engine AUDI A4 1999 B5 / 1.G AFC Engine Lock Carrier Removing For Service Workshop Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 1999, Model line: A4, Model: AUDI A4 1999 B5 / 1.GPages: 35, PDF Size: 0.44 MB

Page 7 of 35

15-13

Cylinder head, removing and installing

Engine installed

This removal procedure refers to the left cylinder

head

Removing

- Remove ribbed belt page 13

-9

- Remove toothed belt page 13

-11

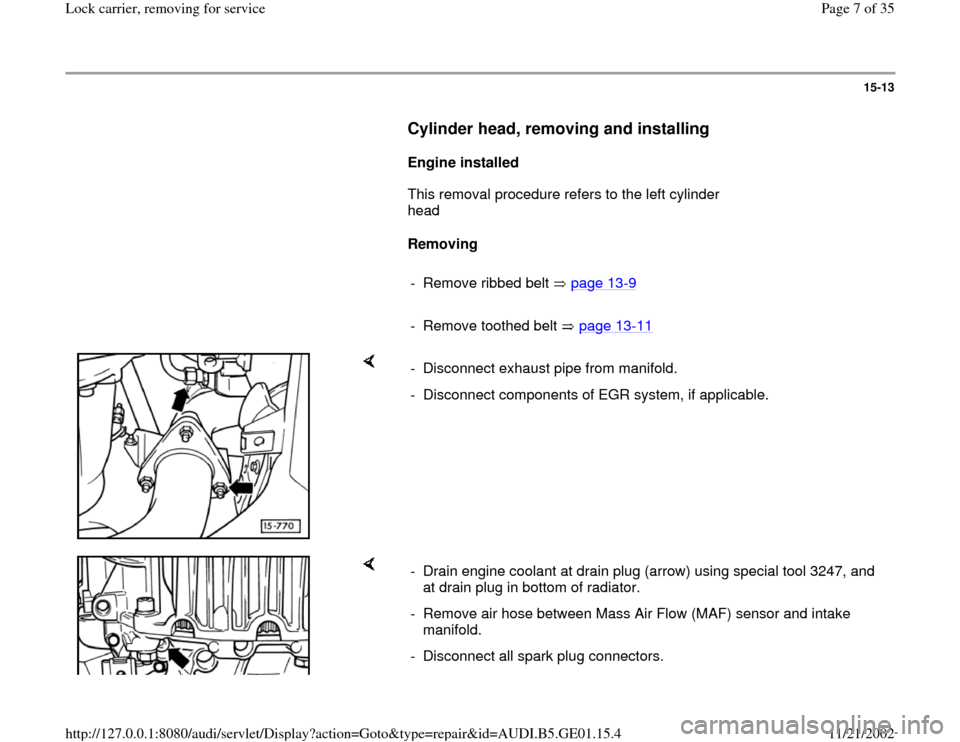

- Disconnect exhaust pipe from manifold.

- Disconnect components of EGR system, if applicable.

- Drain engine coolant at drain plug (arrow) using special tool 3247, and

at drain plug in bottom of radiator.

- Remove air hose between Mass Air Flow (MAF) sensor and intake

manifold.

- Disconnect all spark plug connectors.

Pa

ge 7 of 35 Lock carrier, removin

g for service

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.15.4

Page 11 of 35

15-15

- Disconnect harness connectors for Heated

Oxygen Sensors (H02S) and oxygen sensor

heaters at engine compartment bulkhead, and

move to one side.

- Disconnect vacuum line to EGR vacuum

regulator solenoid valve at throttle body.

- Remove EGR valve from intake manifold.

