AUDI A6 2015 Owners Manual

Manufacturer: AUDI, Model Year: 2015, Model line: A6, Model: AUDI A6 2015Pages: 314, PDF Size: 77.57 MB

Page 281 of 314

M N

0 I.J "". rl I.O

Fuses and bulbs

Fuses

Replacing fuses

Fuses that have blown will have metal strips

that have burned through.

Fig . 2 14 Driver side of the cockp it: fuse panel cove r

The fuses are located at the front left and

r igh t of the cockpit and behi nd the trim on

the right side of the luggage compartment .

.. Switch the ign ition and the affected electr i

ca l equ ipment off .

.. Check the following table to see which fuse

belongs to the consume r .

.. Remove the cover

r:!;> fig. 214 or r:!;> page 218,

Opening the side trim .

.. To remove the purple plastic cl ip if necessa

ry

ll, hold onto it at the small s ide and pull

it out of the fuse panel

r:!;> page 279,

fig. 215 .

.. Remove the clamp from the rea r side of the

fuse cover ¢

fig. 214 .

.. Remove the fuse using the cl amp and re

pla ce the blown fuse w ith an identical new

one.

& WARNING , -

Do not repair f uses and never replace a

blown fuse w ith one that has a higher amp

rating. This can cause damage to the e lec

trical system and a fire.

"' rl

~ 11 You can dis pose of the plastic clip after remov ing it.

Fu se s and bulb s 2 79

(D Note

If a new fuse burns out again after short ly

have you have insta lled it, have the electri

ca l system c hecked by yo ur authorized

A udi dealer .

{!) Tips

-The following table does not list fuse lo

cat ions that are not used .

- Some of the equipment items listed are

opt ional or only available on certa in

mode l configurations.

Driver side cockpit fuse assignment

Fi g. 215 Dr iver side cockpit : fuse pa nel w ith plastic

bracket

Fuse panel @ (blac k)

No . Equipment Amps

Switch panel, electromechanica l

1 parking brake, seat heating, 5

starting assist, control module

2 Au toma tic d imm ing in terior

5 rearview mir ro r, horn

3 Exhaust system (diesel engine) 10

Page 282 of 314

28 0 Fu ses and bulb s

No. Equ ipment Amps

4 Suspension control system sen-

5

sor

5 E

lectronic Stabilization Control

5

(ESC) mod ule

6 Climate control

5

7 Adaptive cruise control 10

8

Airbag control module, front

5

passenger's seat sensor system

9 Gateway 5

Garage door opener (Homelink),

10 night vision system contro l 5

module

11 Image

processing (active lane

10

ass ist, adaptive cruise control)

12 Dynamic steering 5

13 Terminal 15 in the

instrument

15

panel

14 Termina

l 15 in the luggage com-

partment 30

15 T

erminal 15 (engine)

15

16 Starter 40

Fuse p anel @ (b rown )

No . Equipment Amps

1 Gateway

5

2 Cl imate control 10

Electronic Stabilization Contro l

10

3

(ESC) module

4 Front door

(driver's side)

30

5 Power seat adjustment (driver's

7,5

seat)

6 Dynamic steering

35

7 Su nroof 20

Rear door control module (driv-

15

8

er's side)

9 Lumbar support

(Front passen-

5

ger seat)

10 Tire pressure monitoring system

5

11 Su

nroof, rear spoiler (Sportback)

20

12 Driver

door control module

15

Fuse panel © (r e d )

No . Equipment

2 Fuel pump

3 Brake light

sensor/brake pedal

sensor system

4 AdBlue

control module (Diesel)/

Engine acoustics

5 Left rear door contro l modu le

6 Power seat adjustment

(pas-

senger's seat)

