tow AUDI S4 1997 B5 / 1.G 01E Transmission Bearing House And Torsen Differential Workshop Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 1997, Model line: S4, Model: AUDI S4 1997 B5 / 1.GPages: 38, PDF Size: 0.87 MB

Page 5 of 38

34-57

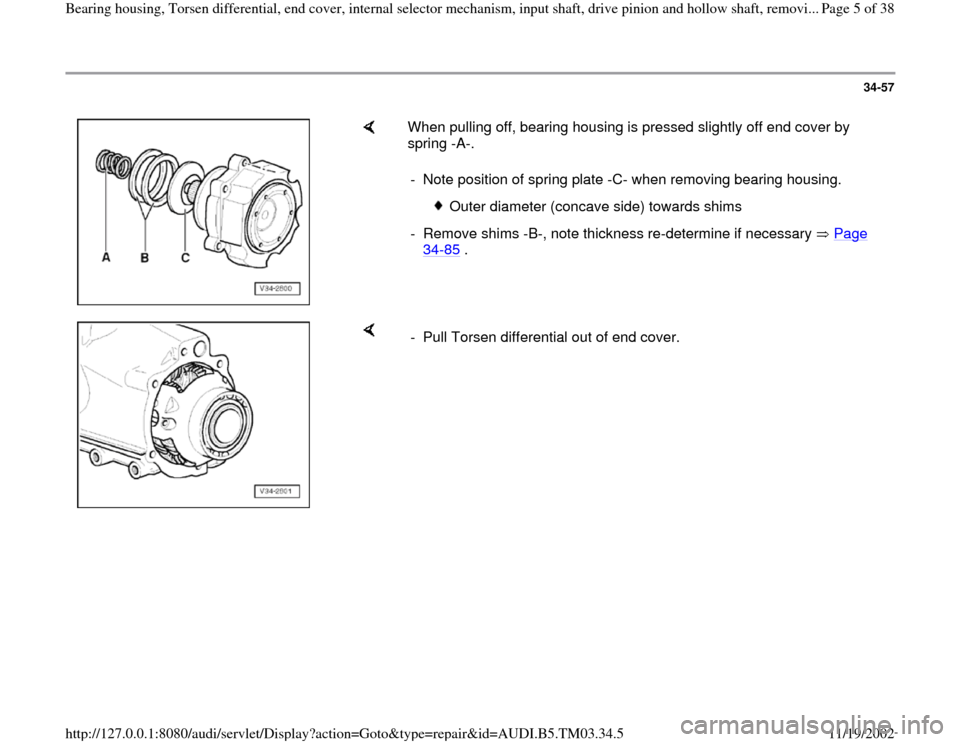

When pulling off, bearing housing is pressed slightly off end cover by

spring -A-.

- Note position of spring plate -C- when removing bearing housing.

Outer diameter (concave side) towards shims

- Remove shims -B-, note thickness re-determine if necessary Page

34

-85

.

- Pull Torsen differential out of end cover.

Pa

ge 5 of 38 Bearin

g housin

g, Torsen differential, end cover, internal selector mechanism, in

put shaft, drive

pinion and hollow shaft, removi...

