ECU AUDI A6 2000 C5 / 2.G Changing Clutch 5Speed Manual Gearbox

[x] Cancel search | Manufacturer: AUDI, Model Year: 2000, Model line: A6, Model: AUDI A6 2000 C5 / 2.GPages: 71, PDF Size: 1.82 MB

Page 23 of 71

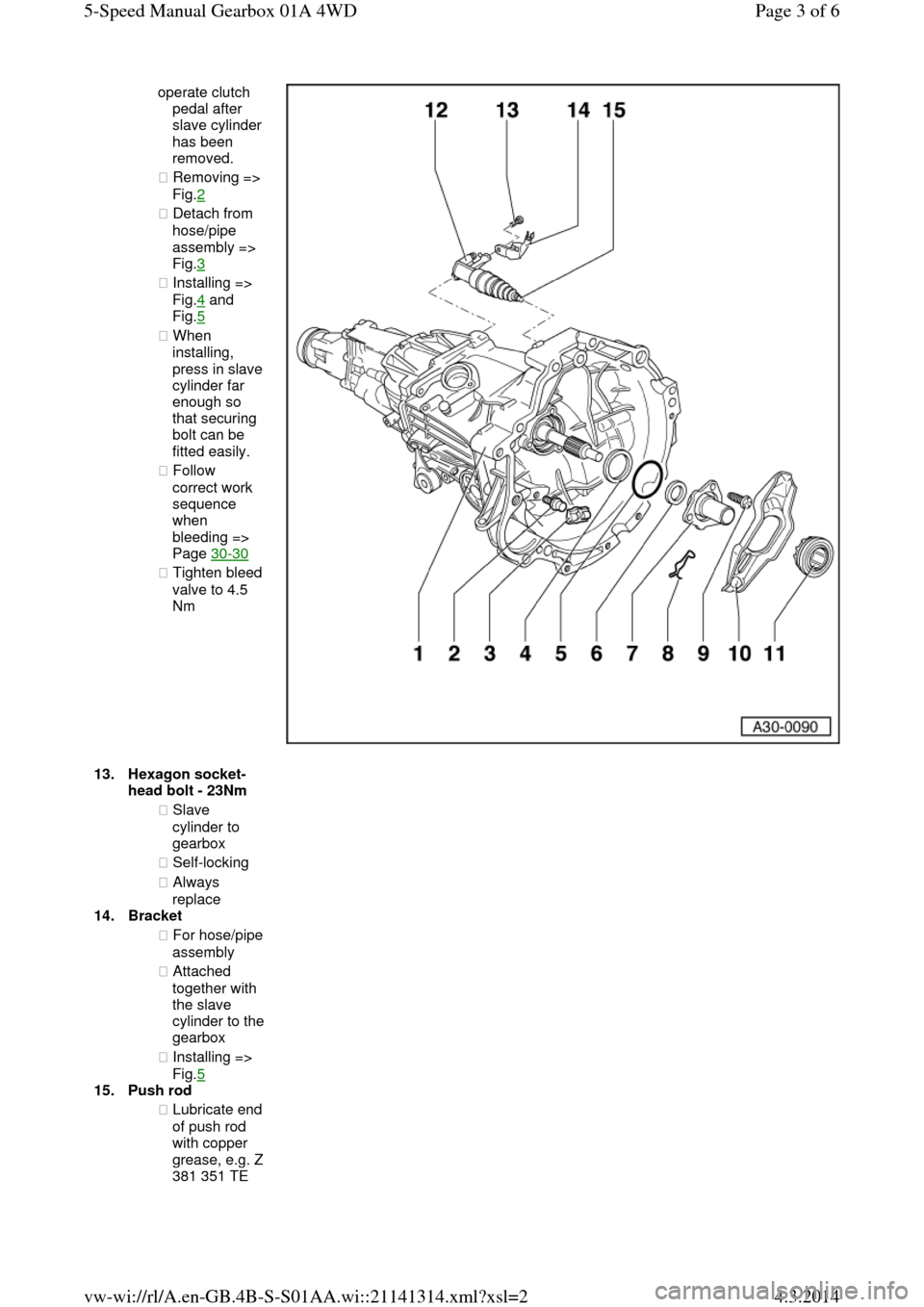

operate clutch

pedal after slave cylinder has been

removed.

◆ Removing => Fig.2

◆ Detach from

hose/pipe

assembly =>

Fig.3

◆ Installing =>

Fig.4 and

Fig.5

◆ When

installing, press in slave cylinder far

enough so

that securing

bolt can be

fitted easily.

