service AUDI S4 1998 B5 / 1.G Engine Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 1998, Model line: S4, Model: AUDI S4 1998 B5 / 1.GPages: 72, PDF Size: 3.25 MB

Page 1 of 72

Service.

For internal use only

198

All rights reserved. Subject

to change.

AUDI AG

Dept.I/GS-5

D-85045 Ingolstadt

Fax +49.841/89-6367

740.2810.17.20

Technical status: 01/98

Printed in Germany

The 2.7-litre V6 Biturbo

Design and Function

Self-study Programme 198

Page 3 of 72

3

This Self-study Programme provides you with information

regarding design and function.

The Self-study Programme is not a Workshop Manual!

Please refer to the Service Literature for all the relevant

maintenance and repair instructions.

Page

Engine .........................................................

Technical data, crankshaft, cylinder head,

camshaft timing, cooling circuit, engine

lubrication, overview of components, air ducting,

charging, exhaust system, pneumatically

controlled systems, charge pressure control, air

divert control in overrun, ACF system, crankcase

breather

4

Motronic ME 7.1 ..........................................

Subfunctions, system overview

31

Subsystems of the Motronic .....................

Torque-oriented engine management, torque-

oriented functional structure, Electronic throttle,

exhaust gas temperature control

33

Sensors .......................................................

Additional sensors of the Motronic

49

Auxiliary signals/interfaces ...................... 57

Functional diagram ..................................... 62

Self-diagnosis .............................................

Vehicle diagnosis, test and information system

VAS 5051, test box V.A.G 1598/31

64

Transmission ..............................................

Self-adjusting clutch, gearbox

66

Contents

Important!/Note!

New!

