wheel AUDI S3 2010 Repair Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2010, Model line: S3, Model: AUDI S3 2010Pages: 320, PDF Size: 75.34 MB

Page 268 of 320

___ T _i_r e_=- p_r_e _ s_ s_ u_r_ e _ m_ o_ n_i_t _o _r_ i _ n .,;:g ::;.._ s_ y=--- s_t _e _m_ * __________________________________________ _

All pressure warning indicators in the display will be canceled.

Following each intentional change in specified pressures, tire pres

sures must be saved again .

After the pressures are saved, the tire pressure monitoring system measures the current tire pressures and saves them as the new

specified pressures.

[ i ] Tip s

• The tire pressure is shown on the tire pressure label. The tire

pressure label is located either on the driver's side 8 -pillar or on the

inside of the fuel filler flap . The tire pressure label lists the recom

mended cold tire inflation pressures for the vehicle at its maximum

capacity weight and the tires that were on your vehicle at the time

it was manufactured. For recommended tire pressures for normal

load conditions, p lease see chapter=>

page 246.

• The tire pressure monitoring system helps the driver monitor t ire

pressures, but the driver is still responsible for mainta ining the

correct tire pressure. •

Applie s to v ehic les : wi th tir e pr essure monito ring syst em

Wheel change

If a wheel is changed, the wheels that were exchanged

have to be reprogrammed.

- Turn o n the igniti on.

- Press the button=>

page 265, fig. 179 for approximately 5

seco nds . You will he ar a beep and the symbol in the

button flas hes three times .

Programming is necessary :

• after the tires have been rotated on the vehicle, or the spare tire

is used, •

if tires with new wheel sensors are used .

All pressure warning indicators in the disp lay wil l be canceled . The

system malfunction error message will not disappear until the

vehic le is underway. With pressing the button=>

page 265, fig. 179,

t he reprogramming of the new sensors a nd storing of actua l pres

sures starts. This learning phase can take up to 10 minutes driving

time .

During the learning process the tire pressure monitoring system is

no t avai lable. •

Applies t o vehicl es: with tire pr essur e mon itoring syst em

Malfunctions *

A mal functi on can have various c auses.

Fig . 18 0 Di sp lay:

Syst em m alfunction

If the I warning l ight in the instrument clus ter flashes for approxi

mately one minute and then remains continuously illuminated and

additiona lly the

T M => fig. 180 symbol appears in the display, the

tire pressure monitoring system is not available. This can have

various causes .

• I f the message appears at the end of the learning process, the

system cannot recognize the wheels installed on the vehicle . This

can be because one or more whee ls without a whee l sensor were

insta lled. ..,_

Page 269 of 320

__________________________________________ T_i_r e _ p =----r_e _s _ s_ u_ r_e _ m_ o_n_ i_ t _o _r_ i_n -=g =-- s....: y:.... s_ te_ m_ * __ !II

•

• A wheel sensor or other component may have failed.

• During initia lization the system has detected more than 4 wheels

on the vehicle, for example while driving next to another car with a

tire pressure monitoring system.

• A wheel change was made but the button

=> page 265, fig. 179

was not pressed.

• Audi Genuine Parts were not used for parts replacement.

• If snow chains are being used, system function can be compro

mised due to the shielding properties of the chains.

• The tire pressure monitoring system may not be available

because of a radio ma lfunction.

• Transmitters with the same frequency, such as radio head

phones in the veh icle or radio equipment, can cause a temporary

disruption of the system through excessive electromagnetic fields.

• Eliminate the interference if possible and then proceed as

follows: Turn off the engine for 20 minutes. Then drive another 10

min . If the warning light comes on again, you shou ld contact your

authorized Audi dealer immediately to have the problem corrected.

• Do not use commercially available tire sealants. Otherwise, the

e lectrical components of the tire pressure monitoring system will

no longer work properly and the sensor for the tire pressure moni

toring system will have to be replaced by an authorized Audi dealer

or other qualified workshop. •

Certification

This device complies with part 15 of the FCC ru les and RSS -210 .

Operation is subject to the following conditions:

• this device may not cause harmfu l interference, and

• this device must accept interference received, including interfer

ence that may cause undesired operation.

