fuel pump AUDI A8 2003 D3 / 2.G Technical Features Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2003, Model line: A8, Model: AUDI A8 2003 D3 / 2.GPages: 96, PDF Size: 5.51 MB

Page 30 of 96

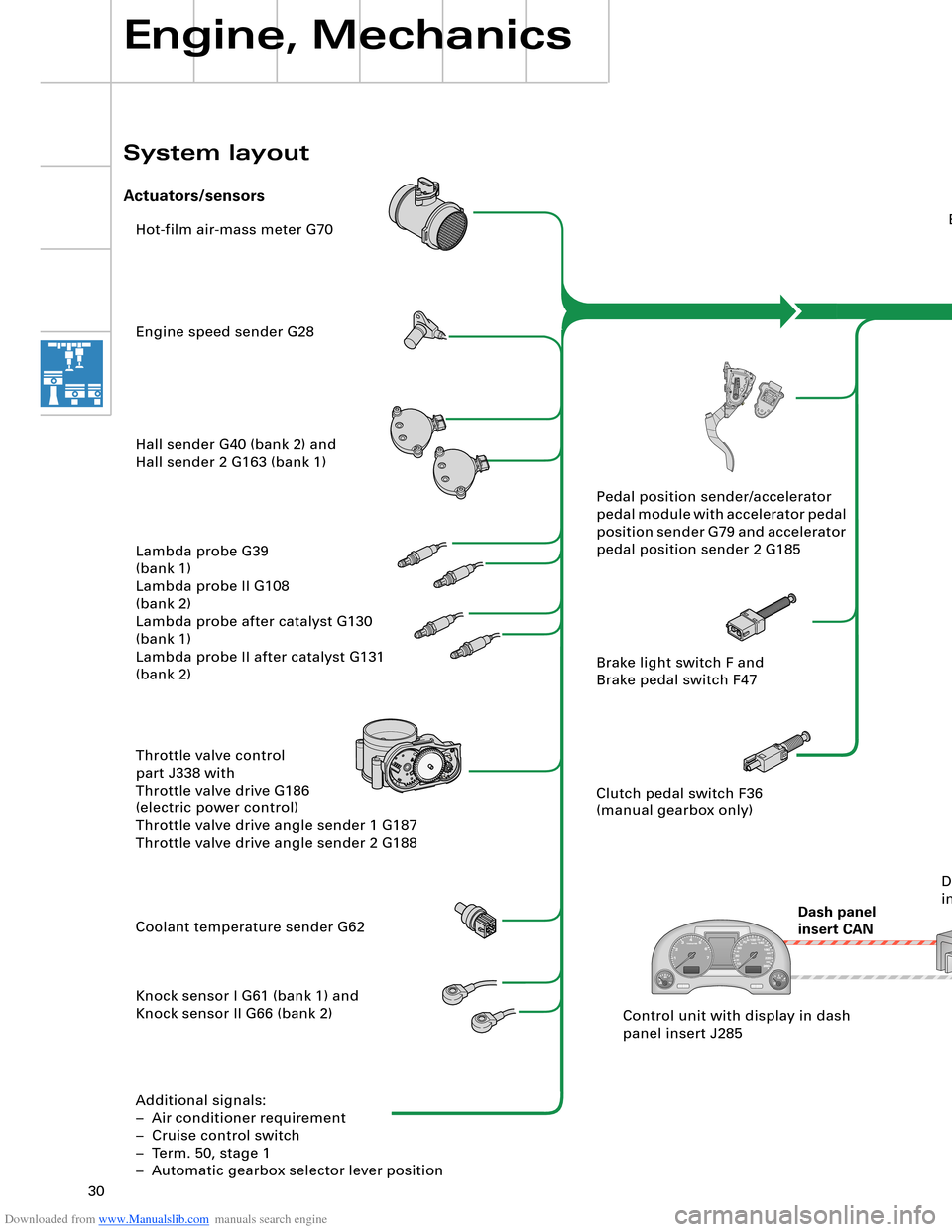

Downloaded from www.Manualslib.com manuals search engine 30

Hot-film air-mass meter G70

Engine speed sender G28

Hall sender G40 (bank 2) and

Hall sender 2 G163 (bank 1)

Lambda probe G39

(bank 1)

Lambda probe II G108

(bank 2)

Lambda probe after catalyst G130

(bank 1)

Lambda probe II after catalyst G131

(bank 2)

Throttle valve control

part J338 with

Throttle valve drive G186

(electric power control)

Throttle valve drive angle sender 1 G187

Throttle valve drive angle sender 2 G188

Coolant temperature sender G62

Knock sensor I G61 (bank 1) and

Knock sensor II G66 (bank 2)

Additional signals:

