transmission AUDI A8 2016 User Guide

[x] Cancel search | Manufacturer: AUDI, Model Year: 2016, Model line: A8, Model: AUDI A8 2016Pages: 302, PDF Size: 75.68 MB

Page 195 of 302

Operating noi se

Noises may occur when braki ng depend ing on the

speed, braking force and outside cond itions s uch

as temperature and humidity.

Due to the na ture of t he mate ria ls used in ce ram

ic bra ke rotors*, noises m ay become mo re appa

ren t at low speeds.

Effect of wat er and road salt

In ce rtain situat ions, for example after driving

through water, in heavy ra in, afte r ove rnig ht con

densat ion or after washing your car, the braking

effe ct can be red uced by moisture or ice on the

b rake rotors and brake pads. The brakes must be

dried first w ith a few careful brake applications .

At highe r speeds and with t he windsh ie ld wipers

turned o n, the bra ke pads p ress against the bra ke

rotors for a short amount of time . This occ urs at

regular intervals without the driver noticing and

provides for better bra ke response time under

wet conditions.

The effectiveness of the brakes can be reduced

when the vehicle is dr iven on a salt-covered road

and the brakes are not used. L ikewise, you clean

off accumu lated salt coat ing from brake discs

and pads with a few cautious applications of the

brake

c::> ,& .

Due to their sur face characteristics, ceramic

brake rotors* absorb mo isture in such condit ions.

This can cause a temporary reduction in braking

force compared to dry brakes. You can compen

sate for this by pressing the brake peda l harder.

Cor rosion

There may be a tendency for dirt to b uild up on

the brake pads and corros ion to form on the discs

if the car is not driven regularly or only for short

tr ips with little use of the brakes.

If the brakes are not used frequently, or if corro

sion has formed on the discs, it is adv isable to

clean off the pads and discs by brak ing firmly a

few t imes from a moderately high speed

c::> ,& .

Sma rt Technology

Faults in the brake system

If you s hou ld notice a sudden increase in br ake

peda l travel, then one of the two bra ke circu its

may have fai led

c::> ,& .

Low brake fluid level

Malfunctions ca n occu r in the brake system if the

brake fluid level is too low . T he brake flu id leve l

is monitored elect ronically.

Brake boost er

The brake booster works w ith vacuum pressure

wh ich is created only when the engine is runn ing

c::> ,& .

Brake lining wear status

Brake lining wear may be checked by visua l in

spect ion of the cond ition of the brake pads

t hr ough the openings in the wheel. If necessary,

the wheel may be removed for t his inspection

c::> page 259, Replacing wheels .

.8_ WARNING

-New b rake p ads don't h ave the bes t stop

p ing power an d must be "broken-in" during

the initial 250 miles (400 km) . The break-in

pe riod can be considerably longer for

veh icles with ceramic brake rotors*. You can

compensate for this by pressing the brake

pedal more firmly. This also applies late r

when new pads are installed.

- You shou ld perform braking maneuvers for

the purpose of cleaning the brake system only i f road co ndit ions pe rmit . Other road

users m ust not be put at r is k -you may

cause an ac cident!

- Before descending a steep g rade, reduce

speed and sh ift transmission into a lower

gear o r lower dr iving range. Do not r ide the

b ra kes or hold the pe dal down too long or

too often. This cou ld cause the b rakes to ge t

hot and dimin ish b raking effic iency .

- Do not " ride the bra kes" by rest ing you r foot

on the pedal when you do no t intend to

brake. This may cause the brakes to over

heat, premature wear and increased stop

p ing distance.

193

Page 199 of 302

Driving and the

environment

Breaking in

New eng ine

The engine needs to be run-in during the first

1,000 miles (1 ,500 km).

For the first 600 miles (1 ,000 kilometers):

"' Do not use full throttle .

"' Do not drive at engine speeds that are more

than 2/3 of the max imum permitted RPM .

"' Avoid high eng ine speeds.

From 600 to 1 ,000 miles (1,000 to 1,500

kilometers ):

"' Speeds can gradually be increased to the maxi

mum pe rm issib le road or e ngine speed.

During and after b reak-in period

"' Do not rev the engine up to high speeds when it

is cold . This applies whether the transmission is

in N (Neutral) or in gear .

After the bre ak-in period

"' Do not exceed maximum engine speed under

any circumstances .

"' Upshift into the nex t higher gear

before reach

ing the red area at the end of the tachometer

sca le

c:::;, page 10.

During the first few hours of driving , the eng ine's

internal friction is higher than later when all the

mov ing parts have been broke n in. How well this

b reak-in process is done depends to a considera

b le exte nt o n the way the veh icle is d rive n du ring

the first 1,0 00 miles (1,500 kilome ters).

(D Note

E xtremely high eng ine speeds a re au toma ti

cally reduced. However, t hese rpm li mits are

p rogr amme d fo r an eng ine well run-in, not a

new engine .

Driving and the envir onment

{® For the sake of the environment

Do not drive with unnecessarily high engine

spe eds -upshifting early saves fuel, red uces

no ise and protects the environment.

New tires

If your vehicle is runni ng on new tires, drive par

t icularly careful for the first 3S0 m iles (500 kilo

meters) after fitting .

