Fuel BMW 3 SERIES 1983 E30 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1983, Model line: 3 SERIES, Model: BMW 3 SERIES 1983 E30Pages: 228, PDF Size: 7.04 MB

Page 24 of 228

stripes moulded into them. Various systems

require hoses with different wall thicknesses,

collapse resistance and temperature

resistance. When fitting new hoses, be sure

the new ones are made of the same material.

5Often the only effective way to check a

hose is to remove it completely from the

vehicle. If more than one hose is removed, be

sure to label the hoses and fittings to ensure

correct refitting.

6When checking vacuum hoses, be sure to

include any plastic T-fittings in the check.

Inspect the connections for cracks which

could cause leakage.

7A small piece of vacuum hose can be used

as a stethoscope to detect vacuum leaks.

Hold one end of the hose to your ear and

probe around vacuum hoses and fittings,

listening for the “hissing” sound characteristic

of a vacuum leak.

Warning: When probing with the

vacuum hose stethoscope, be

careful not to touch moving

engine components such as the

drivebelt, cooling fan, etc.

Fuel hoses

Warning: There are certain

precautions which must be taken

when servicing or inspecting fuel

system components. Work in a

well-ventilated area, and do not allow open

flames (cigarettes, appliance pilot lights,

etc.) or bare light bulbs near the work

area. Mop up any spills immediately, and

do not store fuel-soaked rags where they

could ignite. If you spill any fuel on your

skin, rinse it off immediately with soap and

water. When you perform any kind of work

on the fuel system, wear safety glasses,

and have a fire extinguisher on hand.

8The fuel hoses are usually under pressure,

so if any fuel hoses are to be disconnected,

be prepared to catch spilled fuel.

Warning: On vehicles equipped

with fuel injection, you must

depressurise the fuel system

before servicing the fuel hoses.

Refer to Chapter 4 for details.9Check all rubber fuel hoses for deterioration

and chafing. Check especially for cracks in

areas where the hose bends, and just before

connectors, such as where a hose attaches to

the fuel pump or fuel filter, for example.

10Only high-quality fuel hose should be

used. Never, under any circumstances, use

unreinforced vacuum hose, clear plastic

tubing or water hose for fuel hoses.

11Band-type clamps are commonly used on

fuel hoses. These clamps often lose their

tension over a period of time, and can be

“sprung” during removal. Renew all band-type

clamps with screw clamps whenever a hose is

renewed.

Metal lines

12Sections of metal line are often used

between the fuel pump and fuel injection

system. Check carefully to make sure the line

isn’t bent, crimped or cracked.

13If a section of metal line must be renewed,

use seamless steel tubing only, since copper

and aluminium tubing do not have the

strength necessary to withstand the vibration

caused by the engine.

14Check the metal brake lines where they

enter the master cylinder and brake

proportioning or ABS unit (if used) for cracks

in the lines and loose fittings. Any sign of

brake fluid leakage calls for an immediate

thorough inspection of the braking system.

Power steering hoses

15Check the power steering hoses for leaks,

loose connections and worn clamps. Tighten

loose connections. Worn clamps or leaky

hoses should be renewed.

11 Drivebelt check, adjustment

and renewal

1

Check

1The drivebelts, sometimes called V-belts or

simply “fan” belts, are located at the front of

the engine, and play an important role in the

overall operation of the vehicle and itscomponents. Due to their function and

material make-up, the belts are prone to

failure after a period of time, and should be

inspected and adjusted periodically to prevent

major engine damage.

2The number of belts used on a particular

vehicle depends on the accessories fitted.

Drivebelts are used to turn the alternator,

power steering pump, water pump, and air

conditioning compressor. Depending on the

pulley arrangement, a single belt may be used

to drive more than one of these components.

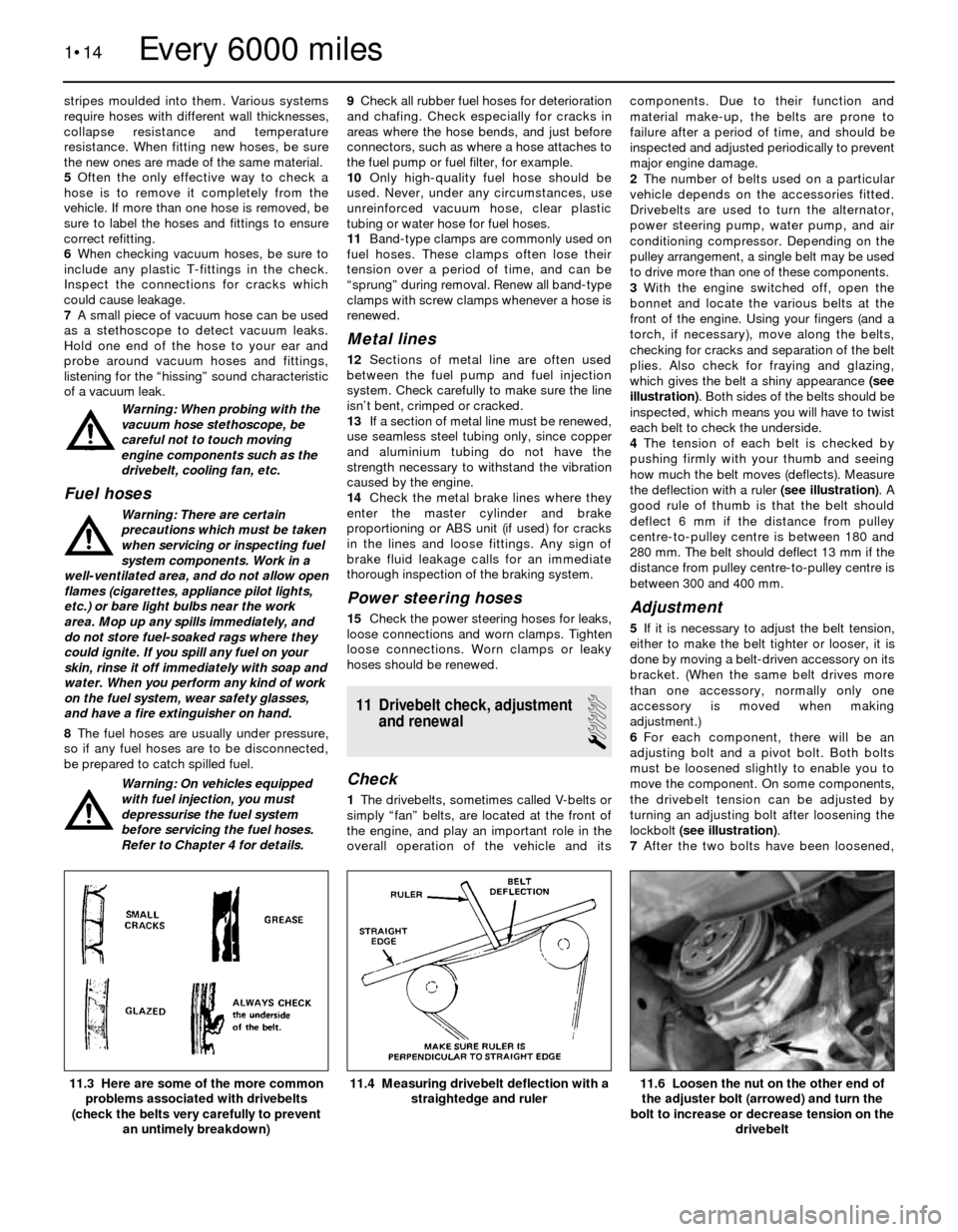

3With the engine switched off, open the

bonnet and locate the various belts at the

front of the engine. Using your fingers (and a

torch, if necessary), move along the belts,

checking for cracks and separation of the belt

plies. Also check for fraying and glazing,

which gives the belt a shiny appearance (see

illustration). Both sides of the belts should be

inspected, which means you will have to twist

each belt to check the underside.

4The tension of each belt is checked by

pushing firmly with your thumb and seeing

how much the belt moves (deflects). Measure

the deflection with a ruler (see illustration). A

good rule of thumb is that the belt should

deflect 6 mm if the distance from pulley

centre-to-pulley centre is between 180 and

280 mm. The belt should deflect 13 mm if the

distance from pulley centre-to-pulley centre is

between 300 and 400 mm.

Adjustment

5If it is necessary to adjust the belt tension,

either to make the belt tighter or looser, it is

done by moving a belt-driven accessory on its

bracket. (When the same belt drives more

than one accessory, normally only one

accessory is moved when making

adjustment.)

6For each component, there will be an

adjusting bolt and a pivot bolt. Both bolts

must be loosened slightly to enable you to

move the component. On some components,

the drivebelt tension can be adjusted by

turning an adjusting bolt after loosening the

lockbolt (see illustration).

7After the two bolts have been loosened,

1•14

11.6 Loosen the nut on the other end of

the adjuster bolt (arrowed) and turn the

bolt to increase or decrease tension on the

drivebelt11.4 Measuring drivebelt deflection with a

straightedge and ruler11.3 Here are some of the more common

problems associated with drivebelts

(check the belts very carefully to prevent

an untimely breakdown)

Every 6000 miles

Page 30 of 228

drag when the feeler gauge is moved back

and forth.

6If the gap is too large or too small, loosen

the locknut, insert a hook made from large-

diameter metal wire, and rotate the eccentric

to obtain the correct gap (see illustration).

7Once the gap has been set, hold the

eccentric in position with the hook, and

retighten the locknut securely. Recheck the

clearance - sometimes it’ll change slightly

when the locknut is tightened. If so, re-adjust

until it’s correct.

8On the M10 engine, the valves are adjusted

in the firing order, which is 1-3-4-2. After

adjusting No 1 cylinder valves, rotate the

crankshaft half a turn (180º), then check and

adjust the valves on No 3 cylinder. Repeat the

procedure on the remaining cylinders.