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM03.34.5

Page 16 of 38

34-68

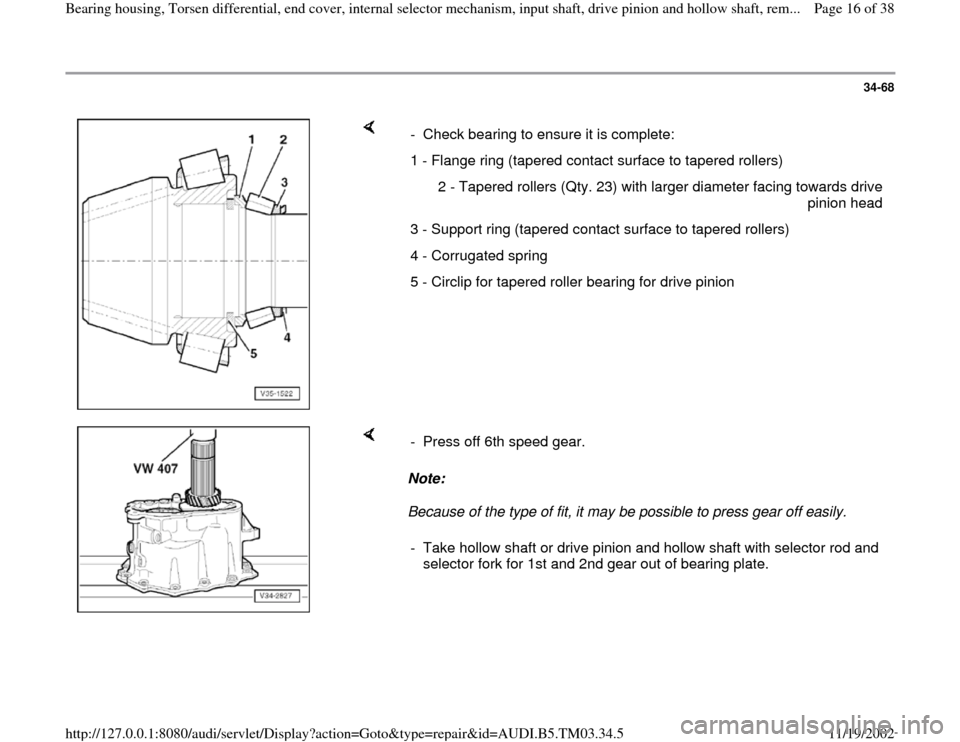

- Check bearing to ensure it is complete:

1 - Flange ring (tapered contact surface to tapered rollers)

2 - Tapered rollers (Qty. 23) with larger diameter facing towards drive

pinion head

3 - Support ring (tapered contact surface to tapered rollers)

4 - Corrugated spring

5 - Circlip for tapered roller bearing for drive pinion

Note:

Because of the type of fit, it may be possible to press gear off easily. - Press off 6th speed gear.

- Take hollow shaft or drive pinion and hollow shaft with selector rod and

selector fork for 1st and 2nd gear out of bearing plate.

Pa

ge 16 of 38 Bearin

g housin

g, Torsen differential, end cover, internal selector mechanism, in

put shaft, drive

pinion and hollow shaft, rem...

