brake light AUDI A5 CABRIOLET 2017 Owner's Guide

[x] Cancel search | Manufacturer: AUDI, Model Year: 2017, Model line: A5 CABRIOLET, Model: AUDI A5 CABRIOLET 2017Pages: 266, PDF Size: 66.64 MB

Page 204 of 266

Checking and Filling

Brake fluid

Checking brake fluid level

The brake fluid level can be checked with a quick

glance.

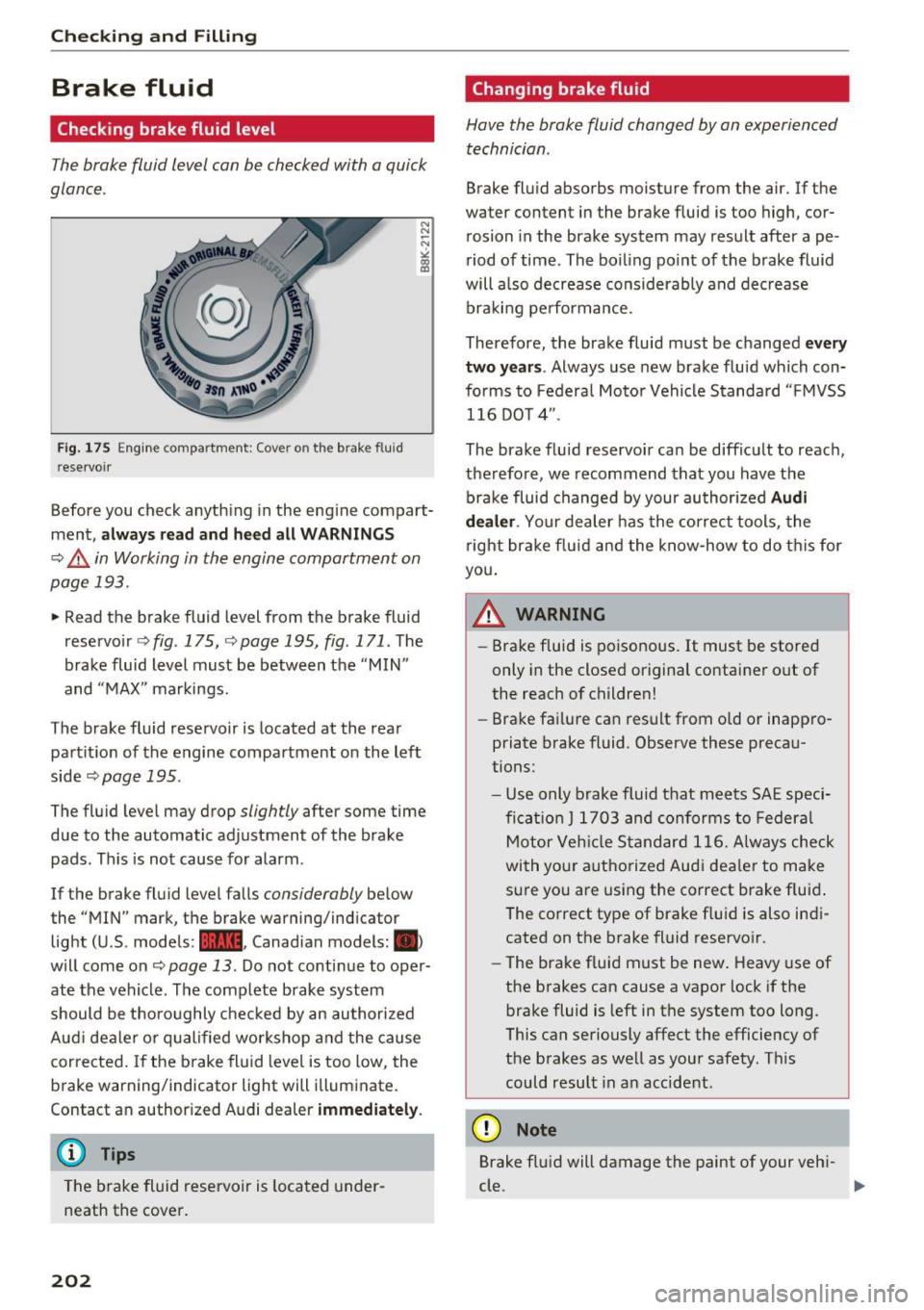

Fig. 175 Engine compartment: Cover on the brake fluid

r eservoir

Before you check anything in the engine compart

ment,

always read and heed all WARNINGS

¢ A in Working in the engine compartment on

page 193.

., Read the brake fluid level from the brake fluid

reservoir

<=> fig . 175, ¢page 195, fig . 171 . The

brake fluid level must be between the

" MIN"

and "MAX " markings.

The brake fluid reservoir is located at the rear

partition of the engine compartment on the left

side

¢ page 195.

The fluid level may drop slightly after some time

due to the automatic adjustment of the brake

pads . This is not cause for alarm .

If the brake fluid level falls

considerably below

the ' 'MIN" mark, the brake warning/indicator

light (U .S. models:

1111 , Canadian models: 1111)

will come on¢ page 13 . Do not continue to oper

ate the vehicle . The complete brake system

should be thoroughly checked by an authorized

Aud i dealer or qualified workshop and the cause

corrected . If the brake fluid level is too low, the

brake warning/indicator light w ill illuminate.

Contact an author ized Audi dealer

immediately.

