warning AUDI S4 CABRIOLET 2009 Owners Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2009, Model line: S4 CABRIOLET, Model: AUDI S4 CABRIOLET 2009Pages: 340, PDF Size: 77.32 MB

Page 299 of 340

_____________________________________________ W_ h_ a_t _d_ o _ l _d_o _ n_o_ w_ ? _ __,_

& WARNING

• You or your passengers could be injured while changing a

wheel if you do not follow safety precautions:

-Mounting the jack under the vehicle at any other place than

indicated above may damage the vehicle or may result in

personal injuries.

- A soft or unstable surface under the jack may cause the

vehicle to slip off the jack . Always provide a firm base for the

jack on the ground.

If necessary , use a sturdy board under the

jack .

- On hard, slippery surface (such as tiles ) use a rubber mat or

similar to prevent the jack from slipping .

• To help prevent injury to yourself and your passengers :

- Do not raise the vehicle until you are sure the jack is securely

engaged.

- Passengers must not remain in the vehicle when it is jacked

up.

- Make sure that passengers wait in a safe place away from

the vehicle and well away from the roadway and traffic .

- Make sure jack position is correct , adjust as necessary and

then continue to raise the jack. •

Taking the wheel off /putting the spare on

Follow thes e instru ctions s tep-by -step for chang ing the

wheel

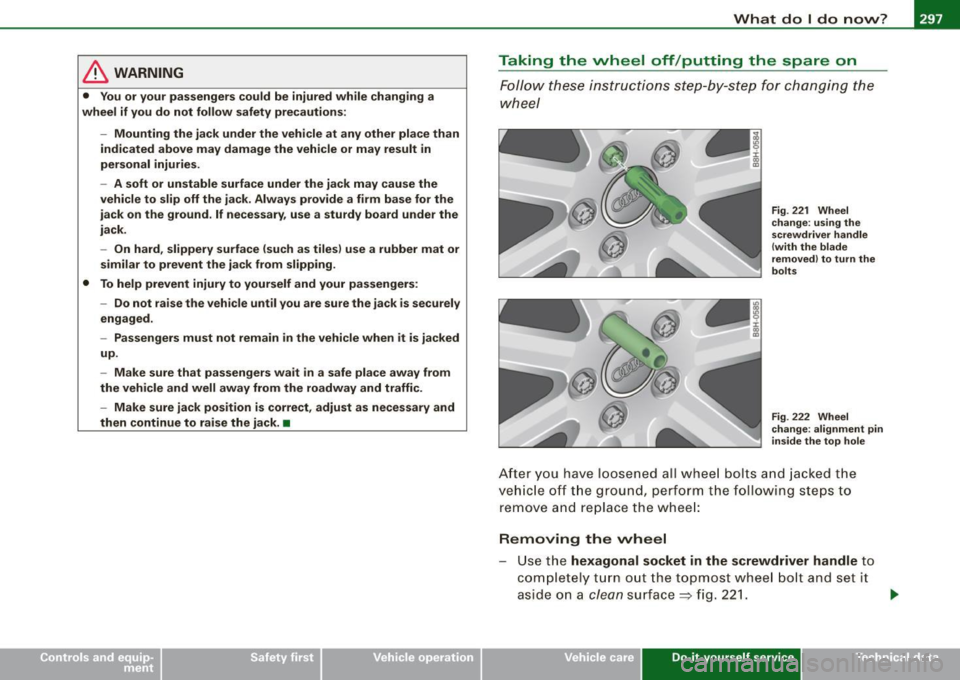

Fig . 2.21 Wheel

change : using the

screwdriver handle

( with the blade

removed) to turn the

bo lts

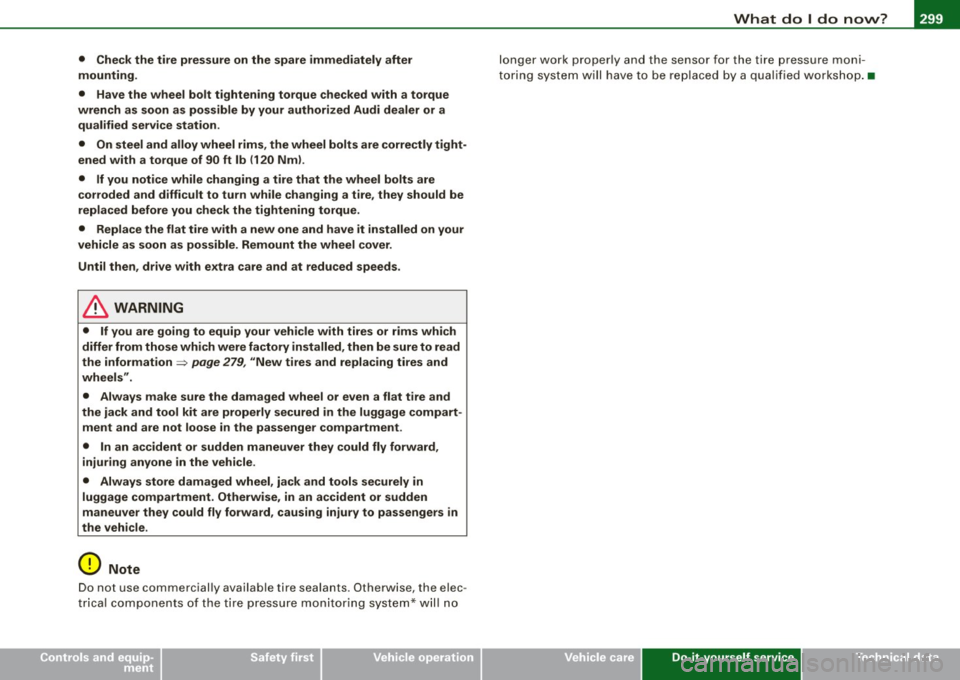

Fig .

222 Wheel

change : alignment pin

inside the top hole

Af te r yo u h ave l oo sened a ll wheel b olts and jacked the

vehicle off the gr ound, perform the fo llow ing steps to

remove and repla ce t he wheel:

Removing the wheel

Use th e hexagonal socket in the screwdriver handle t o

comple te ly turn ou t the t opmos t whe el b olt an d set i t

as ide on a

cl ean surfac e~ fig. 221. ..,

~ehicle care Do-it-yourse lf service irechnical data

Page 301 of 340