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM03.34.5

Page 17 of 38

34-69

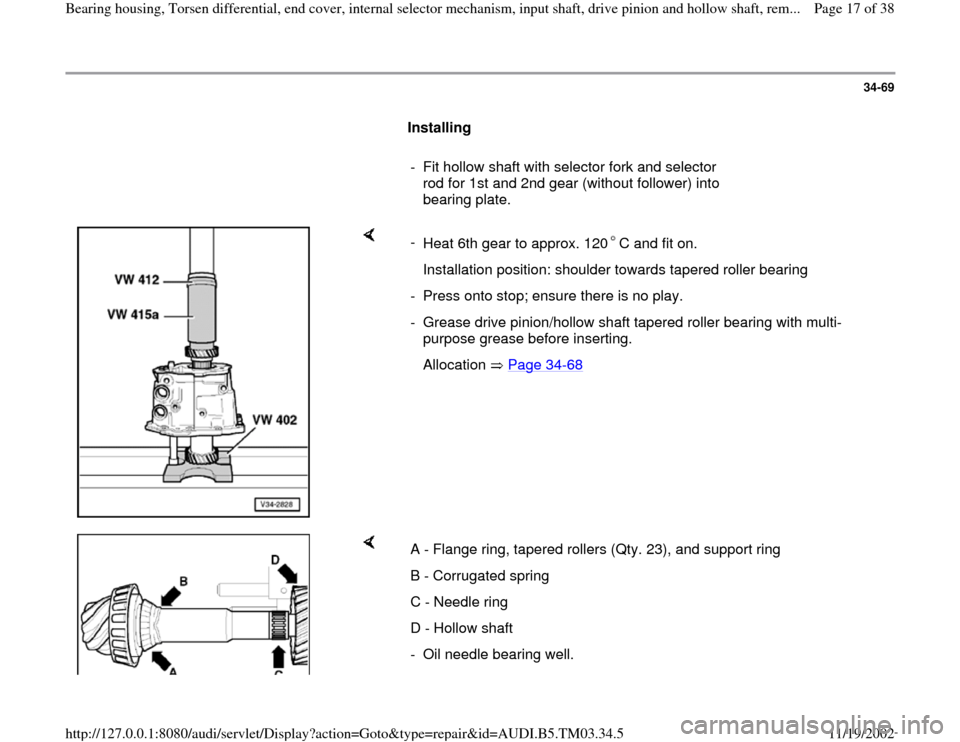

Installing

- Fit hollow shaft with selector fork and selector

rod for 1st and 2nd gear (without follower) into

bearing plate.

-

Heat 6th gear to approx. 120 C and fit on. Installation position: shoulder towards tapered roller bearing

- Press onto stop; ensure there is no play.

- Grease drive pinion/hollow shaft tapered roller bearing with multi-

purpose grease before inserting.

Allocation Page 34

-68

A - Flange ring, tapered rollers (Qty. 23), and support ring

B - Corrugated spring

C - Needle ring

D - Hollow shaft

- Oil needle bearing well.

Pa

ge 17 of 38 Bearin

g housin

g, Torsen differential, end cover, internal selector mechanism, in

put shaft, drive

pinion and hollow shaft, rem...

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM03.34.5

Page 19 of 38

34-70

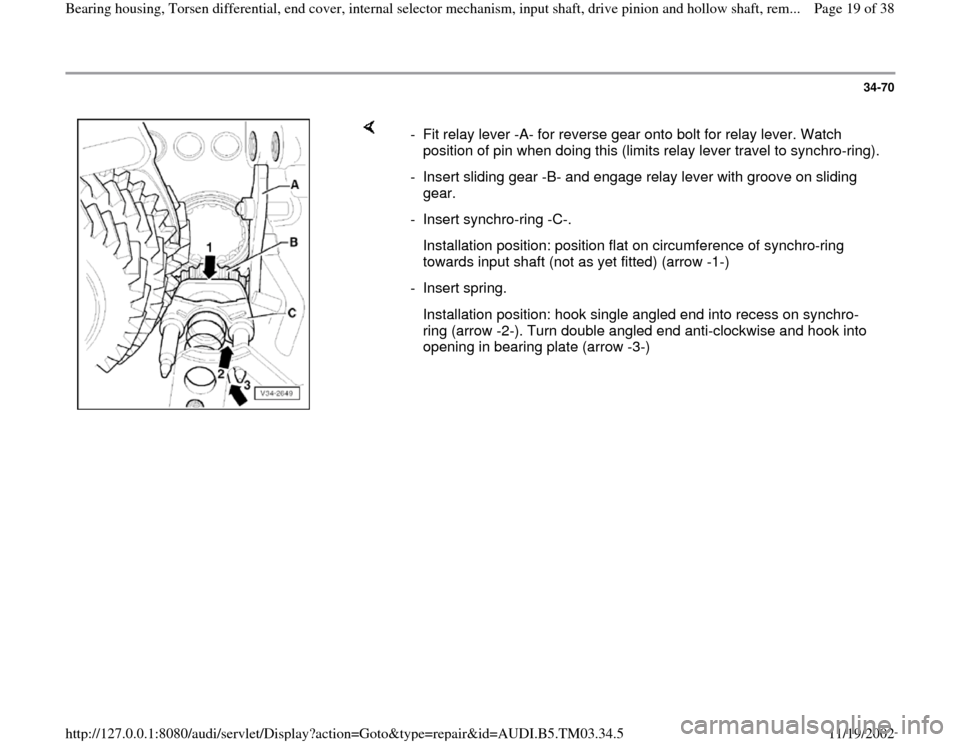

- Fit relay lever -A- for reverse gear onto bolt for relay lever. Watch

position of pin when doing this (limits relay lever travel to synchro-ring).