7 Horn

8 Windshield wiper motor

9

Light/rain sensor,

heater for vid-

eo camera in windscreen

10 Lumbar support (driver seat)

11 Front

passenger door control

module

12 Right rear door control mod ule

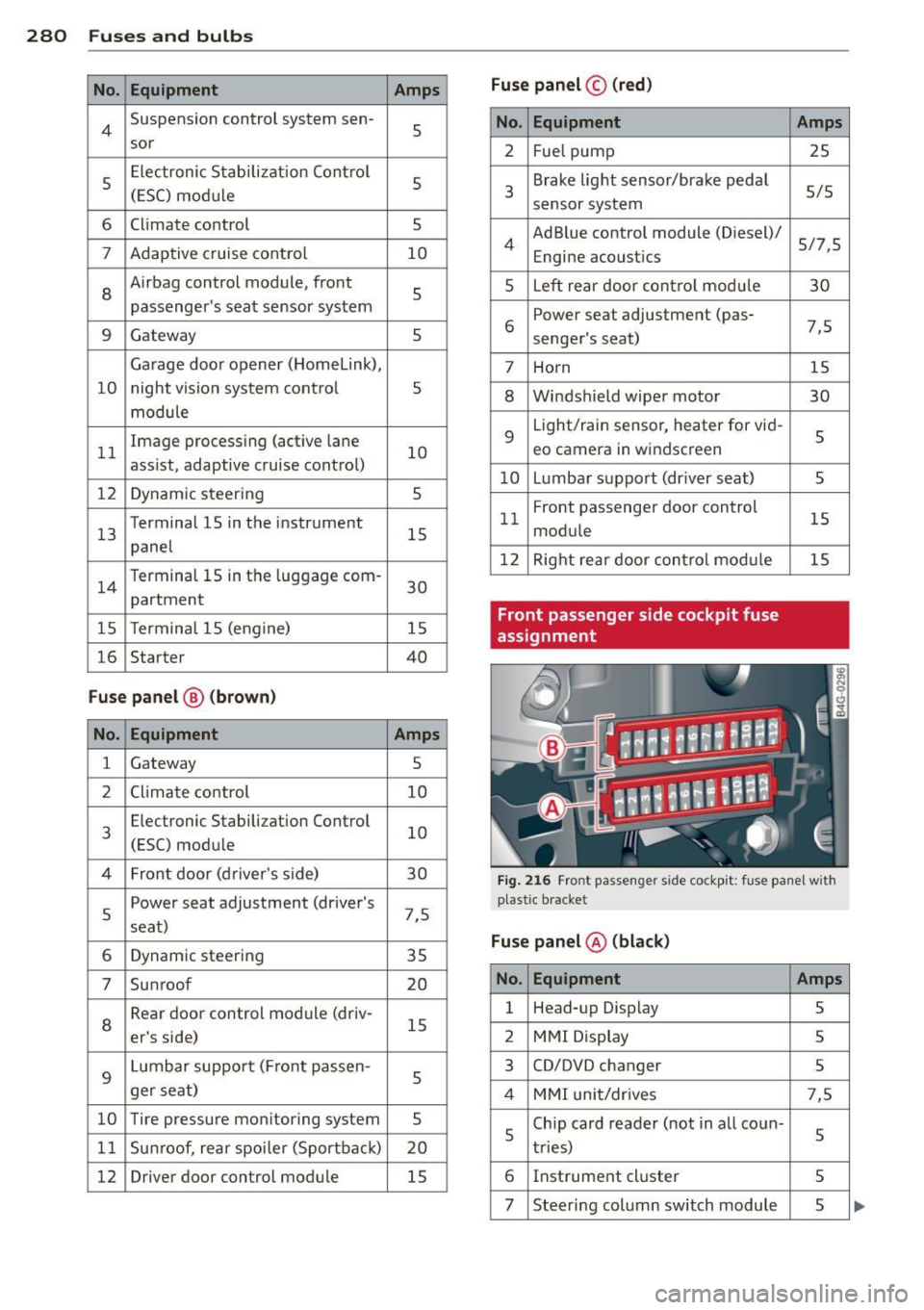

Front passenger side cockpit fuse

assignment Amp

s

25

5/5

5/7,5 30

7,5 15

30

5

5

15

15

Fig . 2 1 6 Front passenger side cockp it: fuse pane l w ith

plastic bracket

Fu se p anel @ (bla ck)

No . Equipment Amps

1 Head-up Display

5

2 MMI Display 5

3 CD/DVD changer

5

4 MMI unit/dr ives 7,5

5 Chip

card reader (not in all coun-

5

tries)

6 Instrument cluster

5

7 Steering column

switch module 5

Page 283 of 314

M N

0 I.J "". rl I.O

"' rl

"' rl

No. Equ ipment Amps

8

Headlight range adjustment/ 5/7,5

adaptive lighting system

10

Left headlight (headlight with 7,5 adaptive light)

11 Supplementary heater s

Fuse p anel @ (b ro w n)

