technical data AUDI Q7 2011 Owner´s Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2011, Model line: Q7, Model: AUDI Q7 2011Pages: 392, PDF Size: 93.29 MB

Page 343 of 392

_______________________________________________ W __ h_a _t_ d_o_ I_ d_o_ n_ o_ w_ ? _ __._

Release the two hook-and-loop fasteners, and remove the two

chocks . To use the chocks, you first have to raise the support plate

=>

page 340, fig . 250 (D and then insert the locking plate with the

two "tabs" into the elongated holes in the base plate @=>& .

& WARNING

• The chock cannot fulfil its function and may lose its stability if

the "tabs" on the support plate are not inserted correctly into the

elo ngated holes in the base plate. If this happens, the vehicle may

start to move while a wheel is being changed.

• Never use the folding chocks if they are damaged or if they

have not been assembled correctly.

& WARNING

Improper use of the vehicle jack can cause serious personal inju

ries.

• Never use the jack supplied with your Audi on another vehicle,

particularly on a heavier one. The jack is only suitable for use on

the vehicle it came with.

• Using a bumper jack to raise the vehicle will damage the

bumper system. The jack may slip, causing injury.

• Never support your vehicle on cinder blocks, bricks or other

objects . These may not be able to support the load and could cause

injury when they fail.

• Never start or run the engine while the vehicle is supported by

the jack.

• If you must work under the vehicle, always use safety stands

specifically designed for this purpose.

• Always make sure the inflatable spare tire and even a flat tire

are secured in place and not loose, otherwise they could fly

forward, causing personal injury to passengers in the vehicle in an

accident or sudden maneuver. •

Vehicle OP-eration

Applies to vehicles : with bass box

Removing bass box

Before the inflatable spare tire can be taken out, the bass

box must be removed.

Fig. 251 Spare wheel

well: Bass box

Removing bass box

-Squeeze the locking tabs=> fig. 251 (D of the connector.

- Disconnect the connector @ and place the lead to one

side.

- Turn the large screw counter-clockwise.

- Carefully remove the bass box.

Installing bass box

-Carefully place the bass box in the wheel. The inscription

"FRONT" on the bass box must face forward.

- Reconnect the connector that was removed.

- Secure the bass box with the large screw. •

Vehicle care Do-it-yourself service iTechnical data

Page 345 of 392

_____________________________________________ W __ h_a_ t_ d_o_ I_ d_o _ n_ o_ w _ ? __ _

& WARNING (continued)

-Never store the inflatable spare tire or jack and tools in the

passenger compartment.

- Always store all jacking equipment, tools, and the inflatable

spare tire in the luggage compartment.

- Tighten the knurled retaining screw for the inflatable spare

tire securely.

0 Note

• The inflatable spare tire has been developed specifically for this

vehicle model. It must not be exchanged or used for other vehicle

models . Similarly, inflatable tires from other vehicle models must

not be used.

• Normal summer or winter tires must not be installed on the inflat

able tire rim. •

Inflating inflatable spare tire

-Remove the compressor from the luggage compartment

~ page 342, fig. 252.

- Unscrew the valve stem from the spare tire.

- Screw the tire filler hose from the compressor firmly onto

the valve of the spare tire.

- Insert the plug from the compressor into a socket of the

vehicle ~

page 106.

- Switch the compressor on .

- Let the compressor run until the value specified on the tire

pressure label is reached=>

page 322, fig. 242. Switch the

compressor off after running for 12 minutes at the most -

danger of overheating!

Safety first

& WARNING

The compressor and the tire filler hose can become extremely hot

while they are running · danger of burns!

0 Note

Switch the compressor off after running for 12 minutes at the most

danger of overheating! Allow the compressor to cool down for a few

minutes before you use it again.

[ i] Tips

The compressor must not be connected to the cigarette lighter

socket, as this socket does not provide the required power.•

Changing a wheel

Before changing a wheel

Observe the following precautions for your own and your

passenger's safety when changing a wheel.

- After you experience a tire failure, pull the car well away

from moving traffic and try to reach

level ground before

you stop => & .

- All passengers should

leave the car and move to a safe

location (for instance, behind the guardrail)=> &.

