wheel bolts AUDI A4 1999 B5 / 1.G APB Engine Cylinder Block Crankshaft And Flywheel Assembly Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 1999, Model line: A4, Model: AUDI A4 1999 B5 / 1.GPages: 26, PDF Size: 0.41 MB

Page 3 of 26

13-16

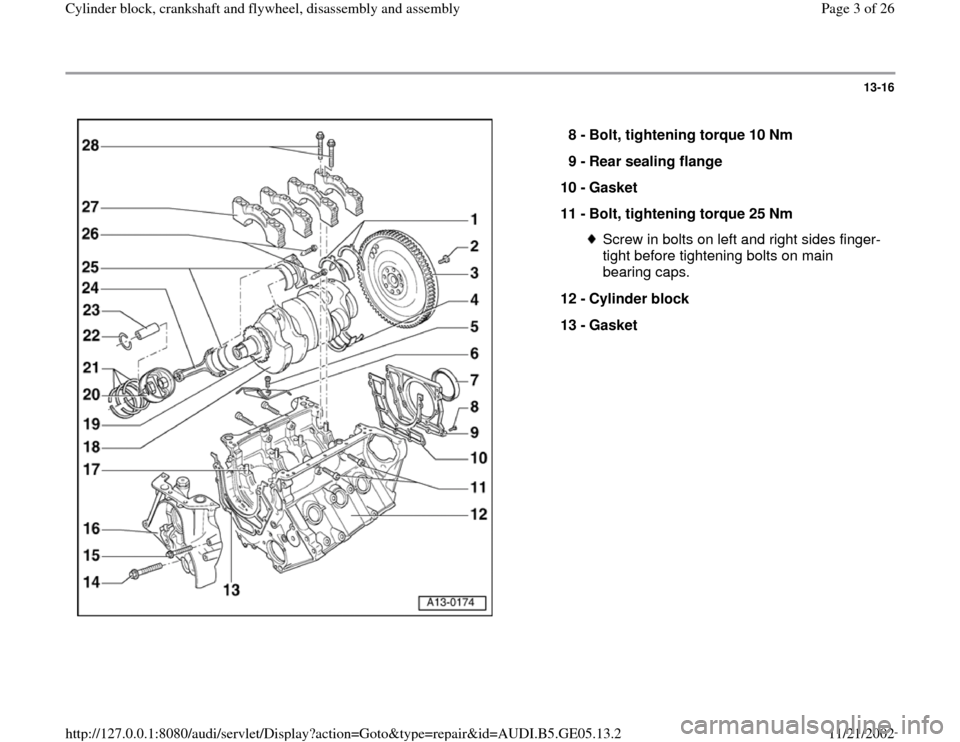

8 -

Bolt, tightening torque 10 Nm

9 -

Rear sealing flange

10 -

Gasket

11 -

Bolt, tightening torque 25 Nm

Screw in bolts on left and right sides finger-

tight before tightening bolts on main

bearing caps.