The receiver 5WK49069 uses the same schematic, assemb ly, layout

and PCB as 5WK49097 . 5WK49097 is a multi channe l receiver and 5WK49069 is a single channel receiver

. They only differ in: SAW

Filter V1 _4 was changed from A2C00038979 to V1 _2 A2C00032378,

I nductor L5_3 and L6_233nH were changed to L5 _2 and L6 _247nH.

BAND PASS FILTER V3_2 was changed from A2C00038762 to V3_3

A2C00036085. V10 : ATIC75 C1, A2C000029505 was changed to V10:

ATIC75 C2-Light, A2C000043220 . 01 14.246MHz A2C00037710 was

changed to 01 15.27MHz A2C00041280 . The BAND PASS FILTER V2

is not populated .

These modif ications were necessary to opt imize the characteristic

of the receiver.

Proof is shown with test report T30739 -00 -00KJ issued by Mikes

Testingpartners GmbH, OhmstraP..e 2-4, 94342 Strasskirchen that

the receiver is below the limit .•

Vehicle care I t •

Page 270 of 320

1111...__W_ h_ a _ t_d_ o_ l _d _o_ n_ o_ vv_ ? ______________________________________________ _

What do I do now?

Jack, tools and spare wheel

Jack and tools

The tools and jack are stored underneath the floor panel

in the luggage compartment.

Raise the floor panel with the loop.

Fig. 181 Floor panel

hung on the bottom of

the luggage compart

ment cover

Fig . 182 Vehicle tool

kit and jack

- Hang the loop on the underside of the luggage compart

ment cover ~ fig. 181.

Remove the tool kit or the jack.

The onboard tool kit includes:

• Hook for removing wheel covers*

• Plasti c hook to remove wheel bolt covers

• Wheel bolt wrench

• Alignment pin for changing wheels

• Screwdriver with reversible blade

• Towing eye

Before storing the jack, make sure it is wound back down as far as it

will go.

After use, the jack and tools must be put back in place underneath

the floor panel in the luggage compartment.

Note: some of the on-board items listed above are provided on

certain models only or are optional extras.

& WARNING

Improper use of the vehicle jack can cause serious personal inju

ries.

• Using a bumper jack to raise the vehicle will damage the

bumper system. The jack may slip, causing injury.

• Never support your vehicle on cinder blocks, bricks or other

objects. These may not be able to support the load and could

cause injury when they fail.

• Never start or run the engine while the vehicle is supported by

the jack.

• If you must work under the vehicle, always use safety stands

specifically designed for this purpose.

• Never try and use the hexagonal socket

in the handle of the

screwdriver to loosen or tighten the wheel bolts.

Page 271 of 320

_______________________________________________ W_ h_ a _ t_d_ o_ l _d _o_ n_ o_ w_ ? _ __.ffllll

& WARNING !continued)

• Always make sure the spare tire and even a flat tire are secured

in place and not loose, otherwise they could fly forward, causing

personal injury to passengers in the vehicle in an accident or

sudden maneuver .