No . Equipment Amps

1 Climate control 10

2

Climate control system blower 40

3

Diagnostic interface 10

4

E lectrical ignition lock 5

5

Power steering column adjust-

ment

5

6 Steering column switch module 10

7

Power steering column adjust-

ment

25

8 Light switch 5

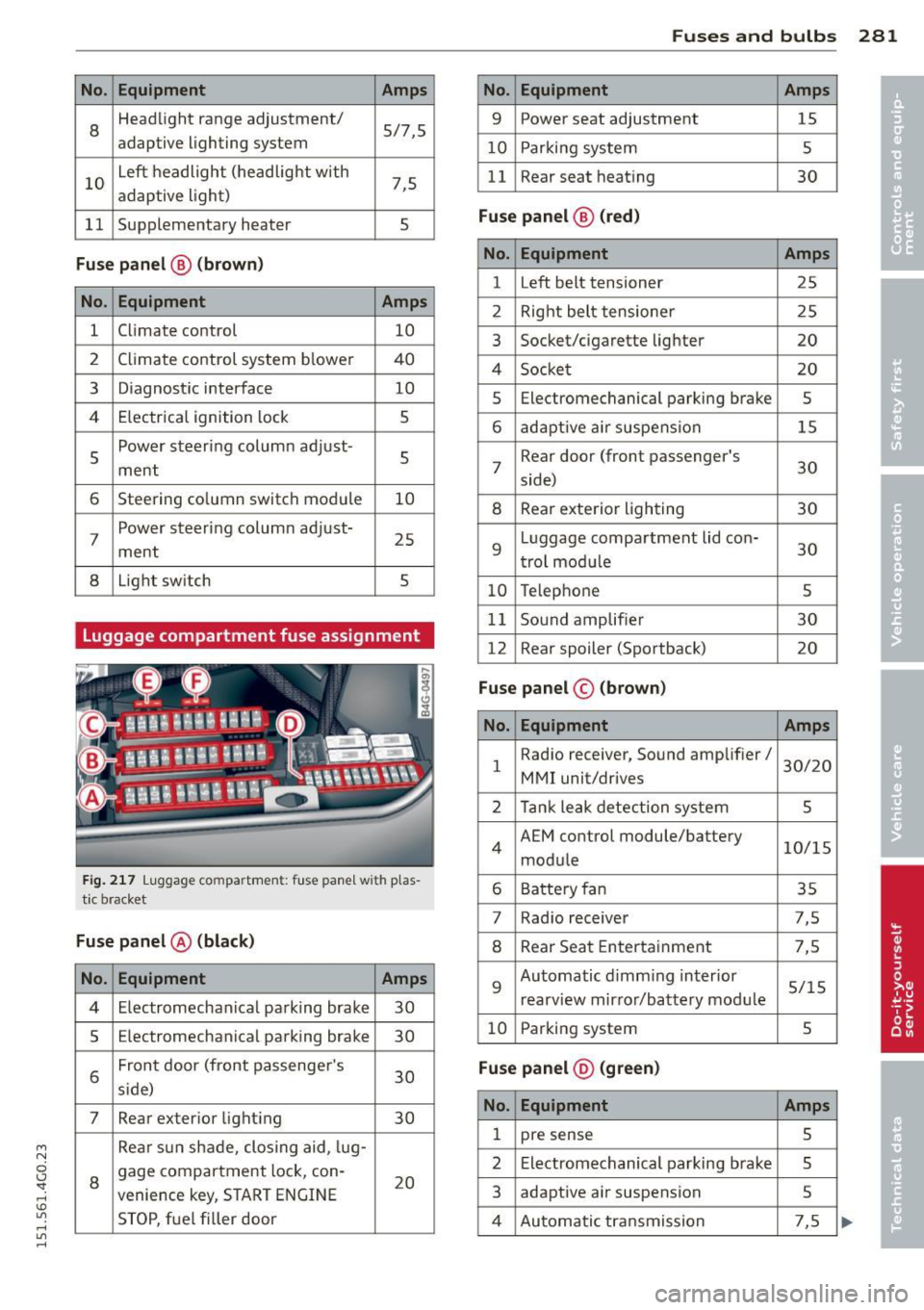

Luggage compartment fuse assignment

Fig . 217 Luggage compa rtmen t: fuse panel wit h p las

tic bracket

Fuse p anel @ (black )

No. Equipment Amps

4 Electromechan ical parking brake 30

5

Electromechanical parking brake 30

6

Front door (front passenge r's

30 s ide)

7 Rear exterior light ing 30

Rea r sun shade, closing aid, lug-

8

gage compartment lock, con-

20 venience key, START ENGINE

STOP, fuel filler door

Fu se s and bulb s 281

No. Equipment Amps

9 Power seat adjustment 15

10

Parking system 5

11

Rear seat heating 30

Fu se p an el@ (r e d )

No . Equipment Amps

1 Left belt tensioner 25

2

Right belt tensioner 25

3

Socket/cigarette lighter 20

4

Socket 20

5

Electromechanical parking brake 5

6 adaptive air suspension 15

7

Rear door (front passenger's

30 side)

8 Rear exterior lighting 30

9

Luggage compartment lid con-

30 trol modu le

10 Telephone 5

11

Sound amplifier 30

12

Rear spoiler (Sportback) 20

Fuse panel© (brown)

No . Equ ipment Amps

1

Radio receiver, Sound amplifier/

30/20

MMI unit/drives

2 Tank leak detection system 5

4

AEM control module/battery 10/15

module

6 Battery fan 35

7

Rad io receiver 7,5

8 Rear Seat Entertainment 7,5

9

Automatic d imm ing interior 5/15

rearview mirror/battery module

10 Parking system 5

Fu se pan el@ (gr ee n)

No . Equipment Amps

1 pre sense s

2 Electromechanical parking brake 5

3

adaptive air suspension 5

4 Automatic transmission 7,5

Page 284 of 314

282 Fuses and bulb s

No. Equipment Amps

s Parking system s

6 Rear Seat Entertainment s

7 Start-Stop-System s

8 side ass ist s

9

Gateway, Vehicle electrical sys-

s tern control module 1

10 Sport d ifferential s

Fuse panel © (black)

No. Equipment Amps

1 Rear seats 20

Fuse panel ® (black)

No. Equipment Amps

1 Movement-activated luggage 1

compartment lid opening

Bulbs

Replacing light bulbs

For your safety, we recommend that you have

your authorized Audi dealer replace burned

out bulbs for you .

It is becoming increasingly more and more

difficult to replace vehicle light bulbs since in

many cases, other parts of the car must first

be removed before you are able to get to the

bulb . Thi s appl ies especial ly to the light bu lbs

in the front of your car which you can only

reach through the engine compartment .

Sheet metal and bulb ho lders can have sharp

edges that can cause ser ious cuts, and parts

must be co rrectly taken apart and then prop

erly put back together to help prevent break

age of parts and long term damage from wa

ter that can enter housings that have not been

properly resealed.

F or your safety, we recommend that you have

your author ized Audi dealer rep lace any bulbs

for you, since your dealer has the proper tools,

the correct bu lbs and the expertise.

