engine AUDI S3 2009 Owners Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2009, Model line: S3, Model: AUDI S3 2009Pages: 324, PDF Size: 76.02 MB

Page 272 of 324

1111...__W_ h_ a _ t_d_ o_ l _d _o_ n_ o_ vv_ ? ______________________________________________ _

What do I do now?

Jack, tools and spare wheel

Jack and tools

The tools and jack are stored underneath the floor panel

in the luggage compartment.

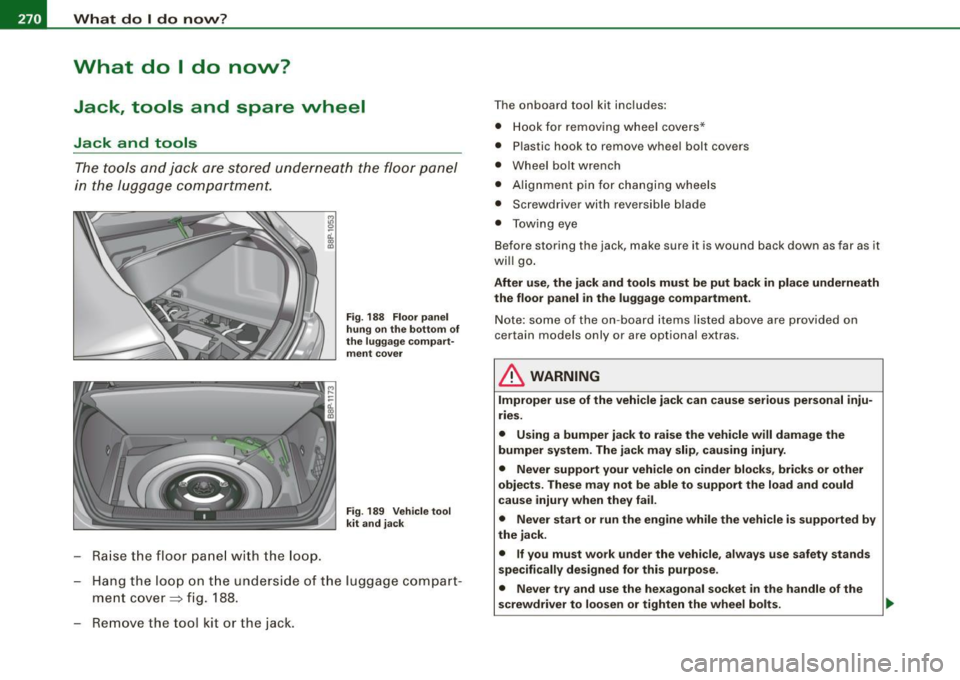

Raise the floor panel with the loop.