– Air conditioner requirement

– Cruise control switch

– Term. 50, stage 1

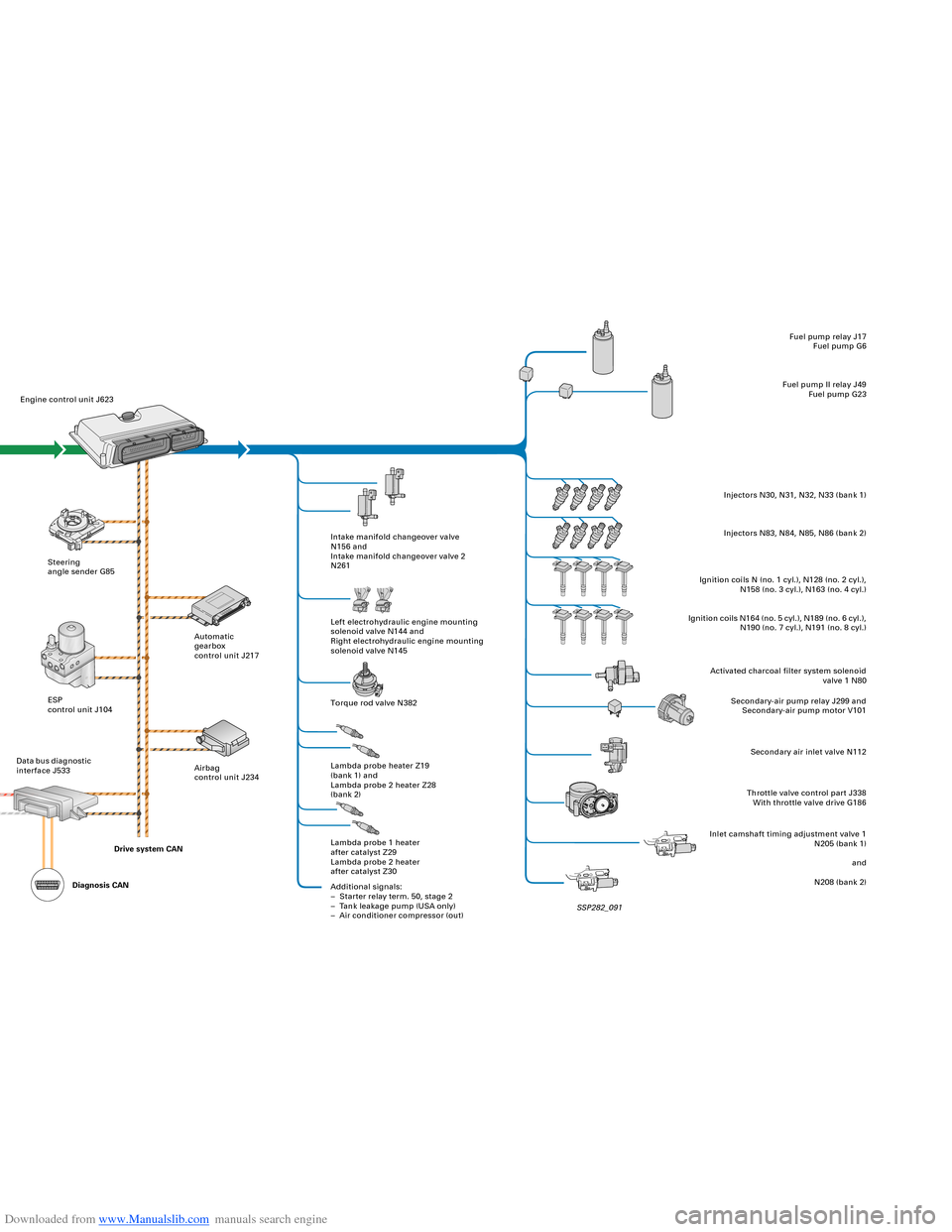

– Automatic gearbox selector lever positionEngine control unit J623

Steering

angle sender G85

ESP

control unit J104

Dash panel

insert CANAutomatic

gearbox

control unit J217

Airbag

control unit J234Intake manifold changeover valve

N156 and

Intake manifold changeover valve 2

N261

Left electrohydraulic engine mounting

solenoid valve N144 and

Right electrohydraulic engine mounting

solenoid valve N145

Torque rod valve N382

Lambda probe heater Z19

(bank 1) and

Lambda probe 2 heater Z28

(bank 2)

Lambda probe 1 heater

after catalyst Z29

Lambda probe 2 heater

after catalyst Z30

Additional signals:

– Starter relay term. 50, stage 2

– Tank leakage pump (USA only)

– Air conditioner compressor (out)Fuel pump relay J17

Fuel pump G6

Fuel pump II relay J49

Fuel pump G23

Injectors N30, N31, N32, N33 (bank 1)

Injectors N83, N84, N85, N86 (bank 2)

Ignition coils N (no. 1 cyl.), N128 (no. 2 cyl.),

N158 (no. 3 cyl.), N163 (no. 4 cyl.)

Ignition coils N164 (no. 5 cyl.), N189 (no. 6 cyl.),

N190 (no. 7 cyl.), N191 (no. 8 cyl.)

Activated charcoal filter system solenoid

valve 1 N80

Secondary-air pump relay J299 and

Secondary-air pump motor V101

Secondary air inlet valve N112

Throttle valve control part J338

With throttle valve drive G186

Inlet camshaft timing adjustment valve 1

N205 (bank 1)

and

N208 (bank 2) Pedal position sender/accelerator

pedal module with accelerator pedal

position sender G79 and accelerator

pedal position sender 2 G185

Brake light switch F and

Brake pedal switch F47

Clutch pedal switch F36

(manual gearbox only)

Control unit with display in dash

panel insert J285Data bus diagnostic

interface J533

Engine, Mechanics

System layout

Actuators/sensors

SSP282_091 Drive system CAN

Diagnosis CAN

Page 31 of 96

Downloaded from www.Manualslib.com manuals search engine 30

Hot-film air-mass meter G70

Engine speed sender G28

Hall sender G40 (bank 2) and

Hall sender 2 G163 (bank 1)

Lambda probe G39

(bank 1)

Lambda probe II G108

(bank 2)

Lambda probe after catalyst G130

(bank 1)

Lambda probe II after catalyst G131

(bank 2)

Throttle valve control

part J338 with

Throttle valve drive G186

(electric power control)

Throttle valve drive angle sender 1 G187

Throttle valve drive angle sender 2 G188

Coolant temperature sender G62

Knock sensor I G61 (bank 1) and

Knock sensor II G66 (bank 2)

