bonnet AUDI S4 2008 User Guide

[x] Cancel search | Manufacturer: AUDI, Model Year: 2008, Model line: S4, Model: AUDI S4 2008Pages: 342, PDF Size: 15.01 MB

Page 70 of 342

Lights and vision

68when they are in the service position you will also avoid damaging

the paintwork on the bonnet.•

off - the windscreen wipers will be moved back to their original

position.Caution

Never move the vehicle with the front wiper arms in a raised posi-

tion as they are automatically moved back to their normal park posi-

tion above a speed of 6 km/h. The paintwork on the bonnet may be

damaged as a result.

Note

•

You can also use the service position, for example, if you want to

fix a cover over the windscreen in the winter to keep it clear of ice.

•

The service position is automatically set to off when you operate

the windscreen wiper lever or the road speed exceeds 6 km/h.

Changing wiper blades

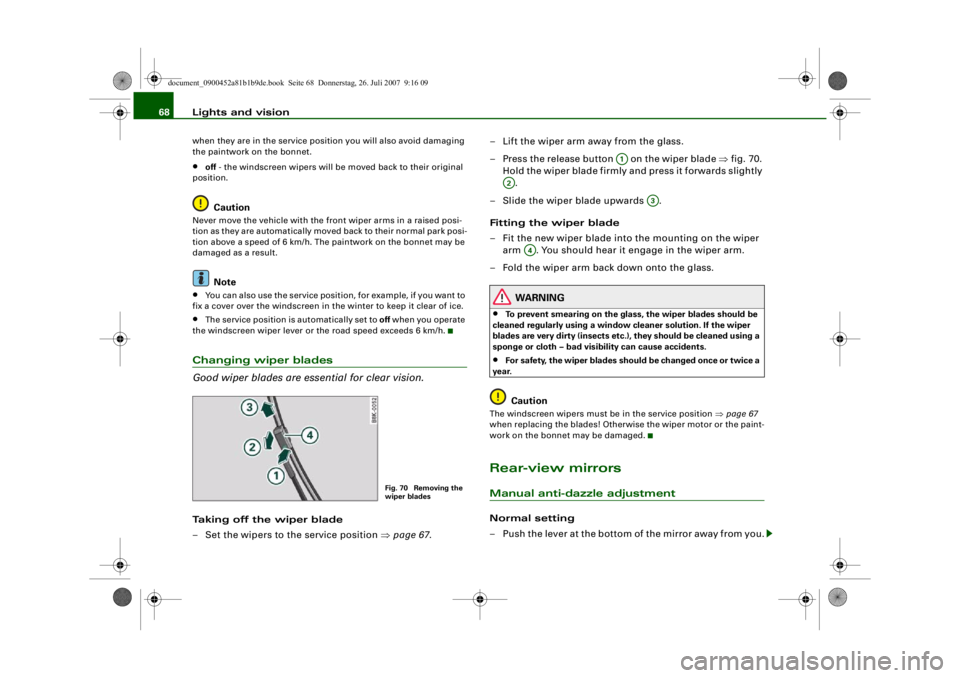

Good wiper blades are essential for clear vision.Taking off the wiper blade

– Set the wipers to the service position ⇒page 67 . – Lift the wiper arm away from the glass.

– Press the release button on the wiper blade

⇒fig. 70.

Hold the wiper blade firmly and press it forwards slightly .

– Slide the wiper blade upwards .

Fitting the wiper blade

– Fit the new wiper blade into the mounting on the wiper

arm . You should hear it engage in the wiper arm.

– Fold the wiper arm back down onto the glass.

WARNING

•

To prevent smearing on the glas s, the wiper blades should be

cleaned regularly using a window cleaner solution. If the wiper

blades are very dirty (i nsects etc.), they should be cleaned using a

sponge or cloth – bad visibility can cause accidents.

•

For safety, the wiper blades shou ld be changed once or twice a

year.Caution

The windscreen wipers must be in the service position ⇒page 67

when replacing the blades! Otherwise the wiper motor or the paint-

work on the bonnet may be damaged.Rear-view mirrorsManual anti-dazzle adjustmentNormal setting

– Push the lever at the bottom of the mirror away from you.

Fig. 70 Removing the

wiper blades

A1

A2

A3

A4

document_0900452a81b1b9de.book Seite 68 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

0 [I)

&

-+

•

+-

0

•

Page 166 of 342

Automatic gearbox

164moving the selector lever either in or out of position P. The lever can

only be moved out of position P when the ignition is on.

