torque AUDI A6 2000 C5 / 2.G Changing Clutch 5Speed Manual Gearbox

[x] Cancel search | Manufacturer: AUDI, Model Year: 2000, Model line: A6, Model: AUDI A6 2000 C5 / 2.GPages: 71, PDF Size: 1.82 MB

Page 27 of 71

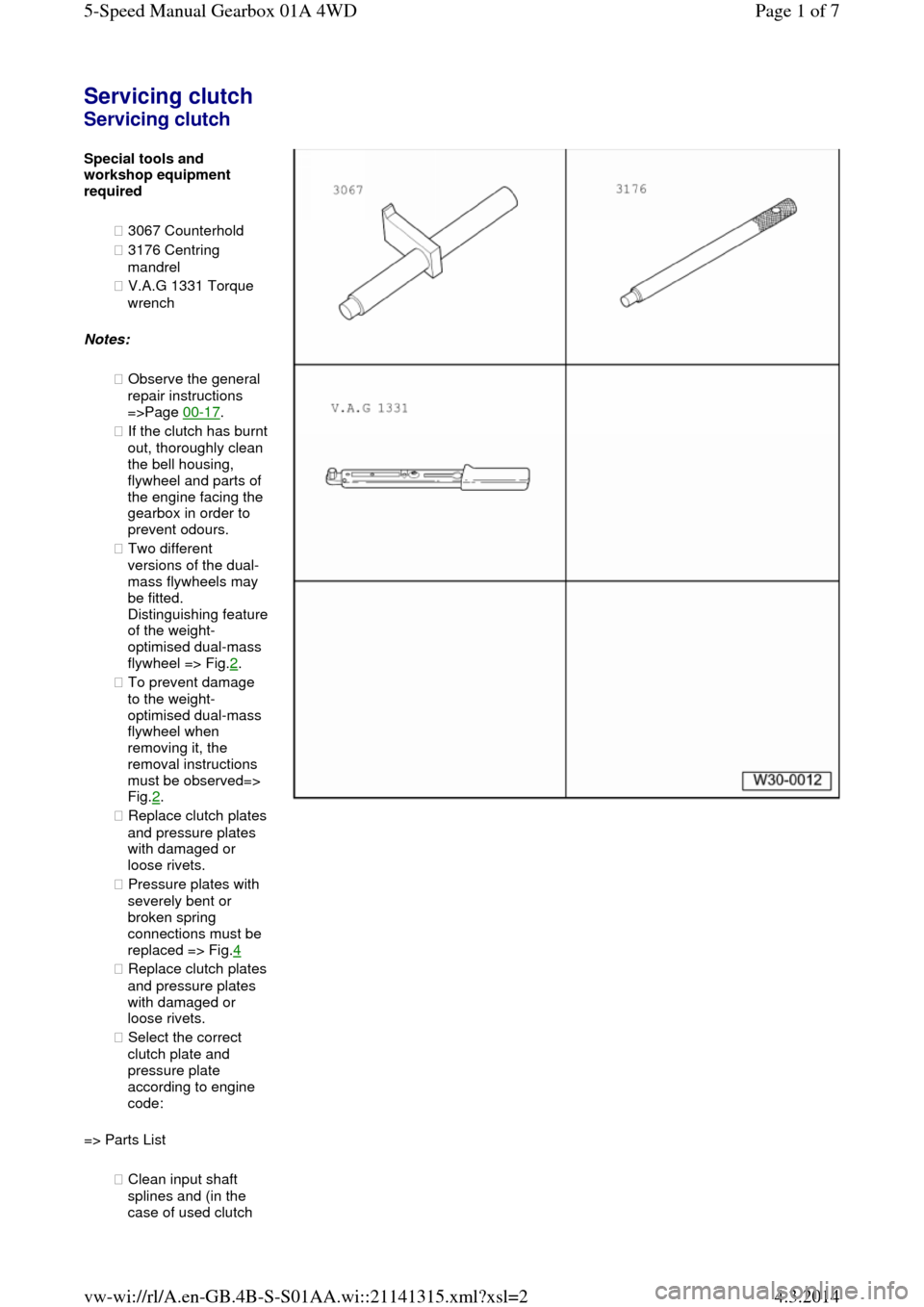

Servicing clutch Servicing clutch Special tools and workshop equipment

required

◆ 3067 Counterhold

◆ 3176 Centring

mandrel

◆ V.A.G 1331 Torque

wrench

Notes:

◆ Observe the general

repair instructions

=>Page 00-17.

