change wheel AUDI S4 2008 User Guide

[x] Cancel search | Manufacturer: AUDI, Model Year: 2008, Model line: S4, Model: AUDI S4 2008Pages: 342, PDF Size: 15.01 MB

Page 271 of 342

Wheels and tyres269

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

– The tyre pressures should only be checked when the

tyres are cold. The slightly raised pressures of warm tyres

must not be reduced.

– The pressures must be altered to suit major changes in the load being carried.

– Avoid fast cornering and hard acceleration.

– Inspect the tyres for irregular wear from time to time.Tyre pressure and vehicle loading

The tyre pressure must be adjusted according to the load the vehicle

is carrying. We recommend adhering to the tyre pressure specifica-

tions for a maximum load. The tyre inflation pressures are listed on

a sticker on the end face of the driver's door ⇒page 268, fig. 261.

However, if you prefer an extra-smooth ride and the vehicle is not

fully loaded, you can select the tyre pressure for a normal load (no

more than three people travelling in the vehicle). However, should

you wish to drive with a full load you must increase the tyre pressure

to the specified maximum.

Under-inflation or over-inflation will reduce the life of the tyres

considerably and also impair the car's handling. Correct inflation

pressures are very important, especially at high speeds. The pres-

sures should therefore be checked at least once a month and before

starting a journey.

Do not forget the spare wheel* when checking the tyre pressures.

Keep the spare tyre inflated to the highest pressure required for the

road wheels.

Driving habits

Fast cornering, heavy acceleration and hard braking (squealing

tyres) all increase tyre wear. Wheel balancing

The wheels on new vehicles are balanced. However, various factors

encountered in normal driving can cause them to become unbal-

anced, which results in steering vibration.

Unbalanced wheels should be rebalanced, as they otherwise cause

excessive wear on steering, suspension and tyres. A wheel must

also be rebalanced when a new tyre is fitted or if a tyre is repaired.

Incorrect wheel alignment

Incorrect wheel alignment causes excessive tyre wear, impairing the

safety of the vehicle. If you notice excessive tyre wear, contact your

Audi dealer.

WARNING

•

Always adapt the tyre pressure

accordingly when the vehicle

load changes.

•

Under-inflated tyres flex more an d can overheat at continuous

high speeds. This can cause trea d separation and tyre blow-out,

which could result in an accident.For the sake of the environment

Under-inflated tyres will increase the fuel consumption.

document_0900452a81b1b9de.book Seite 269 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

-+ +-

•

Page 272 of 342

Wheels and tyres

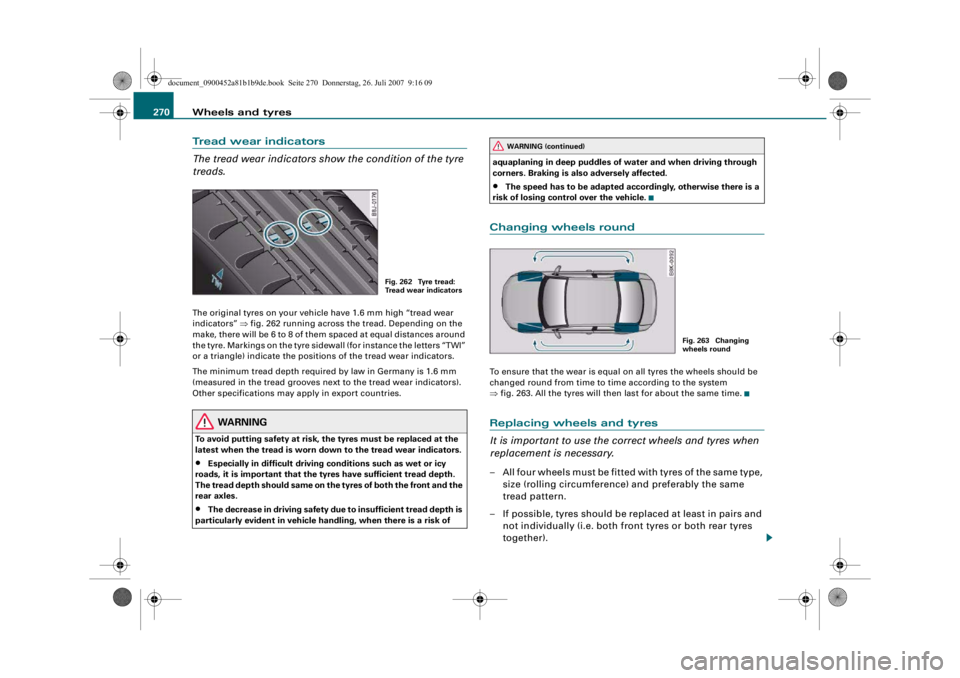

270Tread wear indicators

The tread wear indicators show the condition of the tyre

treads.The original tyres on your vehicl e have 1.6 mm high “tread wear

indicators” ⇒fig. 262 running across the tread. Depending on the

make, there will be 6 to 8 of them spaced at equal distances around

the tyre. Markings on the tyre sidewa ll (for instance the letters “TWI”

or a triangle) indicate the positi ons of the tread wear indicators.