Additional signals:

– Air conditioner requirement

– Cruise control switch

– Term. 50, stage 1

– Automatic gearbox selector lever positionEngine control unit J623

Steering

angle sender G85

ESP

control unit J104

Dash panel

insert CANAutomatic

gearbox

control unit J217

Airbag

control unit J234Intake manifold changeover valve

N156 and

Intake manifold changeover valve 2

N261

Left electrohydraulic engine mounting

solenoid valve N144 and

Right electrohydraulic engine mounting

solenoid valve N145

Torque rod valve N382

Lambda probe heater Z19

(bank 1) and

Lambda probe 2 heater Z28

(bank 2)

Lambda probe 1 heater

after catalyst Z29

Lambda probe 2 heater

after catalyst Z30

Additional signals:

– Starter relay term. 50, stage 2

– Tank leakage pump (USA only)

– Air conditioner compressor (out)Fuel pump relay J17

Fuel pump G6

Fuel pump II relay J49

Fuel pump G23

Injectors N30, N31, N32, N33 (bank 1)

Injectors N83, N84, N85, N86 (bank 2)

Ignition coils N (no. 1 cyl.), N128 (no. 2 cyl.),

N158 (no. 3 cyl.), N163 (no. 4 cyl.)

Ignition coils N164 (no. 5 cyl.), N189 (no. 6 cyl.),

N190 (no. 7 cyl.), N191 (no. 8 cyl.)

Activated charcoal filter system solenoid

valve 1 N80

Secondary-air pump relay J299 and

Secondary-air pump motor V101

Secondary air inlet valve N112

Throttle valve control part J338

With throttle valve drive G186

Inlet camshaft timing adjustment valve 1

N205 (bank 1)

and

N208 (bank 2) Pedal position sender/accelerator

pedal module with accelerator pedal

position sender G79 and accelerator

pedal position sender 2 G185

Brake light switch F and

Brake pedal switch F47

Clutch pedal switch F36

(manual gearbox only)

Control unit with display in dash

panel insert J285Data bus diagnostic

interface J533

Engine, Mechanics

System layout

Actuators/sensors

SSP282_091 Drive system CAN

Diagnosis CAN

Page 34 of 96

Downloaded from www.Manualslib.com manuals search engine 34

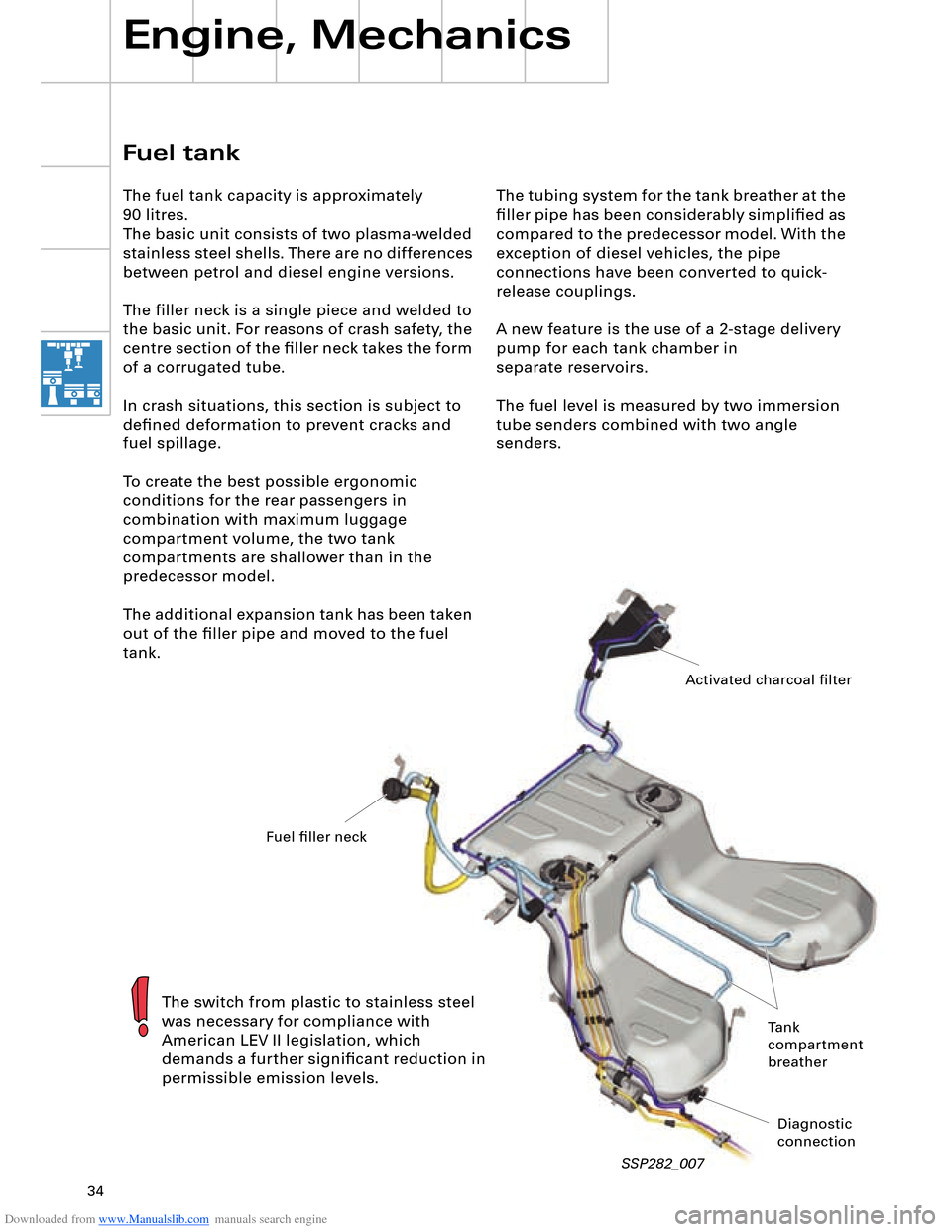

The tubing system for the tank breather at the

filler pipe has been considerably simplified as

compared to the predecessor model. With the

exception of diesel vehicles, the pipe

connections have been converted to quick-

release couplings.

