wheel bolts AUDI S6 2008 Owners Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2008, Model line: S6, Model: AUDI S6 2008Pages: 390, PDF Size: 88.42 MB

Page 329 of 390

________________________________________________ T_ i _r_e _s_ a_n_ d_ w_ h_ e_e _ l_s __ ,n

•

ture . For example, the numbers 2207 mean that the tire was

produced in the 22th week of 2007. The other numbers are

marketing codes that may or may not be used by the tire manufac

turer. This information is used to contact consumers if a tire defect

requires a recall.

Tire ply composition and materials used

The number of plies indicates the number of layers of rubber-coated

fabric in the tire. In general, the greater the number of plies, the

more weight a tire can support . Tire manufacturers also must indi

cate the materials in the tire, which include steel, nylon, polyester,

and others .

Maximum Load Rating

This number indicates the maximum load in kilograms and pounds

that can be carried by the tire.

Tire quality grading for treadwear, traction, and

temperature resistance

Tread wear, traction and temperature grades~ page 328.

Maximum Permissible Inflation Pressure

This number is the greatest amount of air pressure that should ever

be put in the tire under normal driving conditions.

Replacing tires or rims on vehicles equipped with tire

pressure monitoring system

The wheels on your vehicle are equipped with a sensor which

constantly monitors the air pressure inside the tire, and then trans

mits this information to the tire pressure monitoring system. If you

are going to replace the wheel rims on your vehicle, make sure the

new rims also have these sensors . The sensors must be compatible

with the tire pressure monitoring system on your vehicle.

If you install rims, which do not have the sensors, or have sensors

which are not compatible, then the tire pressure monitoring system

will not work properly. In this case, the tire pressure monitoring system would not be able to monitor the

tire pressure or warn you

if it is necessary.

• The battery inside of the tire pressure sensor has a limited

service life.

• Always drive with the valve stem caps securely mounted. We

recommend using factory installed valve stem caps. Ask your autho

rized Audi dealer to replace lost valve stem caps .

The installation of replacement tires with steel cord body plies in

the tire sidewall may cause malfunction of the tire pressure moni

toring system, and is not recommended (cord material information

in molded on the tire sidewall).

Always check your tire pressure monitoring system indicator after replacing one or more tires on your vehicle. If the tire pressure

monitoring system indicator flashes, or is on, your system is not

working properly. Your replacement tire might be incompatible with

your tire pressure monitoring system, or some component of the

tire pressure monitoring system may be damaged.

& WARNING

• Using incorrect or unmatched tires and/ or wheels or improper

tire and wheel combinations can lead to loss of control, collision

and serious personal injury.

• Always use tires, rims and wheel bolts that meet the specifica

tions of original factory-installed tires or other combinations that

have been specifically approved by the vehicle manufacturer.

• Tires age even if they are not being used and can fail suddenly,

especially at high speeds. Tires that are more than 6 years old can

only be used in an emergency and then with special care and at

lower speeds.

• Never mount used tires on your vehicle if you are not sure of

their "previous history." Old used tires may have been damaged

even though the damage cannot be seen that can lead to sudden

tire failure and loss of vehicle control.

~

Vehicle care I t •

Page 333 of 390

Tires and wheels -________________ w-.

•

Remove wheel center covers and trim discs before putting snow

chains on you r veh icle =>

(D. For sa fety reasons c ove r cap s m ust

then be fitted over the wheel bo lts . These are avai lable from autho

r ized Aud i deale rs.

& WARNING

Using the wrong snow chains for your vehicle or in stalling them

incorrectly can increase the risk of loss of control leading to

serious personal injury.

• Snow ch ains are available in different sizes . Always make sure

to follow the instructions provided by the snow chain manufac

turer .

• When driving with snow chains never drive faster than the

speed permitted for your specific snow chains .

• Always observe local regulations .

0 Note

• Remove sn ow chai ns b efore d rivin g on roads not cove red w ith

snow to avoid damaging tires and wearing the snow chains down

u n n ecessa r i ly.

• Snow chains , which come into d irect contact with t he whee l rim,

ca n scratc h or da mage it. T herefore, ma ke sur e tha t th e snow chains

are suitably covered.

• I f the Adaptive Air Suspensio n* shou ld malfunction, do no t

mount or use snow chains because the vehicle will be extremely

l o w. I f yo u do drive w ith snow c hai ns o n w hi le t he ve hicle is a t thi s

level, the snow cha ins might severe ly damage the wheelhouse and

ot her parts o f the vehicle.

[ i ] Tips

W her e sn ow c hai ns are manda tory on certa in roa ds, t his no rm ally

a lso app lies to vehic les with Al l Wheel Drive. •

Wheel bolts

Wheel bo lts must alw ays be t ig hte ned to the correct

to rq ue .

The design of wheel bo lts is matched to the factory instal led rims. If

d iffere nt rim s are fitted, the corr ect w heel bo lts w it h t he rig ht le ngth

and correctly shaped bolt heads must be used. This ensures that

w he els are fitted securely and that the brake sys tem func tions

correctly.