9On M20 and M30 engines, the valves are

adjusted following the firing order, which is

1-5-3-6-2-4. After adjusting No 1 cylinder

valves, rotate the crankshaft a third of a turn

(120º), then check and adjust the valves on No

5 cylinder. Repeat the procedure for the

remaining cylinders.

10Refit the valve cover (use a new gasket)

and tighten the mounting nuts evenly and

securely.

11Start the engine and check for oil leakage

between the valve cover and the cylinder

head.19 Throttle linkage -

check and lubrication

1

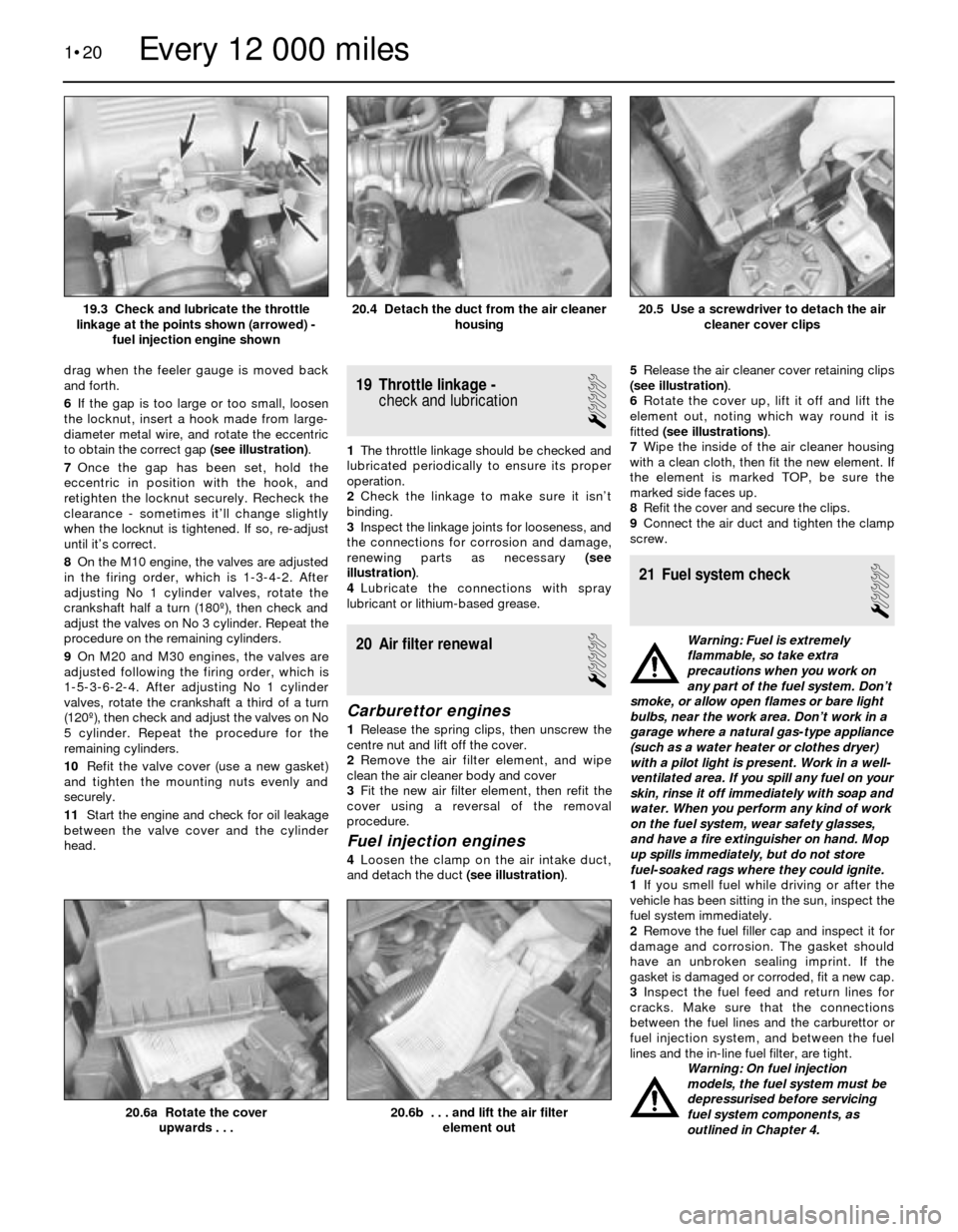

1The throttle linkage should be checked and

lubricated periodically to ensure its proper

operation.

2Check the linkage to make sure it isn’t

binding.

3Inspect the linkage joints for looseness, and

the connections for corrosion and damage,

renewing parts as necessary (see

illustration).

4Lubricate the connections with spray

lubricant or lithium-based grease.

20 Air filter renewal

1

Carburettor engines

1Release the spring clips, then unscrew the

centre nut and lift off the cover.

2Remove the air filter element, and wipe

clean the air cleaner body and cover

3Fit the new air filter element, then refit the

cover using a reversal of the removal

procedure.

Fuel injection engines

4Loosen the clamp on the air intake duct,

and detach the duct (see illustration).5Release the air cleaner cover retaining clips

(see illustration).

6Rotate the cover up, lift it off and lift the

element out, noting which way round it is

fitted (see illustrations).

7Wipe the inside of the air cleaner housing

with a clean cloth, then fit the new element. If

the element is marked TOP, be sure the

marked side faces up.

8Refit the cover and secure the clips.

9Connect the air duct and tighten the clamp

screw.

21 Fuel system check

1

Warning: Fuel is extremely

flammable, so take extra

precautions when you work on

any part of the fuel system. Don’t

smoke, or allow open flames or bare light

bulbs, near the work area. Don’t work in a

garage where a natural gas-type appliance

(such as a water heater or clothes dryer)

with a pilot light is present. Work in a well-

ventilated area. If you spill any fuel on your

skin, rinse it off immediately with soap and

water. When you perform any kind of work

on the fuel system, wear safety glasses,

and have a fire extinguisher on hand. Mop

up spills immediately, but do not store

fuel-soaked rags where they could ignite.

1If you smell fuel while driving or after the

vehicle has been sitting in the sun, inspect the

fuel system immediately.

2Remove the fuel filler cap and inspect it for

damage and corrosion. The gasket should

have an unbroken sealing imprint. If the

gasket is damaged or corroded, fit a new cap.

3Inspect the fuel feed and return lines for

cracks. Make sure that the connections

between the fuel lines and the carburettor or

fuel injection system, and between the fuel

lines and the in-line fuel filter, are tight.

Warning: On fuel injection

models, the fuel system must be

depressurised before servicing

fuel system components, as

outlined in Chapter 4.

1•20

20.6b . . . and lift the air filter

element out20.6a Rotate the cover

upwards . . .

20.5 Use a screwdriver to detach the air

cleaner cover clips20.4 Detach the duct from the air cleaner

housing19.3 Check and lubricate the throttle

linkage at the points shown (arrowed) -

fuel injection engine shown

Every 12 000 miles

Page 31 of 228

4Since some components of the fuel system

- the fuel tank and some of the fuel feed and

return lines, for example - are underneath the

vehicle, they can be inspected more easily

with the vehicle raised on a hoist. If that’s not

possible, raise the vehicle and support it on

axle stands or ramps.

5With the vehicle raised and safely

supported, inspect the fuel tank and filler neck

for punctures, cracks or other damage. The

connection between the filler neck and the

tank is particularly critical. Sometimes a

rubber filler neck will leak because of loose

clamps or deteriorated rubber. Inspect all fuel

tank mounting brackets and straps, to be sure

the tank is securely attached to the vehicle.

Warning: Do not, under any

circumstances, try to repair a fuel

tank (except rubber

components). A welding torch or

any naked flame can easily cause fuel

vapours inside the tank to explode.

6Carefully check all flexible hoses and metal

lines leading away from the fuel tank. Check

for loose connections, deteriorated hoses,

crimped lines, and other damage. Repair or

renew damaged sections as necessary (see

Chapter 4).

22 Cooling system check

1

1Many major engine failures can be

attributed to cooling system problems. If the

vehicle has automatic transmission, the

engine cooling system also plays an importantrole in prolonging transmission life, because it

cools the transmission fluid.

2The engine should be cold for the cooling

system check, so perform the following

procedure before the vehicle is driven for the

day, or after it has been switched off for at

leastthree hours.

3Remove the radiator cap, doing so slowly

and taking adequate precautions against

scalding if the engine is at all warm. Clean the

cap thoroughly, inside and out, with clean

water. Also clean the filler neck on the

radiator. The presence of rust or corrosion in

the filler neck means the coolant should be

changed (see Section 29). The coolant inside

the radiator should be relatively clean and

clear. If it’s rust-coloured, drain the system

and refill with new coolant.

