wheel AUDI Q3 2019 Manual Online

[x] Cancel search | Manufacturer: AUDI, Model Year: 2019, Model line: Q3, Model: AUDI Q3 2019Pages: 280, PDF Size: 72.73 MB

Page 236 of 280

Wheels

check your tires as soon as possible, and inflate

them to the proper pressure. Driving ona signifi-

cantly under-inflated tire causes the tire to over-

heat and can lead to tire failure. Under-inflation

also reduces fuel efficiency and tire tread life,

and may affect the vehicle's handling and stop-

ping

ability.

Please note that the TPMS is not a substitute for

proper tire maintenance, and it is the driver's re-

sponsibility to maintain correct tire pressure,

even if under-inflation has not reached the level

to trigger illumination of the TPMS low tire pres-

sure telltale.

Your vehicle has also been equipped with a TPMS

malfunction indicator to indicate when the sys-

tem is not operating properly. The TPMS mal-

function indicator is combined with the low tire

pressure telltale. When the system detects a

malfunction, the telltale will flash for approxi-

mately one minute and then remain continuously

illuminated. This sequence will continue upon

subsequent vehicle start-ups as long as the mal-

function exists.

When the malfunction indicator is illuminated,

the system may not be able to detect or signal

low tire pressure as intended. TPMS malfunctions

may occur for a variety of reasons, including the

installation of replacement or alternate tires or

wheels on the vehicle that prevent the TPMS

from functioning properly. Always check the

TPMS malfunction telltale after replacing one or

more tires or wheels on your vehicle to ensure

that the replacement or alternate tires and

wheels allow the TPMS to continue to function

properly.

If the tire pressure monitoring indicator

appears

The tire pressure indicator in the instrument

cluster informs you if the tire pressure is too low

or if there is a system malfunction.

Using the ABS sensors, the tire pressure monitor-

ing system compares the tire tread circumference

and vibration characteristics of the individual

tires. If the pressure changes in one or more

tires, this is indicated in the instrument cluster

234

display with an indicator light @ and a message.

If only one tire is affected, the location of that

tire will be indicated.

The tire pressures must be stored again each

time you change the pressures (switching be-

tween partial and full load pressure) or after

changing or replacing a tire on your vehicle

=> page 235. The tire pressure monitoring system

only monitors the tire pressure you have stored.

Refer to the tire pressure label for the recom-

mended tire pressure for your vehicle

=> page 226, fig. 152.

Tire tread circumference and vibration character-

istics can change and cause a tire pressure warn-

ing if:

—the tire pressure in one or more tires is too low

— The tires have structural damage

— the tire was replaced or the tire pressure was

changed and it was not stored > page 235

— Tires that are only partially used are replaced

with new tires

Indicator lights

@ - Loss of pressure in at least one tire > A\.

Check the tires and replace or repair if necessary.

Check and correct the pressures of all four tires

and store the pressure again > page 235.

/TPMS| (Tire Pressure Monitoring System) Tire pres-

sure: malfunction! See owner's manual. If i

appears after switching the ignition on or while

driving and the @ indicator light in the instru-

ment cluster blinks for approximately one minute

and then stays on, there is system malfunction.

Try to store the correct tire pressures

= page 235. In some cases, you must drive for

several minutes after storing the pressures until

the indicator light turns off. If the indicator light

does turn off or turns on again after a short peri-

od of time, drive to an authorized Audi dealer or

authorized Audi Service Facility immediately to

have the malfunction corrected.

ZA\ WARNING

— If the tire pressure indicator appears in the

display, reduce your speed immediately and

avoid any hard steering or braking

Page 237 of 280

83A012721BA

Wheels

maneuvers. Stop as soon as possible and

check the tires and their pressure.

— The driver is responsible for maintaining the

correct tire pressure. You must check the

tire pressure regularly.

— Under certain conditions (such as a sporty

driving style, winter conditions or unpaved

roads), the tire pressure monitoring system

indicator may be delayed.

@ Tips

— The tire pressure monitoring system can al-

so stop working when there is an ESC mal-

function.

— Using snow chains may result in a system

malfunction.

— The tire pressure monitoring system in your

Audi was calibrated with “Audi Original

Tires” > page 223. Using these tires is rec-

ommended.

Storing tire pressures

If the tire pressure changes or a tire is replaced,

it must be confirmed in the system.

> Before storing the tire pressures, make sure the

tire pressures in all four tires meet the speci-

fied values and are adapted to the load

=> page 226.

> Switch the ignition on.

> Select on the home screen: VEHICLE > Settings

& Service > Tire pressure monitoring > Store

tire pressure > Yes, store now.

@) Tips

Do not store the tire pressures if snow chains

are installed.

235

Page 239 of 280

83A012721BA

Care and cleaning

—To reduce the risk of cuts, protect yourself

from sharp metal components when wash-

ing the underbody or the inside of the wheel

housings.

— After washing the vehicle, the braking effect

may be delayed due to moisture on the

brake rotors or ice in the winter. This in-

creases the risk of an accident. The brakes

must be dried first with a few careful brake

applications.

@) Note

— If you wash the vehicle in an automatic car

wash, you must fold the exterior mirrors in

to reduce the risk of damage to the mirrors.

Power folding exterior mirrors* must only

be folded in and out using the power folding

function.

—To reduce the risk of damage to the rims

and tires, compare the width between the

wheels on your vehicle with the distance be-

tween the guide rails in the car wash.

—To reduce the risk of damage, compare the

height and width of your vehicle with the

height and width of the inside of the car

wash.

—To reduce the risk of paint damage, do not

wash the vehicle in direct sunlight.

—To reduce the risk of damage, do not wash

decorative decals* with a pressure washer.

—To reduce the risk of damage to the surface,

do not use insect removing sponges, kitchen

sponges or similar items.

— Matte finish painted vehicle components:

—To reduce the risk of damage to the sur-

face, do not use polishing agents or hard

wax.

— Never use protective wax. It can destroy

the matte finish effect.

— Do not place any stickers or magnetic

signs on vehicle parts painted with matte

finish paint. The paint could be damaged

when the stickers or magnets are re-

moved.

@) For the sake of the environment

Only wash the vehicle in facilities specially de-

signed for that purpose. This will reduce the

risk of dirty water contaminated with oil from

entering the sewer system.