Gas di scharge lamps (Xenon lights):

Due to the high e lectr ica l voltage, have the

bulbs replaced by a qualified technician.

Head lights w ith Xenon light can be identified

by the high voltage sticker .

LED headlights* require no maintenance .

P lease contact your authorized Audi dealer if a

bulb needs to be replaced.

A WARNING

Contact with high-voltage components of

the electrical system and improper re placement of gas discharge (Xenon) head

light bulbs can cause ser ious personal in

jury and death.

- Xenon bulbs are pressur ized and can ex

p lode when being changed.

- Changing Xenon lamps requ ires the spe

cial tra ining, instructions and equip

ment.

- Only an authorized Audi dealer or other

qualified workshop should change the

bu lbs in gas discharge lamps .

_& WARNING

There are parts with sharp edges on the

openings and on the bulb holders that can

cause ser ious cuts.

- If you are uncertain about what to do,

have the work performed by an author

ized Audi dealer or other qualified wo rk

shop . Serious personal injury may result

from improperly performed work .

(D Tips

-If you still prefer to replace the light

bulbs yoursel f, be aware that the engine

compartment is a hazardous area to

work in

c:::> page 222<=::> .&.

- It is best to ask your authorized Audi

dealer whenever you need to change a

bulb .

Page 285 of 314

M N

0 <.J 'SI: ,...., \!) ..,.,

,...., ..,., ,....,

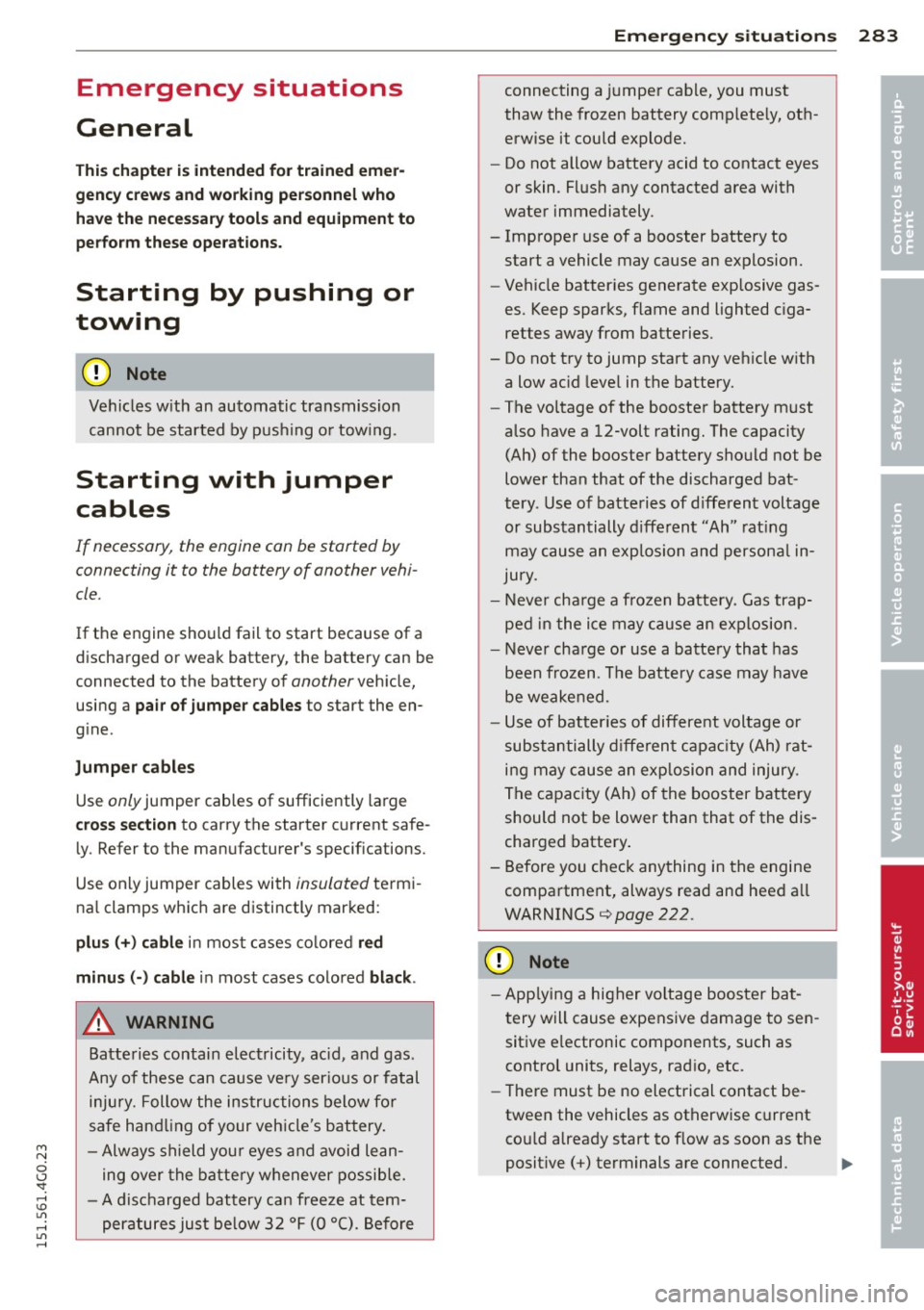

Emergency situations

General

This chapter i s intended for trained emer

gency crews and working personnel who have the necessary tools and equipment to

perform these operations.

