weight AUDI A6 2000 C5 / 2.G Changing Clutch 5Speed Manual Gearbox

[x] Cancel search | Manufacturer: AUDI, Model Year: 2000, Model line: A6, Model: AUDI A6 2000 C5 / 2.GPages: 71, PDF Size: 1.82 MB

Page 27 of 71

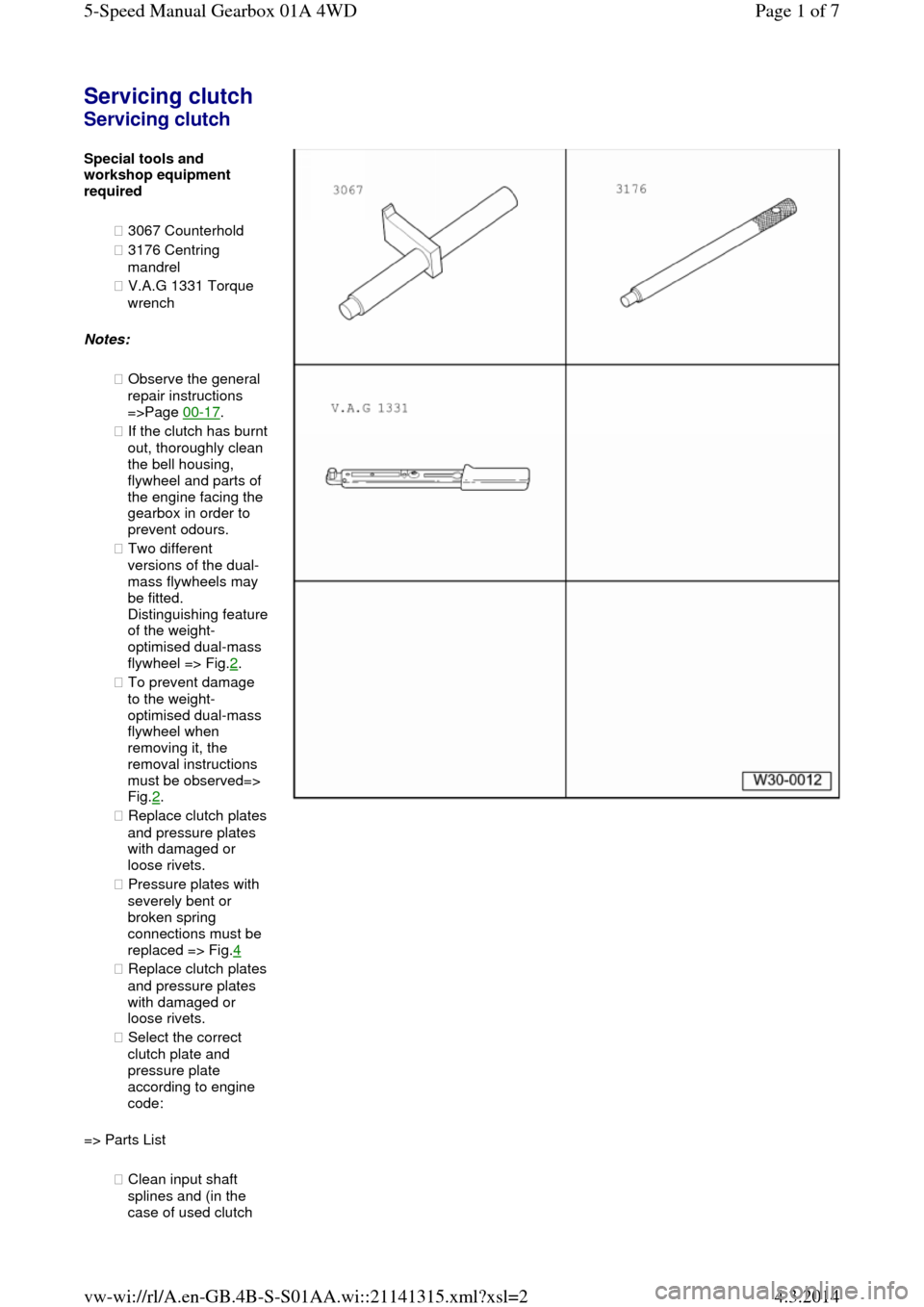

Servicing clutch Servicing clutch Special tools and workshop equipment

required

◆ 3067 Counterhold

◆ 3176 Centring

mandrel

◆ V.A.G 1331 Torque

wrench

Notes:

◆ Observe the general

repair instructions

=>Page 00-17.