_____________________________________________ W_ h _a_t _ d_ o_ l _d _o _ n_o_ w_ ?_ . _ .... I'll

•

• Check the tire pressure on the spare immediately after

mounting.

• Have the wheel bolt t ightening torque checked with a torque

wrench as soon a s possible by your authorized Audi dealer or a

qualified se rvice station .

• On steel and alloy wheel rims , the wheel bolts are correctly tight

ened with a torque of 90

ft lb 1120 Nm ).

• If you notice while changing a tire that the wheel bolts are

corroded and diffi cult to turn while changing a tire , they should be

replaced before you check the tightening torque .

• Replace the flat tire with a new one and have it installed on your

vehicle as soon as possible . Remount the wheel cover.

Until then , drive with extra care and at reduced speeds .

& WARNING

• If you are going to equip your vehicle with tires or r ims which

differ from those which were factory installed , then be sure to read

the information

~ page 279 , "New tires and replacing tires and

wheels ".

• Always make sure the damaged wheel or even a flat tire and

the jack and tool kit are properly secured in the luggage compart

ment and are not loose in the passenger compartment .

• In an accident or sudden maneuver they could fly forward ,

injur ing anyone in the vehicle .

• Always store damaged wheel , jack and tools securely in

luggage compartment . Otherwise , in an accident or sudden

maneuver they could fly forward, causing injury to passengers in

the vehicle .

0 Note

Do not use commercially availab le ti re sealants. Otherw ise, the elec

t rica l compo nents of t he tir e pressure mon itor ing sys te m * w ill no longer work properly and the sensor for

the tire pressure moni

t o ring syste m will have to be re placed by a q ual ified work shop.•

Do-it-yourself service

Page 302 of 340

111!1...__F_ u_ s _ e_s _ a_n_ d_ b_ u_lb _ s _______________________________________________ _

Fuses and bulbs

Fuses

Replacing a fuse

A problem in the electrical system may be caused by a

blown fuse.