Fig. 188 Floor panel

hung on the bottom of

the luggage compart

ment cover

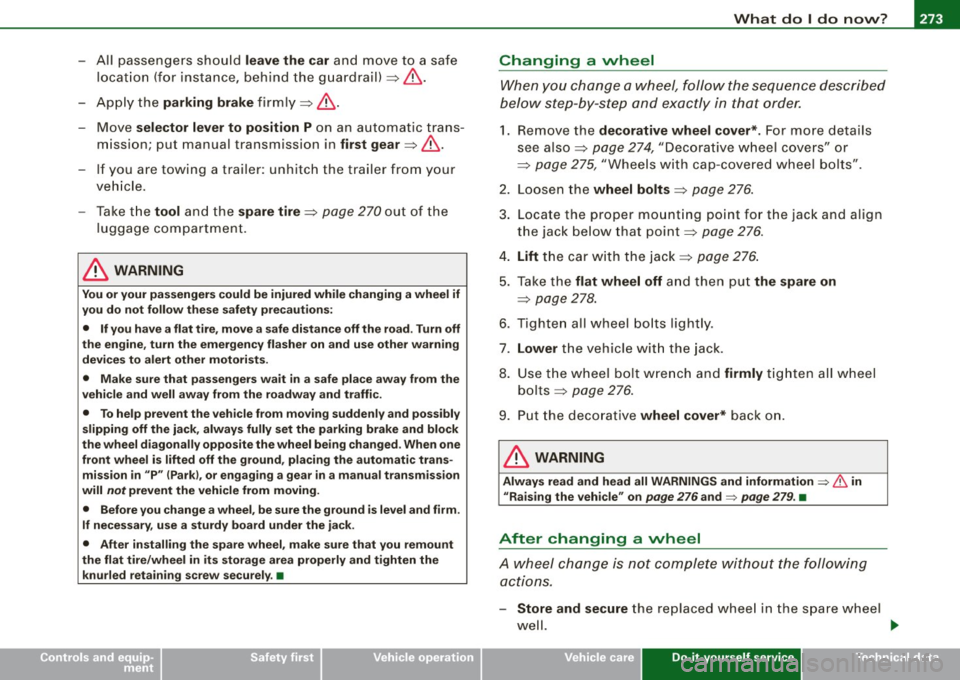

Fig . 189 Vehicle tool

kit and jack

- Hang the loop on the underside of the luggage compart

ment cover ~ fig. 188.

Remove the tool kit or the jack.

The onboard tool kit includes:

• Hook for removing wheel covers*

• Plasti c hook to remove wheel bolt covers

• Wheel bolt wrench

• Alignment pin for changing wheels

• Screwdriver with reversible blade

• Towing eye

Before storing the jack, make sure it is wound back down as far as it

will go.

After use, the jack and tools must be put back in place underneath

the floor panel in the luggage compartment.

Note: some of the on-board items listed above are provided on

certain models only or are optional extras.

& WARNING

Improper use of the vehicle jack can cause serious personal inju

ries.

• Using a bumper jack to raise the vehicle will damage the

bumper system. The jack may slip, causing injury.

• Never support your vehicle on cinder blocks, bricks or other

objects. These may not be able to support the load and could

cause injury when they fail.

• Never start or run the engine while the vehicle is supported by

the jack.

• If you must work under the vehicle, always use safety stands

specifically designed for this purpose.

• Never try and use the hexagonal socket

in the handle of the

screwdriver to loosen or tighten the wheel bolts.

Page 275 of 324

What do I do now? -__________________ __;__:....:....:..:: __ _

•

-All passengers should leave the car and move to a safe

location (for instance, behind the guardrail)~& .

- Apply the

parking brake firmly ~& .

- Move

selector lever to position Pon an automatic trans-

miss ion; put manual transmission in

first gear ~& .

-If you are towing a trailer : unhitch the trailer from your

vehicle.

- Take the

tool and the spare tire~ page 270 out of the

luggage compartment.

& WARNING

You or your passengers could be injured while changing a wheel if

you do not follow these safety precautions:

• If you have a flat tire, move a safe distance off the road. Turn off

the engine, turn the emergency flasher on and use other warning

devices to alert other motorists.

• Make sure that passengers wait

in a safe place away from the

vehicle and well away from the roadway and traffic.

• To help prevent the vehicle from moving suddenly and possibly

slipping off the jack, always fully set the parking brake and block

the wheel diagonally opposite the wheel being changed. When one

front wheel is lifted off the ground, placing the automatic trans

mission in "P" (Park), or engaging a gear in a manual transmission

will

not prevent the vehicle from moving.

• Before you change a wheel, be sure the ground is level and firm.

If necessary, use a sturdy board under the jack.

• After installing the spare wheel, make sure that you remount

the flat tire/wheel in its storage area properly and tighten the

knurled retaining screw securely. •

Changing a wheel

When you change a wheel, follow the sequence described

below step-by-step and exactly in that order.

1. Remove the decorative wheel cover*. For more details

see also

~ page 274, "Decorative wheel covers" or

~ page 275, "Wheels with cap-covered wheel bolts".

2. Loosen the

wheel bolts ~ page 276.