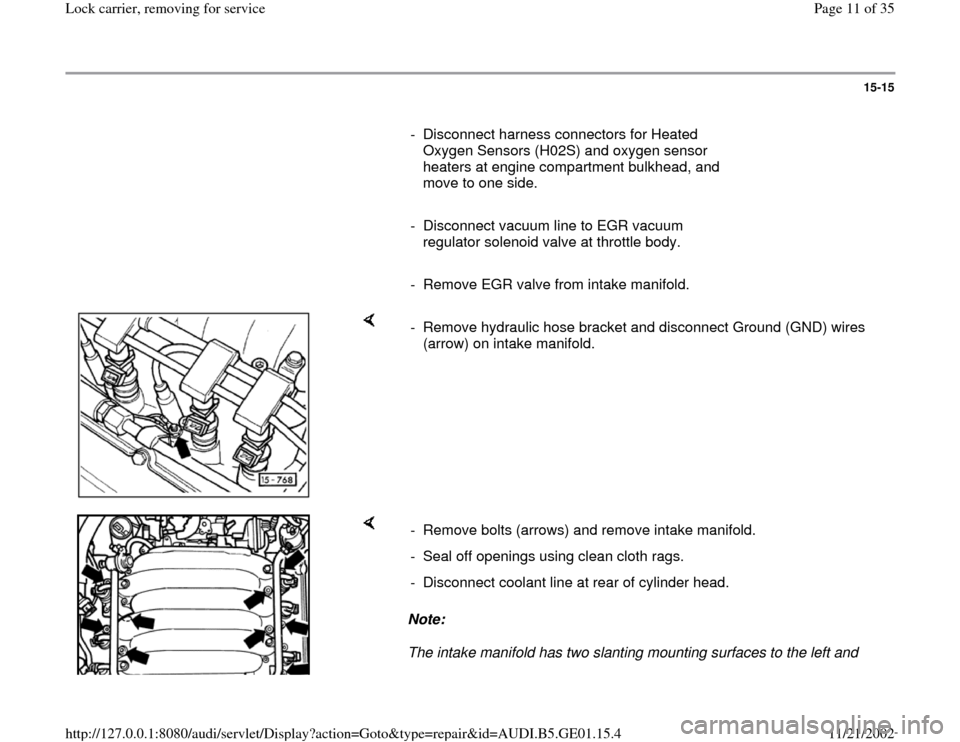

- Remove hydraulic hose bracket and disconnect Ground (GND) wires

(arrow) on intake manifold.

Note:

The intake manifold has two slanting mounting surfaces to the left and - Remove bolts (arrows) and remove intake manifold.

- Seal off openings using clean cloth rags.

- Disconnect coolant line at rear of cylinder head.

Pa

ge 11 of 35 Lock carrier, removin

g for service

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.15.4

Page 16 of 35

15-18

Compression pressure, checking

Engine warm-oil temperature at least 30 C

(86 F)

Throttle valve fully open during cranking

- Disconnect harness connectors from ignition coil

power output stage and from all six fuel

injectors.

- Use compression pressure recorder VAG 1381

together with adapter 1381/5 or equivalent to

measure compression.

Note:

Refer to operating instructions for use of the

recorder.

- Operate starter until tester shows no additional

increase in pressure.

Compression pressures

New: 9-14 bar (131-203 psi)

Wear limit: 7.5 bar (109 psi)