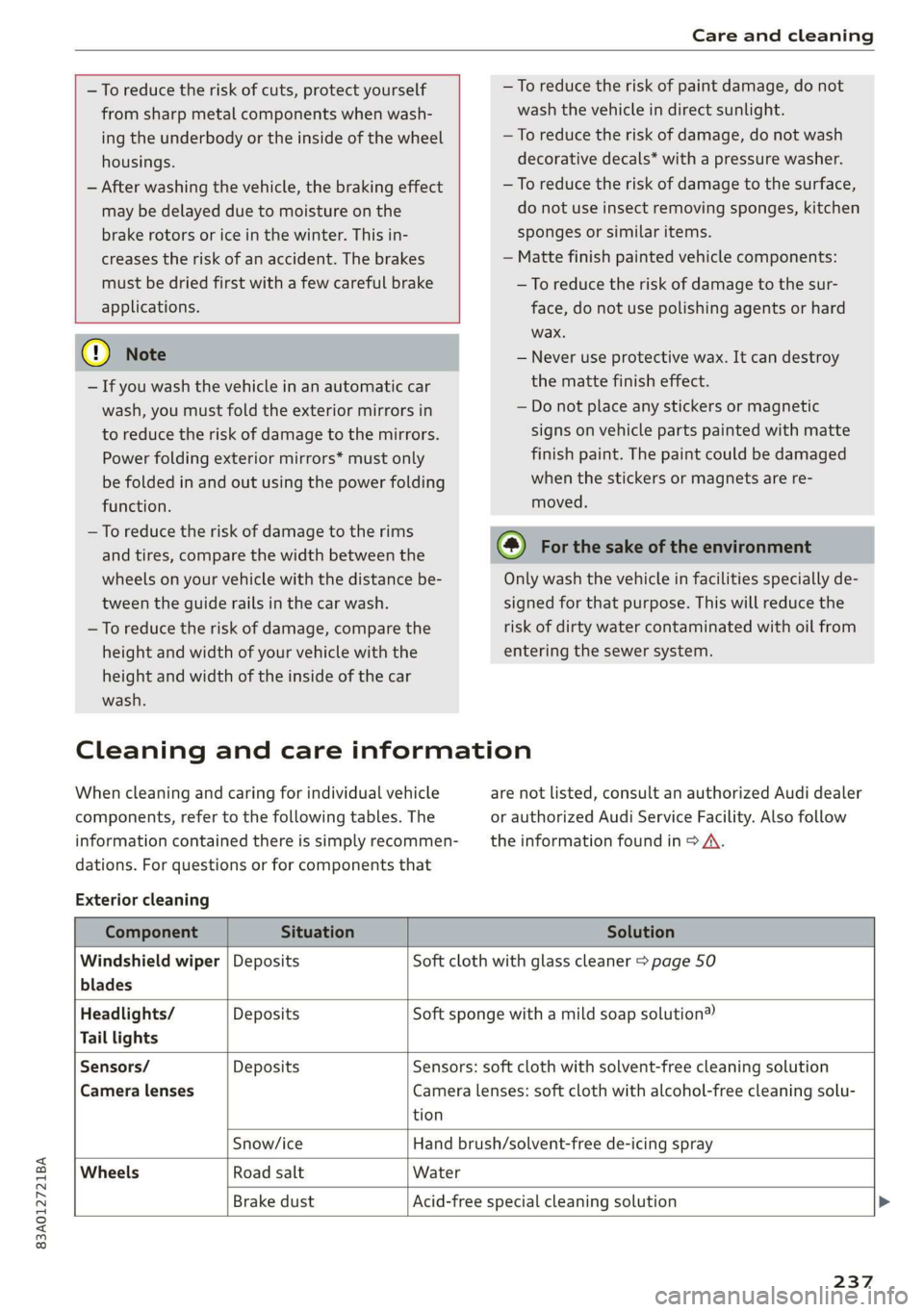

Cleaning and care information

When cleaning and caring for individual vehicle

components, refer to the following tables. The

information contained there is simply recommen-

dations. For questions or for components that

Exterior cleaning

are not listed, consult an authorized Audi dealer

or authorized Audi Service Facility. Also follow

the information found in > A.

