torque AUDI A6 1998 C5 / 2.G 01E Transmission Final Drive Pinion And Ring Gear Adjustment Workshop Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 1998, Model line: A6, Model: AUDI A6 1998 C5 / 2.GPages: 38, PDF Size: 0.43 MB

Page 11 of 38

Universal support V.A.G 1359/2

Dial gauge extension 30 mm

Dial gauge

Torque gauge 0-600 Ncm

Pa

ge 11 of 38 Drive

pinion and rin

g gear, ad

justin

g

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM03.39.19

Page 12 of 38

39-154

Drive pinion, adjusting

Note:

Before adjusting drive pinion, adjust ring gear

(determine total shim thickness "S

total

" for

shims "S1" + "S2") Page 39

-163

.

The drive pinion only has to be readjusted if the

final drive set (ring gear and drive pinion), the

tapered roller bearings for the drive pinion or

the final drive housing are replaced. Adjustment

overview Page 39

-150

.

Do not additionally oil new tapered roller

bearings for friction torque measurement. The

bearings have already been treated with a

special oil by the manufacturer.

Determine thickness of shim "S3"

(Setting preload of tapered roller bearings for

drive pinion)

- Mount final drive onto engine and transmission

support Page 39

-108

.

- Pull outer race of large tapered roller bearing into housing (without

shim).

Pa

ge 12 of 38 Drive

pinion and rin

g gear, ad

justin

g

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM03.39.19

Page 14 of 38

39-155

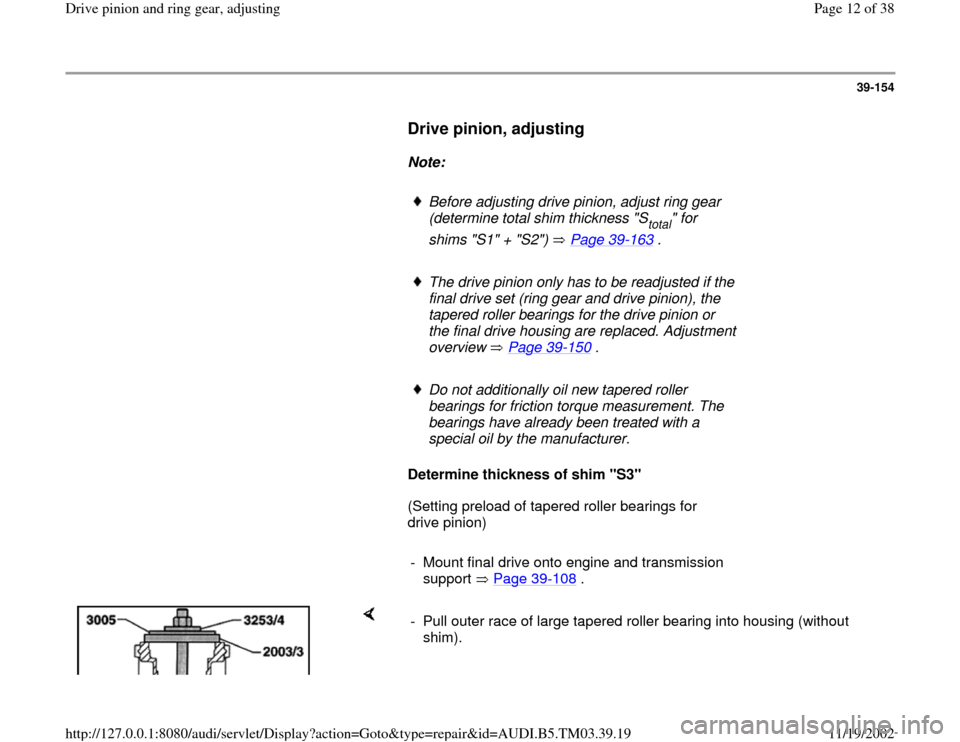

- Pull outer race for small tapered roller bearing into housing.

- Lubricate outer race with oil and fit using press tool VW 408 A and

thrust plate 30-205.

CAUTION!

Wear protective gloves.

Note: - Insert drive pinion without spacer sleeve.

-

Heat inner race for tapered roller bearing to approx. 100 C and fit onto

drive pinion.