R - Reverse gear

When reverse gear is engaged the gearbox automatically selects the

lowest gear ratio.

Reverse gear must only be engaged when the vehicle is stationary

and the engine is idling ⇒.

To move the selector lever to position R, press in the interlock

button and at the same time press the brake pedal. Depending on

the model, one or two reversing lights will come on in selector lever

position R (when ignition is switched on).

N - Neutral

In this position the gearbox is in neutral ⇒.

D - Drive (forwards)

In this position the gearbox auto matically selects the best gear

ratio. This depends on the engine load, the road speed and the

dynamic gear control program (DCP).

Press the brake pedal when moving the selector lever from N to D if

the vehicle is stationary or at speeds below 5 km/h ⇒.

In some situations (such as on mountain roads or when towing a

trailer or caravan) it can be advantageous to switch temporarily to

tiptronic mode ⇒page 166 , so that the gear ratios can be selected

manually to suit the driving conditions.

S - Sport position

Select this position if you wish to take full advantage of the car's

performance. This setting makes use of the engine's maximum

power output. When accelerating the gear shifts will be noticeable.

Press the brake pedal when moving the selector lever from N to S if

the vehicle is stationary or at speeds below 5 km/h ⇒.

WARNING

•

Never move the selector lever to R or P when driving, as this

could cause an accident.

•

In selector position D or S the vehicle must always be held with

the foot brake when the engine is running. This is because an auto-

matic gearbox still transmits powe r even at idling speed, and the

vehicle tends to “creep”. The throttle must on no account be

opened inadvertently (for instan ce by hand from the engine

compartment) when a ge ar is engaged with the vehicle stationary.

The vehicle could otherwise star t moving immediately (in some

cases even if the parking brake is engaged) and possibly cause an

accident.

•

To avoid accidents, apply th e parking brake and put the

selector lever in position P befor e opening the bonnet and working

on the vehicle with the engine running. Please observe the impor-

tant safety warnings ⇒page 255, “Working on components in the

engine compartment”.Note

You can select the sport program for gear changes on vehicles with

Audi drive select* by activating the DYNAMIC mode. There is no S

position on the selector lever.•

Applies to vehicles with tiptronic gearbox:

•

If the lever is moved accidentally to N when driving, release the

accelerator and let the engine speed drop to idling before selecting

D or S again.

•

For the sake of fuel economy (and the environment), the gearbox

ratios on some models are designed so that maximum speed is only

obtained when the selector lever is at position S.

document_0900452a81b1b9de.book Seite 164 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

&

&

-+

[I]

+-

&

•

&

Page 247 of 342

Care of vehicle and cleaning245

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

WARNING

•

Do not wash the vehicle with the ignition switched on – risk of

accident.

•

Do not clean the underside of th e car or inside the wheel arches

without protecting your hands and arms. You may cut yourself on

sharp metal parts.

•

Take care when washing the car during the winter: moisture

and ice on the brakes may affect braking efficiency – this could

cause an accident.Caution

•

Do not wash the vehicle in direct sunlight – otherwise the paint

can be damaged.

•

Do not use insect sponges or ab rasive household sponges, etc.

– they can damage the surfaces.

•

The headlights should only be washed with water – do not wipe

them with a dry cloth or sponge . It is best to use soapy water.

•

Never wash tyres with a jet that sprays the water out in a direct

stream. This could damage the tyres – even if the spray is kept at a

distance and only used for a very short time.For the sake of the environment

The car should only be washed in special wash bays. This prevents

oily water from getting into the pu blic drains. In some districts,

washing vehicles anywhere else may be prohibited.Waxing and polishingWaxing

Waxing protects the paintwork. It is time to apply a good coat of wax

when water no longer forms droplets and rolls off the clean paint-

work. Even if a

wax solution is used regularly in the car wash, it is advis-

able to protect the paint with a coat of wax at least twice a year.

In the summer, you will find it is much easier to remove dead insects

(which accumulate on the bumper an d the front of the bonnet) if the

car has been waxed recently.

Polishing

Polishing is only necessary if the paint has lost its shine, and the

gloss cannot be brought back by putting on wax.

The car must be waxed after polishing if the polish used does not

contain wax compounds to seal the paint.

Caution

Matt painted and plastic parts mu st not be treated with wax or

polish.Ornamental trim and mouldingsThe metal brightwork on the body is made of aluminium rather than

chrome (for environmental reasons).