A new feature is the use of a 2-stage delivery

pump for each tank chamber in

separate reservoirs.

The fuel level is measured by two immersion

tube senders combined with two angle

senders.

Engine, Mechanics

SSP282_007

Fuel tank

The fuel tank capacity is approximately

90 litres.

The basic unit consists of two plasma-welded

stainless steel shells. There are no differences

between petrol and diesel engine versions.

The filler neck is a single piece and welded to

the basic unit. For reasons of crash safety, the

centre section of the filler neck takes the form

of a corrugated tube.

In crash situations, this section is subject to

defined deformation to prevent cracks and

fuel spillage.

To create the best possible ergonomic

conditions for the rear passengers in

combination with maximum luggage

compartment volume, the two tank

compartments are shallower than in the

predecessor model.

The additional expansion tank has been taken

out of the filler pipe and moved to the fuel

tank.

The switch from plastic to stainless steel

was necessary for compliance with

American LEV II legislation, which

demands a further significant reduction in

permissible emission levels.

Activated charcoal filter

Fuel filler neck

Tank

compartment

breather

Diagnostic

connection

Page 35 of 96

Downloaded from www.Manualslib.com manuals search engine 35

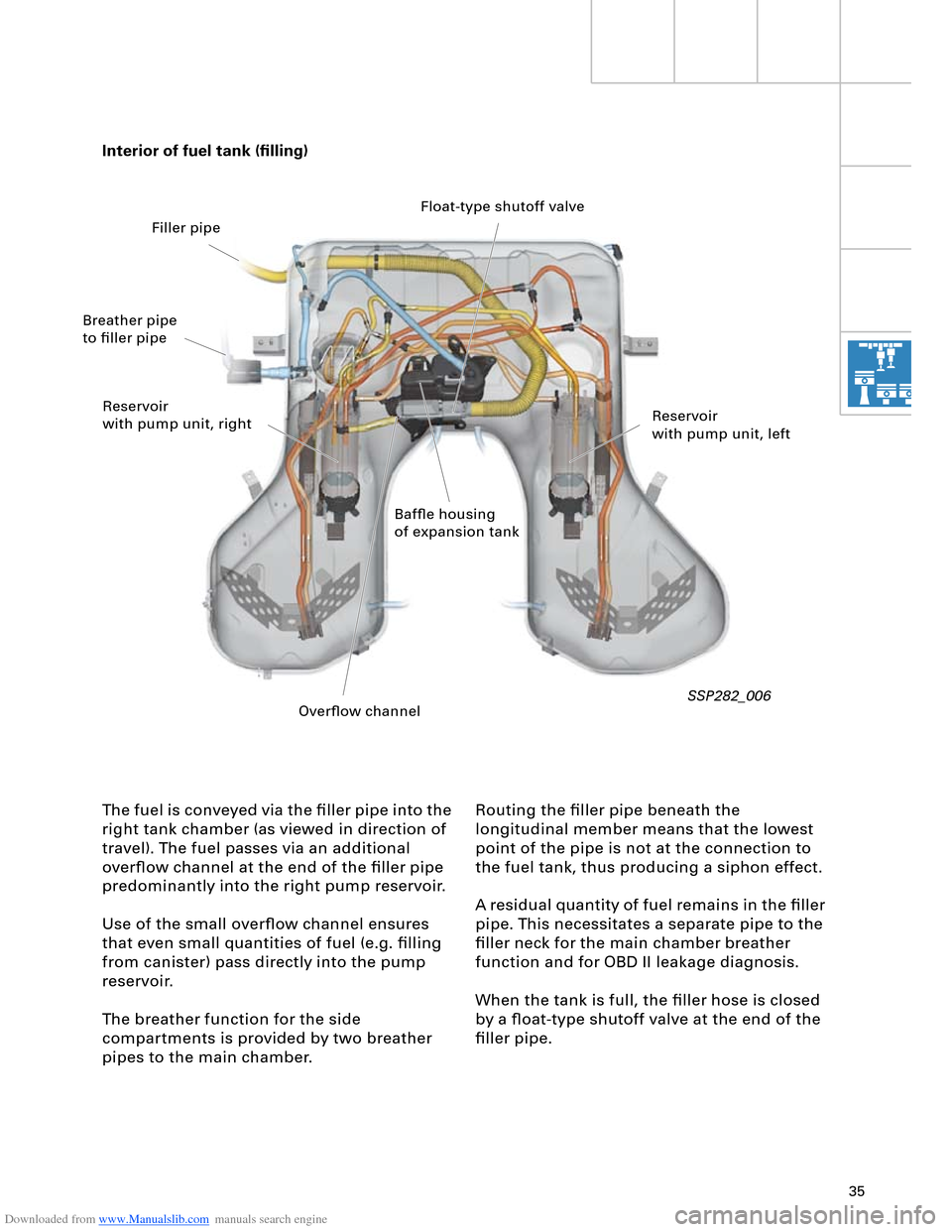

The fuel is conveyed via the filler pipe into the

right tank chamber (as viewed in direction of

travel). The fuel passes via an additional

overflow channel at the end of the filler pipe

predominantly into the right pump reservoir.

