stop start AUDI R8 SPYDER 2012 Owner's Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2012, Model line: R8 SPYDER, Model: AUDI R8 SPYDER 2012Pages: 236, PDF Size: 59.24 MB

Page 157 of 236

Caring for vehicles with matte finish

paint

Applies to vehicles: with matte finish paint

Vehicles with matte finish paint require spe

cial care due to the characteristics of the

paint.

Automatic car washes

You must take the necessary precautions such

as closi ng the windows before us ing an auto

mat ic car wash. See the ca r wash attendant if

the re is special eq uipment on yo ur vehicle

such as a spoiler or remote cont ro l an tenna

¢ 0 .

Only use ca r was hes where t he vehicle re

mains stationary and the washing eq uipment

moves around the vehicle when washing and

d rying.

It is not possible to use ca r washes

that move the ve hicle through the ca r wash

using a chain

~ .&. .

Only use car w ashes tha t use cloth cleaning

eq uipment, not brushes .

Washing with pressure washers

When washing your ve hicles w ith a pressure

washer, always follow the operating instruc

tions provided w ith the pressure washer. This

i s especially important in rega rd to t he

pre s

sure

and s praying di stance. Be su re to keep

enough distance from soft materials such as

rubber hoses or insulat ing mater ial as we ll as

from the parking system sensors*, wh ich are

loca ted in the front or rear bumper.

Never use

rotary nozzle s or high pre ssure

nozzles .

Washing by hand

To avo id damag ing t he pa int when w ash ing ,

firs t remove d ust and large pa rticles from

your vehicle . Insects, grease spots and finger

p rints a re best removed with a

special cleaner

for matte finish pa int .

Apply the produc t using a mi crofiber cloth . To

avoid damaging the paint surface, do not use

too m uch press ure.

Cleaning and protec tion 155

Rinse the ve hicle thoroughly wi th water. Clean

the ve hicle starting at t he top and working to

ward the bottom using a

neutral shampoo

and a soft microfiber cloth . Stop frequent ly to

rinse the cloth thoroughly.

Clean the wheels and si ll pane ls last. Use a

clean

sponge on these areas.

R inse t he ve hicle thoroughly again and le t it

air dry. If there are any water spots, they can

be removed using a

leathe r cloth.

Clean again with the spe cial cleaner for matte

finish paint

if necessary .

Removing stubborn dirt

Bird droppings or tre e sap

are best remov ed

with plenty of wate r and a microfiber cloth .

You should rinse off

gasoline res idue immed i

ate ly w ith plenty of water .

_& WARNING

-Wash your vehicle only whe n the ignition

is switched off to red uce the risk of a

cras h.

- To reduce the risk of c utting yourse lf,

protect your hands and a rms fro m meta l

pa rt s wi th sha rp edges when clea ning

the underbody, the ins ide of the whee l

housings or the whee l covers .

- If washing your ve hicle dur ing the win

ter, mois ture and i ce in the brake system

can affect the vehicle 's braking ab ility .

(D Note

-Do not treat veh icle parts pain te d wi th

m att e fini sh paint u sing pol ishing m ate

r ia ls or hard wax. These p rod ucts cou ld

cause damage to the appearance o r sur

face that cannot be repaired .

- N ever use protective wax . It ca n destroy

the matte finish effect.

- Do not pla ce an y s tickers or magnetic

signs on vehi cle pa rts painted with

matte finish paint. The paint could be

damaged when the stickers or magnets

are removed.

•

•

Page 203 of 236

soon as possible, and inflate them to the

proper pressure . Driving on a significant ly un

der-inflated tire causes the tire to overheat

and can lead to tire failure. Under-inflation a l

so reduces fuel efficiency and tire tread l ife,

and may affect the veh icle 's handling and

stopping ab ility.

Please note that the TPMS is not a substitute

for proper t ire maintenance, and it is the dr iv

er's responsib ility to ma inta in correct t ire

p ress ure , even if under- inflation has not

reached the leve l to t rigger illumination of the

TPMS low tire pressure telltale .

