clock AUDI S5 2008 8T / 1.G User Guide

[x] Cancel search | Manufacturer: AUDI, Model Year: 2008, Model line: S5, Model: AUDI S5 2008 8T / 1.GPages: 294, PDF Size: 12.13 MB

Page 207 of 294

Downloaded from www.Manualslib.com manuals search engine Towing a trailer205

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

– Check that the ball joint fits tightly in the mounting

fixture (try moving it about to check).

Electrical socket for trailer

– The cable of the towing bracket can be connected to the

socket ⇒page 204, fig. 202.If the safety check is not satisfactory, the ball joint must be fitted

again properly.

WARNING

To avoid accidents, the ball joint must meet all the safety require-

ments listed in the safety check. The towing bracket must not be

used if any one of these requirements is not met. If this is the case,

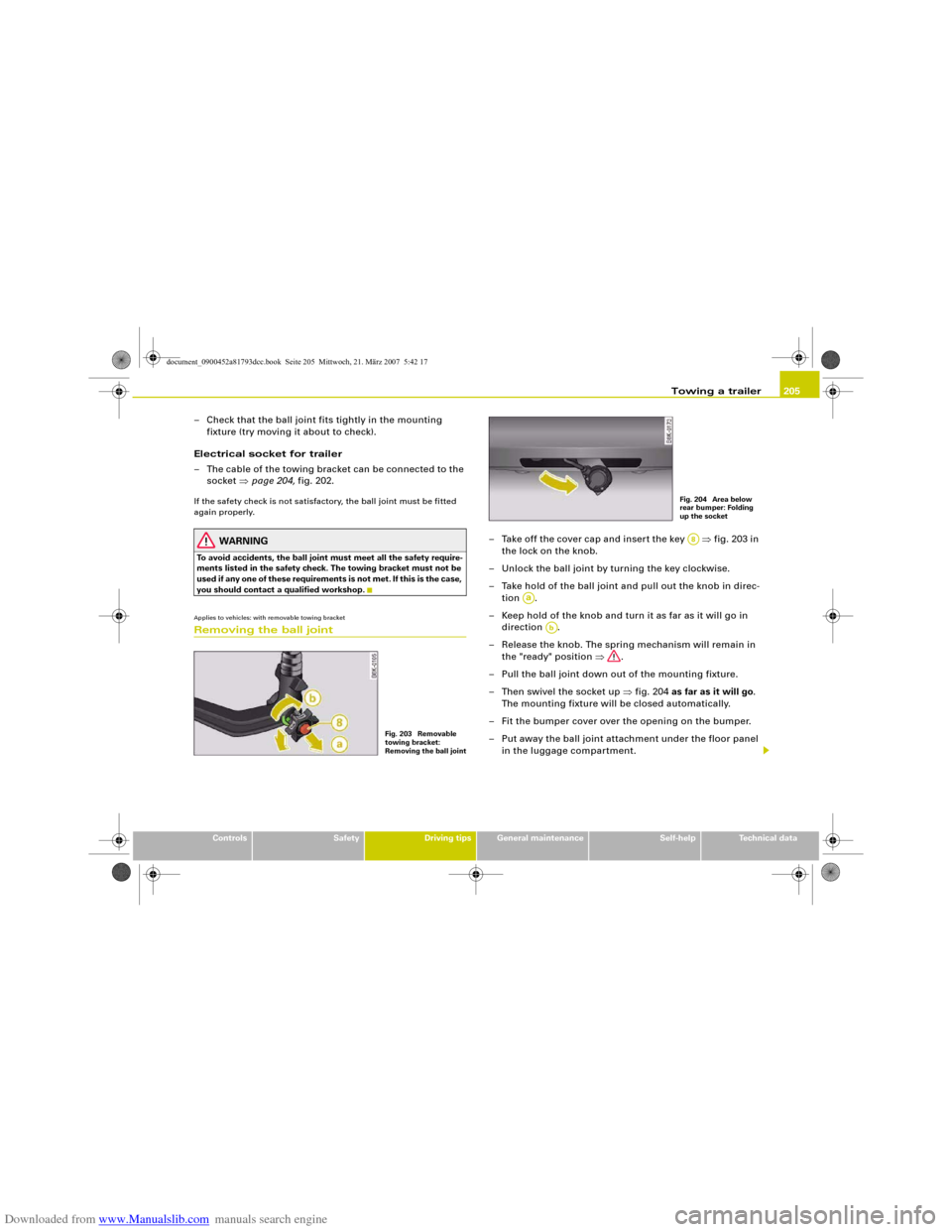

you should contact a qualified workshop.Applies to vehicles: with removable towing bracketRemoving the ball joint

– Take off the cover cap and insert the key ⇒fig. 203 in

the lock on the knob.

– Unlock the ball joint by turning the key clockwise.

– Take hold of the ball joint and pull out the knob in direc-

tion .

– Keep hold of the knob and turn it as far as it will go in

direction .

– Release the knob. The spring mechanism will remain in

the "ready" position ⇒.

– Pull the ball joint down out of the mounting fixture.

– Then swivel the socket up ⇒fig. 204 as far as it will go.

The mounting fixture will be closed automatically.

– Fit the bumper cover over the opening on the bumper.

– Put away the ball joint attachment under the floor panel

in the luggage compartment.