I n certa in c ircums ta nces, you may not use wheel bo lts from

a

different vehicle -even if it is the same model=> page 368.

& WARNING

Improperly tightened or maintained wheel bolts can become loose

causing loss of control , a collision and serious personal injury .

• Always keep the wheel bolts and the threads in the wheel hubs

clean so the wheel bolts can turn easily and be properly tightened.

• Never grease or oil the wheel bolts and the threads in the wheel

hubs. They can become loose while driving if greased or oiled,

even if tightened to the specified torque .

• Only use wheel bolts that belong to the rim being installed .

• Never use different wheels bolts on your vehicle.

• Always maintain the correct tightening torque for the wheel

bolts to reduce the risk of a wheel loss.

If the tightening torque of

the wheel bolts is too low , they can loosen and come out when the

vehicle is moving . If the tightening torque is too high, the wheel

bolts and threads can be damaged and the wheel can become

loose .

0 Note

The specified torque for the wheel bolts is 9 0 ft lb (120 Nm) with a

to lera nce of± 7,4 ft lb(± 10 Nm). Torque whee l b o lt s d ia go nally.

Af ter changing a wheel, the torque must be checked as soon as .,_

Vehicle care I t •

Page 339 of 390

_____________________________________________ W_ h_ a_t _d_ o_l _ d_o _ n_o_ w_ ? _ __._

& WARNING !continued)

• Never start or run the engine while the vehicle is supported by

the jack.

• If you must work under the vehicle, always use safety stands

specifically designed for this purpose.

• Never use the hexagonal socket in the handle of the screw

driver to loosen or tighten the wheel bolts .

• Always make sure the spare tire and even a flat tire are secured

in place and not loose , otherwise they could fly forward , causing

personal injury to passengers in the vehicle in an accident or

sudden maneuver. •

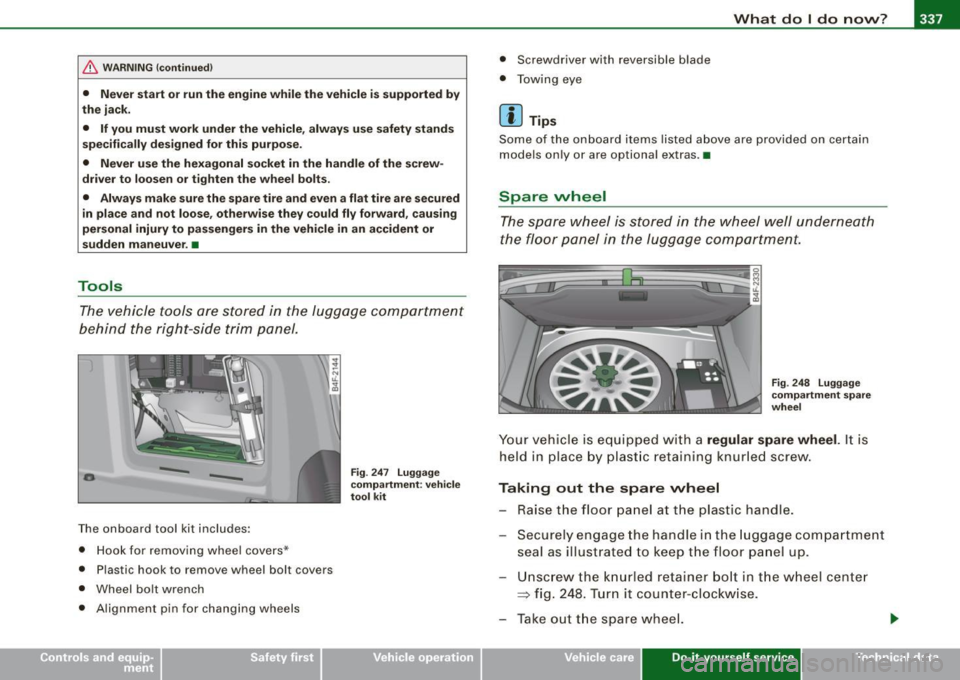

Tools

The vehicle tools are stored in the luggage compartment

behind the right-side trim panel.

-

T he onboard tool kit includes:

• Hook for removing wheel covers *

• Plastic hook to remove wheel bolt covers

• Wheel bolt wrench

• Alignment pin for changing wheels

Fig. 247 Luggage

compartment: vehicle

tool kit

• Screwdriver with reversible blade

• Towing eye

[ i ] Tips

Some of the on board items listed above are provided on certain

models only or are optional extras. •

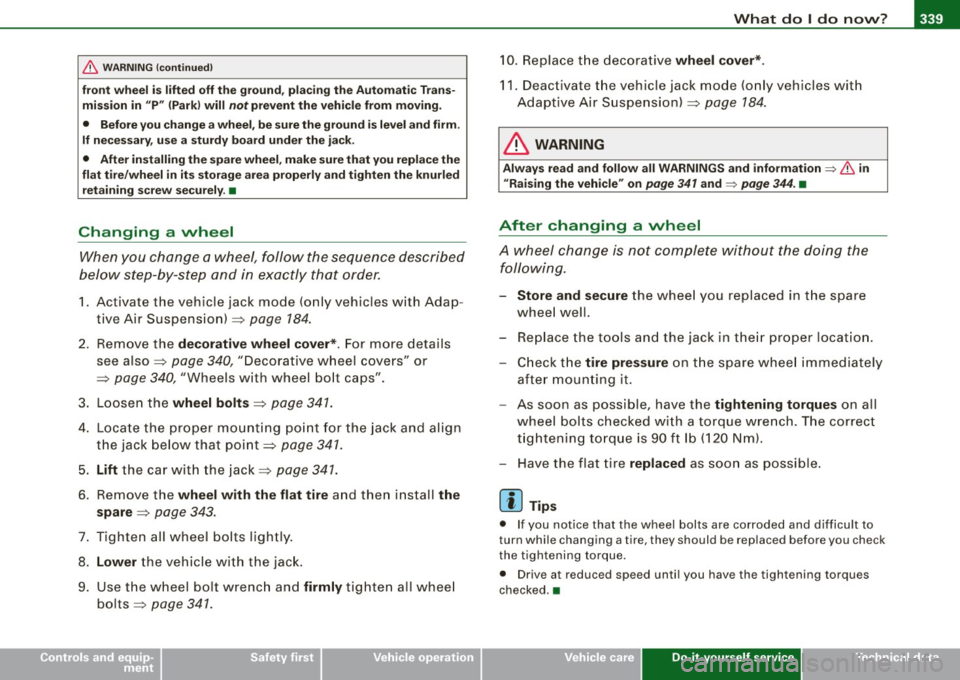

Spare wheel

The spare wheel is stored in the wheel well underneath

the floor panel in the luggage compartment.

Fig. 248 Luggage

compartment spare

wheel

Your vehicle is equipped with a regular spare wheel. It is

held in place by plastic retaining knurled screw.

Taking out the spare wheel

- Raise the floor panel at the plast ic handle.

- Securely engage the handle in the luggage compartment

seal as illustrated to keep the floor panel up.

- Unscrew the knurled retainer bolt in the wheel center

~ fig. 248. Turn it counter-clockwise.

- Take out the spare wheel.

Vehicle care Do-it-yourself service Technical data

Page 341 of 390

-------------------------------------------~W~h~a~t~d~o~l ~d~o~n~o~w~ ?::__fflll

•

& WARNING (continued)

front wheel is lifted off the ground, placing the Automatic Trans

mission in "P" {Park) will

not prevent the vehicle from moving.

• Before you change a wheel, be sure the ground is level and firm.

If necessary, use a sturdy board under the jack.

• After installing the spare wheel, make sure that you replace the

flat tire/wheel in its storage area properly and tighten the knurled

retaining screw securely. •

Changing a wheel

When you change a wheel, follow the sequence described

below step-by-step and in exactly that order.

1. Activate the vehicle jack mode (only vehicles with Adap

tive Air Suspension)~

page 184.

2. Remove the decorative wheel cover*. For more details

see also ~

page 340, "Decorative wheel covers" or

~ page 340, "Wheels with wheel bolt caps".

3. Loosen the

wheel bolts~ page 341.

4. Locate the proper mounting point for the jack and align

the jack below that point~

page 341.

5. Lift the car with the jack ~ page 341.

6. Remove the wheel with the flat tire and then install the

spare

~ page 343.

7. Tighten all wheel bolts lightly.

8.

Lower the vehicle with the jack.

9. Use the wheel bolt wrench and

firmly tighten all wheel

bolts~

page 341 .

10. Replace the decorative wheel cover*.

11. Deactivate the vehicle jack mode (only vehicles with

Adaptive Air Suspension)~

page 184.

& WARNING

Always read and follow all WARNINGS and information => & in

uRaising the vehicle" on

page 341 and=> page 344. •

After changing a wheel

A wheel change is not complete without the doing the

following.

- Store and secure the wheel you replaced in the spare

wheel well.

- Replace the tools and the jack in their proper location.

- Check the tire pressure on the spare wheel immediately

after mounting it.

- As soon as possible, have the

tightening torques on all

wheel bolts checked with a torque wrench. The correct

tightening torque is 90 ft lb (120 Nm).

- Have the flat tire

replaced as soon as possible.

[ i] Tips

• If you notice that the wheel bolts are corroded and difficult to

turn while changing a tire, they should be replaced before you check

the tightening torque.