Pa

ge 16 of 35 Lock carrier, removin

g for service

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.15.4

Page 20 of 35

15-20

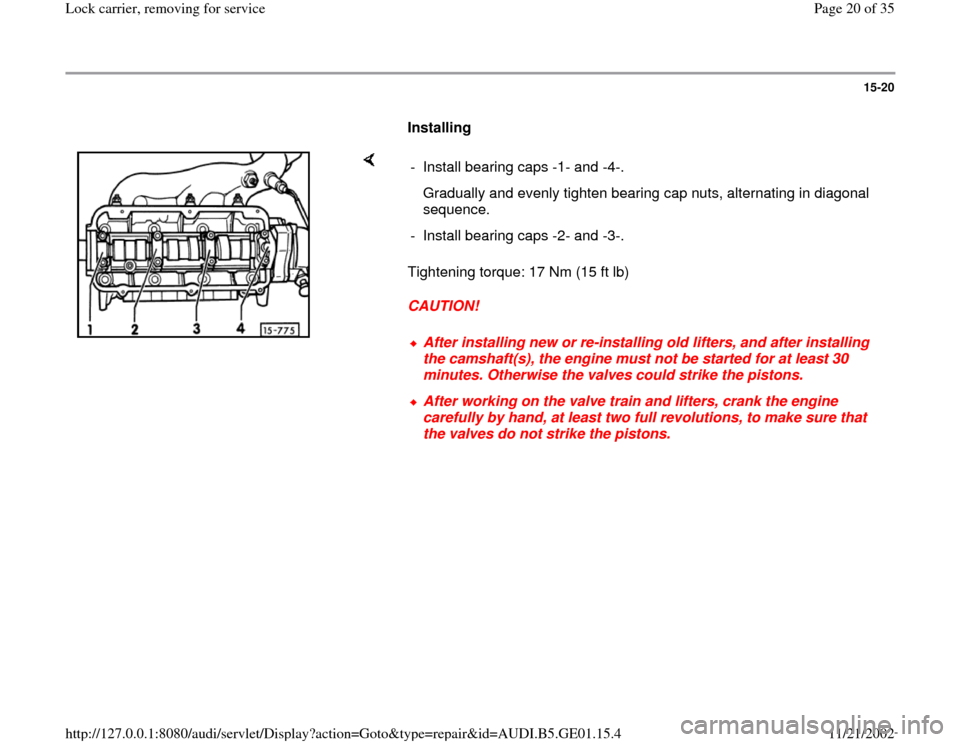

Installing

Tightening torque: 17 Nm (15 ft lb)

CAUTION! - Install bearing caps -1- and -4-.

Gradually and evenly tighten bearing cap nuts, alternating in diagonal

sequence.

- Install bearing caps -2- and -3-.

After installing new or re-installing old lifters, and after installing

the camshaft(s), the engine must not be started for at least 30

minutes. Otherwise the valves could strike the pistons. After working on the valve train and lifters, crank the engine

carefully by hand, at least two full revolutions, to make sure that

the valves do not strike the pistons.

Pa

ge 20 of 35 Lock carrier, removin

g for service

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.15.4

Page 22 of 35

15-22

Hydraulic valve lifters, checking

Note:

Irregular valve noise during cranking is

normal.

Do not interchange hydraulic lifters. If

necessary mark them when they are being

removed.

Place lifters that have been removed on a clean

surface with the contact surface (camshaft end)

facing downward.

Hydraulic lifters cannot be repaired or adjusted.

Faulty lifters must be replaced.

- Start and run engine until warm-until radiator

coolant fan has come on at least once.

- Increase engine speed to approx. 2500 RPM for

2 minutes

If the irregular valve noise stops and then re-

occurs again each time vehicle is used in stop

and go traffic:

-

Replace the oil check valves Repair Group

Pa

ge 22 of 35 Lock carrier, removin

g for service

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.15.4

Page 24 of 35

15-23

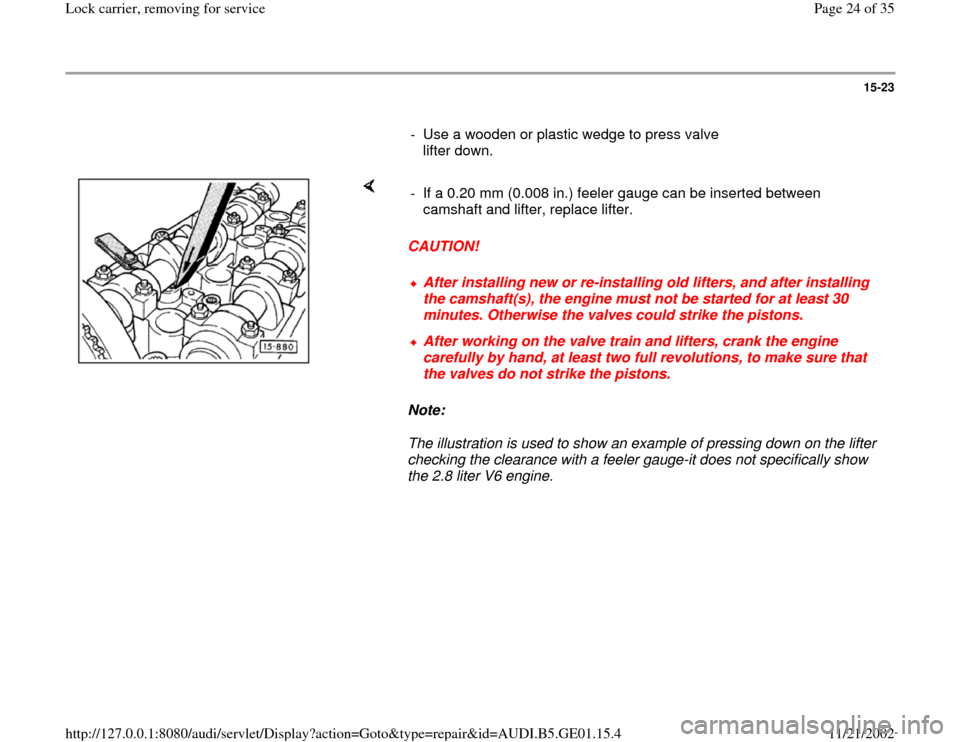

- Use a wooden or plastic wedge to press valve

lifter down.

