AUDI A8 2012 Owners Manual

Manufacturer: AUDI, Model Year: 2012, Model line: A8, Model: AUDI A8 2012Pages: 300, PDF Size: 75.06 MB

Page 271 of 300

Fuse panel® (brown)

No. Equipment

= 11 Radio receiver

12 Rearview camera (park

ing

a id), Top view

Bulbs

Replacing light bulbs Amps

' ' 7,5

5

For your safety, we recommend that you have

your authorized Audi dealer replace burned out bulbs for you.

It is becoming increas ingly more and more

d iff icu lt to replace vehicle light bulbs since in

many cases, other parts of the car must first

be removed before you are able to get to the

bu lb. This applies especially to the light bulbs

in the front of your car which you can on ly

reach through the engine compartment.

Sheet metal and bulb ho lders can have sharp

edges that can cause serious cuts, and parts must be correctly taken apart and then prop

erly put back together to help prevent break

age of parts and long term damage from wa

ter that can enter housings that have not been properly resealed.

For your safety, we recommend that you have

your authorized Audi dealer replace any bulbs for you, since your dealer has the proper tools,

the correct bulbs and the expertise.

Gas discharge lamps (Xenon lights):

Due to the high electrical voltage, have the

bulbs replaced by a qualified technician.

Headlights with Xenon light can be identified

by the high voltage sticker.

LED headlights * require no maintenance .

Please contact your authorized Audi dealer if a

bu lb needs to be replaced.

A WARNING

Contact with high-voltage components of

the electrical system and improper re

placement of gas discharge (Xenon) head-

Fuses and bulbs

light bulbs can cause serious personal in

jury and death.

- Xenon bulbs are pressurized and can ex

plode when being changed.

- Changing Xenon lamps requires the spe

cial tra ining, instructions and equip

ment.

- On ly an authorized Audi dealer or other

qualified workshop should change the bulbs in gas discharge lamps .

A WARNING

There are parts with sharp edges on the

openings and on the bulb holders that can

cause serious cuts.

- If you are uncertain about what to do,

have the work performed by an author

ized Audi dealer or other qualified work

shop . Ser ious personal injury may result

from imprope rly performed wo rk.

Q) Tips

-If you must replace the light bulbs your

self, always remember that the eng ine

compartment of any vehicle is a hazard

ous area to work in. A lways read and

heed all WARNINGS

~page 213, Engine

compartment

Q & .

-It is best to ask your authorized Audi

dealer whenever yo u need to change a

bulb .

-

269

•

•

Page 272 of 300

2 70 Emergency situations

Emergency situations

General

This chapter is intended for trained emer

gency crews and working personnel who

have the necessary tools and equipment to

perform these ope rations.

Starting by pushing or

towing

Q;) Note

Vehicles w ith an automatic transmission

cannot be started by pus hing o r tow ing.

Starting with jumper

cables

If necessary, the engine can be started by

connecting it to the battery of another vehi

cle.

If the engine should fail to start because of a

discharged or weak battery, the battery can be

connected to the battery of

another vehicle,

using a

pair of jumpe r cables to start the en

g ine .

Jumper cables

Use only jumper cables of sufficiently large

cross section to carry the starter current safe

ly. Refer to the manufacturer's specif ications.

Use only jumper cables with

insulated termi

na l clamps which are distinctly marked:

plus(+) cable in most cases colored red

minu s(-) cable

in most cases colored black .

A WARNING

Batteries contain electricity, acid, and gas.

Any of these can cause very serious or fatal

inju ry. Follow the instructions below for

safe handling of your veh icle's battery.

- Always shield you r eyes and avoid lean

ing over the battery whenever possible.

- A discharged battery can freeze at tem

peratures just be low 32 °F (0 °C). Before connecting a

jumper cable, you must

thaw the frozen battery complete ly, oth

erwise it could explode.

- Do not allow battery acid to contact eyes

or skin . Flush any contacted area with

water immediately .

- Improper use of a booster battery to start a vehicle may cause an explosion.

- Vehicle batteries generate explosive gas

es. Keep sparks, flame and lighted ciga

rettes away from batteries.

- Do not try to jump start any vehicle with a low acid level in the battery.

- The vo ltage of the booster battery must

also have a 12-Volt rating. The capacity

(Ah) of the booster battery should not be

lower than that of the discharged bat

tery . Use of batteries of d ifferent voltage

or substantially different "Ah" rating

may cause an exp losion and personal in

jury.

- Never charge a frozen batte ry. Gas trap

ped in the ice may cause an explosion.

- Never charge or use a battery that has

been frozen. The battery case may have

be weakened.