12 -

Cylinder block

13 -

Gasket

Pa

ge 3 of 26 C

ylinder block, crankshaft and fl

ywheel, disassembl

y and assembl

y

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE05.13.2

Page 6 of 26

13-19

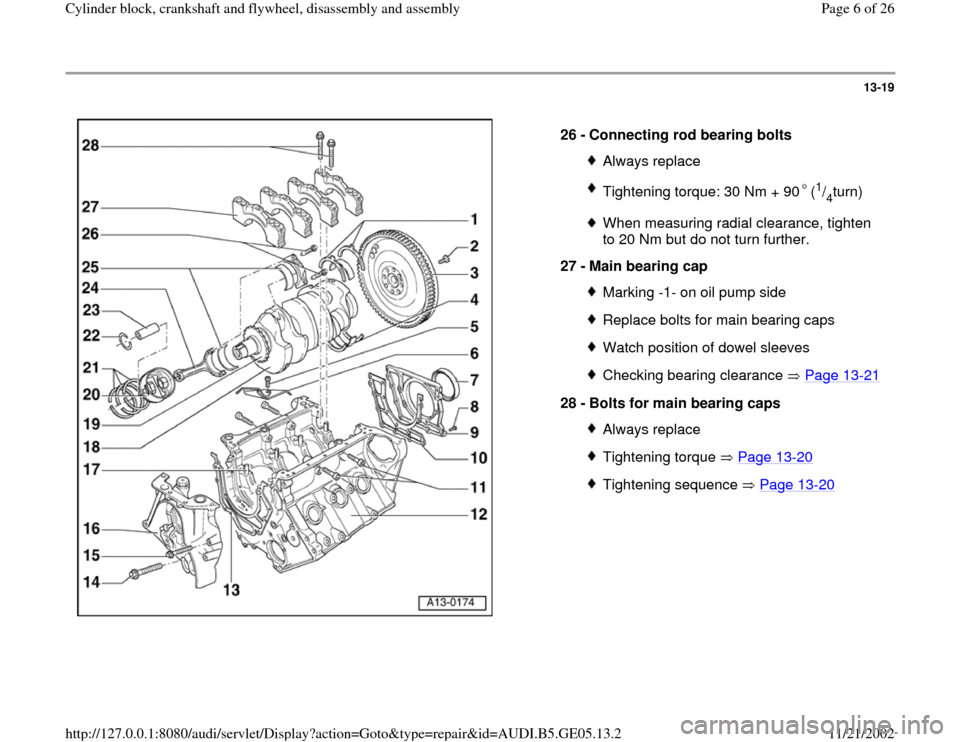

26 -

Connecting rod bearing bolts

Always replaceTightening torque: 30 Nm + 90 (

1/4turn)

When measuring radial clearance, tighten

to 20 Nm but do not turn further.

27 -

Main bearing cap Marking -1- on oil pump sideReplace bolts for main bearing capsWatch position of dowel sleevesChecking bearing clearance Page 13

-21

28 -

Bolts for main bearing caps

Always replaceTightening torque Page 13

-20

Tightening sequence Page 13

-20Pa

ge 6 of 26 C

ylinder block, crankshaft and fl

ywheel, disassembl

y and assembl

y

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE05.13.2

Page 7 of 26

13-20

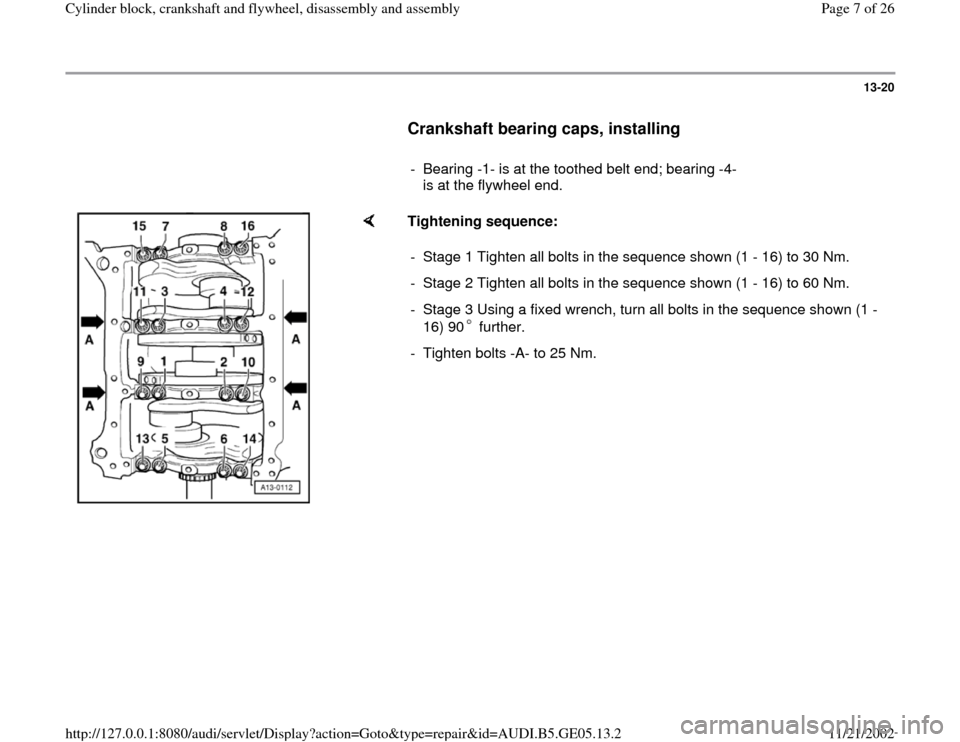

Crankshaft bearing caps, installing

- Bearing -1- is at the toothed belt end; bearing -4-

is at the flywheel end.