CAUTION!

Note:

The illustration is used to show an example of pressing down on the lifter

checking the clearance with a feeler gauge-it does not specifically show

the 2.8 liter V6 engine. - If a 0.20 mm (0.008 in.) feeler gauge can be inserted between

camshaft and lifter, replace lifter.

After installing new or re-installing old lifters, and after installing

the camshaft(s), the engine must not be started for at least 30

minutes. Otherwise the valves could strike the pistons. After working on the valve train and lifters, crank the engine

carefully by hand, at least two full revolutions, to make sure that

the valves do not strike the pistons.

Pa

ge 24 of 35 Lock carrier, removin

g for service

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.15.4

Page 31 of 35

15-29

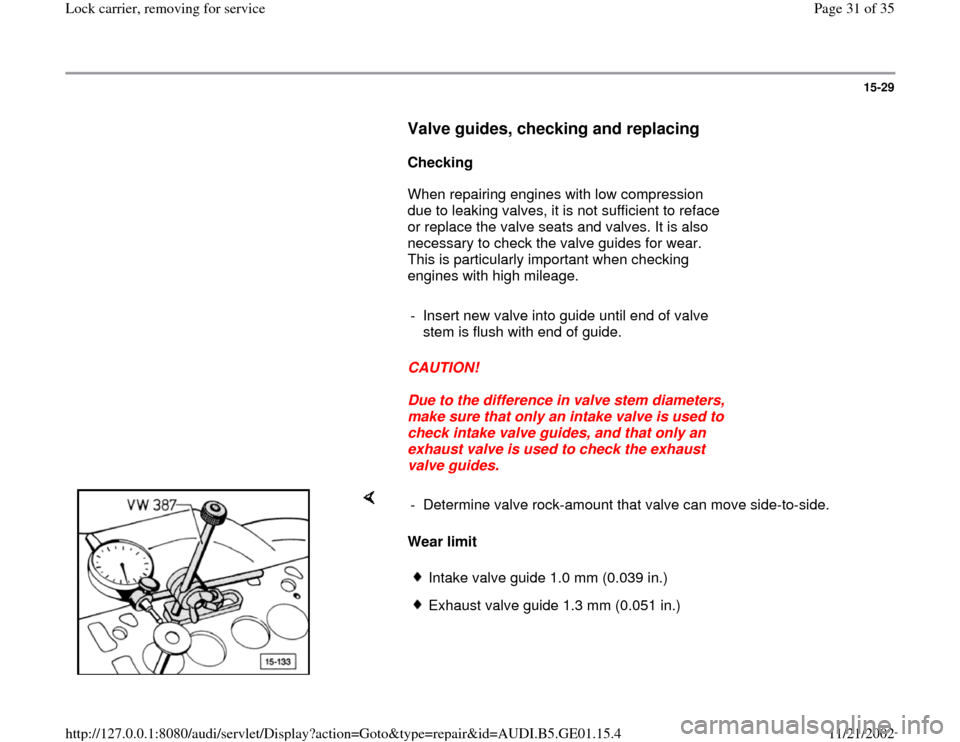

Valve guides, checking and replacing

Checking

When repairing engines with low compression

due to leaking valves, it is not sufficient to reface

or replace the valve seats and valves. It is also

necessary to check the valve guides for wear.

This is particularly important when checking

engines with high mileage.

- Insert new valve into guide until end of valve

stem is flush with end of guide.

CAUTION!

Due to the difference in valve stem diameters,

make sure that only an intake valve is used to

check intake valve guides, and that only an

exhaust valve is used to check the exhaust

valve guides.

Wear limit - Determine valve rock-amount that valve can move side-to-side.

Intake valve guide 1.0 mm (0.039 in.)Exhaust valve guide 1.3 mm (0.051 in.)

Pa

ge 31 of 35 Lock carrier, removin

g for service

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.15.4