◆ Follow

correct work

sequence

when

bleeding =>

Page 30-30

◆ Tighten bleed valve to 4.5

Nm 13.Hexagon socket-head bolt - 23Nm

◆ Slave

cylinder to

gearbox

◆ Self-locking

◆ Always

replace

14.Bracket

◆ For hose/pipe assembly

◆ Attached

together with

the slave cylinder to the gearbox

◆ Installing =>

Fig.5

15.Push rod

◆ Lubricate end of push rod

with copper grease, e.g. Z 381 351 TE Page 3 of 65-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141314.xml?xsl=2

Page 26 of 71

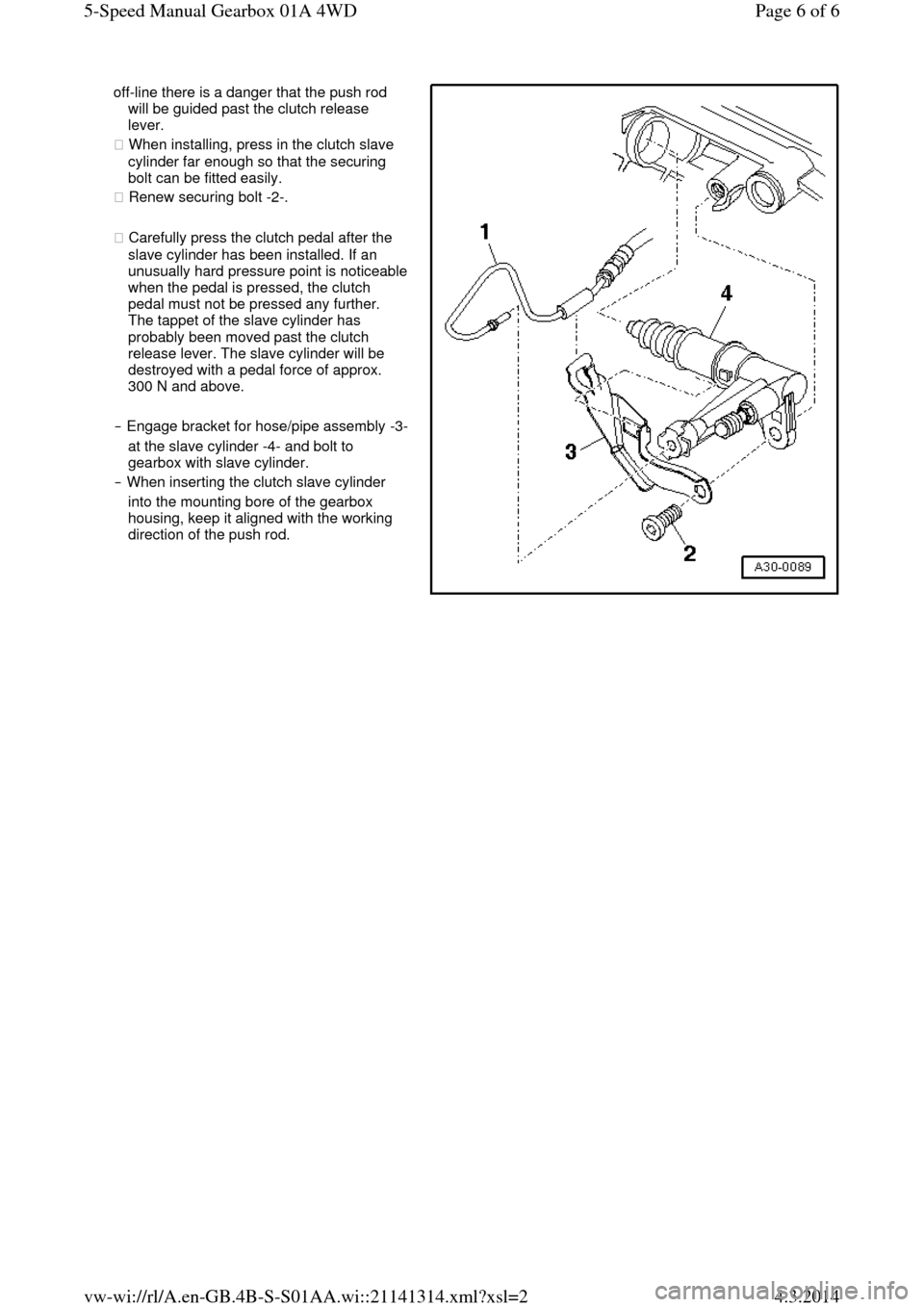

off-line there is a danger that the push rod

will be guided past the clutch release

lever.

