jack points AUDI A5 COUPE 2016 Owners Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2016, Model line: A5 COUPE, Model: AUDI A5 COUPE 2016Pages: 264, PDF Size: 66.92 MB

Page 232 of 264

Emergency assistance

-Make sure that passengers wait in a safe

place away from the vehicle and well away

from the road and traff ic.

- Make sure jack position is correct, adjust

as necessary and then cont inue to raise

the jack.

(D Note

Do not lift the vehicle by the sill. Position the

vehicle jack only at the designated lifting points on the sill. Otherwise, your vehicle will

be damaged.

Taking the wheel off /installing the spare

tire

Follow these instructions step-by-step for chang

ing the wheel .

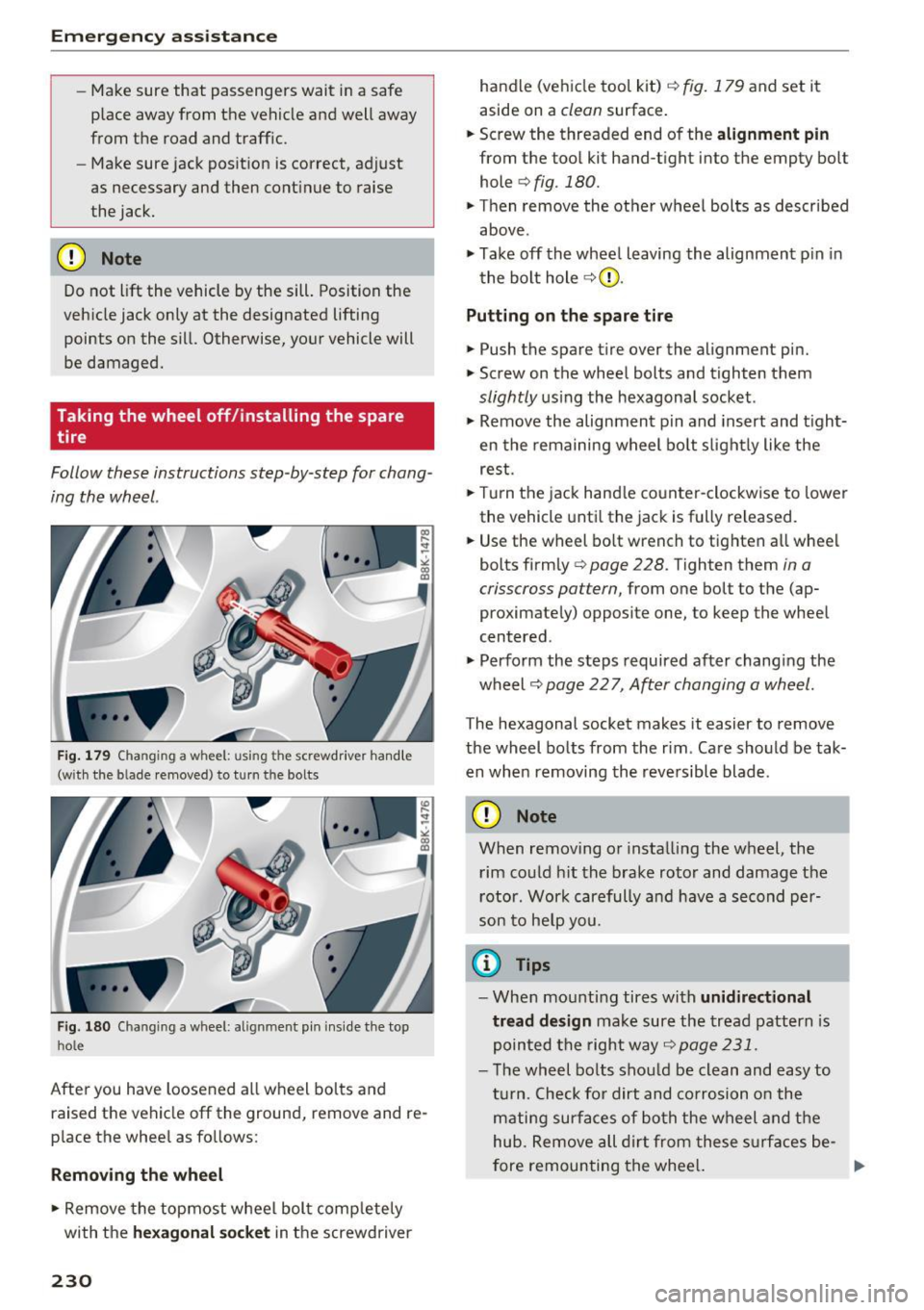

Fig. 179 Changing a wheel: using the screwdriver handl e

(with the blade removed) to turn the bolts

Fig. 180 Changing a wheel: alignment pin insid e the top

hole

After you have loosened all wheel bolts and raised the vehicle off the ground, remove and re

place the whee l as follows:

Removing the wheel

• Remove the topmost wheel bolt comp letely

with the

hexagonal socket in the screwdriver

230

handle (vehicle tool kit) ¢ fig. 179 and set it

aside on a

clean surface.

• Screw the threaded end of the

alignment pin

from the tool kit hand-tight into the empty bolt

hole ¢

fig. 180.

• Then remove the other wheel bolts as described

above.

• Takeoff the whee l leaving the alignment pin in

the bolt hole¢ (!).

Putting on the spare tire

• Push the spare tire over the alignment pin.

• Screw on the wheel bolts and tighten them

slightly using the hexagonal socket.

• Remove the alignment pin and insert and t ight

en the remaining wheel bolt slightly like the

rest.

• Tur n the jack hand le counter-clockw ise to lower

the vehicle until the jack is fully released.

• Use the wheel bolt wrench to tighten a ll wheel

bolts firmly ¢

page 228. Tighten them in a

crisscross pattern,

from one bolt to the (ap

proximately) opposite one, to keep the wheel

centered.

• Perform the steps required after chang ing the

wheel¢

page 227, A~er changing a wheel.

The hexagonal socket makes it easier to remove

the wheel bo lts from the rim . Care should be tak

en when removing the reversible blade.

(D Note

When removing or installing the wheel, the

rim could hit the brake rotor and damage the

rotor . Work carefully and have a second per

son to help you.

(D Tips

-When mounting tires with unidirectional

tread design

make sure the tread pattern is

pointed the right way¢

page 231.

-The wheel bolts should be clean and easy to

turn. Check for dirt and corrosion on the

mating surfaces of both the wheel and the

hub. Remove all dirt from these surfaces be

fore remounting the wheel.