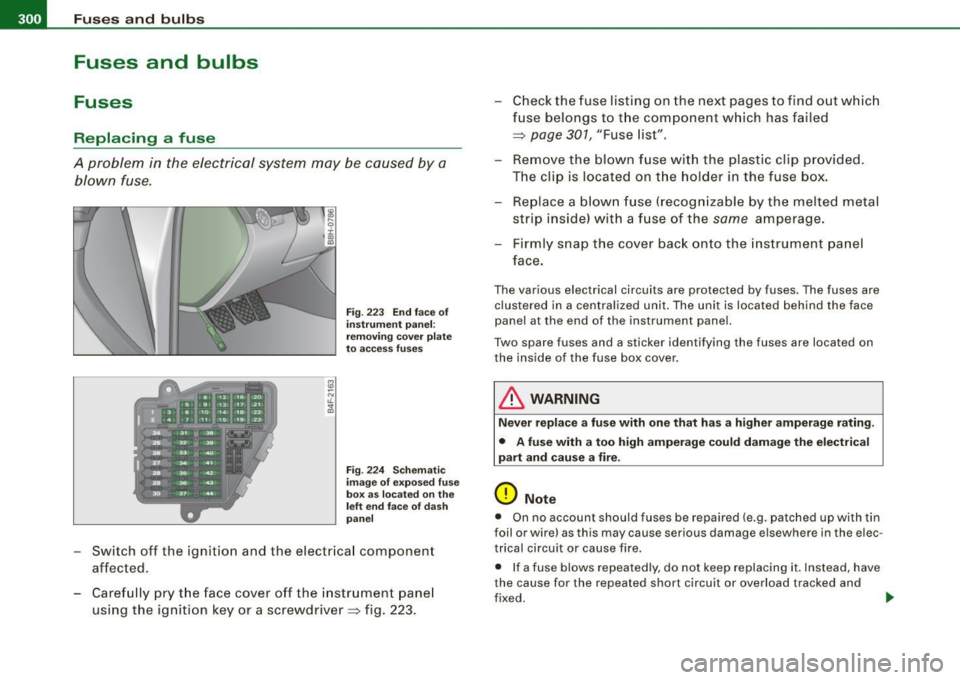

Fig. 223 End face of

instrument panel :

removing cover plate

to access fuses

Fig. 224 Schematic

image of exposed fuse

box as located on the

left end face of dash

panel

- Switch off the ignition and the electrical component

affected.

Carefully pry the face cover off the instrument panel

using the ignition key or a screwdriver~ fig . 223 . -

Check the fuse listing on the next pages to find out which

fuse belongs to the component which has failed

~ page 301 , "Fuse list".

- Remove the blown fuse with the plast ic clip provided.

The clip is located on the holder in the fuse box.

- Replace a blown fuse (recognizable by the melted metal

strip inside) w ith a fuse of the

some amperage.

- Firmly snap the cover back onto the instrument panel

face.

The various electrical circuits are protected by fuses . The fuses a re

clustered in a centralized unit. The unit is located behind the face

panel at the end of the instrument panel.

Two spare fuses and a sticker identifying the fus es are located on

the inside of the fuse box cover.

& WARNING

Never replace a fuse with one that has a higher amperage rating.

• A fuse with a too high amperage could damage the electrical

part and cause a fire.

(D Note

• On no account should fuses be repaired (e.g . patched up with tin

foil or wire) as this may caus e se rious damage elsewhere in the elec

trical circuit or cause fire.

• If a fuse blows repeatedly, do not keep replacing it. Instead, have

the cause for the repeated short circuit or overload tracked and

fixed. _,,

Page 304 of 340

111!11.--___;;F...; u::. s.::..:: e~s :.....:: a..:..n .:..; d::....; b.:..:. u..:..lb ;:..:: s _______________________________________________ _

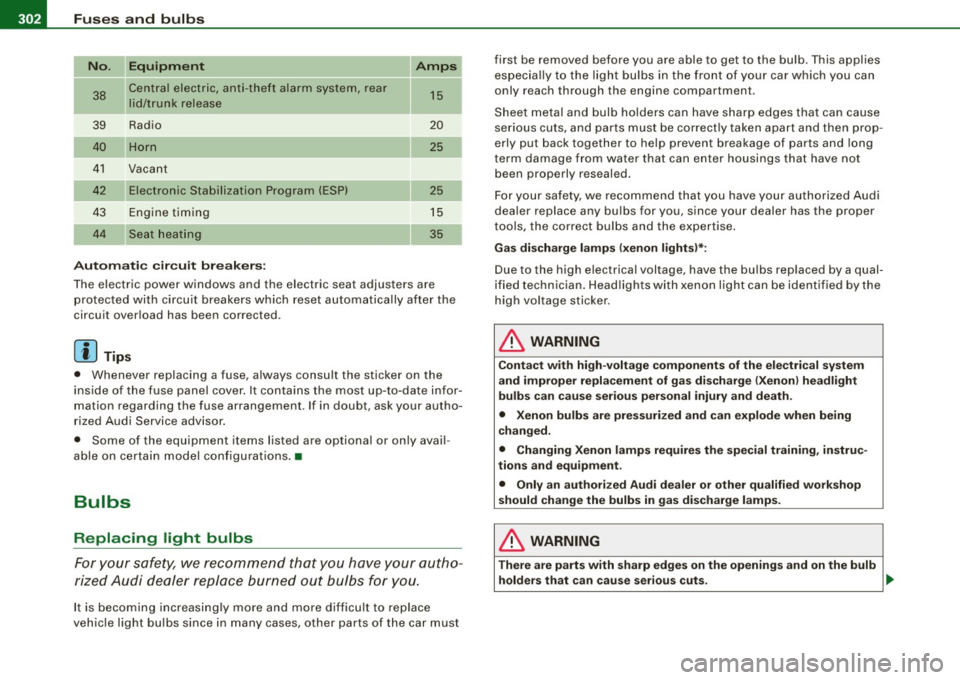

No.