◆ If the clutch has burnt out, thoroughly clean

the bell housing,

flywheel and parts of

the engine facing the

gearbox in order to

prevent odours.

◆ Two different

versions of the dual-

mass flywheels may

be fitted. Distinguishing feature of the weight-

optimised dual-mass

flywheel => Fig.2.

◆ To prevent damage

to the weight-

optimised dual-mass

flywheel when

removing it, the

removal instructions

must be observed=>

Fig.2.

◆ Replace clutch plates and pressure plates

with damaged or

loose rivets.

◆ Pressure plates with

severely bent or

broken spring

connections must be

replaced => Fig.4

◆ Replace clutch plates and pressure plates

with damaged or

loose rivets.

◆ Select the correct

clutch plate and

pressure plate

according to engine

code:

=> Parts List

◆ Clean input shaft

splines and (in the

case of used clutch Page 1 of 75-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141315.xml?xsl=2

Page 28 of 71

plates) the hub splines.

Remove corrosion

and apply only a very thin coating of grease G 000 100 to the

splines. Then move clutch plate to and for on input shaft until

hub moves freely on

shaft. Excess grease

must be removed.

◆ Pressure plates are

protected against

corrosion and

greased. Only the

contact surface may be cleaned, otherwise the service life of the

clutch will be

considerably

reduced.

◆ Tighten securing

bolts in small steps in

diagonal sequence to

avoid damaging

centring holes in

pressure plate and

centring pins on

flywheel.

‒ Remove the gearbox

to work on the

clutch=>Page 34-35.

1.Flywheel/dual mass

flywheel

◆ Ensure that

centring pins

are a tight fit.

◆ Contact

surface for

clutch lining must be free of grooves, oil

and grease

◆ Observe

removal

instructions for

the weight-

optimised dual-

mass flywheel

=>Fig.2

◆ Removing and

installing:

=> Relevant

engine

workshop

manual,

Mechanical

components;

Repair group

13 Page 2 of 75-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141315.xml?xsl=2

Page 31 of 71

installing:

=> Relevant

engine

workshop

manual,

Mechanical

components;