• Never use the jack supplied with your Audi on another vehicle,

particularly on a heavier one. The jack is only suitable for use on

the vehicle it came with. •

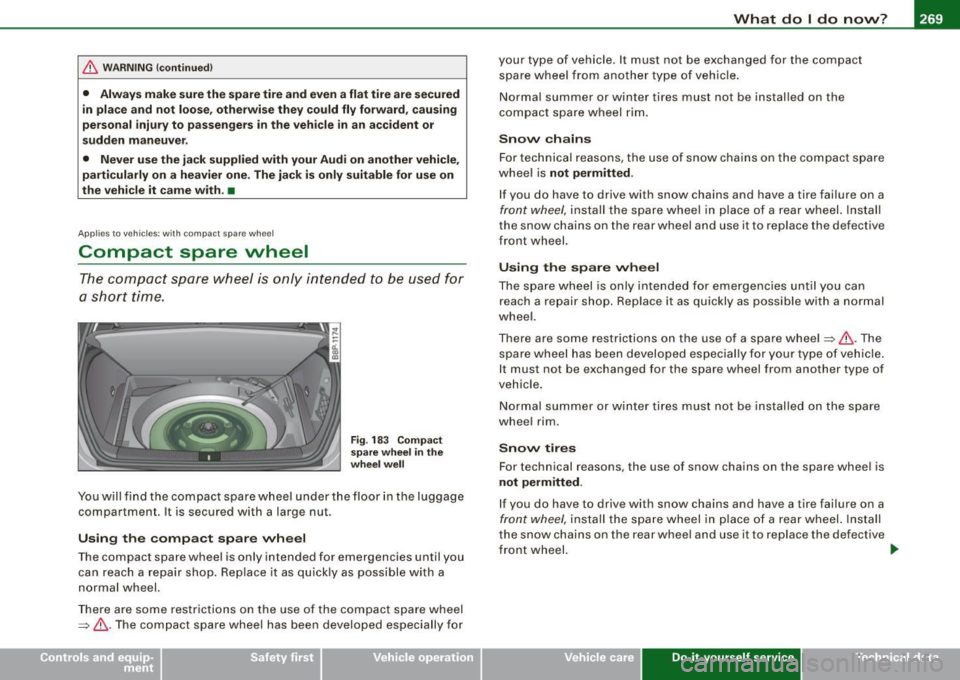

Ap plies to vehicles: w ith compact spare wheel

Compact spare wheel

The compact spare wheel is only intended to be used for

a short Nme.

Fig . 183 Compact

spare wheel in the

wheel well

You will find the compact spare wheel under the floor in the luggage

compartment. It is secured with a large nut.

Using the compact spare wheel

The compact spare wheel is only intended for emergencies until you

can reach a repair shop. Replace it as quickly as possible with a

normal wheel.

There are some restrictions on the use of the compact spare wheel

=>

& -The compact spare wheel has been developed especially for your type of vehicle

. It must not be exchanged for the compact

spare wheel from another type of vehicle.

Normal summer or winter tires must not be installed on the

compact spare wheel rim.

Snow chains

For technical reasons, the use of snow chains on the compact spare

wheel is

not permitted .

If you do have to drive with snow chains and have a tire failure on a

front wheel, install the spare wheel in place of a rear wheel. Install

the snow chains on the rear wheel and use it to replace the defective

front wheel.

Using the spare wheel

The spare wheel is only intended for emergencies until you can

reach a repair shop. Replace it as quickly as possible with a normal

wheel.

There are some restrictions on the use of a spare wheel =>& .The

spare wheel has been developed especially for your type of vehicle.

I t must not be exchanged for the spare wheel from another type of

vehicle.

Normal summer or winter tires must not be installed on the spare

wheel rim .

Snow tires

For technical reasons , the use of snow chains on the spare wheel is

not permitted .

If you do have to drive with snow chains and have a tire failure on a

front wheel, install the spare wheel in place of a rear wheel. Install

the snow chains on the rear wheel and use it to replace the defective

front wheel.

t,.

Vehicle care Do-it-yourself service irechnical data

Page 272 of 320

-L_.:W:..:..: h..:. a :::.: t...:d::::.::: o:....:... I .:::d :.:o::....: n~ o::..: w.:..:. ? ______________________________________________ _

& WARNING

Always store jacking equipment, spare wheel in the luggage

compartment. Tighten screw for the spare wheel securely. Under

no circumstances should you store the spare wheel or jack and

tools unsecured in the passenger compartment. This could cause

serious personal injury to passengers

in the vehicle in case of a

collision.

• The compact spare tire is for temporary use only and is so

marked on the sidewalls.

• Do not drive at speeds exceeding 50 mph (80 km/hi with the

compact spare wheel mounted. Also rapid acceleration, hard

braking and hard cornering must be avoided to help prevent loss

of vehicle control.

• Any continuous road use of the compact spare tire may result

in tire failure, loss of vehicle control and injury to vehicle occu

pants.

• Do not put a snow chain on your compact spare tire. Due to the

smaller tire size, the chain will not fit properly and can thus

damage your vehicle. You could also lose the chain, as well as

control of the vehicle .

• If you have a flat front tire in road conditions which require

snow chains, first remove the undamaged rear wheel and mount

the compact spare wheel in its place. Then remove the damaged

front wheel, take the snow chains off it and attach them to the

wheel taken from the rear. This wheel can now be mounted on the

front with its snow chains. Check and adjust tire pressure promptly.

• Never use two or more compact spare tires at the same time.

0 Note

When using the compact spare wheel, note the following: •

After installing the compact spare wheel, the tire inflation pres

sure should be checked and, if necessary, increased to 60 psi (4 .2

barl.