Tightening sequence:

- Stage 1 Tighten all bolts in the sequence shown (1 - 16) to 30 Nm.

- Stage 2 Tighten all bolts in the sequence shown (1 - 16) to 60 Nm.

- Stage 3 Using a fixed wrench, turn all bolts in the sequence shown (1 -

16) 90 further. - Tighten bolts -A- to 25 Nm.

Pa

ge 7 of 26 C

ylinder block, crankshaft and fl

ywheel, disassembl

y and assembl

y

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE05.13.2

Page 12 of 26

13-25

Installing

- Install sealing flange.

- Install dual-mass flywheel with new bolts.

Note:

Always replace securing bolts for dual-mass

flywheel.

- Install clutch.

Repair Manual, 6 Spd. Manual Transmission

01E, Repair Group 30

Tightening torques

Dual-mass flywheel to

crankshaft 60 Nm + 180

Clutch to dual-mass flywheel 20 Nm

Pa

ge 12 of 26 C

ylinder block, crankshaft and fl

ywheel, disassembl

y and assembl

y

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE05.13.2

Page 14 of 26

13-27

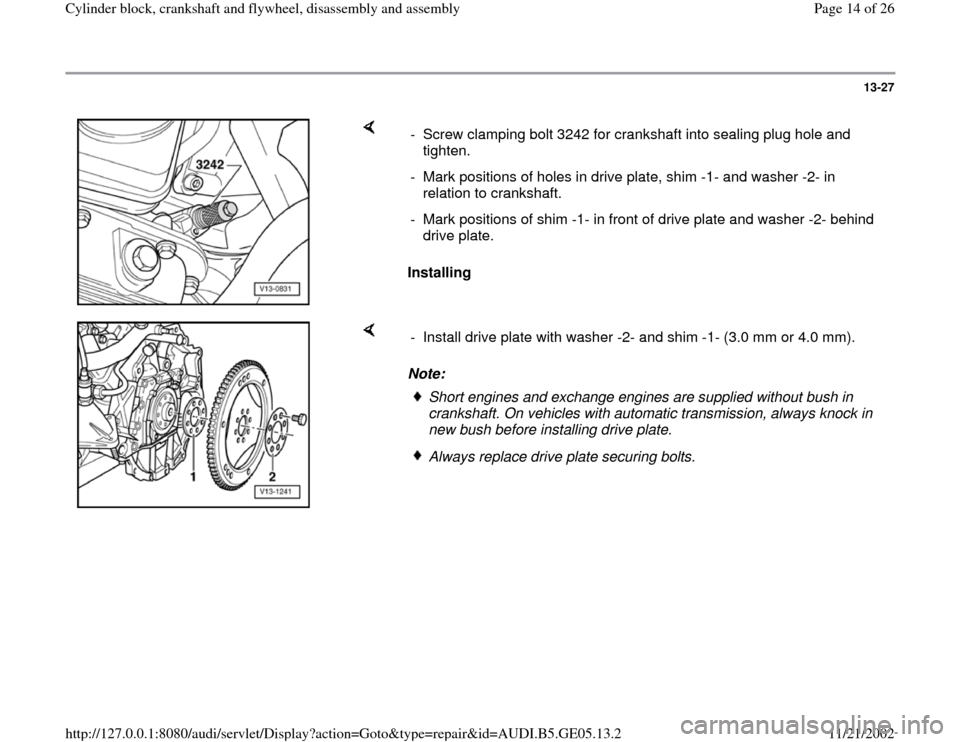

Installing - Screw clamping bolt 3242 for crankshaft into sealing plug hole and

tighten.

- Mark positions of holes in drive plate, shim -1- and washer -2- in

relation to crankshaft.

- Mark positions of shim -1- in front of drive plate and washer -2- behind

drive plate.

Note: - Install drive plate with washer -2- and shim -1- (3.0 mm or 4.0 mm).

Short engines and exchange engines are supplied without bush in

crankshaft. On vehicles with automatic transmission, always knock in

new bush before installing drive plate. Always replace drive plate securing bolts.