Use of the small overflow channel ensures

that even small quantities of fuel (e.g. filling

from canister) pass directly into the pump

reservoir.

The breather function for the side

compartments is provided by two breather

pipes to the main chamber.Routing the filler pipe beneath the

longitudinal member means that the lowest

point of the pipe is not at the connection to

the fuel tank, thus producing a siphon effect.

A residual quantity of fuel remains in the filler

pipe. This necessitates a separate pipe to the

filler neck for the main chamber breather

function and for OBD II leakage diagnosis.

When the tank is full, the filler hose is closed

by a float-type shutoff valve at the end of the

filler pipe. Interior of fuel tank (filling)

SSP282_006

Baffle housing

of expansion tankReservoir

with pump unit, left Reservoir

with pump unit, rightFloat-type shutoff valve

Breather pipe

to filler pipe

Overflow channel Filler pipe

Page 36 of 96

Downloaded from www.Manualslib.com manuals search engine 36

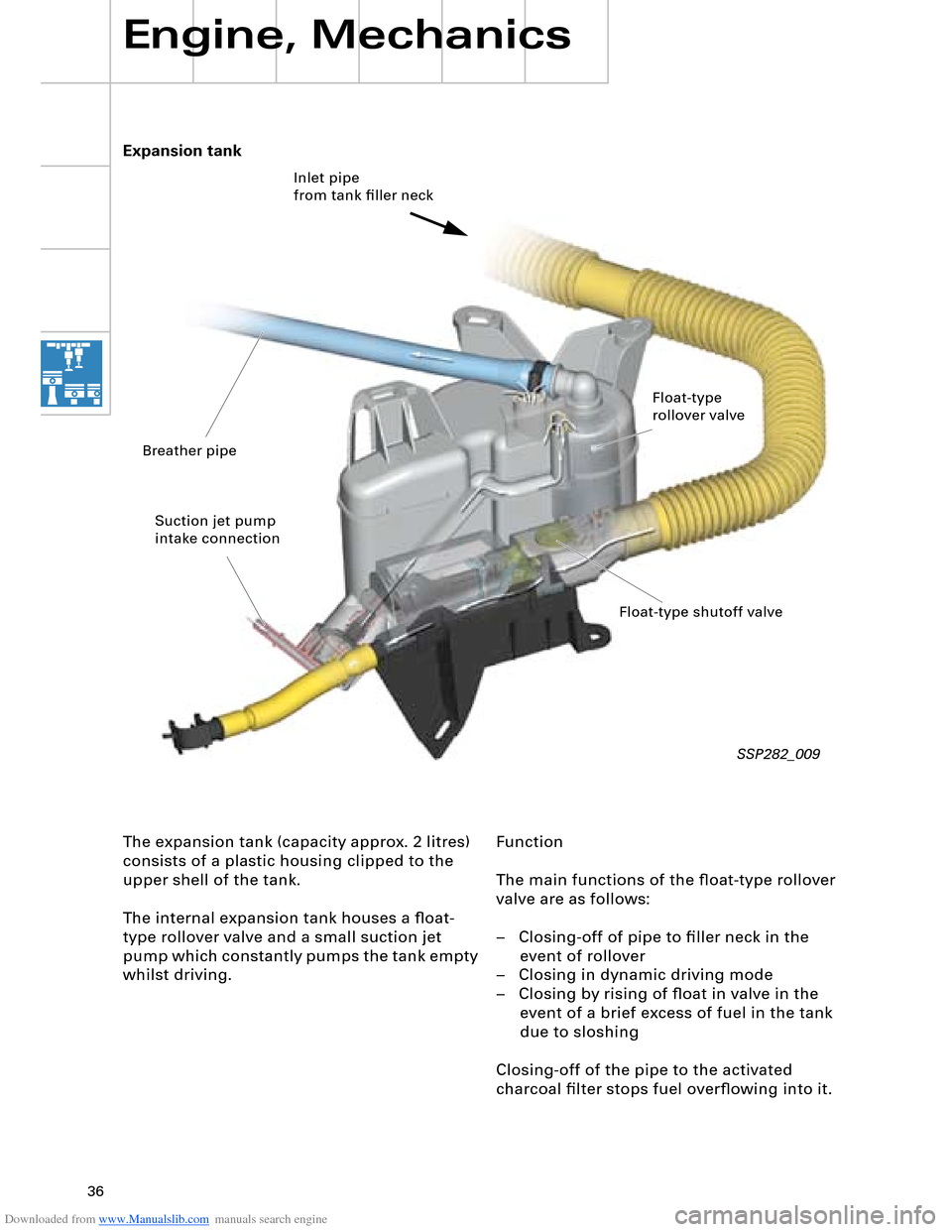

Engine, Mechanics

Function

The main functions of the float-type rollover

valve are as follows:

– Closing-off of pipe to filler neck in the

event of rollover

– Closing in dynamic driving mode

– Closing by rising of float in valve in the

event of a brief excess of fuel in the tank

due to sloshing

Closing-off of the pipe to the activated

charcoal filter stops fuel overflowing into it. Expansion tank

The expansion tank (capacity approx. 2 litres)

consists of a plastic housing clipped to the

upper shell of the tank.

The internal expansion tank houses a float-

type rollover valve and a small suction jet

pump which constantly pumps the tank empty

whilst driving.