_&. WARNING

New tires tend to be slippe ry and mus t also

b e "bro ken- in". Be sure to remembe r th is dur

i ng the first 350 m iles ( 500 k ilome ters).

Brake gent ly . Avoid following closely behin d

other vehicles or other s ituations that might

require sudden, hard braking.

Avoid damaging the

vehicle

When you are dr iv ing on poor roads, or over

curbs, steep ramps, etc., make certai n that low

ly ing parts such as spo ile rs and exhaust system

parts do not bottom o ut and get damaged .

This is espec ially true for veh icles with low-s lung

chass is (sports c hass is)* and fully loaded

vehicles .

Catalytic converter

Applies to: vehicles with gasoline engine

It is very important that your emission control

system (catalytic converter) is functioning prop

erly to ensure that y our vehicle is running in an

environmen tally sound manner.

"' Always use lead-free gasoline c:::;, page 212,

F uel supply .

"' Never run t he tank down all the way to emp ty.

"' Never put too much motor o il in yo ur engine

c:::;, page 225, Adding engine oil ce:r..

"' Never try to push- or tow-start your vehicle.

T he ca talytic co nverter is an efficient "cle an-up"

device built into the exhaust sys tem o f th e vehi -

-

cle. The catalytic converter b urns many of the .,.

197

Page 240 of 302

Wheel s

® Mud and snow capability

"M/5" or "M+S" indicates the tire

has characteristics that make it

suitab le for driving on mud and

snow. ~ indicates a winter tire.

@ Composition of the tire cord

and materials

The number of plies indicates the

number of rubberized fabric lay

ers in the tire . In general : the

more layers, the more weight a

tire can carry. Tire manufacturers

must also specify the materials

used in the tire. These include

steel, nylon, polyester and other materials.

@ Ma ximum permitted load

This number indicates the maxi

mum load in kilograms and

pounds that the tire can carry.

@ Uniform tire quality grade

standards for treadwear,

traction and temperature resistance

T readwear, traction and tempera

ture ranges ~

page 253.

@ Running direction

The arrows indicate the running

direction of unidirectional t ires.

You must always follow the speci-

238

fied running direction

~ page 264 .

(8) Maximum permitted

inflation pressure

This number indicates the maxi

mum pressure to which a tire can

be inflated under normal operat

ing condit ions.

Glossary of tire and loading

terminology

Accessory we ight

means the combined weight (in

excess of those standard items

which may be replaced) of auto matic transmission, power steer

ing, power brakes, power win

dows, power seats, radio, and

heater, to the extent that these

items are available as factory -in

stalled equipment (whether in

stalled or not).

Aspect rat io

means the rat io of the height to

the width of the tire in percent.

Numbers of 55 or lower indicate a

low sidewall for improved steer

ing response and better overa ll

handling on dry pavement.

Page 261 of 302

Replacing wheels

Before changing a wheel

Observe the following precautions for your own

and your passenger's safety when changing a

wheel.

.,. After you experience a tire failure, pull the car

well away from moving traffic and try to reach

level ground before you stop¢.,&. .

.. All passengers should

leave the car and move

to a safe location (for instance, beh ind the

guardrail) ¢.,&. .

.,. Engage the

parking brake to prevent your vehi

cle from rolling unintentionally ¢.,&. .

.. Move

selector lever to position P ¢ .,&. .

1> lfyou are towing a trailer, unhitch the trailer

from your vehicle.

.,. Take the

jack and the spare tire out of the lug

gage compartment,

¢page 257.

..&, WARNING

You or your passengers could be injured wh ile

changing a wheel if you do not follow these

safety precautions:

- If you have a flat tire, move a safe distance

off the road. Turn off the engine, turn the

emergency flashers on and use other warn

ing devices to alert other motorists.

- Make sure that passengers wa it in a safe

place away from the vehicle and well away

from the road and traffic.

- T o help prevent the vehicle from moving

sudden ly and possibly slipping off the jack,

always fully set the parking brake and block

the wheel diagonally opposite the wheel be

ing changed. When one front wheel is lifted

off the ground, plac ing the Automatic

Transmission in "P" (Park) will

not prevent

the vehicle from moving.

- Before you change a wheel, be sure the

ground is level and firm . If necessary, use a

sturdy board under the jack .

- Always store the vehicle tool k it, the jack

and the replaced tire in the luggage com

partment ¢

page 135.

Emergency assistance

{!) Tips

Before changing the wheel, you must activate

the jacking mode, so that the automat ic con

tro ls for the Adaptive Air Suspension do not

make it more difficult to lift the vehicle with

the jack ¢

page 261 .

Changing a wheel

When you change a wheel , follow the sequence

described below step-by-s tep and in exactly tha t

order .

l. Activate the vehicle jack mode ¢ page 261 .

2. Remove the decorative wheel cover*. For

more details see also¢

page 260, Decora

tive wheel covers

or¢ page 260, Wheels

with wheel bolt caps .

3. Loosen the wheel bolts¢ page 260.

4. Locate the proper mounting point for the

jack and align the jack below that point

¢ page 261 or¢ page 262.

5. Raise the car with the jack¢ page 261 or

¢page 262.

