wheel AUDI S3 SEDAN 2017 Owners Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2017, Model line: S3 SEDAN, Model: AUDI S3 SEDAN 2017Pages: 400, PDF Size: 67.32 MB

Page 360 of 400

Emergency assistance

Removing

.. Insert the hook (provided with the vehicle tool

kit) in the hole in the wheel hub cover.

.. Pull off the decorative wheel cover¢ fig. 288.

Wheels with wheel bolt caps

App lies to: vehicles with wheel bolts with caps

The caps must be removed first from the wheel

bolts before the bolts can be unscrewed.

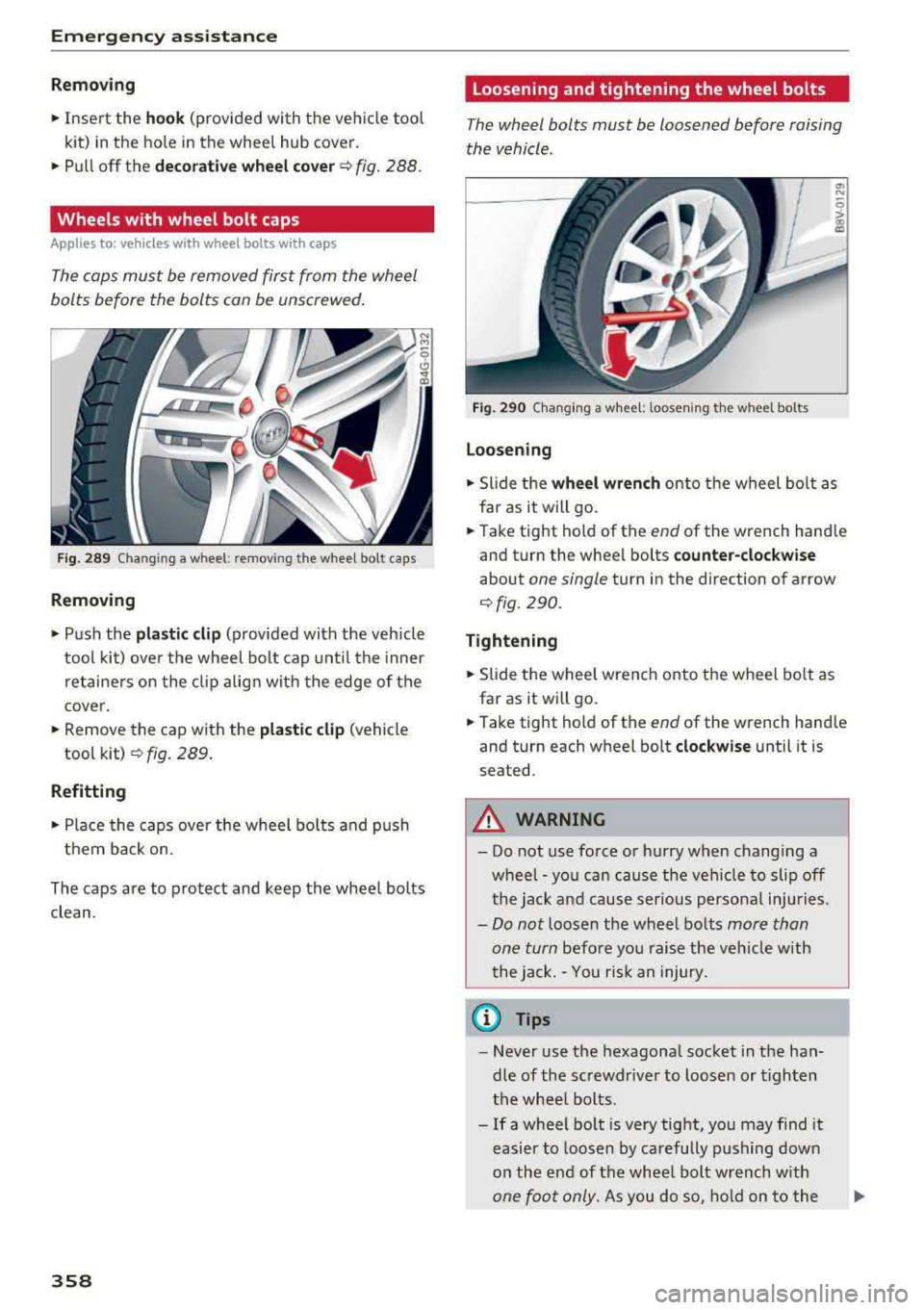

Fig. 289 Changing a wheel: remov ing the wheel bo lt caps

Removing

" Push the plastic clip (provided with the veh icle

tool kit) over the wheel bolt cap until the inn er

retainers on the clip align with the edge of the

cover.

.. Remove the cap with the plastic clip (vehicle

tool kit)

¢fig. 289.

Refitting

" Place the caps over the wheel bolts and push

them back on.

The caps are to protect and keep the wheel bolts

clean.

358

Loosening and tightening the wheel bolts

The wheel bolts must be loosened before raising

the vehicle .