38

39

41

42

43

Equipment

Central electric, anti -theft alarm system, rear

lid/trunk release

Radio

Horn

Vacant

Electronic Stabilization Program (ESP)

Engine timing

Seat heating

Automatic circuit breakers: Amps

15

20

25

25

15

35

The electric power windows and the electric seat adjusters are

protected with circuit breakers which reset automatically after the

circuit overload has been corrected .

[ i] Tips

• Whenever replacing a fuse, always consult the sticker on the

inside of the fuse panel cover. It contains the most up-to-date infor

mation regarding the fuse arrangement . If in doubt, ask your autho

rized Audi Service advisor.

• Some of the equipment items listed are optional or only avail

able on certain model configurations. •

Bulbs

Replacing light bulbs

For your safety, we recommend that you have your autho

rized Audi dealer replace burned out bulbs for you.

It is becoming increasingly more and more difficult to replace

vehicle light bulbs since in many cases, other parts of the car must first be removed before

you are able to get to the bulb. This applies

especially to the light bulbs in the front of your car which you can

only reach through the engine compartment.

Sheet metal and bulb holders can have sharp edges that can cause

serious cuts, and parts must be correctly taken apart and then prop

erly put back together to help prevent breakage of parts and long

term damage from water that can enter housings that have not

been properly resealed.

For your safety, we recommend that you have your authorized Audi

dealer replace any bulbs for you, since your dealer has the proper

tools, the correct bulbs and the expertise.

Gas discharge lamps (xenon lights)*:

Due to the high electrical voltage, have the bulbs replaced by a qual

ified technician. Headlights with xenon light can be identified by the

high voltage sticker.

& WARNING

Contact with high-voltage components of the electrical system

and improper replacement of gas discharge (Xenon) headlight

bulbs can cause serious personal injury and death.

• Xenon bulbs are pressurized and can explode when being

changed.

• Changing Xenon lamps requires the special training, instruc

tions and equipment.

• Only an authorized Audi dealer or other qualified workshop

should change the bulbs in gas discharge lamps.

& WARNING

There are parts with sharp edges on the openings and on the bulb holders that can cause serious cuts .

~

Page 306 of 340

111!1.___E_ m __ e_r -=g :...e_ n_ c-=y _ s_ i_t _u _a _t_ i_o _n_ s _______________________________________________ _

Emergency situations

General

This chapter is intended for trained emergency crew s and working

personnel who have the necessary tools and equipment to perform

these operations. •

Starting by pushing or towing

0 Note

Vehicles with an automatic tran smission cannot be started by

push ing o r towing . •

Starting with jumper cables

If n ece ssa ry, th e engin e ca n be sta rte d by conne cti ng it to

the battery of another veh ic le .

If the engin e should fai l to start because of a discharge d or weak

b at te ry, the batt ery can be con nected t o the batt er y of

another

ve hic le, using a pair of jumper cables to start the engine.

Jumper cables

Use

only jumper cables of suffici ently large cross section to safely

c arry the st ar ter curre nt. Refer to th e m anuf actu rer's sp ec ificati ons.

Use on ly j umper ca bles with

isolated termi na l clam ps and properly

marked fo r distinct ion :

plus (+l cable in mo st c ases c olor ed red

minus (-l cable in most cases colored black.

& WARNING

Batteries contain electricity , acid, and gas. Any of these can cause

very serious or fatal injury. Follow the instructions below for safe

handling of your vehicle 's battery .

• Always shield your eyes and avoid leaning over the battery

whenever possible .

• A discharged battery can already freeze at temperatures just

below 32 °F (0 °C). Before connecting a jumper cable, the frozen

battery must be thawed completely, otherwise it could explode.

• Do not allow battery acid to contact eyes or skin . Flush any

contacted area with water immediately.

• Improper use of a booster battery to start a vehicle may cause

an explosion.

• Vehicle batteries generate e xplosive gases . Keep sparks , flame

and lighted cigarettes away from batteries.

• Do not try to jump start any vehicle with a low acid level in the

battery.

• The voltage of the booster battery must also have a 12-Volt

rating . The capacity (Ahl of the booster battery should not be

lower than that of the discharged battery . Use of batteries of

diffe rent voltage or substantially different "Ah " rating may cause

an explosion and personal injury .