6. Remove the wheel with the flat tire and then

install

the spare ¢ page 263.

7. Tighten all wheel bolts lightly .

8.

Lower the vehicle with the jack .

9. Use the wheel bolt wrench and

firmly tighten

all wheel bolts<=>

page 260.

10. Replace the decorative wheel cover*.

11. Deactivate the vehicle jack mode in the MMI :

I CAR! function button > Car systems contro l

button

> Servicing & checks > Air susp.: jack

mode > Off.

The vehicle jack mode switches off automatically

at speeds above 10 km/h .

..&, WARNING

Always read and follow all WARNINGS and in

formation

¢ .&. in AB: Raising the vehicle on

page 262

and ¢ page 264.

259

Page 269 of 302

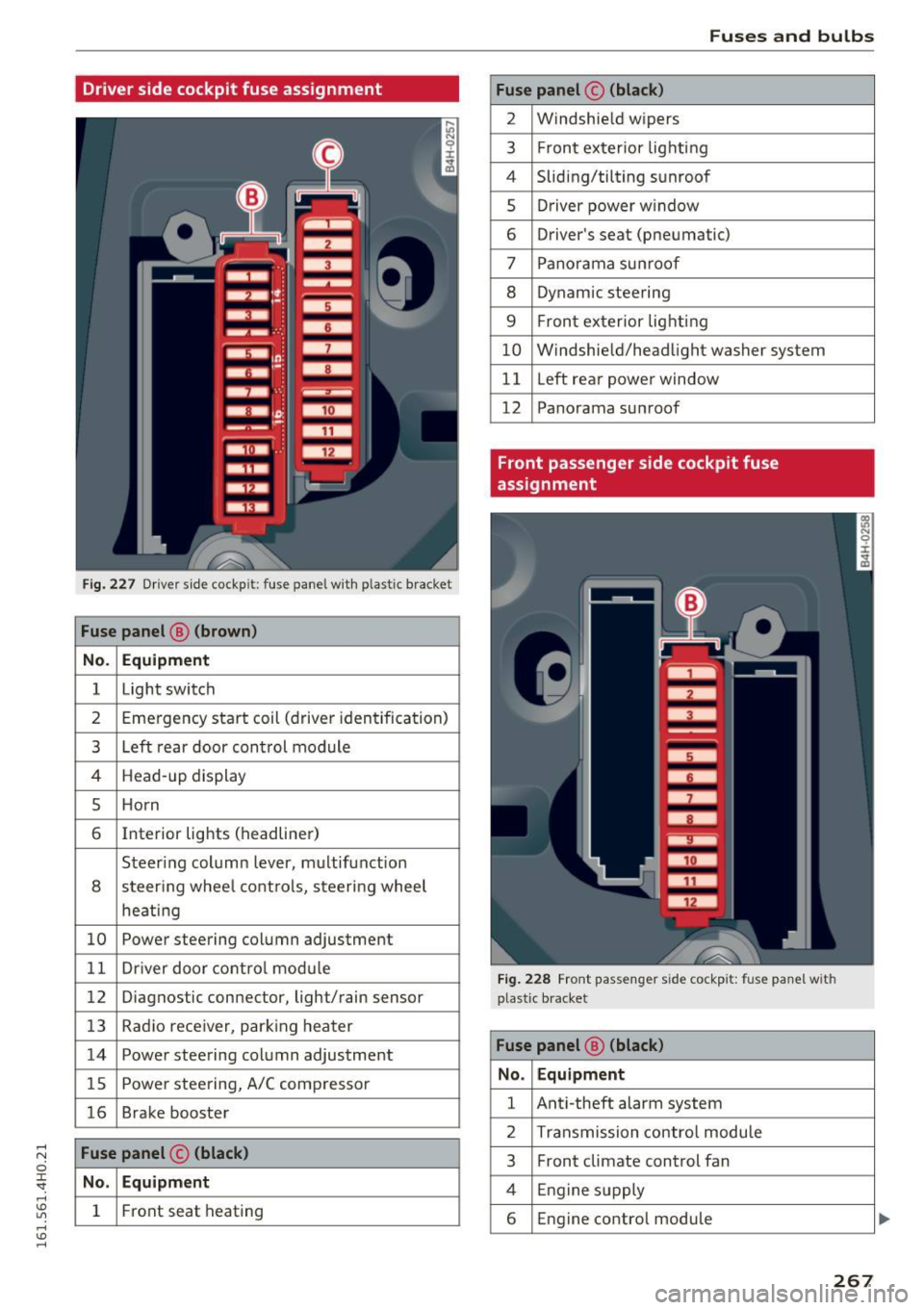

Driver side cockpit fuse assignment

Fig . 227 D river sid e cockpit: fuse panel with plastic bracket

Fuse panel @ (brown )

No . Equipment

1 Light switch

2 Emergency start coil (driver iden tification)

3 Left rear door con trol module

4 Head -up display

5 Ho rn

6 Interior lights (headliner)

Steering column lever, m ultifunction

8 steer ing whee l cont ro ls, steering wheel

heati ng

10 Powe r steering column adjustment

1 1 Dr iver door co ntro l mod ule

12 Diagnostic con nector, light/rain sensor

13 Radio rece iver, par king heater

14 Power steering column adjustment

15 Powe r stee ring, A/C comp resso r

16 Brake booster

Fuse panel © (black)