- Insert sliding gear -B- and engage relay lever with groove on sliding

gear.

- Insert synchro-ring -C-.

Installation position: position flat on circumference of synchro-ring

towards input shaft (not as yet fitted) (arrow -1-)

- Insert spring.

Installation position: hook single angled end into recess on synchro-

ring (arrow -2-). Turn double angled end anti-clockwise and hook into

opening in bearing plate (arrow -3-)

Pa

ge 19 of 38 Bearin

g housin

g, Torsen differential, end cover, internal selector mechanism, in

put shaft, drive

pinion and hollow shaft, rem...

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM03.34.5

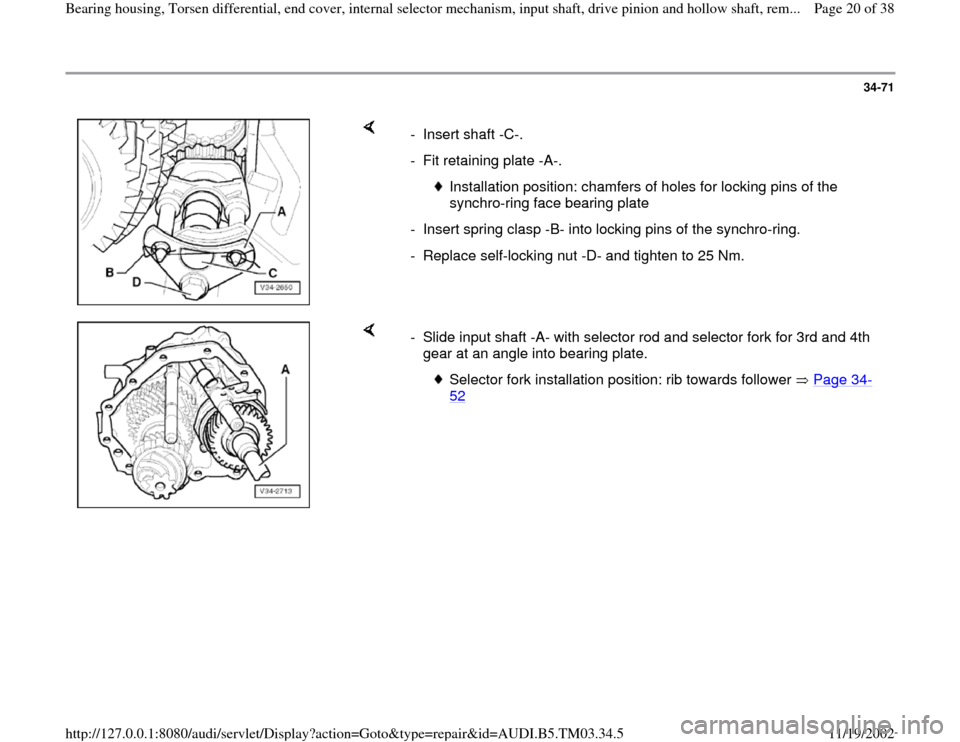

Page 20 of 38

34-71

- Insert shaft -C-.

- Fit retaining plate -A-.

Installation position: chamfers of holes for locking pins of the

synchro-ring face bearing plate

- Insert spring clasp -B- into locking pins of the synchro-ring.

- Replace self-locking nut -D- and tighten to 25 Nm.

- Slide input shaft -A- with selector rod and selector fork for 3rd and 4th

gear at an angle into bearing plate.

