wheel alignment AUDI TT ROADSTER 2015 Owners Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2015, Model line: TT ROADSTER, Model: AUDI TT ROADSTER 2015Pages: 244, PDF Size: 60.74 MB

Page 192 of 244

190 Tires and wheels

Tire service life

The service life of tires depends on a lot of

different things including proper installation

and balancing, correct tire pressure and driv

ing style.

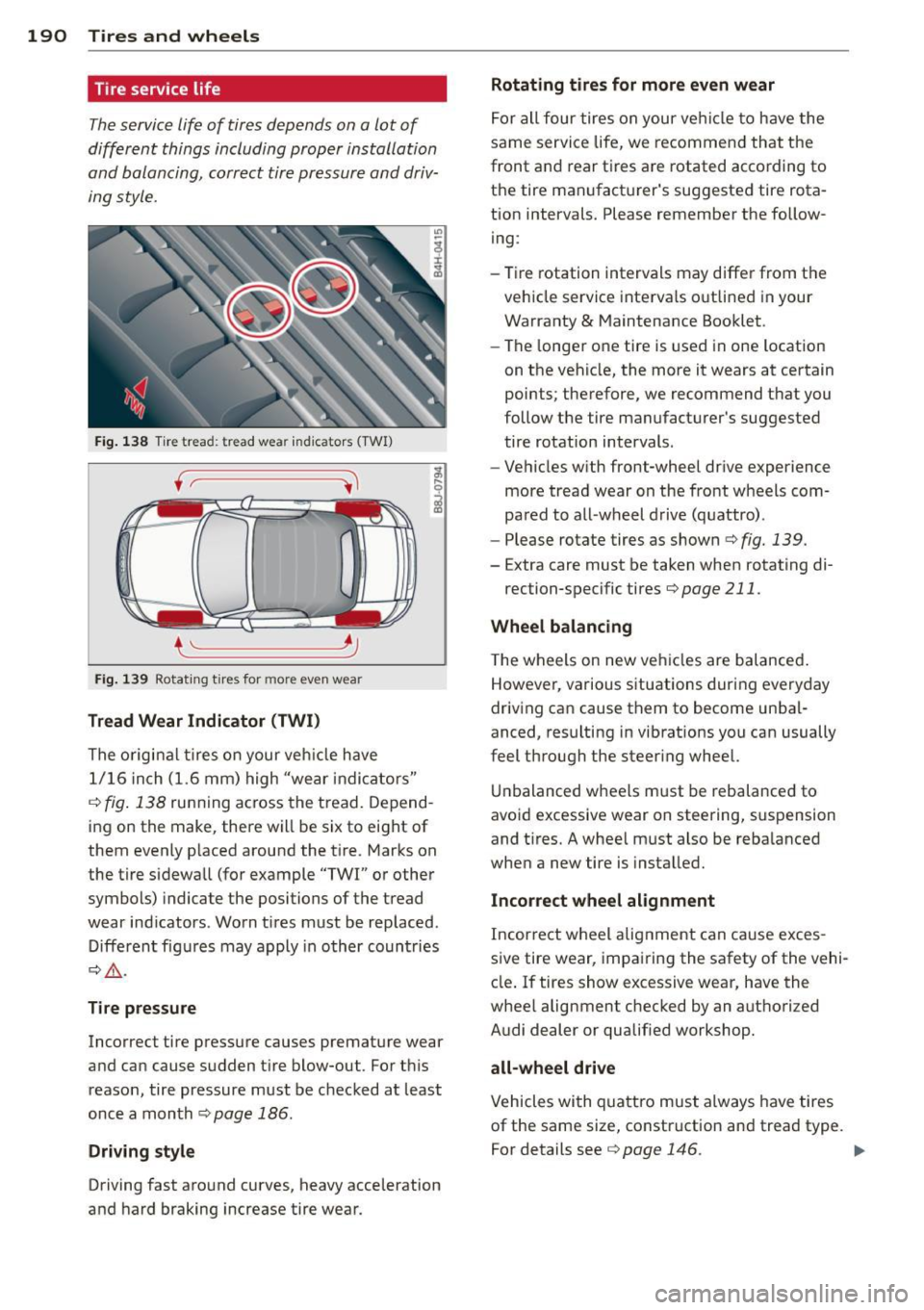

Fig. 138 Tire tread: tre ad wea r ind icators (TWI)

f ~----~

~ ..__ ____ __,

Fig. 139 Rotating t ires for more ev en wea r

Tread Wear Indicator (TWI)

The origina l tires on your veh icle have

1/16 inch (1.6 mm) high "wear indicators"

c::> fig . 138 running across the tread. Depend

i ng on the make, there will be six to eight of

them evenly placed around the tire. Marks on

the tire sidewa ll (for example "TWI" or other

symbols) indicate the positions of the tread

wear ind icators . Worn tires must be replaced .