Component Situation Solution

Windshield wiper | Deposits Soft cloth with glass cleaner > page 50

blades

Headlights/ Deposits Soft sponge with a mild soap solution®

Tail lights

Sensors/ Deposits Sensors: soft cloth with solvent-free cleaning solution

Camera lenses Camera lenses: soft cloth with alcohol-free cleaning solu-

tion

Snow/ice Hand brush/solvent-free de-icing spray

Wheels Road salt Water

Brake dust Acid-free special cleaning solution >

237

Page 241 of 280

83A012721BA

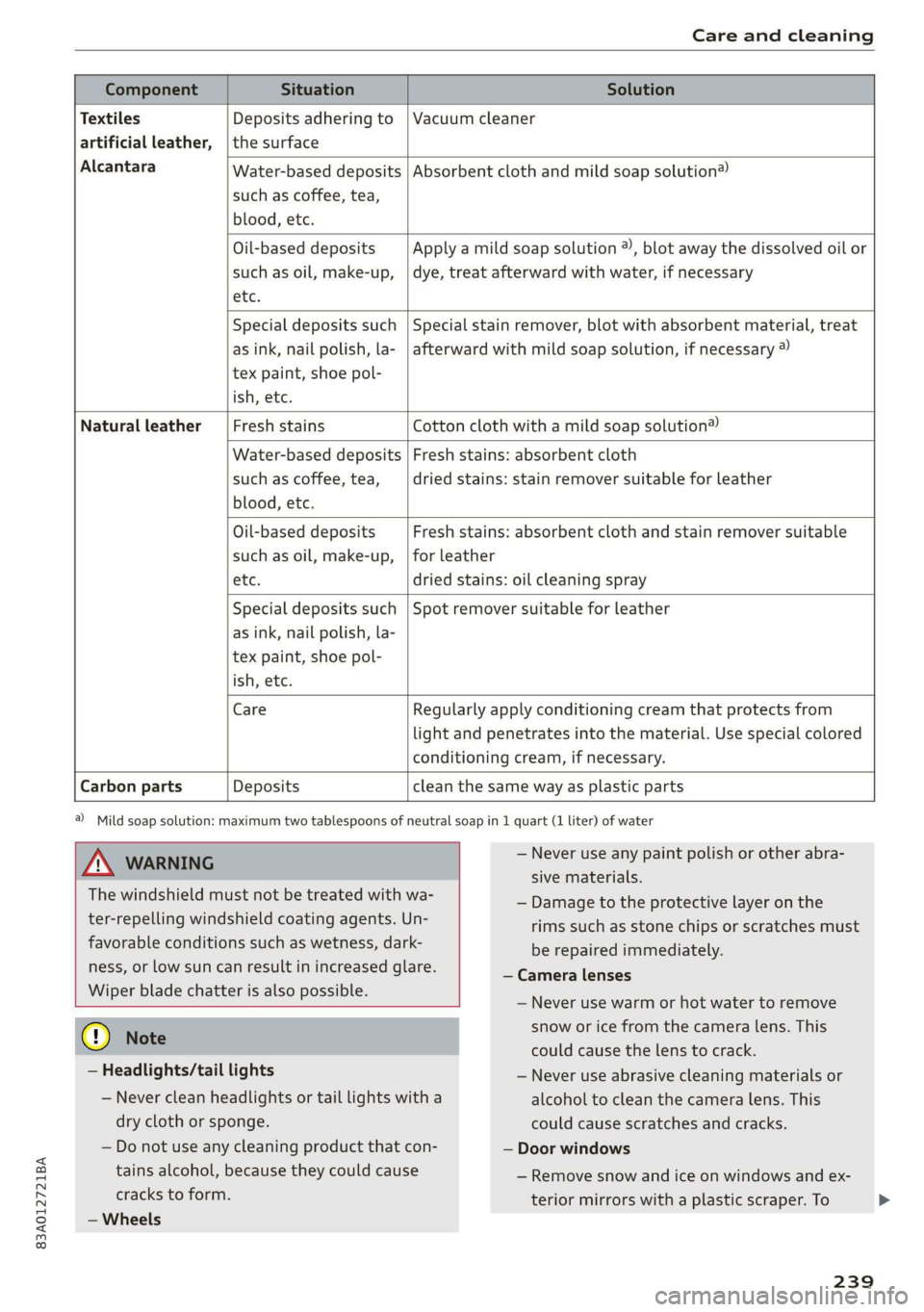

Care and cleaning

Water-based deposits

such as coffee, tea,

blood, etc.

Component Situation Solution

Textiles

Deposits adhering to | Vacuum cleaner

artificial leather, | the surface

Alcantara Absorbent cloth and mild soap solution®

Oil-based deposits

such as oil, make-up,

etc.

Apply a mild soap solution ®), blot away the dissolved oil or

dye, treat afterward with water, if necessary

Special deposits such

as ink, nail polish, la-

tex paint, shoe pol-

ish, etc.

Special stain remover, blot with absorbent material, treat

afterward with mild soap solution, if necessary ®

Natural leather Fresh stains Cotton cloth with a mild soap solution®

Water-based deposits

such as coffee, tea,

blood, etc.

Fresh stains: absorbent cloth

dried stains: stain remover suitable for leather

Oil-based deposits

such as oil, make-up,

etc.

Fresh stains: absorbent cloth and stain remover suitable

for leather

dried stains: oil cleaning spray

Special deposits such

as ink, nail polish, la-

tex paint, shoe pol-

ish, etc.

Spot remover suitable for leather

Care Regularly apply conditioning cream that protects from

light and penetrates into the material. Use special colored

conditioning cream, if necessary.

Carbon parts Deposits clean the same way as plastic parts

a) Mild soap solution: maximum two tablespoons of neutral soap in 1 quart (1 liter) of water

Z\ WARNING

The windshield must not be treated with wa-

ter-repelling windshield coating agents. Un-

favorable conditions such as wetness, dark-

ness, or low sun can result in increased glare.

Wiper blade chatter is also possible.

— Never use any paint polish or other abra-

sive materials.

— Damage to the protective layer on the

rims such as stone chips or scratches must

be repaired immediately.

— Camera lenses

— Never use warm or hot water to remove

@) Note

— Headlights/tail lights

— Never clean headlights or tail lights with a

dry cloth or sponge.

— Do not use any cleaning product that con-

tains alcohol, because they could cause

cracks to form.

— Wheels

snow or ice from the camera lens. This

could cause the lens to crack.

— Never use abrasive cleaning materials or

alcohol to clean the camera lens. This

could cause scratches and cracks.

— Door windows

— Remove snow and ice on windows and ex-

terior mirrors with a plastic scraper. To

239

Page 244 of 280

Emergency assistance

Emergency assistance

General information

> Park the vehicle as far as possible from moving

traffic in the event of a breakdown. In the event

of a flat tire, park the vehicle ona level surface.

It you are ona steep hill, be especially careful.

> Set the parking brake.

> Switch the emergency flashers on.

> Have the passengers exit the vehicle. They

should move to a safe place, for example be-

hind a guard rail.

Z\ WARNING

Follow the steps given above. This is for your

protection and the for the safety of other driv-

ers.