The minimum tread depth required by law in Germany is 1.6 mm

(measured in the tread grooves next to the tread wear indicators).

Other specifications may apply in export countries.

WARNING

To avoid putting safety at risk, the tyres must be replaced at the

latest when the tread is worn down to the tread wear indicators.•

Especially in difficult driving conditions such as wet or icy

roads, it is important that the tyres have sufficient tread depth.

The tread depth should same on th e tyres of both the front and the

rear axles.

•

The decrease in driving safety due to insufficient tread depth is

particularly evident in vehicle handling, when there is a risk of aquaplaning in deep puddles of wa

ter and when driving through

corners. Braking is also adversely affected.

•

The speed has to be adapted accordingly, otherwise there is a

risk of losing control over the vehicle.

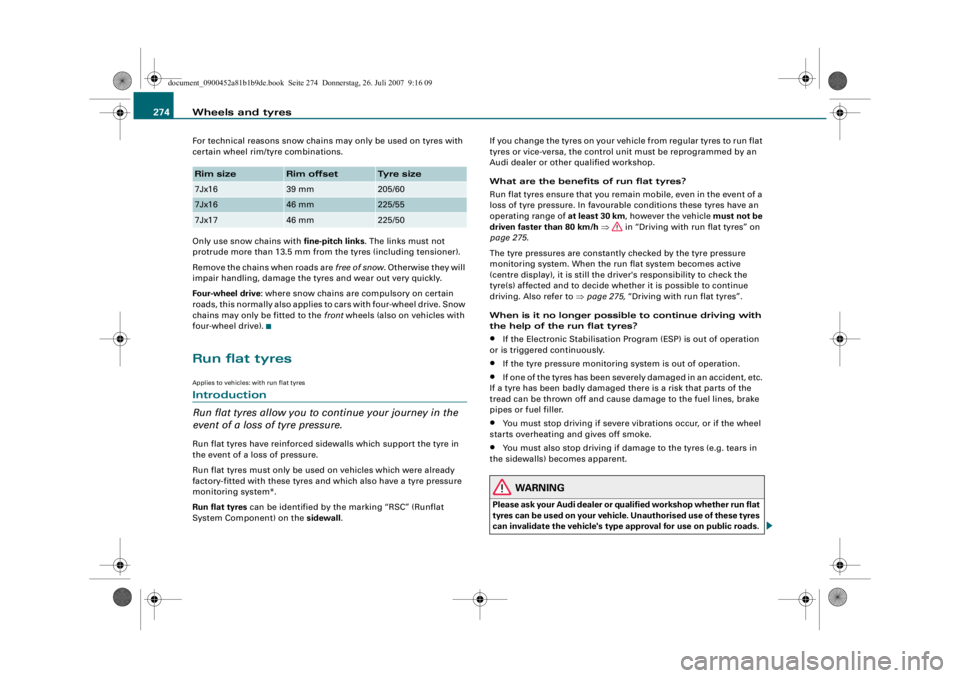

Changing wheels roundTo ensure that the wear is equal on all tyres the wheels should be

changed round from time to time according to the system

⇒ fig. 263. All the tyres will then last for about the same time.Replacing wheels and tyres

It is important to use the correct wheels and tyres when

replacement is necessary.– All four wheels must be fitted with tyres of the same type,

size (rolling circumference) and preferably the same

tread pattern.

– If possible, tyres should be re placed at least in pairs and

not individually (i.e. both front tyres or both rear tyres

together).

Fig. 262 Tyre tread:

Tr e a d w e a r i n d i c a t o r s

WARNING (continued)

Fig. 263 Changing

wheels round

document_0900452a81b1b9de.book Seite 270 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

•

(

,..

/ --.

' ~

I

-+

l

_..

j .,,

'"

+-

•

Page 276 of 342

Wheels and tyres

274For technical reasons snow chains may only be used on tyres with

certain wheel rim/tyre combinations.

Only use snow chains with fine-pitch links. The links must not

protrude more than 13.5 mm from the tyres (including tensioner).

Remove the chains when roads are free of snow. Otherwise they will

impair handling, damage the tyres and wear out very quickly.

Four-wheel drive : where snow chains are compulsory on certain

roads, this normally also applies to cars with four-wheel drive. Snow

chains may only be fitted to the front wheels (also on vehicles with

four-wheel drive).Run flat tyresApplies to vehicles: with run flat tyresIntroduction

Run flat tyres allow you to co ntinue your journey in the

event of a loss of tyre pressure.Run flat tyres have reinforced sidewalls which support the tyre in

the event of a loss of pressure.