• Never charge a frozen battery. Gas trapped in the ice may cau se

an explosion .

• Never charge or use a battery that has been frozen . The battery

case may have be weakened.

• Use of batteries of different voltage or substantially different

capacity (Ah ) rating may cause an explosion and injury . The

capacity (Ahl of the booster battery should not be lower than that of the discharged battery . ...

Page 307 of 340

______________________________________________ E_ m_ e_r -=g :...e _ n_ c __a. y_ s_it _u_ a_ ti_o _ n_ s _ __,11111

& WARNING (continued)

• Before you check anything in the engine compartment, always

read and heed all WARNINGS~ page 242, "Engine compartment".

0 Note

• Applying a higher voltage booster battery will cause expensive

damage to sensitive electronic components, such as control units,

relays, radio, etc .

• There must be no electrical contact between the vehicles as

otherwise current could already start to flow as soon as the positive

(+) terminals are connected.

[ i] Tips

The discharged battery must be properly connected to the vehicle's

electrical system. •

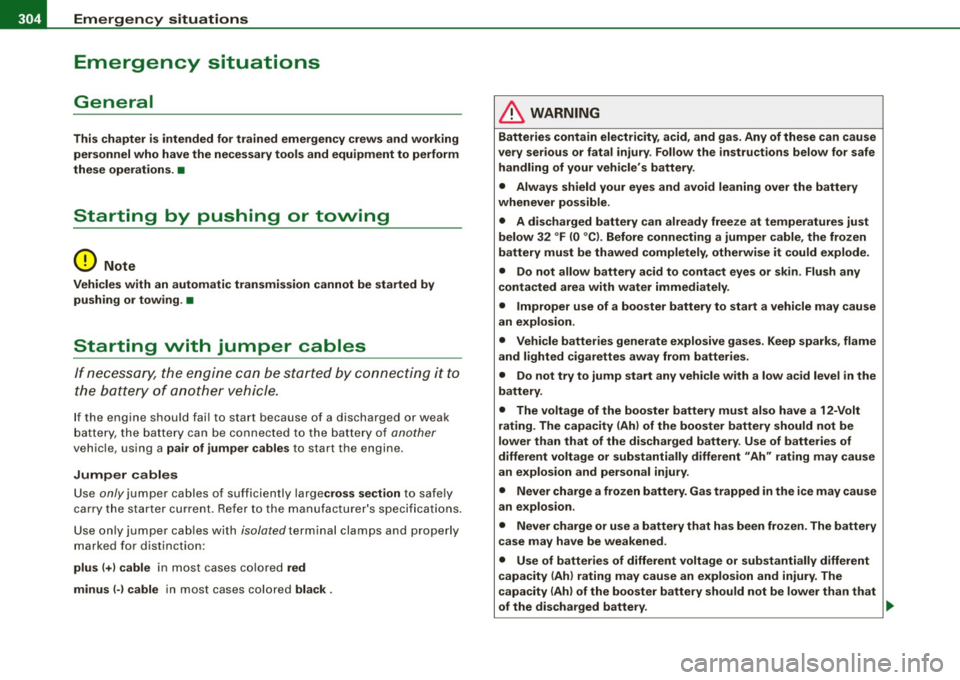

Use of jumper cables

Make sure to connect the jumper cable clamps in exactly

the order described below!

Fig. 225 Jump·

starting with the

battery of another

vehicle : A -discharged

vehicle battery, B -

booster battery

Vehicle with discharged battery:

- Turn off lights and accessories, move lever of automatic

transmission to

N (Neutral) or P (Park) and set parking

brake.

Connect POSITIVE (+) to POSITIVE (+) (red)

1. Connect clamp of plus cable to positive(+) terminal G)

~ fig. 225 of discharged vehicle battery@.

2. Connect clamp on opposite end of cable to positive(+)

terminal

® of booster battery@.

Connect NEGATIVE (-) to NEGATIVE (-) (black)

3. Connect clamp of minus cable (black) to negative( -)

terminal

0 of booster battery@.

4. Connect clamp on opposite end of negative cable to the

negative( -) terminal © of the discharged vehicle battery

@.

- Check that all screw plugs on the battery cells are

screwed in firmly. If not, tighten plugs prior to

connecting clamp on negative battery terminal.

Starting the engine

- Start the engine of the vehicle with the booster battery.

Run the engine at a moderate speed.

- Start engine with discharged vehicle battery in the usual

manner.

- If the engine fails to start: do not keep the starter

cranking for longer than 10 seconds. Wait for about 30

seconds and then try again. .,,.