SSP282_009

Inlet pipe

from tank filler neck

Float-type

rollover valve

Float-type shutoff valve Breather pipe

Suction jet pump

intake connection

Page 37 of 96

Downloaded from www.Manualslib.com manuals search engine 37

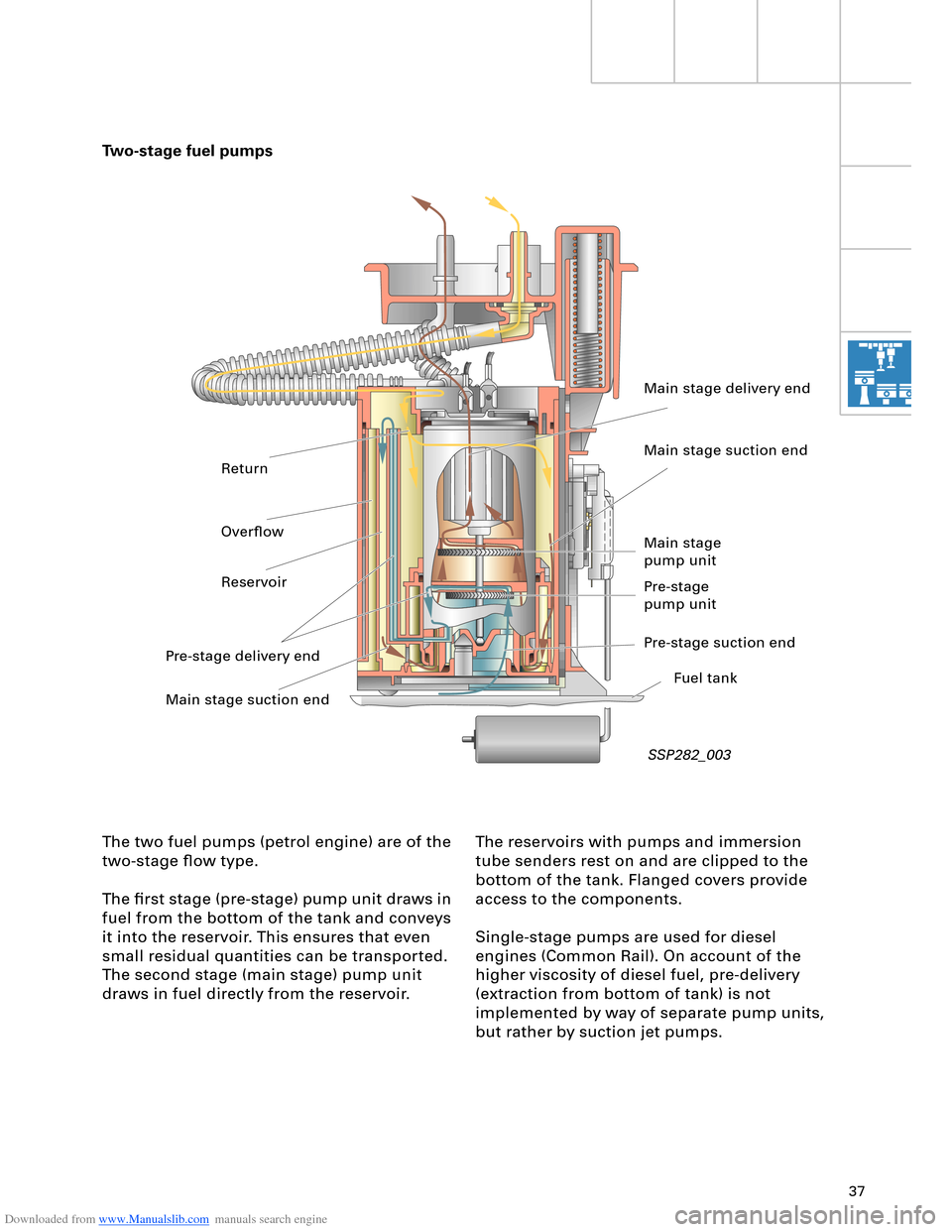

The reservoirs with pumps and immersion

tube senders rest on and are clipped to the

bottom of the tank. Flanged covers provide

access to the components.

Single-stage pumps are used for diesel

engines (Common Rail). On account of the

higher viscosity of diesel fuel, pre-delivery

(extraction from bottom of tank) is not

implemented by way of separate pump units,

but rather by suction jet pumps. Two-stage fuel pumps

The two fuel pumps (petrol engine) are of the

two-stage flow type.

The first stage (pre-stage) pump unit draws in

fuel from the bottom of the tank and conveys

it into the reservoir. This ensures that even

small residual quantities can be transported.

The second stage (main stage) pump unit

draws in fuel directly from the reservoir.