Dirt or marks on the trim mouldings should be removed with an

acid-free cleaning agent (do not use a chrome cleaner). Body polish

is also unsuitable for use on trim mouldings. The intensive cleaning

fluids often used before the car goes into a car wash may contain

alkaline substances, which can cause dull or milky patches when

they dry out.

Audi dealers carry stocks of cleaning products which have been

tested for use on your vehicle and are not harmful to the

environment.

document_0900452a81b1b9de.book Seite 245 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

CD

CD

-+

•

+-

•

•

Page 256 of 342

Checking and topping up fluids

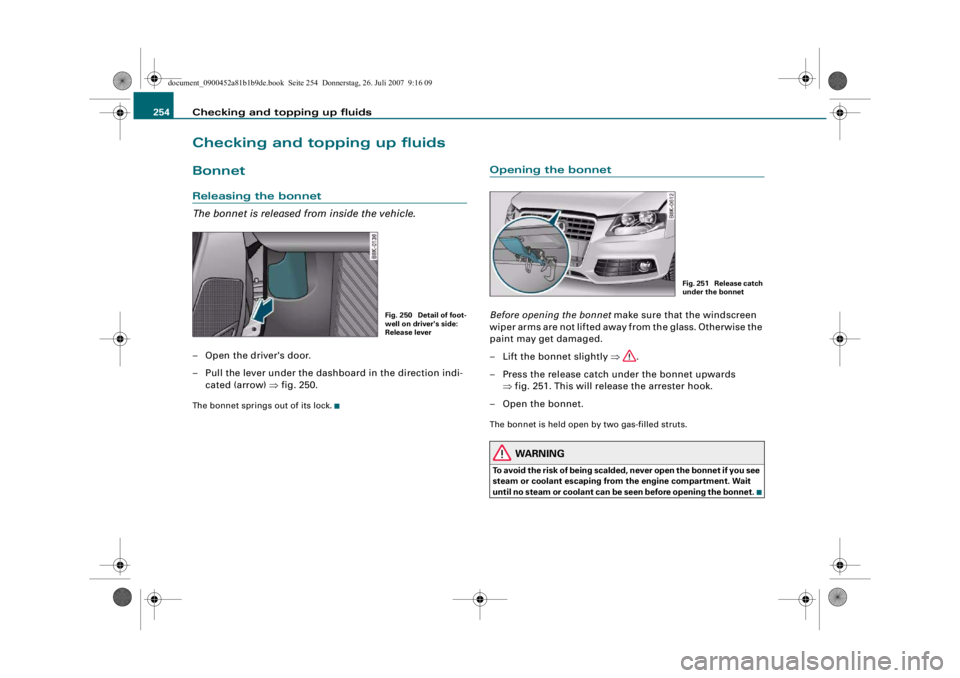

254Checking and topping up fluidsBonnetReleasing the bonnet

The bonnet is released from inside the vehicle.– Open the driver's door.

– Pull the lever under the dash board in the direction indi-

cated (arrow) ⇒fig. 250.The bonnet springs out of its lock.

Opening the bonnetBefore opening the bonnet make sure that the windscreen

wiper arms are not lifted away from the glass. Otherwise the

paint may get damaged.

– Lift the bonnet slightly ⇒.

– Press the release catch under the bonnet upwards ⇒fig. 251. This will release the arrester hook.

– Open the bonnet.The bonnet is held open by two gas-filled struts.

WARNING

To avoid the risk of being scalded, never open the bonnet if you see

steam or coolant escaping from the engine compartment. Wait

until no steam or coolant can be seen before opening the bonnet.

Fig. 250 Detail of foot-

well on driver's side:

Release lever

Fig. 251 Release catch

under the bonnet

document_0900452a81b1b9de.book Seite 254 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

-+ +-

•

.I

Page 258 of 342

Checking and topping up fluids

256Closing the bonnet– To close the bonnet, pull it down to overcome the spring

pressure.

– Then let it drop into the catches; do not press down ⇒ .

WARNING

•

For safety reasons the bonnet must always be completely

closed when the vehicl e is moving. After closing it always check

that it is properly secured. The bonnet must be flush with the adja-

cent body panels.

•

Should you notice that the bonne t is not safely secured when

the vehicle is moving, stop the ve hicle immediately and close the

bonnet properly, otherwise it could cause an accident.