Repair group

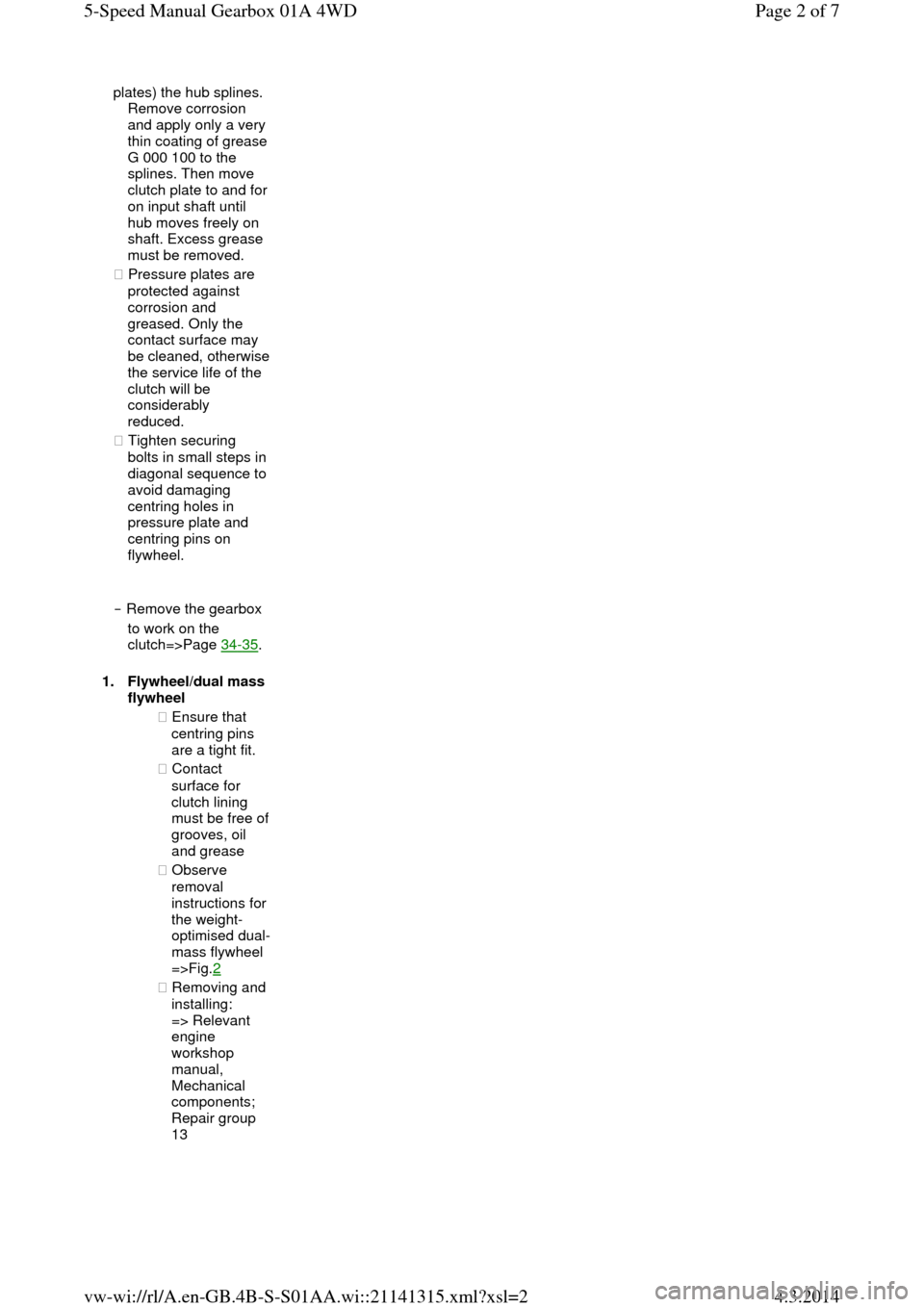

13 → Fig.1 Centring clutch plate and removing and installing thrust plate

‒ Loosen and tighten bolts gradually in

several stages working diagonally.

Tightening torque: 25 Nm.

‒ Reverse position of retainer 3067 when

removing.

‒ Installation position of clutch plate: spring

pack (coil springs) or marking

"Getriebeseite" towards pressure plate and

gearbox.

‒ Clutch lining and contact surface of

pressure plate must make full contact with

flywheel before securing bolts are inserted. ‒ Use mandrel 3176 to centre clutch plate.

→ Fig.2 Weight-optimised dual-mass flywheel

Identification: Cheese-head bolts -B- are

countersunk in the flywheel -A-. Page 5 of 75-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141315.xml?xsl=2