Your veh icle has also been equ ipped with a

TPMS malfunction indicato r to indicate when

the system is not ope rating properly. The

TPMS malfunc tion indica to r i s combined wi th

the low t ire pr essu re tellta le. When the sys

tem detec ts a ma lf u nct ion, the te lltale will

flash for approximately one minute and then remain continuo usly ill uminated . This se

q uence will continue upon subsequent vehicle

start-ups as long as the malfunction ex ists.

When the malfunction indicator is ill uminat

ed, the system may not be able to detect or

signa l low t ire pressure as intended . TPMS

malfunct ions may occ ur for a variety of rea

sons, including the ins talla tio n of replace

ment or a lternate tires o r whee ls on the veh i

cle that prevent the TPMS from funct io ni ng

p roperly . Always check the TPMS malfunct ion

t ellta le afte r replacing one o r more t ires or

wheels o n your veh icle to ensure tha t the re

p lacemen t or a lternate tires and wheels allow

the TPMS to continue to function properly .

Introduction

The tire pressure monitoring system monitors

air pressure in all four road wheels while the

vehicle is moving .

As soon as the tire pressu re mo nitor ing sys

tem senses a s ignificant loss of a ir pressure in

one or severa l ti res, text messages and yellow

symbo ls appear in the instr ument cluster dis

p lay to alert the driver. The

[ti warning light

Tire s an d wheel s 201

in the instrument cluster comes on when the

ti re is significant ly underinflated .

T he wa rni ng lig ht

[ti also illu minates i n the

case of a system mal funct io n.

Be aware that t ire pressure is a lso dependent

o n the tempe ratu re of the t ire. For eve ry 18 ° F

(10 °C) incre ase in tir e te mper ature, tire pres

s u re inc reases by about 1.5 psi (0 .1 bar). The

ti re warms up while the ve hicle is moving and

tire p ress ure rises . So you sho uld ad just tire

pressure only when they a re

cold, when the

temperature of the tires is ro ughly the same

as the ambient a ir temperature.

In order to keep the tire press ure monito ring

system p roperly ca librated, t ire press ure on

all four tires sho uld be checked at regu lar in

terva ls.

The tire pressure is shown on the label located

on the dr iver's side B-pillar (v is ib le when the

door is open) .

A WARNING

When the tire pressure mo nitoring system

war ning light is lit , one o r m ore of your

tires is s ignificantly under-infla ted . You

shou ld stop and check your tires as soon as

pos sib le, and in flate t hem to the proper

p ress ure a s in dic ate d on the ve hicle's ti re

p ress ure lab el

¢page 187. Driving on a

significantly under -inflated ti re causes t he

tire to over heat and can lead to tire failure .

Under-inflat ion also is like ly to impair the

vehicle's handling and stopping ab ility.

@ For the sake of the environment

D riving wit h un der -inflated tires red uces

fuel efficiency an d tire t read life.

(D Tips

- E ach tire should be chec ked monthly

w hen the tem perature of the tires is

about the same as amb ient a ir tempera

t u re and set to the recommended infla

tion press ure as specified on the tire

pressure label¢

page 187.

•

•

Page 208 of 236

206 What do I do now?

• Switch the electric air pump off -switch in

position

0. If the required tire pressure of at

l east 1.8 bar has not been reached, it is not

poss ible to make a repa ir with the tire seal

ant. Seek professional ass istance.

Disassembling Tire Mobility System

• Remove the hose from the valve and pull

the p lug out of the socket .

• Screw the dust cap onto the valve.

• Place the empty sealant bottle back in the

original packaging and clip it in place under

the floor so that no tire sealant can run out into the vehicle .

• Start driving r ight away so that the sealant

is distributed in the tire.

.&_ WARNING

- Follow the manufactur er's safety instruc

tions on the decal for the air pump and

the sea lant bott le .

- If a tire pressure of 1.8 bar cannot be

achieved after pumping for 5 minutes,

the tire is too severely damaged. Do not continue to drive.

- Seek professional assistance if it is not

possible to repair the tire with the tire

sealant.

