transmission AUDI A8 2003 D3 / 2.G Technical Features Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2003, Model line: A8, Model: AUDI A8 2003 D3 / 2.GPages: 96, PDF Size: 5.51 MB

Page 45 of 96

Downloaded from www.Manualslib.com manuals search engine 45

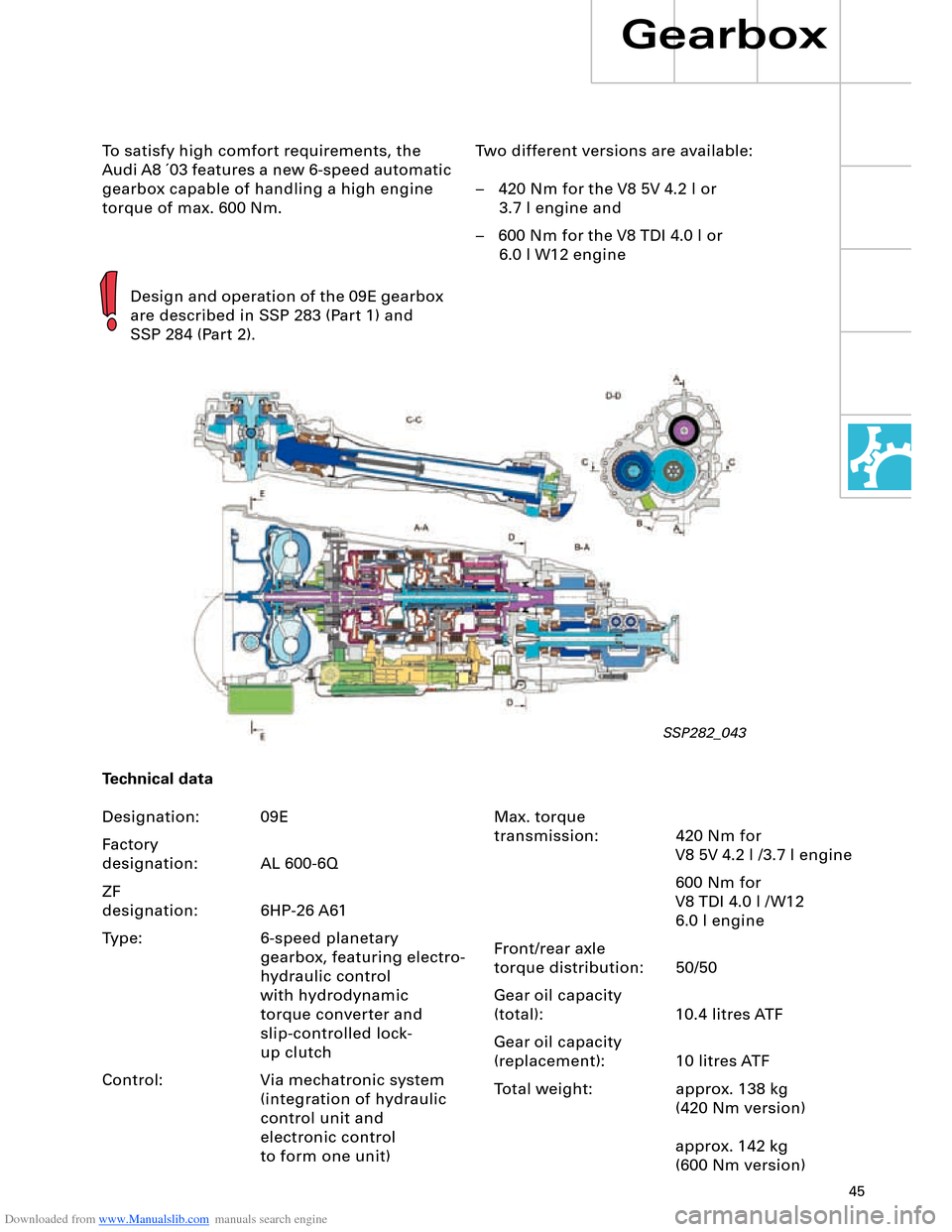

Two different versions are available:

– 420 Nm for the V8 5V 4.2 l or

3.7 l engine and

– 600 Nm for the V8 TDI 4.0 l or

6.0 l W12 engine To satisfy high comfort requirements, the

Audi A8 ´03 features a new 6-speed automatic

gearbox capable of handling a high engine

torque of max. 600 Nm.