Page 22 of 72

23

SSP 198/32

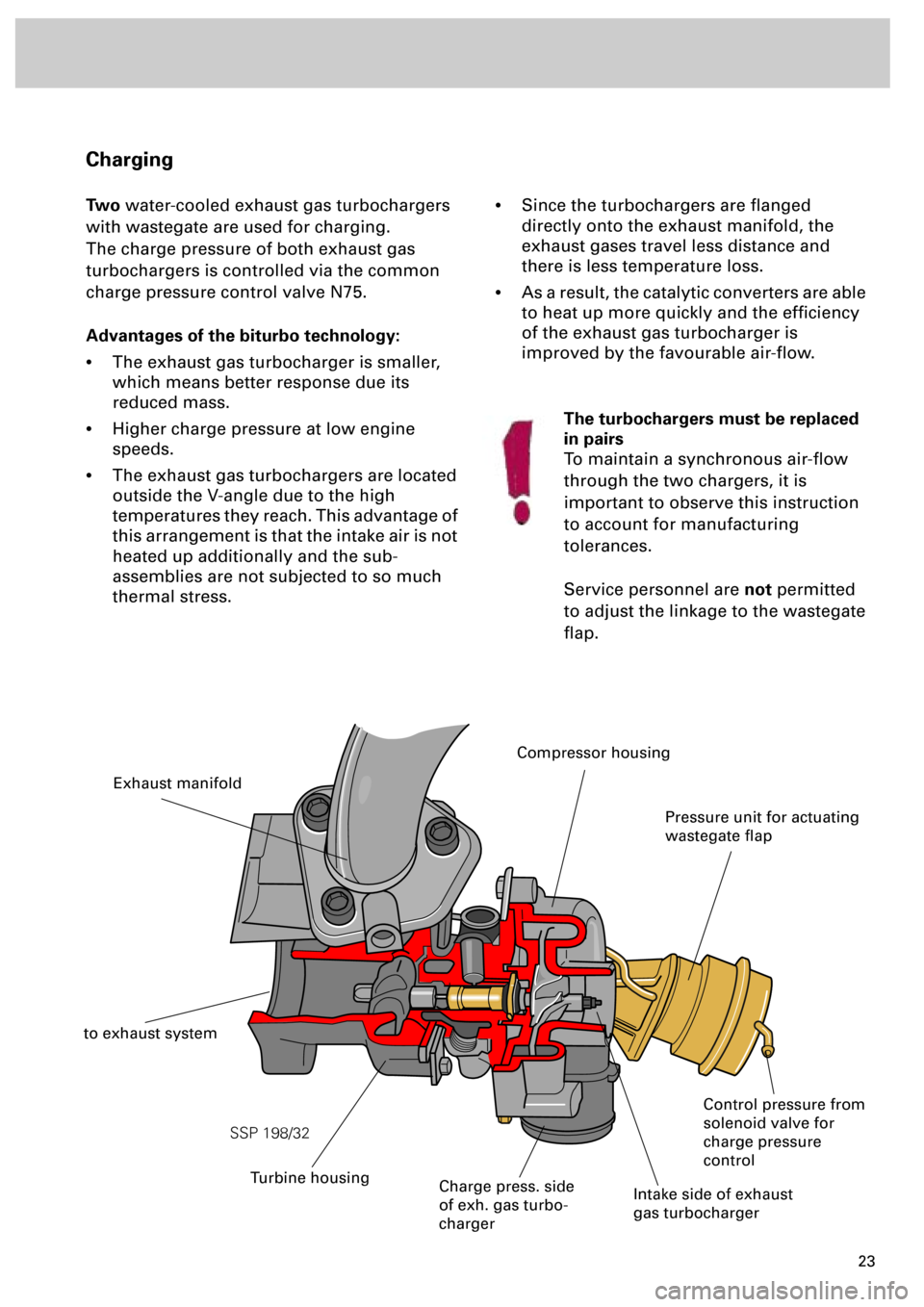

Charging

Two

water-cooled exhaust gas turbochargers

with wastegate are used for charging.

The charge pressure of both exhaust gas

turbochargers is controlled via the common

charge pressure control valve N75.

Advantages of the biturbo technology:

•

The exhaust gas turbocharger is smaller,

which means better response due its

reduced mass.

•

Higher charge pressure at low engine

speeds.

•

The exhaust gas turbochargers are located

outside the V-angle due to the high

temperatures they reach. This advantage of

this arrangement is that the intake air is not

heated up additionally and the sub-

assemblies are not subjected to so much

thermal stress.

•

Since the turbochargers are flanged

directly onto the exhaust manifold, the

exhaust gases travel less distance and

there is less temperature loss.

•

As a result, the catalytic converters are able

to heat up more quickly and the efficiency

of the exhaust gas turbocharger is

improved by the favourable air-flow.

Intake side of exhaust

gas turbocharger

Charge press. side

of exh. gas turbo-

charger

Exhaust manifold

to exhaust system

Pressure unit for actuating

wastegate flap

Control pressure from

solenoid valve for

charge pressure

control

The turbochargers must be replaced

in pairs

To maintain a synchronous air-flow

through the two chargers, it is

important to observe this instruction

to account for manufacturing

tolerances.

Service personnel are

not

permitted

to adjust the linkage to the wastegate

flap.