Selector fork installation position: rib towards follower Page 34

-

52

Pa

ge 20 of 38 Bearin

g housin

g, Torsen differential, end cover, internal selector mechanism, in

put shaft, drive

pinion and hollow shaft, rem...

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM03.34.5

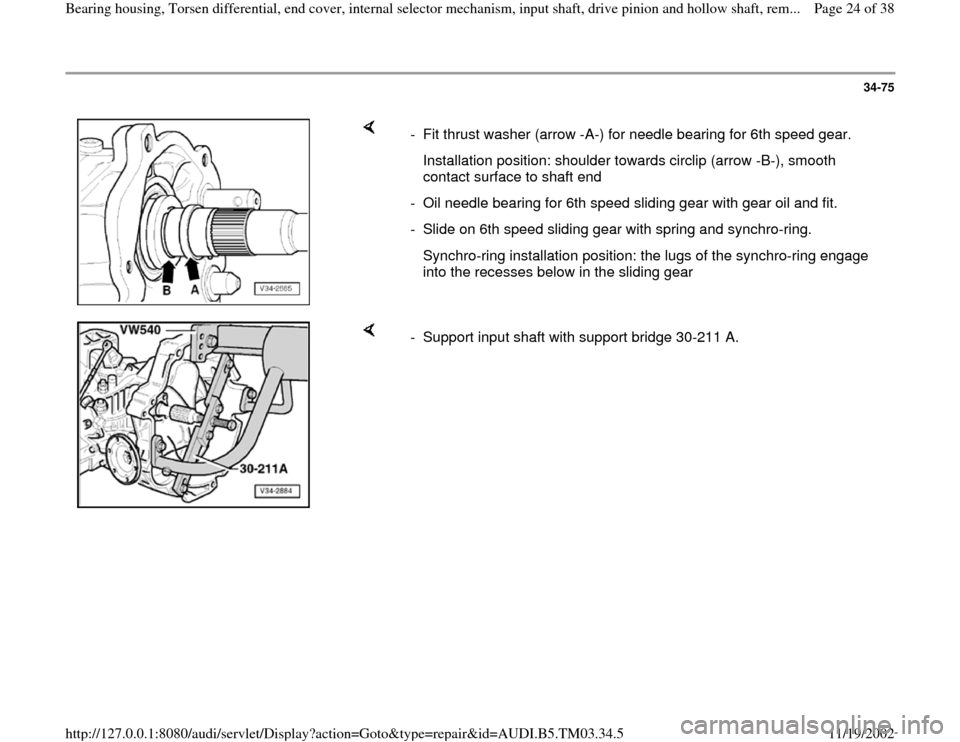

Page 24 of 38

34-75

- Fit thrust washer (arrow -A-) for needle bearing for 6th speed gear.

Installation position: shoulder towards circlip (arrow -B-), smooth

contact surface to shaft end

- Oil needle bearing for 6th speed sliding gear with gear oil and fit.

- Slide on 6th speed sliding gear with spring and synchro-ring.

Synchro-ring installation position: the lugs of the synchro-ring engage

into the recesses below in the sliding gear

- Support input shaft with support bridge 30-211 A.

Pa

ge 24 of 38 Bearin

g housin

g, Torsen differential, end cover, internal selector mechanism, in

put shaft, drive

pinion and hollow shaft, rem...