(D} Tips

The brake fluid reservoir is located under

neath the cover.

202

Changing brake fluid

Have the brake fluid changed by an experienced

technician .

Brake fluid absorbs moisture from the air. If the

water content in the brake fluid is too high, cor

rosion in the brake system may result after ape

riod of time . The boiling po int of the brake fluid

will a lso decrease considerably and decrease

braking performance.

Therefore , the brake fluid must be changed

every

two years .

Always use new brake fluid which con

forms to Feder-al Motor Vehicle Standard "FMVSS

116 DOT 4 ".

The brake fluid reservoir can be difficult to reach ,

therefore, we recommend that you have the

brake fluid changed by your author ized

Audi

dealer .

Your dealer has the correct tools, the

right brake fluid and the know-how to do this for

you.

A WARNING

- Brake fluid is poisonous. It must be stored

only in the closed original container out of

the reach of children!

- Brake fai lure can result from o ld or inappro

priate brake fluid. Observe these precau

tions:

- Use only brake fluid that meets SAE speci

fi cation

J 1703 and conforms to Federal

Motor Veh icle Standard 116. Always check

with your authorized Audi dealer to make

sure you are using the correct brake f luid .

The correct type of brake f luid is also indi

cated on the brake fluid reservoir.

- The brake fluid must be new . Heavy use of

the brakes can cause a vapor lock if the

brake fluid is left in the system too long .

This can seriously affect the efficiency of

the brakes as well as your safety. This

could result in an accident.

(D Note

Brake fluid will damage the paint of your vehi-

cle .

lilJJ,

Page 205 of 266

a:,

a:,

...... N r--. N ...... 0

0

LL 00

@ For the sake of the environment

Because of the problem of proper disposal of

brake fluid as we ll as the special toots re

quired and the necessary expertise, we rec

ommend that you have the brake fluid

changed by your authorized Audi dealer .

Battery

General information

Under normal operating conditions, the battery

in your Audi does not need any maintenance.

With

high outside temperatures or long daily

drives we recommend that you have the electro

lyte level checked by an authorized Audi dealer or

qualified workshop. The electrolyte level should

also be checked each time the battery is charged

¢ page 205.

Have the battery checked when you take your ve

hicle in for serv ice. You are well advised to re

place a battery t hat is older than 5 years.

Disconnecting the battery terminals

Some vehicle functions (power window regula

tors, for example) are lost if the battery termi nals are disconnected. These functions have to be

relearned after the battery terminals are con

nected again. To prevent th is, the battery should

only be disco nnected from the vehicle e lectr ica l

system when abso lutely necessary for repairs.

Vehicles not driven for long periods

If you do not drive your vehicle over a period of

several days or weeks, electrical components are

gradually cut back or sw itched off. This reduces

energy consumption and maintains starting ca

pability over a longer period¢

page 173.

Some of the conven ience functions may not oper

ate, such as the interior lights or the power seat

adjustment. The convenience functions will be

available again when you turn on the ignition and

start the engine.

Winter operation

During the winter months, battery capacity tends

to decrease as temperatures drop . T his is be-

Checking and Filling

cause more power is also consumed while start

ing, and the headlights, rear window defogger,

etc., are used more often.

Avo id unnecessary power consumption, particu

larly in city traff ic or when traveling only short

distances . Let your authorized Audi dealer check

the capacity of the vehicle battery before winter

sets in ¢

page 205. A well charged battery will

not only prevent starting problems when the

weather is cold, but will also last longer .

(D Tips

If your vehicle is left standing for several

weeks at extremely low temperatures, the ve

hicle battery should be removed and stored

where it w ill not freeze. This will prevent it

from be ing damaged and having to be re

placed.

Working on the battery

Be especially careful when working on or near

the battery.

The battery is located in the luggage compart

ment under the floo r. Before you check anything

in the luggage compartment,

read and heed all

WARNINGS ¢

LD.·

Always heed the safety warnings, when working

on the vehicle battery or the veh icle electrical

system to prevent injury.

The following WARNINGS are very important

when working on the battery:

Always heed the following WARNING SYM·

BOLS and safety precautions when working on

the battery.

®

Always wear eye protection.

A

Battery acid contains sulfuric acid. Al·

ways wear gloves and eye protection .

@

No

- sparks

· flames

· smoking.

203

Page 231 of 266

always fully set the parking brake and block

the wheel diagonally opposite the wheel be ing changed with the folding chocks or oth

er objects. When one front wheel is lifted

off the ground, placing the Automatic

Transmission in "P" (Park) will

not prevent

the vehicle from moving.

- Before you change a wheel, be sure the

ground is level and firm. If necessary, use a

sturdy board under the jack.

- Always store the vehicle tool kit, the jack*

and the replaced tire in the luggage com

partment

r::!>page 116.

(D Note

If you are changing the wheel on a steep in

cline, use a rock or similar object to block the

opposite wheel to prevent the vehicle from

moving.

(D Tips

Obey all laws.

Changing a wheel

When you change a wheel, follow the sequence

described below step-by-step and in exactly that

order.

1.

Remove the decorative wheel cover* or the

wheel bolt caps*. For more details see also

r::!> page 229, Decorative wheel covers or

r::!> page 230, Wheels with wheel bolt caps .

2. Loosen the wheel bolts~ page 230.

3. Locate the proper mounting point for the

jack and align the jack below that point

r::!> page 2 31.