◆ If the clutch has burnt out, thoroughly clean

the bell housing,

flywheel and parts of

the engine facing the

gearbox in order to

prevent odours.

◆ Two different

versions of the dual-

mass flywheels may

be fitted. Distinguishing feature of the weight-

optimised dual-mass

flywheel => Fig.2.

◆ To prevent damage

to the weight-

optimised dual-mass

flywheel when

removing it, the

removal instructions

must be observed=>

Fig.2.

◆ Replace clutch plates and pressure plates

with damaged or

loose rivets.

◆ Pressure plates with

severely bent or

broken spring

connections must be

replaced => Fig.4

◆ Replace clutch plates and pressure plates

with damaged or

loose rivets.

◆ Select the correct

clutch plate and

pressure plate

according to engine

code:

=> Parts List

◆ Clean input shaft

splines and (in the

case of used clutch Page 1 of 75-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141315.xml?xsl=2

Page 31 of 71

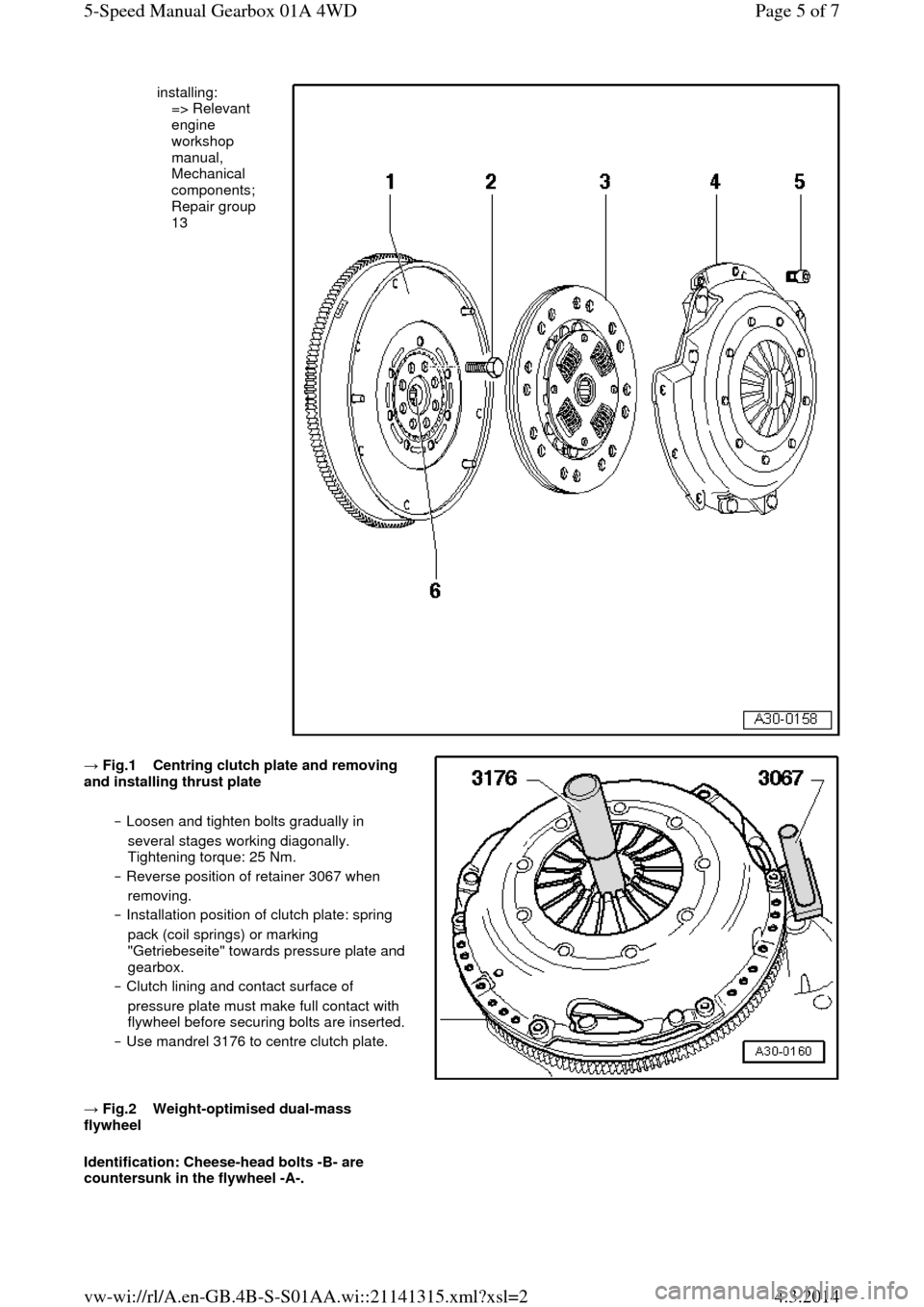

installing:

=> Relevant

engine

workshop

manual,

Mechanical

components;

Repair group

13 → Fig.1 Centring clutch plate and removing and installing thrust plate

‒ Loosen and tighten bolts gradually in

several stages working diagonally.

Tightening torque: 25 Nm.

‒ Reverse position of retainer 3067 when

removing.

‒ Installation position of clutch plate: spring

pack (coil springs) or marking

"Getriebeseite" towards pressure plate and

gearbox.

‒ Clutch lining and contact surface of

pressure plate must make full contact with

flywheel before securing bolts are inserted. ‒ Use mandrel 3176 to centre clutch plate.

→ Fig.2 Weight-optimised dual-mass flywheel

Identification: Cheese-head bolts -B- are

countersunk in the flywheel -A-. Page 5 of 75-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141315.xml?xsl=2