Pa

ge 14 of 26 C

ylinder block, crankshaft and fl

ywheel, disassembl

y and assembl

y

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE05.13.2

Page 15 of 26

13-28

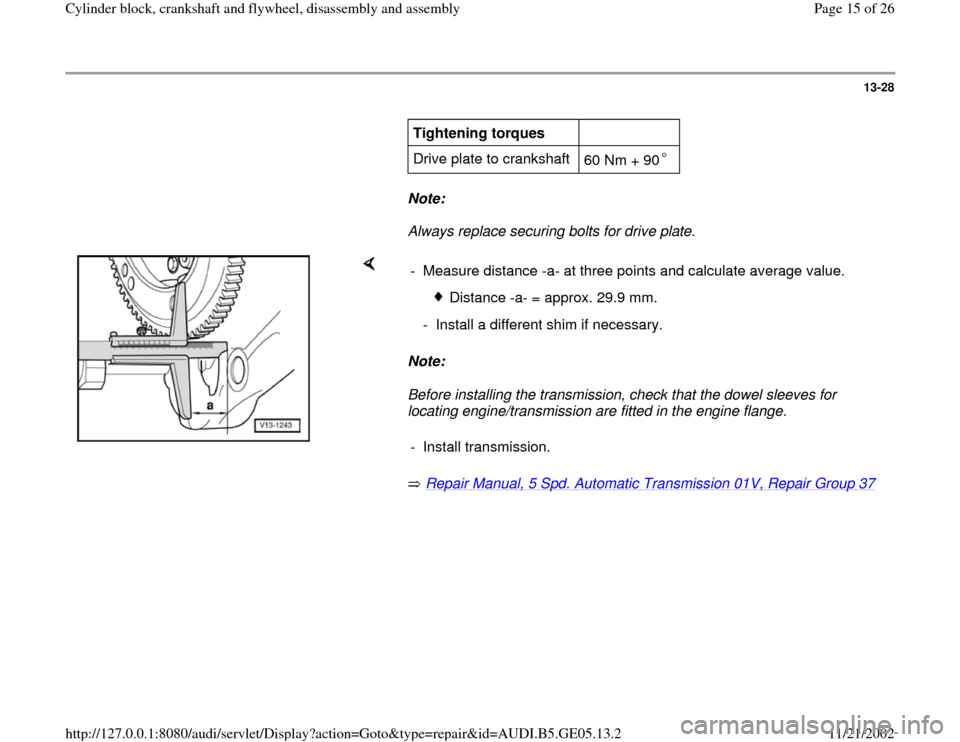

Tightening torques

Drive plate to crankshaft

60 Nm + 90

Note:

Always replace securing bolts for drive plate.

Note:

Before installing the transmission, check that the dowel sleeves for

locating engine/transmission are fitted in the engine flange.

Repair Manual, 5 Spd. Automatic Transmission 01V, Repair Group 37

- Measure distance -a- at three points and calculate average value.

Distance -a- = approx. 29.9 mm.

- Install a different shim if necessary.

- Install transmission.