SSP282_003

Main stage delivery end

Main stage suction end

Main stage

pump unit

Pre-stage

pump unit

Pre-stage suction end

Fuel tank

Main stage suction end Pre-stage delivery endReservoirOverflow Return

Page 38 of 96

Downloaded from www.Manualslib.com manuals search engine 38

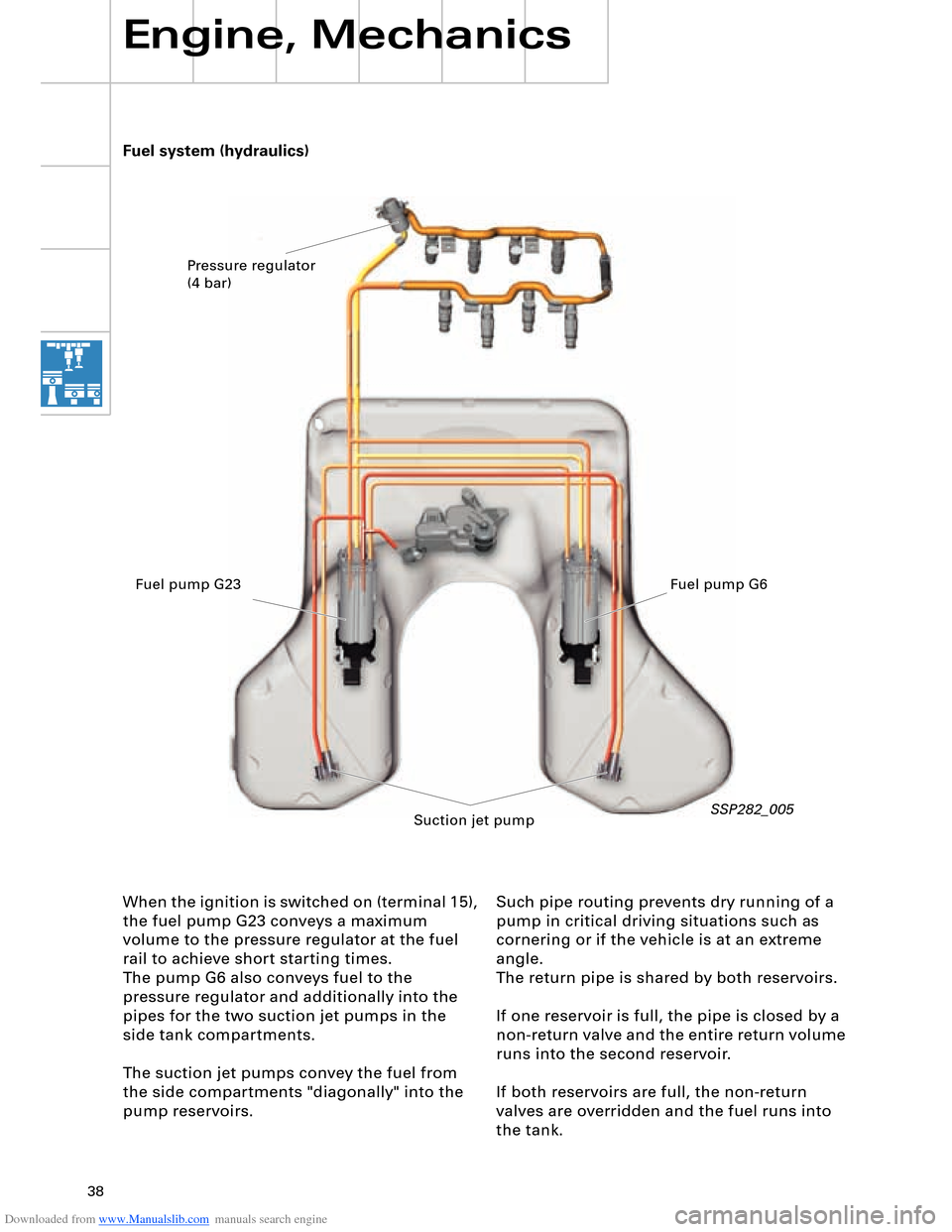

Engine, Mechanics

Such pipe routing prevents dry running of a

pump in critical driving situations such as

cornering or if the vehicle is at an extreme

angle.

The return pipe is shared by both reservoirs.

If one reservoir is full, the pipe is closed by a

non-return valve and the entire return volume

runs into the second reservoir.

If both reservoirs are full, the non-return

valves are overridden and the fuel runs into

the tank. Fuel system (hydraulics)

When the ignition is switched on (terminal 15),

the fuel pump G23 conveys a maximum

volume to the pressure regulator at the fuel

rail to achieve short starting times.

The pump G6 also conveys fuel to the

pressure regulator and additionally into the

pipes for the two suction jet pumps in the

side tank compartments.

The suction jet pumps convey the fuel from

the side compartments "diagonally" into the

pump reservoirs.

SSP282_005

Pressure regulator

(4 bar)