Do not additionally oil new tapered roller bearings for friction torque

measurement. The bearings have already been treated with a special

oil by the manufacturer. Only install spacer sleeve for final friction torque measurement (after

determining shim "S3").

Pa

ge 14 of 38 Drive

pinion and rin

g gear, ad

justin

g

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM03.39.19

Page 15 of 38

39-156

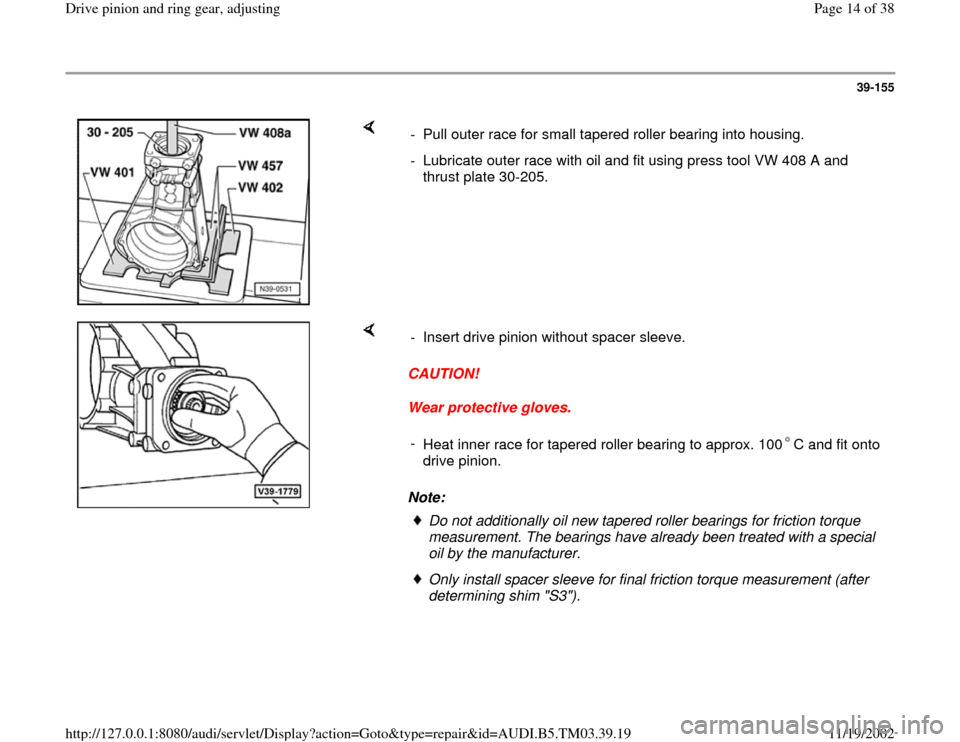

- Secure retainer 3304 with two M8 x 30 hex bolts.

- Support final drive when tightening nut (e.g. using universal support

V.A.G 1359/2 in conjunction with transmission jack V.A.G 1383 A).

- Fit a new drive pinion nut.

- Tighten drive pinion nut just far enough so that no play can be felt at

drive pinion.

- Gradually increase tightening torque, checking friction torque at regular

intervals, unti specified friction torque is obtained.

The following friction torques should be set: 1) run at least 50 km (30 miles) A - Torque gauge, commercially available, 0-600 Ncm

B - Extension with 32 mm socketNew bearings

Used bearings

1)

200-250 Ncm 30-60 Ncm

Pa

ge 15 of 38 Drive

pinion and rin

g gear, ad

justin

g

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM03.39.19

Page 20 of 38

39-161

- Remove drive pinion and outer race of large

tapered roller bearing and install together with

measured shims "S3" and spacer sleeve from

Page 39

-139

.

Install inner race of small tapered roller bearing

and tighten nut for drive pinion until specified

friction torque is obtained

Fig. 11 , Page 39

-144

.

Note:

Do not additionally oil new tapered roller

bearings for friction torque measurement. The

bearings have already been treated with a

special oil by the manufacturer.

Increase tightening torque slowly and check

friction torque at regular intervals, if the

specified friction torque is exceeded, the spacer

sleeve must be replaced and the adjustment

repeated. A spacer sleeve which has been

compressed too much cannot be reused.

