torque AUDI A8 1996 D2 / 1.G AHA ATQ Engines Lubrication System Components Workshop Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 1996, Model line: A8, Model: AUDI A8 1996 D2 / 1.GPages: 34, PDF Size: 0.68 MB

Page 11 of 34

17-7

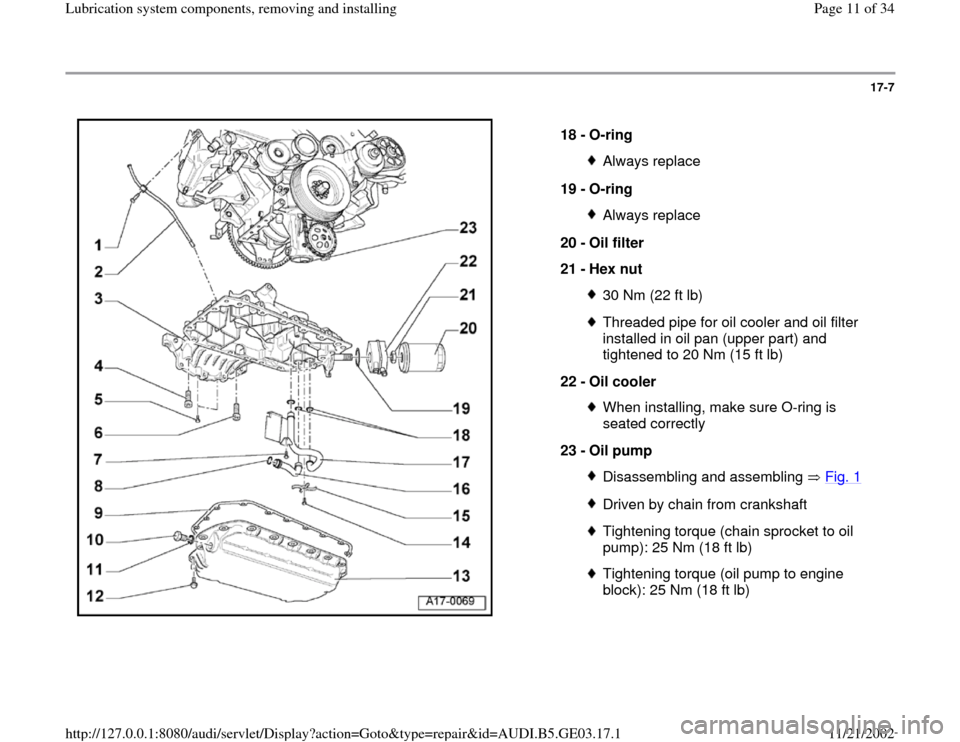

18 -

O-ring

Always replace

19 -

O-ring Always replace

20 -

Oil filter

21 -

Hex nut 30 Nm (22 ft lb)Threaded pipe for oil cooler and oil filter

installed in oil pan (upper part) and

tightened to 20 Nm (15 ft lb)

22 -

Oil cooler When installing, make sure O-ring is

seated correctly

23 -

Oil pump Disassembling and assembling Fig. 1Driven by chain from crankshaftTightening torque (chain sprocket to oil

pump): 25 Nm (18 ft lb) Tightening torque (oil pump to engine

block): 25 Nm (18 ft lb)