Run flat tyres must only be used on vehicles which were already

factory-fitted with these tyres and which also have a tyre pressure

monitoring system*.

Run flat tyres can be identified by the marking “RSC” (Runflat

System Component) on the sidewall. If you change the tyres on your vehicle from regular tyres to run flat

tyres or vice-versa, the control unit must be reprogrammed by an

Audi dealer or other qualified workshop.

What are the benefits of run flat tyres?

Run flat tyres ensure that you remain mobile, even in the event of a

loss of tyre pressure. In favourable conditions these tyres have an

operating range of

at least 30 km, however the vehicle must not be

driven faster than 80 km/h ⇒ in “Driving with run flat tyres” on

page 275 .

The tyre pressures are constantly checked by the tyre pressure

monitoring system. When the run flat system becomes active

(centre display), it is still the driver's responsibility to check the

tyre(s) affected and to decide whether it is possible to continue

driving. Also refer to ⇒page 275, “Driving with run flat tyres”.

When is it no longer possibl e to continue driving with

the help of the run flat tyres?

•

If the Electronic Stabilisation Program (ESP) is out of operation

or is triggered continuously.

•

If the tyre pressure monitoring system is out of operation.

•

If one of the tyres has been severely damaged in an accident, etc.

If a tyre has been badly damaged there is a risk that parts of the

tread can be thrown off and cause damage to the fuel lines, brake

pipes or fuel filler.

•

You must stop driving if severe vibrations occur, or if the wheel

starts overheating and gives off smoke.

•

You must also stop driving if damage to the tyres (e.g. tears in

the sidewalls) becomes apparent.

WARNING

Please ask your Audi dealer or qualified workshop whether run flat

tyres can be used on your vehicle. Unauthorised use of these tyres

can invalidate the vehi cle's type approval for use on public roads.

Rim size

Rim offset

Tyre size

7Jx16

39 mm

205/60

7Jx16

46 mm

225/55

7Jx17

46 mm

225/50

document_0900452a81b1b9de.book Seite 274 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

-+

•

+-

~-

Page 277 of 342

Wheels and tyres275

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

Furthermore, this could cause damage to your vehicle and

possibly also result in an accident.

Note

•

If you cannot continue driving even with run flat tyres please

obtain professional assistance.

•

You should obtain professional assistance if you are in any doubt

regarding the rims and tyres for your vehicle.

Applies to vehicles: with run flat tyresDriving with run flat tyres

Please remember that the vehicle's handling will be

impaired.Driving a vehicle with a deflat ed tyre, or with insufficient

tyre pressure, is an abnormal situation. However, since the

handling of a vehicle equipped with run flat tyres is only

slightly impaired, it is important to remember that you are

driving with a deflated tyre. If you have to make use of the

run flat system please remember the following points:

– The Electronic Stabilisation Program (ESP) must be switched on.

–Do not exceed 80km/h ⇒.

– Anticipate the traffic situation well in advance.

– Be careful when accelerating.

– Avoid unnecessary braking and steering manoeuvres.

– Reduce speed in good time before corners and potential hazards.

Please refer to ⇒page 274, “ When is it no longer possible to

continue driving with the help of the run flat tyres?”

Effects on handling when dr iving with defective tyres

If one of the front tyres is defective , your vehicle will tend to pull

slightly towards that side and braking performance will be

impaired.

A defective rear tyre will also make the vehicle pull slightly to one

side, and the braking response will again be slightly impaired.

These effects will be most noticeable when driving in a corner.

WARNING

•

When using the run flat system the changes in vehicle handling

will be noticeable when braking, in corners and during fast accel-

eration.

•

The maximum permitted speed of 80 km/h is subject to road

and weather conditions. Always observe the relevant rules and

regulations. Run flat tyres allow you to continue your journey in

the event of a loss of tyre pressu re. However, the driver remains

responsible for the safety of the vehicle and for restoring the

correct tyre pressure and having defective parts replaced

⇒ page 276 . For these reasons you should always adjust your

driving to suit the circumstances.Caution

We recommend that you drive with great care when making use of

the run flat system. Avoid abrupt manoeuvres.

WARNING (continued)

document_0900452a81b1b9de.book Seite 275 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

•

-+ +-

0

•

Page 286 of 342

Self-help

284If you need the tools, the Tyre Mobili ty System or the jack*, you will

have to open the floor panel and take out the spare wheel*

⇒ page 284 .

The tool kit includes:•

A hook for removing hub caps

•

Pin for mounting a wheel

•

Screwdriver with reversible blade

•

Tool for changing bulbs

•

Interchangeable socket (Torx socket for changing bulbs)

•

Crank handle for jack

•

Adapter for anti-theft wheel bolts*

•

Jack*

•

Box spanner for wheel bolts

•

Towline anchorage

Some of the parts listed are only fitted on certain models or are

optional extras.

