service AUDI A4 1999 B5 / 1.G Engine Oil Level Checking Workshop Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 1999, Model line: A4, Model: AUDI A4 1999 B5 / 1.GPages: 111, PDF Size: 1.26 MB

Page 10 of 111

16

Delivery inspection:

At delivery inspection coolant level must be at

max. mark on expansion tank (engine cold).

Inspection service:

Coolant level between min. and max. markings.

With engine cold, coolant level must be between

min. and max. markings of reservoir; with engine

warm, level may be slightly above max. marking.

If coolant level is too low but antifreeze protection

is adequate, add required amount of mixture.

If coolant level is too low but antifreeze protection

adequate, add missing quantity according to

following mixing ratios:

Antifreeze

protection down to Coolant

additive Water

-25 C (-13 F)

approx. 40 % approx. 60

%

-35 C (-31 F) approx. 50 % approx. 50

%

-40 C (-40 F) approx. 50 % approx. 50

%

Pa

ge 10 of 111 Descri

ption of wor

k

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.ME01.01.6

Page 15 of 111

21

X DTCs reco

gnized

If control module answers with its identification the number of stored

Diagnostic Trouble Codes (DTCs) will be indicated or "No DTCs

Recognized" will be displayed.

If one or more DTCs are stored, all stored DTCs will be dis played and

printed out in sequence. Following this, VAG 1551 displays the next

address word.

VAG On Board Dia

gnostic

HELP

1 - Rapid data transfer *

)

2 - Blink code output *

)

* Operating modes 1 and 2 are displayed alternately.

Corrective action must be taken if DTCs are stored. Diagnostic report

should be attached to repair order.

Note:

For resetting service internal display and performing any emissions test

VAG 1551 must remain connected. - Automatic test sequence is ended once the readout shown here

appears in the display.