Equipment

Vehicle tool kit/vehicle jack

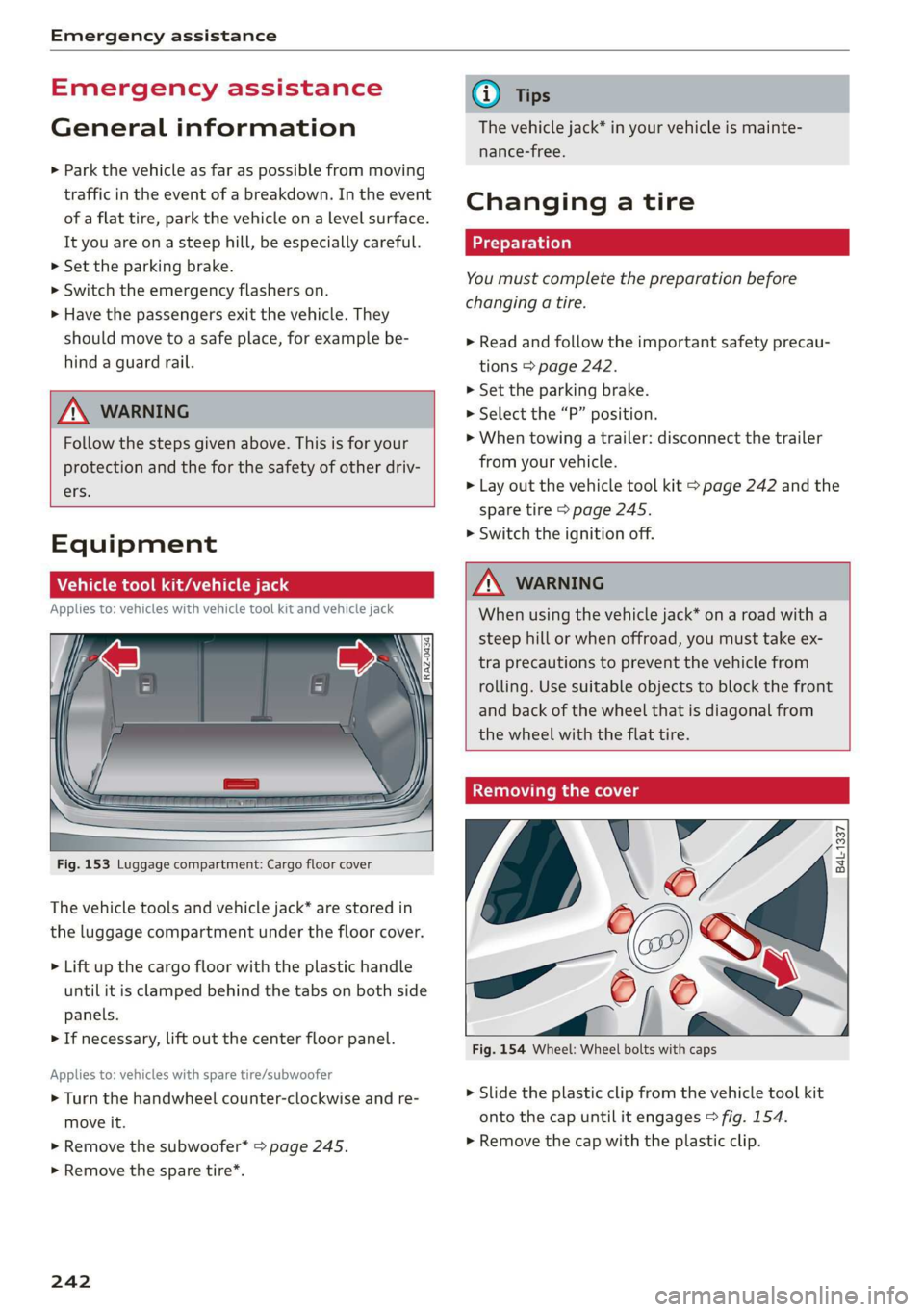

Applies to: vehicles with vehicle tool kit and vehicle jack

Fig. 153 Luggage compartment: Cargo floor cover

The vehicle tools and vehicle jack* are stored in

the luggage compartment under the floor cover.

> Lift up the cargo floor with the plastic handle

until it is clamped behind the tabs on both side

panels.

> If necessary, lift out the center floor panel.

Applies to: vehicles with spare tire/subwoofer

> Turn the handwheel counter-clockwise and re-

move it.

> Remove the subwoofer* > page 245.

> Remove the spare tire*.

242

@ Tips

The vehicle jack* in your vehicle is mainte-

nance-free.

Changing a tire

You must complete the preparation before

changing a tire.

> Read and follow the important safety precau-

tions > page 242.

> Set the parking brake.

> Select the “P” position.

>» When towing a trailer: disconnect the trailer

from your vehicle.

> Lay out the vehicle tool kit > page 242 and the

spare tire > page 245.

> Switch the ignition off.

Z\ WARNING

When using the vehicle jack* on a road with a

steep hill or when offroad, you must take ex-

tra

precautions to prevent the vehicle from

rolling. Use suitable objects to block the front

and back of the wheel that is diagonal from

the wheel with the flat tire.

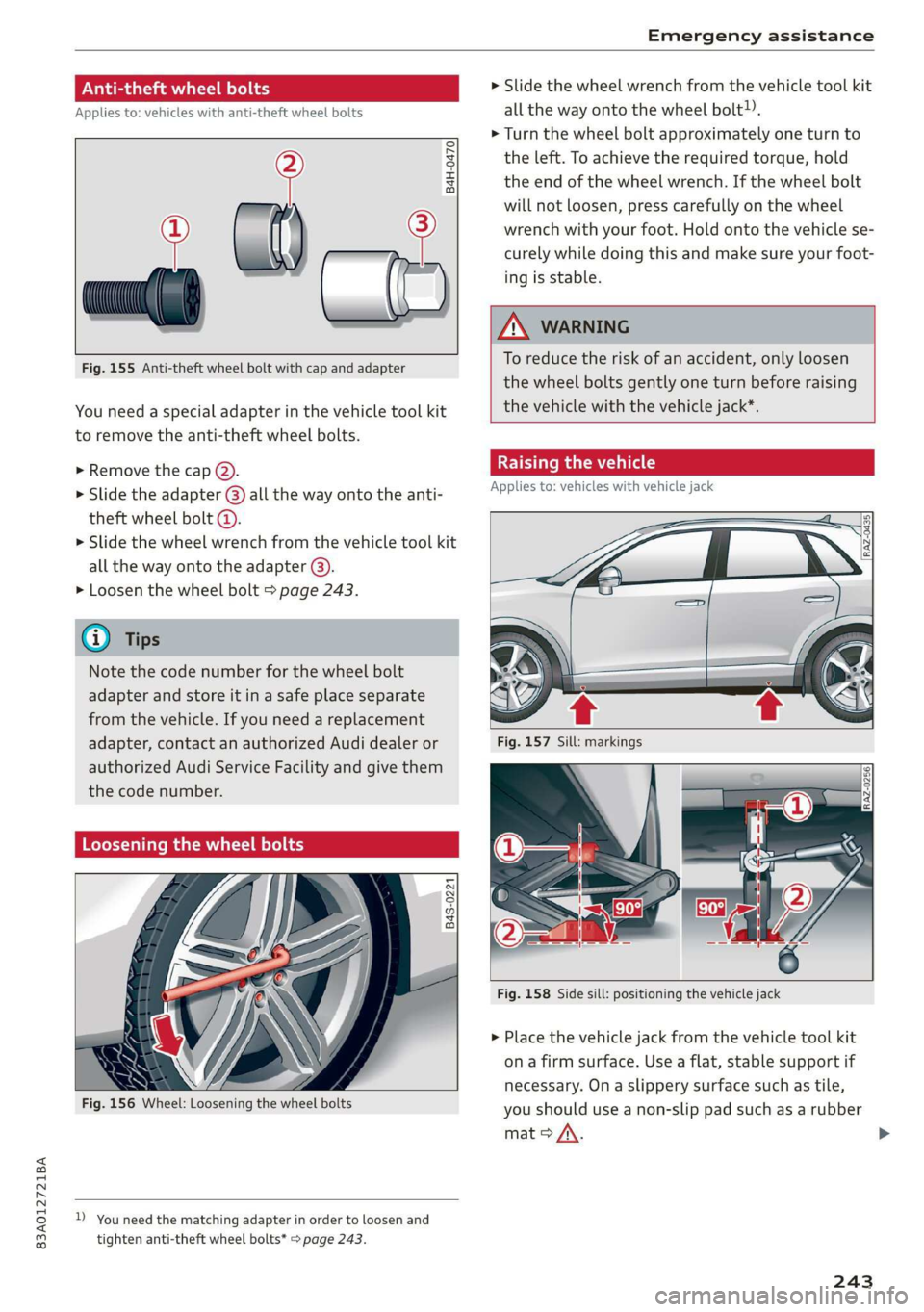

Removing the cover

\

i

Fig. 154 Wheel: Wheel bolts with caps

X

me) 4

> Slide the plastic clip from the vehicle tool kit

onto the cap until it engages > fig. 154.

> Remove the cap with the plastic clip.

Page 245 of 280

83A012721BA

Emergency assistance

ON elated ere) od

Applies to: vehicles with anti-theft wheel bolts

i

»

Fig. 155 Anti-theft wheel bolt with cap and adapter

B4H-0470

ie

You need a special adapter in the vehicle tool kit

to remove the anti-theft wheel bolts.