Page 32 of 71

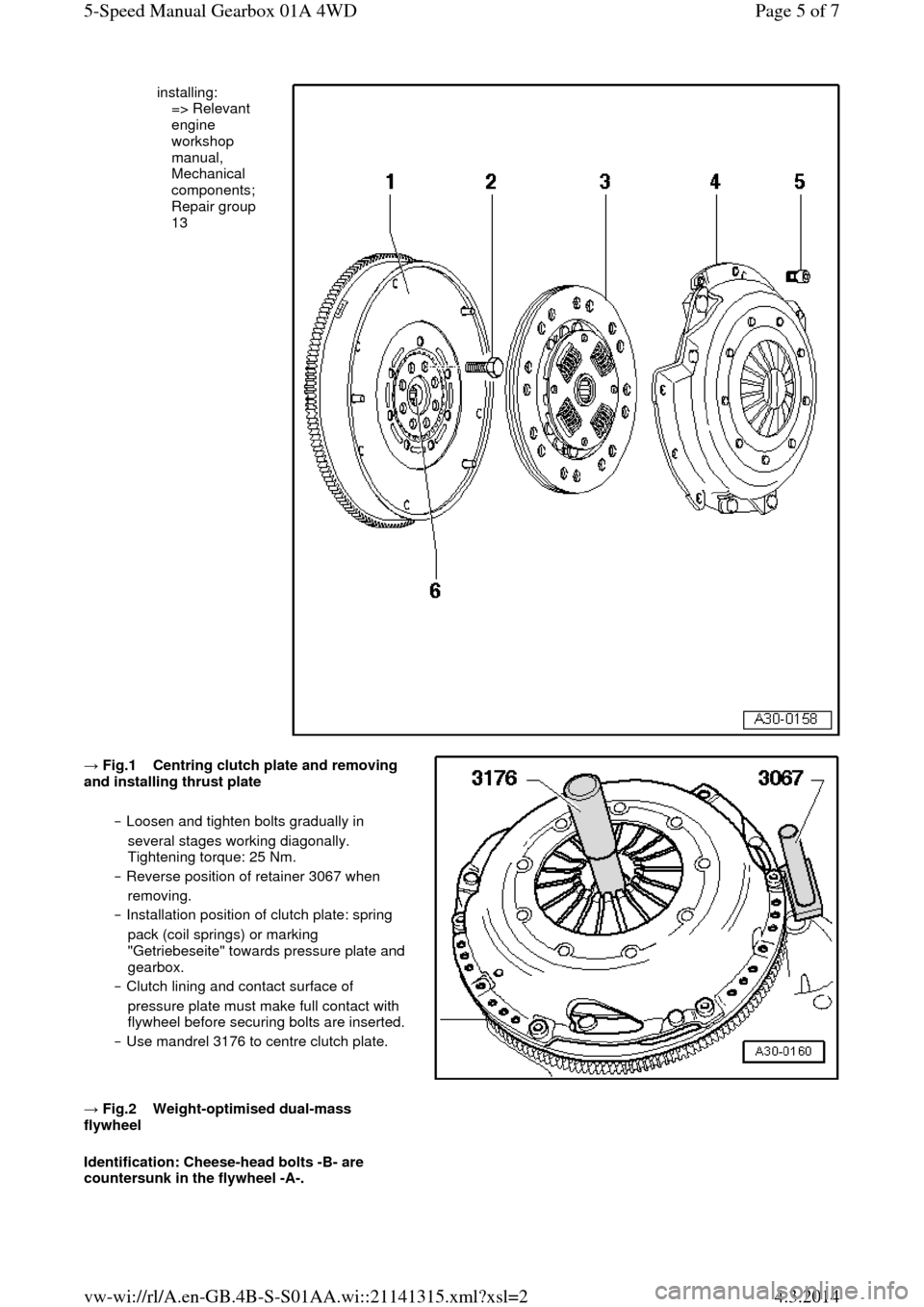

Removing Note:

In order to avoid destroying the weight-optimised

dual-mass flywheel during removal, the bolts -B-

must not be removed using a pneumatic or impact

driver. Only manual removal of the bolts -B- is permissible.

‒ Turn flywheel -A- until the bolts -B- are

positioned centrally with respect to the

holes -arrows-.

‒ When unscrewing bolts -B-, ensure that no

bolt heads are in contact with the flywheel -

arrows- to prevent damage as it turns. → Fig.3 Checking ends of the diaphragm spring

◆ Wear up to half the thickness of the

diaphragm spring is permitted.

Note:

When performing repairs always match up clutch pressure plate and clutch plate by checking engine code (see Parts Catalogue).