Pa

ge 11 of 34 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.17.1

Page 12 of 34

17-8

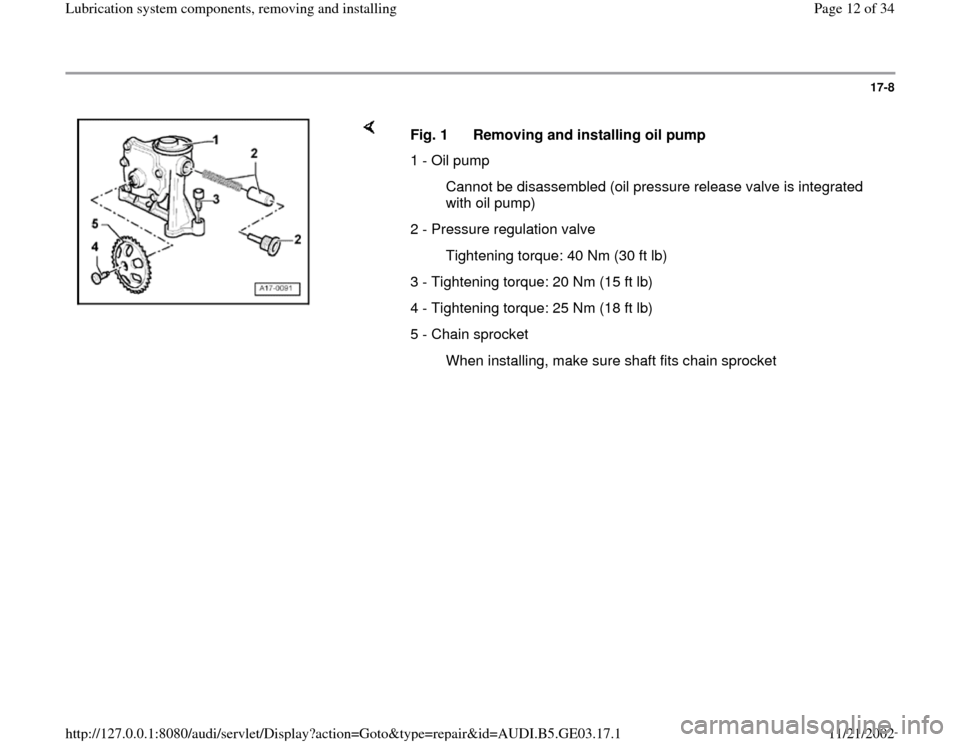

Fig. 1 Removing and installing oil pump

1 - Oil pump

Cannot be disassembled (oil pressure release valve is integrated

with oil pump)

2 - Pressure regulation valve

Tightening torque: 40 Nm (30 ft lb)

3 - Tightening torque: 20 Nm (15 ft lb)

4 - Tightening torque: 25 Nm (18 ft lb)

5 - Chain sprocket

When installing, make sure shaft fits chain sprocket

Pa

ge 12 of 34 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.17.1

Page 13 of 34

17-9

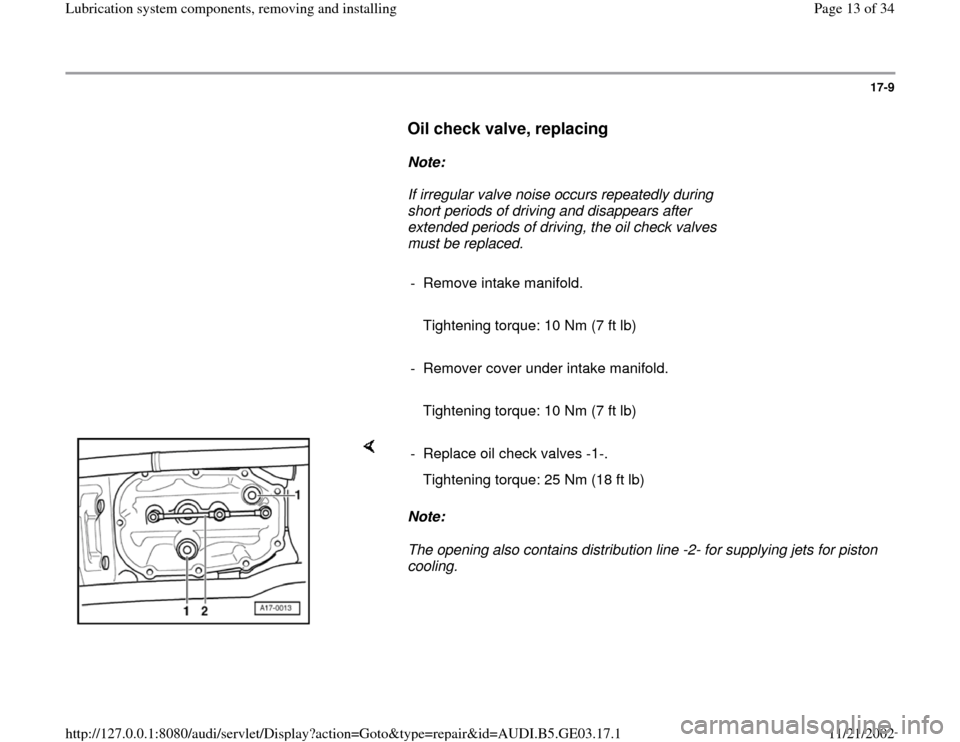

Oil check valve, replacing

Note:

If irregular valve noise occurs repeatedly during

short periods of driving and disappears after

extended periods of driving, the oil check valves

must be replaced.

- Remove intake manifold.