Starting by pushing or

towing

(D Note

Ve hicles w ith an au tomatic tra nsmission

cannot be started by pus hing o r tow ing.

Starting with jumper

cables

If necessary, the engine can be started by

connecting it to the battery of another vehi

cle.

If the engine shou ld fail to start because of a

discha rged o r wea k battery, the battery can be

connected to the battery o f

another vehicle,

using a

pair of jumper cables to start the en

g ine.

Jumper cables

Use only jumper cables of sufficiently la rge

c ross section to carry the starter c urrent safe

l y. Refer to the man ufacturer's specifications.

Use only jumper cables with

insulated te rm i

na l clamps wh ic h are d istinctly marked:

plus(+) cable i n mos t cases co lore d red

minu s(-) cable

in most cases colored black .

A WARNING

Batterie s contain e lec tricity, ac id, an d gas.

A ny of these can cause ve ry ser io us or fatal

inju ry. Follow the instructions below f or

safe han dling of your veh icle's b attery .

- Alway s shield you r eyes and avoid lean

ing over the bat te ry whenever possib le.

- A dis ch arged battery c an free ze at tem

peratures ju st be low 32 °F ( 0 °C ). Befo re

Emergency situations 283

connecting a jumpe r cab le, you must

thaw the fr ozen battery c omp lete ly, ot h

erwise it could explode.

- Do not allow battery acid to contact eyes

or skin. Fl ush any contacted area with

wate r immediately.

- Improper use of a booster battery to start a vehicle may cause an explosion.

- Vehicle batter ies genera te exp losive gas

es. Keep spar ks, flame and lighted c iga

rettes away from batte ries.

- Do not try to jump start any ve hicle w ith

a low ac id leve l in the battery.

- The vo ltage of the booste r batte ry m ust

a lso have a 12-volt rating. The capacity

(Ah) of the booster battery sho uld not be

lowe r tha n that of the discharged bat

tery . U se of batte rie s of d iffe ren t voltage

or substantially diffe rent "Ah" rat ing

may c au se an exp losion and persona l in

JU ry.

- N ever cha rge a fro zen battery. Gas trap

pe d in the ice may cause a n ex plosion.

- Never cha rge or use a batte ry tha t h as

been fr ozen. T he battery case may have

be weakened.

- Us e of b atter ies of differe nt voltage or

sub stant ia lly diffe ren t ca pa city (Ah) ra t

i ng may c ause an ex plosion an d injury .

Th e capac ity (Ah) of the booster bat tery

should not be lower than that of the dis

charged batte ry .

- Before you chec k any thing in the engine

compa rtment, always read and hee d all

WARNINGS¢

page 222.

(D Note

- App lyin g a higher vo ltage booster ba t

t ery w ill cause expens ive damage to se n

sit ive e lectronic com ponents, such as

cont ro l units, relays, rad io, etc.

- The re must be no electrical contact be

tween the vehicles as ot herwise c urrent

co uld a lready start to f low as soon as the

p o sit ive(+) term inals a re connected. ..,. •

•

Page 286 of 314

284 Emergency situations

@ Tips

The discharged battery must be properly

connected to the vehicle's electrical sys

tem. When jump starting or charging the

battery, never connect the negative

ground cable to the battery negative post

because the batte ry manager system must

be able to detect the battery 's state of

charge. Always connect the negative

ground cab le to the negative ground post

of the battery manager control unit.