Before stowing the jack* again, wind down the arm of the jack as far

as it will go.

WARNING

•

Do not use the hexagonal socket in the screwdriver handle to

tighten the wheel bolts. It is not po ssible to tighten the bolts with

the required torque – risk of accident.

•

The jack supplied by the factor y is only designed for changing

wheels on this model. On no account attempt to use it for lifting

heavier vehicles or other loads – risk of injury.

•

Never start the engine when the vehicle is on the jack - risk of

accident.

•

If work has to be done under the ve h i cl e , e n su re t h a t i t is sa fe l y

supported on stands designed for th e purpose, otherwise there is

a risk of injury.

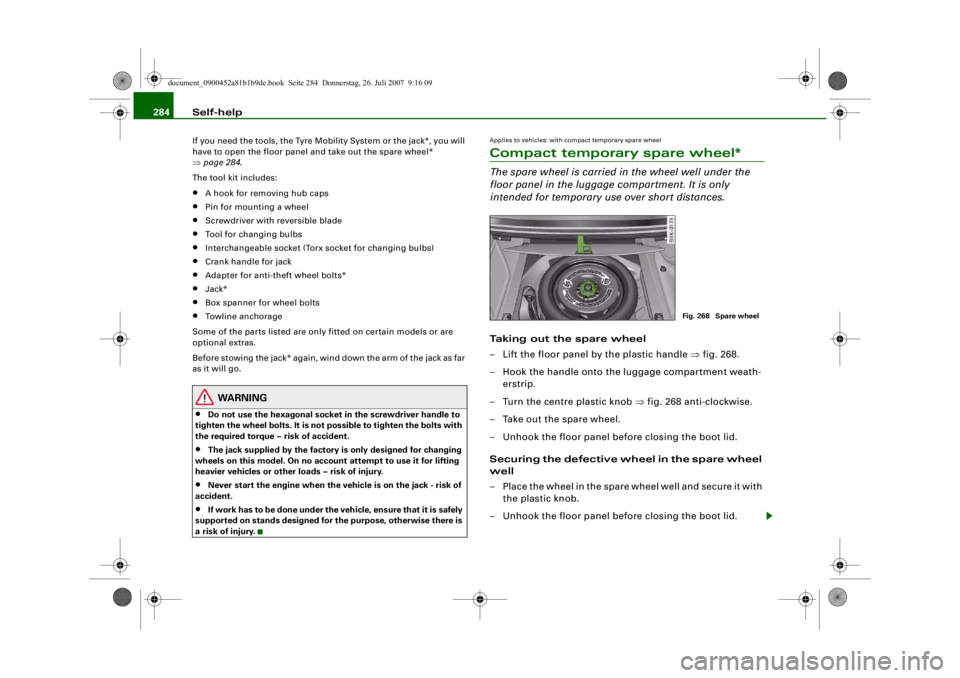

Applies to vehicles: with compact temporary spare wheelCompact temporary spare wheel*The spare wheel is carried in the wheel well under the

floor panel in the luggage compartment. It is only

intended for temporary use over short distances.Taking out the spare wheel

– Lift the floor panel by the plastic handle ⇒fig. 268.

– Hook the handle onto the luggage compartment weath- erstrip.

– Turn the centre plastic knob ⇒ fig. 268 anti-clockwise.

– Take out the spare wheel.

– Unhook the floor panel before closing the boot lid.

Securing the defective wheel in the spare wheel

well

– Place the wheel in the spare wheel well and secure it with the plastic knob.

– Unhook the floor panel before closing the boot lid.

Fig. 268 Spare wheel

document_0900452a81b1b9de.book Seite 284 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

-+ +-

•

Page 288 of 342

Self-help

286The TMS can be used at outside temperatures down to – 20 °C.

WARNING

After repairing a tyre please note the following points:•

Do not drive faster than 80 km/h.

•

Avoid heavy acceleration, hard braking and fast cornering.

•

Vehicle handling could be impaired.

•

Tyres which have been sealed using the TMS are only suitable

for temporary use. Damaged tyres must be renewed.

•

The TMS must NOT be used,

− on cuts and punctures larger than 4 mm

− if the wheel rim has been damaged

− if you have been driving with very low pressure or a

completely flat tyre

•

Seek professional assistance if th e repair of a tyre puncture is

not possible with the sealing compound.

•

Do not allow the sealant to come into contact with your eyes,

skin or clothing.

•

If you do come into contact wi th the sealant immediately rinse

the eyes or skin affected with clean water.

•

Change clothing immediately if it becomes soiled with the tyre

sealant.

•

Make sure you do not breathe in the fumes!

•

If any of the tyre sealant is a ccidentally ingested, immediately

rinse the mouth thoroughly and drink lots of water.

•

Do not induce vomiting. Immediately contact a doctor!

•

If any allergic reactions should occur get medical help immedi-

ately.