- Engage the

parking brake to prevent your vehicle from

rolling unintentionally~ &.

- Move

selector lever to position P ~ & .

- If you are tow ing a trailer: unhitch the trailer from your

vehicle. ..,_

Vehicle care Do-it-yourself service Technical data

Page 347 of 392

_____________________________________________ W __ h_a _ t_ d_o_ I_ d _ o_ n_o_ w_ ? _ ___.lftll

- As soon as poss ible, have the tig htening torqu es on all

wheel bolts checked with a torque wrench . The correct

tightening torque is 120 ft lb (160 Nm).

- Have the flat tire

rep laced as soon as possible.

(I] Tips

• If you notice that the wheel bolts are corroded and difficult to turn

while chang ing a tire, they should be replaced before you check the

tightening torque.

• Drive at reduced speed until you have the t ightening torques

checked. •

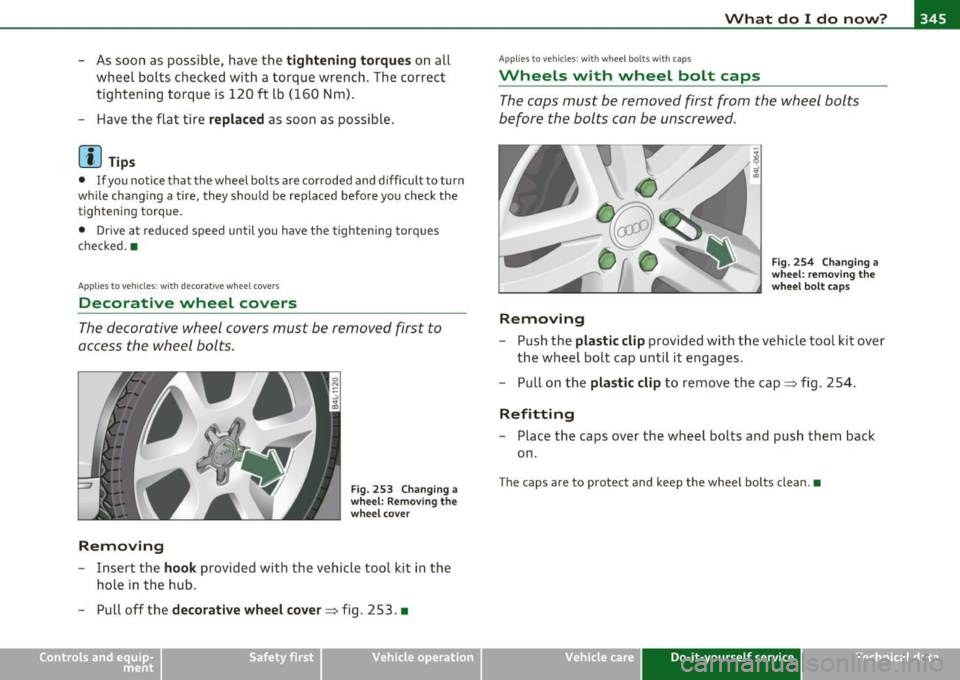

Applies to ve hicl es: w ith dec orative wheel covers

Decorative wheel covers

The decorative wheel covers must be removed first to

access the wheel bolts.

Removing

Fig . 253 Changing a

wheel: Remov ing the

wheel cover

- Insert the hook provided with the vehicle tool k it in the

hole in the hub .

- Pull off the

deco rative whe el co ver => fig . 253 . •

Vehicle OP-eration

Applies to vehicles : w ith wheel bolts w ith caps

Wheels with wheel bolt caps

The caps must be removed first from the wheel bolts

before the bolts can be unscrewed.

Removing

F ig. 254 Ch angi ng a

wheel : removing the

wheel bolt c aps

- Push the plastic clip provided with the veh icle tool kit over

the wheel bolt cap until it engages .

Pull on the

plastic cli p to remove the cap=> fig . 254.

Refitting

- Place the caps over the wheel bolts and push them back

on .

The caps are to pr otect and keep the wheel bolts clean .•

Vehicle care Do-it-yourself service iTechnical data

Page 349 of 392

_____________________________________________ W __ h_a _ t_ d_o_ I_ d _ o_ n_o_ w_ ? _ ___.1111

Fig. 257 Close-up:

proper positioning of

jack

-Activate the vehicle jack mode* (only vehicles with Adap

tive Air Suspension) =>

page 182.