(D Tips

- Do not operate the electric air pump for

more than 8 min utes without stopping,

otherwise it can overheat. When the air

pump has cooled down, you can continue

to use it.

- If sealant has escaped, allow it to dry,

then you can peel it off.

Final check

After driving for a short distance, t ire pressure

must be checked .

• After driving for about 10 minutes, stop

and check the t ire pressure .

• If tire pressure is still at least 1.3 bar, in

flate the tire to specified p ressure (see driv

er's side B-pillar), drive to the next repair shop and have the tire and the sealant

bot

tle replaced.

• If tire pressure is less than 1.3 bar, the t ire

is too severely damaged. Do not continue to

drive. Seek professional assistance.

.&_ WARNING

If tire pressure is less than 1.3 bar after

driving for 10 minutes, the tire is too se

ve rely damaged. Do not continue to drive.

Seek professional assistance.

(D Tips

After a tire repair, have the sealant bottle

replaced at a dealership. This restores full

functionality to the Tire Mobility System .

What should I be

aware of when

changing a tire?

Tires with unidirectional tread design

-

Tires with unidirectional tread design must be

mounted with their tread pattern pointed the

right direction.

A unidirectional tire can be identified by ar

rows on the sidewall, which point in the direc

tion of the rotation. You must follow the

specified direction of rotation. This is necessa

ry in order for these tires to develop their op

timum characteristics regarding grip, road

noise, wear, and hydroplaning .

· Anti-theft wheel bolts

A special adopter is needed to turn the anti

theft wheel bolts.

Fig . 156 A nti-theft wheel bolts wit h adapte r

Page 213 of 236

Use of jumper cables

Make sure to connect the jumper cable

clamps in exactly the order described below'