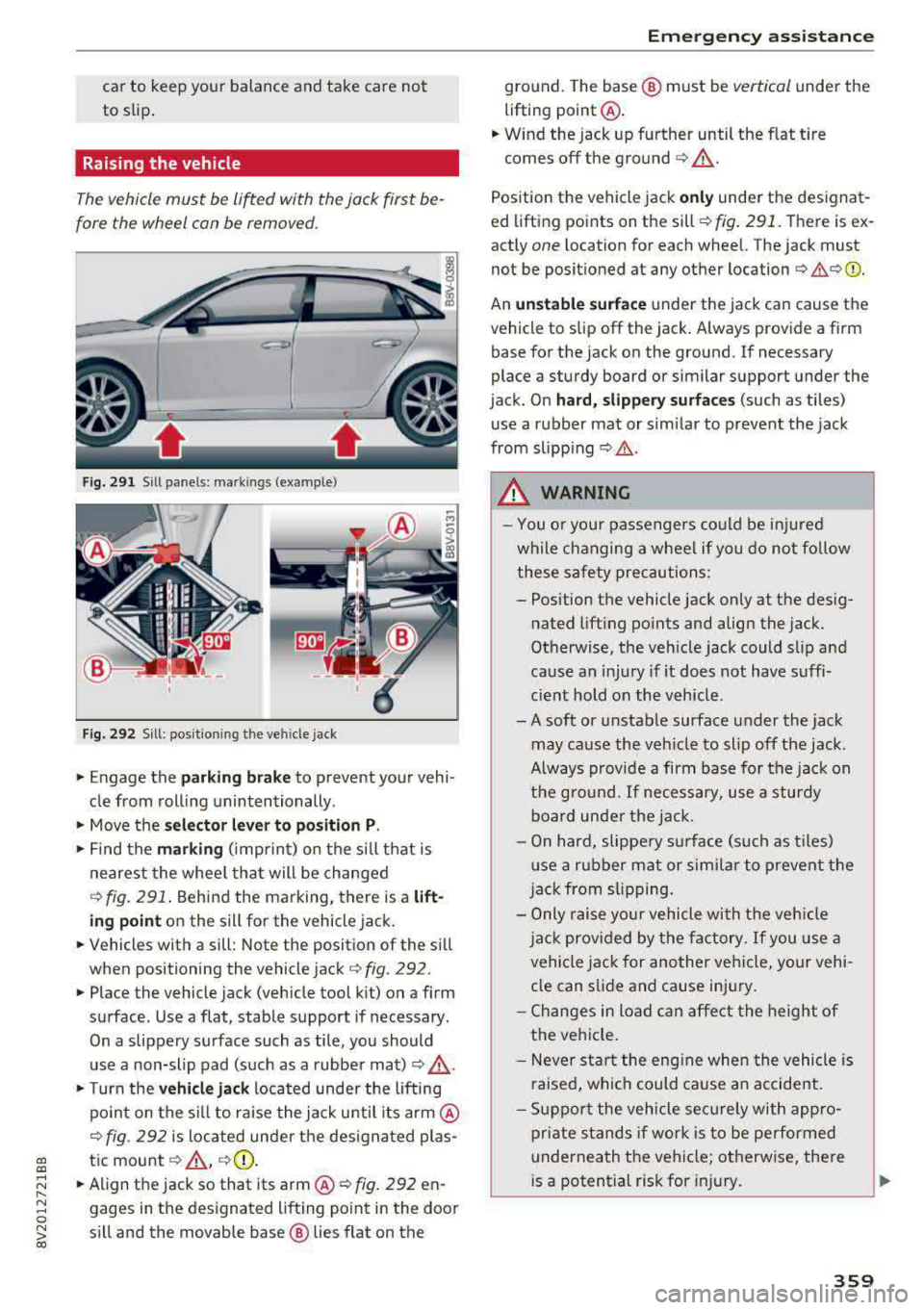

Fig. 290 Changing a whee l: loose ning the wheel bolts

Loosening

"Slid e the wheel wrench onto the wheel bolt as

far as it will go .

.. Take tight hold of the end of the wrench handle

and turn the wheel bolts

counter-clockwise

about one single turn in the direction of arrow

¢fig. 290.

Tightening

.. Slide the wheel wrench onto the wheel bolt as

far as it will go.

.. Take tight hold of the end of the wrench handle

and turn each wheel bolt

clockwise until it is

seated.

A WARNING

-Do not use force or hurry when changing a

wheel - you can cause the vehicle to slip off

the jack and cause serious personal injuries.

-Do not loosen the wheel bolts more than

one turn

before you raise the vehicle with

the jack.

-You risk an injury.

(D Tips

-Never use the hexagonal socket in the han

dle of the screwdriver to loosen or tighten

the wheel bolts.

-If a wheel bolt is very tight, you may find it

easier to loosen by carefully pushing down

on the end of the wheel bolt wrench with

one foot only. As you do so, hold on to the

Page 361 of 400

car to keep your balance and take care not

to slip .

Raising the vehicle

The vehicle must be li~ed with the jack first be

fore the wheel con be removed .

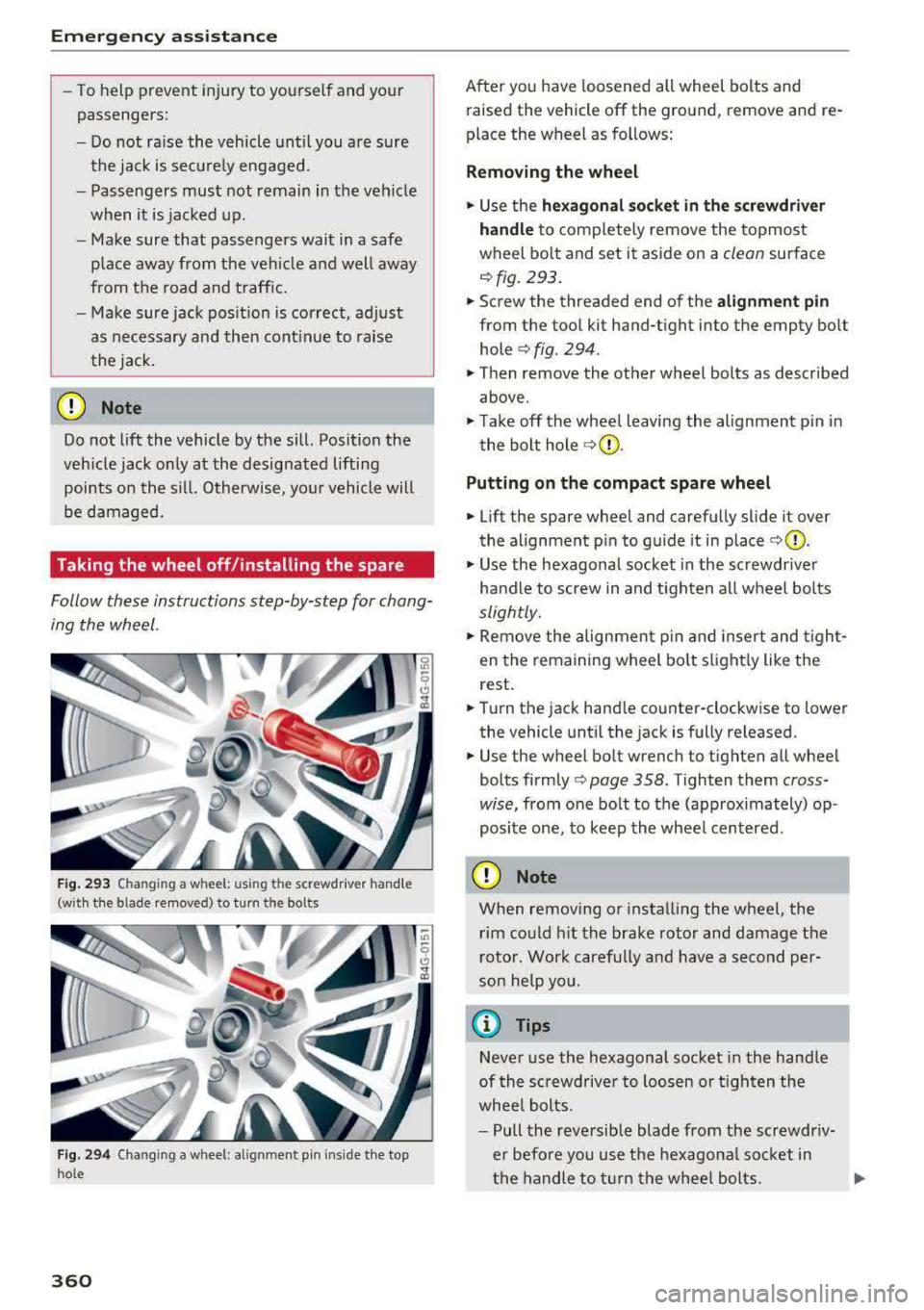

Fig. 291 S ill pane ls: mark ings (example)

F ig. 292 S ill: position ing the ve hicle jack

"Engage the parkin g brak e to prevent your vehi

cle from roll ing unintentionally .

"Move the se lector le ver to p osition P .

"Find the markin g (imprint) on the s ill that is

nearest the whee l tha t will be changed

r::> fig. 291 . Behind the marking, there is a lift

ing point on the sill for the vehicle jack.

"Vehicles with a sill: Note the position of the sill

when positioning the vehicle jack¢

fig. 292.

"Place the vehicle jack (vehicle tool kit) on a firm

surface. Use a flat, stable support if necessary.

On a slippery surface such as tile, you should

use a non-slip pad (such as a rubber mat) ¢

,&.