3. Locate the proper mounting point for the jack and align the jack below that point~

page 276.

4. Lift the car with the jack~ page 276.

5. Take the flat wheel off and then put the spare on

~ page 278.

6. Tighten all wheel bolts lightly .

7.

Lower the vehicle with the jack .

8. Use the wheel bolt wrench and

firmly tighten all wheel

bolts

~ page 276.

9. Put the decorative wheel cover* back on.

& WARNING

Always read and head all WARNINGS and information ::} & in

"Raising the vehicle" on

page 276 and ~ page 279. •

After changing a wheel

A wheel change is not complete without the following

actions.

- Store and secure the replaced wheel in the spare wheel

well. .,._

Do-it-yourself service

Page 282 of 324

1111...__F_ u_ s_ e_s _ a_n _ d_ b_ u_lb _ s _______________________________________________ _

Fuses and bulbs

Fuses

Replacing a fuse

A problem in the electrical system may be caused by a

blown fuse.

Fig . 199 End face of

instrument panel:

removing cover plate

to access fuses

Fig .

200 Left side of

engine compartment :

fuse cover

Fuse cover on the left end face of the instrument

panel

- Switch off the ignition and the electrical component

affected. - Carefully pry the fuse cover off the instrument panel

using the ignition key or a screwdriver~ fig. 199.

- Check the fuse listing on the next pages to find out which fuse belongs to the component which has failed

~ page 281, "Fuse Locatio n, Instrument Panel left".

- Remove the blown fuse with the plastic clip provided.

The clip is located on the holder in the fuse box.

- Replace a blown fuse (recognizable by the melted metal

strip inside) w ith a fuse of the same amperage .

- Firmly snap the cover back onto the instrument panel

face.

Fuse cover in engine compartment

- Switch the ignition and the affected consumer off.

- Unlatch the fuse cover, push the two slides forward

~ fig. 200.

- Find out which fuse belongs to the equipment which

stopped working~ page 283, "Fuse location, left side of

engine compartment".

- Remove the plastic from its reta iner in the fuse box cover

(left face end of the instrument panel), place it on the

fuse in question and pull it out.

- If the fuse is burned out (recognizable by melted strips of

metal), replace it with a new fuse of the same rating.

- Replace the fuse cover.

- Push the two slides to the rear~ fig. 200. Install the fuse

cover carefully to prevent water from entering.

~

Page 284 of 324

11111.___F_ u_ s _ e_s _ a_n _ d_ b_ u_lb _ s _______________________________________________ _