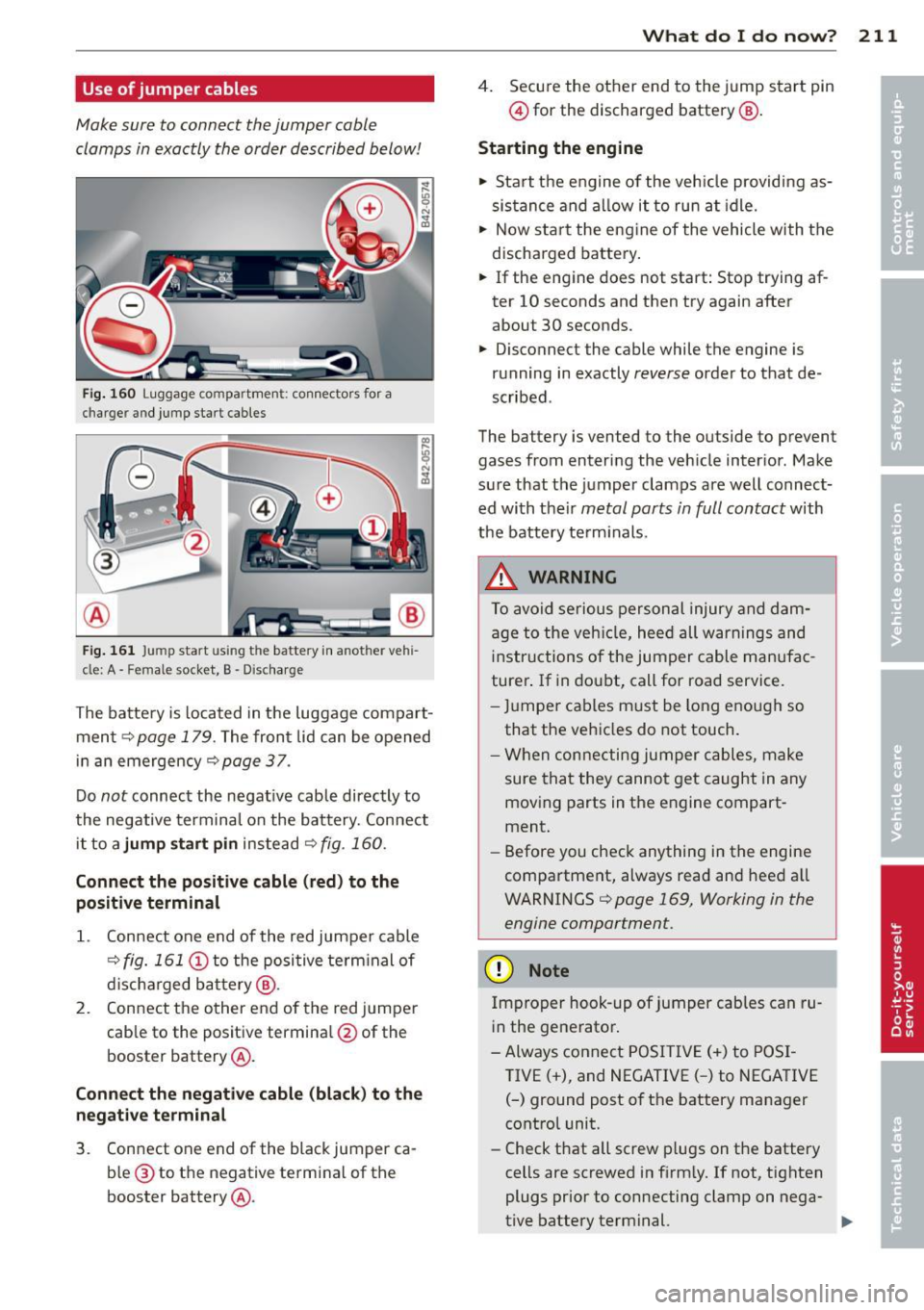

Fig . 160 Luggage co m pa rtme nt: connec tor s for a

ch arge r and jump start cab les

F ig . 161 Ju m p sta rt usin g t he batte ry in a not her ve hi

cl e:

A -Fem ale so cket , B · Di scharge

The batte ry is located in the luggage compart

ment

¢ page 179. The front lid can be opened

in an emergency

~page 37.

Do not connect the negat ive cable directly to

the negative termina l on the battery. Connect

it to a

j u mp start pin instead ¢ fig. 160.

Connect the posi tive cable (red) to the

positive t ermin al

1. Connect one end of the red jumper cable

¢ fig. 161 (D to the positive te rm inal of

d isc harged battery @.

2. Connect the other end of the red jumper

cable to the positive termina l@ of the

booster battery @.

Conn ect the negat ive cable (black ) to the

negati ve t erminal

3. Connect one end of the black jumper ca

b le @ to the negative terminal of the

booster battery @.

What do I d o now ? 211

4. Secu re the other end to the jump start pin

@ for the discharged battery @.

Starting the engine

~ Sta rt the engine of the veh icle providing as

sistance and al low it to run at idle.

~ Now sta rt the eng ine of the vehicle with the

discharged battery .

~ If the engine does not start: Stop trying af

ter 10 seconds and then try again after

about 30 seconds.

~ Disconnect the cable while the engine is

running in exactly

reverse order to that de

scribed .

The ba ttery is vented to the ou tside to prevent

gases from entering the veh icle inter ior . Make

sure that the jumper clamps are well connect

ed with their

metal parts in full contact with

the battery term inals .

.&, WARNING

To avoid serious person al injury and dam

age to the veh icle, heed all warnings and

instructions o f the jumper cable manufac

turer . If in doubt , call for road service.

- Ju mper cables m ust be long enough so

that the vehicles do not touch.

- When connecting jumper cables, make

sure that they canno t get caught in any

mov ing parts in the engine compart

ment.

- Before you check anything in the engine

compartment, always read and heed a ll

WARNINGS

¢ page 169, Working in the

engine compartment.

(D Note

Improper hook-up of jumper cables can ru

in the generator .

- Always co nnect POSITIVE(+) to POSI

TIVE(+), and NEGATIVE( -) to NEGATIVE

( - ) ground post of the battery manager

control unit.

- Check that all screw p lugs on the battery

cells are screwed in firm ly. If not, tighten

plugs prior to connecting clamp on nega-

-

tive battery term inal. .,..