Page 35 of 71

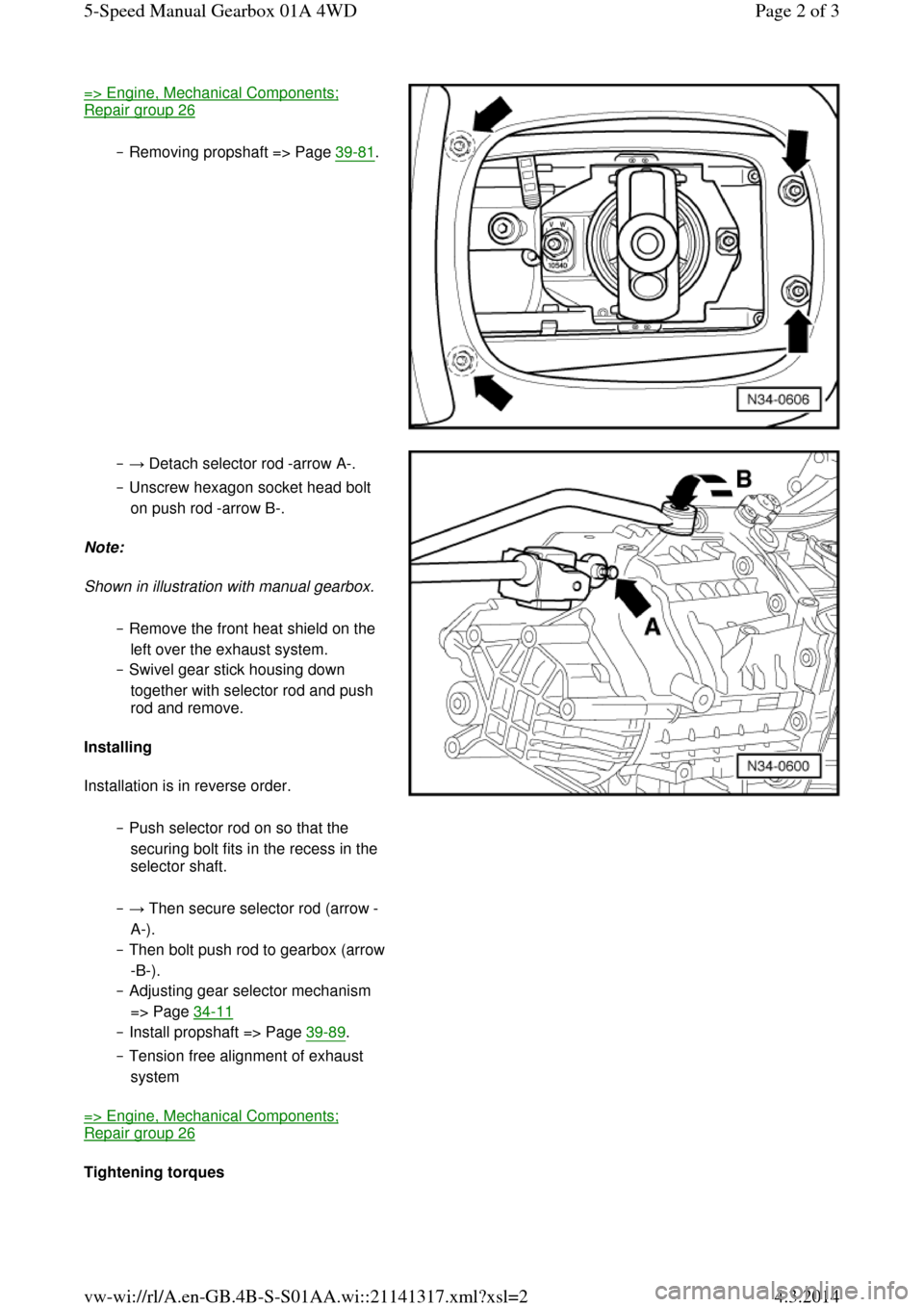

=> Engine, Mechanical Components; Repair group 26

‒ Removing propshaft => Page 39-81. ‒ → Detach selector rod -arrow A-.

‒ Unscrew hexagon socket head bolt

on push rod -arrow B-.

Note:

Shown in illustration with manual gearbox.

‒ Remove the front heat shield on the

left over the exhaust system.

‒ Swivel gear stick housing down

together with selector rod and push

rod and remove.

Installing

Installation is in reverse order.

‒ Push selector rod on so that the

securing bolt fits in the recess in the

selector shaft. ‒ → Then secure selector rod (arrow -

A-).

‒ Then bolt push rod to gearbox (arrow -B-).

‒ Adjusting gear selector mechanism

=> Page 34-11

‒ Install propshaft => Page 39-89.

‒ Tension free alignment of exhaust

system

=> Engine, Mechanical Components; Repair group 26

Tightening torques Page 2 of 35-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141317.xml?xsl=2