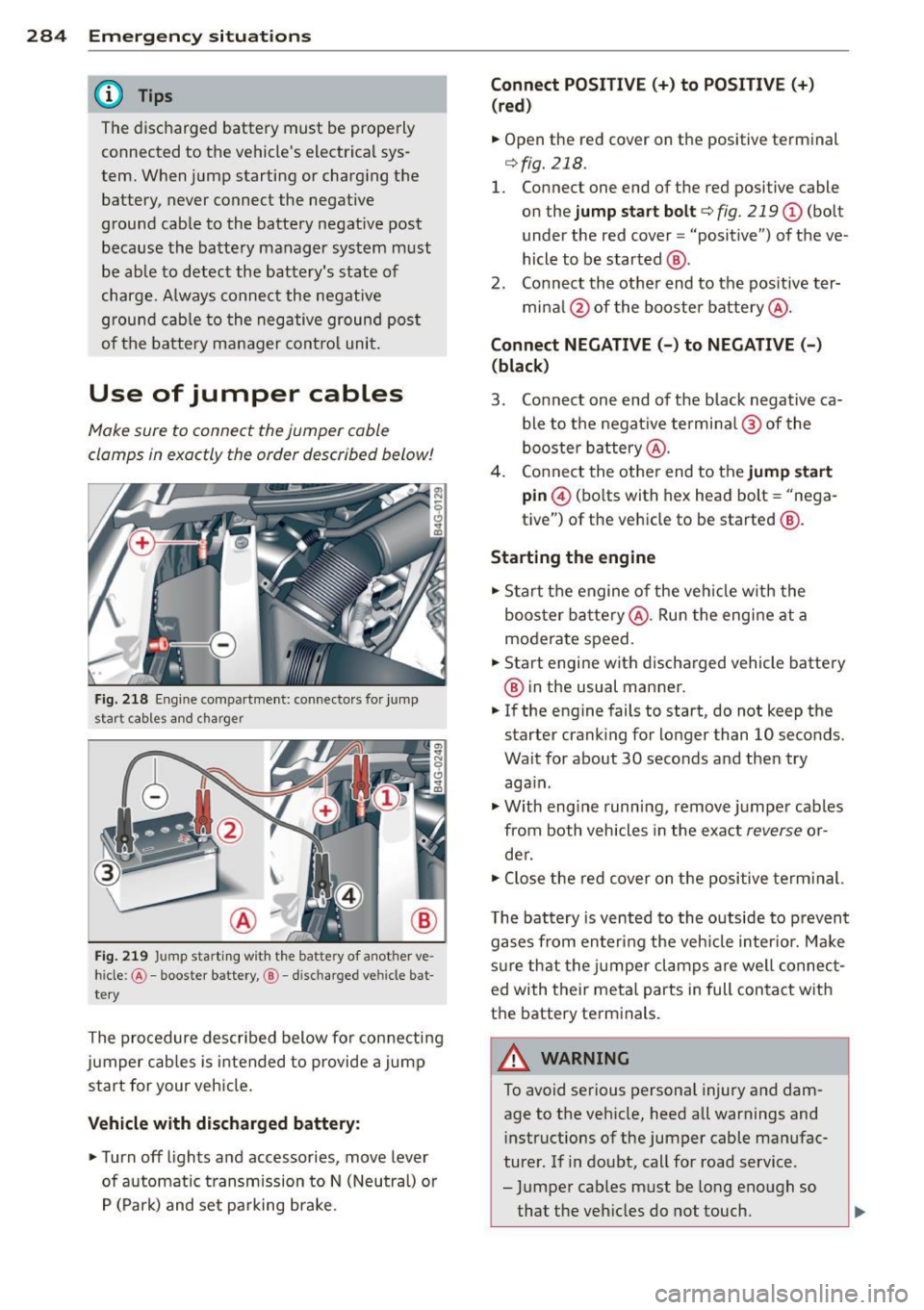

Use of jumper cables

Make sure to connect the jumper cable

clamps in exactly the order described below!

Fig. 218 Engine compartment: connecto rs for jump

start cables and charger

Fig. 219 Jump start ing with the battery of another ve·

hide: @-booster battery, @-discharged ve hicle bat

tery

The procedure described below fo r connecting

jumper cables is intended to provide a jump

start for your vehicle.

Vehicle with discharged battery:

.,. Turn off lights and accessories, move lever

of automatic transmission to N (Neutral) or

P (Park) and set parking brake.

Connect POSITIVE(+) to POSITIVE(+)

(red)

.,. Open the red cover on the positive terminal

¢fig. 218 .

1. Connect one end of the red positive cable

on the

jump start bolt c::;, fig. 219 @ (bolt

under the red cover = "positive") of the ve

hicle to be started @.

2. Connect the other end to the positive ter-

mina l@ of the booster battery@.

Connect NEGATIVE (-) to NEGATIVE (-)

(black)

3. Connect one end of the black negative ca

ble to the negat ive terminal @ of the

booster battery @.

4. Connect the other end to the

jump start

pin © (bolts with hex head bolt= "nega

tive") of the vehicle to be started @.

Starting the engine

.,. Start the engine of the veh icle w ith the

booster battery@. Run the engine at a

moderate speed .

.,. Start engine with discharged vehicle battery

@ in the usual manner.

.,. If the engine fails to start, do not keep the

starter cranking for longer than 10 seconds.

Wait for about 30 seconds and then try aga in .

.,. With engine running, remove jumper cables

from both vehicles in the exact

reverse o r

de r .

.,. Close the red cover on the positive term inal.

T he battery is vented to the outside to prevent

gases from entering the veh icle inter ior. Make

sure that the jumper clamps are well connect

ed with their metal parts in full contact with

the battery terminals.

_& WARNING

To avoid serious personal injury and dam

age to the vehicle, heed all warnings and

instructions of the jumper cable manufac

turer. If in doubt, call for road service .

- Jumper cables must be long enough so

that the veh icles do not touch.

-

Page 287 of 314

M N

0 I.J "". rl I.O

"' rl

"' rl

-When connecting jumper cables, make

sure that they cannot get caught in any

moving parts in the eng ine compart

ment .

- Before you check anything in the engine

compartment, always read and heed all

WARNINGS

¢ page 222.

(D Note

Improper hook-up of jumper cables can r u

in the generator.

- Always connect POSITIVE( +) to POSI

TIVE(+), and NEGATIVE(-) to NEGATIVE

( - ) gro und post of the battery manager

control unit .

- Check that all screw plugs on the battery

cells a re screwed in firmly . If not, tighten

pl ugs p rior to connecting clamp on nega

tive battery term inal.

- Please note that the procedure f or con

nect ing a jump er cable as desc ribed

above appl ies spec ifically to the case of

you r vehi cle be ing jump started. When

you are giv ing a jump star t to an othe r ve

hi cle, do

not connec t the negat ive (-) ca

ble to the negat ive (-) terminal on the

discharged battery@¢fig.

219. In

stead, securely connect the negative( -)

cable to e ithe r a solid metal component

that is firmly bolted to the engine block

or to the e ng ine block itse lf. If the bat

te ry tha t is being charged does not vent

to the outside, escaping batte ry gas

could igni te and exp lode!