» Remove the cap @).

> Slide the adapter @) all the way onto the anti-

theft wheel bolt @.

> Slide the wheel wrench from the vehicle tool kit

all

the way onto the adapter @).

> Loosen the wheel bolt > page 243.

@ Tips

Note the code number for the wheel bolt

adapter and store it in a safe place separate

from the vehicle. If you need a replacement

adapter, contact an authorized Audi dealer or

authorized Audi Service Facility and give them

the code number.

Loosening the wheel bolts

B4S-0221

Sh

Fig. 156 Wheel: Loosening the wheel bolts

D_ You need the matching adapter in order to loosen and

tighten anti-theft wheel bolts* > page 243.

> Slide the wheel wrench from the vehicle tool kit

all the way onto the wheel bolt).

> Turn the wheel bolt approximately one turn to

the left. To achieve the required torque, hold

the end of the wheel wrench. If the wheel bolt

will not loosen, press carefully on the wheel

wrench with your foot. Hold onto the vehicle se-

curely while doing this and make sure your foot-

ing is stable.

ZA\ WARNING

To reduce the risk of an accident, only loosen

the wheel bolts gently one turn before raising

the

vehicle with the vehicle jack*.

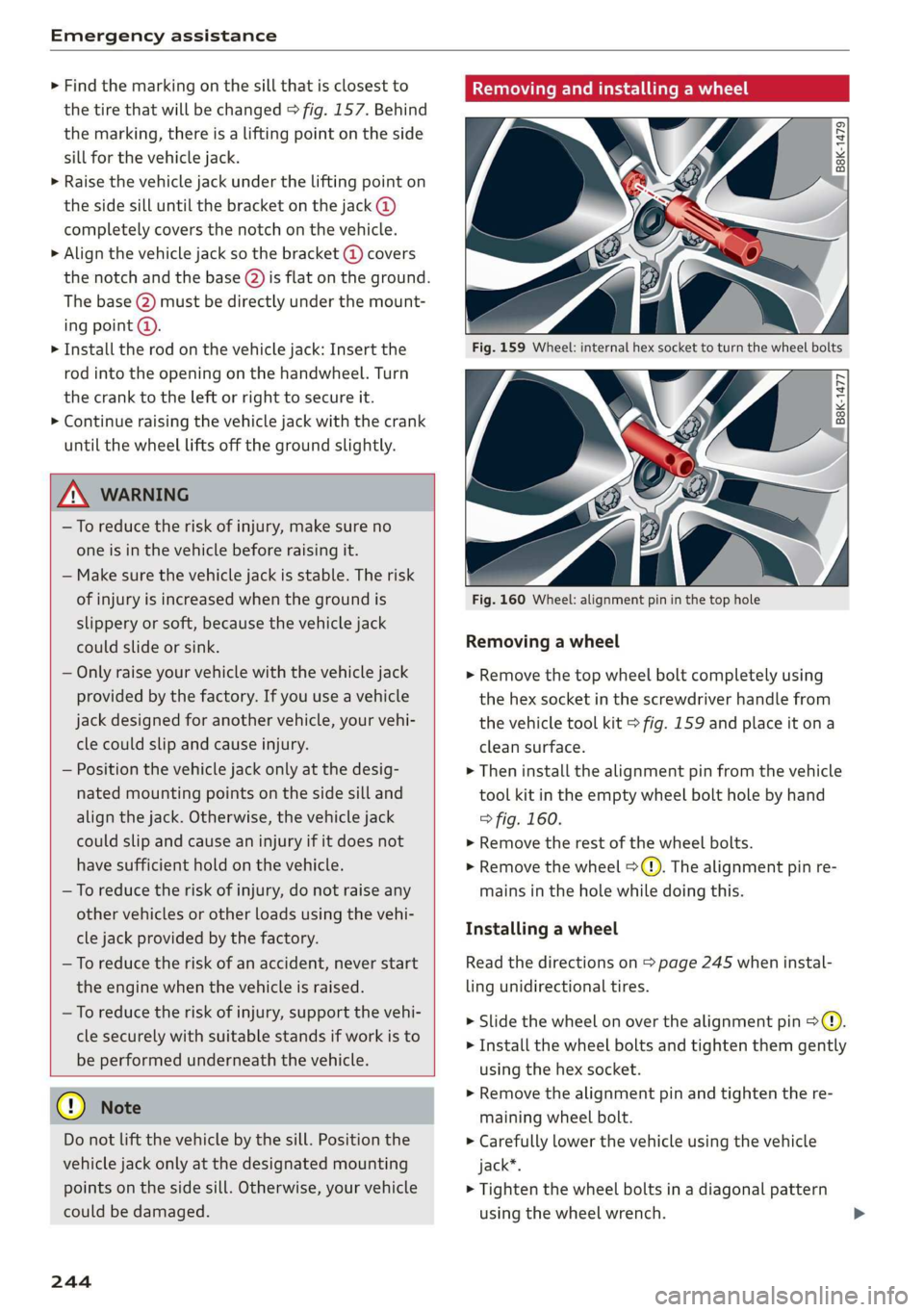

Raising the vehicle

Applies to: vehicles with vehicle jack

Fig. 158 Side sill: positioning the vehicle jack

> Place the vehicle jack from the vehicle tool kit

ona firm surface. Use a flat, stable support if

necessary. On a slippery surface such as tile,

you should use a non-slip pad such as a rubber

mat > A\.

243

>

Page 246 of 280

Emergency assistance

> Find the marking on the sill that is closest to

the tire that will be changed > fig. 157. Behind

the marking, there is a lifting point on the side

sill for the vehicle jack.

> Raise the vehicle jack under the lifting point on

the side sill until the bracket on the jack @)

completely covers the notch on the vehicle.

> Align the vehicle jack so the bracket @ covers

the notch and the base (2) is flat on the ground.

The base @) must be directly under the mount-

ing point @.

> Install the rod on the vehicle jack: Insert the

rod into the opening on the handwheel. Turn

the crank to the left or right to secure it.

> Continue raising the vehicle jack with the crank

until the wheel lifts off the ground slightly.

ZX WARNING

— To reduce the risk of injury, make sure no

one is in the vehicle before raising it.

— Make sure the vehicle jack is stable. The risk

of

injury is increased when the ground is

slippery or soft, because the vehicle jack

could slide or sink.

— Only raise your vehicle with the vehicle jack

provided by the factory. If you use a vehicle

jack designed for another vehicle, your vehi-

cle could slip and cause injury.

— Position the vehicle jack only at the desig-

nated mounting points on the side sill and

align the jack. Otherwise, the vehicle jack

could slip and cause an injury if it does not

have sufficient hold on the vehicle.