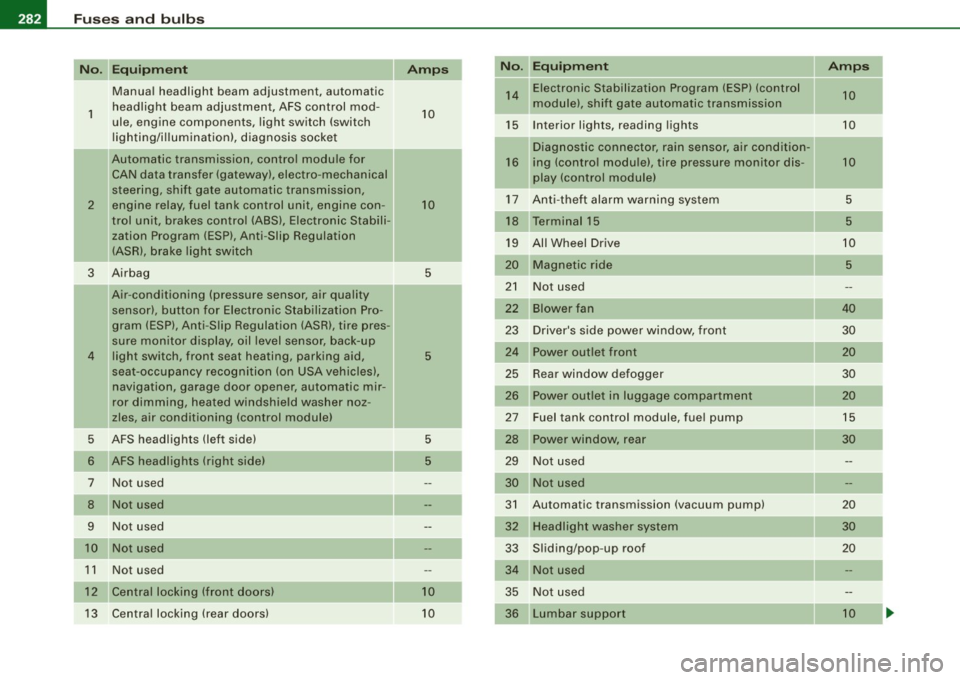

Equipment Amps No. Equipment Amps

Manual headlight beam adjustment, automatic 14 Electronic Stabilization Program (ESP) (control

10

1 headlight beam adjustment, AFS control mod-

10 module),

shift gate automatic transmission

ule, engine components, light switch (switch

15 Interior lights, reading lights 10

lighting/illumination), diagnosis socket

Diagnostic connector, rain sensor, a ir condit ion-

!! Automatic transmission, control module for

16 ing (control module), tire pressure monitor dis- 10

CAN data transfer (gateway), electro -mechanical

play (control module)

steering, shift gate automatic transmission, 17 Anti-theft alarm warning system 5

2 engine relay, fuel tank control unit, engine con

-10

trol unit, brakes control (ABS), Electronic Stabili- 18 Terminal 15

5

zation Program (ESP), Anti -Slip Regulation

19 All Wheel Drive

10

(ASR), brake light switch

-20 Magnetic ride 5

3 Airbag

5

-21 Not used

Air -conditioning (pressure sensor, air quality

sensor), button for Electronic Stabilization Pro- 22

Blower fan 40

gram (ESP), Anti -Slip Regulat ion (ASRl, tire pres -

23 Driver's side power window, front 30

sure mon itor display, oil level sensor, back-up

4 light switch, front seat heating, parking aid, 5 24 Power outlet front

20

seat-occupancy recognition (on USA vehicles), 25 Rear window defogger 30

navigation, garage door opener, automatic mir- 26 Power outlet in luggage compartment 20

ror dimming, heated windshield washer noz-

zles, air conditioning (control module) 27 Fuel tank control module, fuel pump 15

5 AFS headlights (left side)

5 28 Power

window, rear

30

6 AFS headlights (r ight side) 5 29 Not used

7 Not used 30 Not used

8 Not used 31 Automatic transmission (vacuum pump)

20

9 Not used 32 Headlight washer system 30

10 Not used

33 Sliding/pop-up roof

20

1 1 Not used 34 Not used

12 Central locking (front doors} 10 35 Not used

13 Central locking (rear doors) 10

36 Lumbar

support 10

Page 285 of 324

_________________________________________________ F_ u_ s_ e_s _ a_n _d_ b_ u _ lb_ s _ __.ffllll

No . Equipm ent

37 Heated seats, front

38 Passe nger s ide power window, front

39 Special function interface

Starter

41 Rear window wiper

42 Windshield wiper (washer pump)

43 Convenience electronics (control module)

44 Trailer control module

45 Trailer control module

Not used

47 Cell phone package (VOA interface)

48 Not used

49 Not used

Au tom atic cir cuit br eake rs: Amps

20

30

5

40

15

15

20

20

15

5

The electric power windows and the electric seat adjusters are protected with circuit breakers which reset automatically after the

circu it overload has been corrected.

[ i J Tip s

• Whenever replacing a fuse, always consult the sticker on the

inside of the fuse panel cover. It contains the most up-to-date infor

mation regarding the fuse arrangement. If in doubt, ask your autho

rized Audi Service advisor.