•

Keep the sealant away from children.

For the sake of the environment

Used bottles of sealing compound can be returned to an Audi dealer

for disposal.

Note

•

If sealant should leak out, leave it to dry. When it has dried, you

can pull it off like a piece of foil.

•

Observe the expiry date stated on the sealing compound can.

Have the sealing compound exchanged by a qualified workshop.

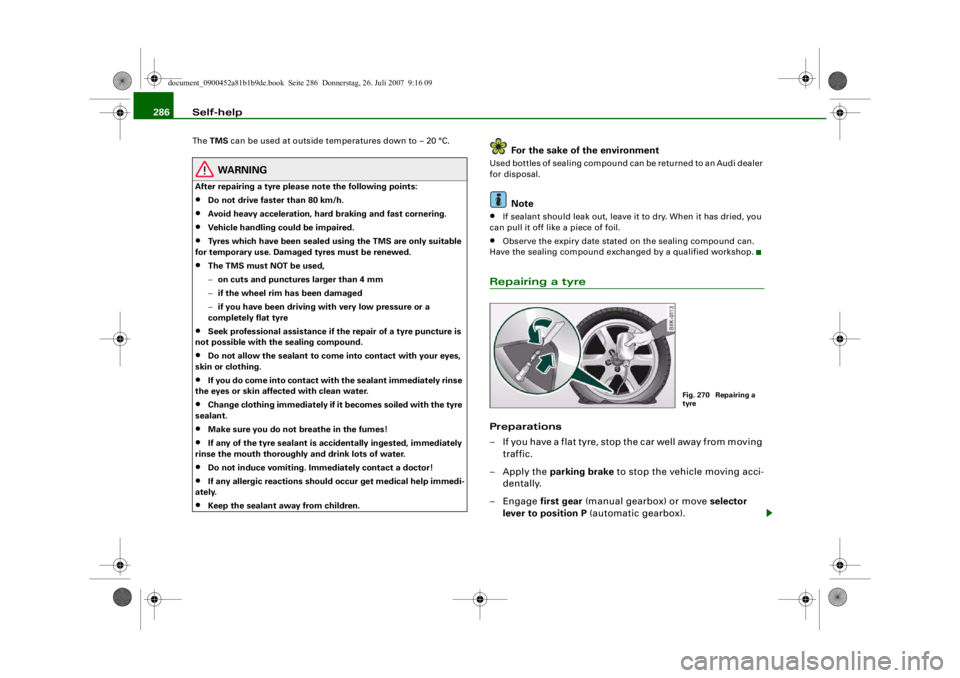

Repairing a tyrePreparations

– If you have a flat tyre, stop the car well away from moving traffic.

– Apply the parking brake to stop the vehicle moving acci-

dentally.

–Engage first gear (manual gearbox) or move selector

lever to position P (automatic gearbox).

Fig. 270 Repairing a

tyre

document_0900452a81b1b9de.book Seite 286 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

[I]

•

-+ +-

Page 290 of 342

Self-help

288•

Seek professional assistance if th e repair of a tyre puncture is

not possible with the sealing compound.

•

If tyre pressure is less than 1.3 bar after driving about 10

minutes, the tyre is too badly damaged. Do not drive on. You

should obtain professional assistance.Caution

Take special care if you have to repair a tyre on a gradient.

Note

•

Do not use the compressor for longer than 6 minutes at a time,

as it could overheat. When the compressor has cooled down, you

can use it again.

•

If tyre sealant should leak out, leave it to dry and then pull it off

like foil.

•

After carrying out a tyre repair remember to buy a new tyre

sealant can at a qualified workshop. This will ensure that the Tyre

Mobility System is operative again.

•

Please observe the relevant regulations.