~ehicle care Do-it-yourse lf service Technical data

Page 308 of 340

111!1.___E_ m __ e_r -=g :...e_ n_ c-=y _ s_ i_t _u _a _t_ i_o _n_ s _______________________________________________ _

-With en gine run ning, r em ove jum per ca bles from both

v ehi cle s in exact

reve rs e o rd er.

T he battery is ve nted t o th e outs ide to preve nt gases from enter ing

the vehicle interior.

M ake s ure t hat th e jum per cla m ps are well co nnecte d with th eir

metal parts in full contact with the battery t erminals .

& WARNING

To avoid serious personal injury and damage to the vehicle , heed

all warnings and instructions of the jumper cable manufacturer. If

in doubt , call for road service .

• Jumper cables must be long enough so that the vehicles do not

touch .

• When connecting jumper cables , make sure that they cannot

get caught in any moving parts in the engine compartment .

• Before you check anything in the engine compartment, always

read and heed all WARNINGS=>

page 242, "Engine compartment ".

0 Note

Improper hook -up of jumper cables can ruin the generator.

• Always connec t POSIT IVE( +) to POS ITIVE ( +J, and NEG ATIV E (- J to

N EGAT IVE(-) te rminal.

• C heck that a ll screw plugs on the battery cel ls are screwed in

firm ly . I f not, tighten plugs prior to connec ting cla m p on nega tive

battery te rminal.

• P lease no te tha t th e procedure fo r con nec ting a ju mp er ca ble as

described above app lies specifical ly to t he case of your vehicle

b eing j ump st arted. When yo u are g iv in g a jum p start to another

veh ic le, do

not conn ect the minus(-) ca ble to the m inus( -) te rmina l

on the discha rge d battery ©=>

page 305, fig. 225. In stead , secu rely

co nnect the m inus(-) cable to e ither a m ass ive metal compone nt

that is firmly bo lted to the engine bloc k or to the engine b lock itse lf. I

f th e battery that is b ein g charged does not vent to the outside,

escapi ng battery ga s cou ld ignit e a nd ex plod e!•

Emergency towing with commercial

tow truck

General hints

Yo ur A udi requires s pecial handl in g f or t owing.

The fol lowing information i s to be used by commercial tow truck

operators who know how to operat e their equ ipment safe ly.

• Never tow your Audi, towing will cause damage to the engine

and transmission.

• Never wrap the safety chains or winch cables around the brake

lines.

• To prevent unnecessary damage , your Audi must be transported

with a car carrier (flat bed truck ).

• To load the vehicle on to the flat bed , use the towing loop found

in the vehicle tools and attach to the front or rear anchorage

=> page 3 07 and => page 307.

& WARNING

A vehicle being towed is not safe for passengers. Never allow

anyone to ride in a vehicle being towed , for any reason. •

Page 309 of 340

________________________________________________ E_ m_ e_r ""g '-e_ n _ c..::y;..._ s_ i_t _u _a_ t_ i_o _n_ s _ __,_

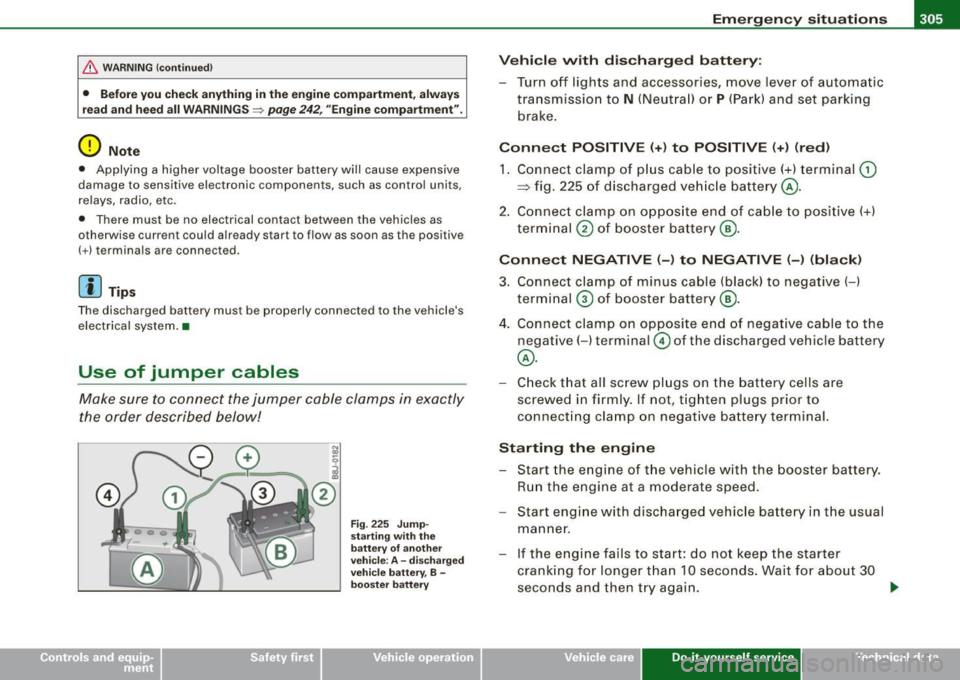

Front towing loop

Do not install the front towing loop until it is needed.