Gearbox

Design and operation of the 09E gearbox

are described in SSP 283 (Part 1) and

SSP 284 (Part 2).

SSP282_043

Technical data

Designation: 09E

Factory

designation: AL 600-6Q

ZF

designation: 6HP-26 A61

Type: 6-speed planetary

gearbox, featuring electro-

hydraulic control

with hydrodynamic

torque converter and

slip-controlled lock-

up clutch

Control: Via mechatronic system

(integration of hydraulic

control unit and

electronic control

to form one unit)Max. torque

transmission: 420 Nm for

V8 5V 4.2 l /3.7 l engine

600 Nm for

V8 TDI 4.0 l /W12

6.0 l engine

Front/rear axle

torque distribution: 50/50

Gear oil capacity

(total): 10.4 litres ATF

Gear oil capacity

(replacement): 10 litres ATF

Total weight: approx. 138 kg

(420 Nm version)

approx. 142 kg

(600 Nm version)

Page 46 of 96

Downloaded from www.Manualslib.com manuals search engine 46

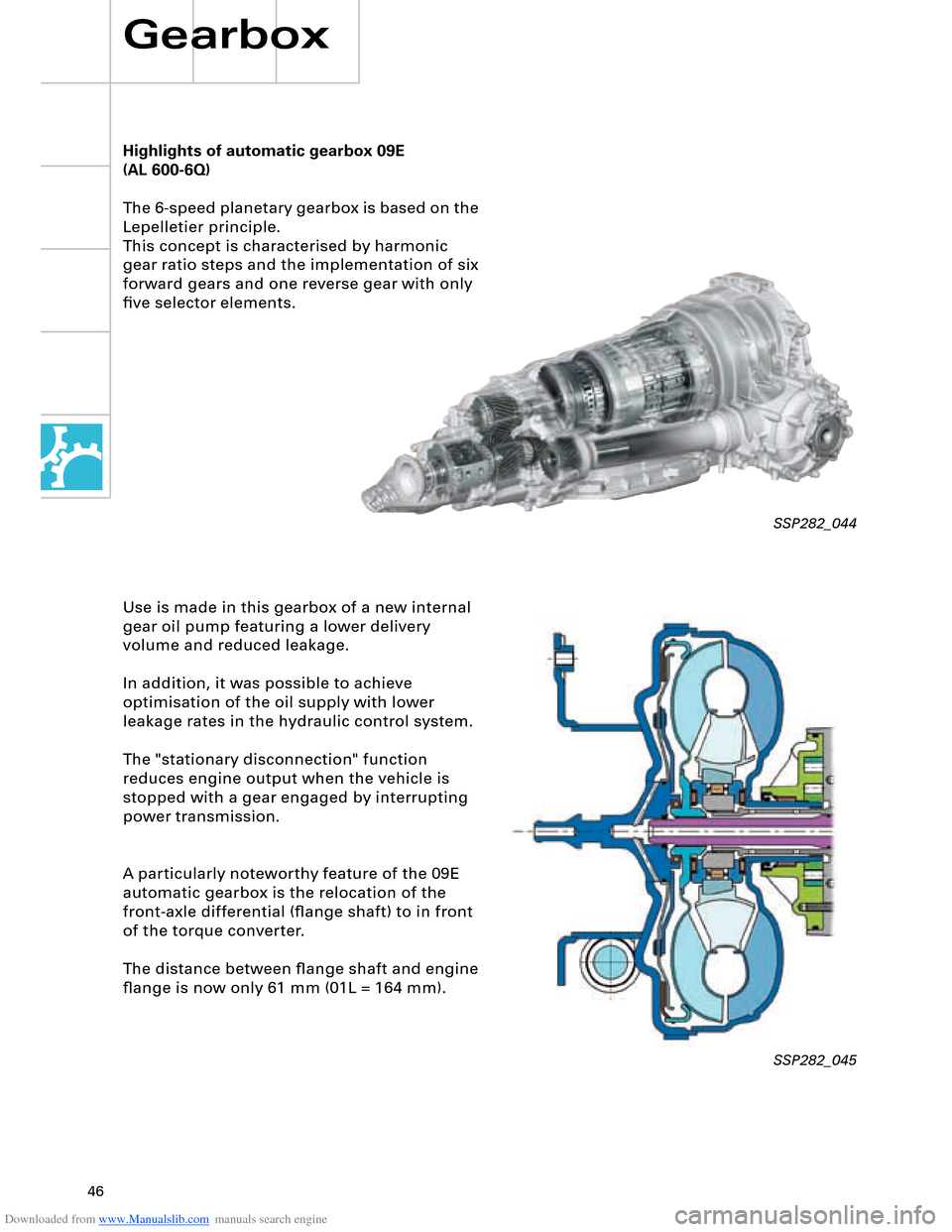

Highlights of automatic gearbox 09E

The 6-speed planetary gearbox is based on the

Lepelletier principle.

This concept is characterised by harmonic

gear ratio steps and the implementation of six

forward gears and one reverse gear with only

five selector elements.

Use is made in this gearbox of a new internal

gear oil pump featuring a lower delivery

volume and reduced leakage.

In addition, it was possible to achieve

optimisation of the oil supply with lower

leakage rates in the hydraulic control system.

The "stationary disconnection" function

reduces engine output when the vehicle is

stopped with a gear engaged by interrupting