• Some of the equipment items listed are optiona l or on ly avail

able on certain model configurations. •

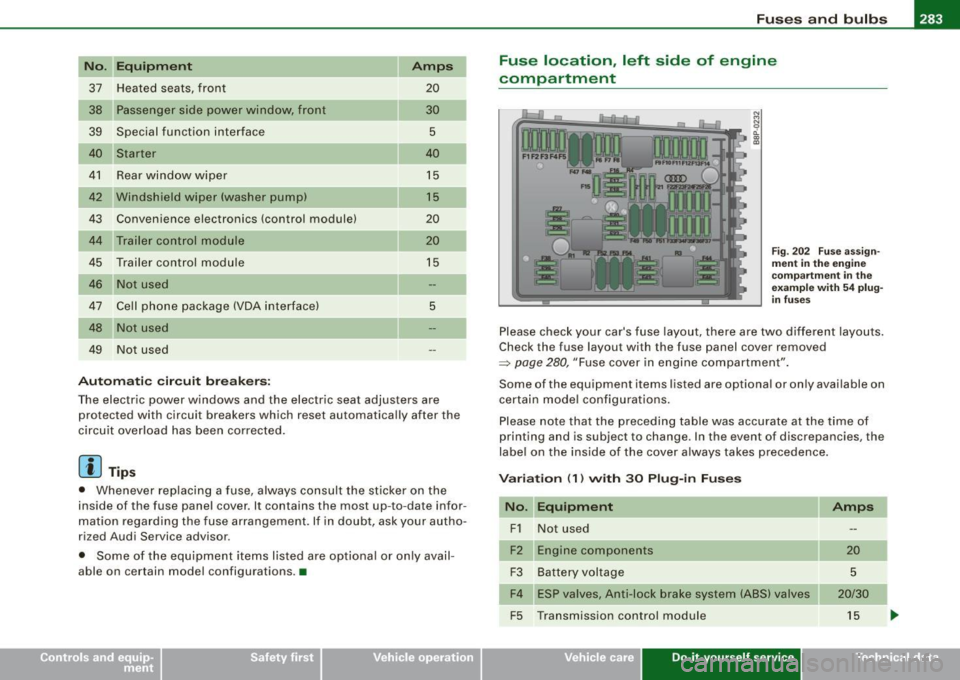

Fuse location , left side of engine

compartment

N M N

~ (X) 0)

Fig . 202 F use ass ign

m ent in th e e ngin e

co mpar tment in th e

e xampl e wit h

54 p lu g

in fu ses

Please check your car's fuse layout, there are two different layouts.

Check the fuse layout with the fuse panel cover removed

~ page 280, "Fuse cover in engine compartment" .

Some of the equipment items listed are optional or on ly available on

certain model configurations.

Please note that the preceding table was accurate at the time of

printing and is subject to change . In the event of discrepancies, the

label on the inside of the cover a lways takes precedence.

V ariation (1 ) with 30 Plu g-in F uses

No . Equipm ent

F1 Not used

Engine components

F3 Battery voltage

F4 ESP v alves, Anti -lock brake system (ABS) valves

F5 Transmission control module

Vehicle care Do-it-yourself service

Amps

20

5

20/30

15

Technical data

Page 286 of 324

IIJII Fuses and bulbs i,.__....;,___;:,,;_,;,,.:_;__;;:_.:.:..:..=-=;____ ______________________ _

No. UEquipment Amps I No. Equipment Amps

F6 Steering wheel electronics, instrument cluster

5 F28

Not used

F7 Transmission control module 30 Fuse assignment in the left-side instrument

F29 50

F8 Navigation system, radio system 15/25 panel (special equipment)

Navigation system, digital radio, cell phone, TV F30 Power supply relay terminal

15 50

F9 equipment 5

F10 Engine control module, main relay 5/10 Variation

(2) with 54 Plug-in Fuses

F11 Not used No. Equipment

Amps

Control module for CAN data transfer (gateway) 5 F1

Vehicle

electrical system control unit (right)