- Set to following friction torques:

New bearings

Used bearings

1)

200-250 Ncm 30-60 Ncm

Pa

ge 20 of 38 Drive

pinion and rin

g gear, ad

justin

g

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM03.39.19

Page 23 of 38

39-163

Ring gear, adjusting

(Adjusting differential)

Repairs after which the ring gear has to be

adjusted Page 39

-150

, Adjustment overview

Note:

Differential tapered roller bearings are low

friction bearings. Therefore the friction torque

only has a limited use as a check. Correct

adjustment is only possible by determining the

total shim thickness "S

total

."

Do not additionally oil new tapered roller

bearings for friction torque measurement. The

bearings have already been treated with a

special oil by the manufacturer.

Determining total shim thickness "S

total

" for

shims "S1" + "S2"

(Setting preload of tapered roller bearing for

differential)

Drive pinion removed or ring gear dismantled

from differential housing

- Pull out drive flange oil seal with lever.

Pa

ge 23 of 38 Drive

pinion and rin

g gear, ad

justin

g

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM03.39.19

Page 30 of 38

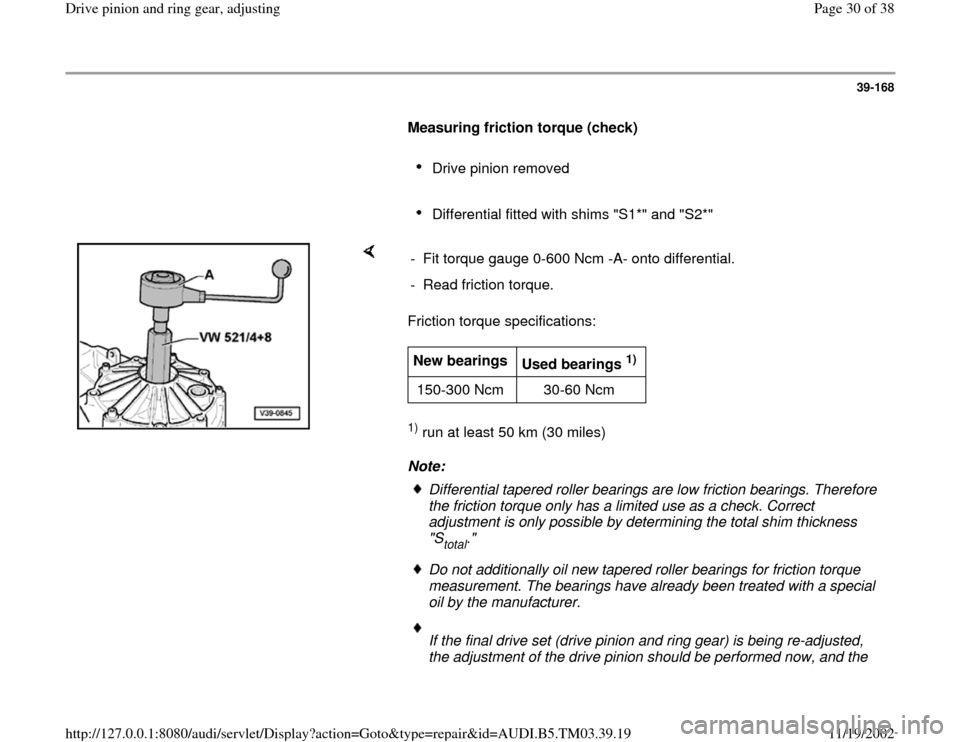

39-168

Measuring friction torque (check)

Drive pinion removed

Differential fitted with shims "S1*" and "S2*"

Friction torque specifications: 1) run at least 50 km (30 miles)

Note: - Fit torque gauge 0-600 Ncm -A- onto differential.

- Read friction torque.New bearings

Used bearings

1)

150-300 Ncm 30-60 Ncm

Differential tapered roller bearings are low friction bearings. Therefore

the friction torque only has a limited use as a check. Correct

adjustment is only possible by determining the total shim thickness

"S

total

."

Do not additionally oil new tapered roller bearings for friction torque

measurement. The bearings have already been treated with a special

oil by the manufacturer. If the final drive set (drive pinion and ring gear) is being re-adjusted,

the adjustment of the drive pinion should be performed now, and the

Pa

ge 30 of 38 Drive

pinion and rin

g gear, ad

justin

g

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM03.39.19