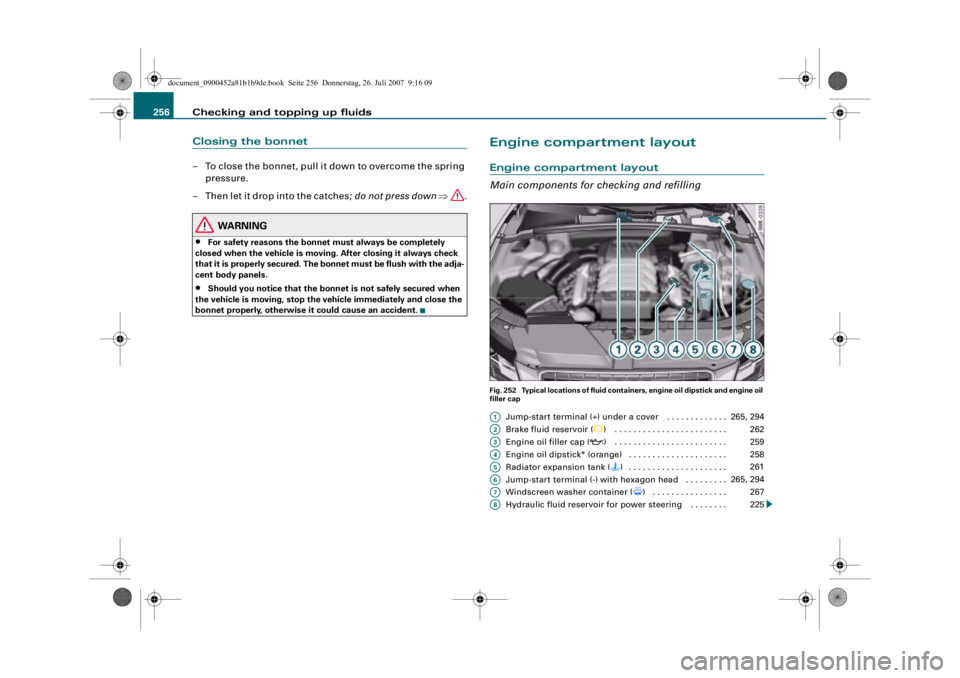

Engine compartment layoutEngine compartment layout

Main components for checking and refillingFig. 252 Typical locations of fluid containers, engine oil dipstick and engine oil

filler cap

Jump-start terminal (+) under a cover . . . . . . . . . . . . .

Brake fluid reservoir (

) . . . . . . . . . . . . . . . . . . . . . . . .

Engine oil filler cap (

) . . . . . . . . . . . . . . . . . . . . . . . .

Engine oil dipstick* (orange) . . . . . . . . . . . . . . . . . . . . .

Radiator expansion tank () . . . . . . . . . . . . . . . . . . . . .

Jump-start terminal (-) with hexagon head . . . . . . . . .

Windscreen washer container (

) . . . . . . . . . . . . . . . .

Hydraulic fluid reservoir for power steering . . . . . . . .

A1

265, 294

A2

262

A3

259

A4

258

A5

261

A6

265, 294

A7

267

A8

225

document_0900452a81b1b9de.book Seite 256 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