power transmission.

A particularly noteworthy feature of the 09E

automatic gearbox is the relocation of the

front-axle differential (flange shaft) to in front

of the torque converter.

The distance between flange shaft and engine

flange is now only 61 mm (01L = 164 mm).

Gearbox

SSP282_044

SSP282_045

(AL 600-6Q)

Page 62 of 96

Downloaded from www.Manualslib.com manuals search engine 62

Electrical System

BluetoothTM

BluetoothTM is an internationally standardised

remote control data interface.

It permits control or monitoring of even

minute units using radio waves.

The primary aim when developing this new

type of interface was to create a wireless

alternative to cable links, which used to be

susceptible to interference and inconvenient

and frequently featured incompatible

connectors.

More and more manufacturers are making use

of "Bluetooth

TM" radio wave technology for

example for wireless interconnection of

notebook and mobile phone accessories.

As initiator and main contributor to the

development of this new transmission

technology, the Swedish company Ericsson

chose the name "Bluetooth".

The name originates from the Viking king

Harald Blåtand II (Danish, literally meaning

"Blue Tooth"), who lived around 1000 years ago

in Denmark and Norway.

Motor vehicle applications

– Wireless telephone receiver

– Wireless mobile phone

– Hands-free unit with no additional adapters

– Wireless internet access

– Access for PCs and Notepads

SSP282_037

Design and operation of the BluetoothTM

are described in SSP 286 – New data bus

systems.