• The load carrying capacity is marked on the tire sidewal ls and

must not be exceeded .

• After installing the compact spare wheel, make sure that you

remount the flat tire in its storage area properly .

• The compact spare tire should be properly remounted in its

storage area as soon as the standard road tire can be replaced.

• Because the compact spare tire was specifically designed for

your vehicle, it must not be used on any other vehicle . Likewise,

compact spare wheels from other vehic les must not be used on your

vehicle.

• The compact spare tire must not be mounted on any other

wheels, nor must standard tires, snow tires, wheel covers or trim

rings be used with the compact spare wheel. If such use is

attempted, damage to these items or other vehicle components

may occur.

[ i] Tips

Check the inflation pressure of the compact spare tire (60 psi/4 .2

bar) periodically to keep the tire ready for use .•

Wheel change

Before changing a wheel

Observe the following precautions for your own and your

passenger's safety when changing a wheel.

- After you experience a tire failure, pull the car well away

from moving traffic and try to reach level ground before

you stop

~ & . ~

Page 273 of 320

What do I do now? -__________________ __;__:....:....:..:: __ _

•

-All passengers should leave the car and move to a safe

location (for instance, behind the guardrail)~& .

- Apply the

parking brake firmly ~& .

- Move

selector lever to position Pon an automatic trans-

miss ion; put manual transmission in

first gear ~& .

-If you are towing a trailer : unhitch the trailer from your

vehicle.

- Take the

tool and the spare tire~ page 268 out of the

luggage compartment.

& WARNING

You or your passengers could be injured while changing a wheel if

you do not follow these safety precautions:

• If you have a flat tire, move a safe distance off the road. Turn off

the engine, turn the emergency flasher on and use other warning

devices to alert other motorists.

• Make sure that passengers wait

in a safe place away from the

vehicle and well away from the roadway and traffic.

• To help prevent the vehicle from moving suddenly and possibly

slipping off the jack, always fully set the parking brake and block

the wheel diagonally opposite the wheel being changed. When one

front wheel is lifted off the ground, placing the automatic trans

mission in "P" (Park), or engaging a gear in a manual transmission

will

not prevent the vehicle from moving.

• Before you change a wheel, be sure the ground is level and firm.

If necessary, use a sturdy board under the jack.

• After installing the spare wheel, make sure that you remount

the flat tire/wheel in its storage area properly and tighten the

knurled retaining screw securely. •

Changing a wheel

When you change a wheel, follow the sequence described

below step-by-step and exactly in that order.

1. Remove the decorative wheel cover*. For more details

see also

~ page 272, "Decorative wheel covers" or

~ page 273, "Wheels with cap-covered wheel bolts".

2. Loosen the

wheel bolts~ page 274.

3. Locate the proper mounting point for the jack and align

the jack below that point~

page 274.

4. Lift the car with the jack~ page 274.

5. Take the flat wheel off and then put the spare on

~ page 276.

6. Tighten all wheel bolts lightly .

7.

Lower the vehicle with the jack .

8. Use the wheel bolt wrench and

firmly tighten all wheel

bolts ~

page 274.

9. Put the decorative wheel cover* back on.

& WARNING

Always read and head all WARNINGS and information ::} & in

"Raising the vehicle" on

page 274 and ~ page 277. •

After changing a wheel

A wheel change is not complete without the following

actions.

- Store and secure the replaced wheel in the spare wheel

well. .,._

Do-it-yourself service

Page 274 of 320

-What d o I do novv ? PcV:I...__ ______________ _

- Put the tool case and the jack back in place in the luggage

compartment.

- Check the

tire pre ssure on the spare whee l immediately

after mounting it.

- As soon as possible, have the

tight ening torque s on all

wheel bo lts checked with a torque wrench . The correct

tightening torque is 90 ft lb (120 Nm) .

- Have the flat tire

repla ced as soon as possible.

[ i ] Tip s

• If you notice while changing a tire that the wheel bolts are

corroded and difficult to turn, then they should be replaced before

you check the tightening torque .

• Drive at reduced speed until you have the tightening to rques

checked .a

Ap plies to ve hicles: w it h full whee l co vers

Full wheel covers

The wheel covers must be removed to access the wheel

bolts.

Remo va l

- Pull the full wheel cov er off manually.