- Engage the parking brake to prevent your vehicle from

rolling unintentionally

- Move the

selector lever to position P.

- Position the jack below the door sill under the mounting

point

that is closest to the wheel to be changed

=>

page 346 , fig. 256.

- Extend the

jack under the lifting point on the door sill until

its arm is positioned directly under the lifting point=>&.

- Align the jack so that its arm©=>

page 347, fig. 257

engages in the designated lifting point in the door sill and

the movable base® lies flat on the ground. The base ®

must be

vertical under the lifting point@.

- Wind the jack up further until the flat tire comes off the

ground =>& .

The jack must be installed only at the places indicated=> page 346,

fig. 256. There is exactly one location for each wheel. The jack must

not be positioned at any other location=>& .

Vehicle OP-eration An

unstable surface under

the jack can cause the vehicle to slip off

the jack . Always provide a firm base for the jack on the ground. If

necessary place a sturdy board or similar support under the jack . On

hard, slippery surfaces (such as tiles) use a rubber mat or similar to

prevent the jack from slipping=>&.

& WARNING

• You or your passengers could be injured while changing a

wheel if you do not follow these safety precautions:

- Positioning the jack under the vehicle at any other place than

those indicated above may damage the vehicle or may result in

personal injuries.

- A soft or unstable surface under the jack may cause the

vehicle to slip off the jack. Always provide a firm base for the

jack on the ground. If necessary, use a sturdy board under the

jack.

- On hard, slippery surface (such as tiles) use a rubber mat or

similar to prevent the jack from slipping.

• To help prevent injury to yourself and your passengers: -Do not raise the vehicle until you are sure the jack is securely

engaged.

- Passengers must not remain in the vehicle when it is jacked

up.

- Make sure that passengers wait in a safe place away from the

vehicle and well away from the road and traffic.

- Make sure jack position is correct, adjust as necessary and

then continue to raise the jack. •

Vehicle care Do-it-yourself service iTechnical data

Page 351 of 392

___________________________________________ W_ h_ a_t _d_ o_ I_ d_o_ n_ o_ w_ ? __ _

• The direct ion of rotation is marked by an arrow on the side of the

ti re.

• If the spare tire has to be installed in the incorrect direct ion, use

th e spare tire only temporarily since the tire will no t be able to

achieve its optimum performance character istics with regard to

aquaplaning, noise and wear.

• We recommend that you pay particular attent ion to th is fact

during wet weather and that you adjust your speed to match road

conditions.

• Replace the flat tire with a new one and have it ins talled on your

vehicle as soon as possible to restore the handling advantages of a

unidi rect ional tire.•

Notes on wheel changing

Please read the information => page 330, "New tires and replacing

tires and wheels" if you are going to use a spare t ire which is different

from the tires on your vehicle.

After you change a tire:

• Check the tire pressure on the spare immediately after installa·

tion .

• Have the wheel bolt tightening torque checked with a torque

wrench as soon as possible by your authorized Audi dealer or a qual ified workshop .

• With steel and alloy wheel rims, the wheel bolts are correctly

tightened at a torque of 120 ft lb (160 Nm).

• If you notice that the wheel bolts are corroded and difficult to

turn while changing a tire, they should be replaced before you check

the tightening torque.

• Replace the flat tire with a new one and have it installed on your

vehicle as soon as possible. Remount the wheel cover.

Until then, drive with extra care and at reduced speeds.

Safety first

& WARNING

• If you are going to equip your vehicle with tires or rims which

differ from those which were factory installed, then be sure to

read the information =>

page 330, "New tires and replacing tires

and wheels".

• Always make sure the damaged wheel or even a flat tire and

the jack and tool kit are properly secured in the luggage compart

ment and are not loose in the passenger compartment.

• In an accident or sudden maneuver they could fly forward,

injuring anyone in the vehicle .