◆ When installing, press in the clutch slave

cylinder far enough so that the securing

bolt can be fitted easily.

◆ Renew securing bolt -2-.

◆ Carefully press the clutch pedal after the

slave cylinder has been installed. If an unusually hard pressure point is noticeable when the pedal is pressed, the clutch

pedal must not be pressed any further.

The tappet of the slave cylinder has

probably been moved past the clutch

release lever. The slave cylinder will be

destroyed with a pedal force of approx.

300 N and above.

‒ Engage bracket for hose/pipe assembly -3- at the slave cylinder -4- and bolt to

gearbox with slave cylinder.

‒ When inserting the clutch slave cylinder

into the mounting bore of the gearbox

housing, keep it aligned with the working

direction of the push rod. Page 6 of 65-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141314.xml?xsl=2

Page 28 of 71

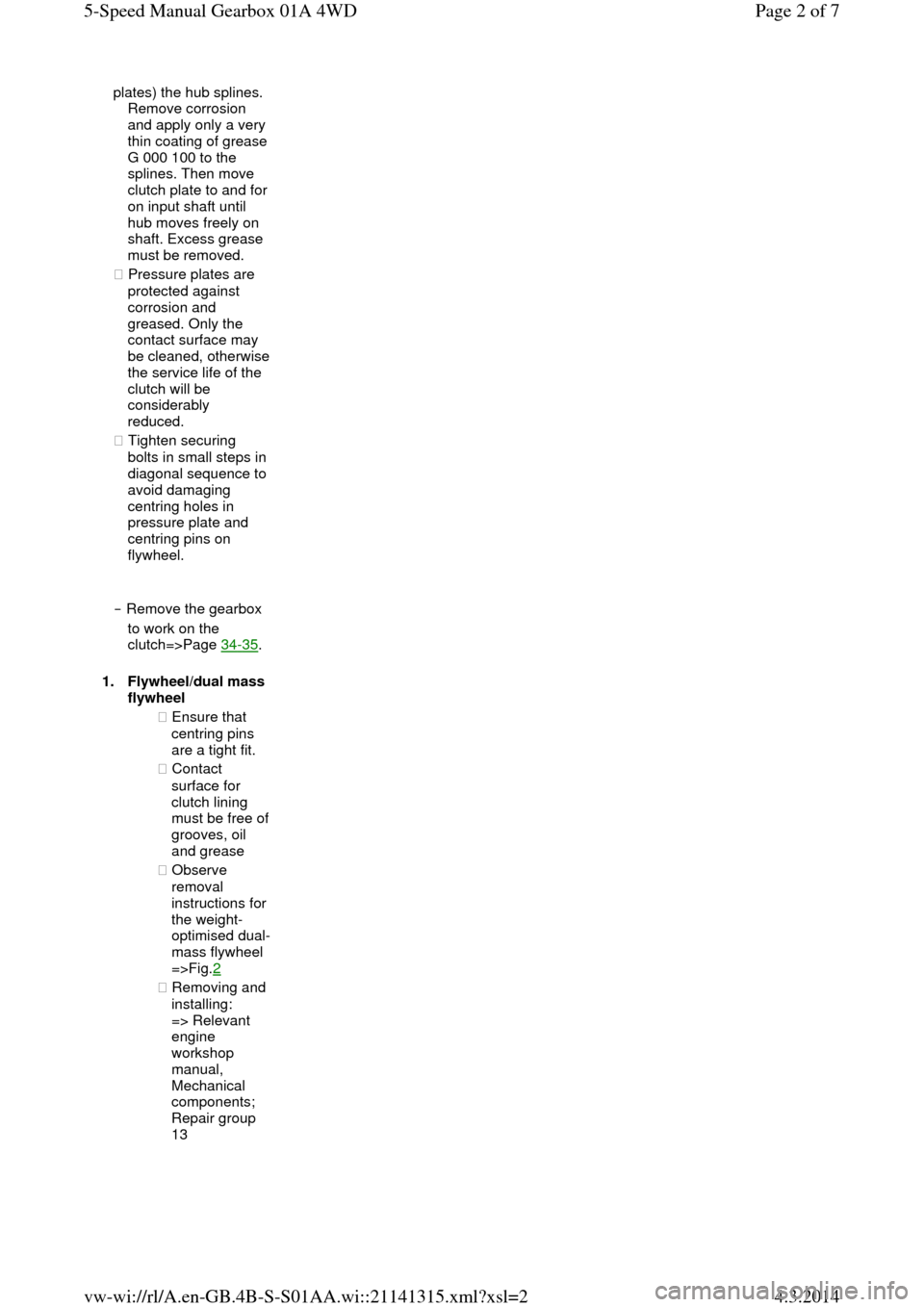

plates) the hub splines.