Page 43 of 71

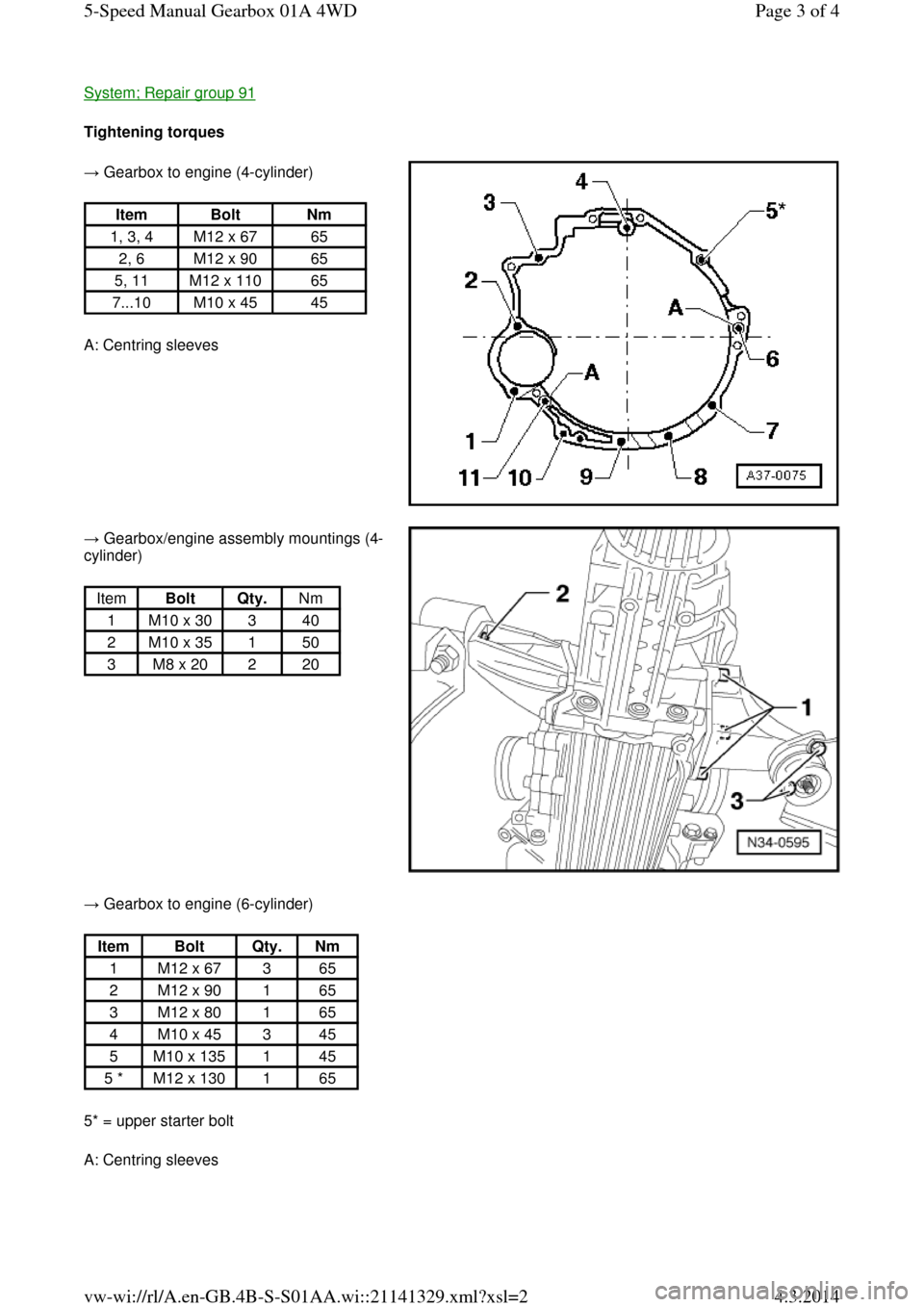

System; Repair group 91 Tightening torques → Gearbox to engine (4-cylinder)

A: Centring sleeves Item Bolt Nm

1, 3, 4 M12 x 67 65

2, 6 M12 x 90 65

5, 11 M12 x 110 65

7...10 M10 x 45 45 → Gearbox/engine assembly mountings (4-

cylinder)

Item Bolt Qty. Nm

1 M10 x 30 3 40

2 M10 x 35 1 50

3 M8 x 20 2 20 → Gearbox to engine (6-cylinder)

5* = upper starter bolt

A: Centring sleeves Item Bolt Qty. Nm

1 M12 x 67 3 65

2 M12 x 90 1 65

3 M12 x 80 1 65

4 M10 x 45 3 45

5 M10 x 135 1 45

5 * M12 x 130 1 65 Page 3 of 45-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141329.xml?xsl=2