- Turn ignition OFE

Pa

ge 15 of 111 Descri

ption of wor

k

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.ME01.01.6

Page 18 of 111

24

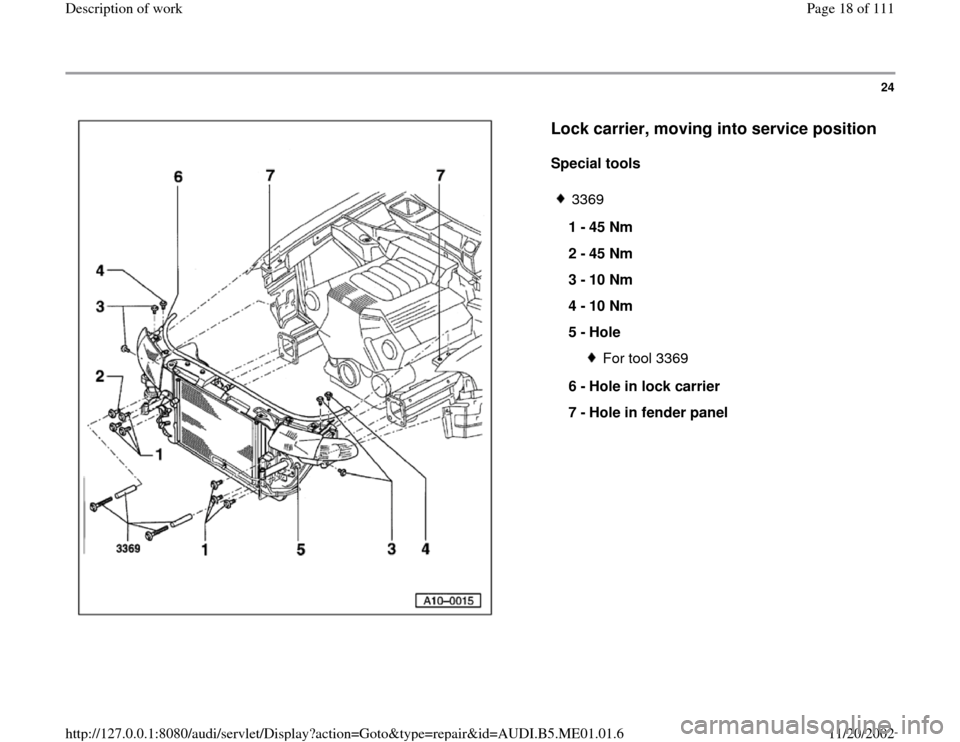

Lock carrier, moving into service position

Special tools

3369

1 -

45 Nm

2 -

45 Nm

3 -

10 Nm

4 -

10 Nm

5 -

Hole

For tool 3369

6 -

Hole in lock carrier

7 -

Hole in fender panel

Pa

ge 18 of 111 Descri

ption of wor

k

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.ME01.01.6

Page 21 of 111

27

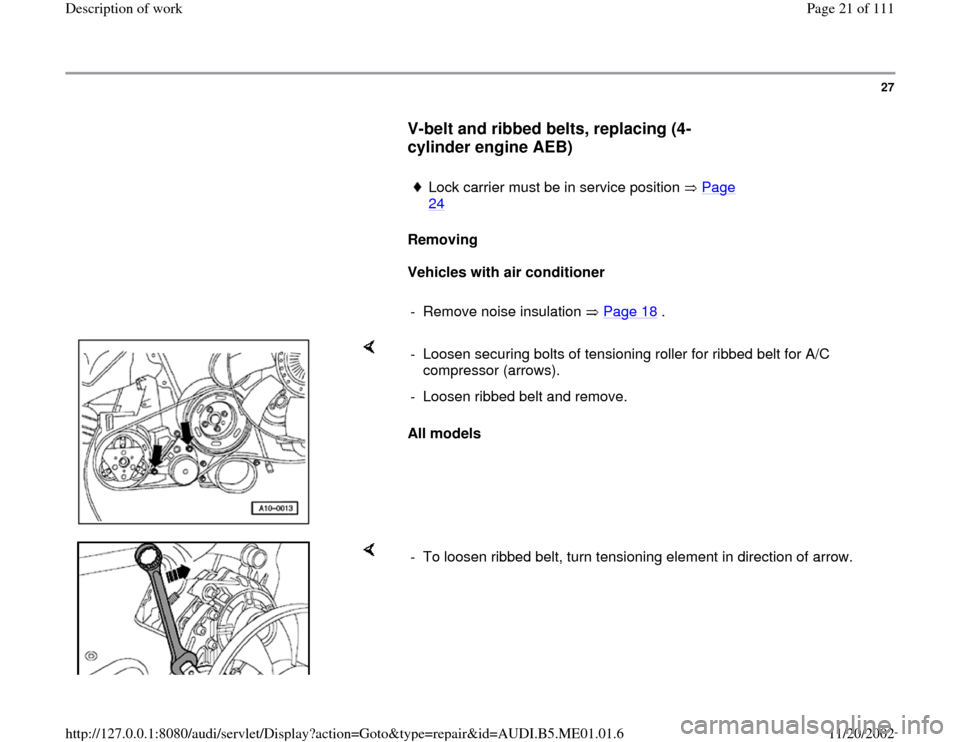

V-belt and ribbed belts, replacing (4-

cylinder engine AEB)

Lock carrier must be in service position Page 24

Removing

Vehicles with air conditioner

- Remove noise insulation Page 18

.

All models - Loosen securing bolts of tensioning roller for ribbed belt for A/C

compressor (arrows).

- Loosen ribbed belt and remove.

- To loosen ribbed belt, turn tensioning element in direction of arrow.

Pa

ge 21 of 111 Descri

ption of wor

k

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.ME01.01.6

Page 29 of 111

Removing

- Move body, front, to engine service position

Page 24

.

- Remove ribbed V-belt cover.