No . Equipment

1 Front seat heating

Fuses and bulbs

Fuse panel © (black)

2 Windshie ld w ipers

3 F ron t ex terior lig hti ng

4 Sliding/tilting s unroof

5 Dr iver power w indow

6 Driver's seat (pneumatic)

7 Pano rama su nroo f

8 Dynam ic steering

9 F ron t ex terior lig hting

10 W indshie ld/head light washer system

11 Left rea r powe r window

12 Panorama su nroof

Front passenger side cockpit fuse

assignment

Fig. 228 Front passenge r side cockp it: fuse panel with

p last ic b racket

Fuse panel @ (black)

No . Equipment

1 Ant i-theft alarm system

2 Transmission contro l modu le

3 Front climate control fan

4 Engine supply

6 Engine control module

267

Page 271 of 302

Fuses an d bulb s

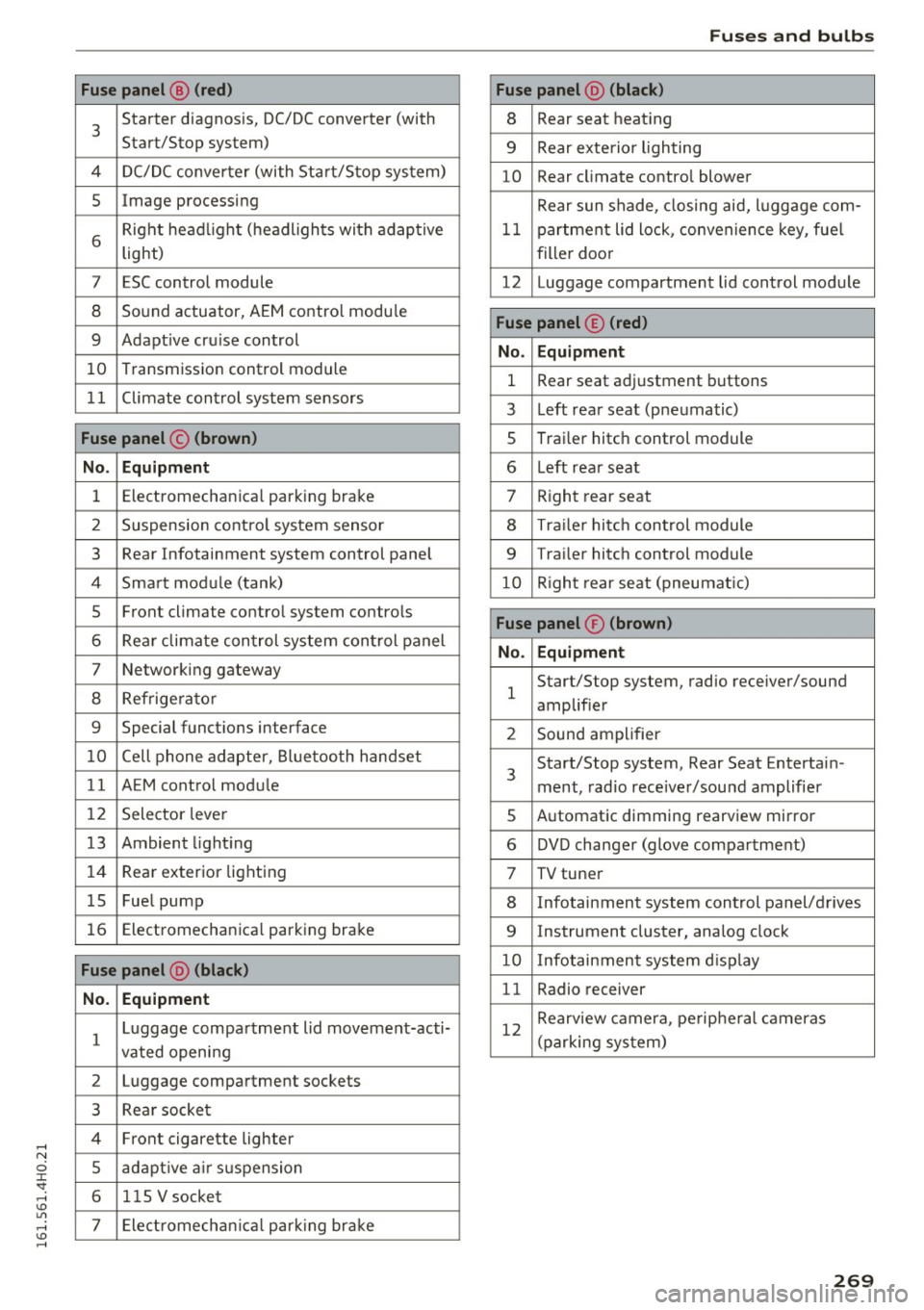

Fuse p anel @ (red ) Fuse panel@ (black )