Different figures may apply in other countries

c::> & .

Tire pressure

Incorrect tire pressure causes premature wear

and can cause sudden t ire blow-out. For th is

reason, tire pressure must be checked at least

once a month

c::> page 186.

Driving style

Driving fast around curves, heavy acceleration

and hard braking increase tire wear.

Rotating tires for more even wear

For all four tires on your vehicle to have the

same service life, we recommend that the

front and rear tires are rotated according to

the tire manufacturer's suggested tire rota

tion intervals. Please remember the follow

ing :

- Tire rotation intervals may differ from the

vehicle service interva ls outlined in your

Warranty

& Maintenance Booklet.

- The longer one tire is used in one location

on the vehicle, the more it wears at certain

points; therefore, we recommend that you

follow the tire manufacturer's suggested

tire rotation intervals .

- Vehicles with front-wheel drive experience

more tread wear on the front wheels com

pa red to all-wheel drive (quattro) .

- Please rotate tires as shown

c::> fig. 139.

-Extra care must be taken when rotating di-

rection-specific tires

c::> page 211 .

Wheel balancing

The wheels on new vehicles are balanced.

However, various situations during everyday

driving can cause them to become unbal

anced, re sulting in vibrat ions you can usually

feel through the steer ing wheel.

Unbalanced wheels must be rebalanced to

avoid excessive wear on steering, suspension

and tires. A wheel must also be rebalanced

when a new tire is installed.

Incorrect wheel alignment

Incorrect wheel alignment can cause exces

sive tire wear, impairing the safety of the veh i

cle. If tires show excessive wear, have the

whee l alignment checked by an authori zed

Audi dealer or qualified workshop.

all-wheel drive

Vehicles with quattro must always have tires

of the same size, construction and tread type .

For details see

c::> page 146 . ..,.

Page 206 of 244

204 What do I do now ?

What do I do now?

Trunk escape handle

In case of an emergency, the rear lid can be

opened from the inside using the trunk es

cape handle.

Fig. 1 46 Luggage compartment: Trunk escape handle

... To open the trunk lid pu ll the handle down

as indicated by the -arrow-~

fig. 146.

The trunk escape handle inside the storage

compartment is made of fluorescent materia l

to g low in the dark.

A WARNING

The trunk escape handle is to be used only

in an emergency.