Page 228 of 236

226 Index

Eng ine

Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . 17 5

Eng ine compartment lid ... .. .. .... . 170

Starting . . . . . . . . . . . . . . . . . . . . . . 70, 71

Stopping . . . . . . . . . . . . . . . . . . . . . . . . . . 72

E ng ine compartment .. ... .. .. ... ... . 17 1

Safety instructions ..... ... .. .. .... . 169

E ng ine compartment lid

C losing ...... ........... .. .. .... . 170

Release lever .......... .. .. .. .. .. . 170

Eng inecoolantsystem ............... 175

Malfunct io n .................. ..... 15

Tempe ratu re ga uge .................. 9

Eng ine data ........................ 217

E ng ine oil ... .. . .. ..... ... .. .. .... . 17 2

Adding ..... .. .. ..... ... .. .. .... . 174

Additives ... ... . ...... ... .. .. .... . 174

Check ing the eng ine o il level . . . . . . . . . 17 4

Dry sump lubrication ............... 149

Indications and condit ions req uiring ex-

tra check ing . . . . . . . . . . . . . . . . . . . . . . 17 4

o·t t· 1 consump 10n .... ...... .. .. .. .. . 173

O il grades .. .......... ...... ... .. . 172

Specif ication and vi scos ity ... ... .. .. . 17 2

T empe ratu re d ispl ay ................. 8

Eng ine oil level ................. ..... 18

Engine oi l pressure (malfunction) ... .. . . 14

E ng ine o il sensor defective .. .. .. .. .. . . 18

Eng ine speed limitat ion ..... .. .. .... .. 17

E nvi ronment

Cata lytic conve rter ..... ... .. .. .... . 150

Fu el . .. .... ... . ...... ... .. .. .... . 166

Un leaded fuel .............. .. .... . 164

E PC

refer to Electronic power control . . . . . . 17

ESC (Elec tronic S tability Control)

War ning/ indica to r lights ....... .. .... 16

Event Data Recorder ( EDR) ... .... .... . 142

E xha ust tail p ipes

C leaning .... .. .. ..... ... .. .. .... . 15 8

E xp ansion ta nk .. .... ...... .. .. .. .. . 176

E xterior mirrors

Ad justing .. .. . .......... .. .. .... .. 57

o· . 1mming ... ............... ...... .. 56

H eating .. ................. ...... .. 57

F

Fan ... ... .. .... .. ... .. .. ..... ... .. . 67

Fasten ing

Boos ter seats .. .. .. ........ ...... . 137

Co nvertib le child safety seats ........ 136

Infan t se ats ... .. ... .......... .... 135

Flat bed truck ..... .......... ....... 212

Flat tire Changi ng ..... .. .... ...... ... .. .. 206

Floo r ma ts . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Folding top

Care and cleaning . ................. 156

Foot peda ls ..... .. .. ... ..... ... .. .. . 96

F o r th e sake of the envi ronment

Gasoline fumes and the e nvir onme nt .. 166

L etting your eng ine warm up . ... .. .. . 71

Ref ueling ..... .. .. ... ..... ... .. .. 166

Front a irbags

Des cription .. .. .. ... .......... .. .. 113

How they wor k ................ .... 118

Frontal collis io ns and the laws of phys ics 103

Front lid

Emergency release .. ... ..... ... .. .. . 37

light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Power locking system .......... ..... 37

Trunk escape handle ... ....... ... .. 203

F ront passenger

refer to Seating position . . . . . . . . . 92, 93

F ron t seats . . . . . . . . . . . . . . . . . . . . . . . . . 59

Childrest rain tsinthefrontseat ......