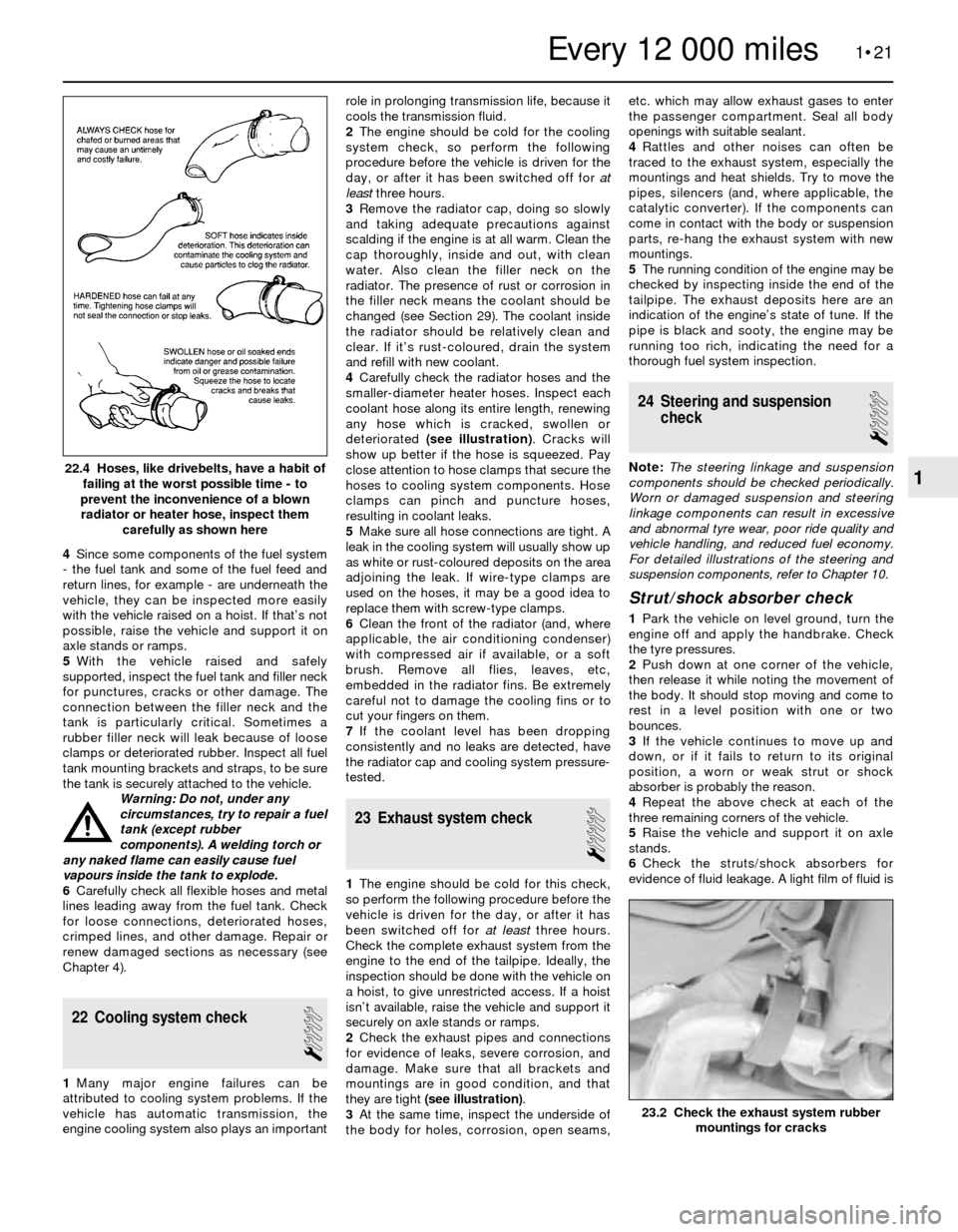

4Carefully check the radiator hoses and the

smaller-diameter heater hoses. Inspect each

coolant hose along its entire length, renewing

any hose which is cracked, swollen or

deteriorated (see illustration). Cracks will

show up better if the hose is squeezed. Pay

close attention to hose clamps that secure the

hoses to cooling system components. Hose

clamps can pinch and puncture hoses,

resulting in coolant leaks.

5Make sure all hose connections are tight. A

leak in the cooling system will usually show up

as white or rust-coloured deposits on the area

adjoining the leak. If wire-type clamps are

used on the hoses, it may be a good idea to

replace them with screw-type clamps.

6Clean the front of the radiator (and, where

applicable, the air conditioning condenser)

with compressed air if available, or a soft

brush. Remove all flies, leaves, etc,

embedded in the radiator fins. Be extremely

careful not to damage the cooling fins or to

cut your fingers on them.

7If the coolant level has been dropping

consistently and no leaks are detected, have

the radiator cap and cooling system pressure-

tested.

23 Exhaust system check

1

1The engine should be cold for this check,

so perform the following procedure before the

vehicle is driven for the day, or after it has

been switched off for at leastthree hours.

Check the complete exhaust system from the

engine to the end of the tailpipe. Ideally, the

inspection should be done with the vehicle on

a hoist, to give unrestricted access. If a hoist

isn’t available, raise the vehicle and support it

securely on axle stands or ramps.

2Check the exhaust pipes and connections

for evidence of leaks, severe corrosion, and

damage. Make sure that all brackets and

mountings are in good condition, and that

they are tight (see illustration).

3At the same time, inspect the underside of

the body for holes, corrosion, open seams,etc. which may allow exhaust gases to enter

the passenger compartment. Seal all body

openings with suitable sealant.

4Rattles and other noises can often be

traced to the exhaust system, especially the

mountings and heat shields. Try to move the

pipes, silencers (and, where applicable, the

catalytic converter). If the components can

come in contact with the body or suspension

parts, re-hang the exhaust system with new

mountings.

5The running condition of the engine may be

checked by inspecting inside the end of the

tailpipe. The exhaust deposits here are an

indication of the engine’s state of tune. If the

pipe is black and sooty, the engine may be

running too rich, indicating the need for a

thorough fuel system inspection.

24 Steering and suspension

check

1

Note: The steering linkage and suspension

components should be checked periodically.

Worn or damaged suspension and steering

linkage components can result in excessive

and abnormal tyre wear, poor ride quality and

vehicle handling, and reduced fuel economy.

For detailed illustrations of the steering and

suspension components, refer to Chapter 10.

Strut/shock absorber check

1Park the vehicle on level ground, turn the

engine off and apply the handbrake. Check

the tyre pressures.

2Push down at one corner of the vehicle,

then release it while noting the movement of

the body. It should stop moving and come to

rest in a level position with one or two

bounces.

3If the vehicle continues to move up and

down, or if it fails to return to its original

position, a worn or weak strut or shock

absorber is probably the reason.

4Repeat the above check at each of the

three remaining corners of the vehicle.

5Raise the vehicle and support it on axle

stands.

6Check the struts/shock absorbers for

evidence of fluid leakage. A light film of fluid is

1•21

22.4 Hoses, like drivebelts, have a habit of

failing at the worst possible time - to

prevent the inconvenience of a blown

radiator or heater hose, inspect them

carefully as shown here

23.2 Check the exhaust system rubber

mountings for cracks

1

Every 12 000 miles

Page 35 of 228

Flushing

7Once the system is completely drained,

flush the radiator with fresh water from a

garden hose until the water runs clear at the

drain or bottom hose. If the radiator is

severely corroded, damaged or leaking, it

should be removed (see Chapter 3) and taken

to a radiator repair specialist.

8Flushing in this way will remove sediments

from the radiator, but will not remove rust and

scale from the engine and cooling tube

surfaces. These deposits can be removed by

using a chemical cleaner. Follow the

procedure outlined in the cleaner

manufacturer’s instructions. Remove the

cylinder block drain plug before flushing the

engine.

9On models so equipped, remove the

overflow hose from the coolant recovery

reservoir. Drain the reservoir and flush it with

clean water, then reconnect the hose.

Refilling

10Tighten the radiator drain plug, or

reconnect the radiator bottom hose. Refit and

tighten the cylinder block drain plug.

Four-cylinder engines

11Slowly add new coolant (a 40%/60%

mixture of antifreeze to water) to the radiator

until it is full. Add coolant to the reservoir up

to the lower mark.

12Leave the radiator cap off, and run the

engine in a well-ventilated area until the

thermostat opens (coolant will begin flowing

through the radiator, and the upper radiator

hose will become hot).

13Turn the engine off, and let it cool. Add

more coolant mixture to bring the coolant

level back up to the lip on the radiator filler

neck. On the M40 engine, unscrew the bleed

screw from the top of the radiator, and add

coolant until it comes out of the bleed screw

hole. Refit and tighten the bleed screw.

14Squeeze the upper radiator hose to expel

air, then add more coolant mixture if

necessary. Refit the radiator cap.

15Start the engine, allow it to reach normal

operating temperature, and check for leaks.

Six-cylinder engines

16Loosen the bleed screw in the thermostat

housing (see illustration)

17Fill the radiator with a 40%/60% solution

of antifreeze and water until it comes out of

the bleed screw opening. Tighten the bleed

screw.

18Refit the radiator cap, and run the engine

until the thermostat opens (the upper radiator

hose will become hot). Slowly loosen the

bleed screw until no bubbles emerge, then

tighten the screw.

19Repeat the procedure until the air is bled

from the system.

