AUDI A6 1998 C5 / 2.G 01V Transmission Drive Pinion Assembly Workshop Manual

A6 1998 C5 / 2.G

AUDI

AUDI

https://www.carmanualsonline.info/img/6/1192/w960_1192-0.png

AUDI A6 1998 C5 / 2.G 01V Transmission Drive Pinion Assembly Workshop Manual

Page 4 of 14

39-155

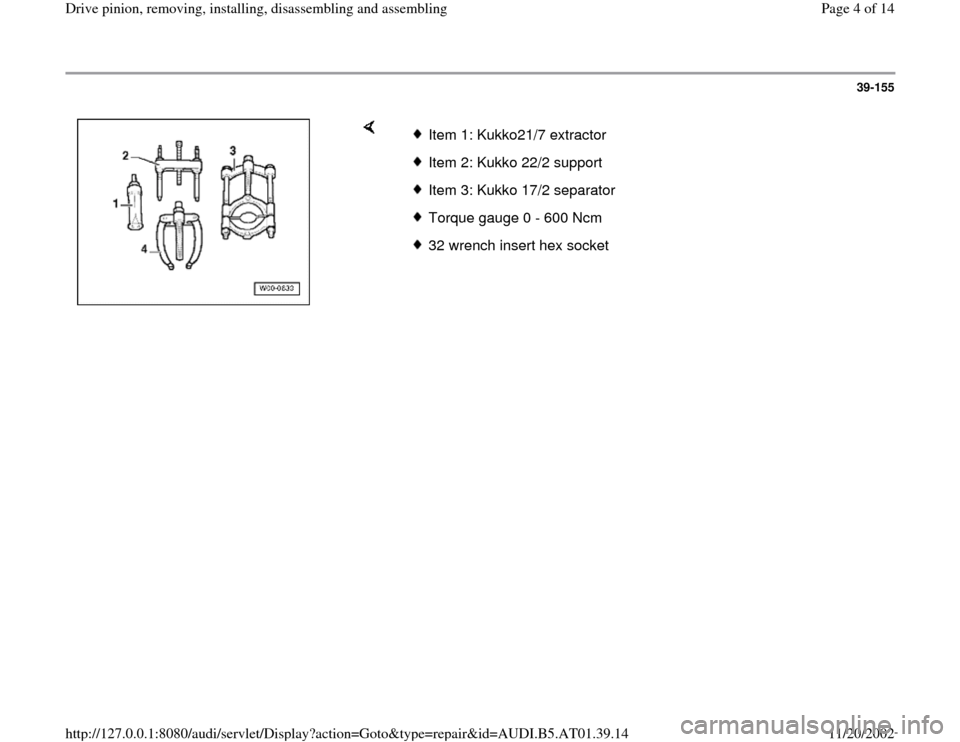

Item 1: Kukko21/7 extractorItem 2: Kukko 22/2 supportItem 3: Kukko 17/2 separatorTorque gauge 0 - 600 Ncm32 wrench insert hex socket

Pa

ge 4 of 14 Drive

pinion, removin

g, installin

g, disassemblin

g and assemblin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.AT01.39.14

Page 5 of 14

39-156

Notes:

General repair notes page 00

-27

.

Disconnect torque tube from rear final drive with

the final drive installed page 39

-96

.

Disconnect torque tube from rear final drive with

the final drive removed page 39

-126

.

Replace both tapered roller bearings together. If

possible, use same manufacturer!

Do not grease new tapered roller bearings

additionally for friction torque measurement.

The bearings are already greased with a

special oil from the factory.

Removing differential page 39

-128

.

Adjustments are required when replacing

components marked with

1) Adjustment

overview page 39

-170

.