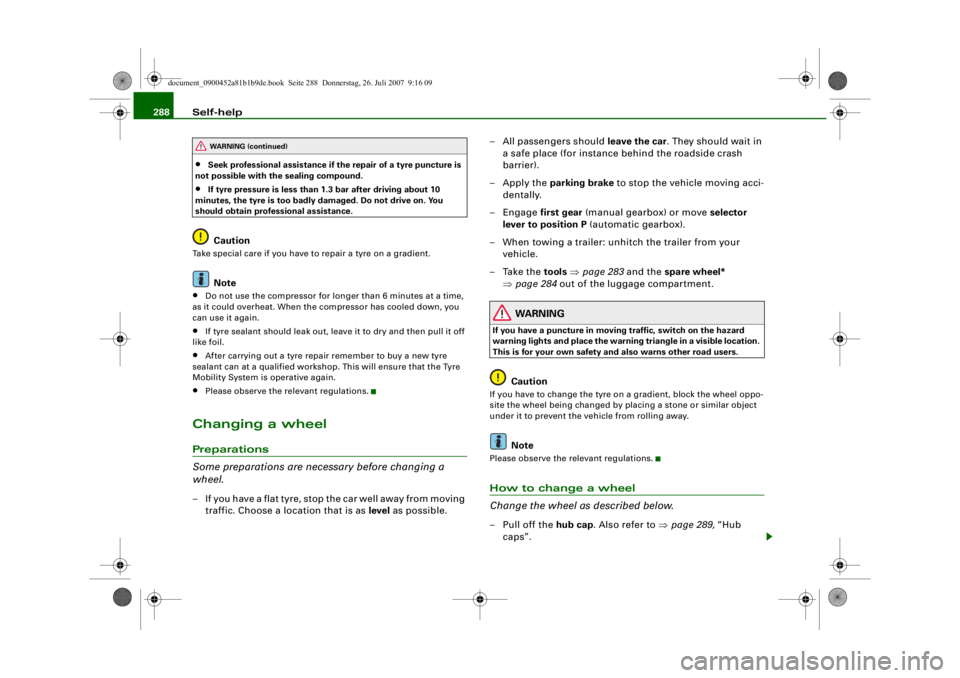

Changing a wheelPreparations

Some preparations are necessary before changing a

wheel.– If you have a flat tyre, stop the car well away from moving traffic. Choose a location that is as level as possible.– All passengers should

leave the car. They should wait in

a safe place (for instance behind the roadside crash

barrier).

– Apply the parking brake to stop the vehicle moving acci-

dentally.

–Engage first gear (manual gearbox) or move selector

lever to position P (automatic gearbox).

– When towing a trailer: unhitch the trailer from your vehicle.

– Take the tools ⇒ page 283 and the spare wheel*

⇒ page 284 out of the luggage compartment.

WARNING

If you have a puncture in moving traffic, switch on the hazard

warning lights and place the warning triangle in a visible location.

This is for your own safety and also warns other road users.

Caution

If you have to change the tyre on a gradient, block the wheel oppo-

site the wheel being changed by placing a stone or similar object

under it to prevent the vehicle from rolling away.

Note

Please observe the relevant regulations.How to change a wheel

Change the wheel as described below.–Pull off the hub cap . Also refer to ⇒page 289, “Hub

caps”.

WARNING (continued)

document_0900452a81b1b9de.book Seite 288 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

0 [I)

-+

I&

+-

0

•

•

Page 292 of 342

Self-help

290

Loosening

–Fit the box spanner as far as it will go over the wheel bolt

5).

– Grip the box spanner as close to the end as possible and

turn the wheel bolts about one turn anti-clockwise

⇒ page 289, fig. 272 -arrow-.

Tightening

– Fit the box spanner as far as it will go over the wheel bolt5).

– Grip the box spanner as close to the end as possible and

tighten the bolt firmly by turning clockwise.

WARNING

To avoid accidents, the wheel bolts should only be loosened

slightly (about one turn) before ra ising the vehicle with the jack*.

Note

•

Do not use the hexagonal socket in the screwdriver handle to

loosen or tighten the wheel bolts.

•

If the wheel bolt is very tight, it may be possible to loosen it by

pushing down the end of the spanner carefully with your foot. Hold

on to the car for support and take care not to slip.

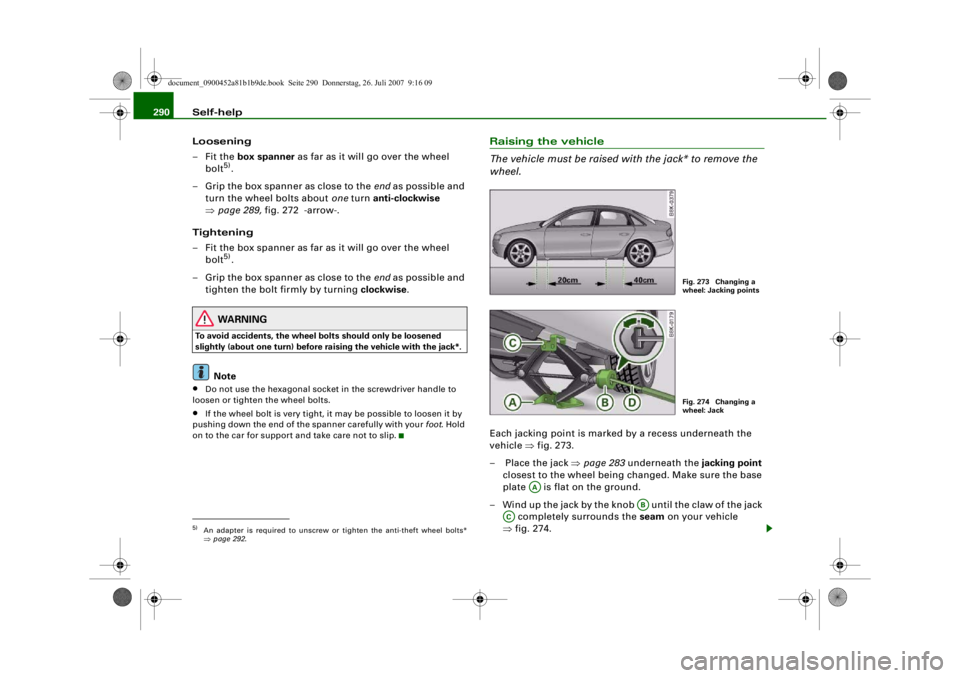

Raising the vehicle

The vehicle must be raised with the jack* to remove the

wheel.Each jacking point is marked by a recess underneath the

vehicle ⇒fig. 273.