Inst alla tion

- First press the full wh eel cove r onto the rim at the cut -out

prov ided for the valve. Then engage the outer edge of the

f ull whe el cover in the steel rim. •

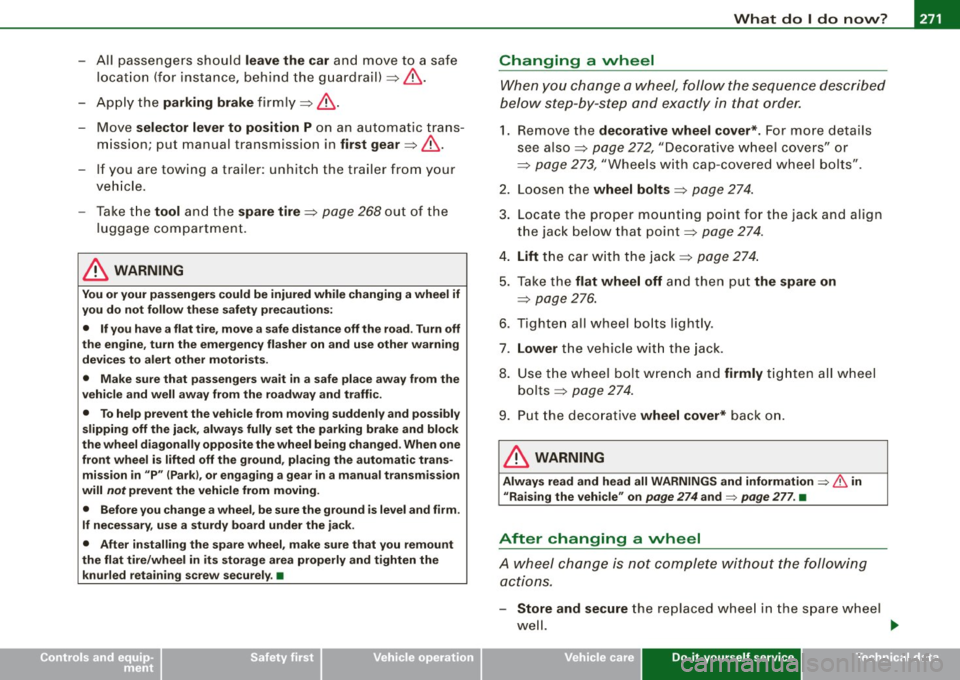

Applies to vehi cles : w it h deco ra tiv e wh eel co vers

Decorative whee l covers

The decorative wheel covers must be removed first to

access the wheel bolts .

Removing

Fig. 18 4 Whee l

ch ange : remov in g th e

w hee l cover

- Inse rt the hook provid ed with the onboard tool kit into

t h e hole on the cen ter hub piece .