-+

•

+-

Page 261 of 342

Checking and topping up fluids259

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

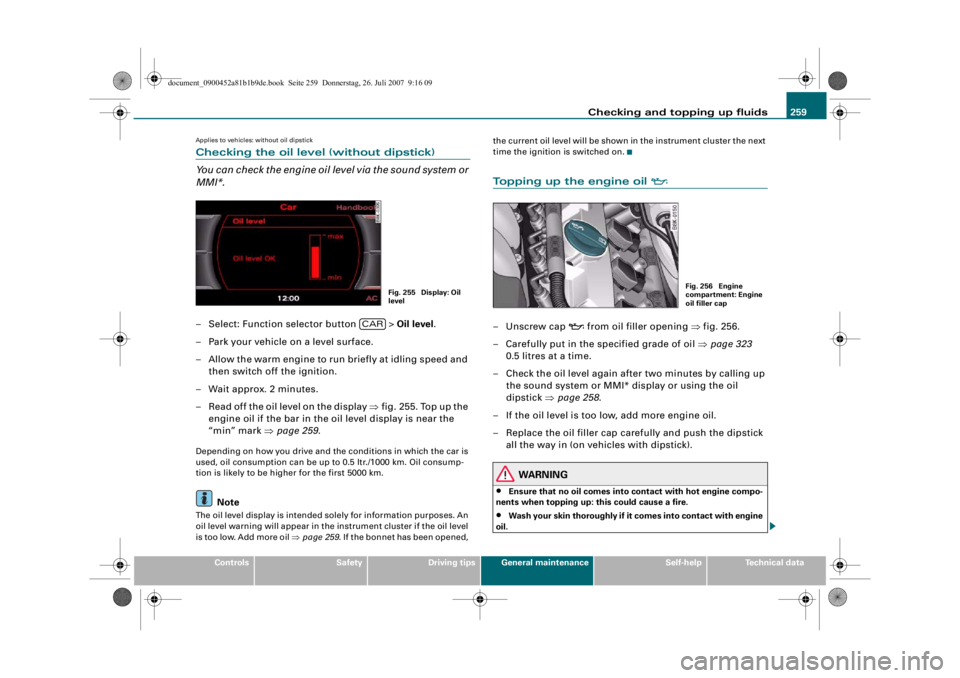

Applies to vehicles: without oil dipstickChecking the oil level (without dipstick)

You can check the engine oil level via the sound system or

MMI*.– Select: Function selector button > Oil level.

– Park your vehicle on a level surface.

– Allow the warm engine to run briefly at idling speed and then switch off the ignition.

– Wait approx. 2 minutes.

– Read off the oil level on the display ⇒fig. 255. Top up the

engine oil if the bar in the oil level display is near the

“min” mark ⇒ page 259.Depending on how you drive and the conditions in which the car is

used, oil consumption can be up to 0.5 ltr./1000 km. Oil consump-

tion is likely to be hi gher for the first 5000 km.

Note

The oil level display is intended solely for information purposes. An

oil level warning will appear in the instrument cluster if the oil level

is too low. Add more oil ⇒ page 259. If the bonnet has been opened, the current oil level will be shown in the instrument cluster the next

time the ignition is switched on.

Topping up the engine oil

–Unscrew cap

from oil filler opening

⇒fig. 256.

– Carefully put in the specified grade of oil ⇒page 323

0.5 litres at a time.

– Check the oil level again after two minutes by calling up the sound system or MMI* display or using the oil

dipstick ⇒page 258 .

– If the oil level is too low, add more engine oil.

– Replace the oil filler cap carefully and push the dipstick all the way in (on vehicles with dipstick).

WARNING

•

Ensure that no oil comes into contact with hot engine compo-

nents when topping up: this could cause a fire.

•

Wash your skin thoroughly if it comes into contact with engine

oil.

Fig. 255 Display: Oil

level

CAR

Fig. 256 Engine

compartment: Engine

oil filler cap

document_0900452a81b1b9de.book Seite 259 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

•

-+ +-

[I]

Page 267 of 342

Checking and topping up fluids265

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

charges) when handling cables

and electrical equipment. Never

cross the battery poles. The re sulting high-energy sparks can

cause injury.

•

A highly explosive mixture of gases is given off when the

battery is under charge. Only char ge battery in a well ventilated

area.

•

Keep children away from the battery and battery acid.

•

Switch off all electrical equipment before starting any work on

the vehicle electrical system. Re move the ignition key. The minus

cable of the battery must be disc onnected. When changing a light

bulb, it is sufficient to only turn off the light.

•

Before disconnecting the battery, turn off the anti-theft

system! Otherwise, the alarm will sound.

•

When disconnecting th e battery from the vehicle's electrical

system, first disconnect the minu s cable and then the plus cable.

•

Before reconnecting the battery, turn off all electrical equip-

ment. First connect the plus cabl e, then the minus cable. The

battery cables must not be connected to the wrong battery poles

- serious risk of cable fire.

•

Never charge a frozen or thawed out battery - risk of explosion

and chemical burns! A battery must be replaced once it has been

frozen. When it is discharged th e battery can freeze at tempera-

tures around 0°C.

•

Make sure that the vapour hose is always attached to the

battery.

•

Never use a damaged battery - risk of explosion! Replace a

damaged battery immediately.Caution

•

Never disconnect the car's battery with the engine running or

with the ignition turned on, otherwise the electrical system or elec-

trical components will be damaged.

•

Do not expose the battery to direct sunlight over a long period of

time, as the intense ultraviolet radiation can affect the battery

housing.

•

If the car is left standing for long periods, protect the battery

from extreme cold temperature so that it does not “freeze up” and

become damaged.