Pa

ge 15 of 26 C

ylinder block, crankshaft and fl

ywheel, disassembl

y and assembl

y

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE05.13.2

Page 16 of 26

13-29

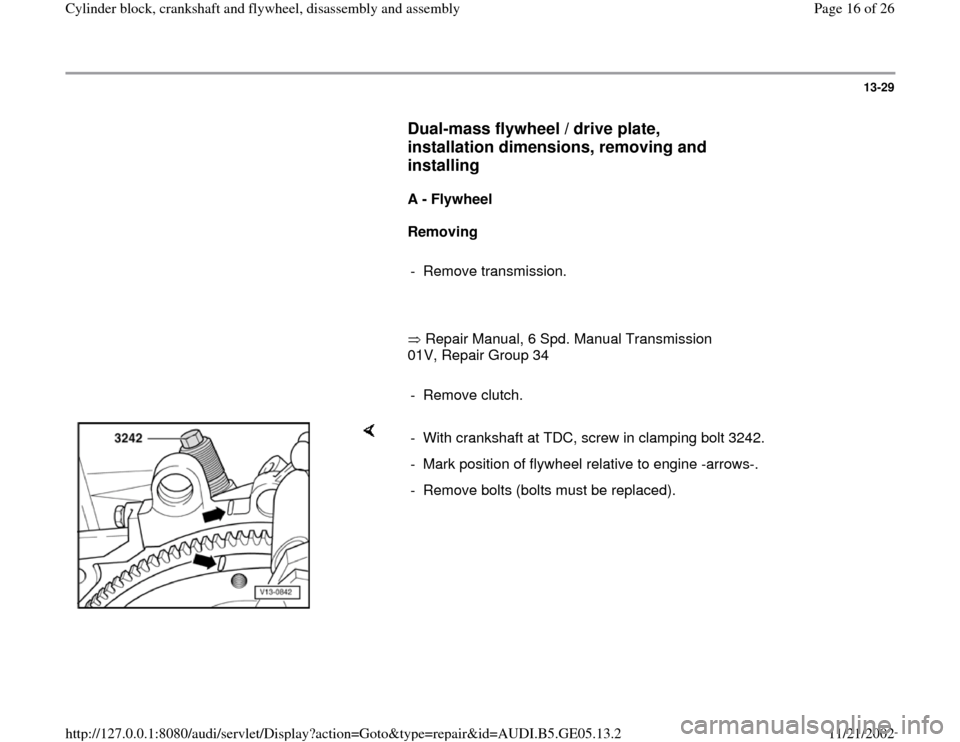

Dual-mass flywheel / drive plate,

installation dimensions, removing and

installing

A - Flywheel

Removing

- Remove transmission.

Repair Manual, 6 Spd. Manual Transmission

01V, Repair Group 34

- Remove clutch.

- With crankshaft at TDC, screw in clamping bolt 3242.

- Mark position of flywheel relative to engine -arrows-.

- Remove bolts (bolts must be replaced).

Pa

ge 16 of 26 C

ylinder block, crankshaft and fl

ywheel, disassembl

y and assembl

y

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE05.13.2

Page 17 of 26

13-30

Note:

The needle bearing is located in the flywheel and

must be pressed in if a new flywheel is installed

Page 13

-35

.

Installing

- Install dual-mass flywheel.

Note:

Always replace flywheel securing bolts.

- Install clutch.

Repair Manual, 6 Spd. Manual Transmission

01E, Repair Group 30

- Install transmission.

Repair Manual, 6 Spd. Manual Transmission

01E, Repair Group 34

Pa

ge 17 of 26 C

ylinder block, crankshaft and fl

ywheel, disassembl

y and assembl

y

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE05.13.2

Page 20 of 26

13-33

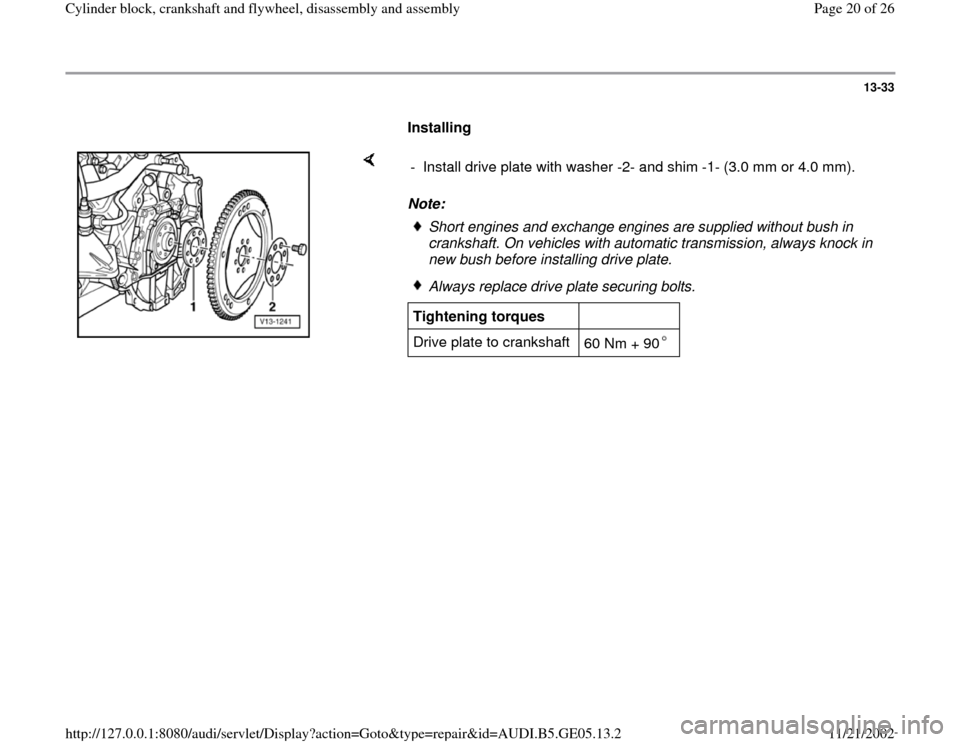

Installing

Note: - Install drive plate with washer -2- and shim -1- (3.0 mm or 4.0 mm).