- P ull off the

d ecorative wheel cover => fig. 184. •

Page 275 of 320

What do I do now ? -

------------------

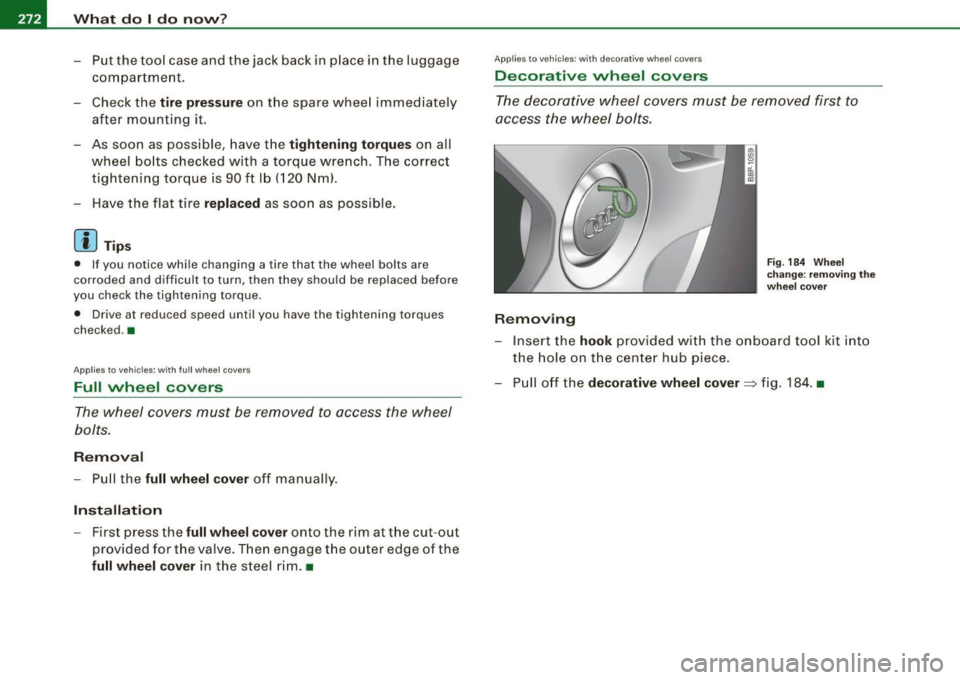

Applies to vehicle s: with cap-covered wheel bolts

Wheels with cap-covered wheel bolts

The caps must be removed first from the wheel bolts

before the bolts can be unscrewed.

Rem ovin g

Fig. 185 W hee l

c h ange : removin g th e

whee l bolt ca ps

- Push the plastic clip provided with the onboard tool kit

down over the wheel bolt cap until it engages.

- Pull on the properly engaged plastic clip to extract the

cap

~ fig . 185.

R efitting

- Place the caps over the whee l bolts and p ush them back

1n.

The caps are there to protect and keep the wheel bo lts clean .•

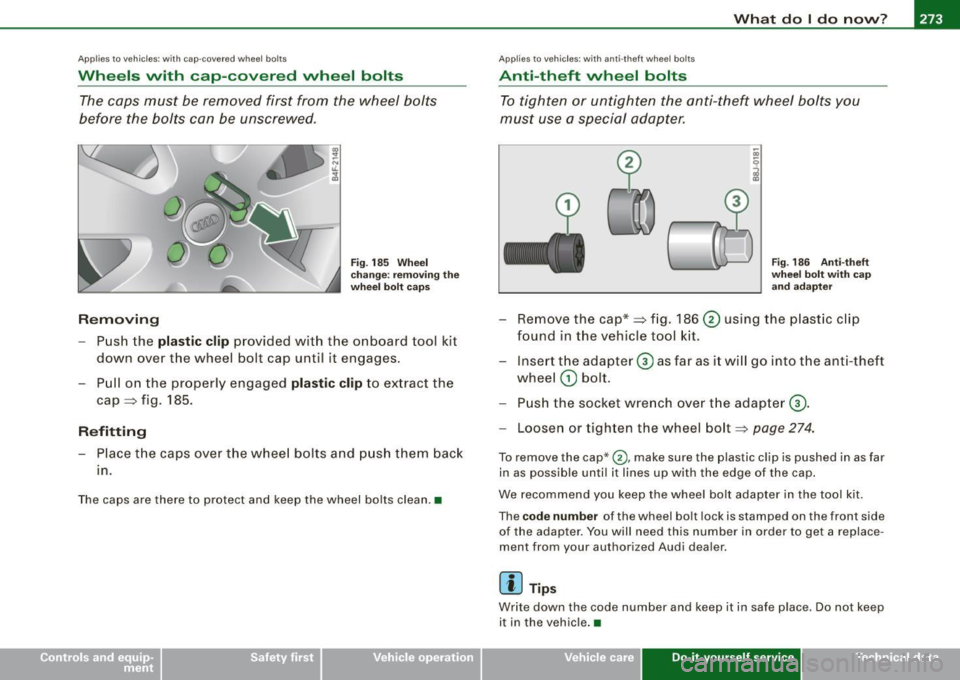

Ap plies to vehicles: with anti-theft wheel bo lts

Anti-theft whee l bolts

To tighten or untighten the anti-theft wheel bolts you

must use a special adapter.

....

(

V"

..

Fi g. 18 6 An ti-t heft

whee l bolt wit h ca p

a n d ada pter

- Remove the cap*~ fig. 186 0 using the plastic clip

found in the vehicle tool kit.

- Insert the adapter

0 as far as i t wi ll go into the anti-theft

wheel

G) bolt.

- Push the socket wre nch over t he adap ter

G) .

- Loosen or tighten the wheel bolt~ page 274.

To remove the cap* 0, make sure the plastic clip is pushed in as far

in as possib le until it lines up wi th the edge of the cap .

We recommend you keep the wheel bolt adapter in the tool kit.