Pa

ge 29 of 111 Descri

ption of wor

k

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.ME01.01.6

Page 42 of 111

44

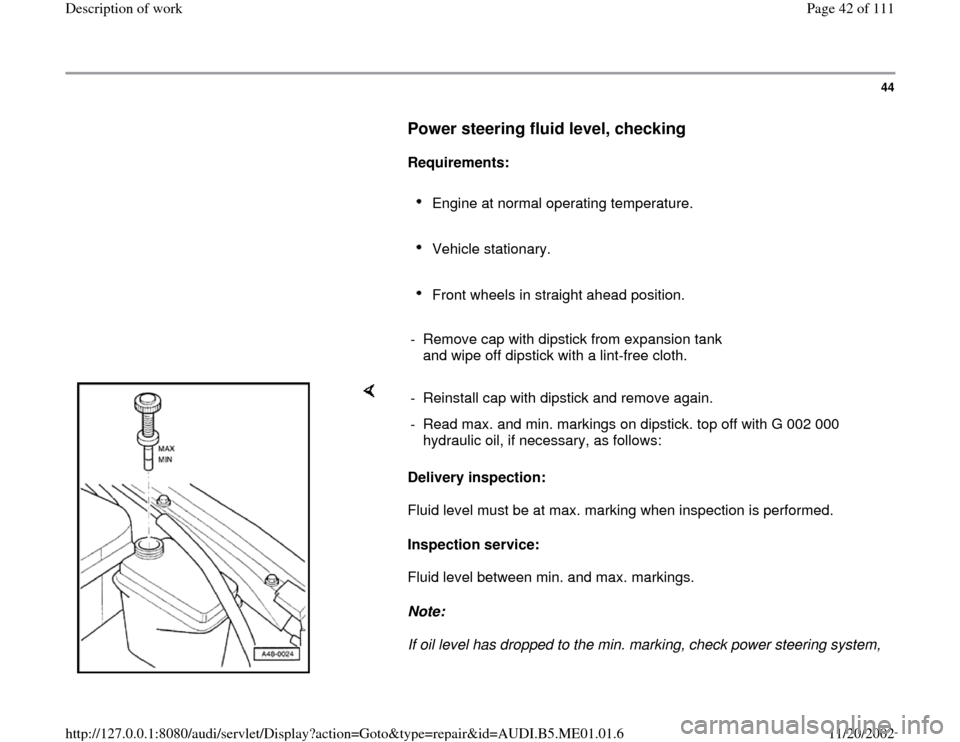

Power steering fluid level, checking

Requirements:

Engine at normal operating temperature.

Vehicle stationary.

Front wheels in straight ahead position.

- Remove cap with dipstick from expansion tank

and wipe off dipstick with a lint-free cloth.

Delivery inspection:

Fluid level must be at max. marking when inspection is performed.

Inspection service:

Fluid level between min. and max. markings.

Note:

If oil level has dropped to the min. marking, check power steering system, - Reinstall cap with dipstick and remove again.

- Read max. and min. markings on dipstick. top off with G 002 000

hydraulic oil, if necessary, as follows:

Pa

ge 42 of 111 Descri

ption of wor

k

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.ME01.01.6

Page 45 of 111

46

Tires, checking

Delivery inspection:

- Check treads and side walls for signs of

damage, if necessary, remove any foreign

bodies, such as nails and glass splinters.

- Check that tires are the same type and tread

pattern.

Inspection service:

- Measure tread depth.

Minimum tread depth: 1.6 mm (0.0625 in.)

If tread depth is close to legal permissible

minimum, i.e. if the 1.6 mm high wear indicator

spaced around tire circumference no longer has

any tread pattern, the customer must be in

formed.

Tires should also be checked for scuffing, wear

on one side, porous side walls, cuts, and

fractures.

Any defects found must be reported to the

customer.

WARNING!

Pa

ge 45 of 111 Descri

ption of wor

k

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.ME01.01.6

Page 51 of 111

51

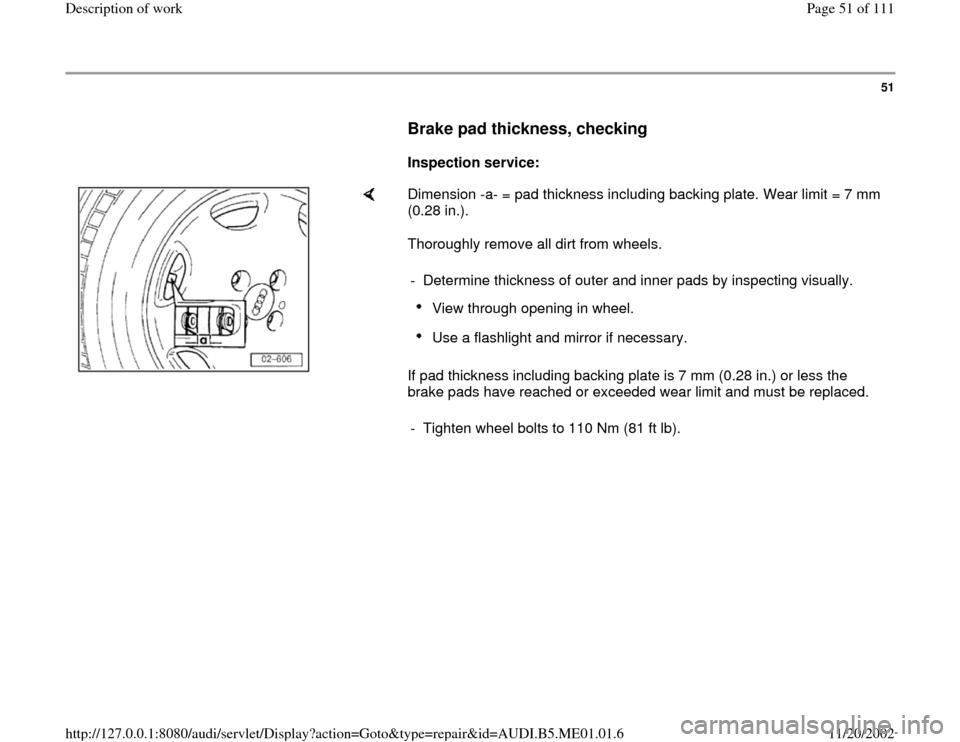

Brake pad thickness, checking

Inspection service:

Dimension -a- = pad thickness including backing plate. Wear limit = 7 mm

(0.28 in.).