• Always store damaged wheel, jack and tools securely in the

luggage compartment. Otherwise, in an accident or sudden

maneuver they could fly forward, causing injury to passengers in

the vehicle. •

Vehicle care Do-it-yourself service Technical data

Page 353 of 392

____________________________________________ .!:F~u~s~e~s ~a~n~d~b~u~l~b~S ~_J-

• The crank in the fuse cover is used for emergency operation of the

Panoramic slid ing sunroof*. •

Left cockpit fuse assignment

Fig . 26 1 L eft coc kpit : fu se panel w ith p lastic clip

Amps

Fu se panel © (re d )

1 DC/DC converter

5

3 MMI 7,5

6 Lumbar support driver's seat 10

7 Window regulators (left side of vehicle)

35

8 Door control module (left side of vehicle)

15

9 Tire pressure monitoring system

5

Vehicle OP-eration

No. Consume r

10

11

.,

Electronic ignition lock,

power steering column adjustment

Switch module steering column

12 Intelligent power module convenience

Fu se pa nel© {b row n)

3 Seat ventilation (left)

4

5

6

7

8

9

10

Wiper system

Rain sensor

Horn

Intelligen t power module driver

Intelligent power modu le dr iver

(lights left side of vehicle)

Intelligen t power module driver

(lights right side of vehicle)

I nstrument cluster

11 Headlight washer system

12 Diagnostic connector

Fuse panel © {black )

1 Headlight electronic system (left side of vehicle)

2 Adaptive Cruise Control

6 Term

inal 15 (interior)

7 Oil level sensor

8 Diagnostic connector

9 Automatic dipping interior mirror

Vehicle care Do-it-yourself service

Amps

30

10

5

15

30

5

25

30

25

25

10

30

10

10 5

5

5

5

5

iTechnical data

Page 355 of 392

Fuses and bulbs -_______________ __.fWI

No. Consumer

3 CD player, DVD drive

4 MMI

Display

5 Automatic transmission

7 Panoramic sliding sunroof segment

l

8 Panoramic sliding sunroof segment 2

9 Panoramic sliding sunroof sunblind

CD player, DVD drive

11 W

indow regulators (right side of vehicle)

12 Rear air-conditioning controls

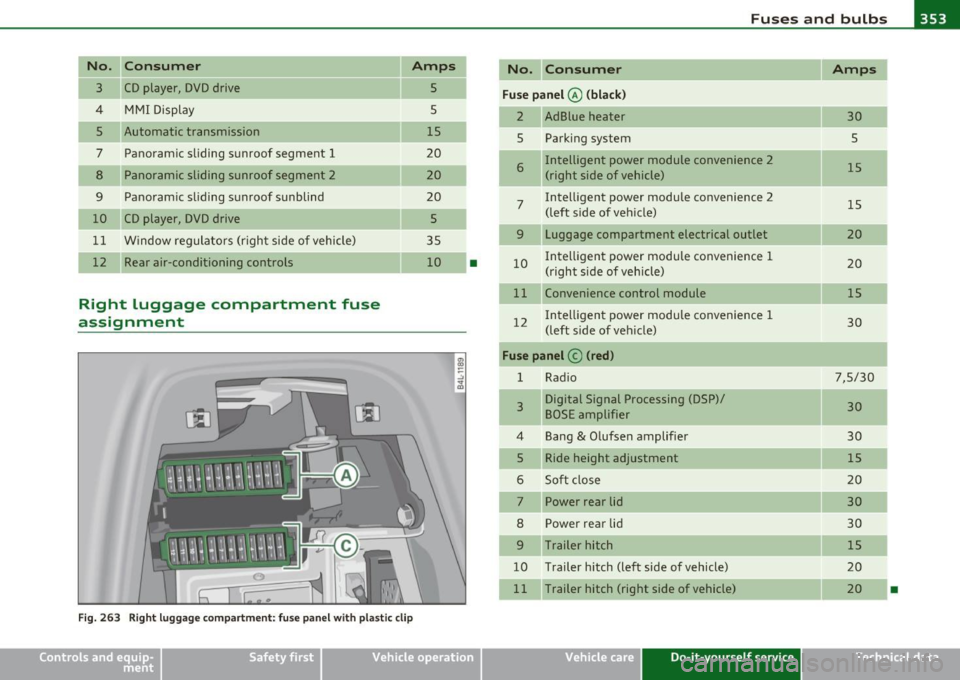

Right luggage compartment fuse

assignment

Amps

5

5

15

20

20

20 5

35 10

Fig. 263 Right luggage compartment: fuse panel with plastic clip

•

"' Q)