The

c od e numb er of the wheel bolt lock is stamped on the front side

of the adap ter. You will need this number in orde r to get a replace

ment from your author ized Audi dealer.

[ i ] Tip s

Write down the code number and keep it in safe place . Do not keep

it in the vehicle. •

Vehicle care Do-it-yourself service Technical data

Page 276 of 320

llffl.,___W_ h_ a _ t_d_ o_ l _d _o_ n_ o_ vv_ ? ______________________________________________ _

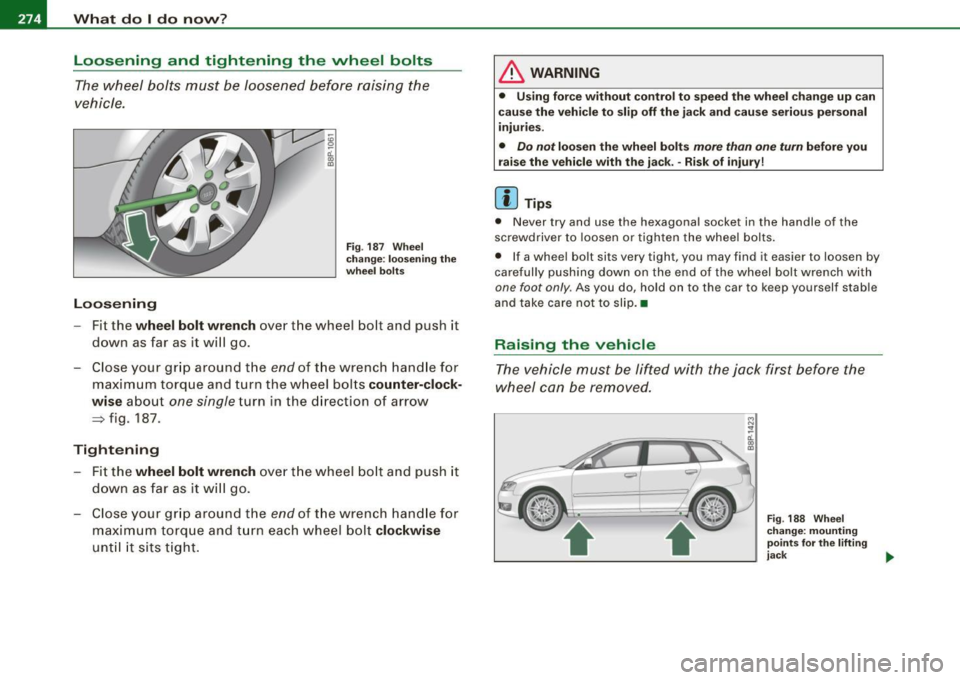

Loosening and tightening the wheel bolts

The wheel bolts must be loosened before raising the

vehicle.

~ a'.. ., m

Loosening

Fig . 187 Wheel

change: loosening the

wheel bolts

- Fit the wheel bolt wrench over the wheel bolt and push it

down as far as it will go .

- Close your grip around the

end of the wrench handle for

maximum torque and turn the wheel bolts

counter-clock

wise

about one single turn in the direction of arrow

~ fig. 187.

Tightening

-Fit the wheel bolt wrench over the wheel bolt and push it

down as far as it will go.

- Close your grip around the

end of the wrench handle for

maximum torque and turn each wheel bolt

clockwise

until it sits tight.

& WARNING

• Using force without control to speed the wheel change up can

cause the vehicle to slip off the jack and cause serious personal

injuries.

• Do not loosen the wheel bolts more than one turn before you

raise the vehicle with the jack. -Risk of injury!

[ i] Tips

• Never try and use the hexagonal socket in the handle of the

screwdriver to loosen or tighten the wheel bolts.