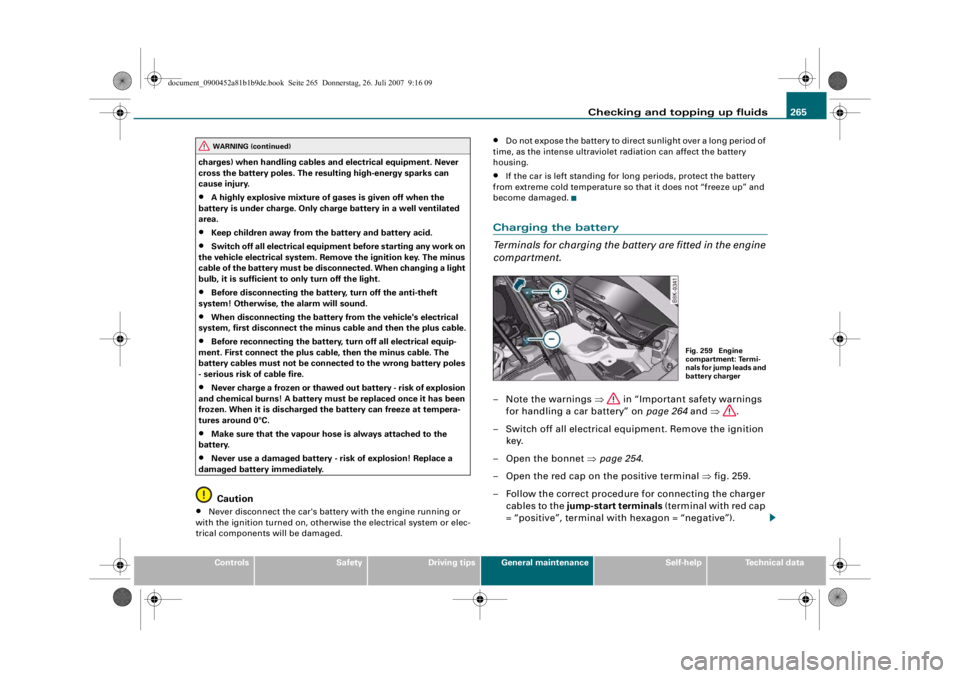

Charging the battery

Terminals for charging the battery are fitted in the engine

compartment.– Note the warnings ⇒ in “Important safety warnings

for handling a car battery” on page 264 and ⇒ .

– Switch off all electrical equi pment. Remove the ignition

key.

– Open the bonnet ⇒page 254 .

– Open the red cap on the positive terminal ⇒fig. 259.

– Follow the correct procedure for connecting the charger cables to the jump-start terminals (terminal with red cap

= “positive”, terminal with hexagon = “negative”).

WARNING (continued)

Fig. 259 Engine

compartment: Termi-

nals for jump leads and

battery charger

document_0900452a81b1b9de.book Seite 265 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

•

-+ +-

CD

Page 268 of 342

Checking and topping up fluids

266

– Now connect the battery charger to the mains and switch on.

– After charging the battery: switch off the battery charger and disconnect the mains cable.

– Now disconnect the charger cables.

– Refit the red cap onto the positive terminal.

– Close the bonnet ⇒page 256 .When it is discharged the battery can freeze at temperatures

around 0°C. A frozen battery must be thawed before charging ⇒.

However, it is advisable to replace the battery if it has frozen,

because the ice can crack the battery casing and allow the battery

acid to escape.

Charging the battery

Important: Before you charge the battery make sure you read the

manufacturer's instructions for using the battery charger.

When charging with a low current (for instance with a small battery

charger ) the battery does not have to be disconnected. The battery

must not be opened while you are charging it.

Fast-charging the battery

For technical reasons it is not permissible to fast-charge the battery

using charging devices with an ou tput voltage higher than 14.8 V.

WARNING

Never charge a frozen battery – it could explode.

Note

Use only the terminals in the engine compartment to charge the

battery.

Replacing the battery

A replacement battery must ha ve the same specifications

as the original equipment battery.Your vehicle is equipped with an intelligent power management

system to control the distribution of electrical energy ⇒page 226 .

The power management function ensures that the battery is

charged much more efficiently than on vehicles without a power

management system. For this additional power to be available after

replacing the battery, we recommend that the replacement battery

used is of the same make and type as the original-equipment

battery. The battery must be encoded in the control unit for power

management. This has to be done by a qualified workshop.

A replacement battery must have the same capacity, voltage (12 V)

and current rating. It must also ha ve the same dimensions as the

original, factory-fitted battery and have sealed caps. The battery

must comply with the standards TL 825 06 (dated December 1997 or

later) and VW 7 50 73 (August 2001 or later).