111

Front towing loop .................. . 212

Fuel Additives ......................... 164

B lended gaso line .............. .... 164

Current fuel mileage ................ 24

Filler neck ... .. .. .. ... ....... ... .. 16S

Fuel supply too low . . . . . . . . . . . . . . . . . 18

Gasoli ne addit ives ................ . 165

O ctane rat ing .. .. ... .......... .... 164

Recommendation .............. .. .. 164

Ref ueling ..... .. ... .. ..... .... . .. 166

Reserve ... .... .. .. ... ..... ... .. .. . 10

Tank capac ity .... ... .. ..... ... .. .. 217

Unlocking the fuel fi ller flap by hand .. 167

F uel gauge . .. .. .. ............. .... . 10

Fuel range . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Page 232 of 236

230 Index

Safety belt position Safety belts worn by pregnant women 106

Safety belt pretens io ner

Service and disposal .... .. .. .. .. .. . 107

Safety belts Cleaning . .. .......... ...... ... .. . 162

Danger to passengers who do not wear a

safety belt ............ .. .. .. .. .. . 104

F astening .... ........... .. .. .... . 104

General notes ............ .. .. .. .. . 101

I mproperly worn .......... ... .... . 106

Not worn . . . . . . . . . . . . . . . . . . . . . . . . 104

Pretensioners ................ .... . 107

Safety belt position . . . . . . . . . . . . . . . . 105

Safety instructions . . . . . . . . . . . . . . . . . 102

Securing child safety seats ....... .. . 138

Special cons iderations for pregnant

women .. .. ................ ... ... 106

Unfasten ing ........... .. .. .. .. .. . 106

Warn ing/ indicato r light ...... .. .... . 101

Why you must wear them .. .. .. .. .. . 102

Worn properly ............ ... .... . 102

Safety belt warn ing light ........ .. .. .. 14

Safety compliance sticker ..... .. .. .. . 215

Safety equipment ........ .. .. .. .. .. .. 91

Safety features for occupant restraint and protection . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Safety guidelines Seat adjustment . . . . . . . . . . . . . . . . . . . . 59

Safety instructions For using chi ld safety seats .......... 133

F or using safety belts .............. 102

Monitoring the Advanced Airbag Sys-

tem ... .. ................. .. .... . 122

Seat adjustment Driver's seat . . . . . . . . . . . . . . . . . . . . . . . 59

Fr ont passenger's seat . . . . . . . . . . . . . . . 60

Front seats . . . . . . . . . . . . . . . . . . . . . . . . 59

Head restraints . . . . . . . . . . . . . . . . . . . . 94

Power seats . . . . . . . . . . . . . . . . . . . . . . . 60

Safety guidelines ..... .... .. .. .. .. .. 59

Seating capacity ............ ... .... . 101

Seating position

Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Fr ont passenger . . . . . . . . . . . . . . . . . . . . 93

I ncorrect seat position . . . . . . . . . . . . . . . 95 Seats

Number of seats

101

Selector lever

Defective ... .. .. ............. .. .. . 19

Serv ice

Airbag system ... ..... ........... . 122

Service and disposal Safety be lt pretensioner ........ .... 107

Serv ice interval display . . . . . . . . . . . . . . . . 22

Service position for windshield wipers .. . 55

Set menu ....... .. ................ .. 26

Setting the t ime ... ... .......... .. .. .. 9

Side airbags Descrip tion .... .. ... .......... .. .. 127

How they work . .. .......... ...... . 128

Side marker lights ................. .. 49

Snow cha ins .. .. . .. ............ .. .. 198

Socket . .... .... ................... . 62

Sound system display ................. 21

Sources of information about child re-

stra ints and their use . ........... .. .. 141

Speedometer . . . . . . . . . . . . . . . . . . . . . . . 10

Speed rating letter code .............. 194

Speed warning system . . . . . . . . . . . . . . . . 29

Spoi ler ............................ 144

Starting on hills

Hill hold assist ... ............. .... . 73

Starting the engine . . . . . . . . . . . . . . . . . . 70

Steering column Adjusting ..... .. ............. .... . 70

Locking the steering . . . . . . . . . . . . . . . . 70

Steps for determining correct load limit . 191

Stopping the eng ine ..... ........... .. 72

Storage ... ..... .. .. .............. .. 62

Sun visors .. .. .. .. .... ......... .... . 53

Symbols Red symbols in the center display ...... 11

Yellow symbols in the center display .. . 12

also refer to Warning/Indicator lights .. 11

T

Tachometer . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Tank flap Unlocking the fuel filler flap by hand .. 167

T echnical modifications ........ .. .. .. 221