- Use of batter ies of different voltage or

substantially different capacity (Ah) rat

ing may cause an exp losion and injury.

The capacity (Ah) of the booster battery

should not be lower than that of the dis

charged battery.

- Before you check anything in the engine

compartment, always read and heed a ll

WARNINGS¢

page 213, Engine com

partment.

«I) Note

-Applying a higher voltage booster bat

tery will cause expensive damage to sen

sitive electronic components, such as

contro l units, relays, rad io, etc .

- There must be no electrical contact be

tween the vehicles as otherwise current

could already start to flow as soon as the

positive(+) terminals are connected. ..,_

Page 273 of 300

@ Tips

- The discharged battery must be properly

connected to the vehicle's electrical sys

tem. When jump start ing or charging the

battery, never connect the negative

ground cable to the battery negative post because the battery manager sys

tem must be able to detect the battery's

state of cha rge. A lways connect the neg

ative g round cab le to the negative

gro und post o f the battery manage r con

trol uni t.

Use of jumper cables

Make sure to connect the jumper coble

clomps in exactly the order described below!

Fig. 2 08 Engine compartment: connecto rs for jump

start cables and charger

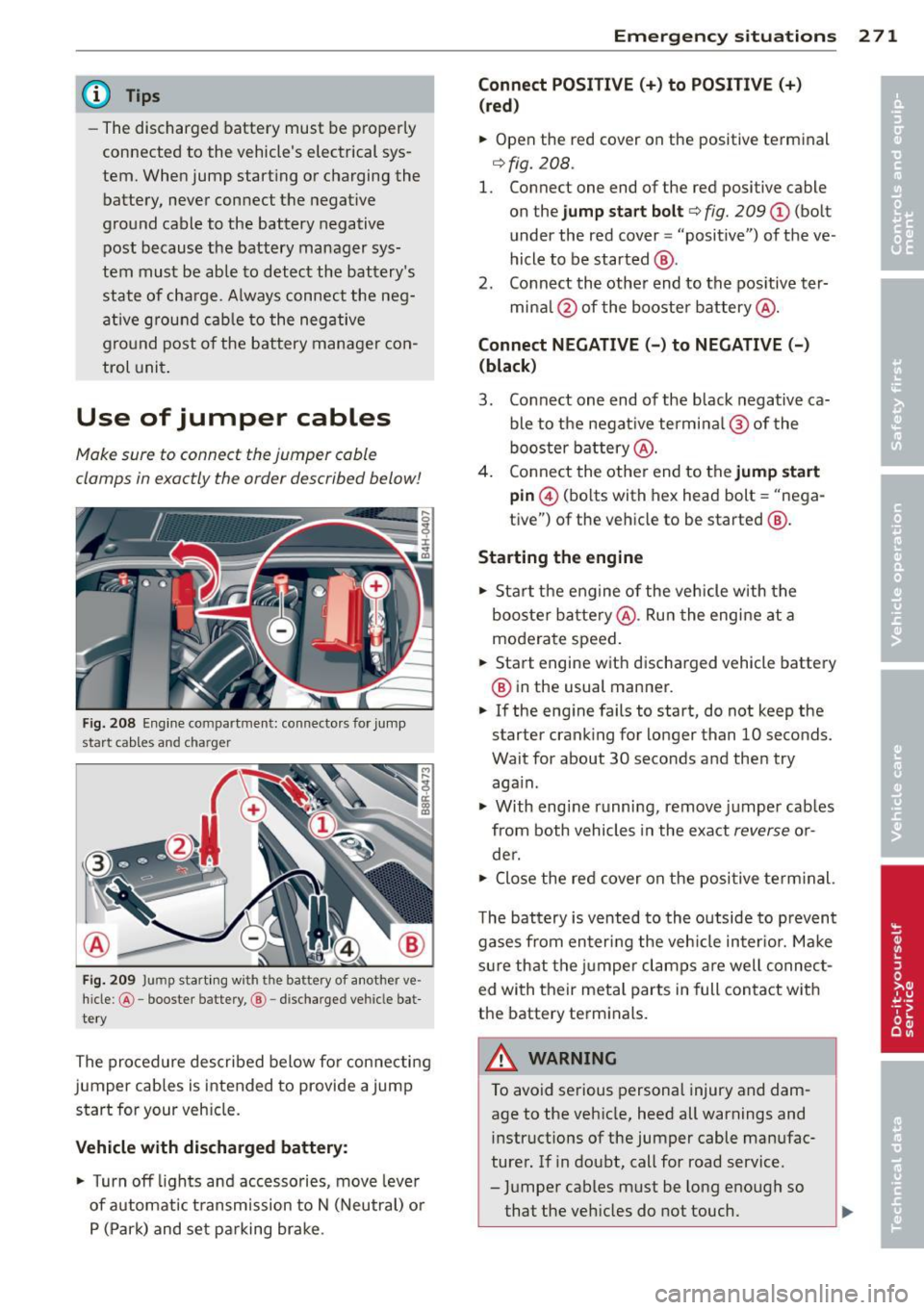

Fi g. 209 Jump start ing w ith the battery of another ve

hicle: @-booste r batte ry, @ -discharged vehicle bat

te ry

The procedure described below fo r connecting

jumper cab les is intended to provide a jump

start for your veh icle.