Tightening torque: 10 Nm (7 ft lb)

- Remover cover under intake manifold.

Tightening torque: 10 Nm (7 ft lb)

Note:

The opening also contains distribution line -2- for supplying jets for piston

cooling. - Replace oil check valves -1-.

Tightening torque: 25 Nm (18 ft lb)

Pa

ge 13 of 34 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.17.1

Page 14 of 34

17-10

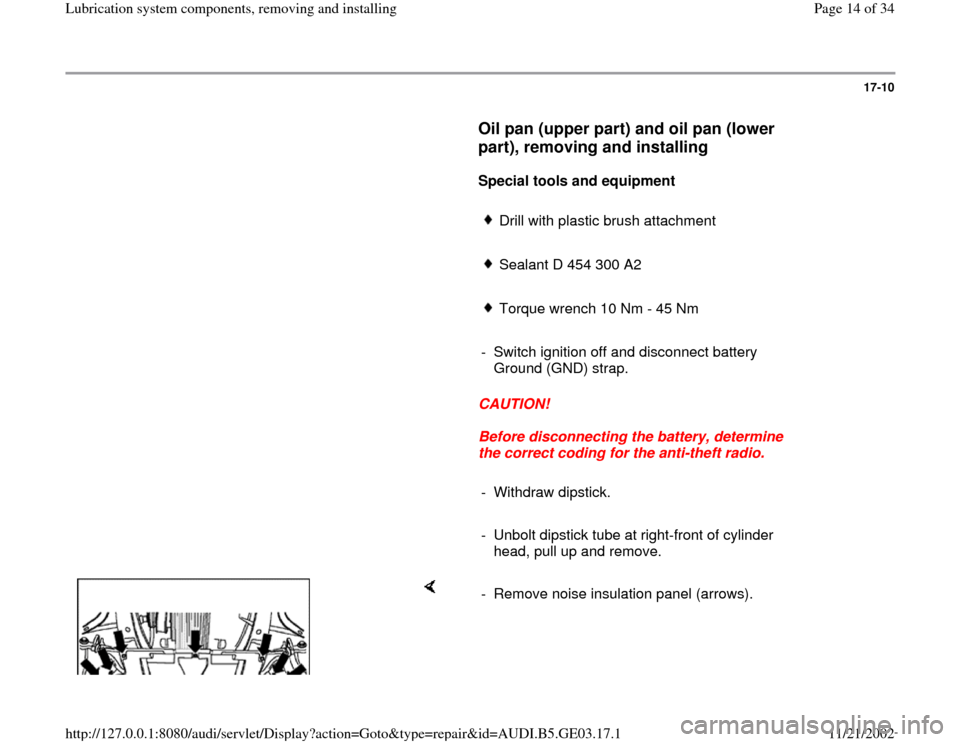

Oil pan (upper part) and oil pan (lower

part), removing and installing

Special tools and equipment

Drill with plastic brush attachment

Sealant D 454 300 A2

Torque wrench 10 Nm - 45 Nm

- Switch ignition off and disconnect battery

Ground (GND) strap.

CAUTION!

Before disconnecting the battery, determine

the correct coding for the anti-theft radio.

- Withdraw dipstick.

- Unbolt dipstick tube at right-front of cylinder

head, pull up and remove.

- Remove noise insulation panel (arrows).