Page 242 of 264

Emergency situations

Raising the vehicle

Lifting with workshop hoist and with floor

jack

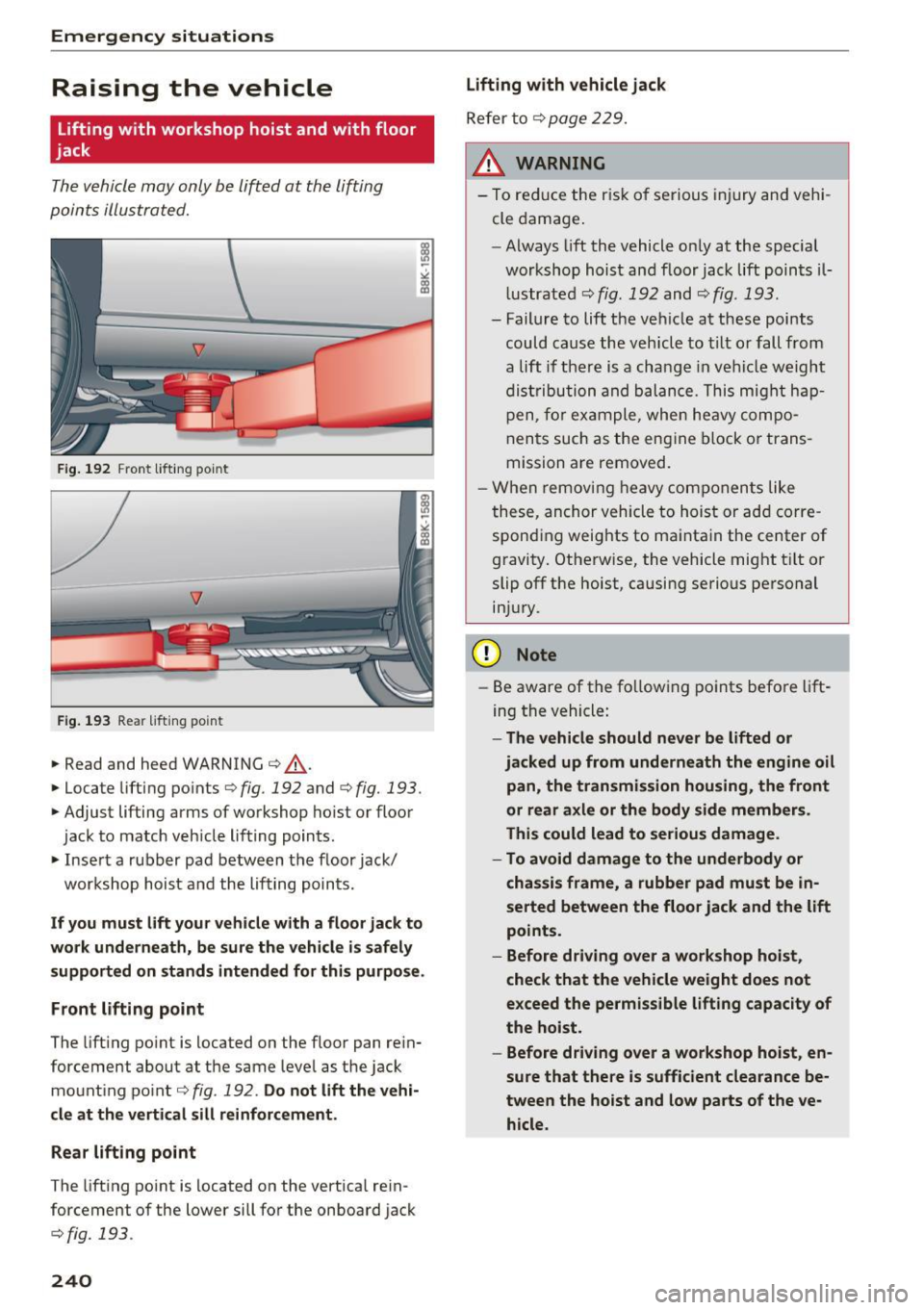

Th e vehicle may only b e lift ed at the lifting

poin ts illust rated.

F ig .. 19 2 Fro nt lift ing po int

F ig. 193 Rea r lifti ng po int

.,. Read and heed WARNING ¢ A-

.,. Locate lifti ng po ints ¢ fig . 192 and ¢ fig. 193.

.,. Adjust li fting arms of wo rkshop hoist or floor

jack to match veh icle lifting points.

.,. In se rt a rubb er pad between t he floor jack/

wor kshop hoist a nd the lif ting poin ts .

If you must lift your vehicle with a floor jack to

work underneath, be sure the vehicle is safely

supported on stands intended for this purpose .

Front lifting point

The lift ing po int is located on the floo r pan re in

forcement about at the same leve l as the jack

mo unt ing point ¢

fig. 192 . Do not lift the vehi

cle at the vertical sill rei nforcement.

Rear lifting point

The lift ing po int is located on the vertica l re in

for cement of the lower sill fo r the on board jack

¢fig. 193.

240

Lifting with vehicle jack

Refer to ~ page 229.

A WARNING

- To re duce the r is k of serious injury and vehi

cle dama ge .

- Always lift the vehicle o nly at the special

workshop hois t an d floor jack lift points il

l ustrat ed

~ fig. 192 and ~ fig. 193.

- Failure to lift the v ehicle at these points

could ca use the veh icle to tilt or fall from

a lift if the re is a cha ng e i n ve hicle weigh t

dis tribu tion and ba lan ce . T his mig ht hap

p en, for exa mple, whe n he avy co mpo

n en ts such as the engine block o r tr an s

mission are removed.

- W hen re m ov in g h eavy co mponen ts like

these, an cho r veh icle to hoist or ad d co rre

spond ing weights to ma inta in the ce nter of

gravity . Othe rw ise, the vehicle mi ght t ilt o r

slip off t he hoist, causing serious pe rsonal

in jur y.

(D Note

- Be aware of the fo llowing po ints befo re lift

ing the vehicle:

- The vehicle should never be lifted or

jacked up from underneath the engine oil pan, the transmission housing, the front

or rear axle or the body side members .

This could lead to serious damage .

- To avoid damage to the underbody or

chassis frame, a rubber pad must be in

serted between the floor jack and the lift

points.

- Before driving over a workshop hoist,

check that the vehicle weight does not

exceed the permissible lifting capacity of

the hoist.

- Before driving over a workshop hoist , en

sure that there is sufficient clearance be

tween the hoist and low parts of the ve

h icle.