Page 47 of 71

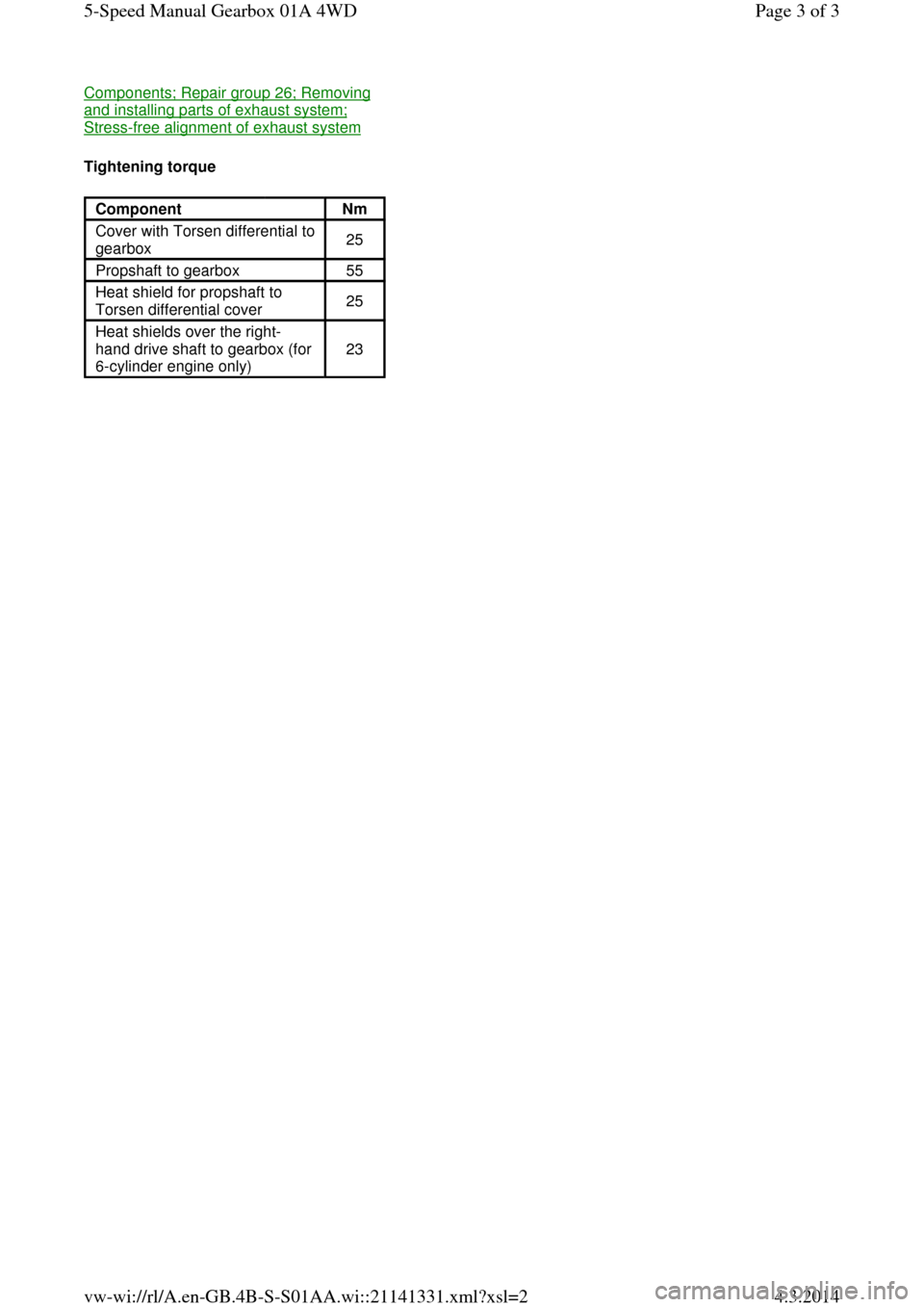

Components; Repair group 26; Removing and installing parts of exhaust system; Stress-free alignment of exhaust system

Tightening torque

Component Nm

Cover with Torsen differential to

gearbox 25

Propshaft to gearbox 55

Heat shield for propshaft to

Torsen differential cover 25

Heat shields over the right-

hand drive shaft to gearbox (for

6-cylinder engine only) 23 Page 3 of 35-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141331.xml?xsl=2

Page 58 of 71

◆ V.A.G 1331 Torque wrench

◆ Sealant AMV 188 001 02 Notes:

◆ It is not necessary to remove the

differential to remove the above-

mentioned components => Page 34-74.

◆ Removal is only necessary when

adjustments have to be carried out

=> adjustment overview, Page 39-45.

Removing

‒ Place drip tray V.A.G 1306

underneath the gearbox.

‒ Drain gearbox oil using socket

attachment 3357.