Remove corrosion

and apply only a very thin coating of grease G 000 100 to the

splines. Then move clutch plate to and for on input shaft until

hub moves freely on

shaft. Excess grease

must be removed.

◆ Pressure plates are

protected against

corrosion and

greased. Only the

contact surface may be cleaned, otherwise the service life of the

clutch will be

considerably

reduced.

◆ Tighten securing

bolts in small steps in

diagonal sequence to

avoid damaging

centring holes in

pressure plate and

centring pins on

flywheel.

‒ Remove the gearbox

to work on the

clutch=>Page 34-35.

1.Flywheel/dual mass

flywheel

◆ Ensure that

centring pins

are a tight fit.

◆ Contact

surface for

clutch lining must be free of grooves, oil

and grease

◆ Observe

removal

instructions for

the weight-

optimised dual-

mass flywheel

=>Fig.2

◆ Removing and

installing:

=> Relevant

engine

workshop

manual,

Mechanical

components;

Repair group

13 Page 2 of 75-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141315.xml?xsl=2

Page 31 of 71

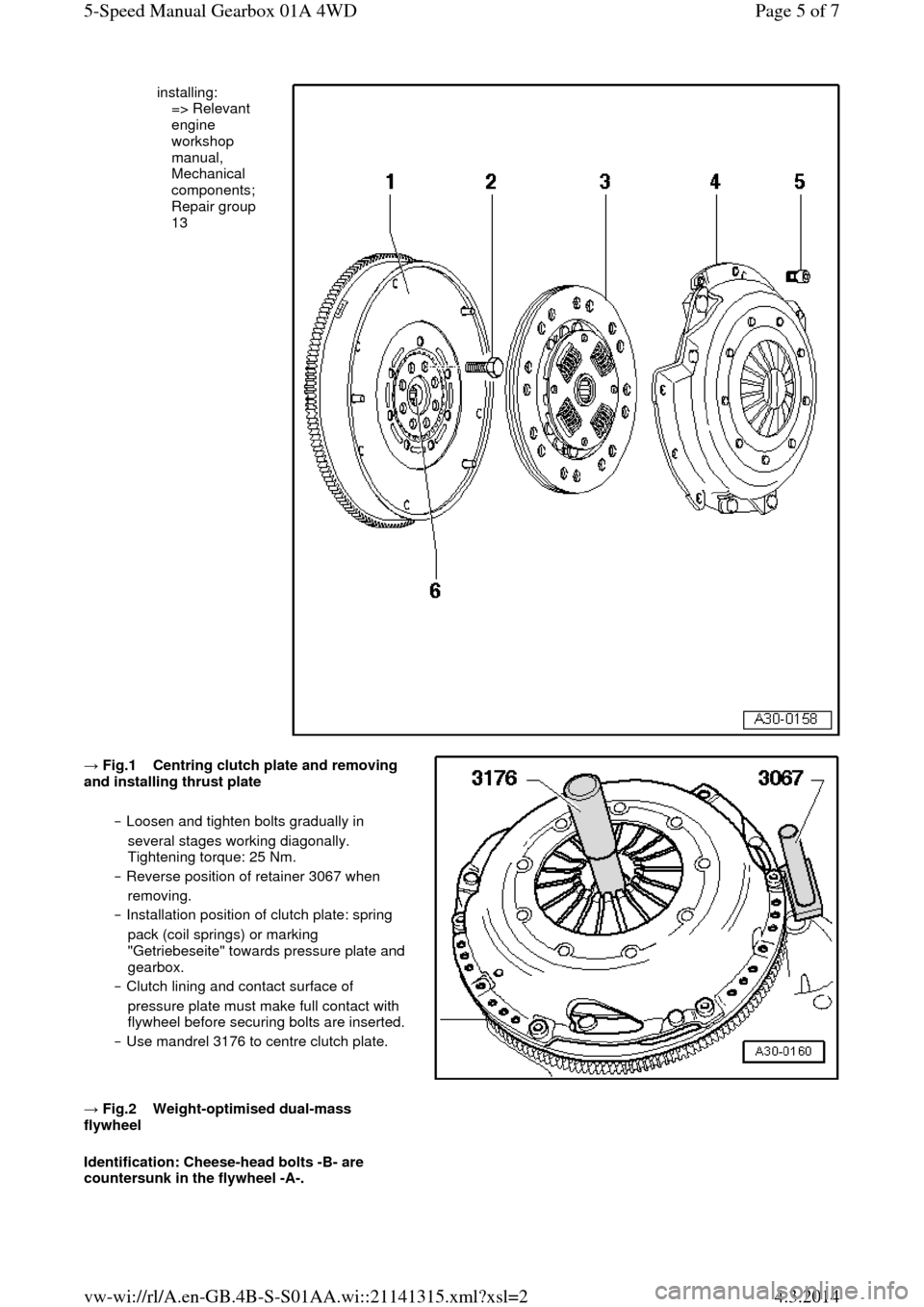

installing:

=> Relevant

engine

workshop

manual,

Mechanical

components;

Repair group

13 → Fig.1 Centring clutch plate and removing and installing thrust plate

‒ Loosen and tighten bolts gradually in

several stages working diagonally.

Tightening torque: 25 Nm.

‒ Reverse position of retainer 3067 when

removing.

‒ Installation position of clutch plate: spring

pack (coil springs) or marking

"Getriebeseite" towards pressure plate and

gearbox.

‒ Clutch lining and contact surface of

pressure plate must make full contact with

flywheel before securing bolts are inserted. ‒ Use mandrel 3176 to centre clutch plate.

→ Fig.2 Weight-optimised dual-mass flywheel

Identification: Cheese-head bolts -B- are

countersunk in the flywheel -A-. Page 5 of 75-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141315.xml?xsl=2

Page 35 of 71

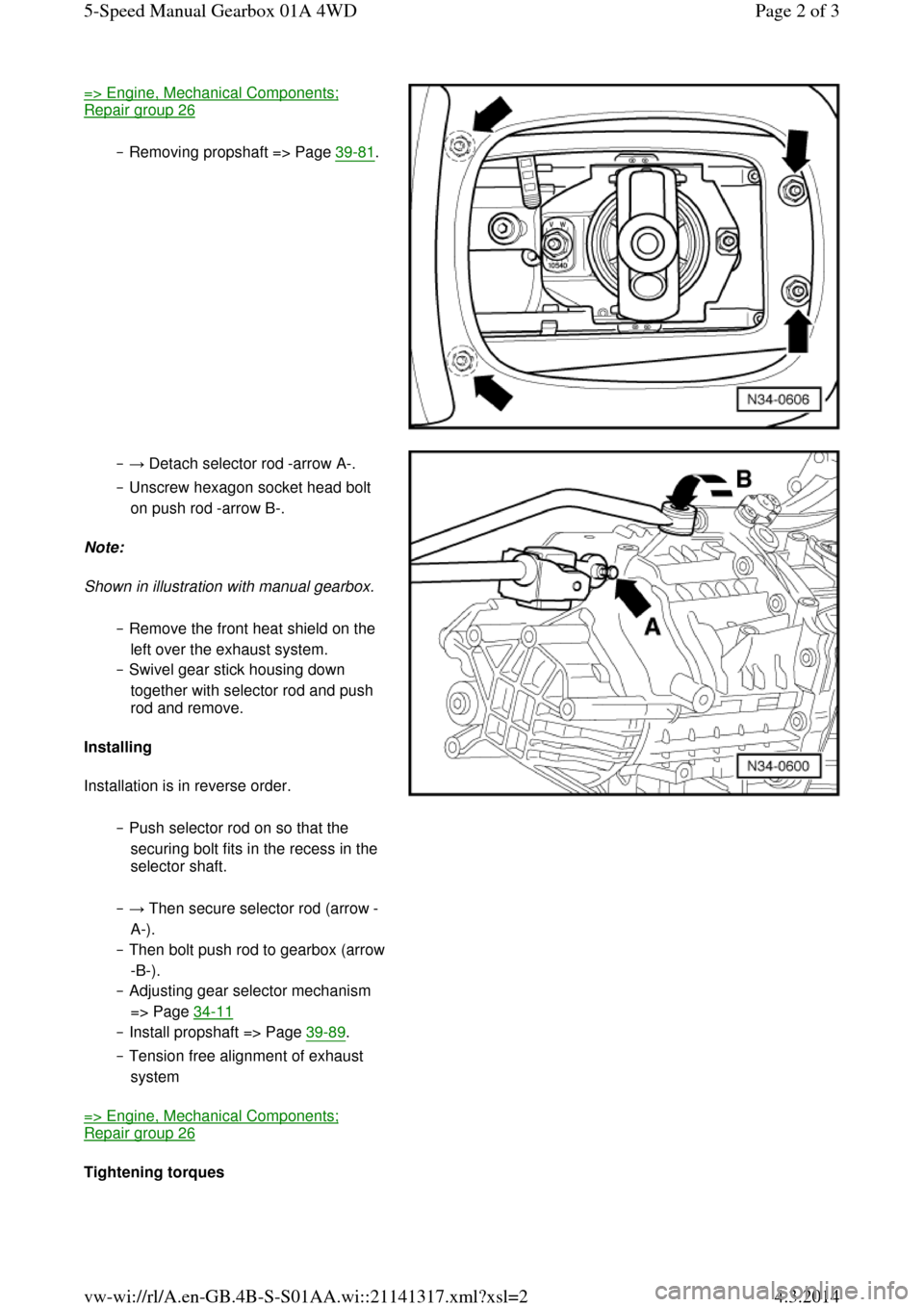

=> Engine, Mechanical Components; Repair group 26

‒ Removing propshaft => Page 39-81. ‒ → Detach selector rod -arrow A-.

‒ Unscrew hexagon socket head bolt

on push rod -arrow B-.

Note:

Shown in illustration with manual gearbox.

‒ Remove the front heat shield on the

left over the exhaust system.

‒ Swivel gear stick housing down

together with selector rod and push

rod and remove.

Installing

Installation is in reverse order.

‒ Push selector rod on so that the

securing bolt fits in the recess in the

selector shaft. ‒ → Then secure selector rod (arrow -

A-).

‒ Then bolt push rod to gearbox (arrow -B-).

‒ Adjusting gear selector mechanism

=> Page 34-11

‒ Install propshaft => Page 39-89.

‒ Tension free alignment of exhaust

system

=> Engine, Mechanical Components; Repair group 26