—To reduce the risk of injury, do not raise any

other vehicles or other loads using the vehi-

cle jack provided by the factory.

— To reduce the risk of an accident, never start

the engine when the vehicle is raised.

—To reduce the risk of injury, support the vehi-

cle securely with suitable stands if work is to

be performed underneath the vehicle.

@) Note

Do not lift the vehicle by the sill. Position the

vehicle jack only at the designated mounting

points on the side sill. Otherwise, your vehicle

could be damaged.

244

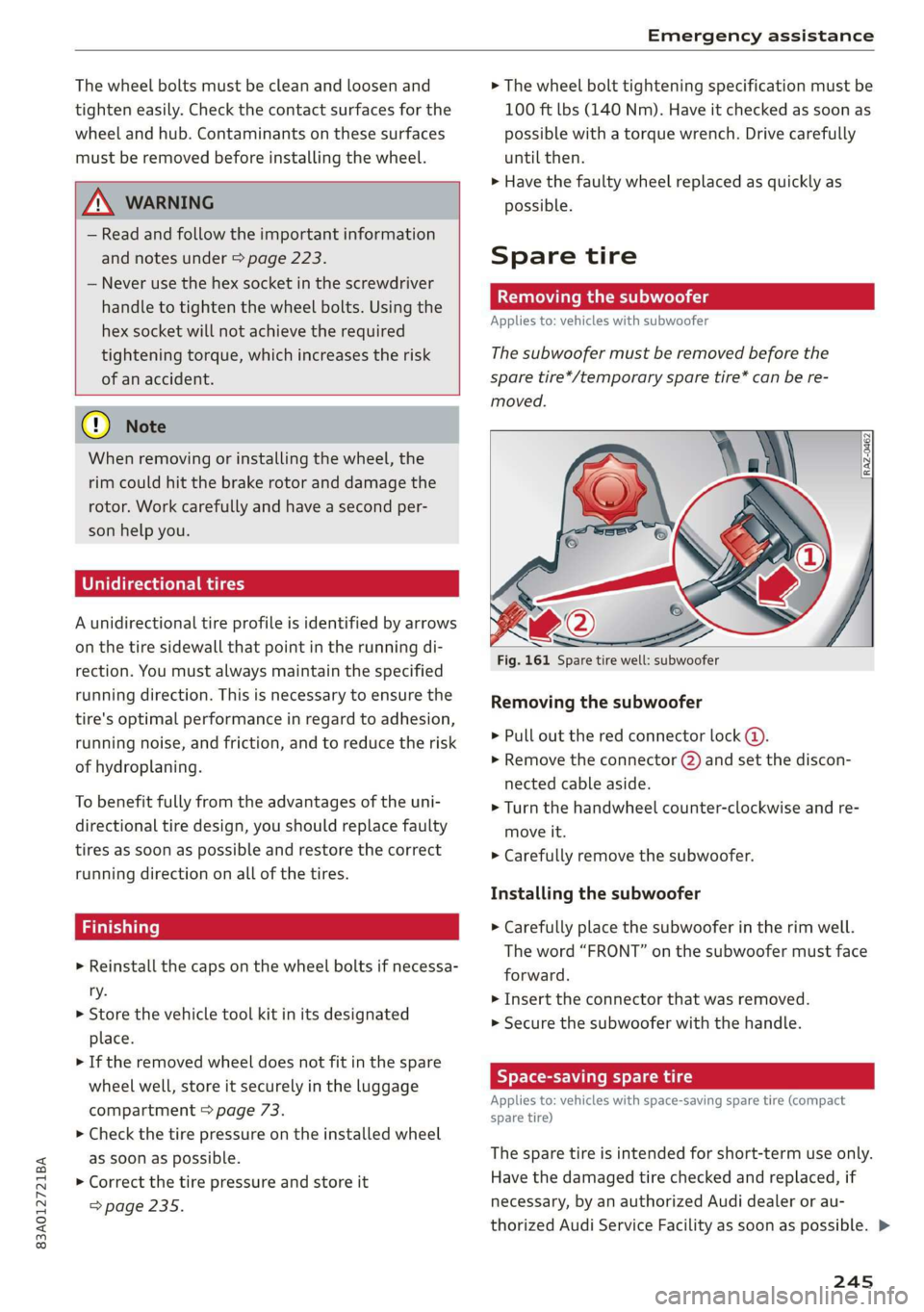

Removing and installing a wheel

Fig. 159 Wheel: internal hex socket to turn the wheel bolts

|

©

B8k-1477

Fig. 160 Wheel: alignment pin in the top hole

Removing a wheel

> Remove the top wheel bolt completely using

the hex socket in the screwdriver handle from

the vehicle tool kit > fig. 159 and place it ona

clean surface.

> Then install the alignment pin from the vehicle

tool kit in the empty wheel bolt hole by hand

> fig. 160.

> Remove the rest of the wheel bolts.

> Remove the wheel >(). The alignment pin re-

mains in the hole while doing this.

Installing a wheel

Read the directions on > page 245 when instal-

ling unidirectional tires.

> Slide the wheel on over the alignment pin >@.

> Install the wheel bolts and tighten them gently

using the hex socket.

> Remove the alignment pin and tighten the re-

maining wheel bolt.

> Carefully lower the vehicle using the vehicle

jack*.

> Tighten the wheel bolts in a diagonal pattern

using the wheel wrench.

Page 247 of 280

83A012721BA

Emergency assistance

The wheel bolts must be clean and loosen and

tighten easily. Check the contact surfaces for the

wheel and hub. Contaminants on these surfaces

must be removed before installing the wheel.

Z\ WARNING

— Read and follow the important information

and notes under > page 223.

— Never use the hex socket in the screwdriver

handle to tighten the wheel bolts. Using the

hex socket will not achieve the required

tightening torque, which increases the risk

of an accident.

C) Note

When removing or installing the wheel, the

rim

could hit the brake rotor and damage the

rotor. Work carefully and have a second per-

son help you.

Unidirectional tires

A unidirectional tire profile is identified by arrows

on the tire sidewall that point in the running di-

rection. You must always maintain the specified

running direction. This is necessary to ensure the

tire's optimal performance in regard to adhesion,

running noise, and friction, and to reduce the risk

of

hydroplaning.

To benefit fully from the advantages of the uni-

directional tire design, you should replace faulty

tires as soon as possible and restore the correct

running direction on all of the tires.

> Reinstall the caps on the wheel bolts if necessa-

ry.

> Store the vehicle tool kit in its designated

place.

> If the removed wheel does not fit in the spare

wheel well, store it securely in the luggage

compartment > page 73.

> Check the tire pressure on the installed wheel

as soon as possible.

> Correct the tire pressure and store it

=> page 235.