Emergency towing

with commercial tow truck

General hints

Your Audi requires special handling for tow

tng.

The follow ing information is to be used by

commercia l tow tr uck operators who know

h ow to ope rate thei r equipme nt safe ly.

Emergenc y situ ation s 285

-Ne ver tow your Audi. Towing will cause

damage to the engine and tran smission.

- Never wrap the safety chain s or w inch ca

ble s around the brake lines.

- To prevent unnece ssary damage , your Audi

must be transported with a flat bed tru ck.

- To load the vehicle on to the fl at bed , use

the towing loop found in the vehicle tools

a nd attach to the front or rear anchora ge

¢ page 285 and ¢ page 286 .

_& WARNING

A vehicle being towed is not safe for pas

sengers. Never allow anyo ne to ride in a

vehicle be ing towed, for any reason.

Front towing loop

Only install the front towing loop when it is

needed.

Fig. 22 0 Front bu mpe r: cove r

Fig. 22 1 Front bu mpe r: in stall ing t he tow ing loop

-

The towing loop fits into the threaded hole lo

cated on the right s ide of the front bumpe r

and cove red by a sma ll cover when not in use.

.. Remove the tow ing loop from the vehicle

too l kit .

Page 288 of 314

286 Emergency situations

• Press inward strongly to the button side of

the cap to remove it from the bumper

¢ fig. 220 .

• Screw the towing loop tightly in the thread

ed hole as far as it will go and tighten it with

the wheel wrench

¢ fig . 221 .

Remove the towing loop when you are done

using it and place it back in the vehicle tool

kit . Install the cover in the bumper. Always

keep the towing loop in the vehicle.

A WARNING

If you do not screw the tow ing loop com

pletely, it could come out of the threaded

hole while the vehicle is being towed caus

ing damage to the vehicle and possible se

rious personal injury.

Rear towing loop

Only install the rear towing loop when it is

needed.

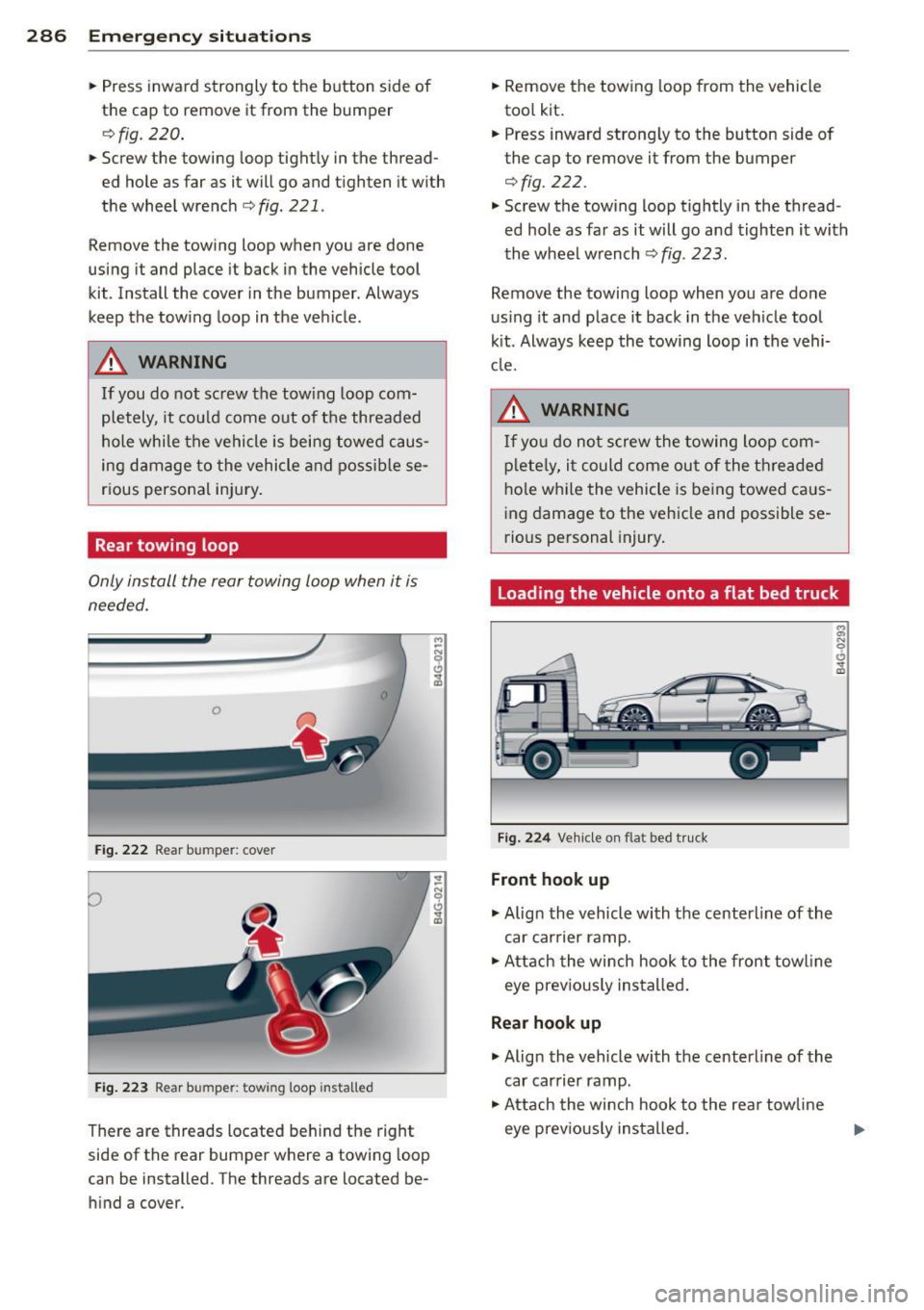

Fig . 222 Rear bum per: cover

Fig. 223 R ear bum per: t owing loop insta lled

There are threads located behind the right

side of the rear bumper where a towing loop

can be installed . The threads are located be

hind a cover.