Vehicle with discharged batt ery:

.. Turn off lights and acc esso ries, move leve r

of automat ic t ransm ission to N (Neutral) o r

P (Park) and set pa rking brake .

Emergenc y situ ation s 2 71

Connect POSI TIVE(+) to POSITIVE (+ )

(red )

.. Open the red cover on the positive terminal

¢fig. 208.

1. Connect one end of the red positive cable

on the

jump sta rt bolt ¢ fig. 209 (D (bolt

under the red cover = "positive") of the ve

hicle to be started @.

2. Co nnect th e other end to the pos itive ter-

mina l@ of the booster battery @.

Connect NEGATIVE( -) to NEGATIVE(-)

(black )

3. Connect one end of the black negative ca ble to the negat ive termina l@ of the

booster b attery @.

4 . Connect the othe r end to the

jump start

pin @ (bolts with hex head bolt = "nega

tive") of the vehicle to be started @.

Starting the engine .. Sta rt the engine of the veh icle w ith the

booste r ba ttery @. Ru n the engine at a

moderate speed .

.. Start engine wit h discha rged vehicle battery

@ in the usual manner .

.. If the eng ine fails to start, do not keep the

starter cranking for longer than 10 seconds.

Wait for about 30 seco nds a nd the n try

aga in .

.. With engi ne runni ng, remove j umper cab les

from both vehicles in the exact

reverse o r

de r .

.. Close the red cover on the positive term inal.

T he battery is vented to th e outside to p revent

gases from en ter ing the veh icle in ter io r. Ma ke

s ur e th at the j umper clamps are well connec t

ed with their meta l parts in full con ta ct w ith

the battery term inals.

A WARNING

To avoid se rious personal injury and dam

age to the veh icle, heed all warnings and

instructions of the jumper cable man ufac

turer. If in doubt, call for road service .

- J umper cables m ust be long enough so

that the veh icles d o not touch.

-

Page 274 of 300

272 Emergen cy sit uat ions

-When connecting jumper cables, make

sure that they cannot get caught in any

moving parts in the engine compart

ment.

- Before you check anything in the engine

compartment, always read and heed all

WARNINGS

c:> page 213, Engine com

partment.

(D Note

Improper hook-up of jumper cables can ru in the generator.

-Always connect POSITIVE(+) to POSI TIVE(+), and NEGATIVE( -) to NEGATIVE

( - ) ground post of the battery manager

control unit.

- Check that all screw plugs on the battery

cells are screwed in firmly . If not, tighten

plugs prior to connecting clamp on nega

tive battery term inal.

- Please note that the procedure for con

nect ing a jumper cable as desc ribed

above applies spe cifically to the case of

you r vehicle being j ump started. When

you are giving a jump star t to anothe r ve

hicle, do

not connect the negative (-) ca

ble to the negat ive(-) term inal on the

discharged battery ©

c:> fig. 209. In

stead, securely connect the negative(-)

cable to either a solid metal component

that is firmly bolted to the engine block

or to the engine block itself. If the bat

te ry that is being charged does not vent

to t he outside, es caping battery gas

could ignite and explode!

Emergency towing

with commercial tow

truck

General hints

Your Audi requires special handling for tow

tng.

The follow ing information is to be used by

commercia l tow tr uck operators who know

h ow to operate the ir equipmen t safe ly.

- Never t ow your Audi. Towing will cau se

da mage to the engine and tr ans mi ssion .

- Ne ver wrap th e safet y chain s or winch c a

ble s around the brake lines.

- To prevent unne ce ssa ry damage , your Aud i

must be t ran spo rted with a flat bed truck.

- To load th e vehi cle on to the fl at bed, use

the towing l oop found in the vehicle t ools

and attach to the front o r rear anchorage

c:>page 272 and c:>page 273.

.&_ WARNING

=

A vehicle being towed is not safe for pas-

sengers. Never allow a nyone to ride in a

vehicle be ing towed, for any reason.

Front towing loop

Only install the front towing loop when it is

needed.