• Drive at reduced speed until you have the tightening torques

checked .•

Do-it -yourself service

Page 342 of 390

11111...__W_ h_ a _ t_d_ o_ l _d _o_ n_ o_ vv_ ? ______________________________________________ _

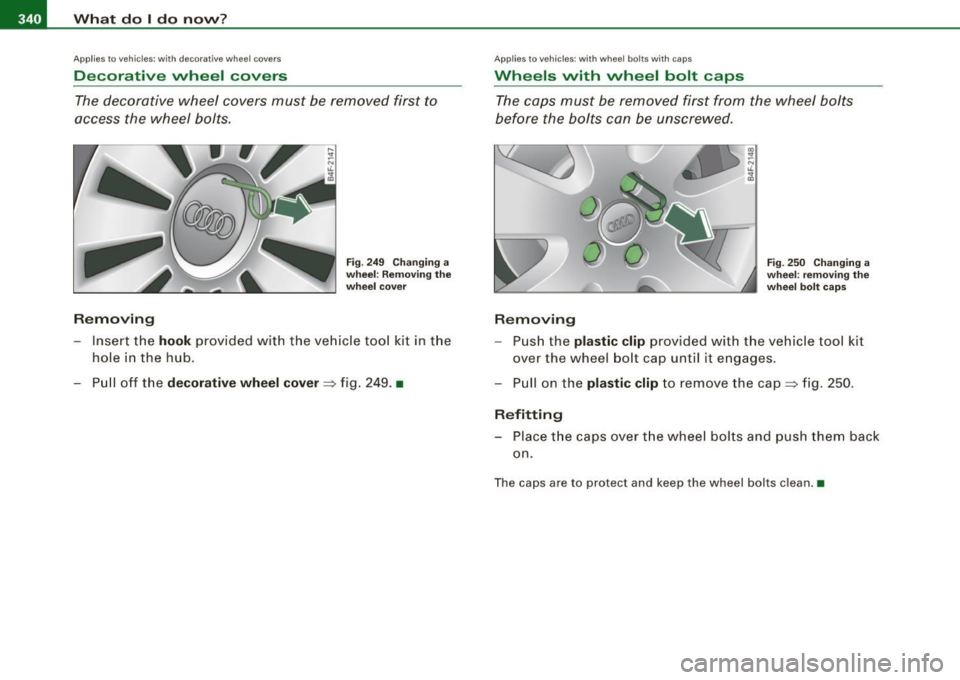

App lies to veh ic les : w ith deco rative whee l covers

Decorative wheel covers

The decorative wheel covers must be removed first to

access the wheel bolts.

Removing

Fig . 249 Changing a

wheel: Removing the

wheel cover

- Insert the hook provided with the vehicle tool kit in the

hole in t he hub.

- Pull off the

decorative wheel cover=> fig. 249. •

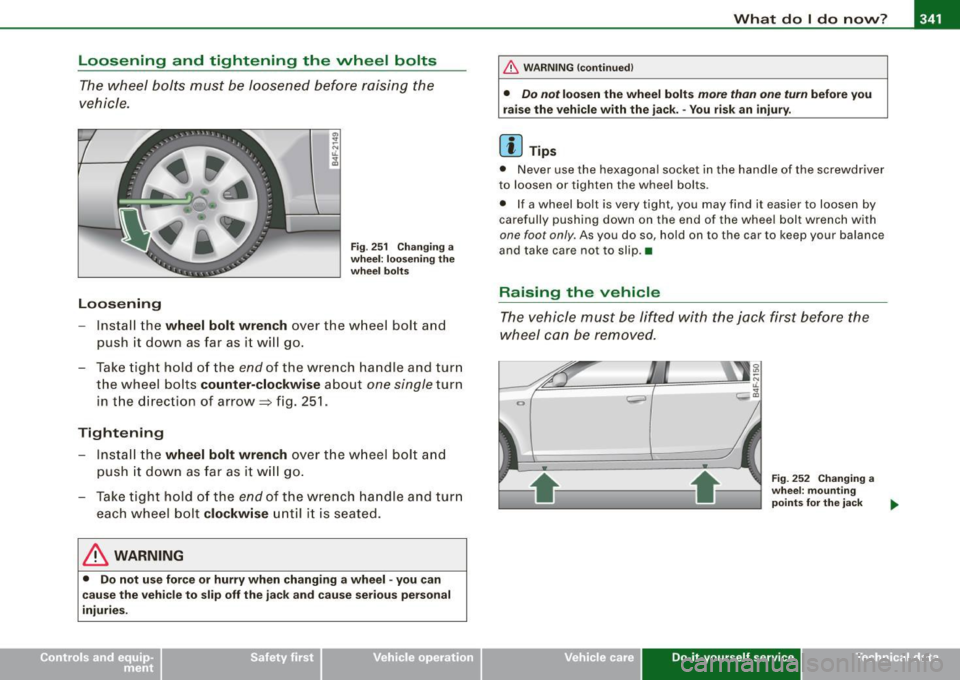

Applies to veh ic les: w ith whee l bolts w ith ca ps

Whee ls vvith wheel bolt caps

The caps must be removed first from the wheel bolts

before the bolts can be unscrewed .

Removing

Fig. 250 Changing a

wheel: removing the

wheel bolt caps

-Push the plastic clip prov ided w ith the vehicle tool kit

ov er the wheel bolt cap unt il it engages .