-

Vehicle OP-eration

No. Consumer Amps

Fuse panel @ (black)

2 AdBlue heater

30

5 Parking system

5

-

6 Intelligent power module convenience

2

15

(right side of vehicle)

7 Intelligent power module convenience 2

15

(left side of veh icle)

9 Luggage compartment electrical outlet 20

10 I

ntell igent power modu le convenience 1

20

(right side of vehicle)

11 Convenience control module

15

12 I

ntell igent power module convenience 1

30

(left side of veh icle)

Fuse panel © (red)

1 Rad io 7,5/30

3 Digital Signal Processing (DSP)/

30

BOSE amplifier

4 Bang & Olufsen amplifier 30

5 Ride height adjustment

15

6 Soft close 20

7 Power rear lid

30

8 Power rear lid 30

9 Trailer hitch 15

10 Trailer hitch (left side of vehicle)

20

1 1 Trailer hitch (right side of vehicle)

20

•

Vehicle care Do-it-yourself service iTechnical data

Page 357 of 392

Emergency situations --------------=----PfN:t'II

Emergency situations

General

This chapter is intended for trained emergency crew s and working

personnel who ha ve the necessar y tools and equipment to perform

the se operations . •

Starting by pushing or towing

(D Note

Your vehicle is equipped with an a utomat ic transmission. Conse

que ntly, the eng ine can not be started by pushing or towing. •

Starting with jumper cables

If necess ary, the engine can be started by connecting it to

the battery of an other vehicle .

If the engine shou ld fai l to start because of a discharged or weak

battery, the battery can be co nnecte d to the battery of

another

vehicle, using a pair of jumper cable s to start the engine .

Jumper cables

Use only jumpe r cables of suffic iently large cross section to carry t he

sta rter cur ren t safely . Refe r to the manufacture r's specifications.

Use on ly j umper cab les with

insulated te rm ina l clamps w hich are

distinct ly marked :

plus(+) cable in most cases colo red red

minus (-) cable i n most cases colored black.

Safety first

& WARNING

Batterie s contain electricity, acid, and gas . Any of these can cause

very serious or fatal injury . Follow the inst ructions below for safe

handling of your vehicle 's battery .

• Always shield your eyes and avoid leaning over the battery

whenever possible.

• A discharged battery can freeze at temperatures just below

32 °F (0 °C). Before connecting a jumper cable, you must thaw the

frozen battery completely , otherwise it could explode.

• Do not allow battery acid to contact eyes or skin . Flush any

contacted area with water immediately .

• Improper use of a booster battery to start a vehicle may cause

an explosion.

• Vehicle batteries generate e xplos ive gases. Keep spa rks, flame

and lighted cigarettes away from batteries.

• Do not try to jump start any vehicle with a low acid level in the

battery.

• The voltage of the booster battery must also h ave a 12 -Volt

rating. The capacity (Ah) of the booster battery should not be

lower than that of the discharged battery. Use of batter ies of

different voltage or sub stantially different "Ah " rating may cau se

an explosion and personal injury.

• Never charge a frozen battery . Ga s trapped in the ice may cause

an e xplosion.

• Never charge or use a battery that has been frozen. The battery

case may have be weakened.

• Use of batteries of different voltage or substantially different

capacity (Ah ) rating may cause an explosion and injury . The

capacity (Ah ) of the booster battery should not be lower than that

of the discharged battery. _..

Vehicle care Do-it-yourself service Technical data

Page 359 of 392

_____________________________________________ E_ m_ e_r-= g ::.. e_ n_c-= y'- s_ i_t _u _a_ t_ i_ o _ n_ s __ ffl'II

Connect POSITIVE (+) to POSITIVE (+) (red)

- Open the red cover on the posi tive pole~ page 356,

fig . 264.

1. Connect one e nd of the pos itive cable (red) on the

jump

start bolt~

page 356, fig. 265 © (Bolts under red cover

= "positive") of the vehicle to be started @.