Fig. 203 Removable

towing bracket:

Removing the ball joint

Fig. 204 Area below

rear bumper: Folding

up the socketA8

Aa

Ab

document_0900452a81793dcc.book Seite 205 Mittwoch, 21. März 2007 5:42 17

Page 219 of 294

Downloaded from www.Manualslib.com manuals search engine Fuel and filling the tank217

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

Fuel and filling the tankPetrolPetrol grade

The correct grade of petrol is listed inside the fuel tank

flap.The vehicle is equipped with a catalytic converter and must only be

run on unleaded petrol. Unleaded petrol must comply with the

European EN 228 standard. The petrol grades have different octane

ratings (RON). If, in exceptional circumstances, the correct octane

rating is not available, please note the following:

Your engine normally requires Super Plus unleaded petrol (98 RON)

according to ⇒page 281, “Performance, weights and dimensions”.

Premium unleaded fuel with 95 RON can also be used. This can,

however, result in a slight loss of power under certain driving condi-

tions. If premium unleaded petrol is not available, the engine can be

run on regular unleaded petrol with 91 RON as an emergency

measure. In this case only use moderate engine speeds and a light

throttle. Avoid using full throttle. Fill up with premium or Super Plus

petrol as soon as possible.

Caution

•

Petrol complying with the EN 228 standard can contain small

quantities of ethanol. However, “bioethanol fuels”, which are

retailed under various different names such as E50 and E85, and

which contain a large proportion of ethanol, must not be put into

the vehicle, as this would damage the fuel system.

•

Even one tankful of leaded fuel would permanently impair the

efficiency of the catalytic converter.

•

High engine speed and full throttle can damage the engine when

using petrol with an octane rating lower than the correct grade for

the engine.

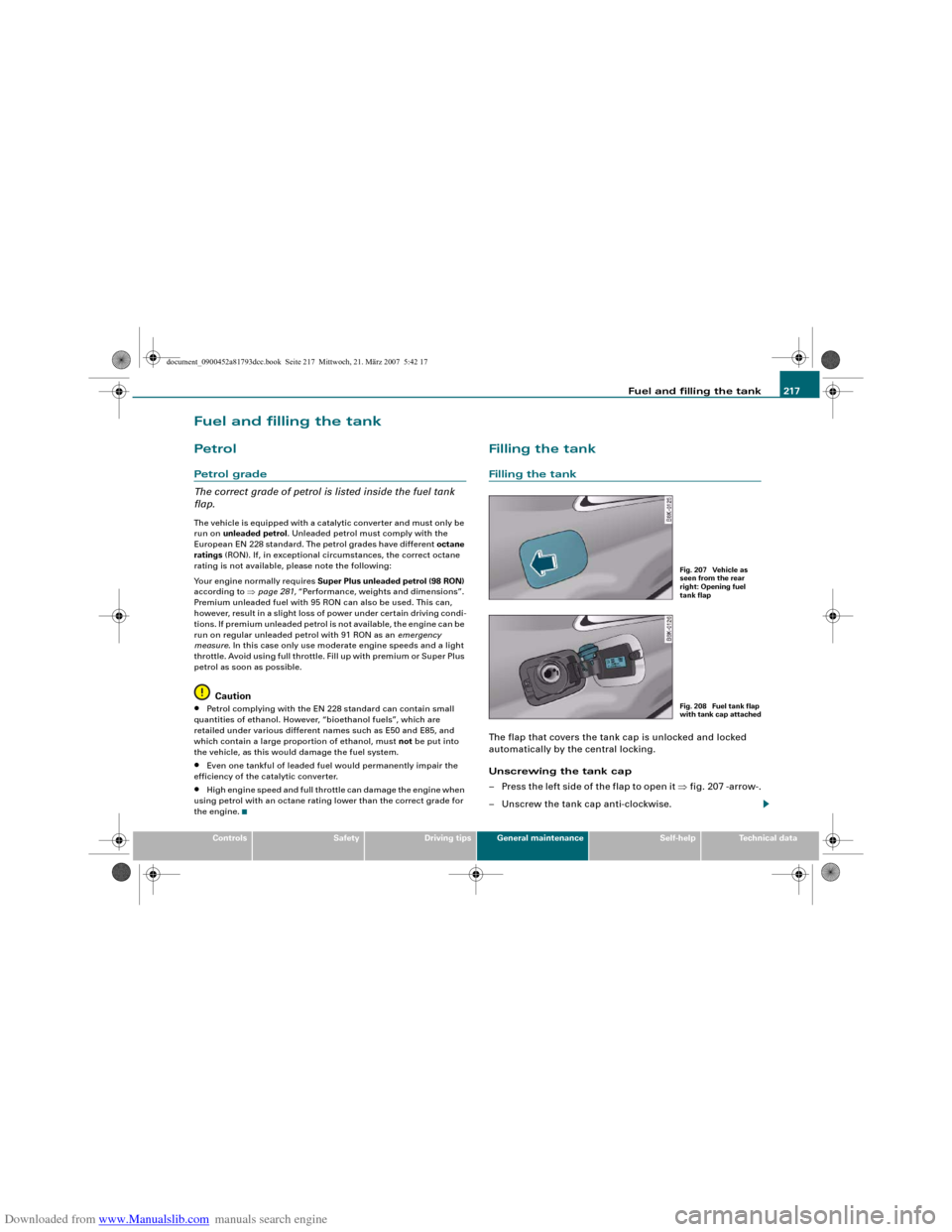

Filling the tankFilling the tankThe flap that covers the tank cap is unlocked and locked

automatically by the central locking.

Unscrewing the tank cap

– Press the left side of the flap to open it ⇒fig. 207 -arrow-.

– Unscrew the tank cap anti-clockwise.

Fig. 207 Vehicle as

seen from the rear

right: Opening fuel

tank flapFig. 208 Fuel tank flap

with tank cap attached

document_0900452a81793dcc.book Seite 217 Mittwoch, 21. März 2007 5:42 17

Page 220 of 294

Downloaded from www.Manualslib.com manuals search engine Fuel and filling the tank 218

– Hook the cap onto the open flap ⇒page 217, fig. 208.