Fig. 226 Front

bumper: removing the

cover cap

Fig . 227 Front

bumper: screwing in

the towing loop

The towing loop fits into the threaded hole located on the

right side of the front bumper and covered by a small cap

when not in use. -

Remove the towing loop from the vehicle tools

=> page 290.

-Press on the bottom edge of the cover cap to disengage

it from the bumper. The cap remains connected to the

bumper => fig. 226.

- Screw the towing loop into the threaded hole as far as it

will go

=> fig. 227, then tighten it with the wheel bolt

wrench.

When it is no longer needed , unscrew the towing loop and put it

back into the onboard toolkit. Make sure to have the towing loop

stored in the vehicle at all times .

& WARNING

If the towing loop is not screwed in as far as it will go, the thread

can pull out when the vehicle is towed -potential risk of an

accident. •

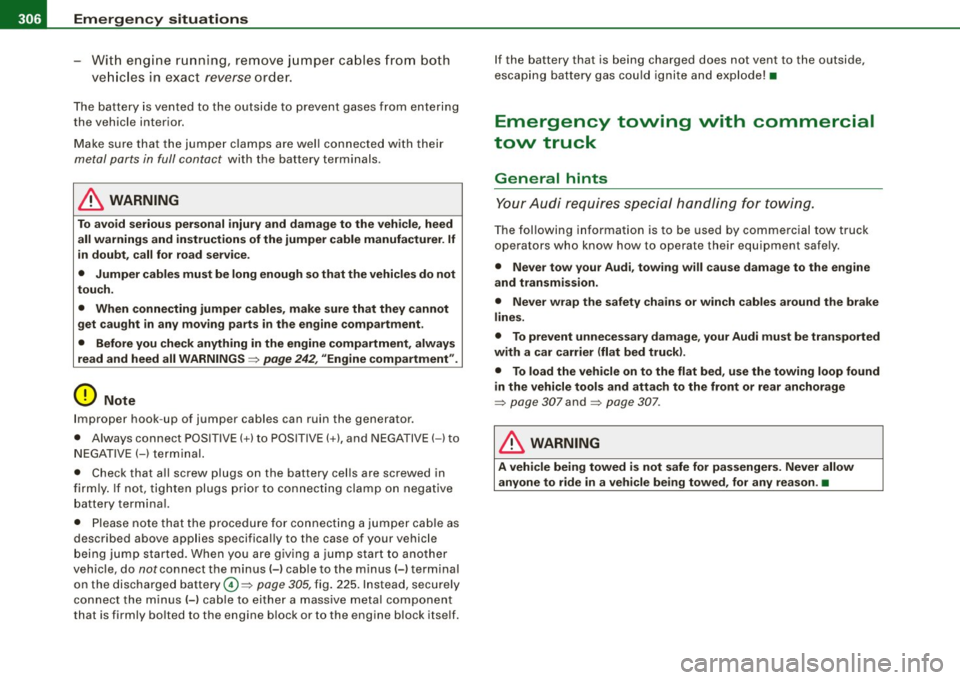

Rear towing loop

Fig. 228 Rear bumper,

right side: location of

rear towing loop

The rear towing eye is welded to the chassis under the rear bumper

on the right side.•

~ehicle care Do-it-yourse lf service Technical data

Page 310 of 340

111'1...__E_ m_ e_ r -'g==-- e_n _c_ y=---- s_ i_ t _u _a _ t_ i_o _n _ s _____________________________________________ _

Loading the vehicle onto a flat bed truck

Front hook up

I

"' m

Fig . 229 Ve hicle on flat

b ed tru ck

- Align the vehicle w ith the centerline of the car carrier

ramp .

- Attach the winch hook to the front towing loop previously

installed .

Rea r hook up

-Align the vehicle wi th t he centerline of the ca r carrier

ramp .

- Attach the winch hook to the rear towing loop previously

i nstalled.