Pa

ge 14 of 34 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.17.1

Page 16 of 34

17-12

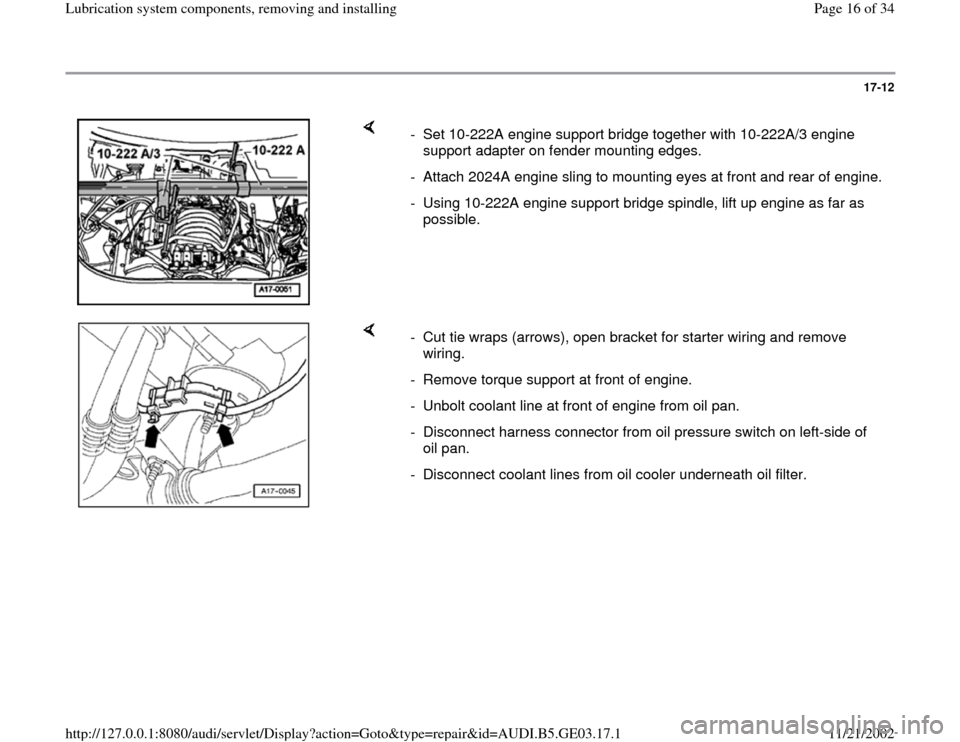

- Set 10-222A engine support bridge together with 10-222A/3 engine

support adapter on fender mounting edges.

- Attach 2024A engine sling to mounting eyes at front and rear of engine.

- Using 10-222A engine support bridge spindle, lift up engine as far as

possible.

- Cut tie wraps (arrows), open bracket for starter wiring and remove

wiring.

- Remove torque support at front of engine.

- Unbolt coolant line at front of engine from oil pan.

- Disconnect harness connector from oil pressure switch on left-side of

oil pan.

- Disconnect coolant lines from oil cooler underneath oil filter.

Pa

ge 16 of 34 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.17.1

Page 21 of 34

17-17

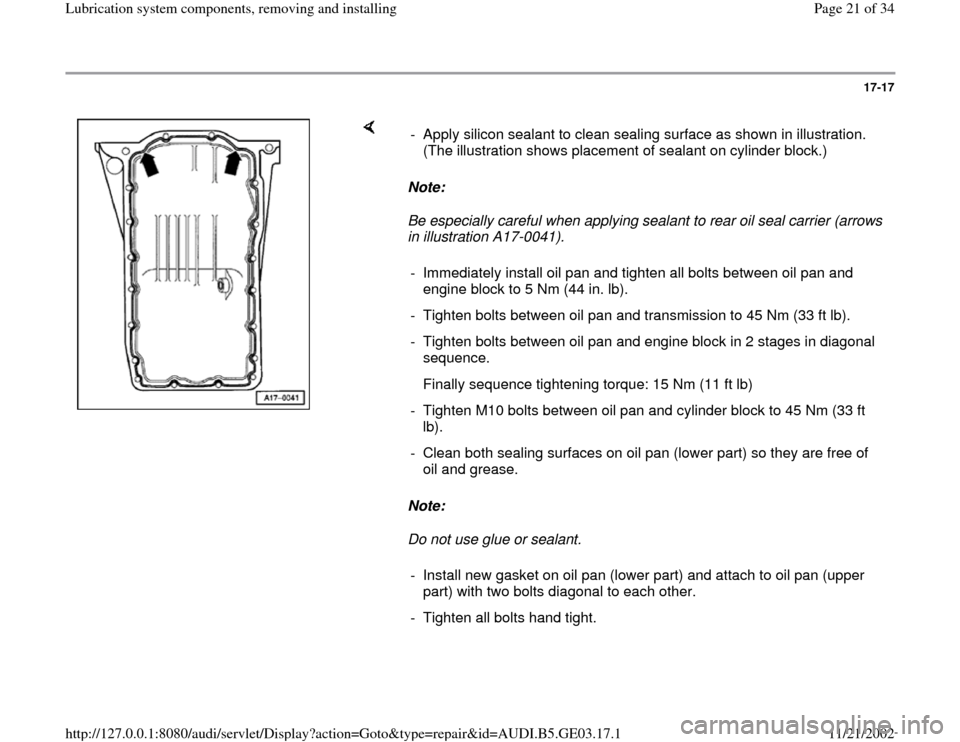

Note:

Be especially careful when applying sealant to rear oil seal carrier (arrows

in illustration A17-0041).