4. lift the car with the jack r::!> page 231.

5. Remove the wheel with the flat tire and then

in stall the

spare tire r::::> page 232.

6. Tighten all wheel bolts lightly .

7 .

lower the vehicle with the jack.

8 . Use the wheel bolt wrench and

firmly tighten

all wheel bolts in a crisscross pattern

r::!> page 230.

~ 9. Replace the decorative wheel cover* or the ......

~ wheel bolt caps*. N ...... 0

0

LL co

Emergency assistance

A WARNING

-Always read and follow all WARNINGS and in-

formation

r::!> .&. in Raising the vehicle on

page231

and r::::> page233.

After changing a wheel

A wheel change is not complete without the do

ing the following.

.. Always store the vehicle tool kit, the jack*, and

the replaced tire in the luggage compartment

r::::>page 116.

.. Check the tire pressure of the spare tire as soon

as possible .

.. As soon as possible, have the

tightening tor

ques

on all wheel bolts checked with a torque

wrench. The correct tightening torque is 90 ft

lbs .

(120 Nm).

.. Have the flat tire

replaced as soon as possible.

@ Tips

-If you notice that the wheel bolts are cor

roded and difficult to turn while changing a

tire, they should be replaced before you

check the tightening torque.

- Drive at reduced speed until you have the tightening torques checked.

Decorative wheel covers

Applies to: vehicles wit h deco rative w heel covers

The decorative wheel covers must be removed

first to access the wheel bolts.

Fig. 18S C ha nging a wheel: removing the wheel cover

229

Page 233 of 266

Raising the vehicle

The vehicle must be li~ed with the jack first be

fore the wheel can be removed .

Fig. 188 S ill panels: markings

Fig. 189 Sill: posit ion ing th e vehicle jack

The location of the jack point is indicated by an

indentat ion on the underside of the vehicle

c::> fig. 188.

;:;; N 0 u. a, ID

~ Activate the parkin g brake to p reve nt the vehi

cle from roll ing unintentionally.

~ Move the selector lever to position P.

~ Find the m ark in g (imprint) on the sill that is

nearest the wheel that will be changed

<=> fig . 188. Behind the marking, there is a lift

i ng p oint on the sill for the vehicle jack .

~ Turn the ve hicle ja ck located under the lifting

po int on the s ill to ra ise the jack until the jaw

<=> fig. 189 @cove rs the n o tch on the vehicle

Q ,& c::>0 .

~ Align the vehicle jack so the jaw @covers the

notch and the base plate @ is flat on the floor.

The base plate @ must be

vertical under the

lifting point @.

~ Install the rod on the vehicle jack: Insert the

; rod into the opening on the handwheel. Turn

~ the rod left or right to secure it. N .... 0

0

LL co

Emergen cy a ssis tanc e

~ Continue ra ising the jack with t he rod unti l the

wheel lifts off the ground slightly .

Pos ition the vehicle jack

only under the des igna t

ed lift ing points on the sill

c::> fig. 188. There is ex

actly

one l ocation for each wheel. The jack must

not be posit ioned at any ot her location

c::> &<=>CD .

Soft ground under the jack can cause the vehicle

to s lip off the jack. A lways p lace the jack on firm

ground . Use a f lat, stab le support if necessary .

Use a non-s lip surface such as a rubber mat on a

slipp ery s urface such as tile.

_& WARNING

--You or your passengers could be injured

while changing a wheel if you do not follow

these safety precautions:

- Position the vehicle jack only at t he des ig

nated lifting points and align the jack .

Otherwise, the vehicle jack could slip and

cause an injury if it does not have suffi

c ient hold on the vehicle.

- A soft or unstable surface under the jack

may cause the veh icle to slip off the jack.

Always provide a firm base for the jack on

the ground . If necessary, use a sturdy

board unde r the jack .

- On hard, slippery surface (such as t iles)

use a rubber mat or similar to prevent the

jack from slipping.

- To help prevent injury to yourse lf and your

passengers:

- Do no t raise the veh icle until you are sure

the jack is securely engaged.

- Passengers m ust not remai n in the vehicle

when it is jacked up.

- Make su re tha t passengers wait in a safe

place away from the vehicle and well away

from the road and traffic.

- Make s ure jack position is correct, adjus t

as necessary and t hen continue to raise

the jack .

(D Note

Do not lift the vehicle by the s ill. Pos ition the

vehicle j ack only at the des ignated lift ing

231

Page 234 of 266

Emergency assistance

points on the sill. Otherwise, your vehicle will

be damaged .

Taking the wheel off/installing the spare

tire

Follow these instructions step-by-step for chang

ing the wheel .

Fig. 190 Cha nging a wheel : usin g the screwdr iver handle

(with the b lade removed) to turn th e bo lts

Fig. 191 Chan gin g a wheel: align ment pin inside the top

h ole

After you have loosened all wheel bolts and

raised the vehicle off the ground, remove and re

p lac e the whee l as follows:

Removing the wheel

"' Remove the topmost wheel bolt completely

with the

hexagonal socket in the screwdriver

handle (vehicle tool kit)

¢fig. 190 and set it

aside on a

clean surface.

"' Screw the threaded end of the

alignment pin

from the tool kit hand -tight into the empty bolt

hole

r=;, fig . 191 .

"'Then remove the other wheel bo lts as described

above.

"' Take off the wheel leaving the alignment pin in

the bolt hole

r=;, (D.