3 Starter diagnosis, DC/DC converter (with

Start/Stop system) 8 Rear

seat heating

9 Rear exterio r lighting

4 DC/DC converter (with Start/Stop system)

10 Rear

climate contro l blower

5 Image processing

Rear sun shade, closing aid, luggage com-

6 Right headl

ight (headlights with adaptive

light) 11 partment lid

lock, convenience key, fue l

filler doo r

7 ESC control module 12 Luggage compartment lid control module

8 Sound actuator, AEM control modu le

9 Adapt ive cru ise control

10 Transmission

control module

Fuse panel © (red )

No . Equ ipm en t

1 Rear seat adjustment buttons

1 1 Climate control system sensors

3 Left rear

seat (pneumatic)

Fuse panel © (br own ) 5 Trai

ler hitch control module

No. Equipm ent 6 L

eft rear seat

1 Electromechanical parking

brake

7 Right rear seat

2 Suspension control system sensor

8 Traile r hitc h control module

3 Rear Infotainment system control

panel

9 Trailer hitch control module

4 Smart module (tank) 10 Right rear seat (pneumatic)

5 Front climate contro

l system controls

6 Rear climate control system control panel

7 Networking gateway

8 Refrige rator

Fuse panel ® (brown )

No. Equipm en t

1 Start/Stop

system, radio receiver/sound

amplifier

9 Special functions interface

2 Sound amplifier

10 Cell phone adapter, Bluetooth handset

11 AEM control module 3 Start/Stop

system, Rear Seat Entertain-

ment, radio receiver/sou nd amplifier

12 Selector lever

5 Automatic dimming

rearview mirror

13 Ambient lighting 6 DVD changer (glove compa rtment)

14 Rear

exterior lighting

7 TV tuner

15 Fuel pump

8 Infotainment system control panel/drives

16 Electromechanica l parking brake

9 Instrument cluster, analog clock

Fuse panel @ (bl ack ) 10 Infotainment system d isp lay

N o. Equi pm en t 11 Radio receiver

1 Luggage compartment lid movement-acti-

vated openi ng 12

Rearview camera, pe

ripheral cameras

(parking system)

2 Luggage compartment sockets

3 Rear socket

4 Front cigarette lighter

5 adapt ive a ir suspension

6 115 V

socket

7 Electromechan ica l park ing brake

269

Page 273 of 302

Emergency situations

General

This chapter is intended for trained emergency

crews and working personnel who have the nec

essary tools and equipment to perform these

ope rations.

Starting by pushing or

towing

(D Note

Veh icles with an automatic transmission can

not be started by pushing or towing.

Starting with jumper

cables

If necessary, the engine can be started by con

necting it to the battery of another vehicle .

If the engine shou ld fail to start because of a dis

charged or weak battery, the battery can be con

nected to the battery of

another vehicle, using a

pair of jumpe r cables to start the engine.

Jumper cables

Use only jumper cables of suffic iently large cross

section

to carry the starter current safely. Refer

to the manufacturer's specifications.

Use only jumper cables with

insulated term inal

clamps which are dis tinct ly marked :

plus(+) cable in most cases colored re d

minus( -) cable

in most cases colored blac k.

A WARNING

Batteries contain electricity, acid, and gas.

Any of these can cause very serious or fatal in

jury. Follow the instructions below for safe

handling of your vehicle's battery.

- Always shield your eyes and avo id leaning

over the battery whenever poss ible.

- A discharged battery can freeze at tempera

tures just below 32 °F (0 °C) . Before con

necting a jumper cable, you must thaw the

Emergency situations

frozen battery completely, otherwise it

could explode .

- Do not allow battery acid to contact eyes or

skin. Flush any contacted area with water immediately.

- Improper use of a booster battery to start a

vehicle may cause an exp losion.

- Vehicle batteries generate exp losive gases.

Keep sparks, flame and lighted cigarettes

away from batteries.

- Do not try to jump start any vehicle with a

low acid level in the battery .

- The vo ltage of the booster battery must also

have a 12-Volt rating. The capacity (Ah) of

the booster battery should not be lower

than that of the discharged battery. Use of

batter ies of different voltage or substantial

ly different "Ah" rating may cause an exp lo

sion and personal injury .

- Never charge a frozen battery. Gas trapped

in the ice may cause an explosion.

- Never charge or use a battery that has been

frozen . The battery case may have be weak

ened .

- Use of batter ies of different voltage or sub

stantially different capacity (Ah) rating may

cause an exp losion and injury. The capac ity

(Ah) of the booster battery should not be

lowe r than that of the discharged battery.

- Before you check anything in the eng ine

compartment, always read and heed all

WARNINGS

r::!)page 220.

(D Note

-Applying a higher voltage booster battery

will cause expensive damage to sensitive

electronic components, such as control

units, relays, radio, etc.

- Th ere must be no electrical contact between

the vehicles as otherwise current could al

ready start to flow as soon as the positive

(+) terminals are connected.

(D Tips

- The discharged battery must be properly

connected to the vehicle's e lectrica l system. ..,.

271

Page 274 of 302

Emergency situations

When jump starting or charging the bat

tery, never connect the negative ground ca

ble to the battery negative post because the

battery manager system must be able to de

tect the battery's state of charge. Always

connect the negative ground cable to the

negative ground post of the battery manag

er contro l unit.

Use of jumper cables

Make sure to connect the jumper cable clamps in

exactly the order described below!