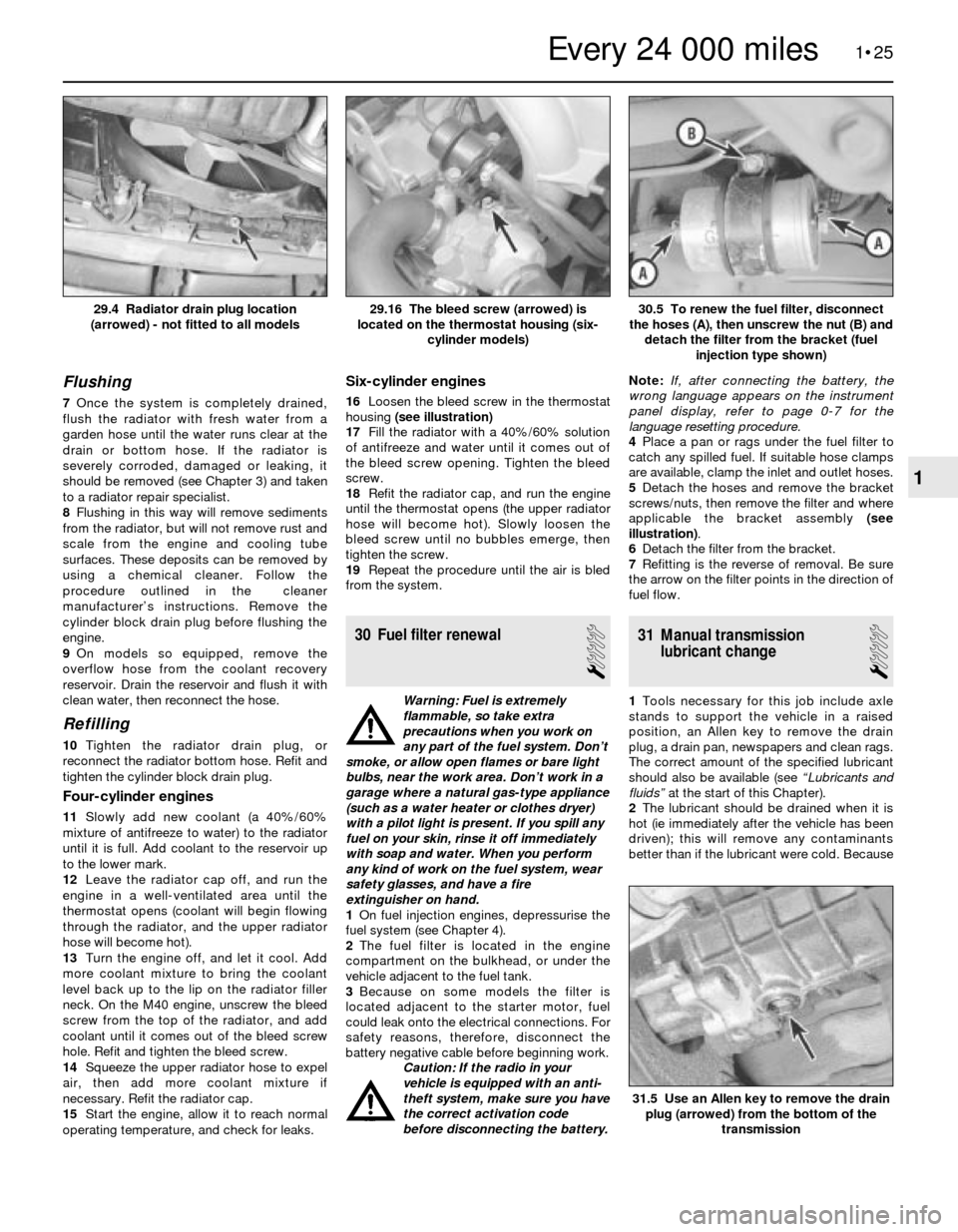

30 Fuel filter renewal

1

Warning: Fuel is extremely

flammable, so take extra

precautions when you work on

any part of the fuel system. Don’t

smoke, or allow open flames or bare light

bulbs, near the work area. Don’t work in a

garage where a natural gas-type appliance

(such as a water heater or clothes dryer)

with a pilot light is present. If you spill any

fuel on your skin, rinse it off immediately

with soap and water. When you perform

any kind of work on the fuel system, wear

safety glasses, and have a fire

extinguisher on hand.

1On fuel injection engines, depressurise the

fuel system (see Chapter 4).

2The fuel filter is located in the engine

compartment on the bulkhead, or under the

vehicle adjacent to the fuel tank.

3Because on some models the filter is

located adjacent to the starter motor, fuel

could leak onto the electrical connections. For

safety reasons, therefore, disconnect the

battery negative cable before beginning work.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you have

the correct activation code

before disconnecting the battery.Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

4Place a pan or rags under the fuel filter to

catch any spilled fuel. If suitable hose clamps

are available, clamp the inlet and outlet hoses.

5 Detach the hoses and remove the bracket

screws/nuts, then remove the filter and where

applicable the bracket assembly (see

illustration).

6Detach the filter from the bracket.

7Refitting is the reverse of removal. Be sure

the arrow on the filter points in the direction of

fuel flow.

31 Manual transmission

lubricant change

1

1Tools necessary for this job include axle

stands to support the vehicle in a raised

position, an Allen key to remove the drain

plug, a drain pan, newspapers and clean rags.

The correct amount of the specified lubricant

should also be available (see “Lubricants and

fluids”at the start of this Chapter).

2The lubricant should be drained when it is

hot (ie immediately after the vehicle has been

driven); this will remove any contaminants

better than if the lubricant were cold. Because

1•25

30.5 To renew the fuel filter, disconnect

the hoses (A), then unscrew the nut (B) and

detach the filter from the bracket (fuel

injection type shown)29.16 The bleed screw (arrowed) is

located on the thermostat housing (six-

cylinder models)29.4 Radiator drain plug location

(arrowed) - not fitted to all models

31.5 Use an Allen key to remove the drain

plug (arrowed) from the bottom of the

transmission

1

Every 24 000 miles

Page 36 of 228

the lubricant will be hot, it would be wise to

wear rubber gloves.

3Raise the vehicle and place it on axle

stands. Make sure it is safely supported, and

as level as possible.

4Move the necessary equipment under the

vehicle, being careful not to touch any of the

hot exhaust components.

5Place the drain pan under the transmission,

and remove the filler/level plug from the side

of the transmission. Loosen the drain plug

(see illustration).

6Carefully remove the drain plug. Be careful

not to burn yourself on the lubricant.

7Allow the lubricant to drain completely.

Clean the drain plug thoroughly, then refit and

tighten it securely.

8Refer to Section 16 and fill the transmission

with new lubricant, then refit the filler/level

plug, tightening it securely.

9Lower the vehicle. Check for leaks at the

drain plug after the first few miles of driving.

32 Differential lubricant change

1

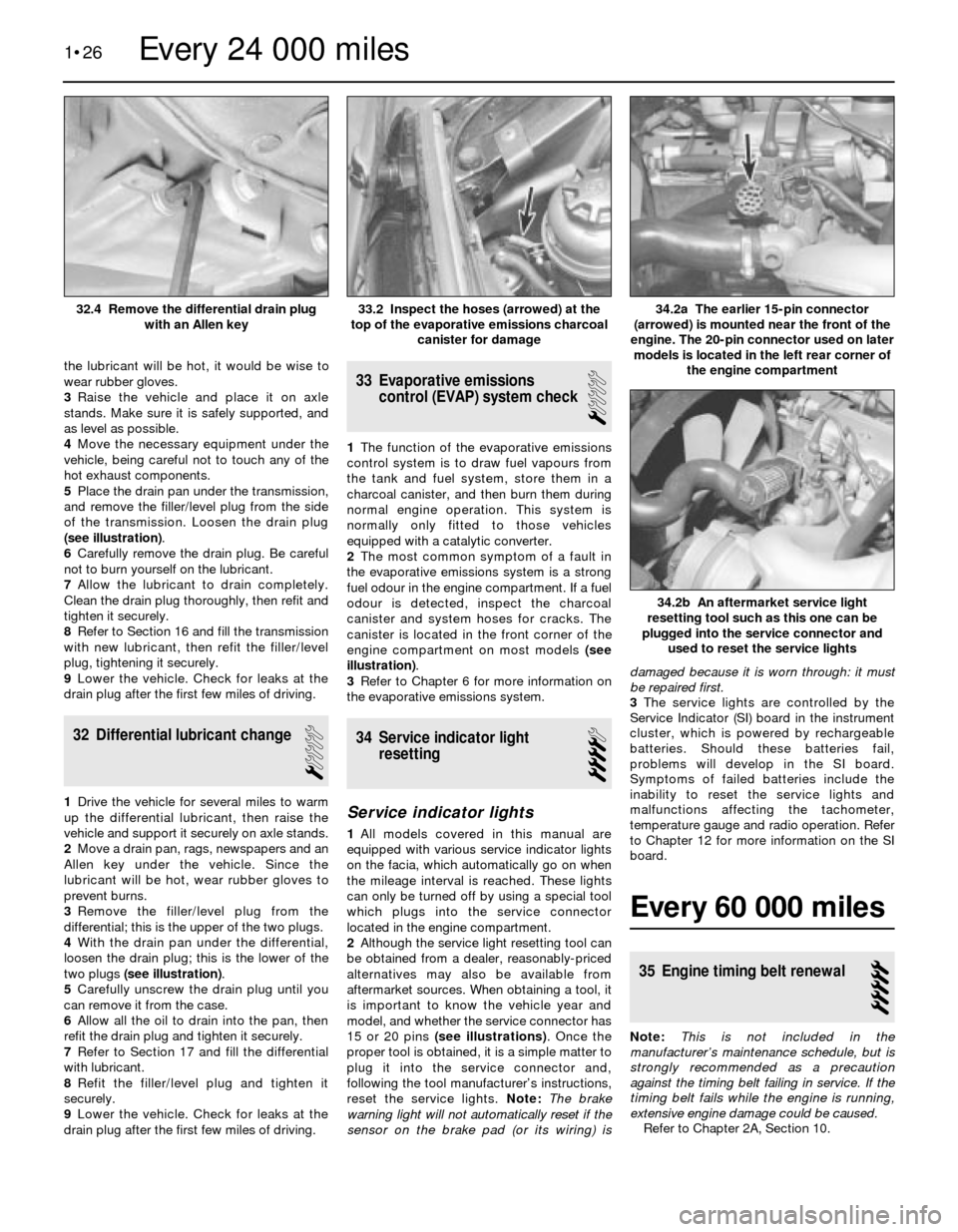

1Drive the vehicle for several miles to warm

up the differential lubricant, then raise the

vehicle and support it securely on axle stands.

2Move a drain pan, rags, newspapers and an

Allen key under the vehicle. Since the

lubricant will be hot, wear rubber gloves to

prevent burns.

3Remove the filler/level plug from the

differential; this is the upper of the two plugs.

4With the drain pan under the differential,

loosen the drain plug; this is the lower of the

two plugs (see illustration).

5Carefully unscrew the drain plug until you

can remove it from the case.

6Allow all the oil to drain into the pan, then

refit the drain plug and tighten it securely.

7Refer to Section 17 and fill the differential

with lubricant.

8Refit the filler/level plug and tighten it

securely.

9Lower the vehicle. Check for leaks at the

drain plug after the first few miles of driving.