– Place the jack ⇒page 283 underneath the jacking point

closest to the wheel being changed. Make sure the base

plate is flat on the ground.

– Wind up the jack by the knob until the claw of the jack completely surrounds the seam on your vehicle

⇒ fig. 274.

5)An adapter is required to unscrew or tighten the anti-theft wheel bolts*

⇒page 292 .

Fig. 273 Changing a

wheel: Jacking pointsFig. 274 Changing a

wheel: Jack

AA

AB

AC

document_0900452a81b1b9de.book Seite 290 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

-+

[I)

+-

•

Page 293 of 342

Self-help291

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

– Now fit the crank handle onto the jack by inserting it

in the opening on the knob ⇒page 290, fig. 274. Turn the

crank handle clockwise or anti-clockwise to secure it in

place.

– Raise the vehicle by windin g the crank handle until the

defective wheel is clear of the ground.Recesses at the front and rear of the door sills mark the jacking

points ⇒page 290, fig. 273. There is one jacking point for each

wheel. The distance from the jacking points to the wheel arches is

approximately 20 cm at the front an d 40 cm at the rear. The jack may

only be applied at the seam of the jacking points shown.

An unstable surface under the jack may cause the vehicle to slip off

the jack. Always provide a firm base for the jack on the ground. If

necessary use a large, strong board or similar support. On a hard,

slippery surface (such as tiles) use a rubber mat or similar to prevent

the jack from slipping.

WARNING

•

Prevent the base of the jack fr om slipping – risk of injury.

•

The car can be damaged if the jack is not applied at the correct

jacking points. There is also a risk of injury since the jack can slip

off suddenly if it is not properly engaged.

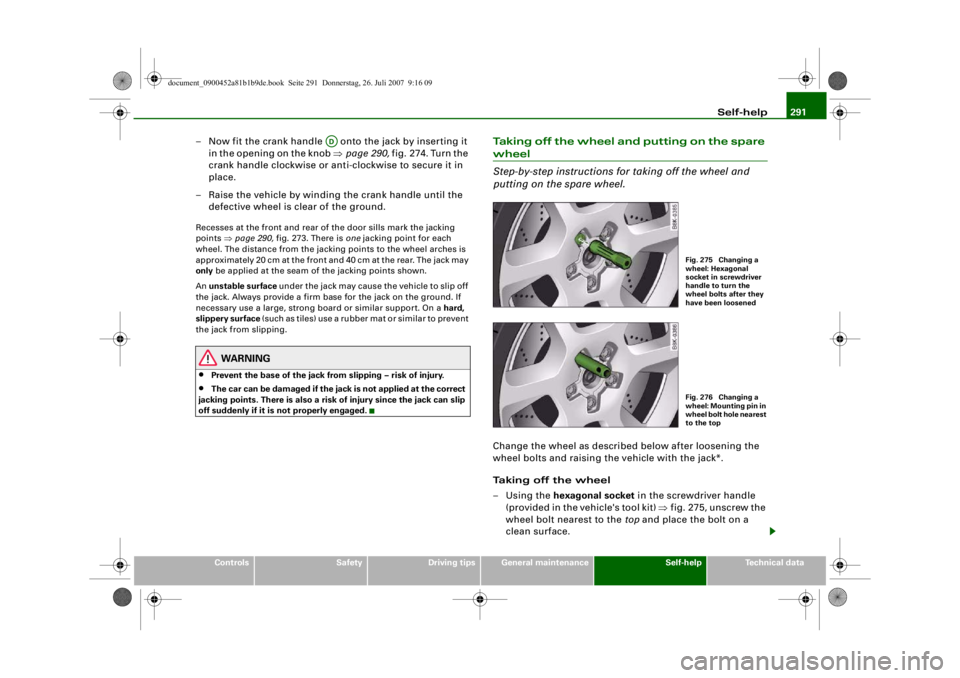

Taking off the wheel and putting on the spare wheel

Step-by-step instructions for taking off the wheel and

putting on the spare wheel.Change the wheel as described below after loosening the

wheel bolts and raising the vehicle with the jack*.

Taking off the wheel

–Using the hexagonal socket in the screwdriver handle

(provided in the vehicle's tool kit) ⇒fig. 275, unscrew the

wheel bolt nearest to the top and place the bolt on a

clean surface.