- Pull on t he

plastic clip to remove the cap=> fig. 250 .

Refitting

-Place the caps over the wheel bolts and push them back

on .

The caps are to pro tect and keep the wheel bolts clean. •

Page 343 of 390

_______________________________________________ W_ h_ a _ t_d_ o_ l _d _o_ n_ o_ w_ ? _ __._

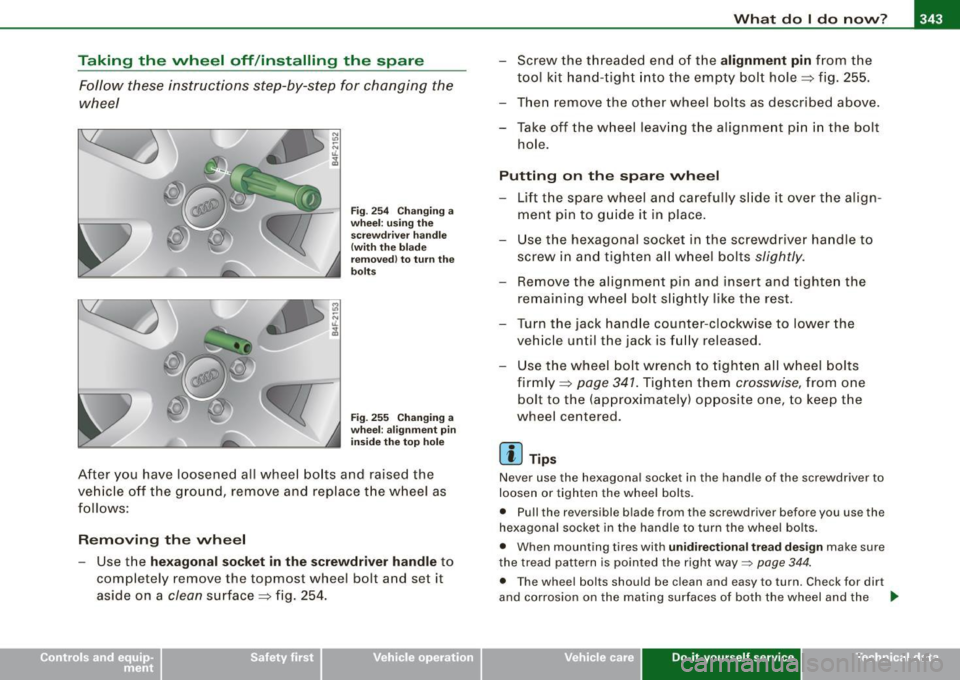

Loosening and tightening the wheel bolts

The wheel bolts must be loosened before raising the

vehicle .

Loosening

Fig . 25 1 Chan ging a

w he el: lo os en ing th e

whe el bolt s

- Install the wheel bolt wrench over the wheel bolt and

push it down as far as it will go.

- Take tight hold of the

end o f the wrench handle and turn

the wheel bolts counter-clockwise about

one single turn

in the direction of arrow =} fig. 251 .

Tightening

-Insta ll the wheel bolt wren ch ov er the w heel bolt a nd

push it down as far as it wi ll go.

- Take tight hold o f the

end of the wrench ha ndle and tur n

each wheel bolt clockwise until i t is sea ted.

& WARNING

• Do not u se for ce or hu rry w hen changing a wheel -you c an

ca use the vehi cle to slip off the j ack a nd cause se rio us perso nal

injurie s.

& W ARNING (continued )

• Do n ot loo sen the wh eel bolt s more than one turn before y ou

rais e the vehicle with the jack . - You ri sk an injur y.

[ i ] Tip s

• Never use the hexagona l socke t in the handle of the screwdriver

to loosen or tighten the wheel bolts .

• If a wheel bolt is

very tight, you may find it easier to loosen by

carefully pushing down on the end of the whee l bolt wrench with

one foot only . As you do so , hold on to the car to keep your balance

and take care not to slip .•

Raising the veh ic le

The vehicle must be lifted with the jack first before the

wheel can be removed .

Vehicle care

Fig. 252 Cha nging a

w he el: m oun ting

poi nts for the jack ..

