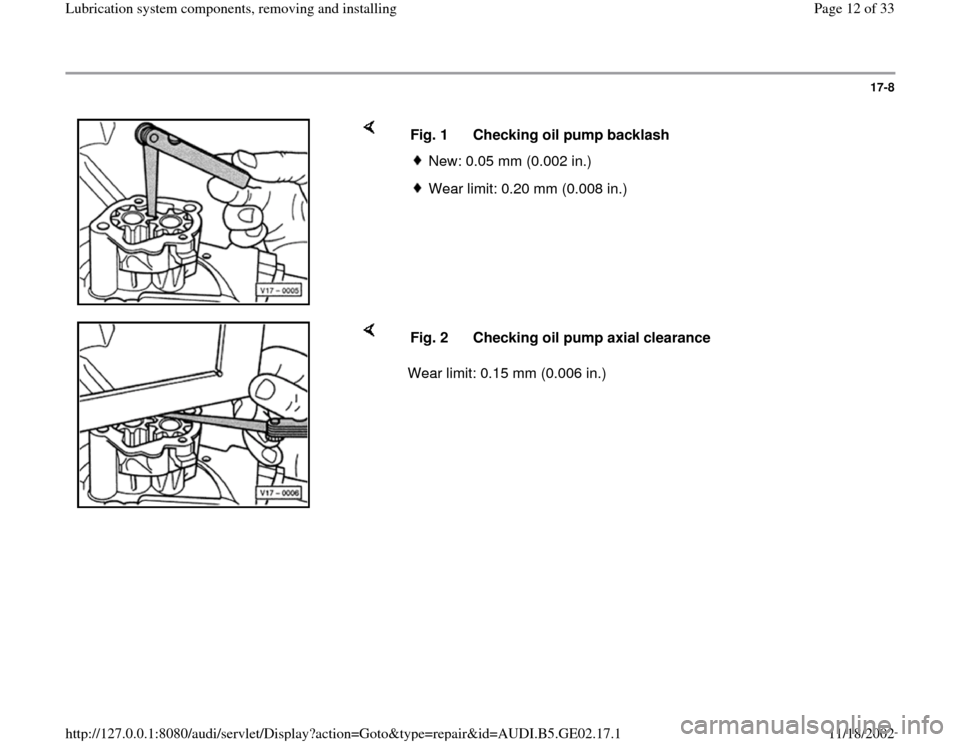

17-16

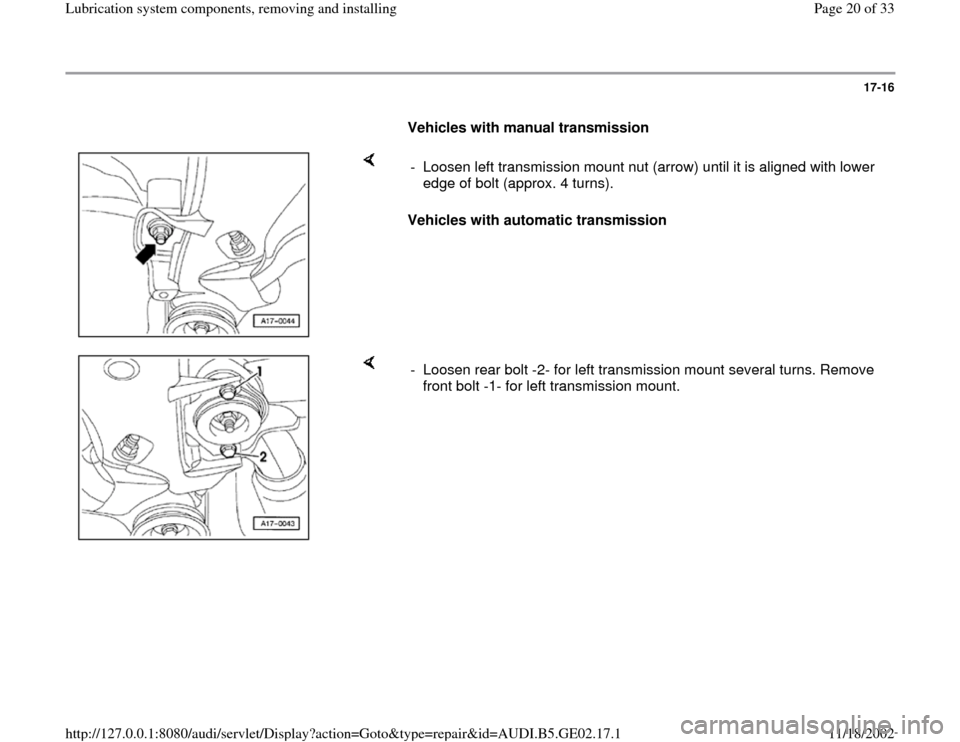

Vehicles with manual transmission

Vehicles with automatic transmission - Loosen left transmission mount nut (arrow) until it is aligned with lower

edge of bolt (approx. 4 turns).

- Loosen rear bolt -2- for left transmission mount several turns. Remove

front bolt -1- for left transmission mount.

Pa

ge 20 of 33 Lubrication s

ystem com

ponents, removin

g and installin

g

11/18/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE02.17.1

Trending: oil temperature, ignition, steering wheel, oil filter, oil dipstick, manual transmission, transmission