Caution

•

Make sure that the vent hose is always attached to the opening

on the side of the battery. Gases or battery acid can otherwise

escape and possibly cause damage.

•

The battery holder and clamps must always be correctly secured.

•

Before starting any work on the battery, always observe the

warnings listed under ⇒page 264, “Important safety warnings for

handling a car battery”.For the sake of the environment

Batteries contain toxic substances including sulphuric acid and

lead. They must be disposed of appropriately and must not be put

together with ordinary househol d waste. Make sure the battery

removed from the vehicle cannot tip over. Otherwise, sulphuric acid

could escape.

document_0900452a81b1b9de.book Seite 266 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

-+

CD

+-

I&

I

r---- . -----------;

ffi

[I]

•

•

Page 308 of 342

Fuses and bulbs

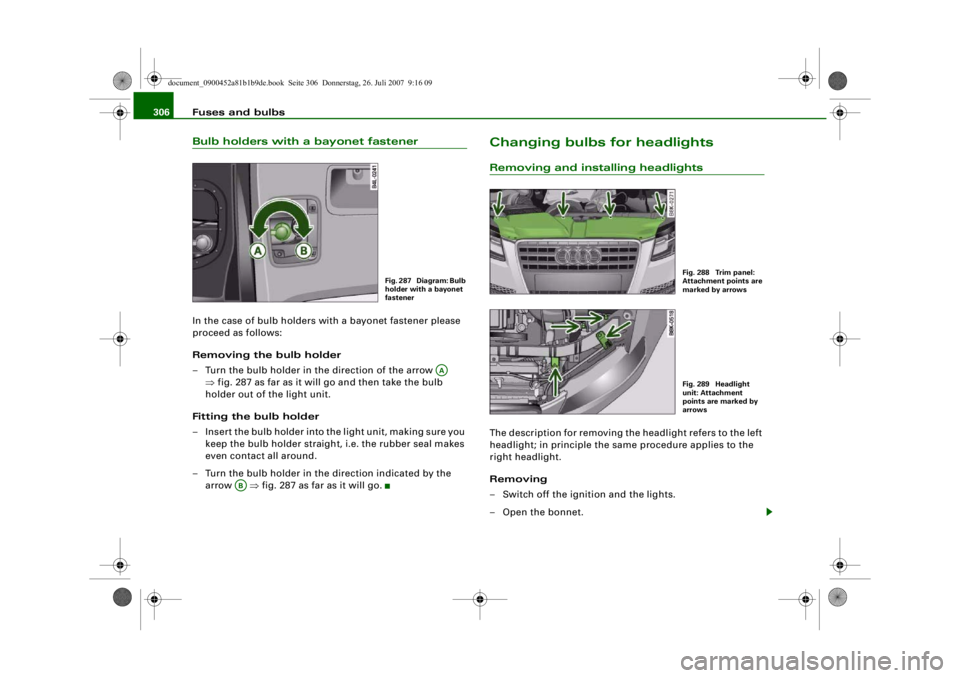

306Bulb holders with a bayonet fastenerIn the case of bulb holders with a bayonet fastener please

proceed as follows:

Removing the bulb holder

– Turn the bulb holder in the direction of the arrow

⇒fig. 287 as far as it will go and then take the bulb

holder out of the light unit.

Fitting the bulb holder

– Insert the bulb holder into the light unit, making sure you keep the bulb holder straight , i.e. the rubber seal makes

even contact all around.

– Turn the bulb holder in the direction indicated by the arrow ⇒fig. 287 as far as it will go.

Changing bulbs for headlightsRemoving and installing headlightsThe description for removing the headlight refers to the left

headlight; in principle the same procedure applies to the

right headlight.

Removing

– Switch off the ignition and the lights.

– Open the bonnet.