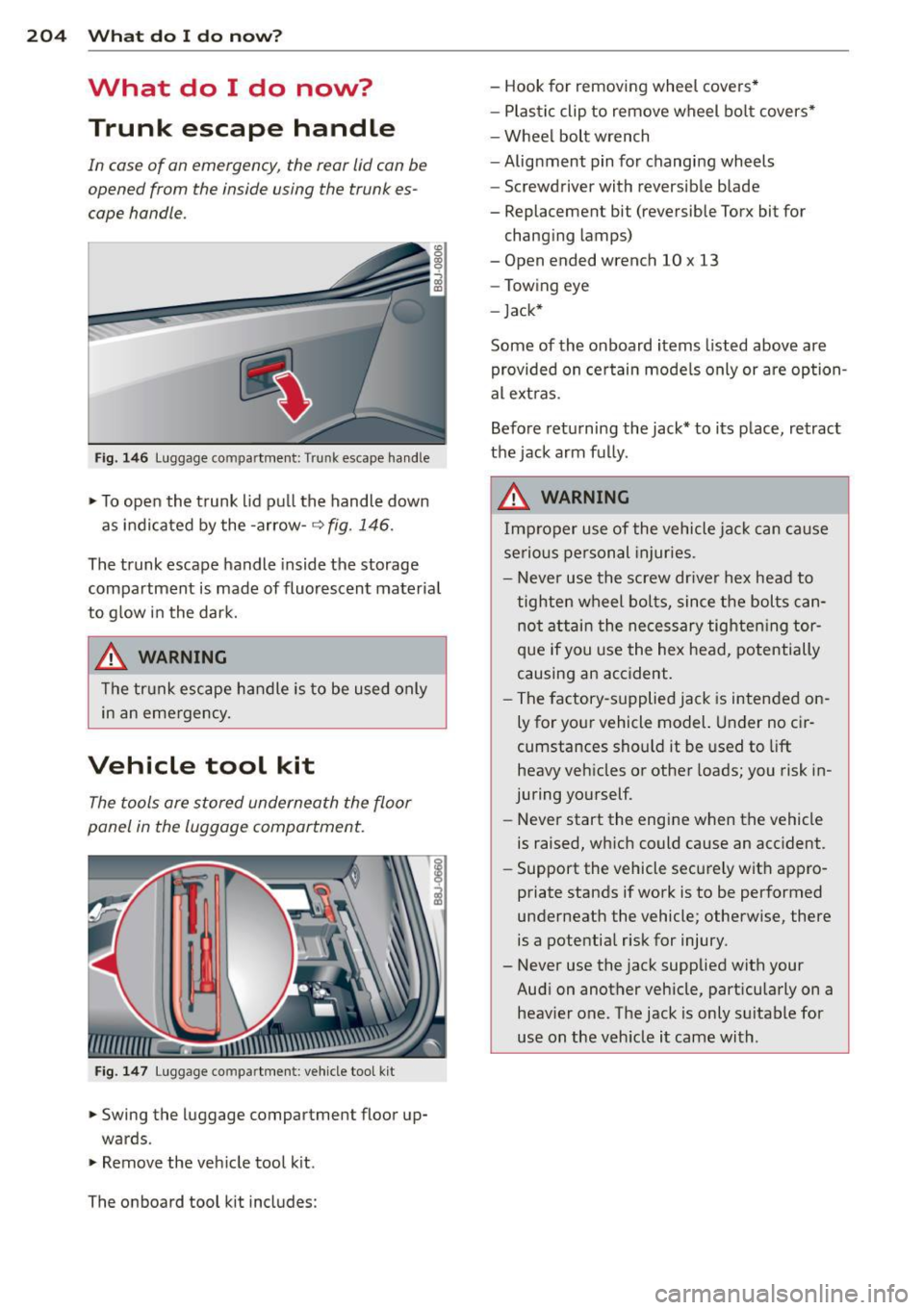

Vehicle tool kit

The tools are stored underneath the floor

panel in the luggage compartment.

Fig. 1 47 Luggage co mpa rtment : veh icle too l kit

... Swing the luggage compartment floor up

wards .

... Remove the veh icle tool k it.

The on board tool kit includes: -

Hook for removing wheel covers *

- Plastic clip to remove wheel bo lt covers•

- Wheel bolt wrench

-Alignment pin for changing wheels

- Screwdriver with reversible blade

- Replacement bit (reversible Torx bit for

chang ing lamps)

- Open ended wrench 10 x 13

- Towing eye

- Jack*

Some of the on board items listed above are

provided on certain mode ls only or are option

al ext ras.

Before returning the jack* to its place, retract

the jack arm fully .

A WARNING

Im proper use of the vehicle jac k can cause

serious personal injuries .

- Never use the screw driver hex head to tighten wheel bo lts, since the bolts can

not attain the ne cessary tighten ing tor

que if you use the hex head, potentially

causing an accident.

- The factory-supplied jack is intended on ly for your vehicle model. Under no cir

cumstances should it be used to lift

heavy vehicles or other loads; you risk in

juring yourself.

- Never start the engine when the vehicle

is raised, wh ich could cause an acc ident.

- Support the vehicle secure ly wit h appro

priate stands if work is to be performed

underneath the vehicle; otherwise, there

is a potential risk for injury.

- Never use the jack supplied with your

Audi on another vehicle, part icularly on a

heavier one. The jack is only su itable for

use on the veh icle it came with .

Page 212 of 244

210 What do I do now?

slip and cause an injury if it does not

have sufficient hold on the vehicle.

- A soft or unstable surface under the

jack may cause the vehicle to slip off

the jack. Always provide a firm base for

the jack on the ground . If necessary,

use a sturdy board under the jack.

- On hard, slippery surface (such as tiles)

use a rubber mat or similar to prevent

the jack from slipp ing .

- To help prevent injury to yourself and

your passengers:

- Do not raise the vehicle unti l yo u are

sure the jack is securely engaged.

- Passengers must not remain in the ve

hicle when it is jacked up.

- Make sure that passengers wait in a

safe p lace away from the vehicle and

well away from the roadway and traffic.

- Make sure jack position is correct, ad

just as necessa ry and then continue to

ra ise the jack .

(D Note

A floor jack or the pads on the hoist arms

must

not be posit ioned at the points

shown

-arrows- .