Do-it-yourself service irechnical data

Page 345 of 390

_____________________________________________ W_ h_ a_t _d_ o_l _ d_o _ n_o_ w_ ?_--J IIIII

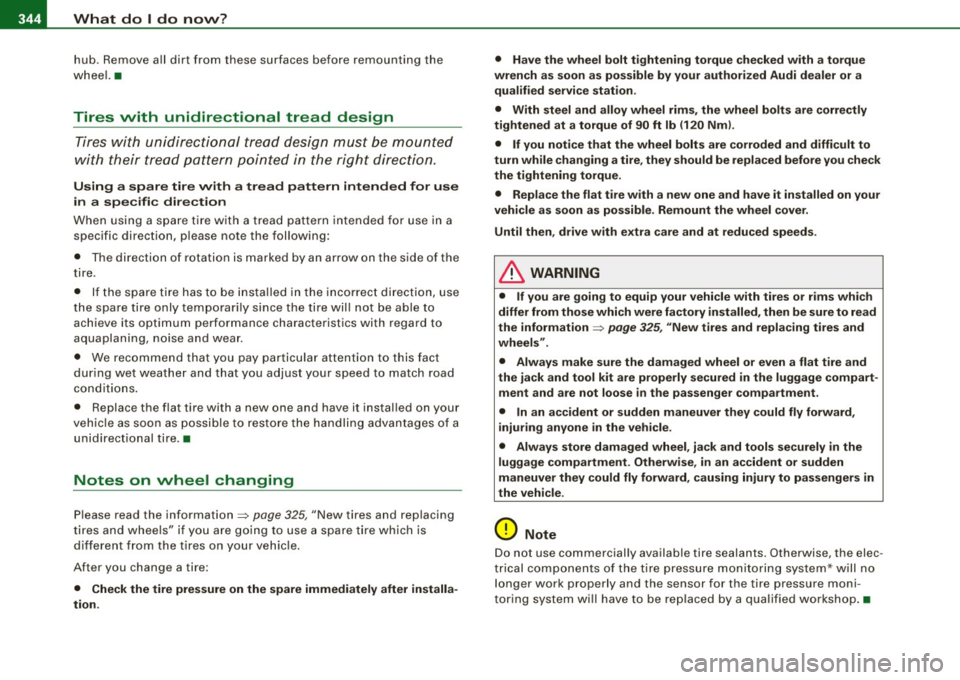

Taking the wheel off /installing the spare

Follow these instructions step-by-step for changing the

wheel

N

"' ;; u.

al

Fig . 254 Changing a

wheel: using the screwdriver handle

!with the blade

removed) to turn the

bolts

Fig . 255 Changing a

wheel: alignment pin

inside the top hole

After you have loosened all wheel bolts and raised the

vehicle off the ground, remove and replace the wheel as

follows:

Removing the wheel

- Use the hexagonal socket in the screwdriver handle to

completely remove the topmost wheel bolt and set it

aside on a clean surface => fig. 254. - Screw the threaded end of the

alignment pin from the

tool kit hand-tight into the empty bolt hole=> fig. 255.

- Then remove the other wheel bolts as described above.

- Take off the wheel leaving the alignment pin in the bolt

hole.

Putting on the spare wheel

- Lift the spare wheel and carefully slide it over the align

ment pin to guide it in place.

- Use the hexagonal socket in the screwdriver handle to

screw in and tighten all wheel bolts slightly.

- Remove the alignment pin and insert and tighten the

remaining wheel bolt slightly like the rest.

- Turn the jack handle counter-clockwise to lower the

vehicle until the jack is fully released .

- Use the wheel bolt wrench to tighten all wheel bolts

firmly => page 341. Tighten them crosswise, from one

bolt to the (approximately) opposite one, to keep the

wheel centered .

[ i] Tips

Never use the hexagonal socket in the handle of the screwdriver to

loosen or tighten the wheel bolts.

• Pull the reversible blade from the screwdriver before you use the

hexagonal socket in the handle to turn the wheel bolts.

• When mounting tires with

unidirectional tread design make sure

the tread pattern is pointed the right way~

page 344.

• The wheel bolts should be clean and easy to turn. Check for dirt

and corrosion on the mating surfaces of both the wheel and the ..

Vehicle care Do-it-yourself service irechnical data

Page 346 of 390

-L___:W:..:..:. h.:.: a::.. t:...:: d:.:o:::....:. l..: d::. O ::::....: n:..:.:: O:..:W :.:..:. ? ____________________________________________ _

hub. Remove all dirt from these surfaces before remounting the

wheel. •

Tires with unidirectional tread design

Tires with unidirectional tread design must be mounted

with their tread pattern pointed in the right direction.

Using a spare tire with a tread pattern intended for use

in a specific direction

When using a spare tire with a tread pattern intended for use in a

specific direction, please note the following:

• The direction of rotation is marked by an arrow on the side of the

tire .

• If the spare tire has to be installed in the incorrect direction, use

the spare tire only temporarily since the tire will not be able to

achieve its optimum performance characteristics with regard to

aquaplaning, noise and wear.

• We recommend that you pay particular attention to this fact

during wet weather and that you adjust your speed to match road

conditions.

• Replace the flat tire with a new one and have it installed on your

vehicle as soon as possible to restore the handling advantages of a

unidirectional tire. •

Notes on wheel changing

Please read the information~ page 325, "New tires and replacing

tires and wheels " if you are going to use a spare tire which is

different from the tires on your vehicle.

After you change a tire:

• Check the tire pressure on the spare immediately after installa

tion . •

Have the wheel bolt tightening torque checked with a torque

wrench as soon as possible by your authorized Audi dealer or a qualified service station .

• With steel and alloy wheel rims, the wheel bolts are correctly

tightened at a torque of 90 ft lb (120 Nml.