Fig. 287 Diagram: Bulb

holder with a bayonet

fastener

AA

AB

Fig. 288 Trim panel:

Attachment points are

marked by arrowsFig. 289 Headlight

unit: Attachment

points are marked by

arrows

document_0900452a81b1b9de.book Seite 306 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

-+ +-

•

Page 333 of 342

Index331

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

Automatic air conditioner plus

See Deluxe automatic air conditioner plus

101

Automatic cruise control See adaptive cruise control . . . . . . . . 128

Automatic gearbox Dynamic gear control program . . . . . 166

Kick-down feature . . . . . . . . . . . . . . . . 165

Manual release (multitronic®) . . . . . . 168

multitronic® . . . . . . . . . . . . . . . . . . . . . 162

Paddle levers (tiptronic mode) . . . . . . 167

Safety interlock for ignition key . . . . . 116

Selector lever lock . . . . . . . . . . . . . . . . 165

Selector lever positions . . . . . . . . . . . 163

Steering wheel with paddle levers . . 167

tiptronic . . . . . . . . . . . . . . . . . . . . 162, 166

Automatic headlight control . . . . . . . . . . . 57

Automatic headlights . . . . . . . . . . . . . . . . . 59

Auxiliary heating Deluxe automatic air conditioner plus . . 110

Description . . . . . . . . . . . . . . . . . . . . . . 110

Remote control . . . . . . . . . . . . . . . . . . 113

Running time . . . . . . . . . . . . . . . . . . . . 112

Switching on/off immediately . . . . . . 111

Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Average fuel consumption . . . . . . . . . . . . . 25

Average speed . . . . . . . . . . . . . . . . . . . . . . . 25

Axle weights See Performance, weights and

dimensions . . . . . . . . . . . . . . . . . . . . 323

BBattery

Charging . . . . . . . . . . . . . . . . . . . . . . . . 265

Low charge . . . . . . . . . . . . . . . . . . . . . . 226

Power level . . . . . . . . . . . . . . . . . . . . . . 226

Power management . . . . . . . . . . . . . . 226

Replacing . . . . . . . . . . . . . . . . . . . . . . . 266

Winter conditions . . . . . . . . . . . . . . . . 263

Battery power . . . . . . . . . . . . . . . . . . . . . . . 38

Bayonet fastener Bulb . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

Bulb holder . . . . . . . . . . . . . . . . . . . . . . 306

Belt tensioners . . . . . . . . . . . . . . . . . . . . . . 199

Bicycle rack Trailer . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Biodiesel . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Bioethanol fuel . . . . . . . . . . . . . . . . . . . . . 251

Blower Deluxe automatic air conditioner . . . . . 96

Deluxe automatic air conditioner plus . . 104

Bonnet Closing . . . . . . . . . . . . . . . . . . . . . . . . . 256

Opening . . . . . . . . . . . . . . . . . . . . . . . . 254

Releasing . . . . . . . . . . . . . . . . . . . . . . . 254

Boot See Loading luggage compartment . 192

See Luggage compartment . . . . . . . . . . 79

Boot lid Central locking system . . . . . . . . . . . . . 51

Manual release . . . . . . . . . . . . . . . . . . . . 52 Brake system

Brake assist system . . . . . . . . . . . . . . . 222

Brake fluid . . . . . . . . . . . . . . . . . . . . . . . 262

Brake light defective . . . . . . . . . . . . . . . 37

Brake pads worn . . . . . . . . . . . . . . . . . . 37

Brake servo . . . . . . . . . . . . . . . . . . . . . . 224

Electro-mechanical parking brake . . . 121

General notes . . . . . . . . . . . . . . . . . . . . 224

Malfunction . . . . . . . . . . . . . . . . . . . . . . 32

Warning lamp . . . . . . . . . . . . . . . . . . . . . 20

braking guard See Audi braking guard . . . . . . . . . . . . 142

Bulb holder Bayonet fastener . . . . . . . . . . . . . . . . . 306

Bulb monitor . . . . . . . . . . . . . . . . . . . . . . . . 37

Bulbs Bayonet fastener . . . . . . . . . . . . . . . . . 305

Changing (general notes) . . . . . . . . . . 304

Bulbs, changing . . . . . . . . . . . . . . . . . . . . . 304 Brake lights . . . . . . . . . . . . . . . . . . . . . . 311

Bulb holder with bayonet fastener . 305, 306

Dipped headlights . . . . . . . . . . . . . . . . 308

Front fog lights . . . . . . . . . . . . . . . . . . . 310

Main beam headlights . . . . . . . . . . . . . 307

Number plate light . . . . . . . . . . . . . . . . 315

Rear fog light . . . . . . . . . . . . . . . . . . . . 314

Rear lights . . . . . . . . . . . . . . . . . . . . . . . 311

Reversing light . . . . . . . . . . . . . . . . . . . 314

Turn signals (rear) . . . . . . . . . . . . . . . . 311

Business equipment . . . . . . . . . . . . . . . . . 278

document_0900452a81b1b9de.book Seite 331 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

-+ +-