Closing the tank cap

– Screw on the tank cap clockwise until it cannot be turned

further.

– Press the left side of the flap to close it (you should hear

it click into place).When the automatic filler nozzle is operated correctly it will switch

itself off as soon as the tank is “full”. Do not try to put in more fuel

after the nozzle cuts out, as this will fill the expansion chamber in

the fuel tank.

The correct fuel grade for your vehicle is given on a sticker on the

inside of the tank flap. Further notes on fuel ⇒page 217.

The tank capacity of your vehicle is given in the Te c h n i c a l d a t a

section ⇒page 279.

WARNING

Fuel is highly inflammable and can cause serious burns and other

injuries.•

For safety reasons always switch off the auxiliary heating*

before refuelling the vehicle.

•

For safety reasons we do not recommend carrying a spare fuel

canister in the vehicle. The canister could become damaged in an

accident and leak.

•

Observe all relevant statutory regulations on using, storing and

transporting spare fuel canisters.

•

When filling your tank or a spare fuel canister with fuel, do not

smoke and keep away from naked flames. Risk of explosion!

•

If, in exceptional circumstances, you have to carry a spare fuel

canister, please observe the following warnings:

−Never fill fuel into the spare fuel canister with the canister

placed in or on top of the vehicle. An electrostatic charge could build up during filling, causing the fuel vapour to ignite. Danger

of explosion. Always place the canister on the ground to fill it.

−Insert the filler nozzle as far as possible into the spare fuel

canister.

−If the spare fuel canister is made of metal, the filler nozzle

must be in contact with the canister during filling. This helps

prevent an electrostatic charge building up.

−Make sure you never spill fuel in the vehicle or in the luggage

compartment. Fuel vapour is explosive. Risk of fatal accident!

Caution

•

Remove any fuel spills from the paintwork immediately.

•

Never run the tank completely dry. If there is an irregular fuel

supply, misfiring can occur. As a result unburnt fuel can enter the

exhaust system and cause damage to the catalytic converter(s).For the sake of the environment

Do not try to put in more fuel after the automatic filler nozzle has

switched off; this may cause the fuel to overflow if it becomes

warm.

WARNING (continued)

document_0900452a81793dcc.book Seite 218 Mittwoch, 21. März 2007 5:42 17

Page 228 of 294

Downloaded from www.Manualslib.com manuals search engine Checking and topping up fluids 226

CautionRadiator sealants must not be added to the coolant. Such additives

could seriously impair the function of the cooling system.Topping up the coolant

Be careful when topping up coolant.– Switch off the engine.

– Wait for the engine to cool down.

– Cover the cap on the expansion tank ⇒page 225, fig. 215

with a cloth, and carefully unscrew the cap anti-clock-

wise ⇒.

– Add coolant.

– Screw the cap on again tightly.Make sure that the coolant meets the required specifications

⇒page 224, “Coolant”. Do not use a different type of additive if anti-

freeze additive G12+, G12 or G11 is not available. In this case use

only water and bring the coolant concentration back up to the

correct level as soon as possible by putting in the specified additive.

Always top up with fresh, unused coolant.

Do not fill above the “MAX” mark. Excess coolant is forced out of the

system through the valve in the filler cap when the engine gets hot.

If a lot of coolant has been lost, wait for the engine to cool down

before putting in cold coolant. Failure to do so could result in

serious engine damage.

WARNING

•

The cooling system is under pressure. Do not unscrew the cap

on the expansion tank when the engine is hot: you could be

scalded by escaping steam

•

The coolant and coolant additive can be a health hazard. Store

the coolant additive in the original container in a safe place out of

reach of children – risk of poisoning.For the sake of the environment

Drained off coolant should not be used again. Drain off the used

coolant into a suitable container and dispose of it in the proper

manner (observe environmental regulations).Radiator fan

The radiator fan can start running spontaneously.The radiator fan is driven by the engine via a poly V-belt. The speed

of the fan is varied by a viscous clutch according to the temperature.

There is also an auxiliary electric fan, which cuts in automatically

whenever the temperature of the coolant and the engine compart-

ment rises above a certain level.

The auxiliary fan can continue to run for as long as 10 minutes after

stopping the engine – even after the ignition is switched off. It may

also start running suddenly ⇒ after a while if•

residual heat raises the coolant temperature, or

•

the hot engine compartment is additionally heated up by the

sun.

WARNING

When working in the engine compartment be aware that the radi-

ator fan may start running suddenly – risk of injury.

document_0900452a81793dcc.book Seite 226 Mittwoch, 21. März 2007 5:42 17

Page 248 of 294

Downloaded from www.Manualslib.com manuals search engine Self-help 246If you need the tools, the Tyre Mobility System or the jack*, you will

have to open the floor panel and take out the spare wheel*

⇒page 246.

The tool kit includes:•

A hook for removing hub caps

•

Pin for mounting a wheel

•

Screwdriver with reversible blade

•

Tool for changing bulbs

•

Interchangeable socket (Torx socket for changing bulbs)

•

Crank handle for jack

•

Adapter for anti-theft wheel bolts*

•

Jack*

•

Box spanner for wheel bolts

•

Towline anchorage

Some of the parts listed are only fitted on certain models or are

optional extras.

Before stowing the jack* again, wind down the arm of the jack as far

as it will go.

WARNING

•

Do not use the hexagonal socket in the screwdriver handle to

tighten the wheel bolts. It is not possible to tighten the bolts with

the required torque – risk of accident.

•

The jack supplied by the factory is only designed for changing

wheels on this model. On no account attempt to use it for lifting

heavier vehicles or other loads – risk of injury.