"Turn the ve hi cle jack located under the lifting

po int on the s ill to ra ise the jack until its

arm @

r::> fig. 292 is located under the des ignated plas-

gi tic mount r::> ,& , ¢0).

~ "Align the jack so that its arm @¢ fig. 292 en-

8 gages in the designated lift ing point in the door

~ sill and the movable base ® lies flat on the

Em ergen cy a ssis tanc e

ground. The base ® must be vertical unde r the

lifting point @.

"Wind the jack up further until the f lat tire

comes off the

ground ¢,& .

Position the vehicle jack only unde r the designat

ed lifting points on the sill¢

fig. 291. T here is ex

actly

one location for each wheel. The jack must

not be positioned at any other

location¢ ,&.¢0) .

An un sta b le surf ace under the jack can cause the

vehicle to slip off the jack . Always provide a firm

base for the jack on the ground. If necessary

place a sturdy board or similar support under the

jack. On

ha rd , s lippery surfa ces (such as tiles)

use a rubber mat or similar to prevent the jack

from

slipp ing ¢,&. .

.&, WARNING

-

-You o r you r passengers could be inj ured

while changing a wheel if you do not fo llow

these sa fety precautions :

- Position the vehicle jack only at the desig

nated lifting points and align the jack.

Otherwise, the vehicle jack could slip and

cause an injury if it does not have suffi

c ient hold on the vehicle .

-A soft or unstable surface under the jack may cause the veh icle to slip off the jack.

Always provide a firm base for the jack on

the g ro u nd. If necessary, use a sturdy

board unde r the jack.

- On hard, slippe ry su rface (s uch as t iles)

u se a r ubber mat or simi lar to prevent the

j ac k from slipping.

- Only raise yo ur vehicle with the veh icle

j ac k prov ided by the factory.

If you use a

vehicle jack for another veh icle, your vehi

cle can s lide and cause injury.

- Changes in load can affe ct the height of

the vehicle.

- Never star t the eng ine when the vehicle is

raised, which could cause an accident.

- Suppor t the vehicle se cur ely with appro

priate stands if work is to be performed

underneath the vehicle; otherwise, there

i s a potential risk for injury.

.,.

359

Page 362 of 400

Emerg ency assis ta nce

-To help prevent injury to yourself and your

passengers:

-Do not ra ise the vehicle until you are sure

the jack is secure ly engaged.

-Passengers must not remain in the vehicle

when it is jacked up.

-Make sure that passengers wait in a safe

place away from the vehicle and well away

from the road and traffic.

-Make sure jack posit ion is correct, adjust

as necessary and then cont inue to raise

the jack.

CD Note

Do not lift the vehicle by the sill. Position the

veh icle jack only at the designated lifting

points on the sill. Otherwise, your vehicle will

be damaged.

Taking the wheel off /installing the spare

Follow these instructions step-by-step for chang

ing the wheel .

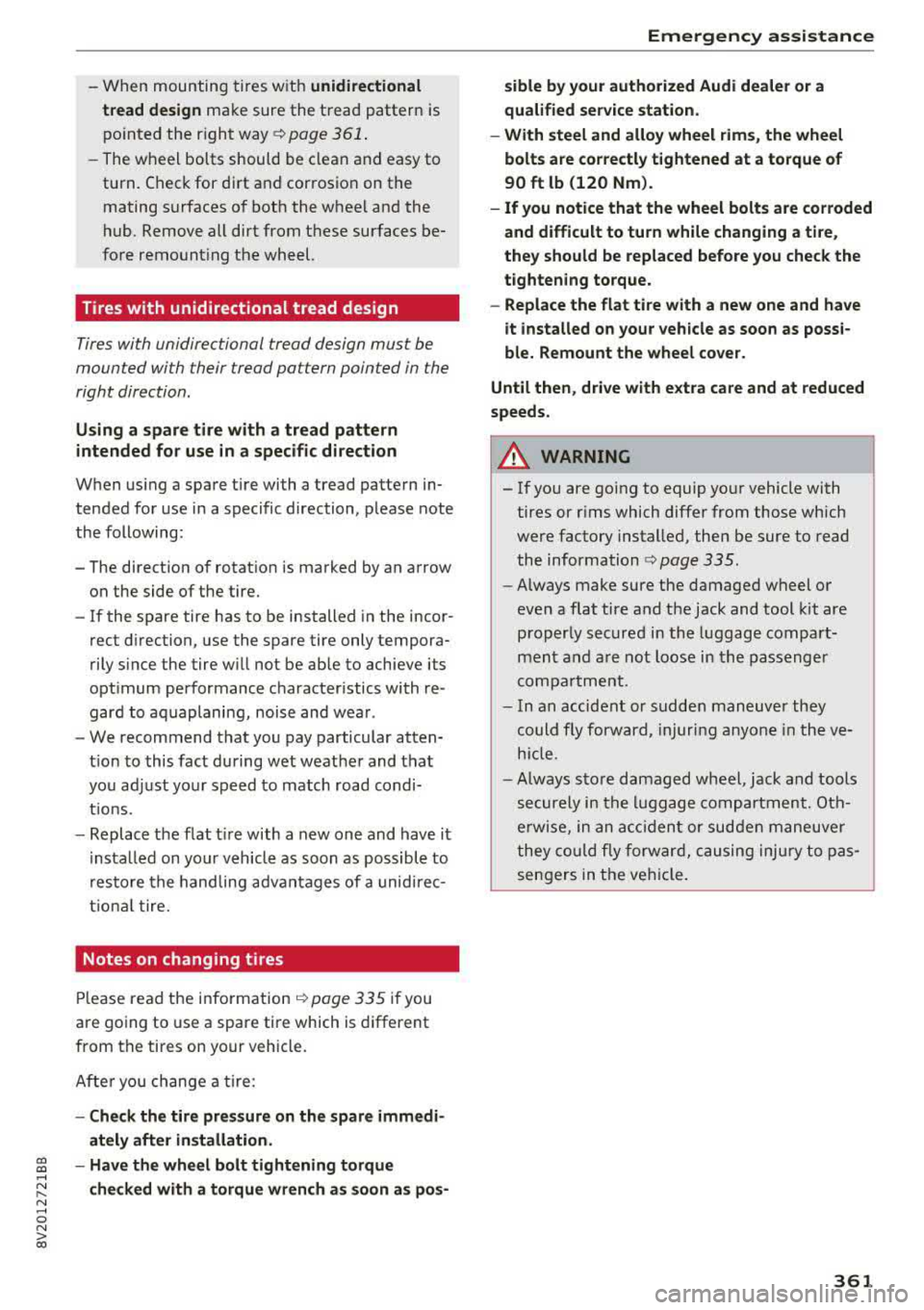

Fig . 293 Changing a wheel: using the screwdr iver hand le

(with the blade removed) to turn the bolts

Fig. 29 4 Changing a wheel: alignm ent pin ins ide the top

ho le

360

After you have loosened all wheel bolts and

raised the vehicle off the ground, remove and re

place the wheel as follows:

Removing the wheel

.. Use the he xago nal socket in th e screwdriver

handle

to comp letely remove the topmost

wheel bo lt and set it aside on a

clean surface

<=> fig. 293.

.. Screw the threaded end of the alig nm ent pi n

from the tool kit hand-tight into the empty bolt

hole

<=> fig. 294.