Turbine housing

Compressor housing

Page 23 of 72

24

SSP 198/33

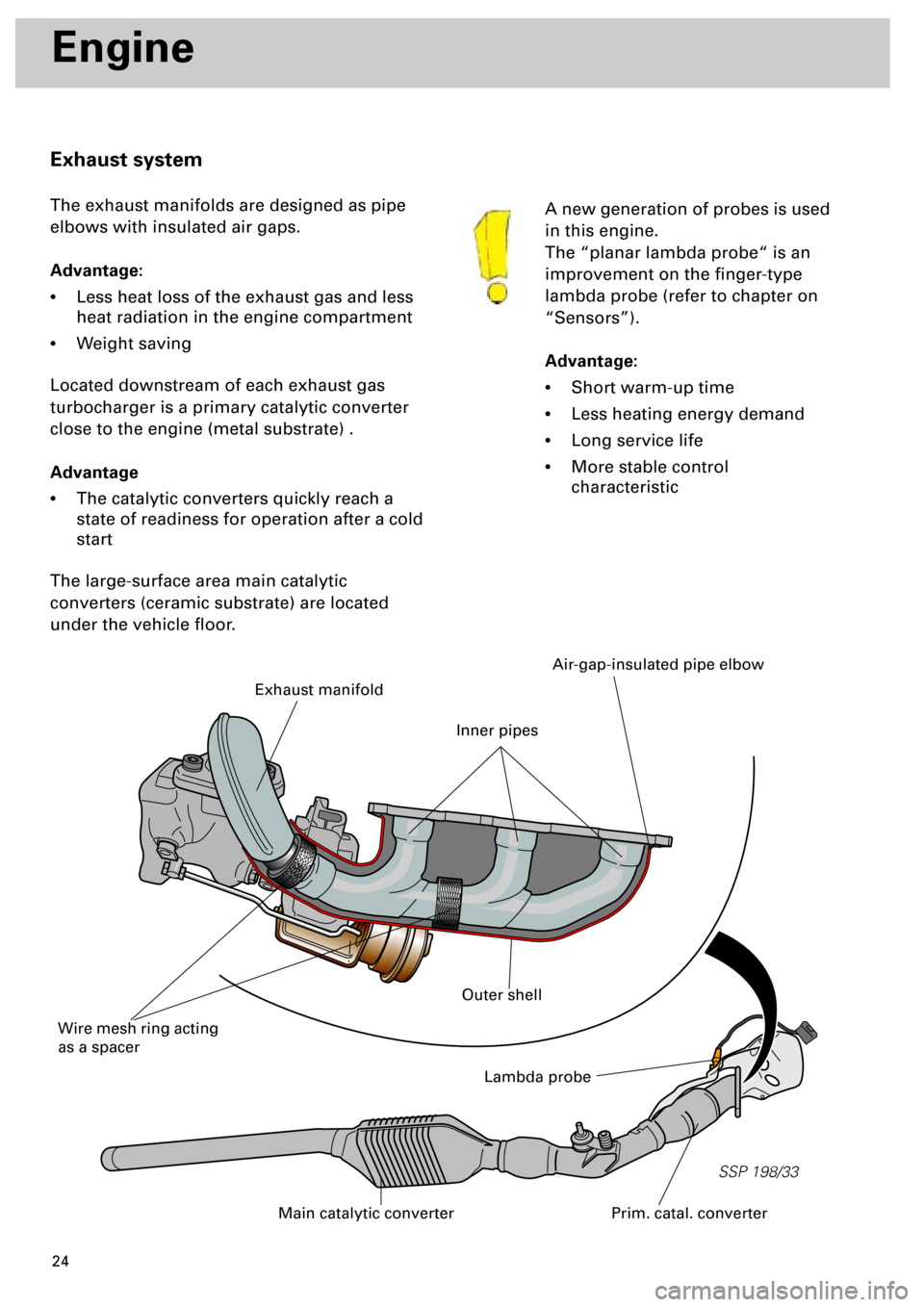

Engine

A new generation of probes is used

in this engine.

The “planar lambda probe“ is an

improvement on the finger-type

lambda probe (refer to chapter on

“Sensors”).

Advantage:

•

Short warm-up time

•

Less heating energy demand

•

Long service life

•

More stable control

characteristic

Exhaust system

The exhaust manifolds are designed as pipe

elbows with insulated air gaps.

Advantage:

•

Less heat loss of the exhaust gas and less

heat radiation in the engine compartment

•

Weight saving

Located downstream of each exhaust gas

turbocharger is a primary catalytic converter

close to the engine (metal substrate) .

Advantage

•

The catalytic converters quickly reach a

state of readiness for operation after a cold

start

The large-surface area main catalytic

converters (ceramic substrate) are located

under the vehicle floor.