Note:

Do not use glue or sealant. - Apply silicon sealant to clean sealing surface as shown in illustration.

(The illustration shows placement of sealant on cylinder block.)

- Immediately install oil pan and tighten all bolts between oil pan and

engine block to 5 Nm (44 in. lb).

- Tighten bolts between oil pan and transmission to 45 Nm (33 ft lb).

- Tighten bolts between oil pan and engine block in 2 stages in diagonal

sequence.

Finally sequence tightening torque: 15 Nm (11 ft lb)

- Tighten M10 bolts between oil pan and cylinder block to 45 Nm (33 ft

lb).

- Clean both sealing surfaces on oil pan (lower part) so they are free of

oil and grease.

- Install new gasket on oil pan (lower part) and attach to oil pan (upper

part) with two bolts diagonal to each other.

- Tighten all bolts hand tight.

Pa

ge 21 of 34 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.17.1

Page 27 of 34

17-23

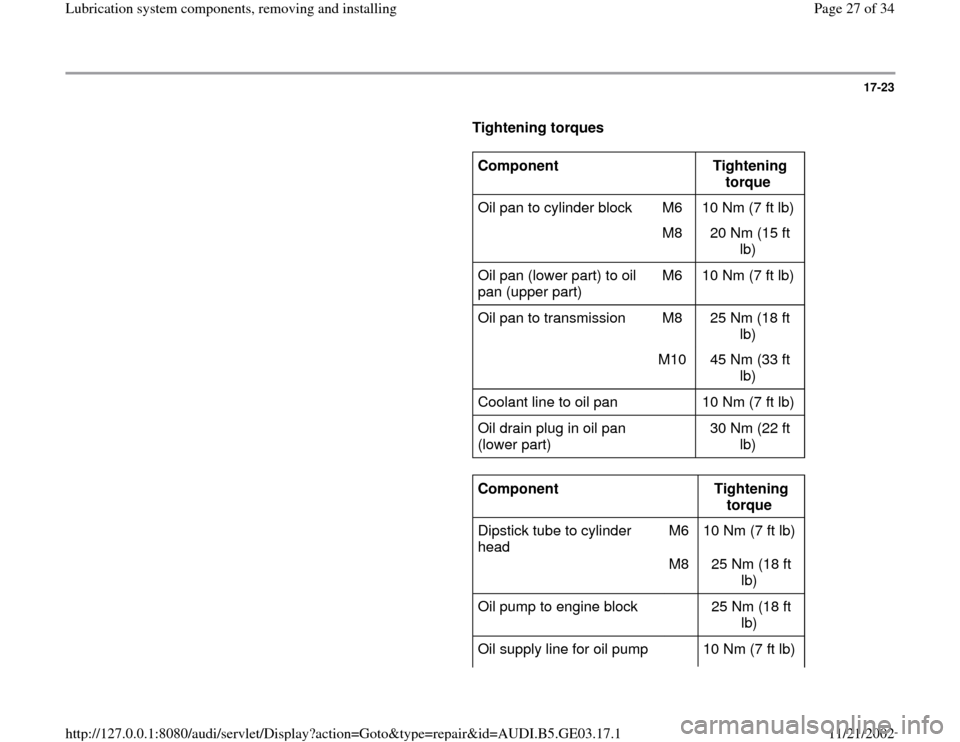

Tightening torques

Component

Tightening

torque

Oil pan to cylinder block M6 10 Nm (7 ft lb)

M8 20 Nm (15 ft

lb)

Oil pan (lower part) to oil

pan (upper part) M6 10 Nm (7 ft lb)

Oil pan to transmission M8 25 Nm (18 ft

lb)

M10 45 Nm (33 ft

lb)

Coolant line to oil pan 10 Nm (7 ft lb)

Oil drain plug in oil pan

(lower part) 30 Nm (22 ft

lb)

Component

Tightening

torque

Dipstick tube to cylinder

head M6

M8 10 Nm (7 ft lb)

25 Nm (18 ft

lb)

Oil pump to engine block 25 Nm (18 ft

lb)

Oil supply line for oil pump 10 Nm (7 ft lb)