[ i ] Tips

Check careful ly to make sure the hook -up is secure before moving

the car up the flatbed truck ramp. •

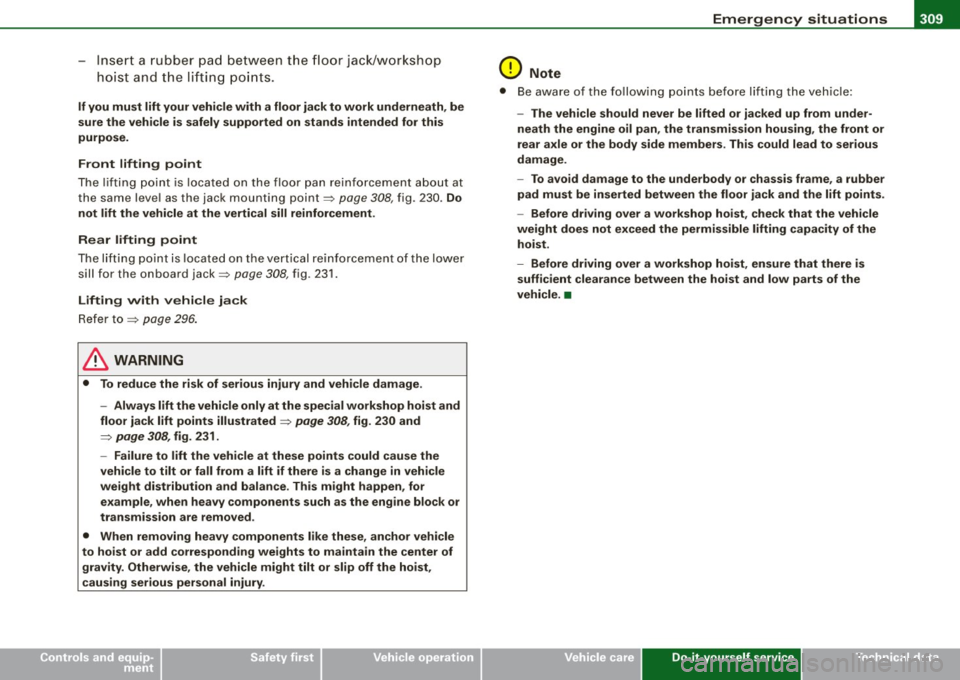

Lifting vehicle

Lifting with workshop hoist and with floor

jack

T he vehicle may only be lifted at the lifting p oints illus

trated.

- Read and heed WARNING =>& .

m 9 :r

"' m

Fig . 2 30 F ront lift in g

po in t

F ig . 2 3 1 Rear lift in g

po int

- Locate lifti ng poi nts =:> fig. 230 =:> fig. 23 1.

- Ad just li fting arms of works hop hoist or floor jack to

match vehicle l ifting points.

Page 311 of 340

________________________________________________ E _m_ e_r.:g :;,. e_ n_c ...: y:.- s_ i_ t _u _a_ t_ i_ o _ n_ s ____ fflll

•

- In se rt a rubber pad betwee n th e floor jack/ wo rk sh op

h oi st and the li ftin g p oin ts .

If you must lift your vehicle with a floor jack to work underneath , be

sure the vehicle is safely supported on stands intended for this

purpose .

Fr ont lifting point

The lifting poi nt is located on the floo r pan rei nforceme nt about at

the same leve l as the jack mounting point~ page

308, fig. 230. Do

not lift the vehicle at the vertical sill reinforcement.

Rear lifting point

The li ftin g point is locate d on t he vert ical re inforceme nt of th e low er

sil l for the on board jack~ page

30 8, fig. 23 1.

Lifting with vehi cle ja ck

Refer to

~ page 296.

& WARNING

• To reduce the ri sk of serious injury and vehicle damage.

- Always l ift the vehicle only at the special workshop hoist and

floor jack lift points illustrated

~ page 308 , fig. 230 and

~ page 308, fig. 231.

- Failure to lift the vehicle at these points could cause the

vehicle to tilt or fall from a lift if there is a change in vehicle

weight distribution and balan ce . This might happen , for

e xample , when heavy components such as the engine block or

transmission are removed .

• When removing heavy components like these, anchor vehicle

to hoist or add correspond ing we ights to maintain the center of

gravity. Otherwise , the vehicle might tilt or slip off the hoist ,

causing ser ious personal injury .

0 Note

• Be aware of the fo llowing po ints be fore l ifting the ve hicle:

- The vehicle should never be lifted o r ja cked up from under

neath the engine oil pan , the tran smis sion housing , the front or

rear a xle or the body side members. This could lead to serious

damage.

- To avoid damage to the underbody or chassis frame , a rubber

pad must be inserted between the floor jack and the lift points .

- Before dr iving over a workshop hoist , check that the vehicle

weight does not exceed the permis sible lifting capacity of the

hoist .

- Before driving over a workshop hoist , en sure that there i s

sufficient clearance between the hoist and low parts of the

vehicle. •

Do-it-yourself service