•

Never start the engine when the vehicle is on the jack - risk of

accident.

•

If work has to be done under the veh i cl e , e n su re t h a t i t is sa fe l y

supported on stands designed for the purpose, otherwise there is

a risk of injury.

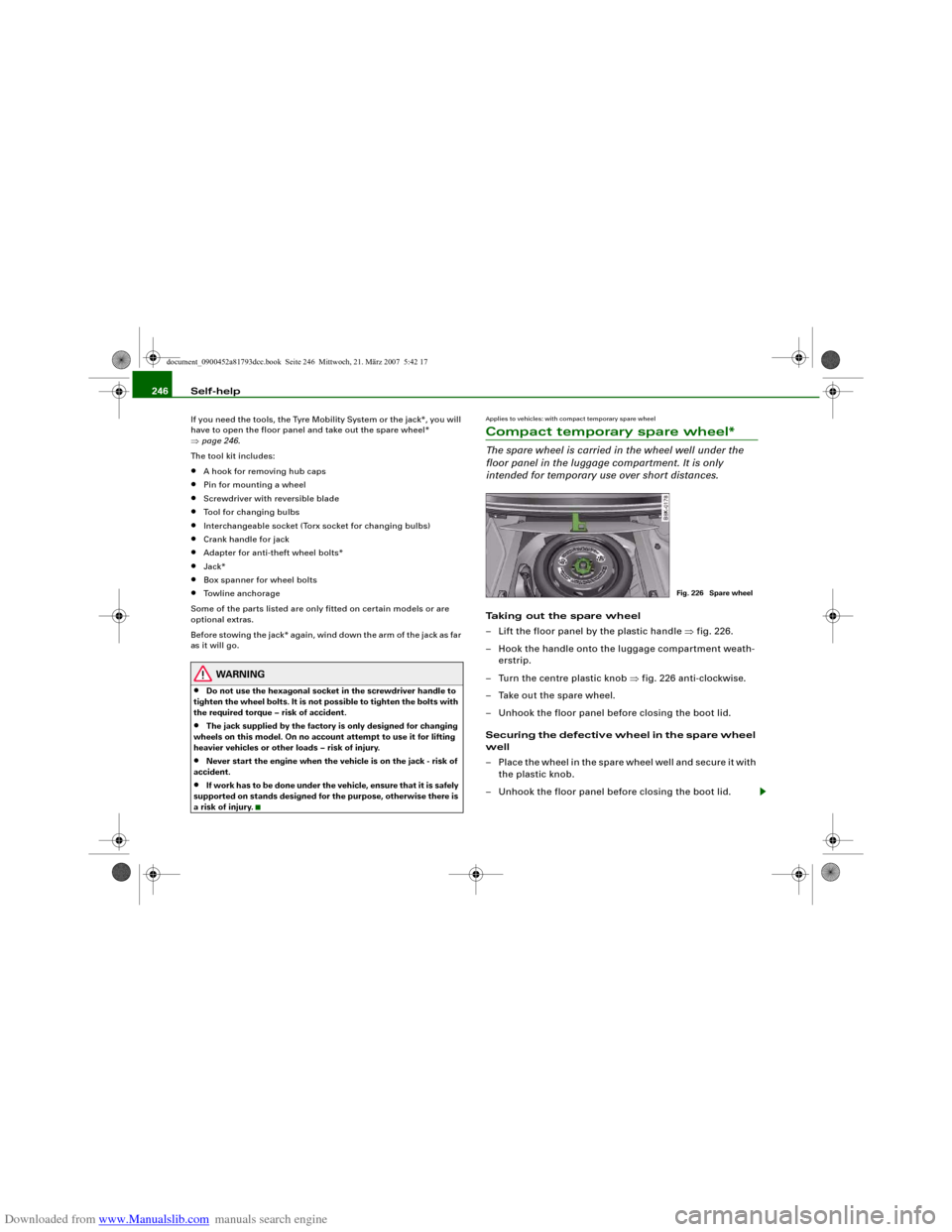

Applies to vehicles: with compact temporary spare wheelCompact temporary spare wheel*The spare wheel is carried in the wheel well under the

floor panel in the luggage compartment. It is only

intended for temporary use over short distances.Taking out the spare wheel

– Lift the floor panel by the plastic handle ⇒fig. 226.

– Hook the handle onto the luggage compartment weath-

erstrip.

– Turn the centre plastic knob ⇒fig. 226 anti-clockwise.

– Take out the spare wheel.

– Unhook the floor panel before closing the boot lid.

Securing the defective wheel in the spare wheel

well

– Place the wheel in the spare wheel well and secure it with

the plastic knob.

– Unhook the floor panel before closing the boot lid.

Fig. 226 Spare wheel

document_0900452a81793dcc.book Seite 246 Mittwoch, 21. März 2007 5:42 17

Page 254 of 294

Downloaded from www.Manualslib.com manuals search engine Self-help 252

Loosening

–Fit the box spanner as far as it will go over the wheel

bolt

7).

– Grip the box spanner as close to the end as possible and

turn the wheel bolts about one turn anti-clockwise

⇒page 251, fig. 230 -arrow-.

Tightening

– Fit the box spanner as far as it will go over the wheel

bolt7).

– Grip the box spanner as close to the end as possible and

tighten the bolt firmly by turning clockwise.

WARNING

To avoid accidents, the wheel bolts should only be loosened

slightly (about one turn) before raising the vehicle with the jack*.

Note

•

Do not use the hexagonal socket in the screwdriver handle to

loosen or tighten the wheel bolts.