Fuel pump G23 Fuel pump G6

Suction jet pump

Page 39 of 96

Downloaded from www.Manualslib.com manuals search engine 39

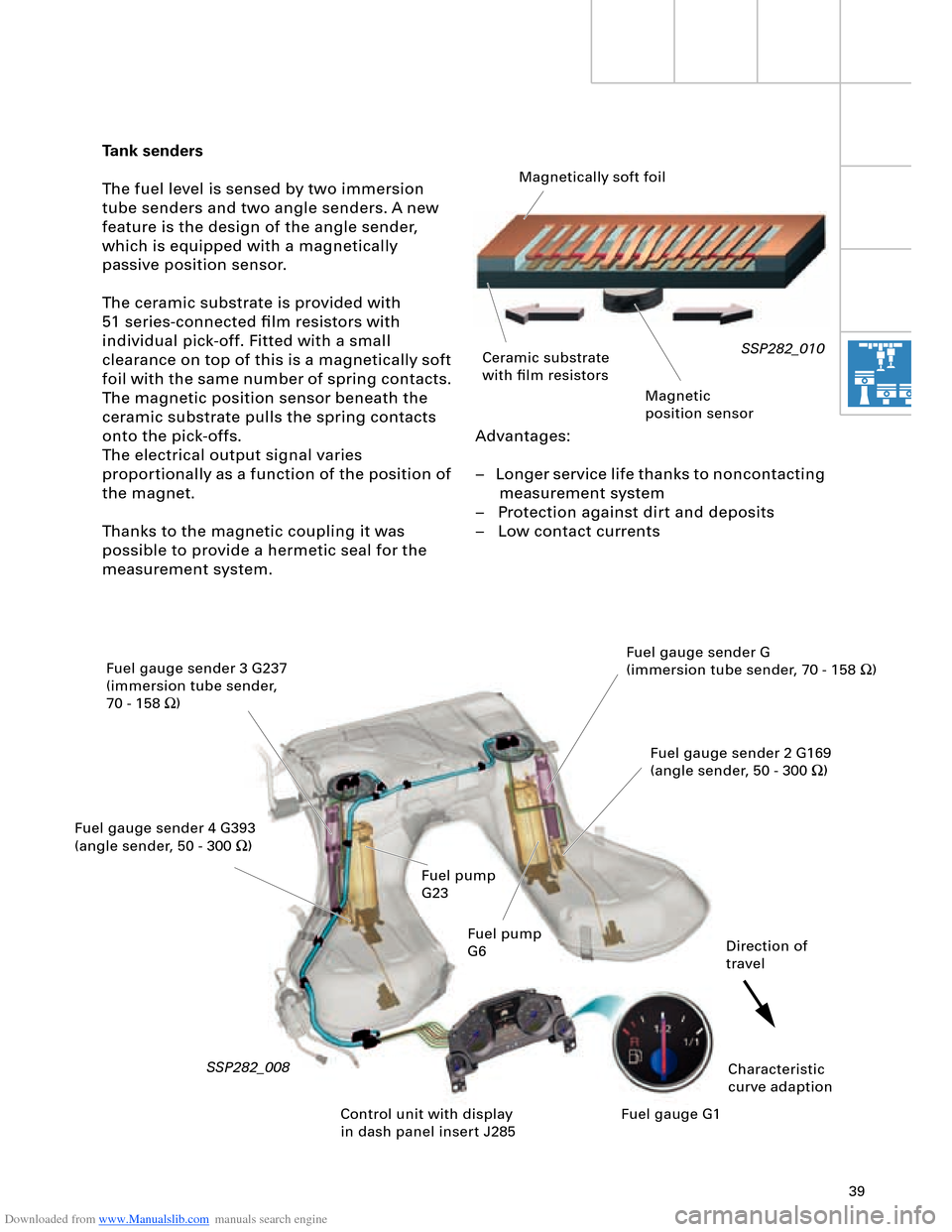

Advantages:

– Longer service life thanks to noncontacting

measurement system

– Protection against dirt and deposits

– Low contact currents

Tank senders

The fuel level is sensed by two immersion

tube senders and two angle senders. A new

feature is the design of the angle sender,

which is equipped with a magnetically

passive position sensor.

The ceramic substrate is provided with

51 series-connected film resistors with

individual pick-off. Fitted with a small

clearance on top of this is a magnetically soft

foil with the same number of spring contacts.

The magnetic position sensor beneath the

ceramic substrate pulls the spring contacts

onto the pick-offs.

The electrical output signal varies

proportionally as a function of the position of

the magnet.

Thanks to the magnetic coupling it was

possible to provide a hermetic seal for the

measurement system.

SSP282_010

SSP282_008

Magnetically soft foil

Ceramic substrate

with film resistors

Magnetic

position sensor

Fuel gauge sender 3 G237

(immersion tube sender,

70 - 158 W)

Fuel gauge sender 4 G393

(angle sender, 50 - 300 W)Fuel gauge sender G

(immersion tube sender, 70 - 158 W)

Fuel gauge sender 2 G169

(angle sender, 50 - 300 W)

Characteristic

curve adaption Direction of

travel

Control unit with display

in dash panel insert J285Fuel gauge G1 Fuel pump

G23

Fuel pump

G6

Page 91 of 96

Downloaded from www.Manualslib.com manuals search engine 91

4.2 Auxiliary heating sequence

The level of fuel in the tank is

interrogated. If the fuel tank is "empty",

the auxiliary heating function is not

permitted and the auxiliary heater symbol

in the dash panel insert goes out. "Empty"

roughly corresponds to the red display

zone. The energy management control

unit J644 checks whether there is

sufficient energy to accept auxiliary

heating. If this is the case, the auxiliary

heater is switched on in the various

operating modes depending on the

characteristic temperature curve and the

fresh-air blower is actuated.

If the auxiliary heating temperature

reaches a level of 30 °C, the fresh-air

blower is activated and the coolant

shutoff valve N279 pulsed in line with the

characteristic curve.

The auxiliary heater is switched off

automatically on completion of the operating

time transmitted by the MMI system to the

Climatronic control unit or it can be switched

off using the remote control OFF button.

Auxiliary heater circulation pump control

To speed up heating of the passenger

compartment and to achieve a better "heat

yield" in the air conditioner unit heat

exchanger, the circulation pump V55 and

coolant shutoff valve N279 are pulsed as a

function of water temperature and the

heating circuit flow rate is thus reduced.

An electric circulation pump is used for the

auxiliary heater. It is not possible to reduce

the supply voltage in the auxiliary heater

control unit and the circulation pump is thus

actuated at specific intervals to decrease its

output.

Additional control curve for "auxiliary heater"

and "additional heater"

When the engine is on, the auxiliary heater

and engine temperatures are constantly

compared. A switch to the large coolant

circuit is made as soon as the engine

temperature exceeds the auxiliary heater

temperature.

Activation of auxiliary heater circulation

pump with engine on

(pulsed operation of circulation pump)

In order to be able to ensure a sufficient flow

of water through the heat exchanger, the

auxiliary heater circulation pump must

additionally be switched on, as is the case for

instance with the 12-cylinder engine.If the engine is switched off again and not

all additional heater criteria (temperature,

time) are satisfied, the auxiliary heater

remains in operation for any residual

operating time before being deactivated.

This function can be encoded.