30

F13 Engine control module 15/25 F2

ESP valves, Anti

-lock brake system (ABS) valves

20/30

F14 Ignition coils 20 F3 Not used

F15 Tank diagnosis, oxygen sensor 5/10 F4

Battery voltage

5

F16 Vehicle electrical system control unit (right) 30 F5 Horn

15

F17 Horn

15 F6 Engine components, fuel pump 15

F18 Audio amplifier 30 F7

Not used

F19 Front windshield wiper system 30 F8

Not used

F20 Water return

-flow pump, volume regulator valve F9 Engine components

10

F21 Oxygen sensor, vacuum pump 15 F10

Fuel tank control, mass air flow sensor

10

F22 Clutch pedal switch, brake light switch 5 F11 Oxygen sensors, in front of catalytic converter 10

F23 Engine relays, engine components

5/10/15 F12 Oxygen sensors, behind catalytic converter

10

F24 Engine components, water return-flow pump 10 F13 Automatic transmission

15

F25 Pump (ESP/ABS), ABS valve 30/40 F14 Not used

F26 Vehicle electrical system control unit (left)

30 F15 Water return-flow pump

10

F27 Secondary air pump 40 F16 Volume control valve

20

F17 Steering wheel electronics, instrument cluster

5

F18 Audio amplifier 30

F19 Navigation system, radio system 15/25

Page 287 of 324

_________________________________________________ F_ u_ s_ e_s _ a_n _ d_ b_ u_lb _ s __ ffllll

N "E .

o . qu1pm ent Amps I No. Equ ipment Amps

F20 Navigation system, digital radio, cell phone, TV

5 F44 Not used

equipm ent

F45 Not used

-

F21 Not used F46 Not used

Not used F47 Left-side lighting (electric system control unit)

30

F23 Engine control module, main re lay 10

Pump (ESP/ABS), ABS valve, Anti-lock brake sys-

F48 30/40

F24 Control module for CAN data transfer (gateway) 5 tern (ABS) valves

F25 Not used F49

Not used

Not us ed Not used

F27 Not used F51 Secondary air pump 40

Engine control module 15/25 F52 Power supply relay terminal 15 50

F29 Engine relays, eng ine components 5

F53 Fuse assign

ment in the left -side instrument

50

F30 Not used panel (special equipment)

F3 1 F

ront windshield wiper system

30

F54 Not use d •

F32 Not us ed

F33 Not used

Bulbs

F3 4 Not used

F35 Not used

Replacing light bulbs

F36 Not used F or your safety, we recommend that you have your autho -

rized Audi dealer replace burned out bulbs for you.

Not used

F37

F38 Eng ine components, ta nk diag nosis 10 It is becom ing increasingly more and more difficult to replace

vehic le light bu lbs since in many cases, other parts of the car must

F39 Clutch pedal switch, brake light switch 5 first be removed before you are able to get to the bulb . This applies

F40 Ignition coils 20 especia lly to the light bu lbs i n the front of your car which you can

only reach through the engine compartment .

F41 Not used

F42 Not used Sheet meta

l and bulb holders can have sharp edges t hat ca n cause

serious cuts, and parts must be correctly taken apart and then prop -

F43 Ignit ion coils 30 erly put back together

to he lp prevent breakage of parts and long

...

• Do-it -yourself service

Page 288 of 324

1111.___F_ u_ s _ e_s _ a_n _ d_ b_ u_lb _ s _______________________________________________ _

term damage from water that can enter housin gs that have not

b ee n prope rly resea le d.

For your safety , we r eco mmend that you have your authoriz ed Audi

dea ler rep lace any bu lbs for yo u, since you r dea le r has the p roper

to ols, t he corr ect b ulbs a nd t he e xp er tis e .

Gas discharge lamps (Xenon lights}* :

Due to th e h igh e lec trica l v o lt age, ha ve the b ulb s rep lace d by a qual

ified technician . Headlights with Xenon light can b e identified by the

hig h vo ltage stic ker .