C7

0

F ig. 210 Fr ont bumpe r: cove r

Fig. 211 Fro nt bu mpe r: sc rew ing in the towing loop

-

The towing loop fits into the threaded hole lo

cated on the right s ide of the front b umpe r

and covered by a sma ll cove r when not in use.

.,. Remove the tow ing loop from the vehicle

tool kit.

Page 275 of 300

.. Press in ward strongly on the left side of the

cap to remove it from the bumper

e::>fig . 210 .

.. Screw the towing loop in the threaded

opening and tighten it until it stops

e::> fig . 211.

Remove the towing loop when you are done

using it and place it back in the vehicle tool

kit. Install the cover in the bumper. Always

keep the towing loop in the vehicle .

..&_ WARNING

If you do not sc rew the tow ing loop com

pletely, it cou ld come out of the threaded

hole while the vehicle is bei ng towed caus

ing damage to the vehicle and possib le se

r ious perso nal injury .

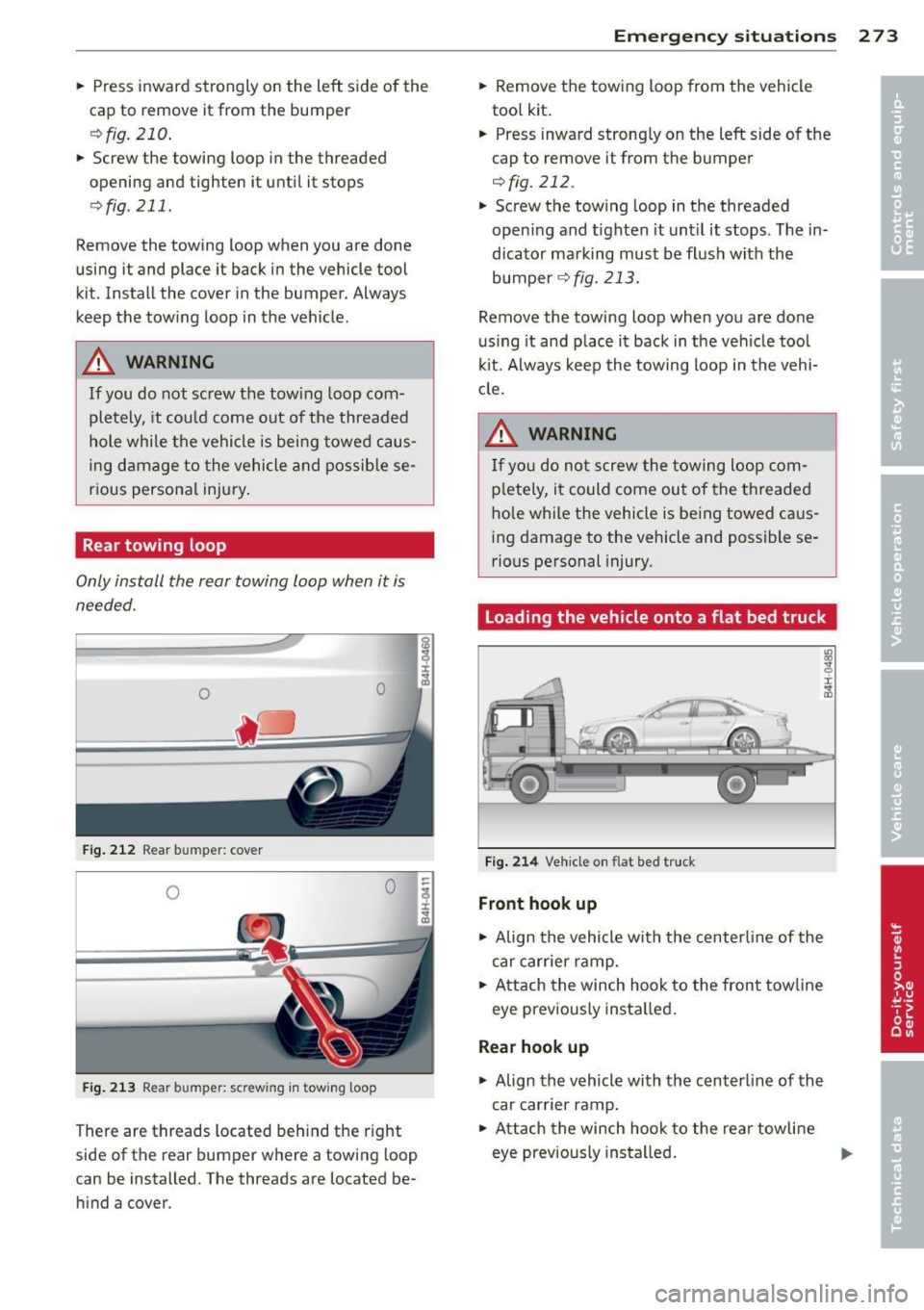

Rear towing loop

Only install the rear towing loop when it is

needed.