• If a wheel bolt sits very tight, you may find it easier to loosen by

carefully pushing down on the end of the wheel bolt wrench with

one foot only . As you do, hold on to the car to keep yourself stable

and take care not to slip.•

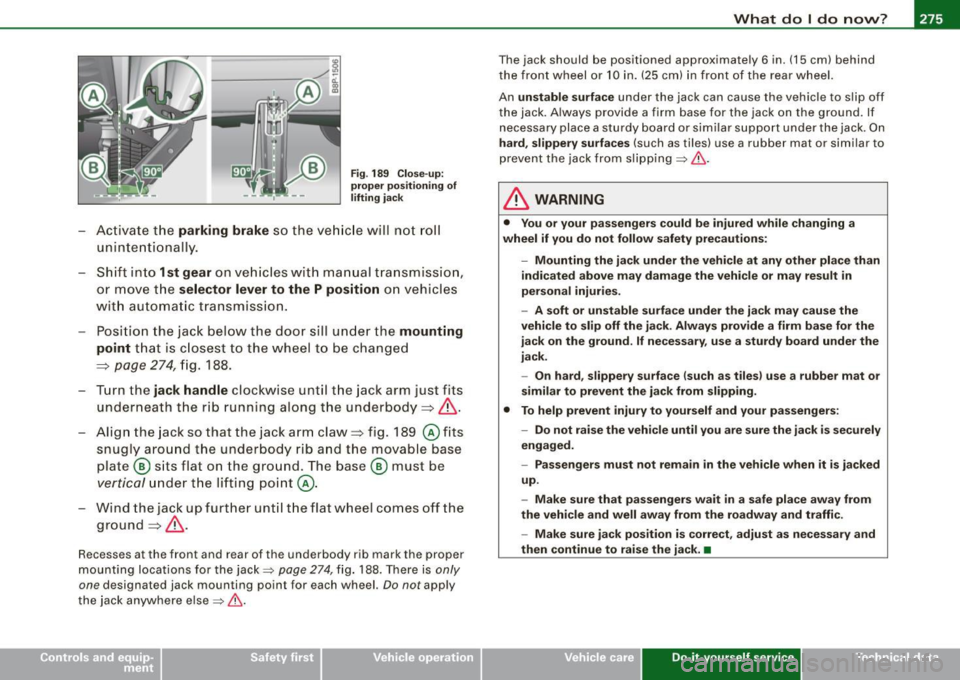

Raising the vehicle

The vehicle must be lifted with the jack first before the

wheel can be removed.

Fig. 188 Wheel

change: mounting

points

for the lifting

jack ..

Page 277 of 320

What do I do now? -

------------------

Fig. 189 Close-up:

proper positioning of

lifting jack

-Activate the parking brake so the vehicle will not roll

unintentionally.

- Shift into

1st gear on vehicles with manual transmission,

or move the

selector lever to the P position on vehicles

with automatic transmission.

- Position the jack below the door sill under the

mounting

point

that is closest to the wheel to be changed

=> page 274, fig. 188.

- Turn the

jack handle clockwise until the jack arm just fits

underneath the rib running along the underbody

=> &.

- Align the jack so that the jack arm claw => fig . 189 @ fits

snugly around the underbody rib and the movable base

plate @ sits flat on the ground. The base @ must be

vertical under the lifting point@.

- Wind the jack up further until the flat wheel comes off the

ground =>& .

Recesses at the front and rear of the underbody rib mark the proper

mounting locations for the jack ~

page 274, fig. 188. There is only

one

designated jack mounting point for each wheel. Do not apply

the jack anywhere else~& . The

jack should be positioned approximately 6 in. (15 cm) behind

the front wheel or 10 in. (25 cm) in front of the rear wheel.

An unstable surface under the jack can cause the vehicle to slip off

the jack. Always provide a firm base for the jack on the ground. If

necessary place a sturdy board or similar support under the jack. On

hard, slippery surfaces (such as tiles) use a rubber mat or similar to

prevent the jack from slipping ~& .

& WARNING

• You or your passengers could be injured while changing a

wheel if you do not follow safety precautions:

-Mounting the jack under the vehicle at any other place than

indicated above may damage the vehicle or may result in

personal injuries.

- A soft or unstable surface under the jack may cause the

vehicle to slip off the jack. Always provide a firm base for the

jack on the ground. If necessary, use a sturdy board under the

jack.

- On hard, slippery surface (such as tiles) use a rubber mat or

similar to prevent the jack from slipping.

• To help prevent injury to yourself and your passengers:

- Do not raise the vehicle until you are sure the jack is securely

engaged.

- Passengers must not remain in the vehicle when it is jacked

up.

- Make sure that passengers wait in a safe place away from

the vehicle and well away from the roadway and traffic.

- Make sure jack position is correct, adjust as necessary and

then continue to raise the jack. •

Vehicle care Do-it-yourself service irechnical data