Lambda probe

Prim. catal. converterMain catalytic converter

Exhaust manifold

Wire mesh ring acting

as a spacer

Air-gap-insulated pipe elbow

Outer shell

Inner pipes

Page 51 of 72

52

Sensors

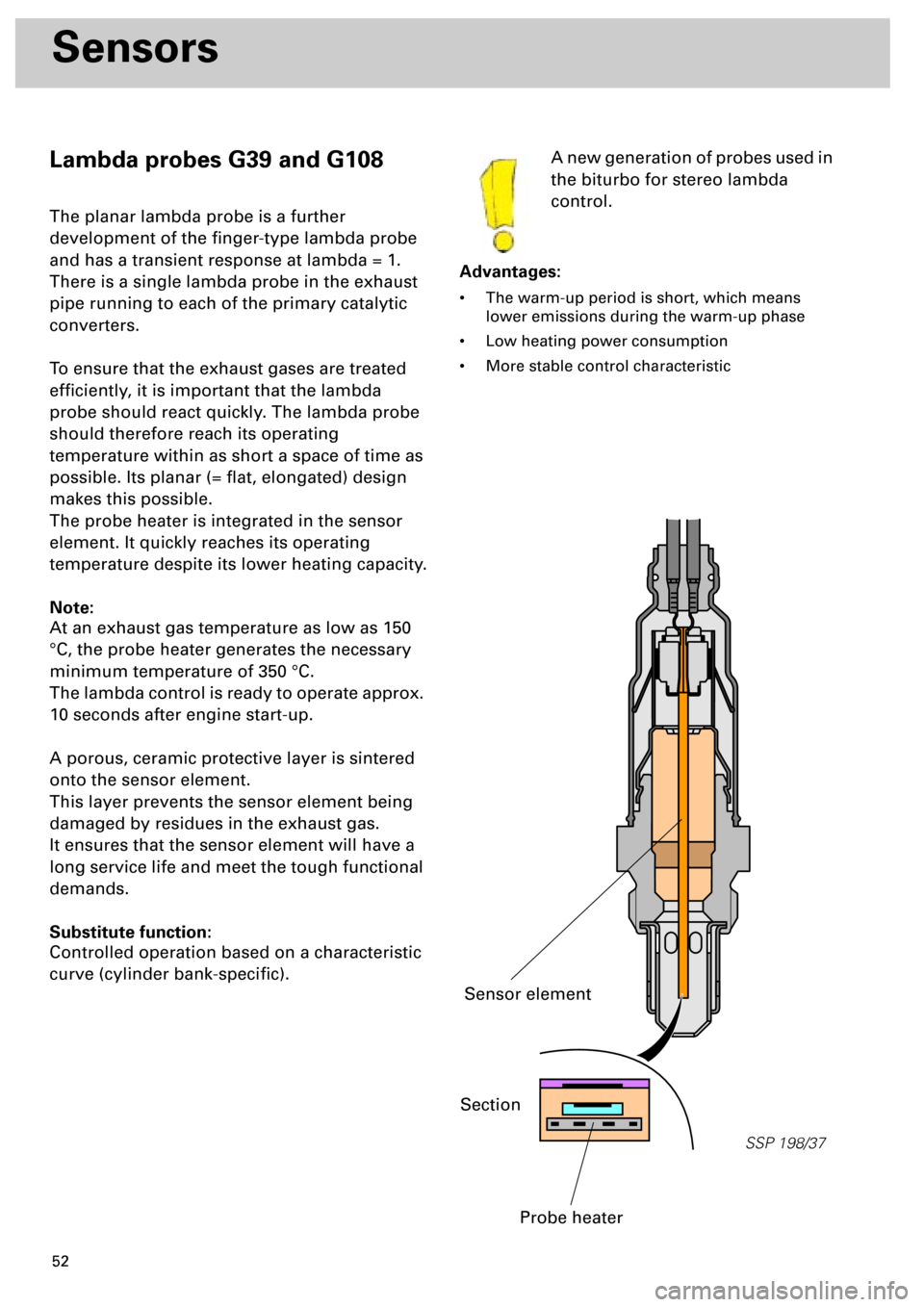

Lambda probes G39 and G108

The planar lambda probe is a further

development of the finger-type lambda probe

and has a transient response at lambda = 1.

There is a single lambda probe in the exhaust

pipe running to each of the primary catalytic

converters.

To ensure that the exhaust gases are treated

efficiently, it is important that the lambda

probe should react quickly. The lambda probe

should therefore reach its operating

temperature within as short a space of time as

possible. Its planar (= flat, elongated) design

makes this possible.

The probe heater is integrated in the sensor

element. It quickly reaches its operating

temperature despite its lower heating capacity.

Note:

At an exhaust gas temperature as low as 150

°C, the probe heater generates the necessary

minimum temperature of 350 °C.

The lambda control is ready to operate approx.

10 seconds after engine start-up.

A porous, ceramic protective layer is sintered

onto the sensor element.

This layer prevents the sensor element being

damaged by residues in the exhaust gas.

It ensures that the sensor element will have a

long service life and meet the tough functional

demands.

Substitute function:

Controlled operation based on a characteristic

curve (cylinder bank-specific).A new generation of probes used in

the biturbo for stereo lambda

control.

Advantages:

• The warm-up period is short, which means

lower emissions during the warm-up phase

• Low heating power consumption

• More stable control characteristic

SSP 198/37

Section

Probe heater

Sensor element

Page 65 of 72

66

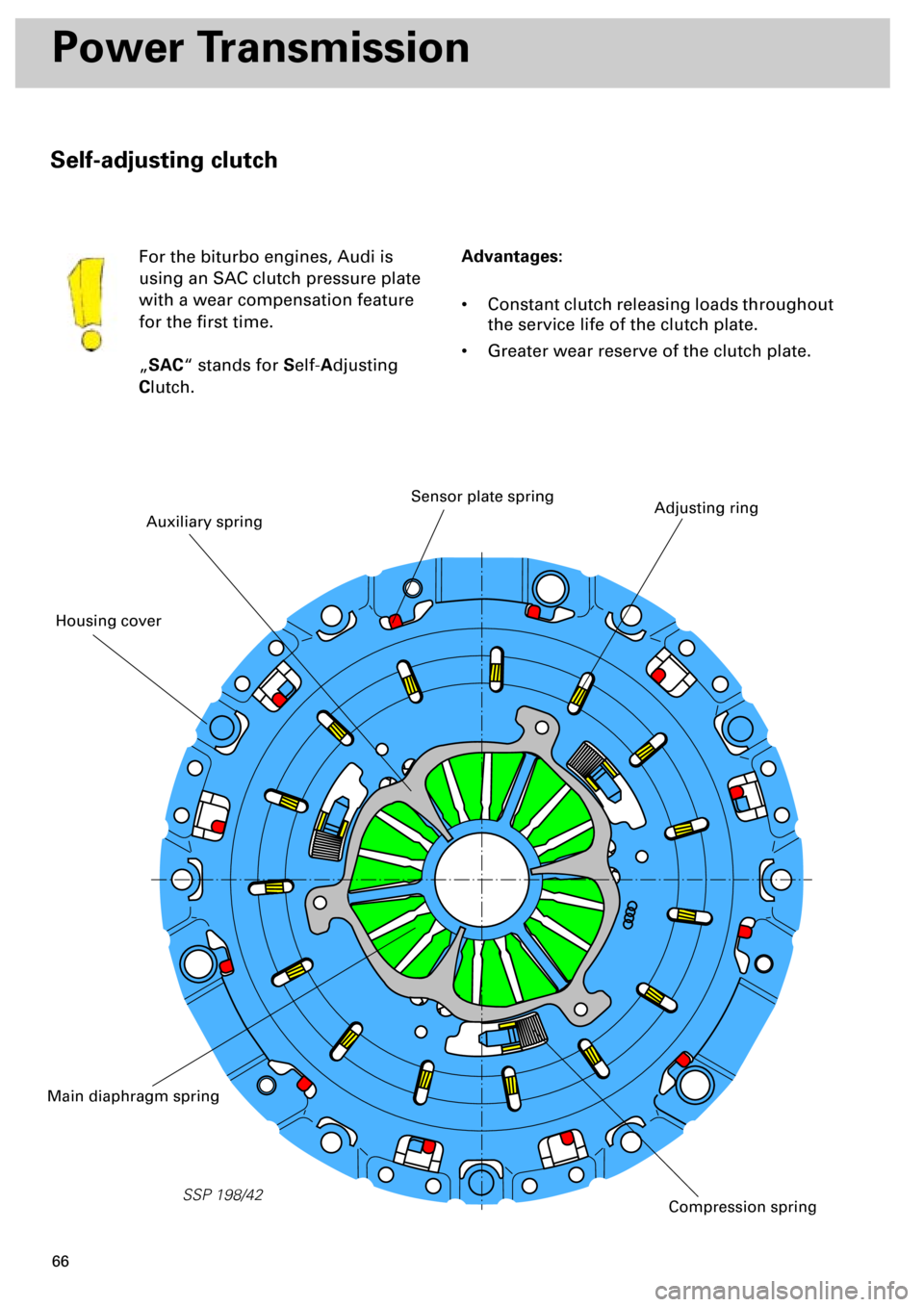

Power Transmission

Self-adjusting clutch

Advantages:

• Constant clutch releasing loads throughout

the service life of the clutch plate.

• Greater wear reserve of the clutch plate. For the biturbo engines, Audi is

using an SAC clutch pressure plate

with a wear compensation feature

for the first time.

„

SAC

“ stands for

S

elf-

A

djusting

C

lutch.

SSP 198/42

Auxiliary spring

Adjusting ringSensor plate spring

Main diaphragm spring

Compression spring

Housing cover

Page 72 of 72

73

Dear reader,

With its innovative development of the new biturbo engine, AUDI has

achieved a further milestone in the field of engineering.

With this Self-study Programme you were able to familiarise yourself with

the technology of the biturbo.

In the course of work on our corporate identity (CI), the Self-study

Programme now has a new format. For example, the SSP number is

printed on the back page of the booklet so that you no longer need to take

the booklet out of the folder when searching for it.

Please fax us your suggestions for improving the Self-study Programmes

on +49 841-89-6367.

With the kind regards of your Technical Service Training Team