-

• Remove the towing loop from the vehicle

tool kit.

• Press inward strong ly to the button side of

the cap to remove it from the bumper

¢fig. 222.

• Screw the towing loop tightly in the thread

ed hole as far as it will go and tighten it with

the wheel wrench

¢ fig . 223.

Remove the towing loop when you are done

using it and place it back in the vehicle tool

kit. Always keep the towing loop in the vehi

cle.

A WARNING

If yo u do not screw the towing loop com

pletely, it could come out of the threaded

hole while the vehicle is being towed caus

ing damage to the vehicle and possible se

rious personal injury.

Loading the vehicle onto a flat bed truck

Fig. 224 Vehicle on flat bed truck

Front hook up

• Align the vehicle with the centerline of the

car carrier ramp.

• Attach the winch hook to the front towl ine

eye previously installed.

Rear hook up

• Align the vehicle with the centerline of the

car carrier ramp .

• Attach the winch hook to the rear tow line

eye prev iously installed.

-

Page 289 of 314

M N

0 I.J "". rl I.O

"'

@ Tips

Check carefully to make sure the hook-up

is secure before moving the car up the flat

bed truck ramp .

Vehicle transport

Whenever you hov e your vehicle transported,

be sure to note the following :

(D Note

Mount the tie-down chains/cables over the

running surface (circumference) of the

tires. Never secure the vehicle by the axle,

the suspension struts or the front or rear

towline eye . For technical reasons, the

pressure in the suspension struts may

change du ring the transport and this will

adve rsely affect vehicle handling.

Lifting vehicle

Lifting with workshop hoist and with

floor jack

The vehicle may onl y be li~ed at the lif ting

points illu stra ted.

Fi g. 2 25 Front l ift ing po int

Fig. 226 Rea r lifti ng poin t

:;:; N 0 6 ., a,

5 .. Read and heed WARNING Q ,&..

Emergenc y situ ation s 287

.. Activate the vehicle jack mode* in the MM I:

!CAR I function button > (C ar)* s ystem s con

trol button>

S e rv ic ing & check s> Air su sp. :

jack m ode> On .

.. Locate lifting poin ts Q fig . 225 and

Q fig . 226 .

.. Adjust lifting arms of workshop hoist or

floor jack to match veh icle lifting points.

.. Insert a rubber pad be tween the floor jack/

workshop hoist and the lift ing po in ts.

The vehicle jack mode* must be activated so

that the automat ic adjustment of the Adap

tive Ai r Suspens ion* does not make it more

diffi cult to raise the vehicle with the floor

jack.

If yo u must lift your v ehi cle with a floor jack

t o wo rk und ern eath , be sure th e vehicle i s

s af ely s upported on s tands intended for thi s

purpo se.

Front lifting point

The lifting po int is located on the floor pan re

inforcement abo ut at the same leve l as the

jac k mounting point

Q fig. 225 . Do n ot lift

t h e ve hicle at th e verti cal sill reinforc em ent .

Re ar lifting point

The lifting point is located on the vert ical rein

forcement of the lower sill for the on-boa rd

ja ck

c::> fig. 226 .

Lifting with veh icle j ack

Re fer to Q page 275.

A WARNING

-To reduce the risk of ser ious injury and

veh icle damage .

- Always lift the veh icle only at the spe

cia l workshop hoist and floor jack lift

po ints illust rated

c::> fig . 225 and

c::> fig . 226.

- Failu re to lift the vehicle at these

po ints could cause the vehicle to tilt or

fall from a lift if there is a change in ve

hicle weight distribution and balance .

This might happen, for example, when

-

Page 290 of 314

288 Emergency situations

heavy components such as the engine

b lock or transmiss io n are removed.

- W he n removing heavy components like

these, ancho r vehicle to ho ist o r add cor

responding weig hts to ma inta in the cen

ter of g ravity . Othe rwise, the vehicle

might tilt or s lip off t he hoist, causing

ser ious p erson al injury.

(D Note

-Be awa re of the follow ing points befo re

li fting the vehicle:

- The vehicle should never be lifted or

jacked up from underneath the engine oil pan, the transmission housing, the

front or rear axle or the body side

membe rs. This could lead to ser ious

damage.

- To avoid damage to the underbody or

chassis frame , a rubber pad must be

i nserted between the floor jack and

the l ift points.

- Before driving over a workshop hoist,

check that the veh icle weight does not

exceed the permissible lifting capacity

of the hoist .

- Before driving over a workshop hoist,

ensure that there is sufficient clear

ance between the hoist and low parts

of the vehicle.