Tightening torques Page 2 of 35-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141317.xml?xsl=2

Page 42 of 71

‒ Install lower engine/gearbox securing bolts and bolts for starter. For this

purpose, insert the starter.

=> Electrical System; Repair group 27; Removing and installing starter

‒ Bolt drive shafts to flange shafts.

=> Running Gear, FWD and 4WD; Repair group 40

‒ The threaded bores in the flange

shaft of the manual gearbox for the

propshaft must be cleaned of

remaining locking fluid with a thread

tap before assembling

‒ Replace front gaskets at propshaft

=> Page 39-79 and at drive shafts.

‒ Attaching propshaft => Page 39-84.

‒ Check selector rod and push rod,

adjust if necessary => Page 34-11.

‒ Tension free alignment of exhaust

system

=> 4-cylinder Engine (5-valve turbo), Mechanical Components; Repair group 26; Removing and installing parts of exhaust system; Stress-free alignment of exhaust system

=> 6-cylinder Engine (5-valve), Mechanical Components; Repair group 26; Removing and installing parts of exhaust system; Stress-free alignment of exhaust system

‒ Check oil level in manual gearbox => Page 34-56.

‒ Electrical connections and routing:

=> Current Flow Diagrams, Electrical Fault-

finding and Fitting Locations binder

‒ Connect the battery.

Notes:

◆ If the battery is reconnected, please

ensure that the vehicle equipment

(radio, radio/navigation system,

clock, electric window lifters) is

activated as described in the

operating instructions.

◆ Deactivate the service mode of the

telematics control unit.

=> Radio, Telephone and Navigation Page 2 of 45-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141329.xml?xsl=2