0 0

Fig . 212 Rear bumper: cover

0 0

Fig. 21 3 Rear bumper : screw ing in towing loop

There are threads located be hind the right

side of the rear bumper where a towing loop

can be installed. The threads are located be

hind a cover.

-

Emergenc y situ ation s 2 7 3

.. Remove the tow ing loop from the vehicle

too l kit .

.. Press inward strongly on the left side of the

cap to remove it from the bumper

¢fig. 212.

.. Screw the towing loop in the threaded

open ing and t ighten it unt il it stops. The in

dicator ma rking must be f lush with the

bumper

e::> fig. 213.

Remove the towing loop when you are done

us ing it and place it back in the ve hicle too l

ki t. Always keep the towing loop in the vehi

cle.

..&_ WARNING

If yo u do not s crew the towing loop com

p letely , it co uld come ou t of the t hreaded

hole while the vehicle is be ing towed caus

ing damage to the vehicle and possible se

rious pe rsonal injury.

loading the vehicle onto a flat bed truck

Fi g. 21 4 Ve hicle on flat bed tru ck

Front hook up

.. Align the vehicle wi th the centerline of the

car car rier ramp .

.,. Attach the winch hook to the front tow line

eye prev iously insta lled .

Rear hook up

.,. Align the vehicle with the c enter line of the

car earner ramp .

.. Attach the winch hook to the re ar towli ne

eye prev ious ly insta lled .

Page 276 of 300

2 7 4 Emergency situations

@ Tips

Check carefully to make sure the hook-up

is secure before moving the car up the flat

bed truck ramp.

Vehicle transport

Whenever you have your vehicle transported,

be sure to note the following:

(D Note

Mount the tie-down chains/cables over the

running surface (circumference) of the

tires. Never secure the vehicle by the axle,

the suspension struts or the front or rear

towline eye. For technical reasons, the

pressure in the suspension struts may

change during the transport and this will

adversely affect vehicle handling.

Lifting vehicle

Lifting with workshop hoist and with

floor jack

The vehicle may only be lifted at the lifting

points illustrated.

Fig. 215 Front lift in g po int

Fig. 216 Rear lifti ng point

.,. Read and heed WARNING ¢ _&.

.,. Activate the vehicle jack mode in the MMI :

!CARI function button > Car systems control

button

> Servicing & checks > Air susp.:

jack mode

> On.

.,. Locate lifting points ¢ fig . 215 and

¢fig. 216 .

.,. Adjust lifting arms of workshop hoist or

floor jack to match veh icle lifting points .

.,. Insert a rubber pad between the floor jack/

wo rkshop hoist and the lifting points.

The vehicle jack mode must be act ivated so

that the automat ic adjustment of the Adap

tive Ai r Suspens ion does not make it more dif

ficult to raise the vehicle with the floor jack.

If you must lift your vehicle with a floor jack

to work underneath, be sure the vehicle is

safely supported on stand s intended for this

purpose.

Front lifting point

The lifting point is located on the floor pan re

i nforcement about at the same level as the

jack mounting point

¢ fig. 215 . Do not lift

the vehicle at the vertical sill reinforcement.

Rear lifting point

The lifting point is located on the vertical rein

forcement of the lower sill for the on-board

jack

¢fig. 216.

Lifting with vehicle jack

Refer to ¢page 262.

A WARNING ,= -

-To reduce the risk of serious injury and

veh icle damage.

- Always lift the vehicle only at the spe

cia l workshop hoist and floor jack lift

points illustrated

¢ fig . 215 and

¢ fig. 216 .

-Failure to lift the vehicle at these

points could cause the vehicle to tilt or

fall from a lift if there is a change in ve

hicle weight distribution and balance.

This might happen, for example, when heavy components such as the eng ine

block or transmission are removed .

Page 277 of 300

-When removing heavy components like

these, anchor vehicle to hoist o r add cor

respond ing weig hts to mai nta in the cen

ter of g ravity. Otherwise, the vehicle

m ight tilt o r sli p off the hoist, causi ng

serious p ersona l injury .

Q) Note

-Be awa re of the fo llowing points befo re

li fting t he vehicle:

- The vehicle should never be lifted or

jacked up from underneath the engine

oil pan, the transmission housing , the

front or rear axle or the body side members. This could lead to serious

damage.