232

Putting on the spare tire

"'Push the spare tire over the alignment pin.

"' Scr ew on the whee l bolts and tighten them

slightly using the hexagona l socket.

"' Remove the alignment pin and insert and tight

en the remaining wheel bolt slightly like the

rest.

"' Turn the jack handle counter-clockw ise to lower

the vehicle until the jack is fully released .

"' Use the wheel bolt wrench to tighten a ll wheel

bolts firmly ¢

page 230. Tighten them in a

crisscross pattern,

from one bolt to the (ap

proximate ly) opposite one, to keep the whee l

centered.

"' Perform the steps required after changing the

wheel

r=;, page 229, After changing a wheel .

The hexagonal socket makes it easier to remove

the wheel bolts from the rim. Care should be tak

en when removing the reversible blade.

(D Note

When removing or installing the wheel, the

rim could hit the brake rotor and damage the

rotor. Work carefully and have a second per

son to help you.

(D Tips

-When mounting tires with unidirectional

tread design

make sure the tread pattern is

pointed the right way¢

page 233.

-The wheel bolts should be clean and easy to

turn. Check for dirt and corrosion on the

mating surfaces of both the wheel and the

hub. Remove all dirt from these surfaces be

fore remounting the wheel.

- Do not use the hexagonal socket in the

screwdriver handle to loosen or tighten the

wheel bolts .

Page 237 of 266

a:,

a:,

...... N

" N ...... 0

0

LL co

Fuse panel @ (black)

No . Consumer

1 Dynamic steering

2 Electronic Stabilization Cont rol (mod ule)

A/C system press ure sensor, elect rome -

chan ica l park ing brake , Homelink, auto-

3 mat

ic dimming interior rear v iew mirror,

air q uality/outside a ir sensor, Electronic

Stabili zation Cont rol (button)

5 Sound actuator

6 Headlight range control/

headlight (cor-

ne ring light)

7 Headlight (cornering light)

Con trol modules (e lectrom echan ica l par k-

8 ing brake, s hock ab so rbe r, q uattro s port),

DCDC converter

9 Adapt ive cru ise control

1 0 Shift ga te/clu tch se nsor

1 1 Side assist

12 Headlight range control

, p arkin g sys tem

13 Airbag

14 Rear wiper (a

llroad)

1 5 Auxiliary fuse (instrument panel)

1 6 Auxiliary fuse terminal 15 (engine area

)

Fuse panel@ (brown)

No . Consumer

2 Brake light senso r

3 Fuel pump

4 Clutch sensor

5

Left seat heating w it h /w it h out seat venti-

l a tion

6 Electronic Stabili zation Cont rol (e lectr ic)

7 Ho rn

8

Front left door (window regulator, central

locki ng, mirror, switch, lig hting)

9 Windshield wiper moto r

10 Electronic Stabilization Cont rol (va lves)

Fuses and bulbs

No . Consumer

Two-door mode ls: rear left w indow reg ula-

1 1 tor; Four-door mode

ls: rear left door (w in-

dow regu lator, central locking, switch,

li ght ing)

1 2 Rain and

light sensor

Fuse panel © (red)

No . Consumer

3 Lumbar support

4 Dynam ic steering

5 Inter

io r ligh ting ( Cabr io let)

6 W

indshie ld washer system, headlight

wash er system

7 Vehicle e lectrica l system control module 1

8 Ve hicl e e lec trica l sy stem con trol module 1

9

Left rear window regu lator motor (Cabr io-

l et)/s unroof

1 0 Vehicle e lec tric al system con trol module 1

1 1 R

ight rear window regulator (Cabriolet)/

su n shade motor

1 2 A

nti- theft alarm warning system

Right cockpit fuse assignment

Fig. 194 R ig h t cockp it : f use pane l wit h plast ic cl ip

235

Page 238 of 266

Fuses and bulbs

Fuse panel @ (black)

No. Consumer

5 Steering column switch module

7 Terminal 15 diagnostic connector

8 Gateway (Databus diagnostic interface)

9 Supplementary heater

Fuse panel @ (brown)

No. Consumer

1 CD/DVD player

2 Wi-Fi

3 MMI/Radio

4 Instrument cluster

5

Gateway (instrument cluster control mod-

ule)

6 Ignition lock

7 Light switch

8 Climate control system blower

9 Steering column lock

10 Climate control system

11 Terminal 30 diagnostic connector

12 Steering column switch module

236

Right luggage compartment fuse

assignment

Fig. 195 Right lugg age compartment: fuse panel wit h

plastic cl ip

Fuse panel @ (black)

No. Consumer

2 Rear window heater (Cabriolet)

3 Power top latch (Cabriolet)

4 Power top hydraulics (Cabriolet)

Fuse panel @ (black)

No. Consumer

Luggage compartment lid control module

1 (allroad)/Power top control module (Cab- riolet)

2 Retractable rear

spoiler

(RS 5 Coupe)

5 Electromechanical

parking brake

6 Electronic damping control

7 Electromechan ical park ing brake

8 Rear exterior lighting

9 quattro sport

10 Rear exterior lighting

11 Central

locking

12 Terminal 30

...