F ig . 230 Engine compar tment: connectors for jump start

cables and cha rger

F ig. 231 Jump starti ng wit h the battery of another veh icle:

@ -boos ter battery, @-disc harged vehicle battery

The procedure described be low for connecting

jumper cables is intended to provide a jump start for your vehicle.

Vehicle with discharged battery:

• Turn off lights and accessories, move leve r of

automatic transmission to N (Neutral) or P

(Park) and set parking brake.

Connect POSITIVE (+) to POSITIVE (+) ( red)

• Open the red cover on the positive term inal

¢ fig. 230.

272

1. Connect one end of the red positive cable on

the

jump start bolt 9 fig. 231 (D (bolt under

the red cover= "positive") of the veh icle to be

started @.

2. Connect the other end to the positive termi-

nal @ of the booster battery @.

Connect NEGATIVE (- ) to NEGATIVE(-)

(black)

3. Connect one end of the black negative cable

to the negative term inal @ of the booster

battery @.

4. Connect the other end to the

jump start pin

@ (bolts with hex head bolt= "negative") of

the vehicle to be started ®·

Starting the engine

• Start the eng ine of the vehicle with the booster

battery @. Run the eng ine at a moderate

speed.

• Sta rt engine w ith discharged vehicle ba ttery @

in the usual manner.

• If the engine fails to start, do not keep the

starter cranking for longer than 10 seconds.

Wait for about 30 seconds and then try again.

• With engine running, remove jumper cables

from both vehicles in the exact

reverse order.

• Close the red cover on the positive terminal.

The battery is vented to the outside to prevent

gases from entering the vehicle interior . Make

sure that the jumper clamps are well connected

with their metal parts in full contact with the battery terminals.

&_ WARNING

To avoid ser ious personal injury and damage

to the vehicle, heed all warnings and instruc

tions of the jumper cable manufacturer. If in

doubt, call for road service.

- Jumper cables must be long enough so that

the vehicles do not touch .

- When connecting jumper cables, make sure

that they cannot get caug ht in any moving

parts in the engine compartment.

- Before you check anything in the engine

compartment, always read and heed all

WARNINGS

¢ page 220.

Page 275 of 302

(D Note

Im pro per hook-u p of jum per cables can ru in

the gene ra tor.

- Always connect P OSITI VE( +) to POS ITI VE

( + ), and NEGATIVE( -) to NEGATIVE( -)

ground post of t he battery manager contro l

u nit .

- Check that a ll sc rew p lugs on the battery

ce lls a re sc rewed in firmly . If not, t igh ten

pl ugs p rio r to connecting clamp on negative

batte ry te rminal.

- Please note t hat the procedure fo r con nect

i ng a jumper cab le as desc ribe d above ap

p lies specifica lly to the case of yo ur vehicle

being jump s tarte d. W hen you are giv ing a

ju mp s ta rt to an othe r vehicl e, do

not con

n ect t he nega tive (- ) ca b le t o t he nega tive

(-) t ermin al on the di scharged battery @

c> fig . 23 1. Instead, securely connec t the

negative (-) cable to either a solid metal

com ponent that is f irm ly bolted t o the e n

gine block o r to t he engine bloc k itsel f. If

the batt ery that is be ing c ha rge d d oes not

vent to the outs ide, escap ing batte ry gas

could ignite and e xplode!

Towing with a tow truck

General hints

Your Audi require s speci al handling f or towing.

Th e follow ing informat ion is to be used by com

mercia l tow tr uck o pera tors who know how to op

e rat e the ir equip men t sa fely.

- Never tow your Audi. Towing will cause dam

age to the engine and transmission .

- Never wrap the safety chains or winch cables

around the brake lines.

- To prevent unnecessary damage, your Audi

must be transported with a flat bed truck.

- To load the vehicle on to the flat bed, use the

towing loop found in the vehicle tools and at

tach to the front or rear anchorage

¢page273 and ¢pag e 274 .

Emergency situations

A WARNING

-A ve hicle being towe d is not safe for passen-

ge rs. Neve r allow a nyo ne to ride in a vehicle

b eing towed, for any reason.