• If you notice that the wheel bolts are corroded and difficult to

turn while changing a tire, they should be replaced before you check

the tightening torque.

• Replace the flat tire with a new one and have it installed on your

vehicle as soon as possible. Remount the wheel cover.

Until then, drive with extra care and at reduced speeds .

& WARNING

• If you are going to equip your vehicle with tires or rims which

differ from those which were factory installed, then be sure to read

the information

~ page 325, "New tires and replacing tires and

wheels".

• Always make sure the damaged wheel or even a flat tire and

the jack and tool kit are properly secured in the luggage compart ment and are not loose in the passenger compartment.

• In an accident or sudden maneuver they could fly forward,

injuring anyone in the vehicle .

• Always store damaged wheel, jack and tools securely in the

luggage compartment . Otherwise, in an accident or sudden

maneuver they could fly forward, causing injury to passengers in

the vehicle .

0 Note

Do not use commercially available tire sealants. Otherwise, the elec

trical components of the tire pressure monitoring system* will no

longe r work properly and the sensor for the tire pressure moni

toring system will have to be replaced by a qualified workshop. •

Page 385 of 390

______________________________________________ A_ l_,_ p _h_ a_ b_e _t_i c_ a _ l _in _ d_e _ x __ lllll

T ank flap

Un locking the fuel fi ller flap by hand 295

Technical modifications .... .... ...... 368

Temperature Climate controls .. .... .... ... .... . 114

Setting for the driver's and front passen- ger's side .. ... ... ..... .... ... .. 114

Tether strap ... .... .... .. ... ........ 254

Securing the upper tether strap 255

The first 1,000 miles (1,500 km) and afterwards .... .. .. .. ... ...... .. 267

Tie-downs . ... .... .... .... ....... .. 201

Tilt sensors . .... .... ...... .... .... .. 62

Tips for the environment Saving fuel . ..... ... .... ... ..... . 102

Using the air conditioner only when necessary .. ..... ... .... ... .... . 119

tiptronic® .. ... ... .. .... .... ....... . 153

Automatic Shift Lock (ASU . ...... .. 155

Driving ............. ....... ..... 153

Dynamic shift program ............ 156

Fail-safe mode ... ... ... .. ...... .. 158

Kick-down ... .... .... .... ... .... . 156

Manual shift program ........ .... . 157

Se lector lever ... .... .... ... .... .. 154

Tire pressure ..... .. .... .... ....... . 319

Tire pressure monitoring system ... .... 43

Changing wheels .... .... ..... .... . 46

L earning process . .... .... ... .... .. 45

Loss of air pr essure ........ ... .. 20, 44

Mal functions ...... ...... .... ..... 46

Sensors . .......... .............. 327

Storing tire pressures .... .... .... .. 45

Controls and equip

ment Safety first

Tires and wheels ..

...... .... . .... 327 Towing

Valves ..... .. ...... ........ ..... 327 Front eyelet .. .. .. ... ... .. .... .... 354

Tire service life .... . .. .. ...... .... .. 323 Rear eyelet

... .... ... ... ..... ... . 355

Tires .... ..... .. ... ... .. .... .... ... 313 Tow truck procedures

..... ... .... . 354

Replacing .... .... .... ..... .. .... 327 Trailer towing .

.... .... ... .... ..... .. 272

Service life . .... . .. .. .... .... .... 323 Operating instructions .

...... ... .. 273

speed rating letter code .... ... .... 326 Technical r

equirem ents ... .... 272 , 273

Tire manufacturing date .... .... ... 326 Trailer towing tips .