> The wheel bolt tightening specification must be

100 ft lbs (140 Nm). Have it checked as soon as

possible with a torque wrench. Drive carefully

until then.

> Have the faulty wheel replaced as quickly as

possible.

Spare tire

tute Mae eis

Applies to: vehicles with subwoofer

The subwoofer must be removed before the

spare tire*/temporary spare tire* can be re-

moved.

Fig. 161 Spare tire well: subwoofer

Removing the subwoofer

> Pull out the red connector lock @).

>» Remove the connector (2) and set the discon-

nected cable aside.

> Turn the handwheel counter-clockwise and re-

move it.

> Carefully remove the subwoofer.

Installing the subwoofer

> Carefully place the subwoofer in the rim well.

The word “FRONT” on the subwoofer must face

forward.

> Insert the connector that was removed.

> Secure the subwoofer with the handle.

Byer leet Ue iy re

Applies to: vehicles with space-saving spare tire (compact

spare tire)

The spare tire is intended for short-term use only.

Have the damaged tire checked and replaced, if

necessary, by an authorized Audi dealer or au-

thorized Audi Service Facility as soon as possible. >

245

Page 248 of 280

Emergency assistance

There are some restrictions on the use of the

compact spare tire. The compact spare tire has

been designed specifically for your type of vehi-

cle. Do not replace it with the spare tire from an-

other type of vehicle.

The compact spare tire is located in the luggage

compartment under the cargo floor cover

=> page 242.

The tire pressure must be 61 PSI (420 kPA).

Snow chains

For technical reasons, the use of snow chains on

the compact spare tire is not permitted.

If you have to drive with snow chains and a front

tire fails, mount the spare tire in place of a rear

tire. Install the snow chains on the rear tire that

you removed, and install that in place of the

front tire that failed.

ZA WARNING

— After installing a spare tire, the tire pressure

must be checked as soon as possible.

— Do not drive faster than 50 mph (80 km/h)

with a compact spare tire. Driving faster

than that increases the risk of an accident.

— To reduce the risk of an accident, avoid hard

acceleration or braking and driving fast

around curves with the compact spare tire.

— To reduce the risk of an accident, never drive

with more than one compact spare tire.

— Normal summer or winter tires must not be

mounted on the compact spare wheel rim.

battery that is giving power must not be less

than the capacity of the drained vehicle battery.

Jump start cable

Only use a jump start cable with a large enough

diameter. Note the manufacturer's specifica-

tions.

Only use a jump start cable with insulated termi-

nal clamps.

Positive cable - usually red.

Negative cable - usually black.

ZA WARNING

— A drained battery can freeze at tempera-

tures around 32 °F (0 °C). If the vehicle bat-

tery is frozen, it must be thawed before con-

necting the jump start cables. If it is not,

the risk of an explosion and chemical burns

increases. After jump starting the vehicle,

drive to an authorized Audi dealer or author-

ized Audi Service Facility immediately to

have the vehicle battery checked.

— Read the warnings when working in the en-

gine compartment > page 203.

— Handling the jump start cables incorrectly

may cause the vehicle battery to explode

and lead to serious injuries.

—To reduce the risk of chemical burns, do not

bend over the vehicle battery.

Jump starting

You should only perform the steps that follow if

you have the necessary tools and technical ex-

pertise.

If the engine does not start because the vehicle

battery is drained, you can jump start your vehi-

cle using another vehicle. Jump start cables are

needed to do this.

Both vehicle batteries must have 12 V nominal

voltage. The voltage capacity (Ah) of the vehicle

246

() Note

Jump start cables can cause considerable

damage to the vehicle electrical system if

they are connected incorrectly.

G) Tips

— There must be no contact between the vehi-

cles, or else voltage could flow when con-

necting the positive terminal and drain the

vehicle battery of the vehicle providing the

jump start.

— The drained vehicle battery must be con-

nected correctly to the electrical system.

— Switch off electrical equipment that is not

needed.

Page 251 of 280

83A012721BA

Emergency assistance

— Follow the local legal regulations for tow-

ing.

Read and follow the important information under

=> page 248.

Preparations

> Only secure the towing cable or tow bar at the

designated towing loops > page 249,

=> page 249.

> Make sure the towing cable is not twisted. Oth-

erwise it could disconnect from the towing loop

while towing.

> Switch the emergency flashers on in both vehi-

cles > page 45. However, do not do this if it

prohibited by law.

Towing vehicle (front)

> Only start to drive when the towing cable is

taut.

> Press the brake pedal very carefully.

> Avoid sudden braking or driving maneuvers.

Vehicle being towed (rear)

> Make sure the ignition is switched on so that

the steering wheel is not locked and so that you

can use the turn signals, the horn, and the

windshield wipers if needed > A\.

> Switching it off before the vehicle has stopped

may impair the function of the brake booster

and power steering. You would then need to

use more force to steer and brake the vehicle.

> Release the parking brake > page 90.

> Select the “N” selector lever position.

> Make sure the towing cable is always taut.

A WARNING

Never tow a vehicle using a tow bar or towing

cable if the vehicle does not have electrical

power.