Thoroughly remove all dirt from wheels.

If pad thickness including backing plate is 7 mm (0.28 in.) or less the

brake pads have reached or exceeded wear limit and must be replaced. - Determine thickness of outer and inner pads by inspecting visually.

View through opening in wheel. Use a flashlight and mirror if necessary.

- Tighten wheel bolts to 110 Nm (81 ft lb).

Pa

ge 51 of 111 Descri

ption of wor

k

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.ME01.01.6

Page 54 of 111

54

Inspection service:

- Always consider brake pad wear when checking

brake fluid level. When driving, a slight drop in

brake fluid level results from normal wear and

automatic adjustment of brake pads.

- If brake fluid level is at minimum marking or

slightly above, brake pads are close to wear

limit, it is not necessary to add fluid.

- If brake pads are new or well away from wear

limit, brake fluid level must be between min. and

max. markings.

- If brake fluid level has dropped below min.

marking, check brake system before adding

brake fluid.

Pa

ge 54 of 111 Descri

ption of wor

k

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.ME01.01.6

Page 68 of 111

68

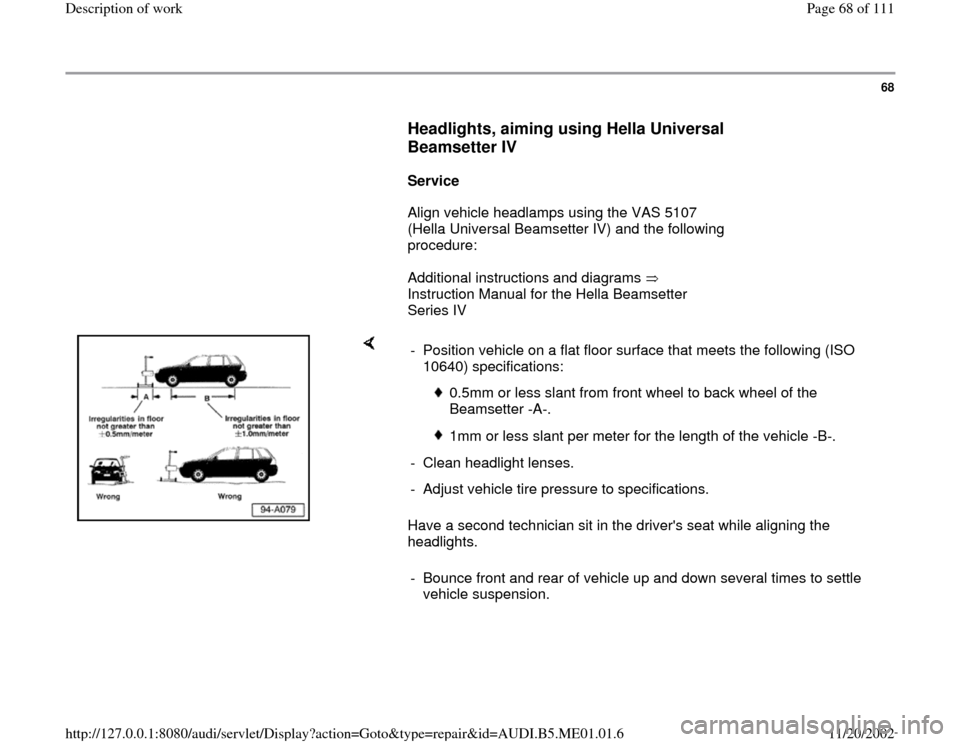

Headlights, aiming using Hella Universal

Beamsetter IV

Service

Align vehicle headlamps using the VAS 5107

(Hella Universal Beamsetter IV) and the following

procedure:

Additional instructions and diagrams

Instruction Manual for the Hella Beamsetter

Series IV

Have a second technician sit in the driver's seat while aligning the

headlights. - Position vehicle on a flat floor surface that meets the following (ISO

10640) specifications:

0.5mm or less slant from front wheel to back wheel of the

Beamsetter -A-.

1mm or less slant per meter for the length of the vehicle -B-.

- Clean headlight lenses.

- Adjust vehicle tire pressure to specifications.

- Bounce front and rear of vehicle up and down several times to settle

vehicle suspension.

Pa

ge 68 of 111 Descri

ption of wor

k

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.ME01.01.6