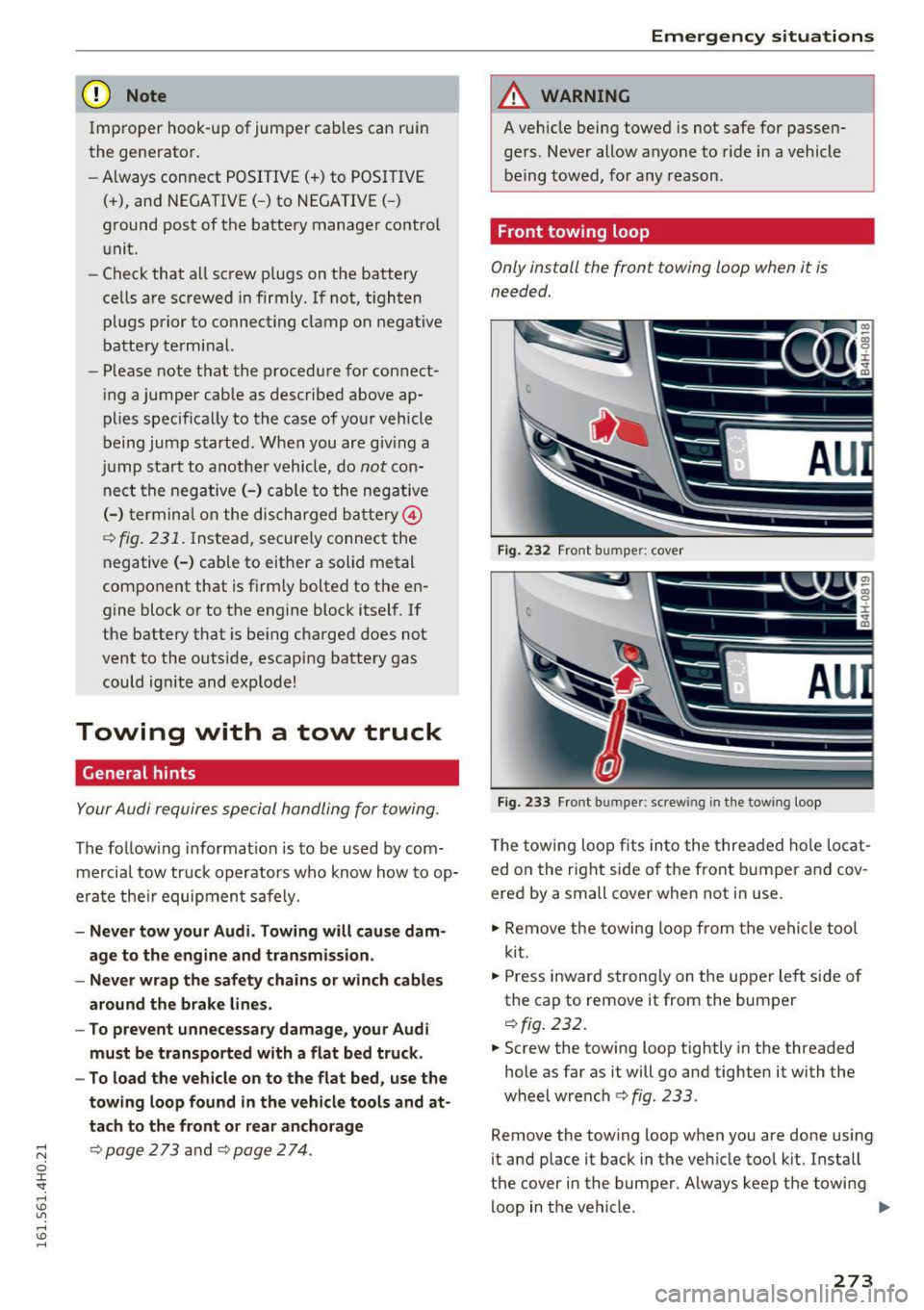

Front towing loop

Only install the front towing loop when it is

needed .

Fig. 232 Front bumper: cover

Fig. 233 Front bumper: screwing in th e towing loo p

The towing loo p fits in to the thre aded hole locat

ed o n the r ig ht side o f the fron t bumper a nd cov

ered by a small cover when not in use.

" Re move the towing loo p from the vehi cle too l

ki t.

" Press inward s tron gly on the up per left si de of

the cap to remove it from the bum per

¢ fig . 232.

" Screw the towing loop tightly in the threaded

hole as far as it will go and tighten it with the

wheel wrench

<=> fig . 233.

Remove the towing loop when you are done using

it and place it back in the ve hicle too l kit. Insta ll

the cover in the bumper . Always keep the towing

loop in the vehicle . ..,.

273

Page 277 of 302

eye. For technica l reasons, the pres sure in the

suspension st ruts may change during the

t ra nspo rt a nd this will adverse ly affect vehicle

handling.