Page 239 of 266

a:,

a:,

...... N r--. N ...... 0

0

LL 00

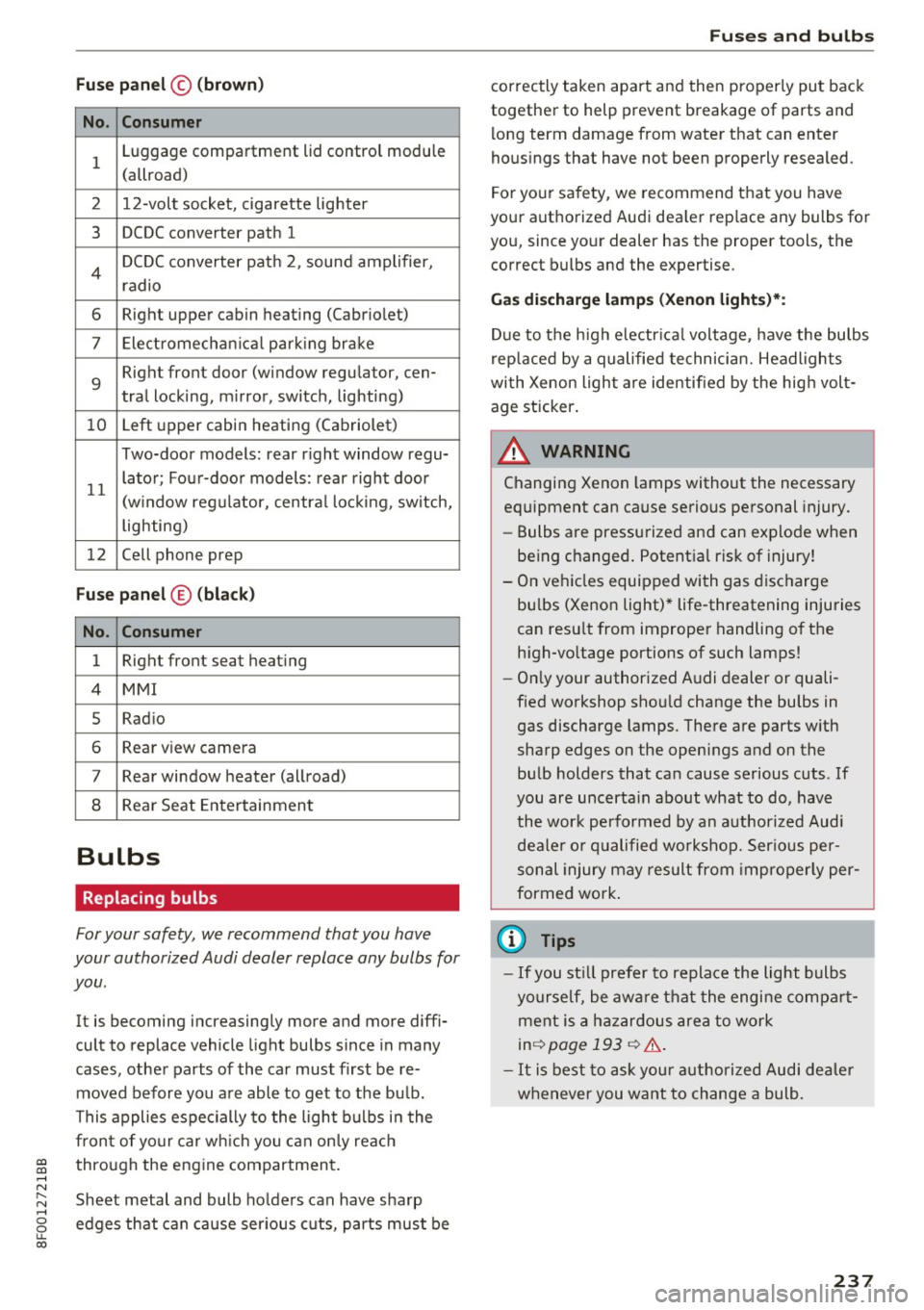

Fuse panel© (brown)

No . Consumer

1 Luggage compartment lid control module

(allroad)

2 12-volt socket, cigarette lighter

3 DCDC converter path 1

4 DCDC converter path 2, sound amplifier,

radio

6 Right upper cabin heating (Cabriolet)

7 Elect romechan ical park ing brake

9

Right front door (window regulator, cen-

tral locking, m irror, switch, lighting)

10 Left

upper cabin heating (Cabriolet)

Two-door models: rear r ight window regu-

11 lator; Four-door models:

rear right door

(w indow regulator, central locking, switch,

lighting)

12 Cell phone prep

Fuse panel ® (black )

No . Consumer

1 Right front seat

heating

4 MMI

5 Radio

6 Rear view camera

7 Rear window heater (allroad)

8 Rear Seat Entertainment

Bulbs

Replacing bulbs

For your safety, we recommend that you have

your authorized Audi dealer replace any bulbs for

you .

It is becoming increasingly more and more diffi

cult to replace vehicle light bulbs since in many

cases, other parts of the car must first be re

moved before you are able to get to the bu lb.

This applies especially to the light bulbs in the

front of your car which you can only reach

through the eng ine compartment.

Sheet metal and bulb ho lders can have sharp

edges that can cause serious cuts, parts must be

Fuses and bulbs

correctly taken apart and then properly put back

together to help prevent breakage of parts and

long term damage from water that can enter

hous ings that have not been properly resealed.

For your sa fety, we recommend that you have

your authorized Audi dea ler replace any bulbs for

you, since your dealer has the proper tools, the

correct bulbs and the expertise.