‒ → Secure gearbox in assembly

stand VW 540. Page 2 of 115-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141337.xml?xsl=2

Page 71 of 71

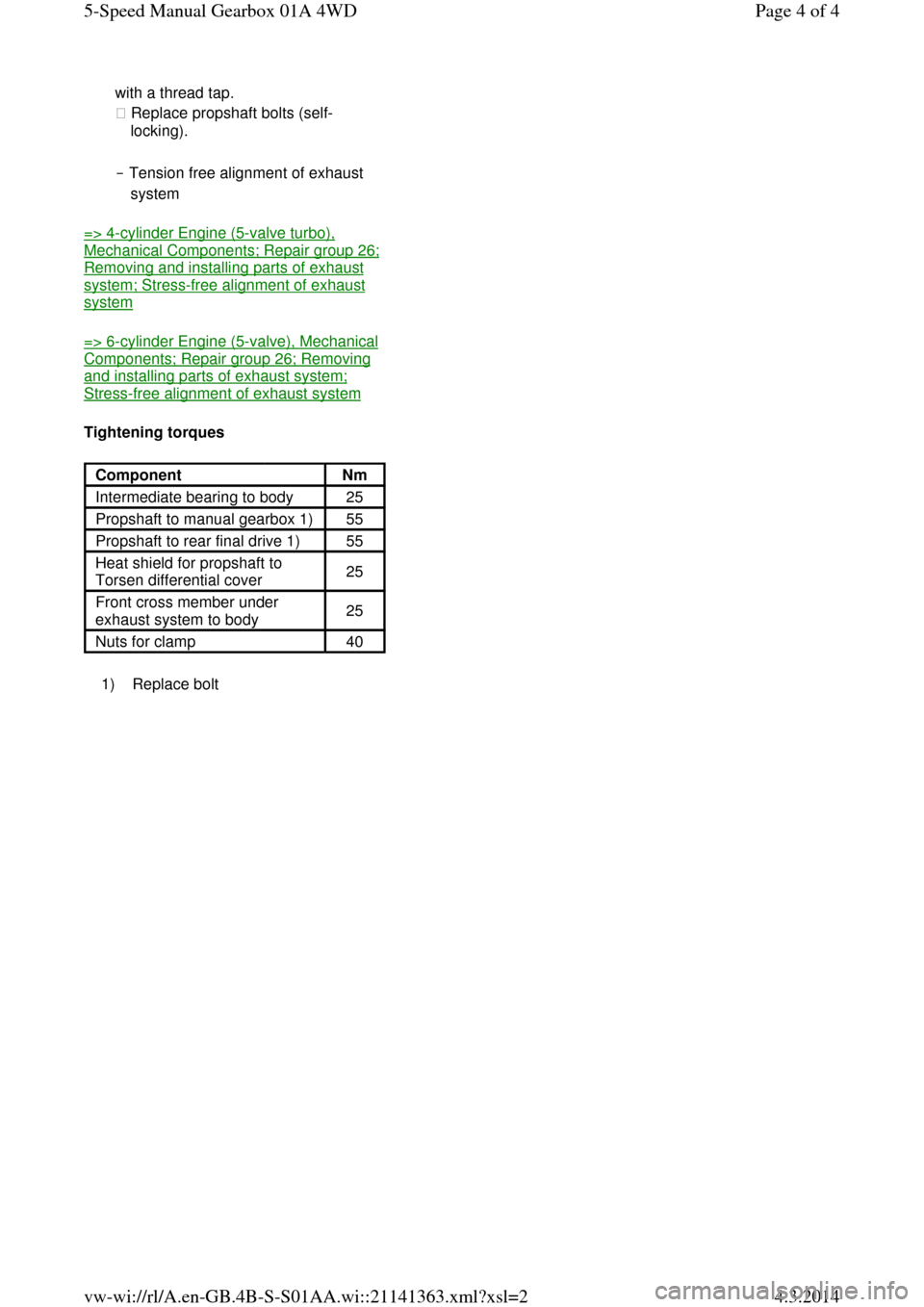

with a thread tap.

◆ Replace propshaft bolts (self-

locking).

‒ Tension free alignment of exhaust

system

=> 4-cylinder Engine (5-valve turbo), Mechanical Components; Repair group 26; Removing and installing parts of exhaust system; Stress-free alignment of exhaust system

=> 6-cylinder Engine (5-valve), Mechanical Components; Repair group 26; Removing and installing parts of exhaust system; Stress-free alignment of exhaust system

Tightening torques

1) Replace bolt Component Nm

Intermediate bearing to body 25

Propshaft to manual gearbox 1) 55

Propshaft to rear final drive 1) 55

Heat shield for propshaft to

Torsen differential cover 25

Front cross member under

exhaust system to body 25

Nuts for clamp 40 Page 4 of 45-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141363.xml?xsl=2