& WARNING

Contact with high-voltage components of the electrical system

and improper replacement of gas d ischarge (Xenon } headlight

bulbs can cause serious personal injury and death.

• Xenon bulbs are pressurized and can explode when being

changed.

• Changing Xenon lamps requires the special training , instruc

tions and equipment.

• Only an authorized Audi dealer or other qualified workshop

should change the bulbs in gas discharge lamps .

& WARNING

There are parts with sharp edges on the openings and on the bulb

holders that can cause serious cuts.

• If you are uncertain about what to do , have the work performed

by an authorized Audi dealer or other qualified workshop. Serious

personal injury may result from improperly performed work.

[ i ] Tips

• If you must replace th e light bulbs yours elf, always rem ember

that the engine compartment of any vehicle is a haza rdou s area to w

or k in. A lways read and h eed al l WAR NINGS=>

pa ge 217, " E ngin e

com pa rtm ent" =>& .

• I t is best to ask your authorized A udi dealer whenever you need

t o chang e a bulb. •

Page 290 of 324

11111.___E_ m _ e _r-==g :...e_ n_ c...:y _ s_ i_t _u _a _t_ i_o _n_ s _______________________________________________ _

& WARN ING (continued )

• Before you check anything in the engine compartment , always

read and heed all WARNINGS=>

page 217, "Engine compa rt m ent" .

0 Note

• Applying a higher voltage booster battery wil l cause expensive

damage to sensitive electronic components, such as contro l units,

relays, rad io, etc.

• There must be no electrical contact between the vehicles as

otherwise current cou ld already star t to flow as soon as th e positive

(+ ) termina ls are connected .

• Improperly connected jumper cab les can cause substantia l

damage to the electrica l system of the vehic le.

[ i ] Tips

• The disc harged battery must be p ro per ly connected to the

ve hicle's elec trica l syste m.•

General information of starting

assistance

Please observe that the p rocedure described below for conn ect in g

jumper cab les is intended to provide a jump start for your vehicle.

M ake s ure th at th e connec ted cla mps have su ffic ien t

me tal contact .

Start assistance differs for vehicles with a 4-cylinder engine and a 6-

cy lind er eng ine:

=> page 289, "Use of jumper cables (4 cyl inder eng ine)"

=> page 290, "Use of jumper cables (6 cylinder engine)"

& WARNING

Improper handling of the jumper cables can lead to an explosion

of the battery and severe injuries. To reduce the risk of injury , note

the following :

• The sections of the terminal clamps that are not insulated

must not tou ch ea ch other . In addition , the cable clamped to the

battery 's positive terminal must not come in contact with electri

cally conne cted parts of the vehicle -danger of short cir cuit!

• Route the jumper cable so that it cannot cat ch in any rotating

parts in the engine compartment .

• Do not bend over the batteries -danger of chemical burns!

• The battery cell locking screws must be tightened securely .

• Keep ignition sources (open flame, burning cigarettes, etc .)

away from the batteries -danger of explosion!

• Do not clamp the minus cable to parts of the fuel system or the

brake lines.

0 Note

If you prov id e s ta rt assi sta nce f or others w ith your veh icle, yo u

should not c lamp the mi nus cab le (-) to the negative termina l of the

discharged battery=>

page 289 , fig . 203 © but to a solid metal pa rt

screwed firmly to t he engi ne b lock, or to the engin e block itsel f. In

case of an inadequately vent ilated battery of the vehicle receiving

p owe r, the re is a danger o f expl osio n due to deton ati ng gas! •

Page 291 of 324

______________________________________________ E_ m_ e_r .;::g ;...e _ n_ c __,c. y_ s_it _u_ a_ ti_o _ n_ s _ __.ffllll

Use of jumper cables (4 cylinder

engine)