- To avoid damage to the underbody or

chassis frame, a rubber pad must be

i nserted between the floor jack and

the lift points .

- Before driv ing over a wo rkshop hoist,

check that the veh icle weight does not

exceed the permissibl e lifting capacity

of the hoist.

- Before driving over a workshop hoist,

ensure that there is sufficient clear ance between the hoist and low parts

of the vehicle.

Emergency situations 275

•

•

Page 278 of 300

2 76 Genera l in formati on

General information

Explanation of

technical data

Some of the technical data listed in this man

ual requires further explanation .

The technical data for your vehicle is listed in

the charts starting on

r:::> page 2 78. This sec·

tion provides general information, notes and restrictions wh ich apply to this data .

Vehicle identification

The key data is given on the vehicle identifica·

tion number (VIN) plate and the vehicle data

sticker .

Fig. 2 17 Veh icle Ide ntific atio n Number (V lN) p late: lo

cation on driver's sid e das h panel

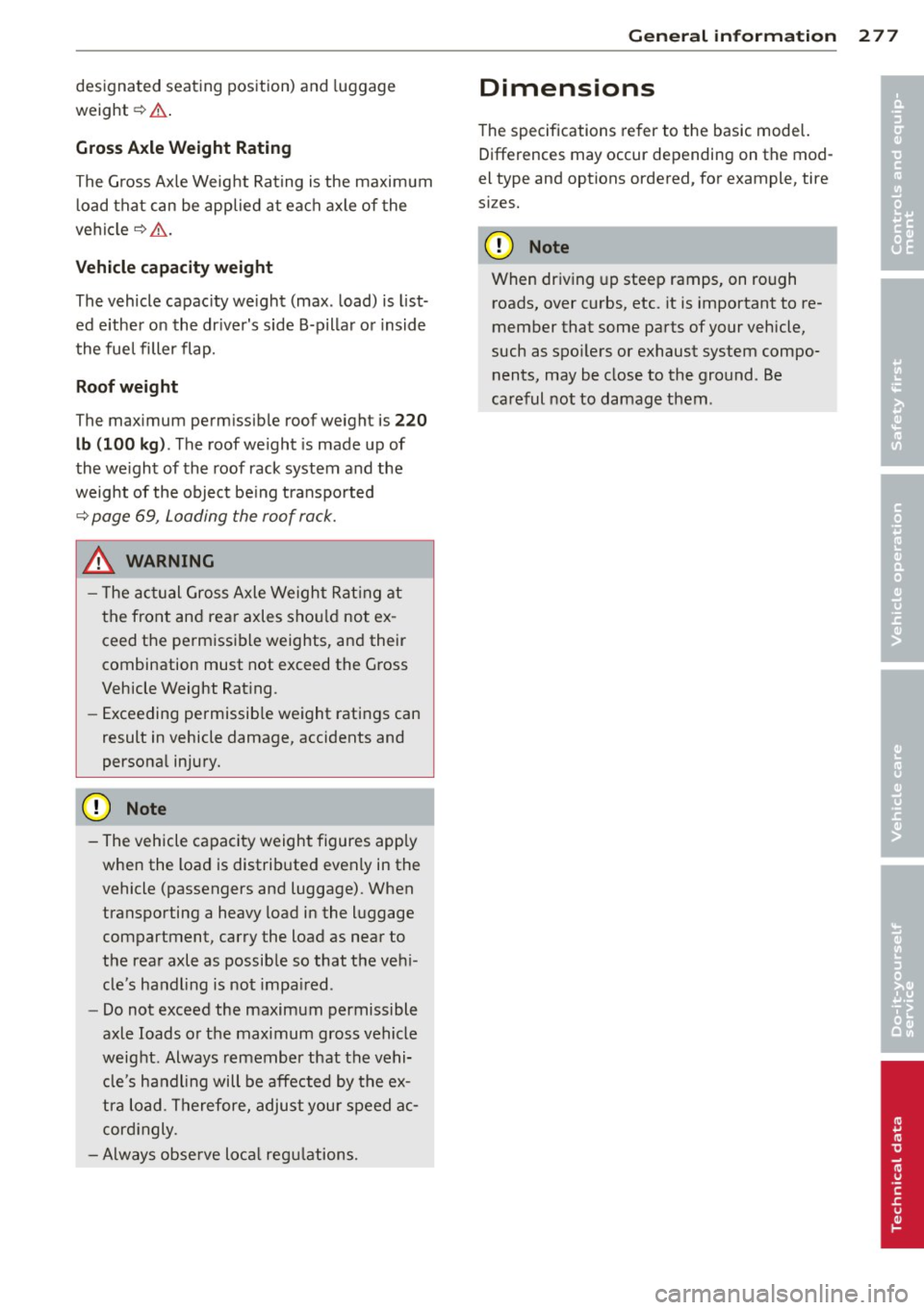

Fig . 2 18 The ve hicle identi fication label -inside the

luggage co mpa rtmen t

The Vehicle Iden tification Numb er (VIN )