Short engines and exchange engines are supplied without bush in

crankshaft. On vehicles with automatic transmission, always knock in

new bush before installing drive plate. Always replace drive plate securing bolts.

Tightening torques

Drive plate to crankshaft

60 Nm + 90

Pa

ge 20 of 26 C

ylinder block, crankshaft and fl

ywheel, disassembl

y and assembl

y

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE05.13.2

Page 26 of 26

13-39

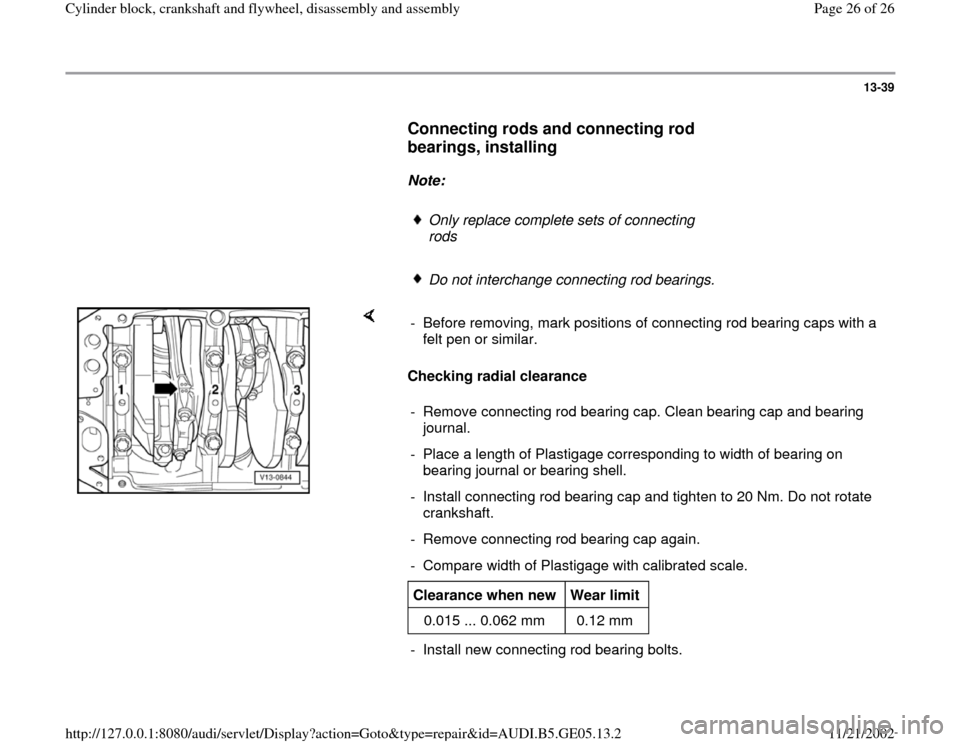

Connecting rods and connecting rod

bearings, installing

Note:

Only replace complete sets of connecting

rods

Do not interchange connecting rod bearings.

Checking radial clearance - Before removing, mark positions of connecting rod bearing caps with a

felt pen or similar.

- Remove connecting rod bearing cap. Clean bearing cap and bearing

journal.

- Place a length of Plastigage corresponding to width of bearing on

bearing journal or bearing shell.

- Install connecting rod bearing cap and tighten to 20 Nm. Do not rotate

crankshaft.

- Remove connecting rod bearing cap again.

- Compare width of Plastigage with calibrated scale.Clearance when new

Wear limit

0.015 ... 0.062 mm 0.12 mm - Install new connecting rod bearing bolts.

Pa

ge 26 of 26 C

ylinder block, crankshaft and fl

ywheel, disassembl

y and assembl

y

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE05.13.2