AD

Fig. 275 Changing a

wheel: Hexagonal

socket in screwdriver

handle to turn the

wheel bolts after they

have been loosenedFig. 276 Changing a

wheel: Mounting pin in

wheel bolt hole nearest

to the top

document_0900452a81b1b9de.book Seite 291 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

-+ +-

•

Page 294 of 342

Self-help

292

– Screw in the mounting pin (provided in the vehicle's tool

kit) by hand in place of the wheel bolt ⇒page 291,

fig. 276.

– Then unscrew the other wheel bolts as described above.

– Take off the wheel. The mounting pin stays where it is.

Putting on the spare wheel

– Put on the spare wheel, using the mounting pin to guide it into place.

– Screw in the wheel bolts and tighten them lightly using

the hexagonal opening in the screwdriver handle.

– Then unscrew the mounting pin and tighten the remaining wheel bolt lightly.

– Carry out the steps required after you have changed the wheel ⇒page 289, “After changing a wheel”.The wheel bolts should be clean and turn easily. Before putting on

the spare wheel, inspect the condition of the wheel and hub

mounting surfaces. These surfaces must be clean before mounting

the wheel.

The wheel bolts are easier to remove from the wheel rim if you use

the hexagonal socket in the screwdriver handle. The reversible

screwdriver blade should be removed as a precautionary measure

when the tool is used for this purpose.

Note the direction of rotation when putting on a tyre with direc-

tional tread pattern ⇒page 292 .

Note

Do not use the hexagonal socket in the screwdriver handle to loosen

or tighten the wheel bolts.

Tyres with directional tread pattern

Tyres with directional tread pattern must be mounted so

that they rotate in the correct direction.A directional tread pattern is identified by arrows on the sidewall

pointing in the forward running direction. Always note the direction

of rotation indicated when mounting the wheel. This is important so

that these tyres can give maximum grip and avoid excessive noise,

tread wear and aquaplaning.

Drive carefully should you ever have a puncture and have to mount

the spare wheel so it rotates in the wrong direction. This is because

the tyre will not give optimum performance. Bear this in mind

particularly when driving on wet roads.

To benefit from the advantages of tyres with this type of tread

pattern, the defective tyre should be replaced and refitted as soon

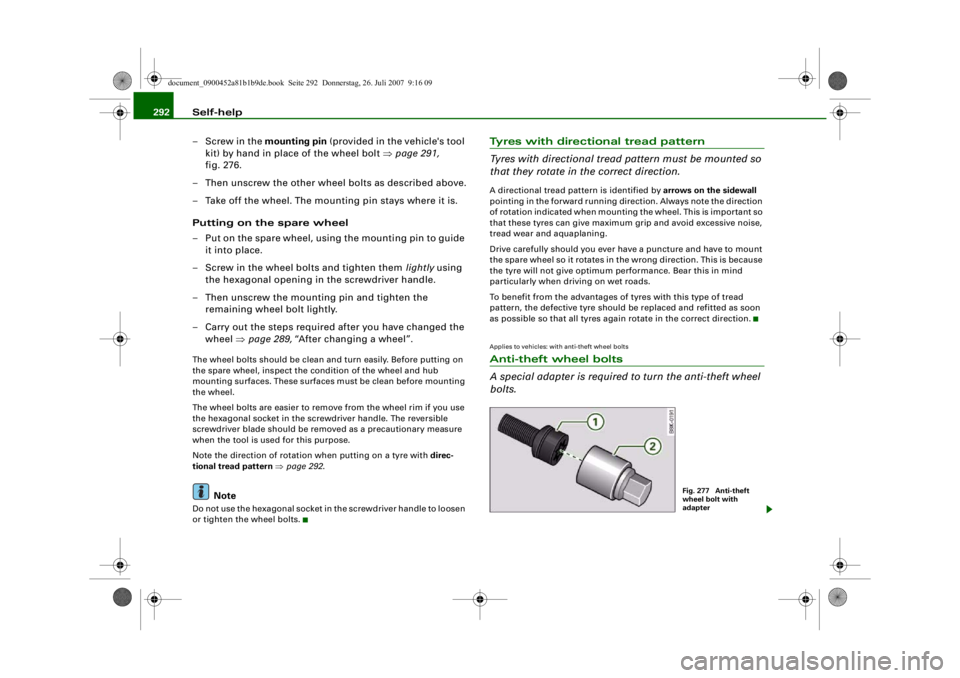

as possible so that all tyres agai n rotate in the correct direction.Applies to vehicles: with anti-theft wheel boltsAnti-theft wheel bolts

A special adapter is required to turn the anti-theft wheel

bolts.

Fig. 277 Anti-theft

wheel bolt with

adapter

document_0900452a81b1b9de.book Seite 292 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

-+

•

+-

[I)

•