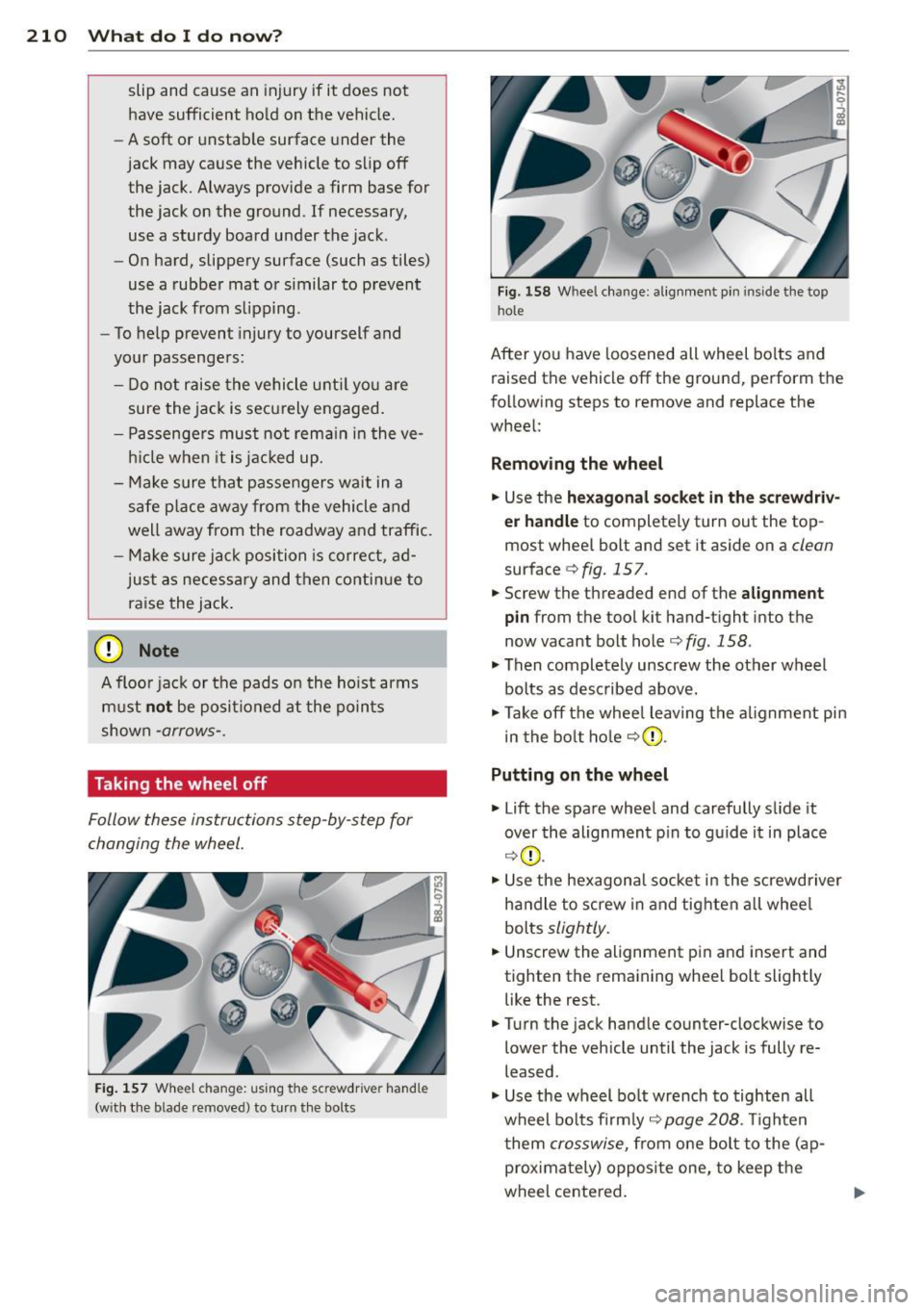

Taking the wheel off

Follow these instructions step-by-step for

changing the wheel.

Fig. 157 Wheel ch an ge: us ing the sc rewdrive r hand le

(w ith the b lade removed) to turn the bolts

Fig. 158 Whee l change : alignmen t pin inside the top

hol e

After you have loosened all wheel bolts and

raised the vehicle off the ground, perform the

following steps to remove and replace the

wheel:

Removing the wheel

.,. Use the hexagonal socket in the screwdriv

er handle

to completely turn out the top

most whee l bolt and set it aside on a

clean

surface c;, fig. 15 7.

.,. Screw the threaded end of the

alignment

pin from the tool kit hand-tight into the

now vacant bolt hole <=>

fig. 158 .

.,. Then completely unscrew the other wheel

bolts as described above.

.,. Take off the whee l leaving the alignment pin

in the bolt hole

c;,(D .

Putting on the wheel

.,. Lift the spare wheel and carefully s lide it

over the alignment p in to guide it in place

c;,(D .

.,. Use the hexagonal socket in the screwdriver

handle to screw in and tighten all whee l

bolts

slightly .

.,. Unscrew the alignment p in and insert and

tighten the remaining wheel bolt slightly like the rest .

.,. Turn the jack handle counter-clockwise to

lower the vehicle until the jack is fully re

leased .

.,. Use the wheel bo lt wrench to tighten all

wheel bolts firmly ,=:,

page 208 . Tighten

t hem

crosswise, from one bolt to the ( ap

proximately) opposite one, to keep the

wheel centered.