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM03.34.5

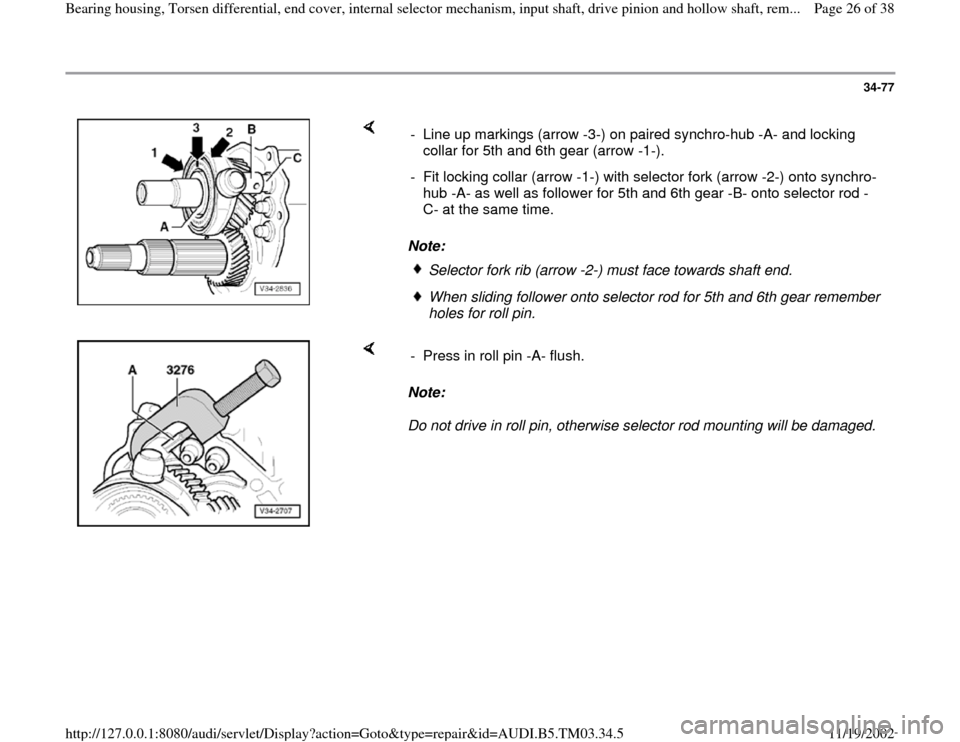

Page 26 of 38

34-77

Note: - Line up markings (arrow -3-) on paired synchro-hub -A- and locking

collar for 5th and 6th gear (arrow -1-).

- Fit locking collar (arrow -1-) with selector fork (arrow -2-) onto synchro-

hub -A- as well as follower for 5th and 6th gear -B- onto selector rod -

C- at the same time.

Selector fork rib (arrow -2-) must face towards shaft end. When sliding follower onto selector rod for 5th and 6th gear remember

holes for roll pin.

Note:

Do not drive in roll pin, otherwise selector rod mounting will be damaged. - Press in roll pin -A- flush.

Pa

ge 26 of 38 Bearin

g housin

g, Torsen differential, end cover, internal selector mechanism, in

put shaft, drive

pinion and hollow shaft, rem...