.. Then remove the other wheel bolts as described

above .

.. Take off the whee l leaving the alignment p in in

the bolt hole

<=> (j) .

Putting on the c omp act spare wheel

.. Lift the spare wheel and carefully slide it over

the alignment p in to gu ide it in place

<=>(j) .

.. Use the hexagonal socket in the screwdr iver

handle to screw in and t igh ten all wheel bolts

slightly.

.. Remove the alignmen t pin and insert and t igh t

en the remaining wheel bolt s light ly like the

rest .

.. Turn the jack hand le counter-clockwise to lower

the vehicle until the jack is fully released .

.. Use the wheel bolt wrench to tighten all wheel

bolts

firmly <=> page 358. Tighten them cross

wise,

from one bolt to the (approximately) op

posite one, to keep the wheel centered.

CD Note

When removing o r insta lling the wheel, the

rim could h it the brake rotor and damage the

r otor. Wor k carefully and have a second per

son he lp yo u.

{!) Tips

Neve r use the hexagonal socket in the handle

of th e sc rewdriver to loos en o r tigh ten the

whee l bolts.

-Pull the reve rsible blade from the screwdr iv

er befo re you use the hexagona l socket in

the handle to turn the whee l bolts.

Page 363 of 400

CXl CXl .... N ,.__

N .... 0 N > 00

-When mountin g tires w ith unidirectional

tread design

ma ke sure the t read pattern is

p oin ted the r ight way ¢

page 36 1.

-The wheel bolts should be clean and easy to

turn. C heck for d irt a nd cor rosion on the

ma ting surfaces o f both the wheel an d the

hub. Remove all dirt from t hese surfaces be

fo re remo unt ing the wheel.

Tires with unidirectional tread design

Tires with unidirectional tread design must be

mounted with their tread pattern pointed in the

right direction.

Using a spare t ire with a tread pattern

intended for use in a specific direction

W hen using a spa re t ire with a tread patte rn in

tended fo r use in a specific direction, please note

the following:

-The direct ion of rotat ion is ma rked by an a rrow

on the side of the tire .

-If the spare tire has to be installed in the incor

rect d irection, use the spare tire only tempora

ri ly s ince the tire w ill not be ab le to achieve its

opt imum p erformance c harac ter istics wi th re

gard to aquaplaning, noise and wea r.

-We recommend t hat you pay particular atten

t io n t o this fac t during we t weat her and that

yo u adju st yo ur speed to match road condi

ti ons.

-Rep lace the flat t ire with a new one and have it

insta lled on yo ur ve hicl e as soon as possibl e to

r es to re th e hand li n g adva ntages of a unid irec

tional t ire.

Notes on changing tires

Please read the info rmation I:!> page 3 35 if you

are go ing to use a spare tire which is different

from the tires on your veh icle.

Af te r yo u c hange a tire:

-Check the tire pressure on the spare immedi

ately after in stallation .

-Have the wheel bolt tightening torque

checked with a torque wrench as soon as pos -

Emergency assistance

sible by your authorized Audi dealer or a

qualified service station.

-With steel and alloy wheel rims, the wheel bolts are correctly tightened at a torque of

90 ft lb (120 Nm).

-If you notice that the wheel bolts are corroded

and difficult to turn while changing a tire ,

they should be replaced before you check the

tightening torque.

-Replace the flat tire with a new one and have

it installed on your vehicle as soon as possi ·

ble. Remount the wheel cover .

Until then , dr ive with extra care and at reduced

speeds.

_& WARNING

-I f you are going to equip yo ur vehicle with

tires or r ims which differ from those w hich

were factory installed, the n be sure to read

th e information

¢ pag e 335.

-Always make sure the damaged wheel or

e ven a flat tire a nd the jack and tool kit are

p rop erly secur ed in t he lu ggag e compart

m en t an d are not l oose in th e p asseng er

compa rtme nt.

-In an accide nt or sudde n man euv er th ey

could fly forward, injuri ng a nyo ne in the ve

hicl e.

-Always s tor e damag ed w heel, jack and t ools

securely i n the lu ggage compa rtm ent. Ot h

erwise, in an accid ent or sud den m aneuve r

t he y c ould fl y forwar d, ca using injury to pas

sen gers in the ve hicle.

-

361

Page 364 of 400

Emergency assistance

Spare tire

General information

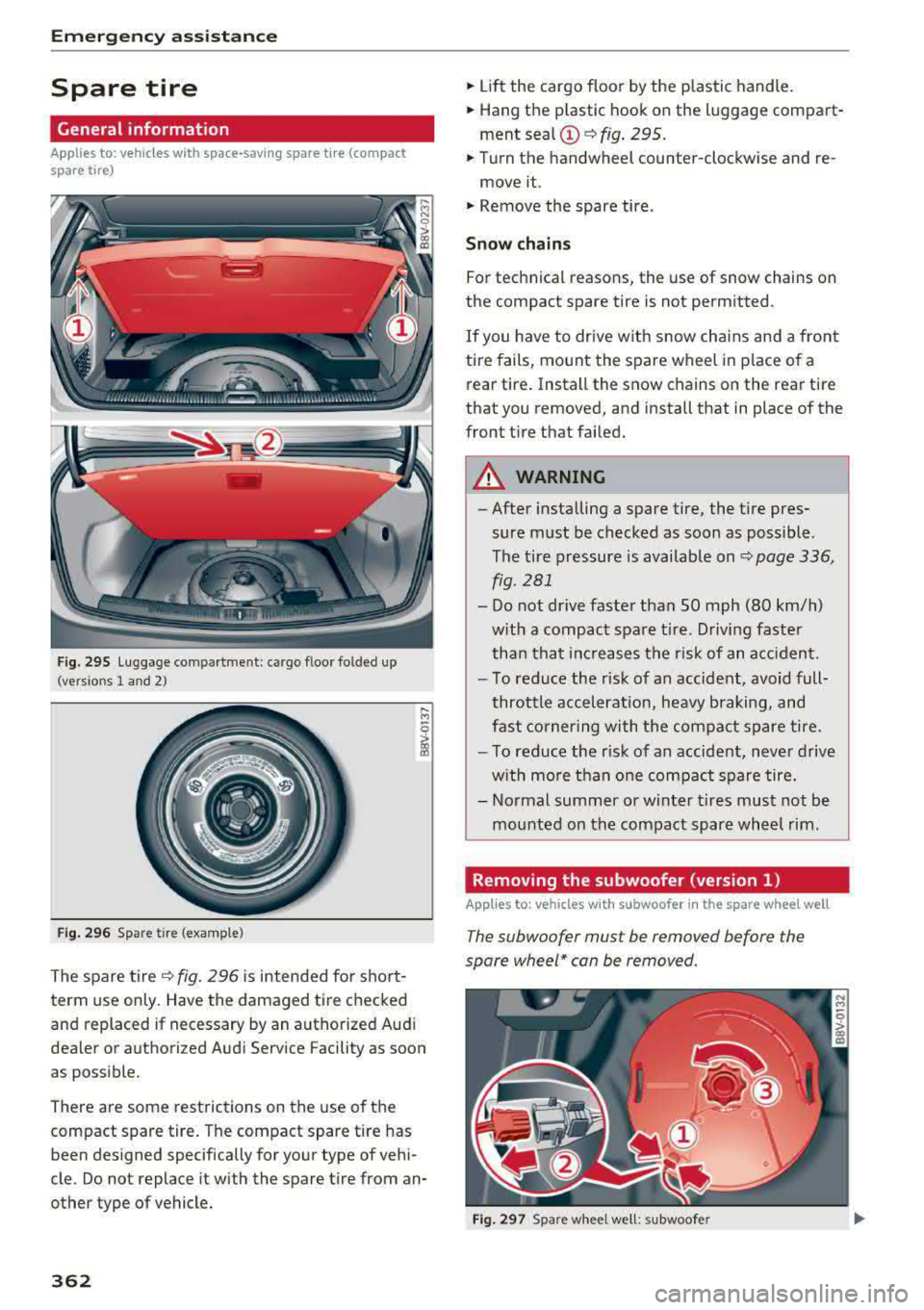

Applies to: vehicles with space-saving spare tire (compact

spare tire)