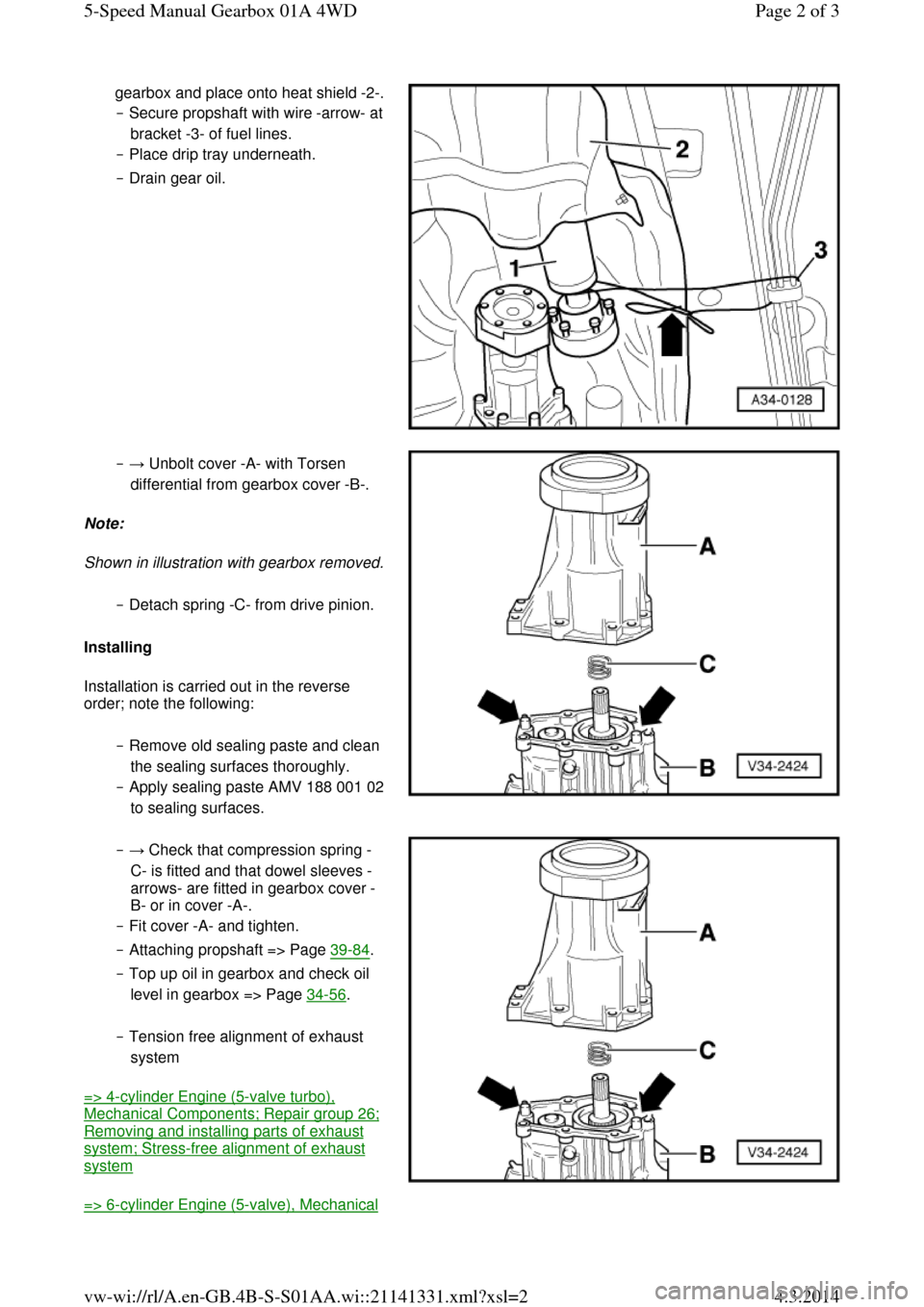

Page 46 of 71

gearbox and place onto heat shield -2-. ‒ Secure propshaft with wire -arrow- at bracket -3- of fuel lines.

‒ Place drip tray underneath.

‒ Drain gear oil. ‒ → Unbolt cover -A- with Torsen

differential from gearbox cover -B-.

Note:

Shown in illustration with gearbox removed. ‒ Detach spring -C- from drive pinion.

Installing

Installation is carried out in the reverse

order; note the following:

‒ Remove old sealing paste and clean

the sealing surfaces thoroughly.

‒ Apply sealing paste AMV 188 001 02 to sealing surfaces. ‒ → Check that compression spring -

C- is fitted and that dowel sleeves -

arrows- are fitted in gearbox cover -

B- or in cover -A-.

‒ Fit cover -A- and tighten.

‒ Attaching propshaft => Page 39-84.

‒ Top up oil in gearbox and check oil

level in gearbox => Page 34-56.

‒ Tension free alignment of exhaust

system

=> 4-cylinder Engine (5-valve turbo), Mechanical Components; Repair group 26; Removing and installing parts of exhaust system; Stress-free alignment of exhaust system

=> 6-cylinder Engine (5-valve), Mechanical Page 2 of 35-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141331.xml?xsl=2

Page 58 of 71

◆ V.A.G 1331 Torque wrench

◆ Sealant AMV 188 001 02 Notes:

◆ It is not necessary to remove the

differential to remove the above-

mentioned components => Page 34-74.

◆ Removal is only necessary when

adjustments have to be carried out

=> adjustment overview, Page 39-45.

Removing

‒ Place drip tray V.A.G 1306

underneath the gearbox.

‒ Drain gearbox oil using socket

attachment 3357.