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM03.34.5

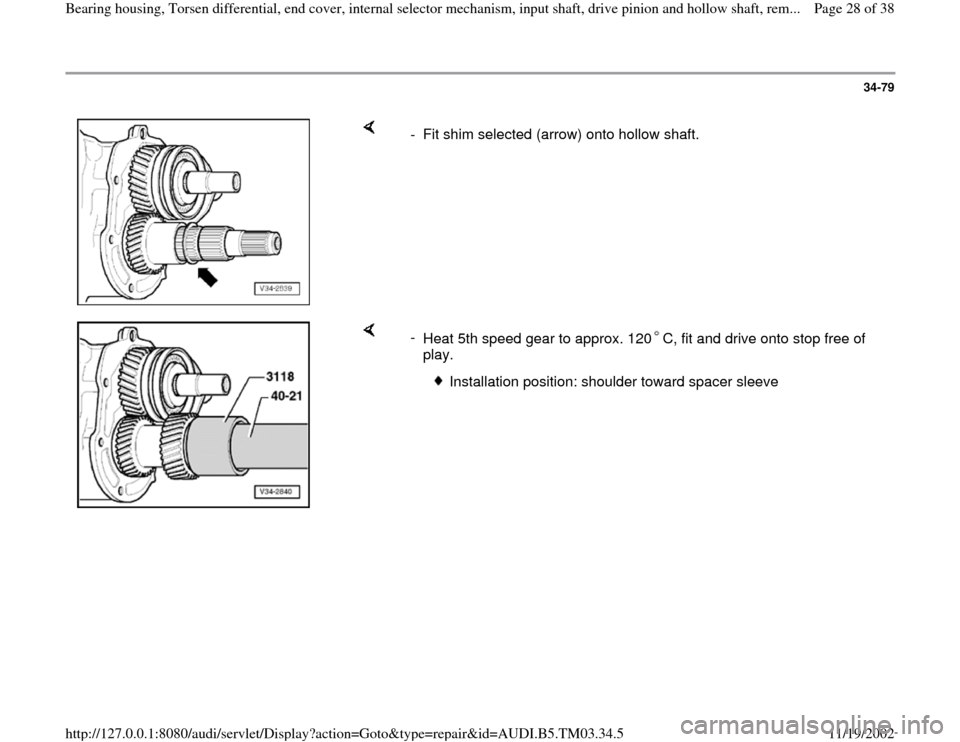

Page 28 of 38

34-79

- Fit shim selected (arrow) onto hollow shaft.

-

Heat 5th speed gear to approx. 120 C, fit and drive onto stop free of

play.

Installation position: shoulder toward spacer sleeve

Pa

ge 28 of 38 Bearin

g housin

g, Torsen differential, end cover, internal selector mechanism, in

put shaft, drive

pinion and hollow shaft, rem...

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM03.34.5

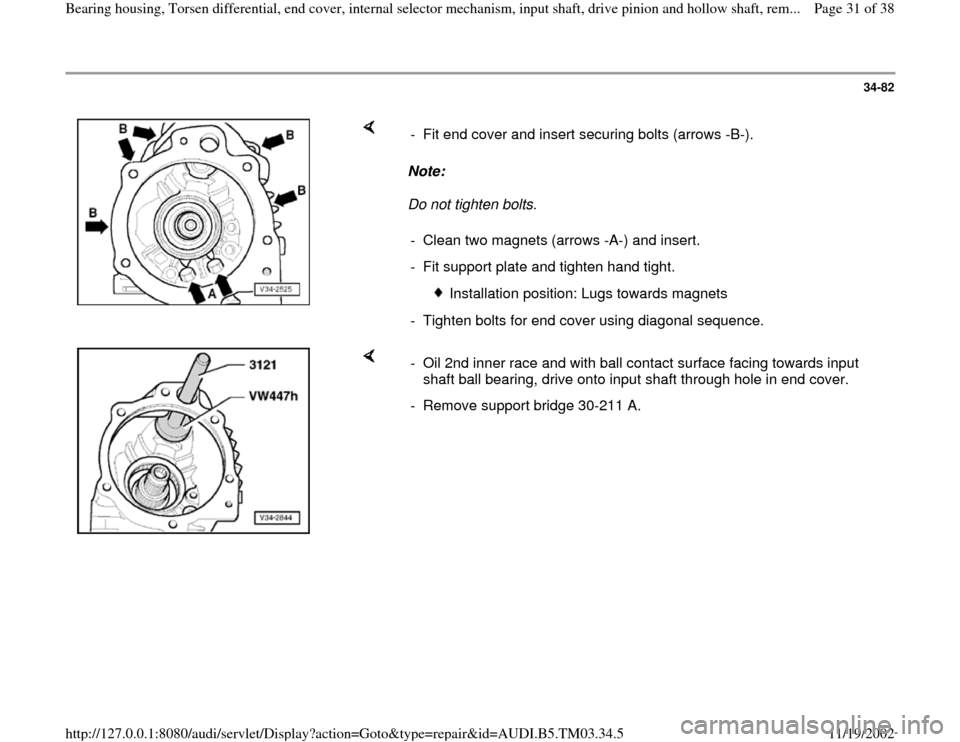

Page 31 of 38

34-82

Note:

Do not tighten bolts. - Fit end cover and insert securing bolts (arrows -B-).