Fig. 295 L uggage compartment: cargo floor folded up

(versions 1 and 2)

Fig. 296 Spare tire (example)

The spare tire ~ fig. 296 is intended for short

term use only. Have the damaged tire checked

and replaced if necessary by an authorized Audi

dealer or authorized Audi Service Facility as soon

as possible.

There are some restrictions on the use of the

compact spare tire . The compact spare tire has

been designed specifically for your type of vehi

cle. Do not replace it with the spare tire from an

other type of vehicle.

362

.,. Lift the cargo floor by the plastic handle .

.,. Hang the p lastic hook on the luggage compart

ment

sea l© ~ fig. 295.

.,. Turn the handwheel counter-clockwise and re-

move it .

.,. Remove the spare tire.

Snow chains

For technical reasons, the use of snow chains on

the compact spare tire is not permitted .

If you have to drive with snow chains and a front

tire fails, mount the spare wheel in p lace of a

rear tire. Install the snow chains on the rear tire

that you removed, and install that in place of the

front tire that failed.

A WARNING

-

-After installing a spare tire, the tire pres

sure must be checked as soon as possible.

The tire pressure is available on

~ page 336,

fig.

281

- Do not dr ive faster than SO mph (80 km/h)

w ith a compact spare tire. Driving faster

than that increases the risk of an accident.

- To reduce the r isk of an accident, avoid full

throttle acceleration, heavy braking, and

fast cornering with the compact spare tire.

- To reduce the r isk of an accident, never drive

w ith more than one compact spare tire.

- Normal summer or w inter t ires must not be

mounted on the compact spare wheel rim.

Removing the subwoofer (version 1)

Applies to: vehicles with subwoofer in the spare whee l well

The subwoofer must be removed before the

spare wheel* can be removed.

Fig. 297 Spare whee l we ll: subwoofer

Page 365 of 400

a, a, ..... N

" N ..... 0 N > 00

Removing the subwoofer

• Lift up the cargo floor ¢ page 362, fig. 295.

• Press the connector tabs CD¢ fig. 297 togeth

er.

• Remove the connector @and set the discon-

nected cab le aside.

• Remove the bolt@.

• Carefully remove the subwoofer .

Installing the subwoofer

• Carefully place the subwoofer in the rim wel l.

The word "FRONT" on the subwoofer must face

forward.

• Insert the connector that was removed .

• Secure the subwoofer with the bolt.

• Fold the cargo floor cover back into place .

@ Tips

The subwoofer can also be mounted when the

spare tire is not in the spare wheel wheel.

Removing the subwoofer (version 2)

App lies to: vehicles with subwoofer in the spare wheel well

The subwoofer must be removed before the

spore wheel* can be removed .

Fig. 298 Spare w heel well : su bwoofer

Removing the subwoofer

• Lift up the cargo floor ¢ page 362, fig . 295.

• Pull the lock CD¢ fig. 298 toward the cable.

• Press the locking tab@down.

• Remove the connector @ and set the removed

cable aside .

"' Remove the bolt@.

• Caref ully remove the subwoofer.

Emergency assistance

Installing the subwoofer

• Carefully place the subwoofer in the rim well.

The word "FRON T" on the subwoofer must face

forward.

• Insert the connector that was removed .

• Slide the lock CD back in the direction of the

subwoofer .

• Secure the subwoo fer with the bolt.

"' Fold the cargo floor cover back into place .

@ Tips

The subwoofer can also be mounted when the

spare tire is not in the spare wheel wheel.