33 Evaporative emissions

control (EVAP) system check

1

1The function of the evaporative emissions

control system is to draw fuel vapours from

the tank and fuel system, store them in a

charcoal canister, and then burn them during

normal engine operation. This system is

normally only fitted to those vehicles

equipped with a catalytic converter.

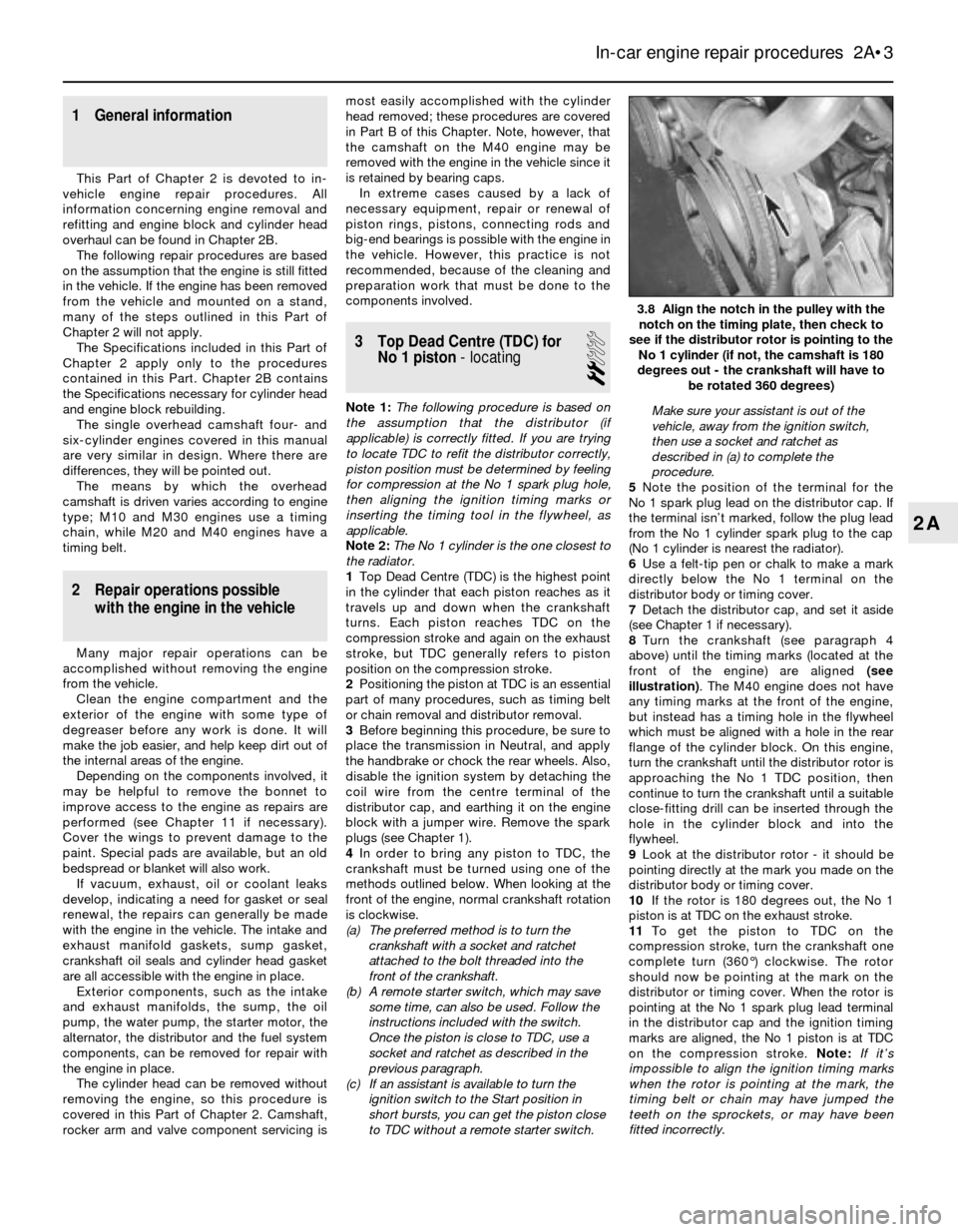

2The most common symptom of a fault in

the evaporative emissions system is a strong

fuel odour in the engine compartment. If a fuel

odour is detected, inspect the charcoal

canister and system hoses for cracks. The

canister is located in the front corner of the

engine compartment on most models (see

illustration).

3Refer to Chapter 6 for more information on

the evaporative emissions system.