•

If the wheel bolt is very tight, it may be possible to loosen it by

pushing down the end of the spanner carefully with your foot. Hold

on to the car for support and take care not to slip.

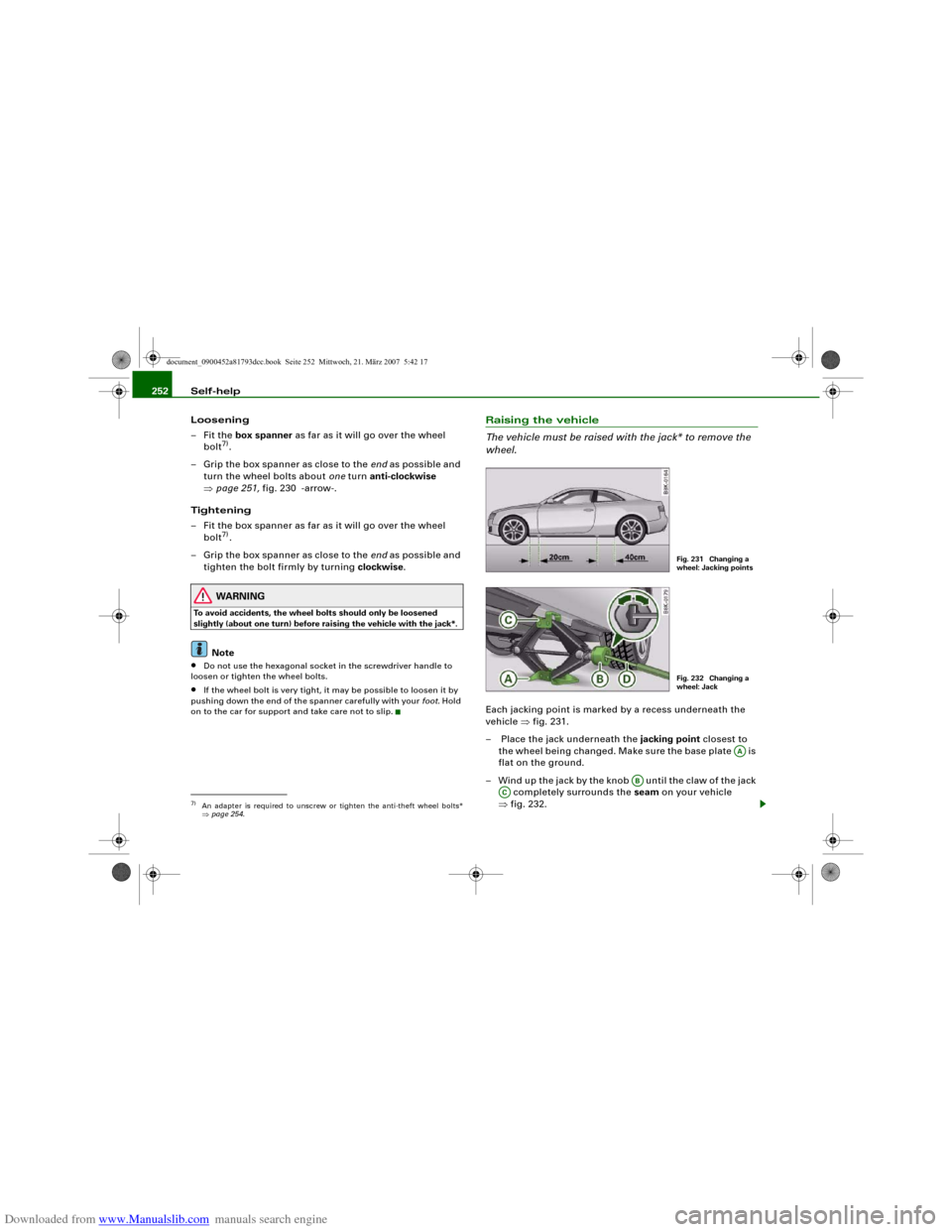

Raising the vehicle

The vehicle must be raised with the jack* to remove the

wheel.Each jacking point is marked by a recess underneath the

vehicle ⇒fig. 231.

– Place the jack underneath the jacking point closest to

the wheel being changed. Make sure the base plate is

flat on the ground.

– Wind up the jack by the knob until the claw of the jack

completely surrounds the seam on your vehicle

⇒fig. 232.

7)An adapter is required to unscrew or tighten the anti-theft wheel bolts*

⇒page 254.

Fig. 231 Changing a

wheel: Jacking pointsFig. 232 Changing a

wheel: Jack

AA

AB

AC

document_0900452a81793dcc.book Seite 252 Mittwoch, 21. März 2007 5:42 17

Page 255 of 294

Downloaded from www.Manualslib.com manuals search engine Self-help253

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

– Now fit the crank handle onto the jack by inserting it

in the opening on the knob ⇒page 252, fig. 232. Turn the

crank handle clockwise or anti-clockwise to secure it in

place.

– Raise the vehicle by winding the crank handle until the

defective wheel is clear of the ground.Recesses at the front and rear of the door sills mark the jacking

points ⇒page 252, fig. 231. There is one jacking point for each

wheel. The distance from the jacking points to the wheel arches is

approximately 20 cm at the front and 40 cm at the rear. The jack may

only be applied at the seam of the jacking points shown.

An unstable surface under the jack may cause the vehicle to slip off

the jack. Always provide a firm base for the jack on the ground. If

necessary use a large, strong board or similar support. On a hard,

slippery surface (such as tiles) use a rubber mat or similar to prevent

the jack from slipping.

WARNING

•

Prevent the base of the jack from slipping – risk of injury.

•

The car can be damaged if the jack is not applied at the correct

jacking points. There is also a risk of injury since the jack can slip

off suddenly if it is not properly engaged.