363

Page 367 of 400

a, co ..... N

" N ..... 0 N > 00

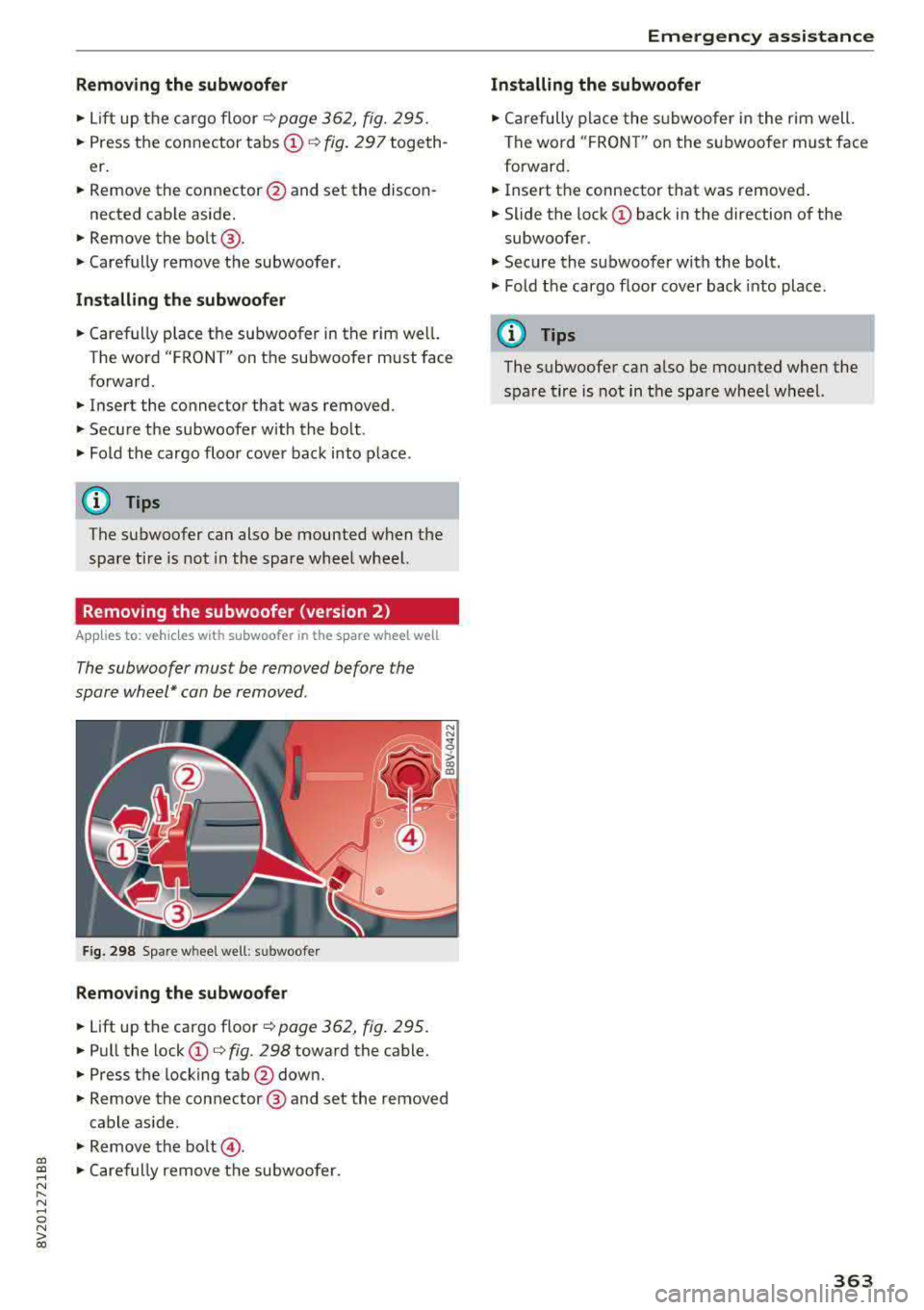

Fuse assignment -interior

Fig. 301 Vehicle interior: fuse assignment

No. Equipment

Fl Ad

Blue engine components

F2 Seat adjustment

F3 Power top hyd

raulic pump

F4 Infotainment control panel, Infotainment

components

FS Gateway

F6 Selector lever (automat ic transmission)

F7 Climate/heating control, auxiliary heating,

rear window defogger relay

Electromechan ica l parking brake sw itch,

F8 light switch,

rain/light sensor, inte rior

lighting, anti-theft alarm system, diagnos -

tic connector, communication box

F9 Steering column sw itch module

Fl0 Infotainment system display

Fll Dr iver's side safety belt tens ioner

F12 Infotainment components

F13 Suspension

control control module, diag-

nostic connector

F14 Heating/air conditioning system blower

FlS Electronic steering column lock

No .

Fl6

F 17

Fl8

F 19

F20

F21

F2 3

F24

F 2S

F26

F 27

F28

F2 9

F 31

F32

F33

F34

F 3S

F36

F3 7

F38

F39

F 40

F41

F42

F43

F44

F47

F4 8

Fuses and bulbs

Equipment

Infotainment components

Instrument cluster

Rearview camera

Convenience access cont rol module

Engine components

Steering column, steering wheel heating

switch module

Right vehicle electrical system control

module

Panorama glass roof/power top control

module, power top latch

Driver's s ide front/rear power w indows

Seat heating

Sound-amplifier

Convertible top control module

Interior lights

Left vehicle electrical system control mod-

ule

Rearview camera, radar sensor control

module

A irbag

Button i llumination, interior sound, re-

versing light switch, temperature sensor,

coil for neck heating relay and socket relay

Fu nct ion lighting, headl ight range control,

a ir quality sensor, automatic dimming

rearview mirror

R ight headlight

l eft headlight

High-voltage battery

Passenger's s ide front/rear power win -

dows

Sockets Passenger's side safety belt tensioner

Cen tral locking components, windshield

washer system

Interior lights

Al l wheel drive

Rear w indow wiper

Outer sound actuator

365

Page 373 of 400

a, a, ..... N

" N ..... 0 N > 00

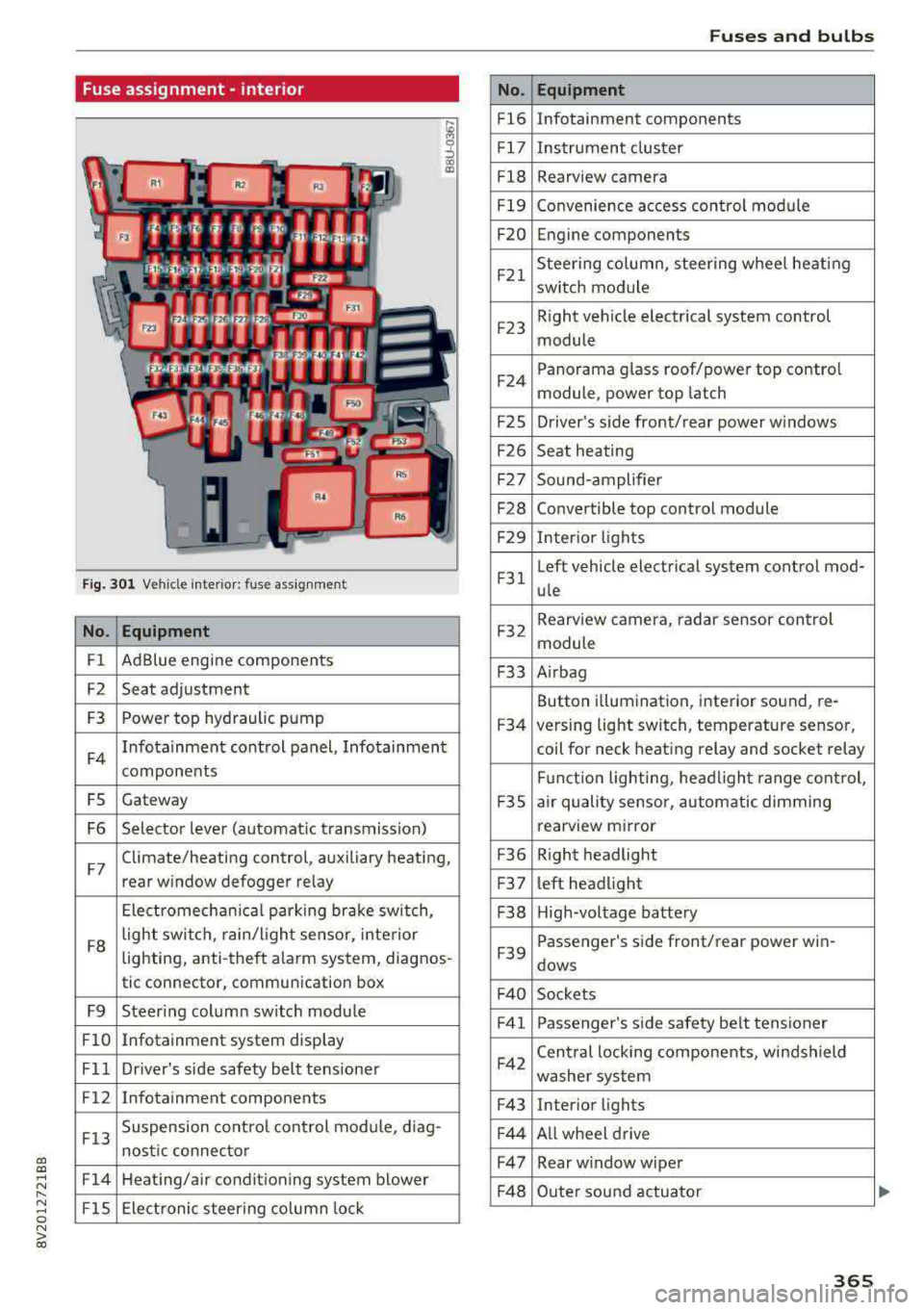

Front towing loop

____

•

Fig. 305 Right fro nt bumper : rem ov ing the cover

\___,

•

Fig. 306 Right front bumper: towing loo p installed

The threaded opening for the towing loop is lo

cated behind a

cover on the right side of the front

bumper .

• Remove the towing loop from the vehicle tool

kit

¢ page 353 .

• Press inward on the upper left area of the cap

with br ief , strong pressure to

remove it from

the

bumper ¢ fig. 305 .