Gas discharge lamps (Xenon lights)*:

Due to the high e lectr ica l voltage, have the bulbs

replaced by a qualified technician. Headlights

with Xenon light are identified by the high volt

age sticker .

A WARNING

Changing Xenon lamps without the necessary

equipment can cause serious personal injury.

- Bulbs are pressurized and can explode when

being changed . Potential risk of injury!

- On vehicles equipped with gas discharge

bu lbs (Xenon light)* life-threatening injuries

can resu lt from improper handling of the

high -vo ltage portions of such lamps!

- Only your authorized Audi dealer or quali

fied workshop shou ld change the bulbs in

gas discharge lamps. There are parts w ith

sharp edges on the openings and on the bulb holders that can cause serious cuts . If

you are uncerta in about what to do, have

the wor k performed by an authorized Audi

dealer or qualified workshop. Serious per

sonal injury may result from improperly per

formed work.

(D Tips

- If you st ill prefer to replace the light bulbs

yourself, be awa re that the engine compa rt

ment is a hazardous area to work

inq page 193 q &,.

- It is best to ask your authorized Audi dealer

whenever you want to change a bulb.

237

Page 241 of 266

a:,

a:,

...... N

" N .... 0

0

LL co

@ Tips

The discharged battery must be properly con

nected to the vehicle's electrical system .

When jump starting or charg ing the battery,

never connect the negative ground cable to

the battery negative post because the battery

manager system must be able to detect the

battery's state of charge. Always connect the

negative ground cable to the negative ground

post of the battery manager control unit.

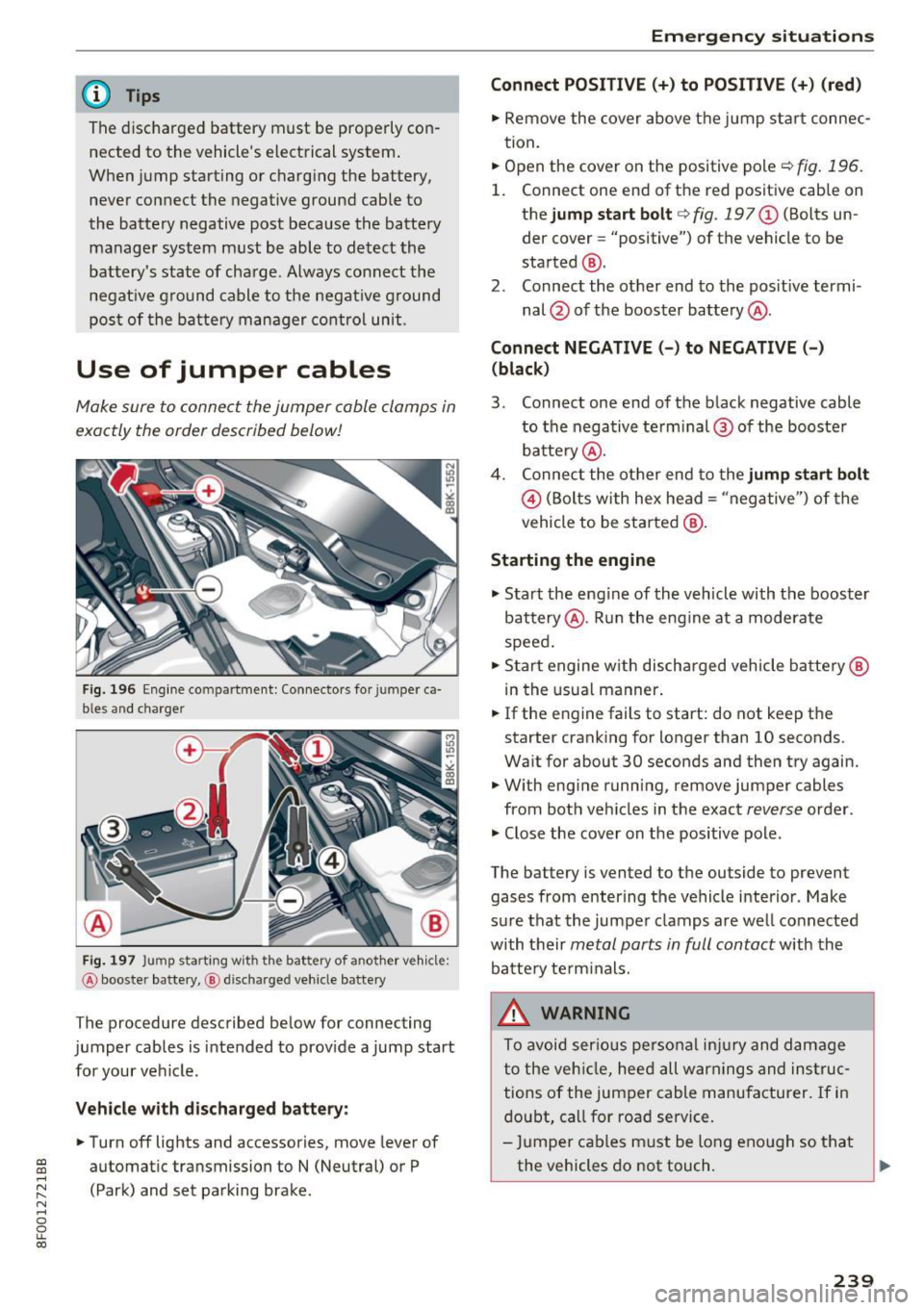

Use of jumper cables

Make sure to connect the jumper cable clamps in

exactly the order described below!