34 Service indicator light

resetting

4

Service indicator lights

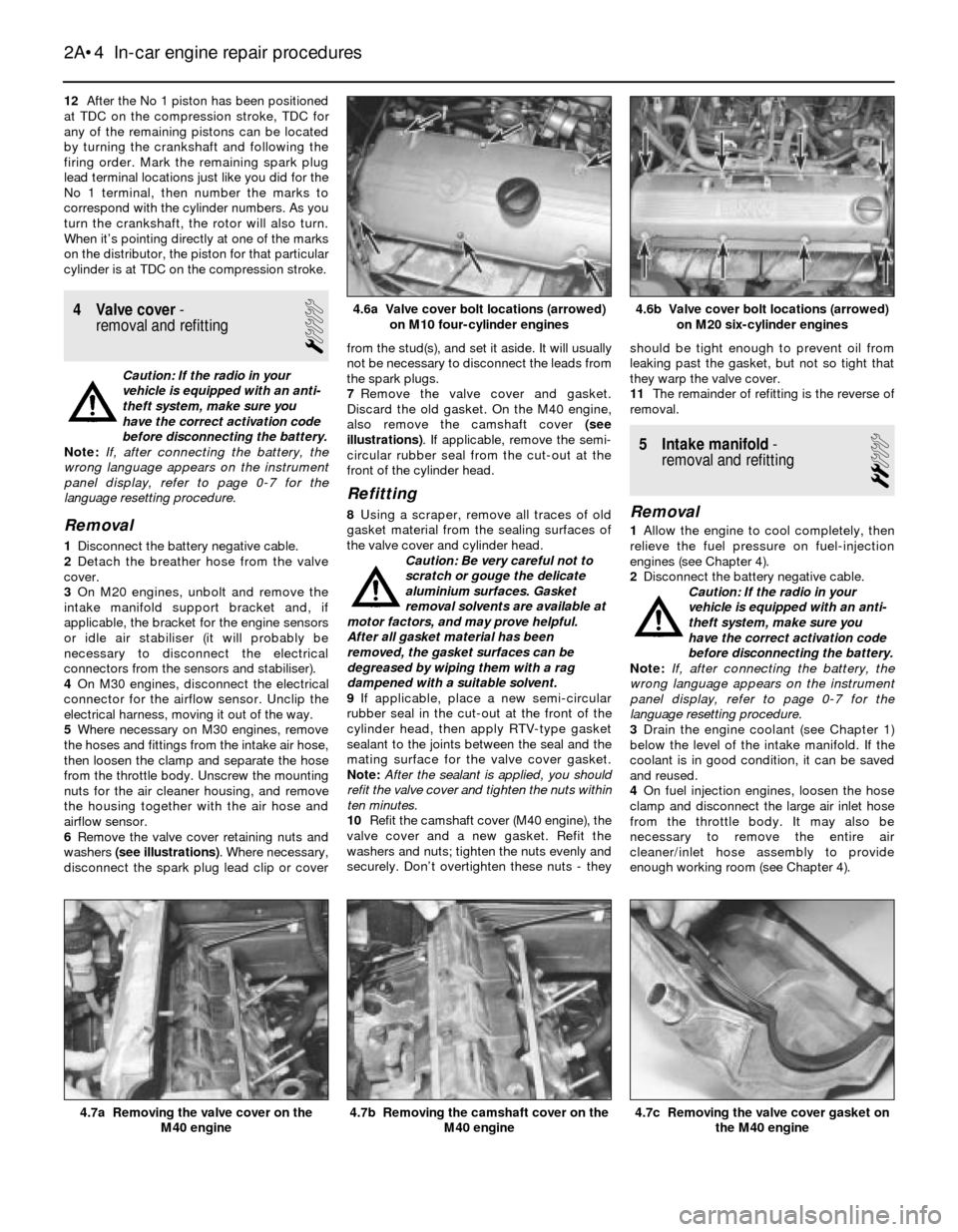

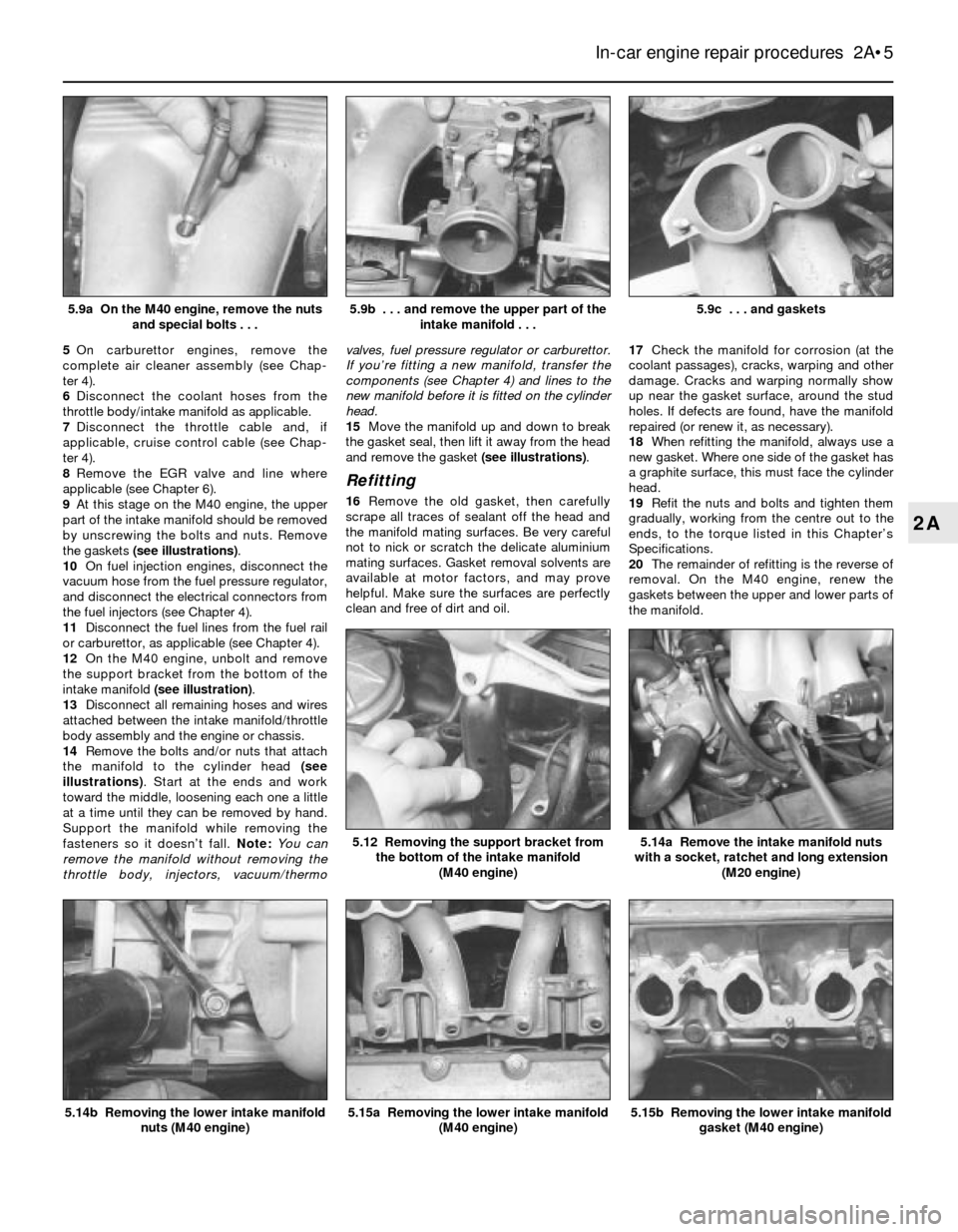

1All models covered in this manual are

equipped with various service indicator lights

on the facia, which automatically go on when

the mileage interval is reached. These lights

can only be turned off by using a special tool

which plugs into the service connector

located in the engine compartment.

2Although the service light resetting tool can

be obtained from a dealer, reasonably-priced

alternatives may also be available from

aftermarket sources. When obtaining a tool, it

is important to know the vehicle year and

model, and whether the service connector has

15 or 20 pins (see illustrations). Once the

proper tool is obtained, it is a simple matter to

plug it into the service connector and,

following the tool manufacturer’s instructions,

reset the service lights. Note: The brake

warning light will not automatically reset if the

sensor on the brake pad (or its wiring) isdamaged because it is worn through: it must

be repaired first.

3The service lights are controlled by the

Service Indicator (SI) board in the instrument

cluster, which is powered by rechargeable

batteries. Should these batteries fail,

problems will develop in the SI board.

Symptoms of failed batteries include the

inability to reset the service lights and

malfunctions affecting the tachometer,

temperature gauge and radio operation. Refer

to Chapter 12 for more information on the SI

board.

Every 60 000 miles

35 Engine timing belt renewal

5

Note:This is not included in the

manufacturer’s maintenance schedule, but is

strongly recommended as a precaution

against the timing belt failing in service. If the

timing belt fails while the engine is running,

extensive engine damage could be caused.

Refer to Chapter 2A, Section 10.

1•26

34.2b An aftermarket service light

resetting tool such as this one can be

plugged into the service connector and

used to reset the service lights

34.2a The earlier 15-pin connector

(arrowed) is mounted near the front of the

engine. The 20-pin connector used on later

models is located in the left rear corner of

the engine compartment33.2 Inspect the hoses (arrowed) at the

top of the evaporative emissions charcoal

canister for damage32.4 Remove the differential drain plug

with an Allen key

Every 24 000 miles

Page 39 of 228

1 General information

This Part of Chapter 2 is devoted to in-

vehicle engine repair procedures. All

information concerning engine removal and

refitting and engine block and cylinder head

overhaul can be found in Chapter 2B.

The following repair procedures are based

on the assumption that the engine is still fitted

in the vehicle. If the engine has been removed

from the vehicle and mounted on a stand,

many of the steps outlined in this Part of

Chapter 2 will not apply.

The Specifications included in this Part of

Chapter 2 apply only to the procedures

contained in this Part. Chapter 2B contains

the Specifications necessary for cylinder head

and engine block rebuilding.

The single overhead camshaft four- and

six-cylinder engines covered in this manual

are very similar in design. Where there are

differences, they will be pointed out.

The means by which the overhead

camshaft is driven varies according to engine

type; M10 and M30 engines use a timing

chain, while M20 and M40 engines have a

timing belt.

2 Repair operations possible

with the engine in the vehicle

Many major repair operations can be

accomplished without removing the engine

from the vehicle.

Clean the engine compartment and the

exterior of the engine with some type of

degreaser before any work is done. It will

make the job easier, and help keep dirt out of

the internal areas of the engine.

Depending on the components involved, it

may be helpful to remove the bonnet to

improve access to the engine as repairs are

performed (see Chapter 11 if necessary).

Cover the wings to prevent damage to the

paint. Special pads are available, but an old

bedspread or blanket will also work.

If vacuum, exhaust, oil or coolant leaks

develop, indicating a need for gasket or seal

renewal, the repairs can generally be made

with the engine in the vehicle. The intake and

exhaust manifold gaskets, sump gasket,

crankshaft oil seals and cylinder head gasket

are all accessible with the engine in place.

Exterior components, such as the intake

and exhaust manifolds, the sump, the oil

pump, the water pump, the starter motor, the

alternator, the distributor and the fuel system

components, can be removed for repair with

the engine in place.

The cylinder head can be removed without

removing the engine, so this procedure is

covered in this Part of Chapter 2. Camshaft,

rocker arm and valve component servicing ismost easily accomplished with the cylinder

head removed; these procedures are covered

in Part B of this Chapter. Note, however, that

the camshaft on the M40 engine may be

removed with the engine in the vehicle since it

is retained by bearing caps.

In extreme cases caused by a lack of

necessary equipment, repair or renewal of

piston rings, pistons, connecting rods and

big-end bearings is possible with the engine in

the vehicle. However, this practice is not

recommended, because of the cleaning and

preparation work that must be done to the

components involved.

3 Top Dead Centre (TDC) for

No 1 piston- locating

2

Note 1:The following procedure is based on

the assumption that the distributor (if

applicable) is correctly fitted. If you are trying

to locate TDC to refit the distributor correctly,

piston position must be determined by feeling

for compression at the No 1 spark plug hole,

then aligning the ignition timing marks or

inserting the timing tool in the flywheel, as

applicable.

Note 2:The No 1 cylinder is the one closest to

the radiator.

1Top Dead Centre (TDC) is the highest point

in the cylinder that each piston reaches as it

travels up and down when the crankshaft

turns. Each piston reaches TDC on the

compression stroke and again on the exhaust

stroke, but TDC generally refers to piston

position on the compression stroke.

2Positioning the piston at TDC is an essential

part of many procedures, such as timing belt

or chain removal and distributor removal.

3Before beginning this procedure, be sure to

place the transmission in Neutral, and apply

the handbrake or chock the rear wheels. Also,

disable the ignition system by detaching the

coil wire from the centre terminal of the

distributor cap, and earthing it on the engine

block with a jumper wire. Remove the spark

plugs (see Chapter 1).

4In order to bring any piston to TDC, the

crankshaft must be turned using one of the

methods outlined below. When looking at the

front of the engine, normal crankshaft rotation

is clockwise.

(a) The preferred method is to turn the

crankshaft with a socket and ratchet

attached to the bolt threaded into the

front of the crankshaft.

(b) A remote starter switch, which may save

some time, can also be used. Follow the

instructions included with the switch.

Once the piston is close to TDC, use a

socket and ratchet as described in the

previous paragraph.

(c) If an assistant is available to turn the

ignition switch to the Start position in

short bursts, you can get the piston close

to TDC without a remote starter switch.Make sure your assistant is out of the

vehicle, away from the ignition switch,

then use a socket and ratchet as

described in (a) to complete the

procedure.

5Note the position of the terminal for the

No 1 spark plug lead on the distributor cap. If

the terminal isn’t marked, follow the plug lead

from the No 1 cylinder spark plug to the cap

(No 1 cylinder is nearest the radiator).

6Use a felt-tip pen or chalk to make a mark

directly below the No 1 terminal on the

distributor body or timing cover.

7Detach the distributor cap, and set it aside

(see Chapter 1 if necessary).

8Turn the crankshaft (see paragraph 4

above) until the timing marks (located at the

front of the engine) are aligned (see

illustration). The M40 engine does not have

any timing marks at the front of the engine,

but instead has a timing hole in the flywheel

which must be aligned with a hole in the rear

flange of the cylinder block. On this engine,

turn the crankshaft until the distributor rotor is

approaching the No 1 TDC position, then

continue to turn the crankshaft until a suitable

close-fitting drill can be inserted through the

hole in the cylinder block and into the

flywheel.

9Look at the distributor rotor - it should be

pointing directly at the mark you made on the

distributor body or timing cover.

10If the rotor is 180 degrees out, the No 1

piston is at TDC on the exhaust stroke.

11To get the piston to TDC on the

compression stroke, turn the crankshaft one

complete turn (360°) clockwise. The rotor

should now be pointing at the mark on the

distributor or timing cover. When the rotor is

pointing at the No 1 spark plug lead terminal

in the distributor cap and the ignition timing

marks are aligned, the No 1 piston is at TDC

on the compression stroke. Note:If it’s

impossible to align the ignition timing marks

when the rotor is pointing at the mark, the

timing belt or chain may have jumped the

teeth on the sprockets, or may have been

fitted incorrectly.