• Tighten the towing loop in the threaded open

ing until it stops

¢ fig. 306 and then tighten it

with a whee l wrench.

• After using, place the towing loop back in the

v ehicl e tool kit.

A WARNING

If the towing loop is not tightened until it

stops when installing, the threads may be

pulled out when tow ing the veh icle and that

could cause an accident .

-

Emergency situations

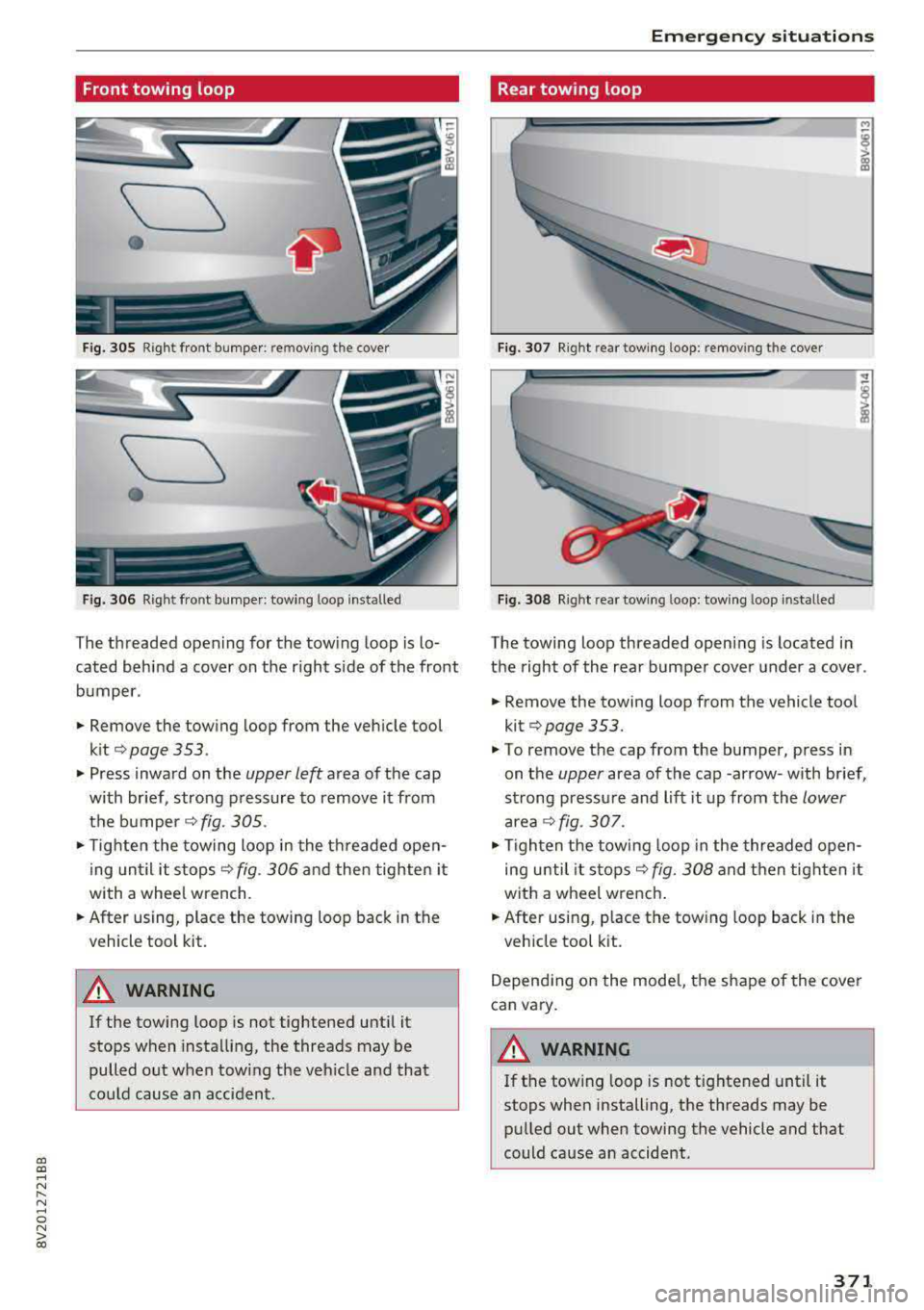

Rear towing loop

Fig. 307 R ig ht re ar towing loo p: remov ing the cover

Fig. 308 Right rea r towing loop: towing loop insta lled

The towing loop threaded opening is located in

the right of the rear bumper cover under a cover .

• Remove the tow ing loop from the vehicle tool

kit ¢

page 353 .

.,. To remove the cap from the bumper, press in

on the

upper area of the cap -arrow -with br ief,

strong pressure and lift it up from the

lower

area¢ fig. 307.

• Tigh ten the towing loop in the threaded open

ing until it stops ¢

fig. 308 and then tighten it

with a wheel wrench .

• After using, place the tow ing loop back in the

v e hicle tool k it.

Depending on the model, the shape of the cover

can vary.

WARNING

If the tow ing loop is not tightened until it

stops when installing, the threads may be

pulled out when towing the vehicle and that

could cause an accident .

371

Page 377 of 400

CXl CXl .... N ,.__

N .... 0 N > 00

Gross Axle Weight Rating

The G ross Axle We igh t Rating is the max imum

l oad that can be applied at each axle of the vehi

cle~.& .

Vehicle capacity weight

The vehicle capac ity we ight (max. load) is listed

e ithe r o n the dr iver's side B-pillar o r inside the

f u el fi ller flap.

& WARNING

-T he actual Gross Ax le Weight Rating at the

front and rear axles sho uld not exceed the

permissible weights, and their comb inat ion

must not exceed the Gross Vehicle We ight

Rat ing.