Pa

ge 27 of 34 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.17.1

Page 29 of 34

17-24

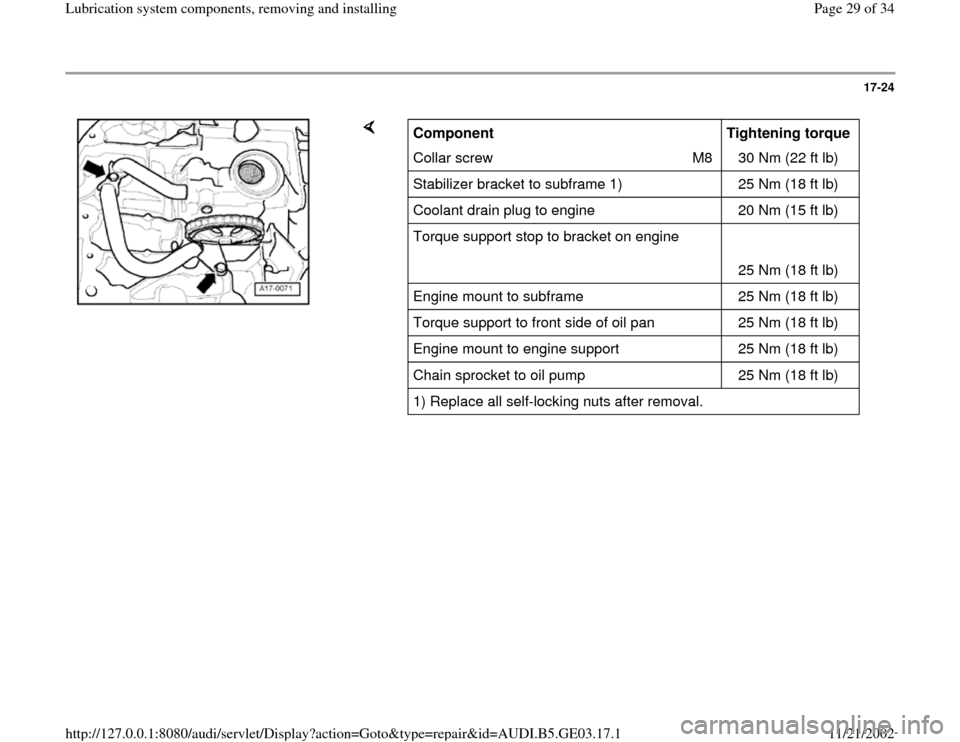

Component

Tightening torque

Collar screw M8 30 Nm (22 ft lb)

Stabilizer bracket to subframe 1) 25 Nm (18 ft lb)

Coolant drain plug to engine 20 Nm (15 ft lb)

Torque support stop to bracket on engine

25 Nm (18 ft lb)

Engine mount to subframe 25 Nm (18 ft lb)

Torque support to front side of oil pan 25 Nm (18 ft lb)

Engine mount to engine support 25 Nm (18 ft lb)

Chain sprocket to oil pump 25 Nm (18 ft lb)

1) Replace all self-locking nuts after removal.