Fig. 196 Engine compartment: Connectors fo r jumper ca

bles and charger

Fig. 197 Jump starting with the battery of another vehicle:

@ booster battery, @ discharged vehicle battery

The procedure described below for connecting

jumper cables is intended to provide a jump start

for your vehicle.

Vehicle with discharged battery: .. Turn off lights and accessories, move lever of

automatic transmission to N (Neutral) or P

(Park) and set parking brake.

Emergency situations

Connect POSITIVE(+) to POSITIVE (+) (red)

.. Remove the cover above the jump start connec

tion.

.. Open the cover on the positive pole

c;, fig. 196.

1. Connect one end of the red positive cab le on

the jump start bolt

c;, fig. 197@ (Bolts un

der cover= "positive") of the vehicle to be

started @.

2. Connect the other end to the positive termi-

nal @ of the booster battery @.

Connect NEGATIVE(-) to NEGATIVE(-) (black)

3. Connect one end of the black negative cable

to the negative te rm i nal @of the booster

battery @.

4. Connect the other end to the jump start bolt

@ (Bolts with hex head= "negative") of the

vehicle to be started @.

Starting the engine

"' Start the engine of the vehicle with the booster

battery @. Run the engine at a moderate

speed.

"' Start engine w ith discharged vehicle battery@

in the usual manner.

"' If the eng ine fails to start: do not keep the

starter cranking for longer than 10 seconds.

Wait for about 30 seconds and then try again.

"' With engine running, remove jumper cables

from both vehicles in the exact

reverse order .

"' Close the cover on the positive pole.

The battery is vented to the outside to prevent gases from entering the vehicle interior. Make

sure that the jumper clamps are well connected

with their

metal parts in full contact with the

battery term inals.

_&. WARNING

To avoid serious personal injury and damage

to the veh icle, heed all warnings and instruc

tions of the jumper cable manufacturer. If in

doubt, call for road service.

- Jumper cables must be long enough so that

the vehicles do not touch. ""