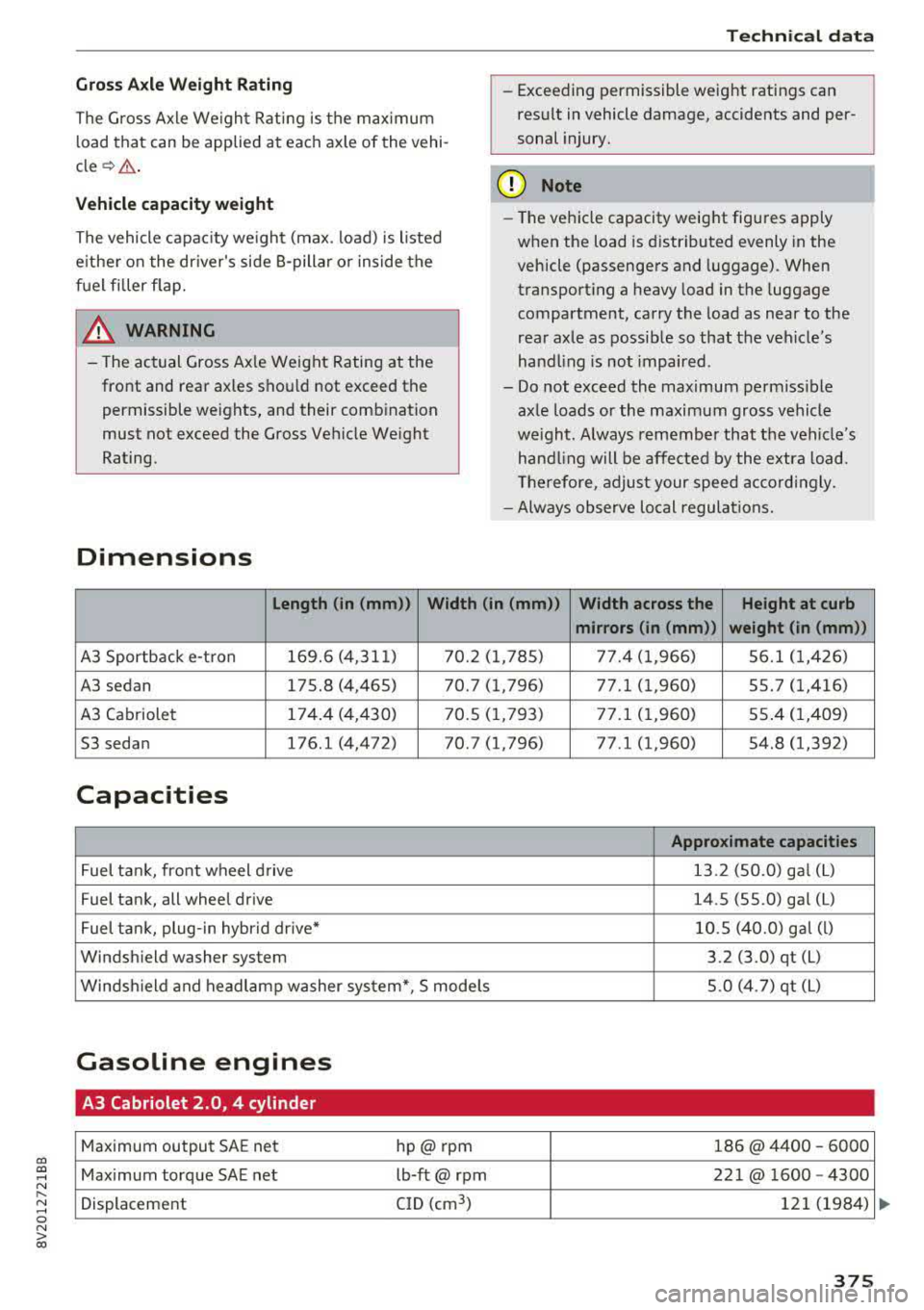

Dimensions

Techn ical data

-Exceeding permissible weight ratings can

res ult in vehicle damage, accidents and per

sonal injury.

(D Note

-T he vehi cle capacity weig ht figu res apply

when the load is d istributed evenly in the

vehicle (passengers and luggage). When

transport ing a heavy load in the luggage

compartment, ca rry the load as near to the

rear axle as possib le so that t he veh icle's

hand ling is no t impaired .

-Do not exceed the maximum perm iss ible

ax le loads or the maximum gross vehicle

we igh t. Always remember that the veh icle's

han dling will be affe cted by the extra load.

Th erefore, adjust your spee d accordingly.

-Always observe local regulations.

Length (in (mm)) Width (in (mm )) Width across the Height at curb

mirrors (in (mm )) weight (in (mm))

A3 Sportback e-t ron 169.6 (4,31

1) 7 0.2 ( 1,785) 77.4 ( 1,966) 56.1 (1, 426)

A3 sedan 175.8 (4,465) 70.7 (1,796) 77.1 (1,960) 55.7 (1,416)

A3 Cabriole t 174

.4 (4,430) 7 0.5 ( 1,793) 77 .1 ( 1,960) 55.4 ( 1,409)

53 seda n 176.1 (4,472) 70.7 (1,796) 77.1 (1,960) 54 .8 (1,392)

Capacities

Appro ximate capacities

Fuel ta nk, front w heel d rive 13

.2 (50.0) ga l (L )

Fuel tank, all wheel drive 14.S (55.0) gal

(L)

Fuel tank, plug -in hybr id drive* 10

.5 (40.0) g al (l)

Windshield washer system 3.2 (3.0) qt (L)

Winds hield and headlamp washer sys tem*, S mode ls 5.0 (4.7) qt

(L)

Gasoline engines

A3 Cabriolet 2.0, 4 cylinder

Maximum output SA

E net hp@rpnn 186@ 4400 -6000

Maximum torque SAE net lb-ft@ rpm 221@ 1600

-4300

Displacement C

ID (cm

3

) 12 1 (1984)

375

Page 381 of 400

CXl CXl .... N ,.__

N .... 0 N > 00

today's automobiles, have steadily reduced the

scope of maintenance and repairs which can be

carried out by vehicle owners.

Also, safety and

environmental

concerns place very strict limits

on the nature of repairs and adjustments to en

gine and transmission parts which an owner can perform .

Maintenance, adjustments and repairs usually re

quire special tools, testing devices and other

equipment available to specially trained work

shop personnel in order to assure proper per

formance, reliability and safety of the vehicle and its many systems.

Improper maintenance, adjustments and repairs

can impair the operation and reliability of your

vehicle and even void your vehicle warranty .

Therefore, proof of servicing in accordance with

the maintenance schedule may be a condition for upholding a possible warranty claim made within

the warranty period.

Above all , operational safety can be adversely af

fected, creating unnecessary risks for you and

your passengers.

If in doubt about any servicing, have it done by

your authorized Audi dealer or any other properly equipped and qualified workshop. We strongly urge you to give your authorized Audi dealer the

opportunity to perform all scheduled mainte nance and necessary repairs. Your dealer has the

facilities, original parts and trained specialists to keep your vehicle running properly .

Performing limited maintenance yourself

The following pages describe a limited number of

procedures which can be performed on your vehi

cle with ordinary tools, should the need arise and

trained personnel be unavailable. Before per

forming any of these procedures, always thor

oughly read all of the applicable text and careful ly follow the instructions given . Always rigorously

observe the

WARNINGS provided .

Before you check anything in the engine com

partment, always read and heed all WARNINGS

c::> .&. and c::> page 316 .

Consumer information

A WARNING

-Serious personal injury may occur as a result

of improperly performed maintenance, ad

justments or repairs .

- Always be extremely careful when working

on the vehicle. Always follow commonly ac

cepted safety practices and general com mon sense. Never risk personal injury.

- Do not attempt any of the maintenance,

checks or repairs described on the following pages if you are not fully familiar with these

or other procedures with respect to the ve hicle, or are uncertain how to proceed.

- Do not do any work without the proper tools

and equipment. Have the necessary work

done by your authorized Audi dealer or an

other properly equipped and qualified work

shop.

- The engine compartment of any motor vehi cle is a potentially hazardous area. Never

reach into the area around or touch the radi

ator fan.

It is temperature controlled and

can switch on suddenly - even when the en

gine is off . The radiator fan switches on au

tomatically when the coolant reaches a cer

tain temperature and will continue to run

until the coolant temperature drops.

- Always switch off the ignition before anyone

gets under the vehicle.

-Always support your vehicle with safety

stands if it is necessary to work underneath

the vehicle . The jack supplied with the vehi

cle is not adequate for this purpose and

could collapse causing serious personal in

jury.

- If you must work underneath the vehicle

with the wheels on the ground, always make

sure the vehicle is on level ground, that the

wheels are always securely blocked and that

the engine cannot be started.

- Always make sure the transmission selector

lever (automatic transmission) is in P (Park

position) and the park brake is applied .

II>

379