- Clean two magnets (arrows -A-) and insert.

- Fit support plate and tighten hand tight.

Installation position: Lugs towards magnets

- Tighten bolts for end cover using diagonal sequence.

- Oil 2nd inner race and with ball contact surface facing towards input

shaft ball bearing, drive onto input shaft through hole in end cover.

- Remove support bridge 30-211 A.

Pa

ge 31 of 38 Bearin

g housin

g, Torsen differential, end cover, internal selector mechanism, in

put shaft, drive

pinion and hollow shaft, rem...

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM03.34.5

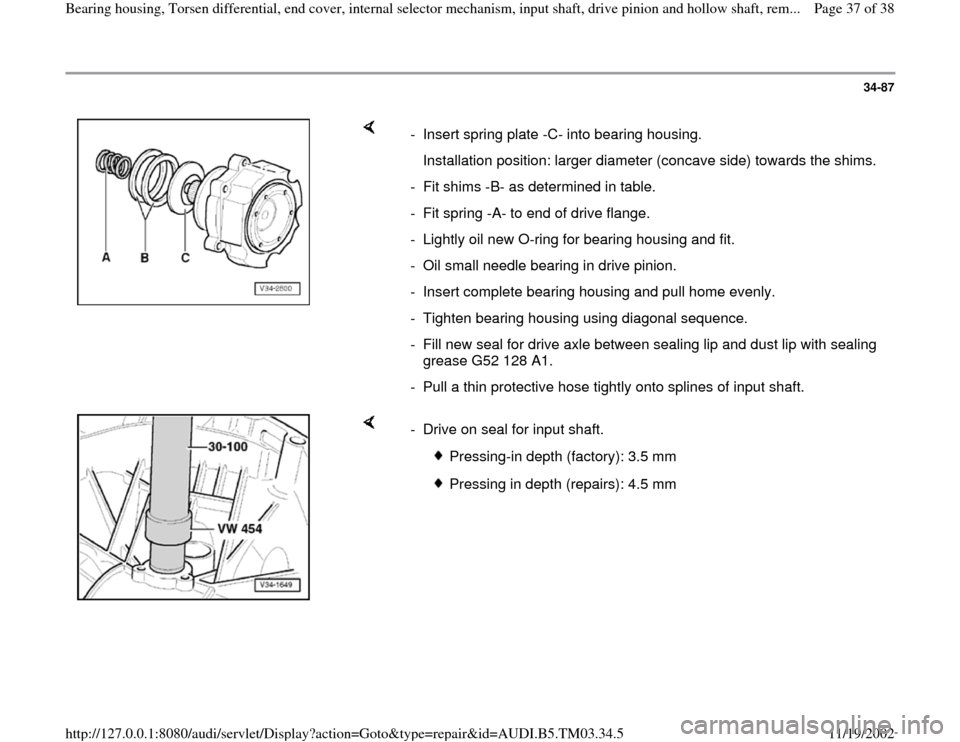

Page 37 of 38

34-87

- Insert spring plate -C- into bearing housing.

Installation position: larger diameter (concave side) towards the shims.

- Fit shims -B- as determined in table.

- Fit spring -A- to end of drive flange.

- Lightly oil new O-ring for bearing housing and fit.

- Oil small needle bearing in drive pinion.

- Insert complete bearing housing and pull home evenly.

- Tighten bearing housing using diagonal sequence.

- Fill new seal for drive axle between sealing lip and dust lip with sealing

grease G52 128 A1.

- Pull a thin protective hose tightly onto splines of input shaft.

- Drive on seal for input shaft.

Pressing-in depth (factory): 3.5 mm

Pressing in depth (repairs): 4.5 mm

Pa

ge 37 of 38 Bearin

g housin

g, Torsen differential, end cover, internal selector mechanism, in

put shaft, drive

pinion and hollow shaft, rem...

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM03.34.5