239

Page 253 of 266

a:,

a:,

...... N r--. N ...... 0

0

LL 00

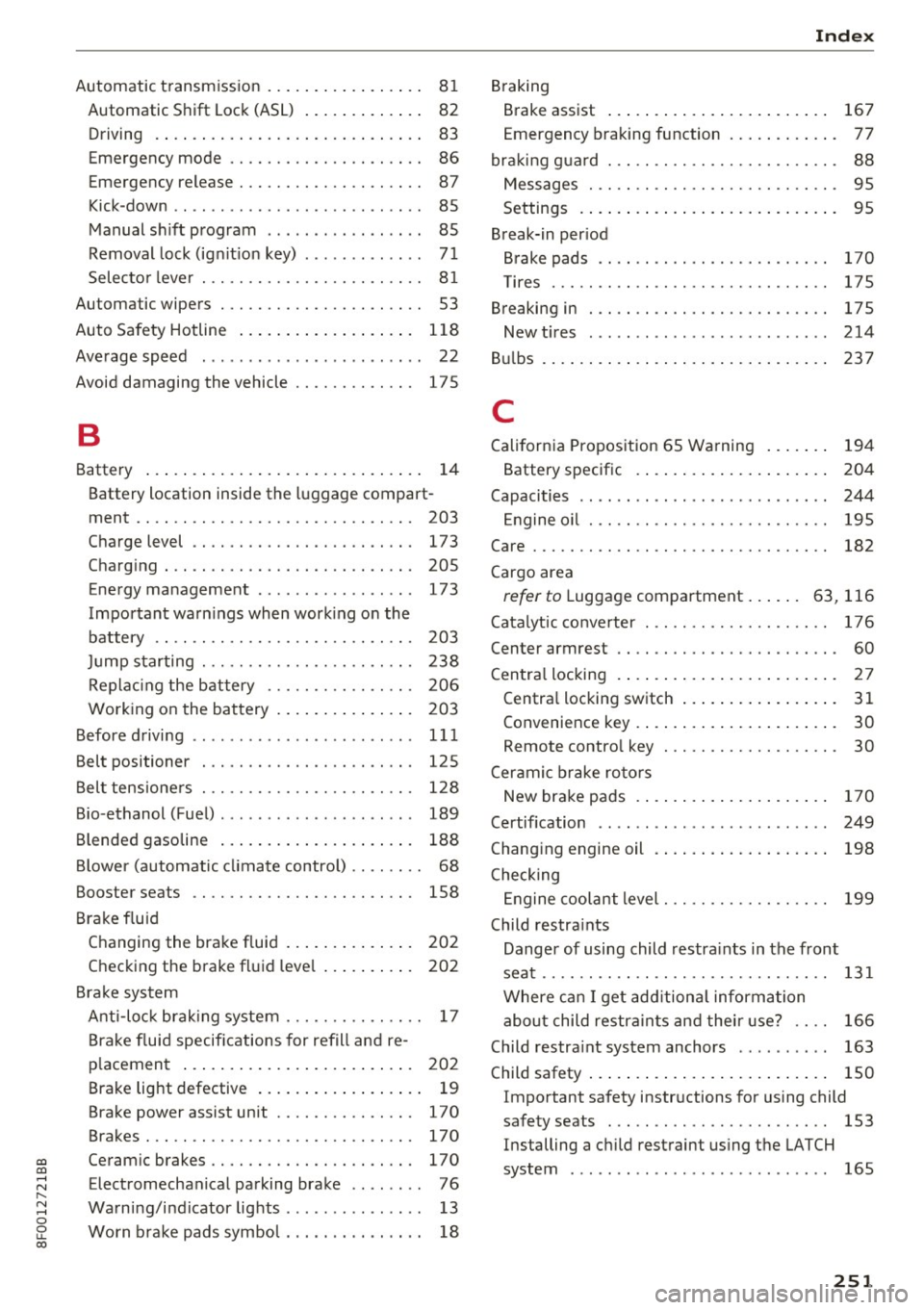

Automatic transmission . . . . . . . . . . . . . . . . . 81

Automatic Shift Lock (ASL) . . . . . . . . . . . . . 82

Driving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Emergency mode . . . . . . . . . . . . . . . . . . . . . 86

Emergency release . . . . . . . . . . . . . . . . . . . . 87

Kick -down . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Manua l shift program . . . . . . . . . . . . . . . . . 85

Removal lock (ignition key) . . . . . . . . . . . . . 71

Selector lever . . . . . . . . . . . . . . . . . . . . . . . . 81

Automatic wipers . . . . . . . . . . . . . . . . . . . . . . 53

Auto Safety Hotline . . . . . . . . . . . . . . . . . . . 118

Average speed . . . . . . . . . . . . . . . . . . . . . . . . 22

Avoid damaging the vehicle . . . . . . . . . . . . . 175

B

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Battery location inside the luggage compart-

ment ..............................

203

Charge level . . . . . . . . . . . . . . . . . . . . . . . . 173

Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Energy management . . . . . . . . . . . . . . . . . 173

Important warnings when working on the

battery . . . . . . . . . . . . . . . . . . . . . . . . . . . .

203

Jump starting . . . . . . . . . . . . . . . . . . . . . . . 238

Replac ing the battery . . . . . . . . . . . . . . . . 206

Work ing on the battery . . . . . . . . . . . . . . . 203

Before driving . . . . . . . . . . . . . . . . . . . . . . . . 111

Belt positioner . . . . . . . . . . . . . . . . . . . . . . . 125

Belt tensioners . . . . . . . . . . . . . . . . . . . . . . . 128

Bio -ethanol (Fuel) . . . . . . . . . . . . . . . . . . . . . 189

Blended gasoline . . . . . . . . . . . . . . . . . . . . . 188

Blower (automatic climate control) . . . . . . . . 68

Booster seats . . . . . . . . . . . . . . . . . . . . . . . . 158

Brake fluid

Changing the brake fluid . . . . . . . . . . . . . .

202

Checking the brake fluid l evel . . . . . . . . . . 202

Brake system

Anti-lock brak ing system . . . . . . . . . . . . . . .

17

Brake fluid specifications for refill and re

placement . . . . . . . . . . . . . . . . . . . . . . . . .

202

Brake light defective . . . . . . . . . . . . . . . . . . 19

Brake power assist unit . . . . . . . . . . . . . . . 170

Brakes. .. .. .. ............... .. ..... 170

Ceramic brakes . . . . . . . . . . . . . . . . . . . . . . 170

Electromechan ical parking brake . . . . . . . . 76

Warning/indicator lights . . . . . . . . . . . . . . . 13

Worn brake pads symbol . . . . . . . . . . . . . . . 18

Index

Braking

Brake assist . . . . . . . . . . . . . . . . . . . . . . . .

167

Emergency braking function . . . . . . . . . . . . 77

braking guard . . . . . . . . . . . . . . . . . . . . . . . . . 88

Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Break-in period

Brake pads .. .. .. .. ............. .. . .

Tires ..... .... .. .. ........ · · · · · · · · ·

Breaking in ... .. .. .. ............... . .

New tires

Bulbs

C

170

175

175

214

237

California Proposition 65 Warning . . . . . . . 194

Battery specific . . . . . . . . . . . . . . . . . . . . . 204

Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Engine oil . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Cargo area

refer to Luggage compartment ...... 63, 116

Catalytic converter . . . . . . . . . . . . . . . . . . . . 176

Center armrest . . . . . . . . . . . . . . . . . . . . . . . . 60

C en tral locking . . . . . . . . . . . . . . . . . . . . . . . .

27

Central locking switch . . . . . . . . . . . . . . . . . 31

Convenience key . . . . . . . . . . . . . . . . . . . . . . 30

Remote control key . . . . . . . . . . . . . . . . . . . 30

Ceramic brake rotors

New brake pads . . . . . . . . . . . . . . . . . . . . .

170

Certification . . . . . . . . . . . . . . . . . . . . . . . . . 249

Changing engine oil . . . . . . . . . . . . . . . . . . . 198

Checking

Engin e coolant level. . . . . . . . . . . . . . . . . .

199

Child restraints

Danger of using child restraints in the front

seat.... .. .. .. .. .. ............. ....

131

Where can I get add itiona l information

about child restra ints and their use? . . . .

166

Child restraint system anchors . . . . . . . . . . 163

Child safety . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Impo rtant safety instructions for using child

safety seats . . . . . . . . . . . . . . . . . . . . . . . .

153

Installing a c hild restraint using the LATCH

system . . . . . . . . . . . . . . . . . . . . . . . . . . . .

165

251