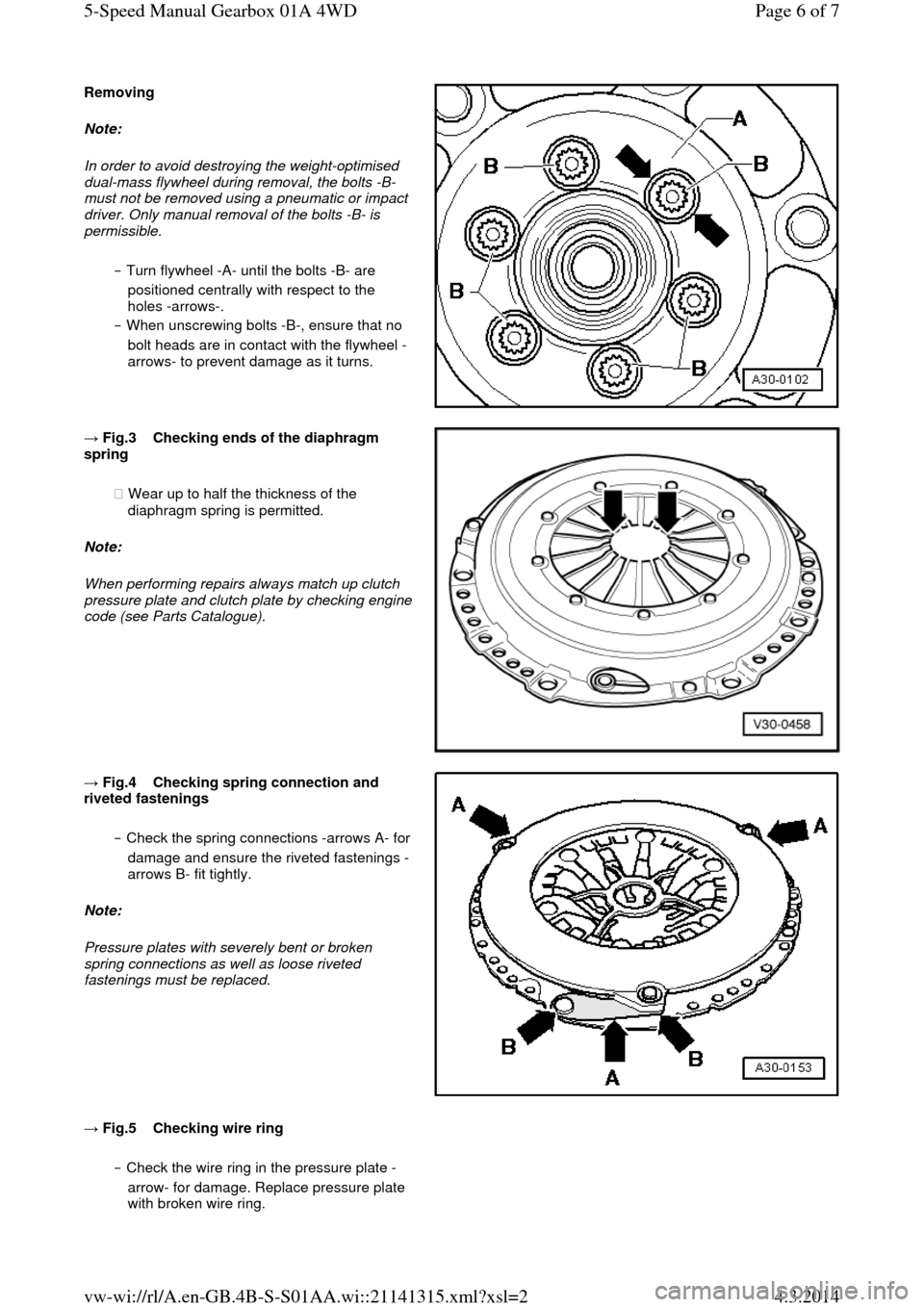

→ Fig.4 Checking spring connection and riveted fastenings

‒ Check the spring connections -arrows A- for damage and ensure the riveted fastenings -

arrows B- fit tightly.

Note:

Pressure plates with severely bent or broken

spring connections as well as loose riveted

fastenings must be replaced.

→ Fig.5 Checking wire ring ‒ Check the wire ring in the pressure plate -

arrow- for damage. Replace pressure plate

with broken wire ring. Page 6 of 75-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141315.xml?xsl=2