In-car engine repair procedures 2A•3

3.8 Align the notch in the pulley with the

notch on the timing plate, then check to

see if the distributor rotor is pointing to the

No 1 cylinder (if not, the camshaft is 180

degrees out - the crankshaft will have to

be rotated 360 degrees)

2A

Page 40 of 228

12After the No 1 piston has been positioned

at TDC on the compression stroke, TDC for

any of the remaining pistons can be located

by turning the crankshaft and following the

firing order. Mark the remaining spark plug

lead terminal locations just like you did for the

No 1 terminal, then number the marks to

correspond with the cylinder numbers. As you

turn the crankshaft, the rotor will also turn.

When it’s pointing directly at one of the marks

on the distributor, the piston for that particular

cylinder is at TDC on the compression stroke.

4 Valve cover-

removal and refitting

1

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

Removal

1Disconnect the battery negative cable.

2Detach the breather hose from the valve

cover.

3On M20 engines, unbolt and remove the

intake manifold support bracket and, if

applicable, the bracket for the engine sensors

or idle air stabiliser (it will probably be

necessary to disconnect the electrical

connectors from the sensors and stabiliser).

4On M30 engines, disconnect the electrical

connector for the airflow sensor. Unclip the

electrical harness, moving it out of the way.

5Where necessary on M30 engines, remove

the hoses and fittings from the intake air hose,

then loosen the clamp and separate the hose

from the throttle body. Unscrew the mounting

nuts for the air cleaner housing, and remove

the housing together with the air hose and

airflow sensor.

6Remove the valve cover retaining nuts and

washers (see illustrations). Where necessary,

disconnect the spark plug lead clip or coverfrom the stud(s), and set it aside. It will usually

not be necessary to disconnect the leads from

the spark plugs.

7Remove the valve cover and gasket.

Discard the old gasket. On the M40 engine,

also remove the camshaft cover (see

illustrations). If applicable, remove the semi-

circular rubber seal from the cut-out at the

front of the cylinder head.

Refitting

8Using a scraper, remove all traces of old

gasket material from the sealing surfaces of

the valve cover and cylinder head.

Caution: Be very careful not to

scratch or gouge the delicate

aluminium surfaces. Gasket

removal solvents are available at

motor factors, and may prove helpful.

After all gasket material has been

removed, the gasket surfaces can be

degreased by wiping them with a rag

dampened with a suitable solvent.

9If applicable, place a new semi-circular

rubber seal in the cut-out at the front of the

cylinder head, then apply RTV-type gasket

sealant to the joints between the seal and the

mating surface for the valve cover gasket.

Note:After the sealant is applied, you should

refit the valve cover and tighten the nuts within

ten minutes.

10Refit the camshaft cover (M40 engine), the

valve cover and a new gasket. Refit the

washers and nuts; tighten the nuts evenly and

securely. Don’t overtighten these nuts - theyshould be tight enough to prevent oil from

leaking past the gasket, but not so tight that

they warp the valve cover.

11The remainder of refitting is the reverse of

removal.

5 Intake manifold-

removal and refitting

2

Removal

1Allow the engine to cool completely, then

relieve the fuel pressure on fuel-injection

engines (see Chapter 4).

2Disconnect the battery negative cable.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

3Drain the engine coolant (see Chapter 1)

below the level of the intake manifold. If the

coolant is in good condition, it can be saved

and reused.

4On fuel injection engines, loosen the hose

clamp and disconnect the large air inlet hose

from the throttle body. It may also be

necessary to remove the entire air

cleaner/inlet hose assembly to provide

enough working room (see Chapter 4).

2A•4 In-car engine repair procedures

4.7b Removing the camshaft cover on the

M40 engine4.7a Removing the valve cover on the

M40 engine4.7c Removing the valve cover gasket on

the M40 engine

4.6b Valve cover bolt locations (arrowed)

on M20 six-cylinder engines4.6a Valve cover bolt locations (arrowed)

on M10 four-cylinder engines

Page 41 of 228

5On carburettor engines, remove the

complete air cleaner assembly (see Chap-

ter 4).

6Disconnect the coolant hoses from the

throttle body/intake manifold as applicable.

7Disconnect the throttle cable and, if

applicable, cruise control cable (see Chap-

ter 4).

8Remove the EGR valve and line where

applicable (see Chapter 6).

9At this stage on the M40 engine, the upper

part of the intake manifold should be removed

by unscrewing the bolts and nuts. Remove

the gaskets (see illustrations).

10On fuel injection engines, disconnect the

vacuum hose from the fuel pressure regulator,

and disconnect the electrical connectors from

the fuel injectors (see Chapter 4).

11Disconnect the fuel lines from the fuel rail

or carburettor, as applicable (see Chapter 4).

12On the M40 engine, unbolt and remove

the support bracket from the bottom of the

intake manifold (see illustration).

13Disconnect all remaining hoses and wires

attached between the intake manifold/throttle

body assembly and the engine or chassis.

14Remove the bolts and/or nuts that attach

the manifold to the cylinder head (see

illustrations). Start at the ends and work

toward the middle, loosening each one a little

at a time until they can be removed by hand.

Support the manifold while removing the

fasteners so it doesn’t fall. Note: You can

remove the manifold without removing the

throttle body, injectors, vacuum/thermovalves, fuel pressure regulator or carburettor.

If you’re fitting a new manifold, transfer the

components (see Chapter 4) and lines to the

new manifold before it is fitted on the cylinder

head.

15Move the manifold up and down to break

the gasket seal, then lift it away from the head

and remove the gasket (see illustrations).

Refitting

16Remove the old gasket, then carefully

scrape all traces of sealant off the head and

the manifold mating surfaces. Be very careful

not to nick or scratch the delicate aluminium

mating surfaces. Gasket removal solvents are

available at motor factors, and may prove

helpful. Make sure the surfaces are perfectly

clean and free of dirt and oil.17Check the manifold for corrosion (at the

coolant passages), cracks, warping and other

damage. Cracks and warping normally show

up near the gasket surface, around the stud

holes. If defects are found, have the manifold

repaired (or renew it, as necessary).

18When refitting the manifold, always use a

new gasket. Where one side of the gasket has

a graphite surface, this must face the cylinder

head.

19Refit the nuts and bolts and tighten them

gradually, working from the centre out to the

ends, to the torque listed in this Chapter’s

Specifications.

20The remainder of refitting is the reverse of

removal. On the M40 engine, renew the

gaskets between the upper and lower parts of

the manifold.

In-car engine repair procedures 2A•5

5.9c . . . and gaskets5.9b . . . and remove the upper part of the

intake manifold . . .5.9a On the M40 engine, remove the nuts

and special bolts . . .

5.15b Removing the lower intake manifold

gasket (M40 engine)5.15a Removing the lower intake manifold

(M40 engine)

5.14a Remove the intake manifold nuts

with a socket, ratchet and long extension

(M20 engine)5.12 Removing the support bracket from

the bottom of the intake manifold

(M40 engine)

5.14b Removing the lower intake manifold

nuts (M40 engine)

2A

Page 42 of 228

6 Exhaust manifold-

removal and refitting

1

Warning: Make sure the engine is

completely cool before beginning

work on the exhaust system.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

1Disconnect the battery negative cable.

2On models where the air cleaner is on the

exhaust manifold side of the engine, remove

the air cleaner housing assembly and/or

airflow sensor to provide sufficient working

area (see Chapter 4, if necessary).

3Unplug the HT leads and set the spark plug

lead harness aside (see Chapter 1).

4Clearly label, then disconnect or remove, all

wires, hoses, fittings, etc. that are in the way.

Be sure to disconnect the oxygen sensor,

where fitted.