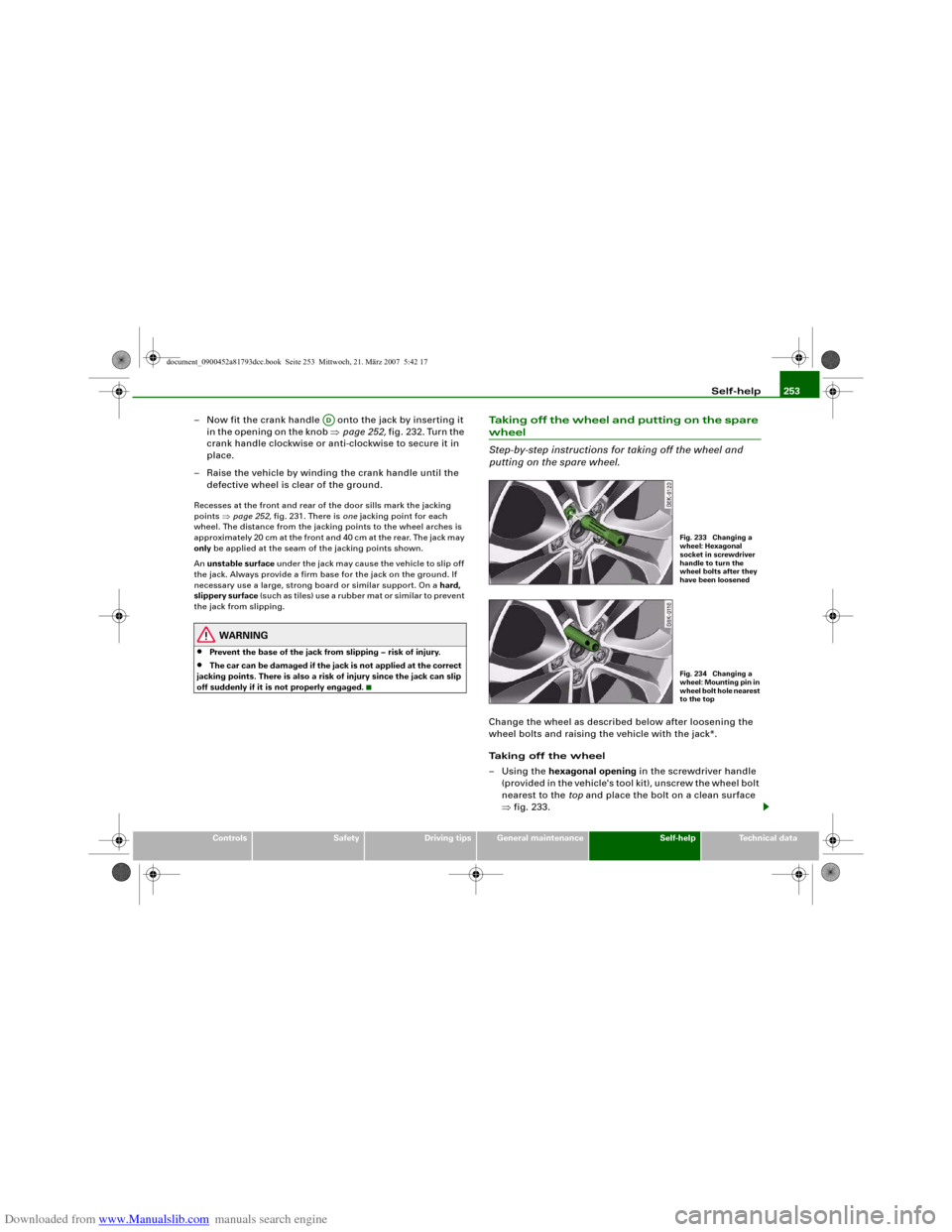

Taking off the wheel and putting on the spare wheel

Step-by-step instructions for taking off the wheel and

putting on the spare wheel.Change the wheel as described below after loosening the

wheel bolts and raising the vehicle with the jack*.

Taking off the wheel

–Using the hexagonal opening in the screwdriver handle

(provided in the vehicle's tool kit), unscrew the wheel bolt

nearest to the top and place the bolt on a clean surface

⇒fig. 233.

AD

Fig. 233 Changing a

wheel: Hexagonal

socket in screwdriver

handle to turn the

wheel bolts after they

have been loosenedFig. 234 Changing a

wheel: Mounting pin in

wheel bolt hole nearest

to the top

document_0900452a81793dcc.book Seite 253 Mittwoch, 21. März 2007 5:42 17

Page 268 of 294

Downloaded from www.Manualslib.com manuals search engine Fuses and bulbs 266•

Incorrect handling of the high-voltage element of xenon gas-

discharge bulbs* can have potentially fatal consequences.

•

When changing bulbs, please take care not to injure yourself on

sharp edges, in particular on the headlight housing.Caution

•

Always remove the ignition key before carrying out any work on

the electrical system - danger of short circuiting!

•

Switch off the lights or parking lights before you change a bulb.

•

Take good care to avoid damaging any components.

•

Removing the lights in particular can lead to the paintwork

becoming damaged. This is another reason why we recommend

having the bulbs changed by a qualified workshop.For the sake of the environment

Please ask your specialist retailer how to dispose of used bulbs in

the proper manner.

Note

Place the parts you have removed on a soft cloth so that they do not

become scratched.•

Please check at regular intervals that all lighting (especially the

exterior lighting) on your vehicle is functioning properly. This is not

only in the interest of your own safety, but also in that of all other

road users.

•

Before changing a bulb, make sure you have the correct new

bulb.