Page 63 of 96

Downloaded from www.Manualslib.com manuals search engine 63

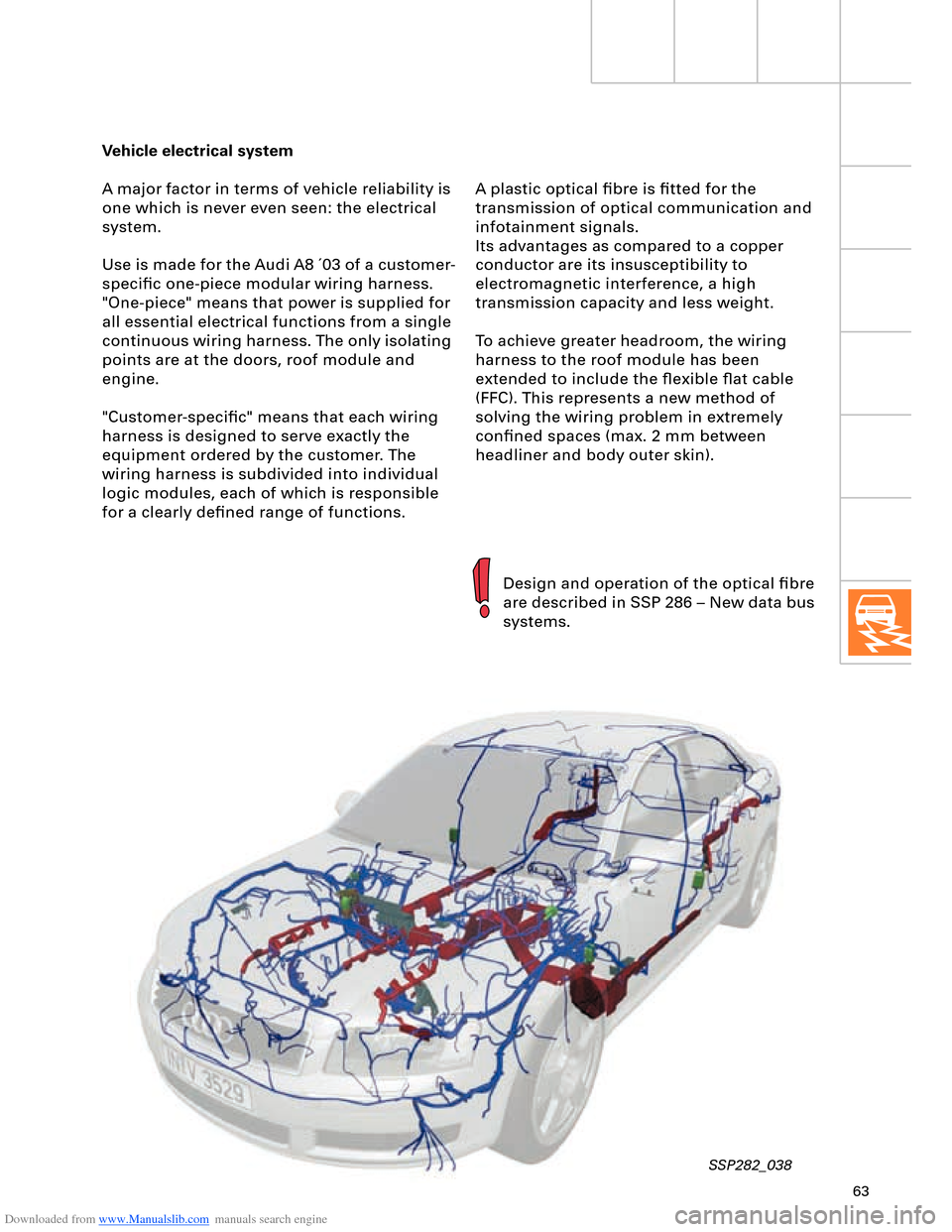

Vehicle electrical system

A major factor in terms of vehicle reliability is

one which is never even seen: the electrical

system.

Use is made for the Audi A8 ´03 of a customer-

specific one-piece modular wiring harness.

"One-piece" means that power is supplied for

all essential electrical functions from a single

continuous wiring harness. The only isolating

points are at the doors, roof module and

engine.

"Customer-specific" means that each wiring

harness is designed to serve exactly the

equipment ordered by the customer. The

wiring harness is subdivided into individual

logic modules, each of which is responsible

for a clearly defined range of functions.

SSP282_038

Design and operation of the optical fibre

are described in SSP 286 – New data bus

systems. A plastic optical fibre is fitted for the

transmission of optical communication and

infotainment signals.

Its advantages as compared to a copper

conductor are its insusceptibility to

electromagnetic interference, a high

transmission capacity and less weight.

To achieve greater headroom, the wiring

harness to the roof module has been

extended to include the flexible flat cable

(FFC). This represents a new method of

solving the wiring problem in extremely

confined spaces (max. 2 mm between

headliner and body outer skin).