is located on the driver's side so that it is vis i

b le from the outside through the windshield

r:::> fig . 217 . You can a lso display the Vehicle

Identification Number of your vehicle in the

MMI. Select: Function button

I CAR ! > Car s ys

t e ms

> V IN numb er. The

vehicl e identification labe l

is located in the luggage compartment in the

spare wheel wel l.

T he labe l¢

fig. 218 shows the fo llowing vehi

cl e data :

(D Product ion control No .

@ Vehicle identification No.

® Type code number

@ Type designation/engine output in K ilo·

wat ts

® Engine and transmission code letter

@ Paint No./Interior

(f) Optional equipmen t No.'s

Vehicle data 2 to 7 are also found in your War·

ran ty

& Ma intenance booklet.

The safety compliance stick er

is your assurance that your new vehicle com

plies with all applicable Federal Motor Vehicle

Safety Standards which were in effect at the

time the vehicle was manufac tured . You can

find this sticker on the left door jamb .

It

shows the month and year of production and

the ve hicl e ident ificat ion number of yo ur vehi ·

cle (perforation) as well as the G ross Vehicle

Weight Rating (GVWR) and the Gross Axle

Weight Rating (GAWR) .

The high volta ge warning label

is loca ted on the lock ca rr ier .

The spark ignition s ystem complies w ith

the Canadian standard ICES -002.

Weights

Gr oss V ehicl e Weight Rating

The Gross Vehicle Weight Rat ing (GVWR), and

t h e Gross Axle Weight Rating (GAWR) for

front and rear are Listed on a sticker on the

left door jamb .

T he Gross Vehicle Weight Rat ing includes the

weight of the bas ic vehicle plus fu ll fuel tank,

oi l and coo lant, plus maximum load , wh ich in·

eludes passenger weight (lSO lbs/68 kg per

Ill>

Page 279 of 300

designated seating position) and luggage

weight~&. .

Gros s Axle W eight Rating

The G ross Axle Weight Rating is the maximum

l oad tha t can be applied at each axle of the

vehicle

q .&. .

Vehicle capacit y weight

The vehicle capac ity we ight (max. load) is list

ed either on the dr iver's side B-pillar or inside

the fuel filler flap.

Roof weight

The max imum perm issible roof weight is 220

lb (100 kg ).

The roof weight is made up of

the we ight of the roof rack system and the

weight of the object be ing transported

q page 69, Loading the roof rack .

.&, WARNING

- T he ac tual Gross Axle Weight Rat ing at

the front and rear axles shou ld not ex

ceed the permiss ible weights, and their

combination must not exceed the Gross

Vehicle Weight Rat ing .

- Exceeding permissib le weight ratings can

result in vehicle damage, accidents and

personal injury.

CD Note

- The vehicle capacity weight figures apply

when the load is distributed evenly in the

vehicle (passengers and luggage). When

transporting a heavy load in the luggage

compartment, carry the load as near to

the rear axle as possib le so that the veh i

cle's handling is not impa ired.

- Do not exceed the maximum permissible

axle loads or the maximum gross vehicle

weight. Always remember that the vehi

cle's handling will be affected by the ex

tra load. Therefore, adjust you r speed ac

cord ingly.

- Always observe loca l regu lations.

-

G ene ral in formation 2 77

Dimensions

The specifications refer to the basic model.

Differences may occur depending on the mod

el type and options ordered, for example, tire

sizes.

CD Note

When driving up steep ramps, on rough roads, over curbs, etc. it is important to re

member that some parts of your vehicle,

such as spoilers or exhaust system compo nents, may be close to the ground . Be

careful not to damage them .