•

Do not touch the glass part of the bulb with your bare hands, use

a cloth or paper towel instead. Otherwise, the fingerprints left on

the glass will vaporise as a result of the heat generated by the bulb,

be deposited on the reflector and impair its surface.

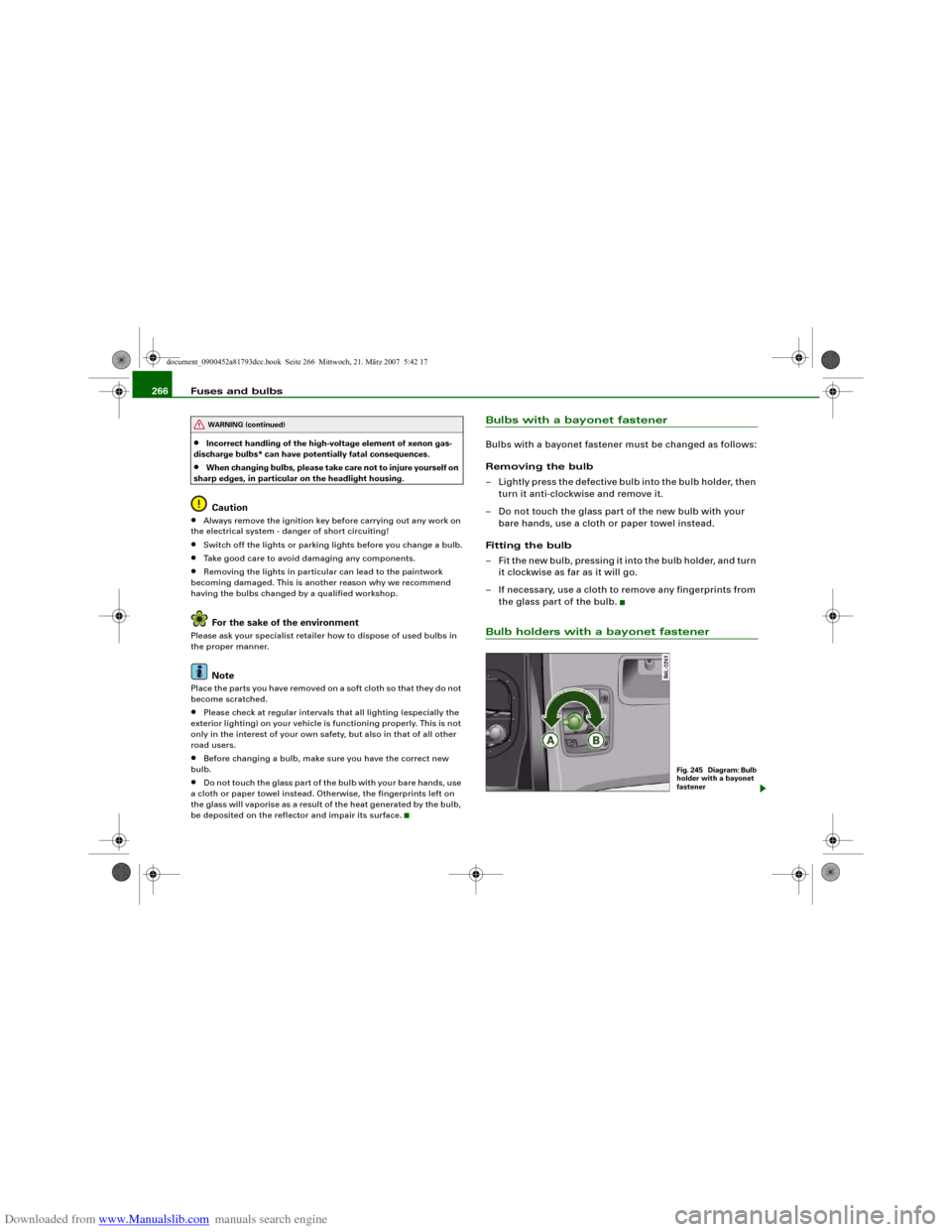

Bulbs with a bayonet fastenerBulbs with a bayonet fastener must be changed as follows:

Removing the bulb

– Lightly press the defective bulb into the bulb holder, then

turn it anti-clockwise and remove it.

– Do not touch the glass part of the new bulb with your

bare hands, use a cloth or paper towel instead.

Fitting the bulb

– Fit the new bulb, pressing it into the bulb holder, and turn

it clockwise as far as it will go.

– If necessary, use a cloth to remove any fingerprints from

the glass part of the bulb.Bulb holders with a bayonet fastener

WARNING (continued)

Fig. 245 Diagram: Bulb

holder with a bayonet

fastener

document_0900452a81793dcc.book Seite 266 Mittwoch, 21. März 2007 5:42 17

Page 270 of 294

Downloaded from www.Manualslib.com manuals search engine Fuses and bulbs 268

Installing

– Perform all of the above steps in reverse sequence.The headlight must be inserted in two guides (on the underside of

the headlight). This is the only way to ensure that the headlight is

installed in the correct position. To determine whether the headlight

is correctly installed, check that it is aligned flush with adjacent

body parts (such as the wing panel).

Do not interchange the securing screws.

Caution

Please take particular care not to damage or scratch the adjacent

parts of the body when removing or installing the headlights.Applies to vehicles: with xenon headlight bulbsChanging bulb for turn signalsThe bulb is secured in the bulb carrier with a bayonet

fastener.

– Remove the headlight ⇒page 267.

– Take off the rubber cap (small cover) and remove the bulb

carrier.

– Lightly press the defective bulb into the bulb carrier, then

turn it anti-clockwise and remove it.

– Do not touch the glass part of the new bulb with your

bare hands, use a cloth or paper towel instead.