‒ → Secure gearbox in assembly

stand VW 540. Page 2 of 115-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141337.xml?xsl=2

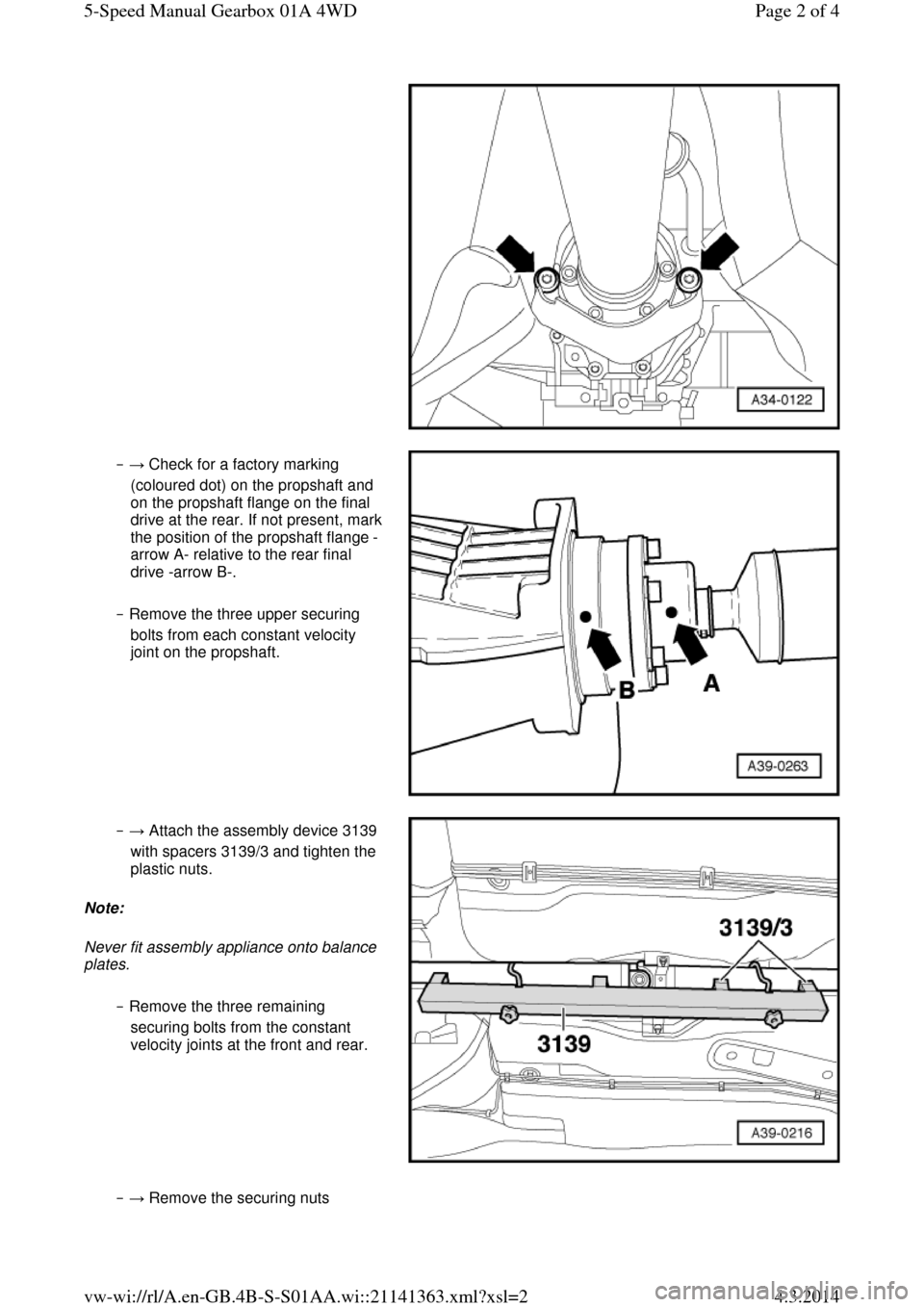

Page 69 of 71

‒ → Check for a factory marking

(coloured dot) on the propshaft and

on the propshaft flange on the final drive at the rear. If not present, mark the position of the propshaft flange -

arrow A- relative to the rear final

drive -arrow B-.

‒ Remove the three upper securing

bolts from each constant velocity

joint on the propshaft. ‒ → Attach the assembly device 3139

with spacers 3139/3 and tighten the

plastic nuts.

Note:

Never fit assembly appliance onto balance plates.

‒ Remove the three remaining

securing bolts from the constant

velocity joints at the front and rear. ‒ → Remove the securing nuts Page 2 of 45-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141363.xml?xsl=2