Pa

ge 5 of 14 Drive

pinion, removin

g, installin

g, disassemblin

g and assemblin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.AT01.39.14

Page 6 of 14

39-157

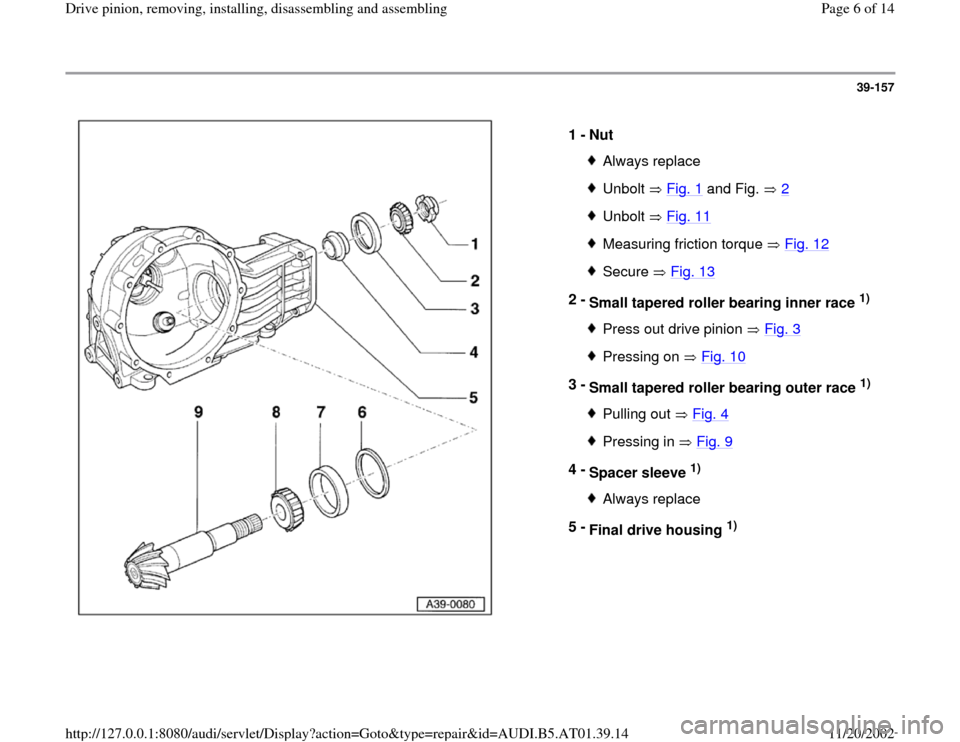

1 -

Nut

Always replaceUnbolt Fig. 1

and Fig. 2

Unbolt Fig. 11Measuring friction torque Fig. 12Secure Fig. 13

2 -

Small tapered roller bearing inner race

1)

Press out drive pinion Fig. 3Pressing on Fig. 10

3 -

Small tapered roller bearing outer race

1)

Pulling out Fig. 4Pressing in Fig. 9

4 -

Spacer sleeve

1)

Always replace

5 -

Final drive housing

1)

Pa

ge 6 of 14 Drive

pinion, removin

g, installin

g, disassemblin

g and assemblin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.AT01.39.14

Page 13 of 14

39-164

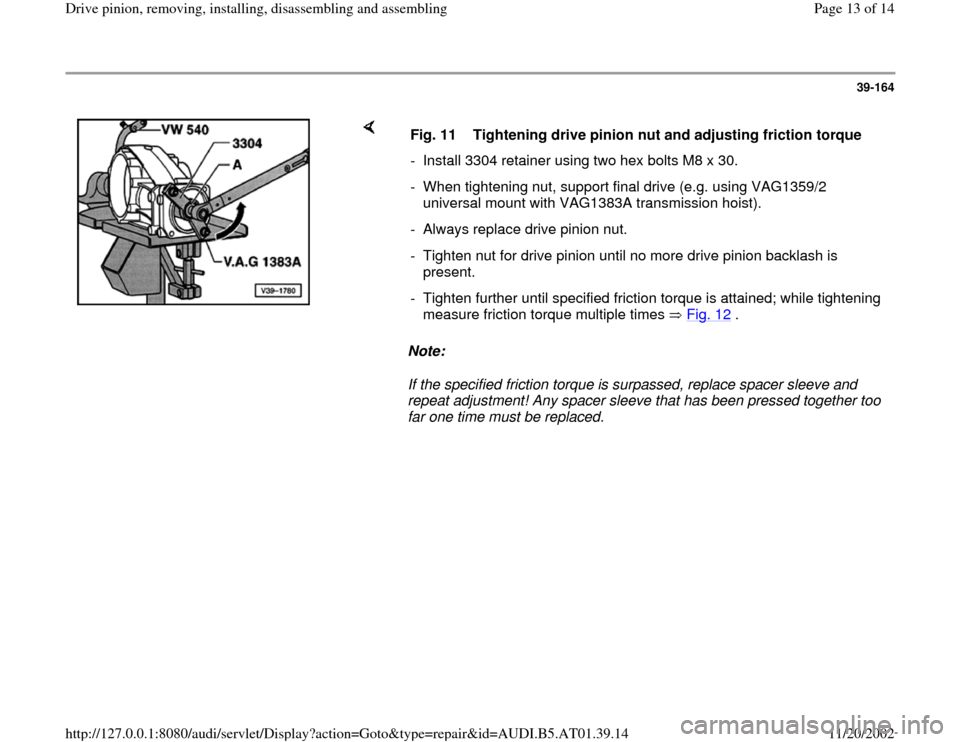

Note:

If the specified friction torque is surpassed, replace spacer sleeve and

repeat adjustment! Any spacer sleeve that has been pressed together too

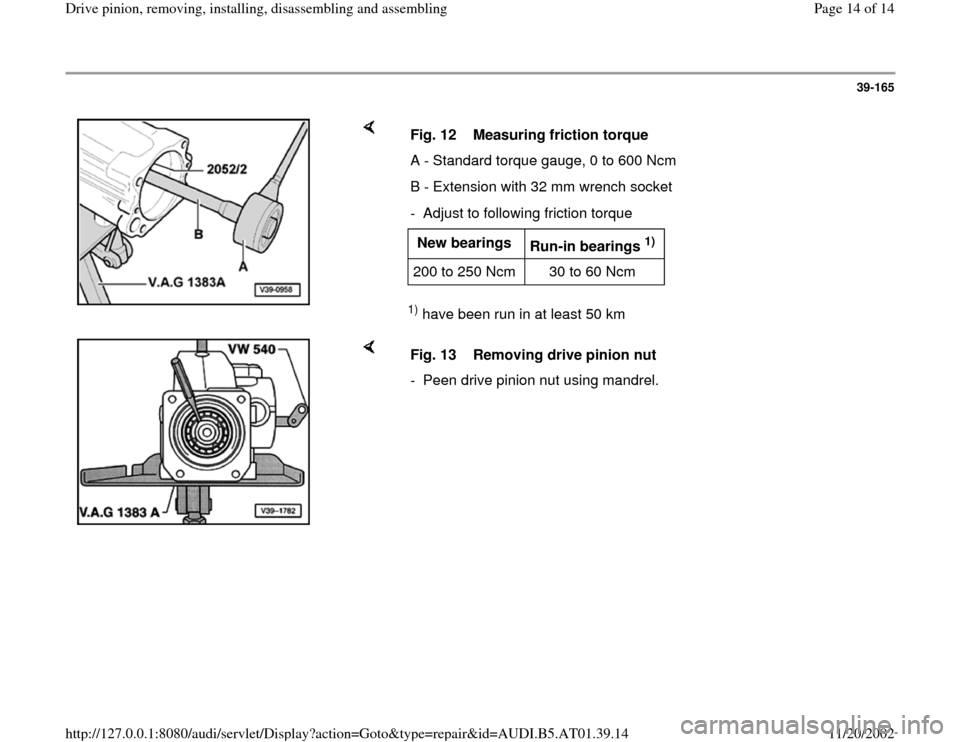

far one time must be replaced. Fig. 11 Tightening drive pinion nut and adjusting friction torque

- Install 3304 retainer using two hex bolts M8 x 30.

- When tightening nut, support final drive (e.g. using VAG1359/2

universal mount with VAG1383A transmission hoist).

- Always replace drive pinion nut.

- Tighten nut for drive pinion until no more drive pinion backlash is

present.

- Tighten further until specified friction torque is attained; while tightening

measure friction torque multiple times Fig. 12

.

Pa

ge 13 of 14 Drive

pinion, removin

g, installin

g, disassemblin

g and assemblin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.AT01.39.14

Page 14 of 14

39-165

1) have been run in at least 50 km Fig. 12 Measuring friction torque

A - Standard torque gauge, 0 to 600 Ncm

B - Extension with 32 mm wrench socket

- Adjust to following friction torqueNew bearings

Run-in bearings

1)

200 to 250 Ncm 30 to 60 Ncm

Fig. 13 Removing drive pinion nut

- Peen drive pinion nut using mandrel.

Pa

ge 14 of 14 Drive

pinion, removin

g, installin

g, disassemblin

g and assemblin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.AT01.39.14