– Fit the new bulb, pressing it into the bulb carrier, and turn

it clockwise as far as it will go.

– If necessary, use a cloth to remove any fingerprints from

the glass part of the bulb.– Insert the bulb carrier into the headlight.

Note

Ensure that the rubber cap is seated correctly so that no water can

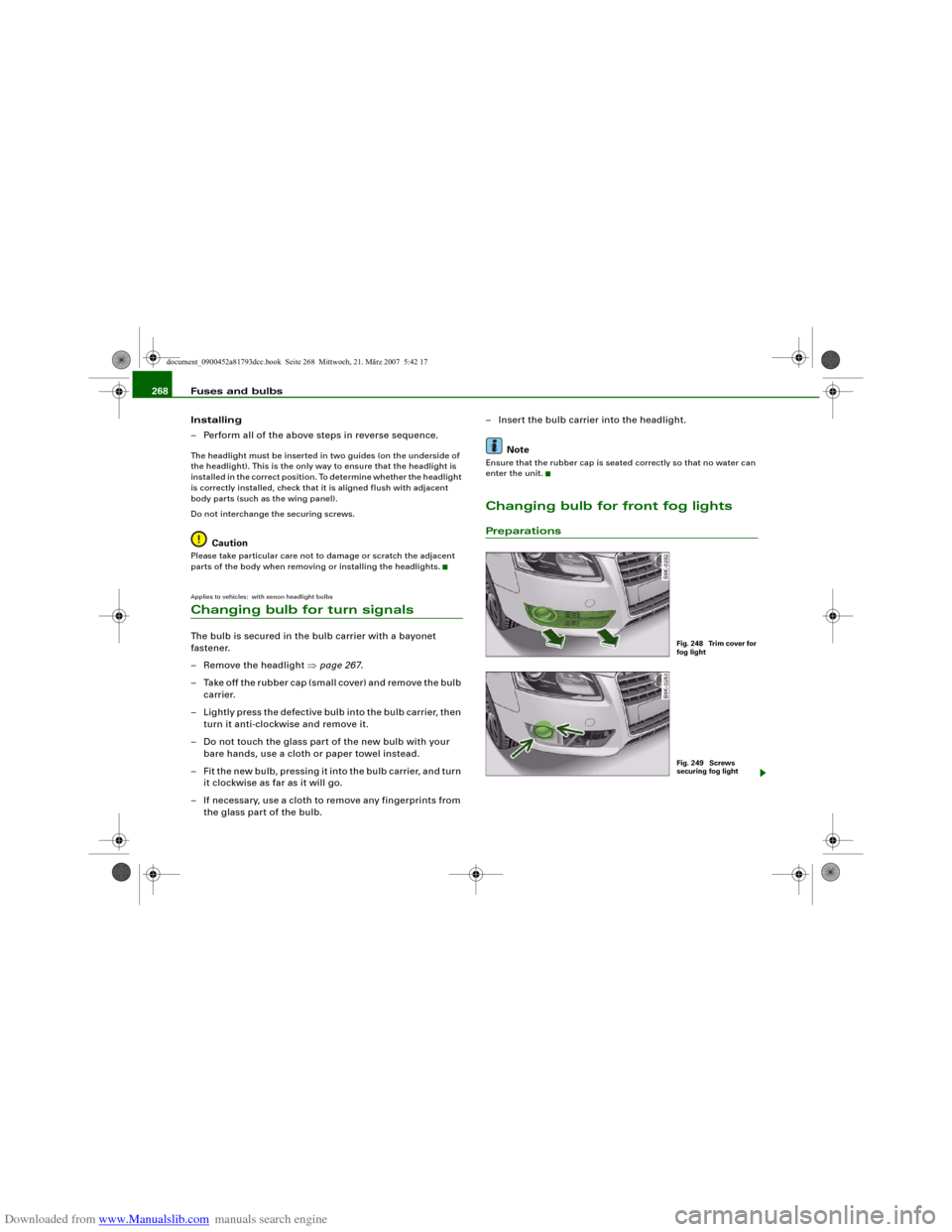

enter the unit.Changing bulb for front fog lightsPreparations

Fig. 248 Trim cover for

fog lightFig. 249 Screws

securing fog light

document_0900452a81793dcc.book Seite 268 Mittwoch, 21. März 2007 5:42 17

Page 271 of 294

Downloaded from www.Manualslib.com manuals search engine Fuses and bulbs269

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

The description for changing the bulb refers to the left fog

light; in principle the same procedure applies to the right

fog light.

– Switch off the ignition and the lights.

– Detach the trim cover ⇒page 268, fig. 248 (pull it care-

fully in the direction of the arrow).

– Remove the two securing screws ⇒page 268, fig. 249

and pull the fog light unit out of the bumper.

– Unplug the electrical connector.

CautionThe trim cover is secured to the bumper by several retaining hooks.

Do not use force when removing the trim cover to avoid damaging

it.Changing bulb– Turn the bulb holder anti-clockwise ⇒page 266 and take

it out of the fog light housing.– Insert the new bulb holder and turn it clockwise as far as

the stop ⇒page 266.

After changing the bulb re-install all parts in the reverse sequence

and check that the bulb is working.Changing bulbs for rear lights in side

panelOverview of rear lights•

Brake lights

•

Turn signals

The following instructions for changing the bulb refer to the left side

of the vehicle. Follow the same procedure for changing the bulb on

the other side of the vehicle.

Fig. 250 Front fog

light: Bulb holder is

highlighted

Fig. 251 Rear lights in

side panel

document_0900452a81793dcc.book Seite 269 Mittwoch, 21. März 2007 5:42 17