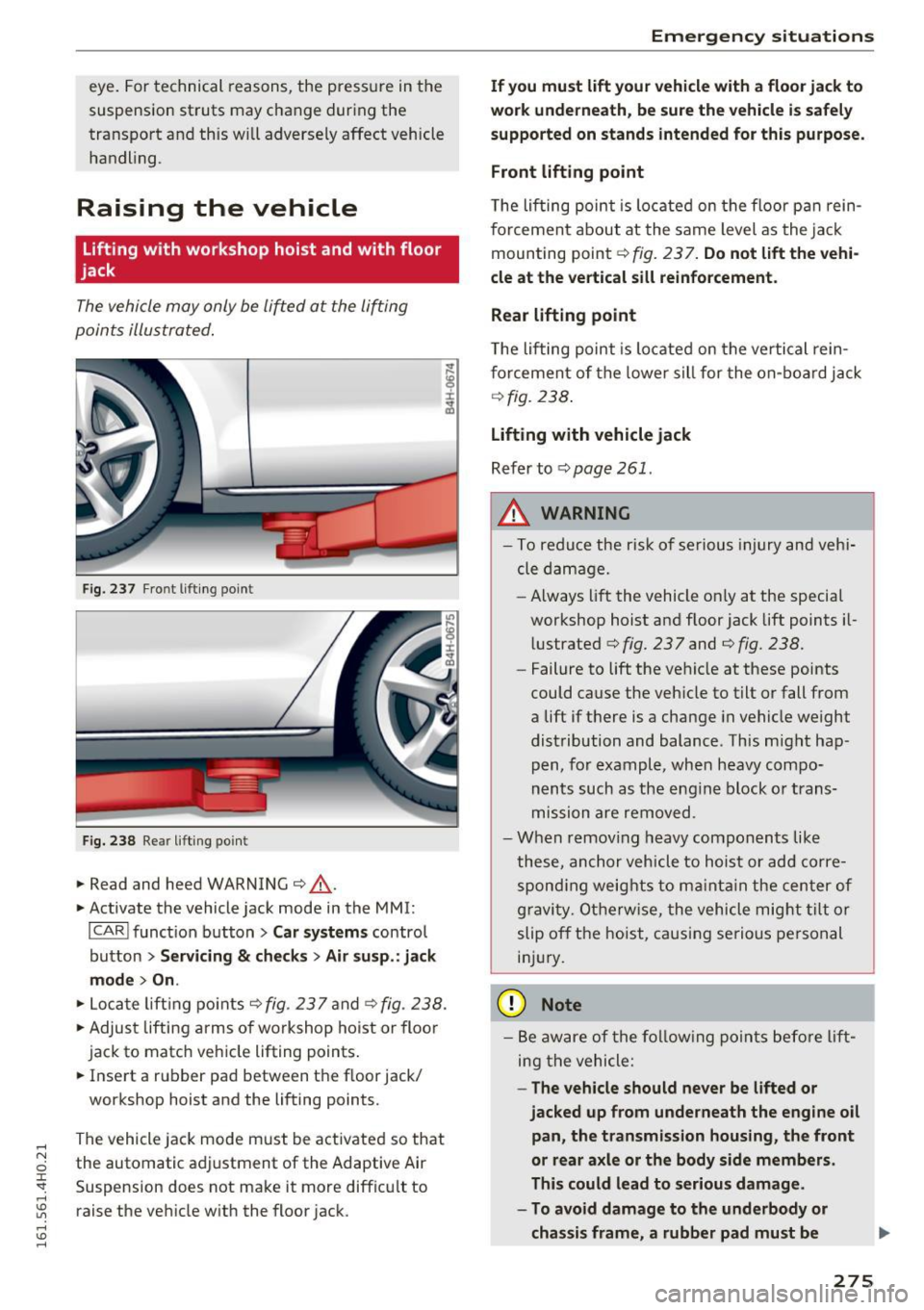

Raising the vehicle

Lifting with workshop hoist and with floor

jack

T he vehicle may only be lifted at the lifting

poin ts illus trated .

Fig . 237 Front lift ing point

F ig. 238 Rear lift ing po int

.,. Read and heed WARNING¢&_.

... Activate the vehicle jack mode in the MMI:

I CAR I funct io n button> Car system s control

button >

Servicing & checks > Air susp .: jack

mode > On .

... Loc ate lift ing po ints ¢fig. 237 and ¢ fig. 23 8 .

.,. Adjus t lifting arms of wo rkshop hoist or floo r

jack to matc h ve hicle lifting points .

... Inse rt a ru bber pad between t he f loor jack/

workshop hoist and the lifting points.

T h e vehicle jack mode m ust be act ivate d so that

the automatic adjustment of the Adaptive Air

Suspension does not ma ke it more diffic ult to

raise the ve hicle w it h the floor jack .

Emergency situations

If you must lift your vehicle with a floor jack to

work unde rneath , be sure the vehicle is safely

supported on stands intended for this purpose.

Front lifting point

T he li fting poi nt is locate d on the floor p an rein

f o rcement about at the sa me level as the ja ck

mounting point¢

fig. 237 . Do not lift the vehi

cle at the vertical sill re inforcement .

Rear lifting point

T he lif ting point is locate d on the vertical rei n

f o rcement of the lowe r sill for the on-bo ard j ack

¢fig. 238 .

Lifting with vehicle jack

Refer to¢ page 261 .

A WARNING

-- To reduce the r is k of se rious inju ry and veh i-

cle dama ge.

- Always lift the vehicle on ly at the special

w orkshop hoist and f loor jack lift points

il

lu strated¢ fig. 237 and¢ fig. 238.

- Failure to lift the ve hicle at these points

could cause the veh icle to tilt or fall fr om

a lift if t here is a change in vehicle weight

dist ribution and balance . Th is m ig ht hap

pen , fo r e xampl e, wh en heavy compo

n ents such as the eng in e block o r trans

mi ssion are removed.

- W hen re mov ing heavy componen ts like

t hese, anchor veh icle to hoist or add co rre

s p ondin g weig hts to maintai n the center of

g ra vity. O therw ise, the vehicle mig ht tilt or

slip

o ff th e hois t, c ausing se rious pe rsonal

i njur y.

(D Note

- Be aw are of the fo ll ow ing poi nts before lift

ing the vehicle:

-The vehicle should never be lifted or

jacked up from underneath the engine oil

pan, the transmission housing, the front

or rear axle or the body side members .

This could lead to serious damage .

- To avoid damage to the underbody or

chassis frame, a rubber pad must be

275