Front towing loop

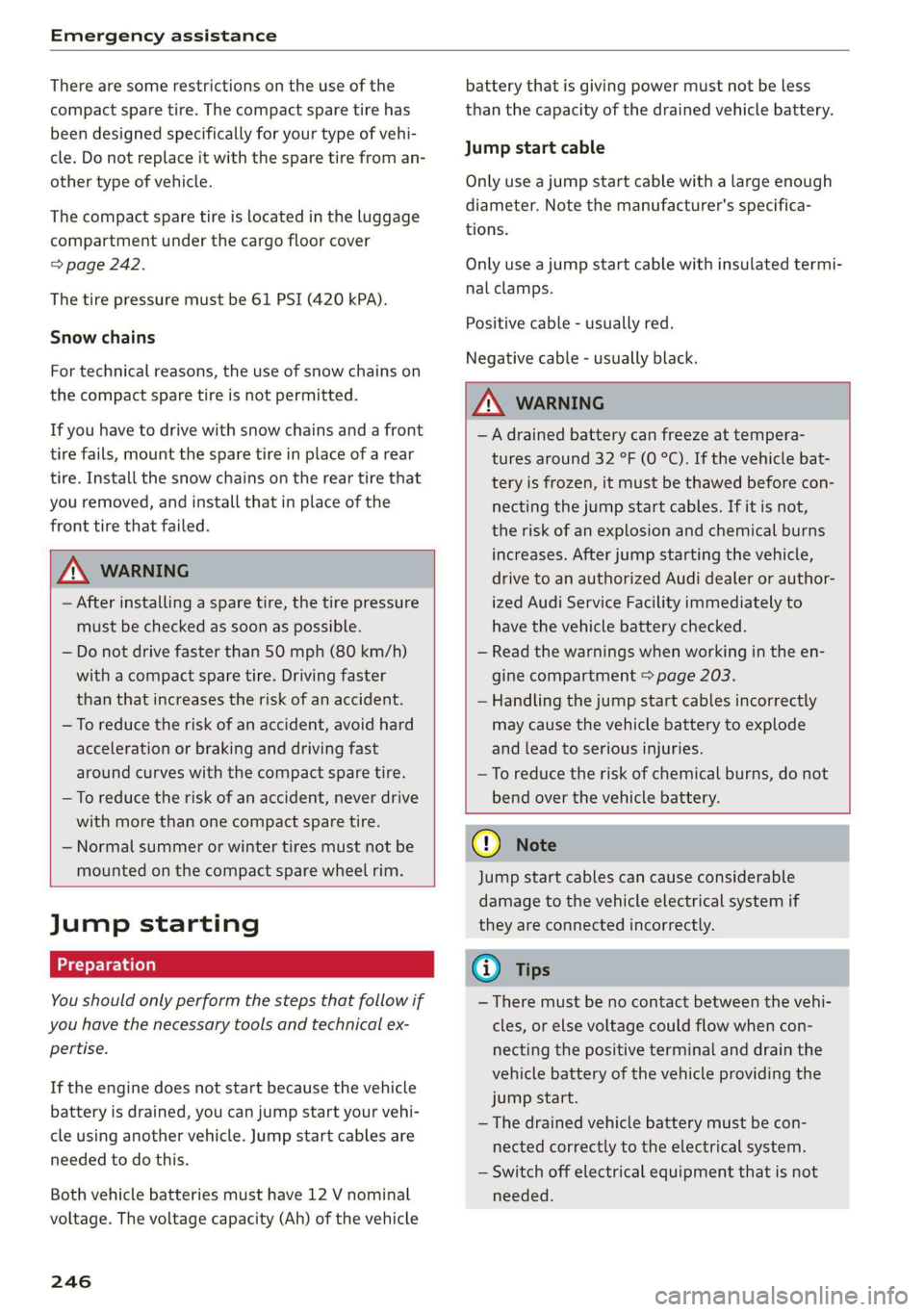

Fig. 164 Front bumper: installing the towing loop

The threaded opening for the towing loop is lo-

cated on the right side of the front bumper.

> Remove the towing loop from the vehicle tool

kit > page 242.

> Press the cap inward with brief, strong pressure

> fig. 164. The cap will loosen from the bump-

er.

> Tighten the towing loop in the threaded open-

ing until it stops and then tighten it with a

wheel wrench.

> After using, place the towing loop back in the

vehicle tool kit.

ZX WARNING

If the towing loop is not tightened until it

stops when installing, the threads may be

pulled out when towing the vehicle and that

could cause an accident.

Rear towing loop

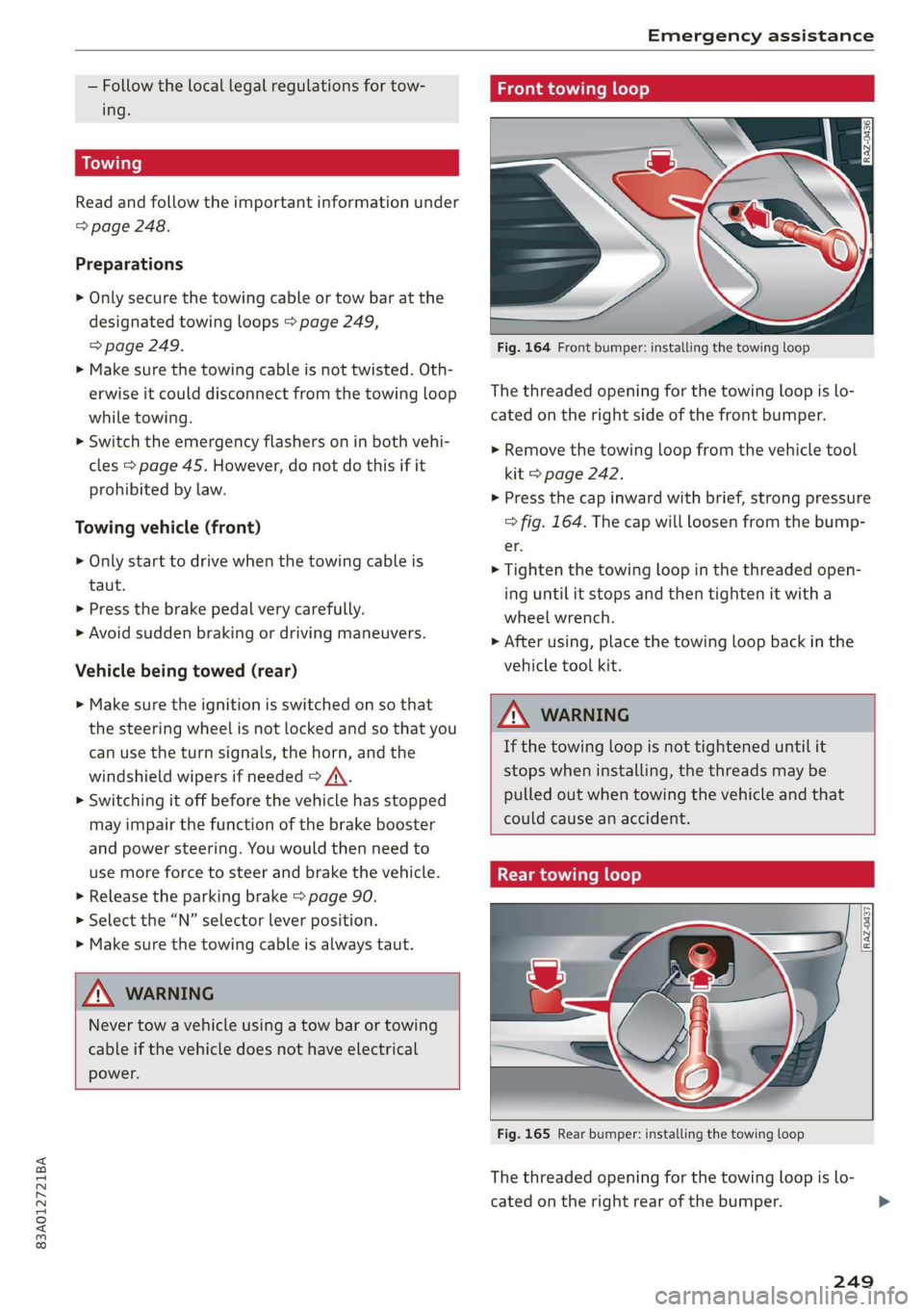

Fig. 165 Rear bumper: installing the towing loop

The threaded opening for the towing loop is lo-

cated on the right rear of the bumper.

249