•

•

Page 280 of 300

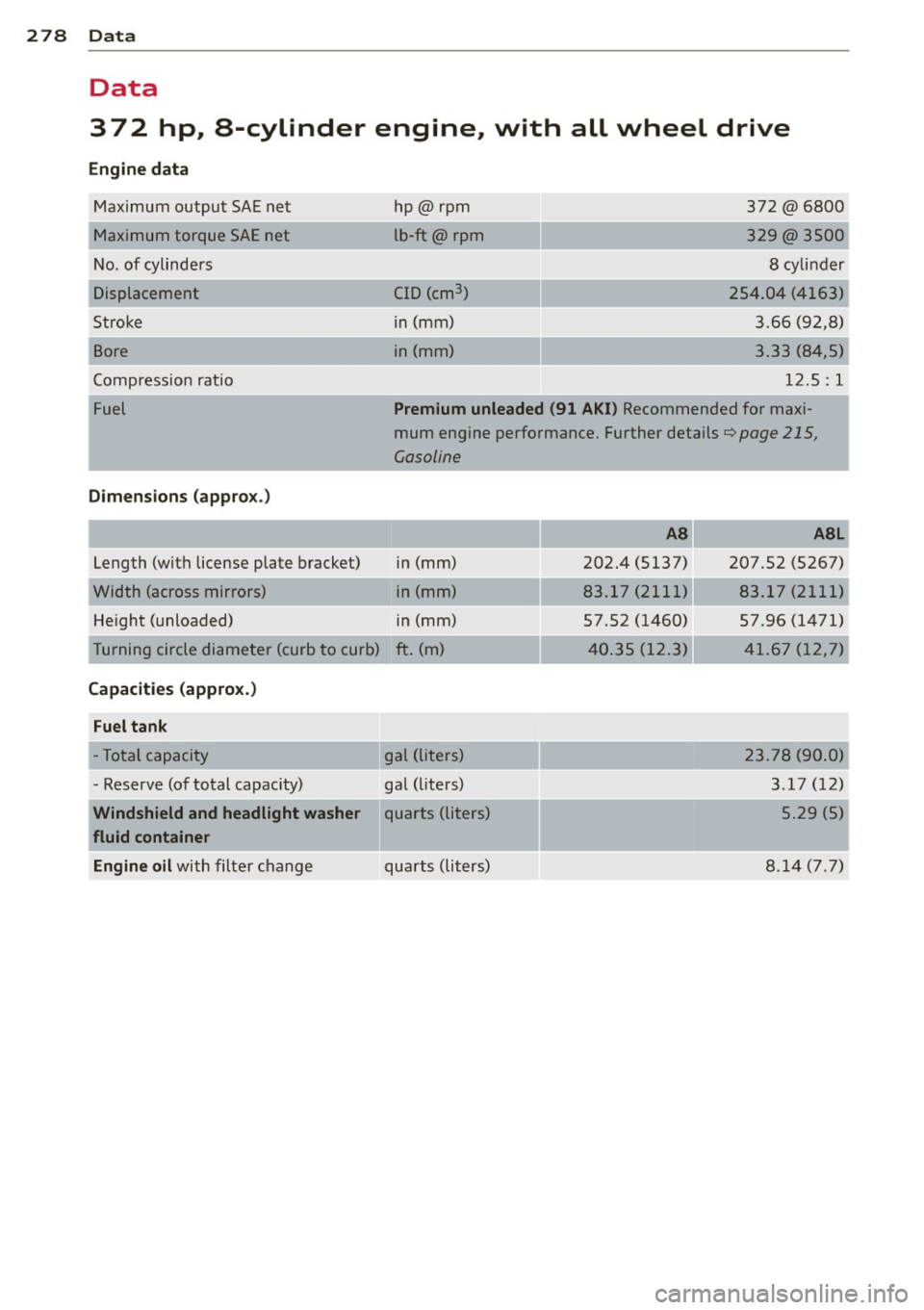

278 Data

Data

372 hp, a-cylinder engine, with all wheel drive

Engine data

Maximum output SAE net

Maximum torque SAE net

No. of cylinders

Displacement

Stroke

Bore

Compression ratio hp@rpm

l

b-ft@ rpm

CID (cm

3 )

in (mm)

i n (mm)

372 @6800

329@3500

8 cylinder

254.04 (4163)

3.66 (92,8)

3.33 (84,5)

12.5 : 1

Fuel Premium unleaded (91 AKI) Recommended for maxi

mum engine performance. Further details¢

page 215,

Gasoline

Dimens ions (appro x.)

Length (with license plate bracket) in (mm)

Width (across mirrors) ____ in (mm)

He ight (unloaded) in (mm)

Turning circle diameter (curb to curb) ft . (m)

Capacities (approx.)

Fuel tank

- Total capacity gal (liters)

- Reserve (of total capacity) gal (liters)

Windshield and headlight washer quarts (liters)

fluid container

Engine oil

with filter change quarts (liters)

AS ASL

202.4 (5137) 207.52 (5267) _,, __

83.17 (2111) 83.17 (2111)

57 .52 (1460) 57.96 (1471)

4 0.35 (12.3) 41.67 (12,7)

23. 78 (90 .0)

3.17 (12)

5.29 (5)

8 .14 (7 .7)