... ... . .. .. .... 274

Tire specifications ... ..... ... ... .. 326 Transmission

Tread depth .... . .. .. ...... .. .... 323

tiptronic® ...... .... .. .. .... ..... 153

Uniform tire quality grading ... ..... 328

Transport Canada . .. ... .... .. ... ... . 365

Winter tires ... .... .... .... .... ... 329

Tread Wear Indicator (TWll ... .... .... . 323

Tires and vehicle load limits ... ...... . 321

Trip computer

Tires and wheels Fuel consumption ... .. .. . ... ...... 40

Checking tire pressure .......... .. 319

Mileage . ..... .... .... ...... .... .. 40

Cold tire inflation pressure .. .... ... 317

Single-trip memory .. .... . .... .. .. . 41

Dimensions ... ... ..... ... .... .... 325

Total-trip memory .... .... .... ... .. 41

Genera l notes ... ...... ..... .... .. 313

Trip odometer .. ... .. .... .... ... .. .. . 15

Glossary of tire and loading termino logy

What does it mean when dEF appears in

314 the trip odometer display? ......... 15

New tires and wheels .. .... .... ... 325

Trunk

Replacing .... .... .... ...... ... .. 325

See Rear lid ... .... .... ... .... .... . 58

Snow chains .. .... ... .... .... .... 330

Tire pressure monitoring system .. .. 327

Tires and vehicle load limits . .. . .... 321

Wheel bolts .. ....... ... .. ... ..... 331 Trunk escape handle

...... .. . .... ... . 336

Turn signals . .... .... .... ...... .... .. 74

Warning/indicator lights ...... .... .. 20

Winter tires .. ... ... .. ... .... .... . 329

Tires/Wheels

u

Low aspect ratio tires . ...... .. .... 332

Undercoating ...... .... ....... .. ... . 284

Tire pressure monitoring system .. 20 , 43

Unfastening safety be lts ...... .... .. . . 209

Tools ... .... .... ... ..... ... .... .... 337

Unidirectiona l tires ... .... ...... .... . 313

Torn or frayed safety be lts ... .. . ..... . 205

Uniform tire quality grading .. .... ... . 328

Touch-up pa int . .... ... .... .... ..... 282

Vehicle operation Vehicle care Do-it-yourself service Technical data

Page 386 of 390

___ A_l.:,. p _h_ a_ b_e _t _ic _ a_l _in _ d_e _x ____________________________________________ _

Unlocking

Power locking switch . . . . . . . . . . . . . . 56

Rear lid/trunk lid .. .... .... .... .... 58

Remote control key . . . . . . . . . . . . . . . . 54

Using the key .. .... ....... ........ 55

V

Valet key function

Activating and deactivating .. ..... .. 51

Vanity mirror ...... .. .......... ...... 76

Vehic le electrical system . . . . . . . . . . . . . . 19

Vehicle Identification Number (VIN) .... 360

Vehicle jack ...... .... .......... 336, 34 1

Vehic le literature ..................... 5

Vehicle-care products . . . . . . . . . . . . . . . 278

w

Warning lights . . . . . . . . . . . . . . . . . . . . . . 17

Warning/indicator lights ... .. .... .... . 13

Adaptive Air Suspension . ........ .. 21

Adaptive Cruise Control ... .... .... 143

Airbag system .................... 20

Anti -lock brake system (ABS) . . . . . . . . 22

Brake system . . . . . . . . . . . . . . . . . . . . . 23

Cruise control . . . . . . . . . . . . . . . . . . . . 22

Electromechanical parking brake .... 23

Electronic power control ........... 19

Electronic stabilization program (ESP) 19

Generator . . . . . . . . . . . . . . . . . . . . . . . . 19

H igh beam . . . . . . . . . . . . . . . . . . . . . . . 22 T

ire pressure monitoring system .. .. 20

Turn signals ... ...... ...... ....... 20

Warranty coverages ...... .... .... ... 365

Washer reservoir .. ..... .. ...... ..... 312

Washing .. ........ ........... .... .. 278

Automatic car wash .............. 279

by hand ........................ 279

General information .............. 278

with a power washer ... .... .... ... 280

Waxing ... ........ ... .... .... .... .. 281

Wear indicato r .... .... ... .... .... ... 323

Weatherstrips ..................... .

Weights ....... .. .... ...... ... .. .. . 283

361

What happens if you wear your safety belt too

loose? .. ... .. .... .... .... ...... 207

What happens to unbelted occupants? . 204

What impairs driving safety? ......... . 193

What should I do after changing a wheel?

320

What should I do after replacing wheels?

320

Wheel bolts Torqu e ...... ....... ..... ..... .. 331

Wheels . ......... ... ... .. .... ...... 313

Cas t alloy ... ... ... .... .... .... .. 283

Checking tire pressure ...... ...... 319

Cold tire inflation pressure ...... .. 317

General notes .. ... .... .... .... .. 313

Glossary of tire and loading terminology.

314

New tir es and wheels . .... ... .. ... 325

Tires and vehicle load limits .. ..... 321

Malfunction Indicator Lamp (MIU . ... 20

Safety belt ..... .. .... .... ...... ..

21 When must a safety belt be

replaced? .. 205 When

must the airbag system be inspected?

223

When should I adjust the tire pressures?

320

When should I check the tire pressures? 320

Where can I find the tire pressures for my

car? ... .. .... .... .... ... .... ... 319

Why safety belts? ...... ...... ... 202, 203

Windows Cleaning .... ...... .... ..... .. ... 282

Convenience close/open feature ... .. 65

Defogging .... ... .... .... .... ... 116

Defrosting . . . . . . . . . . . . . . . . . . . . . . 116

Rapid defrosting/defogging ........ 118

Windshield washer fluid Low level .......... .... ... .... .... 36

Windshield wipers Faulty ............ ... .... .... .... 38

Inte rmittent wiping ......... ....... 78

One -tap wiping .. ...... ...... .... . 78

Rain sensor . ...... .... ... .... .... 78

Service position . ...... .... ........ 80

Washer reservoir ....... ..... .... . 312

Winter operation Battery . . . . . . . . . . . . . . . . . . . . . . . . . 307

Coolant system ............... ... 303

Steering wheel heating ...... .... .. 115

Tir es ...... .... ....... .... ...... 264

Windows ...... .... .... ..... .. ... 282

Winter tires ... .... ....... .... .... .. 329

All -wheel drive ... .. .... .... .... .. 329