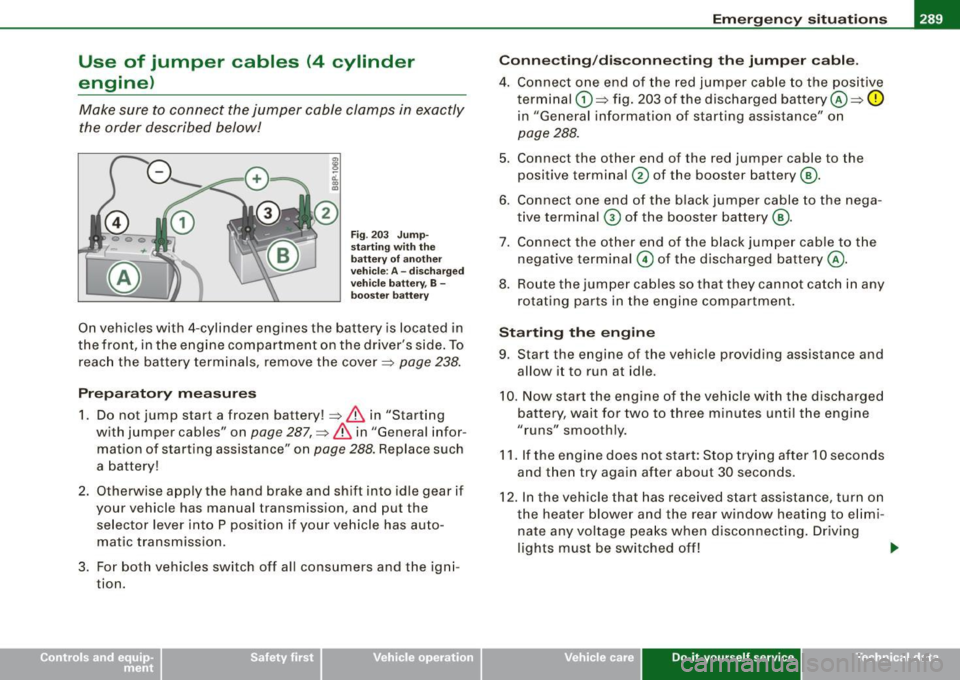

Make sure to connect the jumper cable clamps in exactly

the order described below!

Fig . 203 Jump

starting with the

battery of another

vehicle: A -discharged

vehicle battery, B -

booster battery

On vehicles with 4-cylinder engines the battery is located in

the front, in the engine compartment on the driver's side. To

reach the battery terminals, remove the cover=>

page 238.

Preparatory measures

1. Do not jump start a frozen battery!=> & in "Starting

with jumper cables" on

page 287, => & in "General infor

mat ion of starting assistance" on

page 288. Replace such

a battery!

2. Otherwise apply the hand brake and shift into idle gear if your vehicle has manual transmission, and put the selector lever into P position if your vehicle has automatic transmission.

3. For both vehicles switch off all consumers and the igni

tion.

Connecting/disconnecting the jumper cable.

4. Connect one end of the red jumper cable to the positive

terminal

G) => fig. 203 of the discharged battery©=> 0

in "General information of starting assistance" on

page 288.

5. Connect the other end of the red jumper cable to the

positive terminal

@ of the booster battery ®·

6. Connect one end of the black jumper cable to the nega tive terminal

G) of the booster battery ®·

7. Connect the other end of the black jumper cable to the negative terminal

© of the discharged battery@.

8. Route the jumper cables so that they cannot catch in any

rotating parts in the engine compartment.

Starting the engine

9. Start the engine of the vehicle providing assistance and

allow it to run at idle.

10. Now start the engine of the vehicle with the discharged

battery, wait for two to three minutes until the engine

"runs " smoothly.

11. If the engine does not start: Stop trying after 10 seconds

and then try again after about 30 seconds.

12. In the vehicle that has received start assistance, turn on

the heater blower and the rear window heating to elimi nate any voltage peaks when disconnecting. Driving

lights must be switched off! ._

Vehicle care Do-it-yourself service irechnical data