Pa

ge 29 of 34 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.17.1

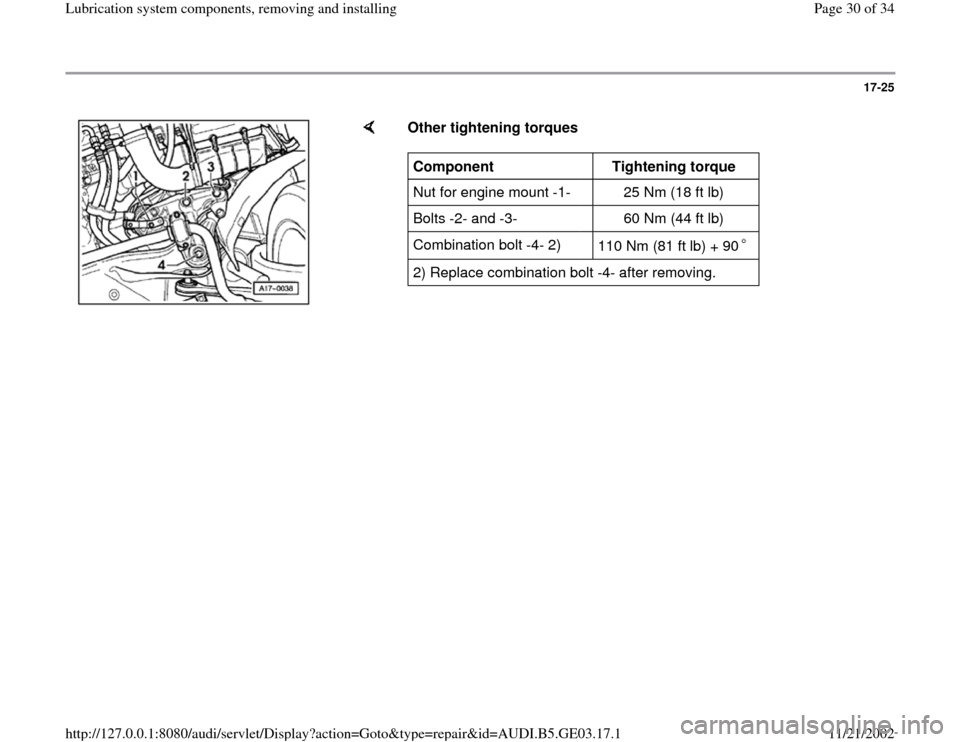

Page 30 of 34

17-25

Other tightening torques Component

Tightening torque

Nut for engine mount -1- 25 Nm (18 ft lb)

Bolts -2- and -3- 60 Nm (44 ft lb)

Combination bolt -4- 2)

110 Nm (81 ft lb) + 90 2) Replace combination bolt -4- after removing.

Pa

ge 30 of 34 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.17.1

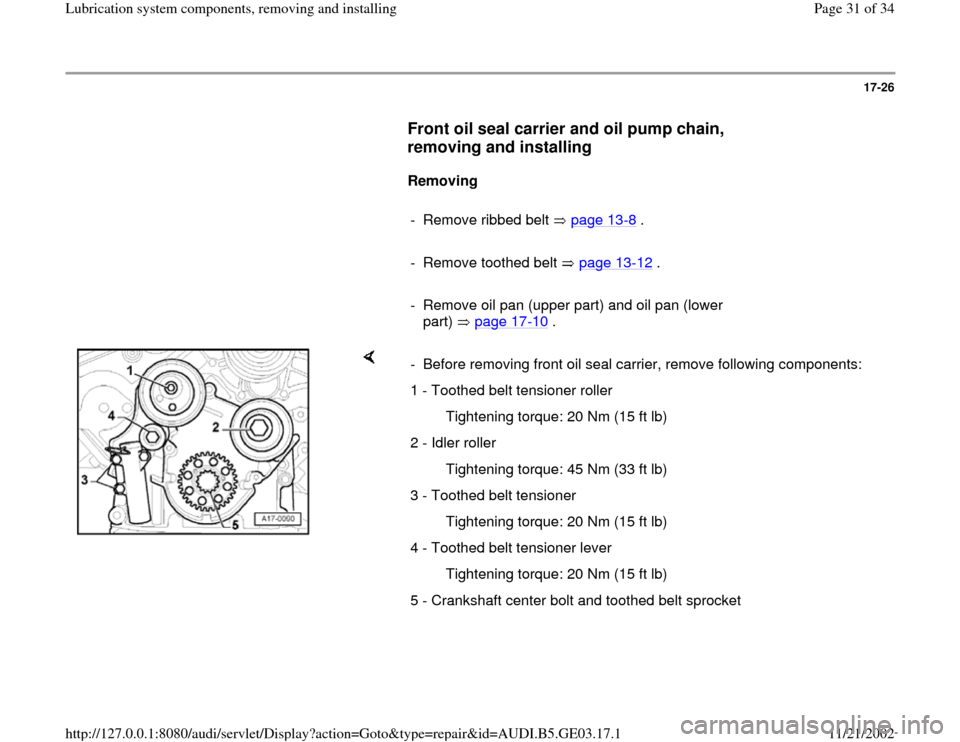

Page 31 of 34

17-26

Front oil seal carrier and oil pump chain,

removing and installing

Removing

- Remove ribbed belt page 13

-8 .

- Remove toothed belt page 13

-12

.

- Remove oil pan (upper part) and oil pan (lower

part) page 17

-10

.

- Before removing front oil seal carrier, remove following components:

1 - Toothed belt tensioner roller

Tightening torque: 20 Nm (15 ft lb)

2 - Idler roller

Tightening torque: 45 Nm (33 ft lb)

3 - Toothed belt tensioner

Tightening torque: 20 Nm (15 ft lb)

4 - Toothed belt tensioner lever

Tightening torque: 20 Nm (15 ft lb)

5 - Crankshaft center bolt and toothed belt sprocket

Pa

ge 31 of 34 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.17.1