2 . Connect the other end to the pos itive terminal @ of the

booster battery ®·

Connect NEGATIVE(-) to NEGATIVE(-)

(black)

3 . Connec t one end to the negative te rmi nal @ of the

booster battery ®·

4. Conn ect t he other end o f the n ega tive cabl e (black) to t he

jump start bolt© (Bolts w it h hex head = "n egat ive") of

the vehic le to be s tarte d

@.

Starting the engine

- Start the engine of t he vehicle w ith the booster battery.

Run the engi ne at a moderate speed.

- Start e ng ine w it h discharged ve hicle battery in the usu al

ma nner .

- If the engine fai ls to star t: do no t ke ep the s tar ter

crank ing for lo nger than 10 secon ds. W ait for abou t

30 seco nds and then t ry again .

- Wi th engine running, remove jum per cable s from bot h

v eh icle s in t he exact

re vers e order.

- C lose the re d cove r on the positive pole.

Safety first

T he battery is vented to the outside to prevent gases from entering

t he ve hicl e inter ior. Make su re t hat t he ju mper clamps are we ll

connected with the ir

metal parts in full contact with the battery

terminals .

& WARNING

To avoid serious per sonal injury and damage to the vehicle, heed

all warnings and instructions of the jumper cable manufacturer . If

in doubt, call for road service .

• Jumper cables must be long enough so that the vehicles do not

tou ch.

• When connecting jumper cables , make sure that they cannot

get caught in any moving part s in the engine compartment .

• Before you che ck anything in the engine compartment , always

read and heed all WARNINGS~

page 290, "Engine compart

ment ".

0 Note

Improper hook-up of j umper cab les can ruin the generator.

• Always co nnect POSITIVE(+) to POSI TIVE(+), and NEGATIV E(- )

to NEGA TIVE( -) ground post of the battery manager cont rol unit.

• Check that all screw p lugs on the battery ce lls are sc rewed in

firmly. If not, tighten p lugs prior to connecting clamp on negative

battery terminal.

• Please note that the proced ure for connecting a jumper cable as

described above applies specifically to t he case of your vehicle being

jump started . When you a re giving a jump start to another vehicle, do

not connect the negative( -) cab le to the nega tive (-) te rm inal on the

discharged battery©~

page 356, fig. 265. Instead, securely

c onne ct the negative (- ) cab le to ei ther a so lid met al componen t th at

is f irm ly bolted to the eng ine b lock or to the eng ine b lock itself. If the

ba ttery tha t is bei ng charged does not ven t to t he ou tside, escap ing

battery gas could ignite and explode! •

Vehicle care Do-it-yourself service Technical data

Page 361 of 392

_____________________________________________ E_ m __ e_r-=g =- e_ n_c -==y "- s_i_ t _u _a _ t_ i_ o _ n_ s _ __._

When it is no longer needed, unscrew the towing loop and put it back

in to the vehicle toolkit. Be sure to have the towing loop stored in the

vehicle at all times .

& WARNING

If the towing loop is not screwed in as far as it will go, the thread

can pull out when the vehicle is towed -potential risk of an

accident. •

Rear towing loop

Do not install the rear towing loop until it is needed.

Fig. 268 Rear

bumper : Cover

Fig. 269 Rear

bumper: Screwing in

towing loop

Vehicle OP-eration

The threaded opening for the towing loop is located behind a

cover on the right side of the rear bumper.

- Remove the towing loop from the vehicle tool kit

=>

page 340.

- To release the cover from the bumper, press it in by

applying short, sharp pressure to the outer part

=> fig . 268.

- Screw the towing loop tightly into the threaded hole as far

as it will go=> fig. 269.

Unscrew the towing loop again after use and install the cover in the

bumper . Return the towing loop to the toolkit. Be sure to have the

towing loop stored in the vehicle at all t imes.

& WARNING

If the towing loop is not screwed in as far as it will go, the thread

can pull out when the vehicle is towed · potential risk of an

accident. •

Loading the vehicle onto a flat bed truck

Fig. 270 Vehicle on

flat bed truck ~

Vehicle care Do-it-yourself service iTechnical data