5Raise the vehicle, and support it securely

on axle stands. Working from under the

vehicle, separate the exhaust downpipe from

the manifold. Use penetrating oil on the

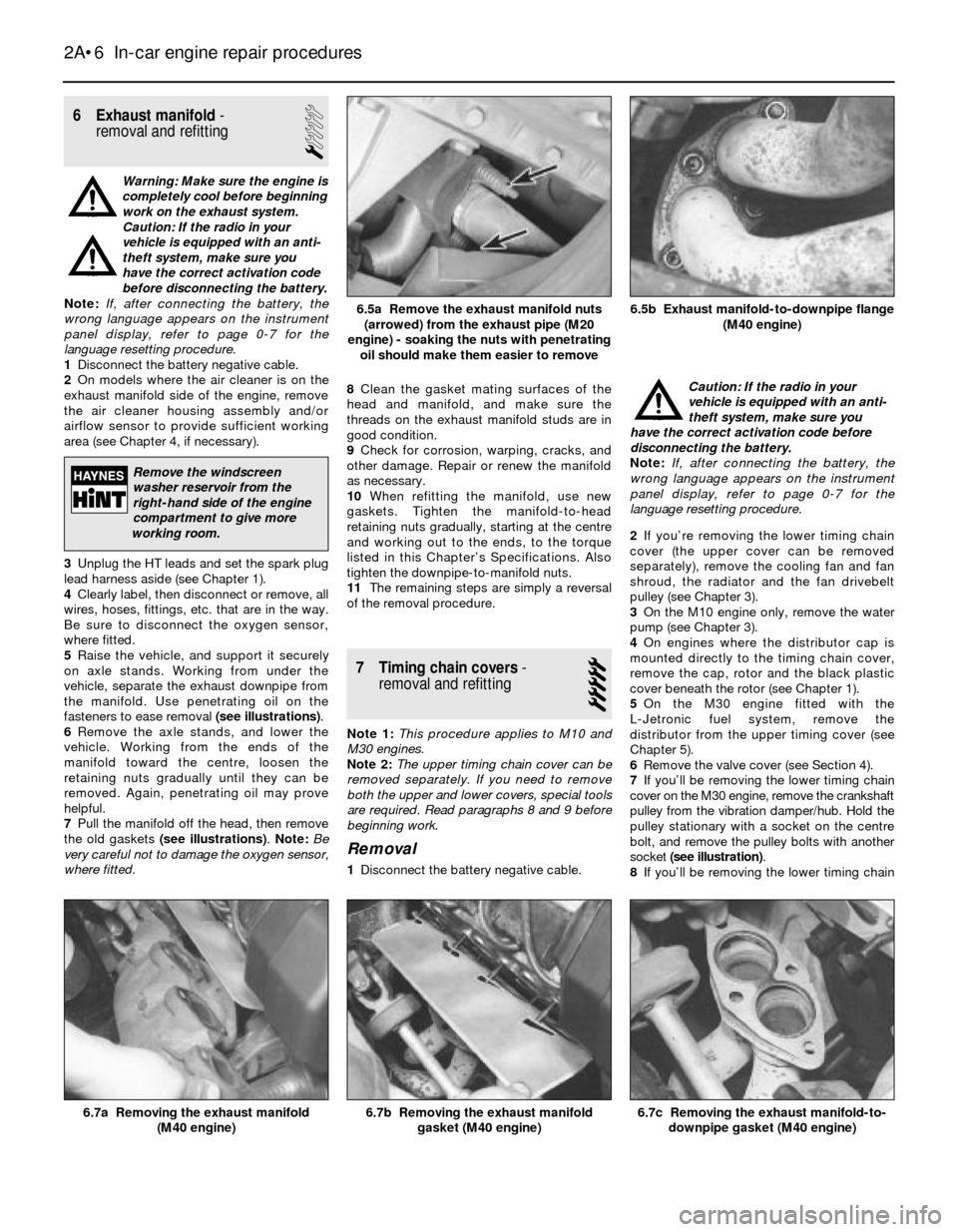

fasteners to ease removal (see illustrations).

6Remove the axle stands, and lower the

vehicle. Working from the ends of the

manifold toward the centre, loosen the

retaining nuts gradually until they can be

removed. Again, penetrating oil may prove

helpful.

7Pull the manifold off the head, then remove

the old gaskets (see illustrations). Note:Be

very careful not to damage the oxygen sensor,

where fitted.8Clean the gasket mating surfaces of the

head and manifold, and make sure the

threads on the exhaust manifold studs are in

good condition.

9Check for corrosion, warping, cracks, and

other damage. Repair or renew the manifold

as necessary.

10When refitting the manifold, use new

gaskets. Tighten the manifold-to-head

retaining nuts gradually, starting at the centre

and working out to the ends, to the torque

listed in this Chapter’s Specifications. Also

tighten the downpipe-to-manifold nuts.

11The remaining steps are simply a reversal

of the removal procedure.

7 Timing chain covers-

removal and refitting

5

Note 1:This procedure applies to M10 and

M30 engines.

Note 2:The upper timing chain cover can be

removed separately. If you need to remove

both the upper and lower covers, special tools

are required. Read paragraphs 8 and 9 before

beginning work.

Removal

1Disconnect the battery negative cable.Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code before

disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

2If you’re removing the lower timing chain

cover (the upper cover can be removed

separately), remove the cooling fan and fan

shroud, the radiator and the fan drivebelt

pulley (see Chapter 3).

3On the M10 engine only, remove the water

pump (see Chapter 3).

4On engines where the distributor cap is

mounted directly to the timing chain cover,

remove the cap, rotor and the black plastic

cover beneath the rotor (see Chapter 1).

5On the M30 engine fitted with the

L-Jetronic fuel system, remove the

distributor from the upper timing cover (see

Chapter 5).

6Remove the valve cover (see Section 4).

7If you’ll be removing the lower timing chain

cover on the M30 engine, remove the crankshaft

pulley from the vibration damper/hub. Hold the

pulley stationary with a socket on the centre

bolt, and remove the pulley bolts with another

socket (see illustration).

8If you’ll be removing the lower timing chain

2A•6 In-car engine repair procedures

6.7c Removing the exhaust manifold-to-

downpipe gasket (M40 engine)6.7b Removing the exhaust manifold

gasket (M40 engine)6.7a Removing the exhaust manifold

(M40 engine)

6.5b Exhaust manifold-to-downpipe flange

(M40 engine)6.5a Remove the exhaust manifold nuts

(arrowed) from the exhaust pipe (M20

engine) - soaking the nuts with penetrating

oil should make them easier to remove

Remove the windscreen

washer reservoir from the

right-hand side of the engine

compartment to give more

working room.

Page 43 of 228

cover, remove the vibration damper/hub by

locking the crankshaft in position and

loosening the large centre bolt. Since the bolt

is on very tight, you’ll need to use an

extension bar and socket to break it loose. On

M30 engines, BMW recommends using a

3/4-inch drive socket and extension bar, since

the bolt is extremely tight on these engines.

To lock the crankshaft in place while the bolt

is being loosened, use BMW special tool

No. 11 2 100 (or equivalent).

9On the M10 engine, if the special tool listed

in the previous paragraph is not available, you

may try locking the crankshaft by removing

the flywheel/driveplate inspection cover and

jamming a wide-bladed screwdriver into the

ring gear teeth. On the M30 engine, since the

bolt is so extremely tight, we don’t

recommend substitute methods. Use the

correct tool. On the M10 engine, after the

centre bolt is removed, it will probably be

necessary to use a jaw-type puller to pull the

vibration damper off the crankshaft. Position

the jaws behind the inner pulley groove, and

tighten the puller centre bolt very slowly,

checking the pulley to make sure it does not

get bent or otherwise damaged by the puller.

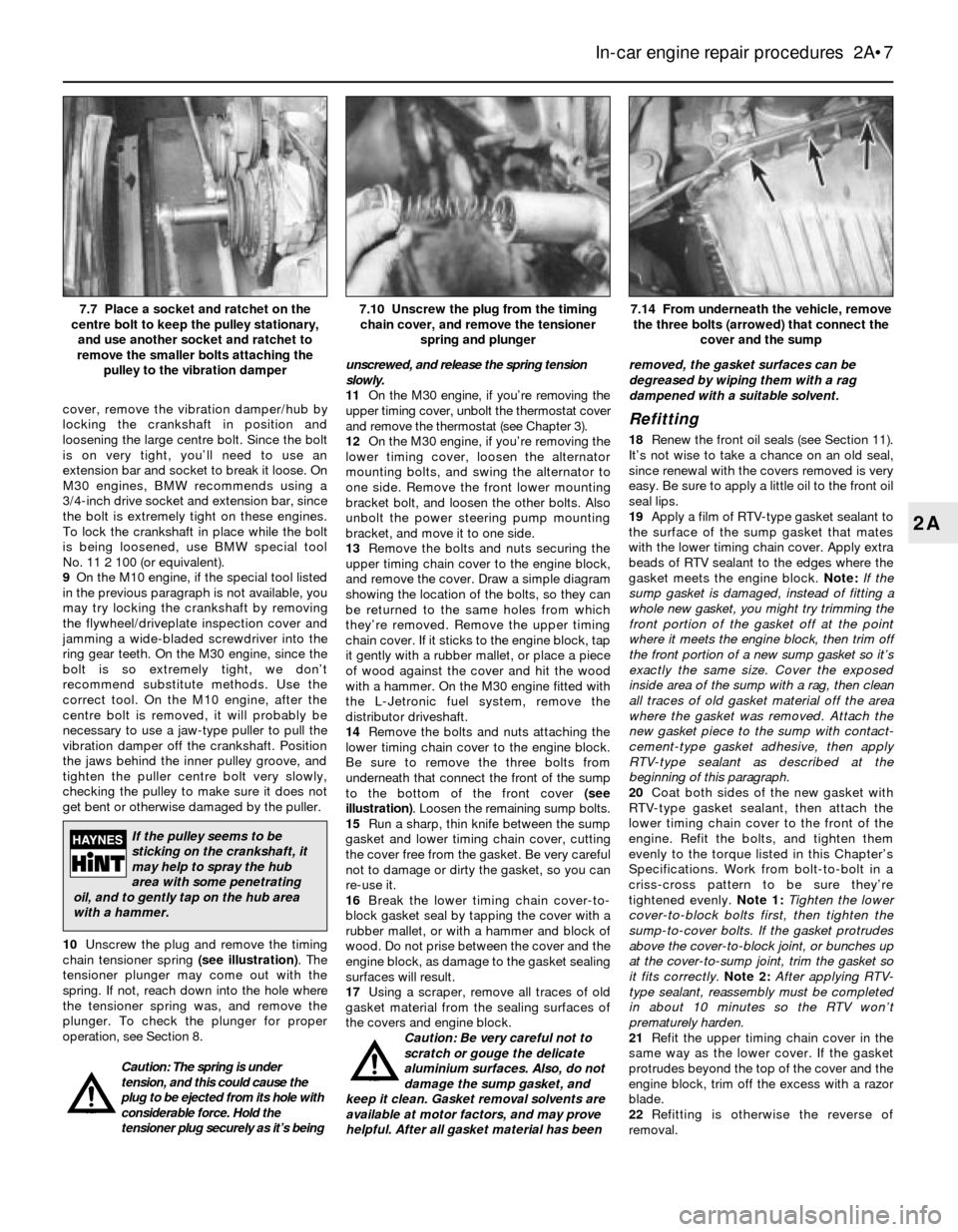

10Unscrew the plug and remove the timing

chain tensioner spring (see illustration). The

tensioner plunger may come out with the

spring. If not, reach down into the hole where

the tensioner spring was, and remove the

plunger. To check the plunger for proper

operation, see Section 8.

Caution: The spring is under

tension, and this could cause the

plug to be ejected from its hole with

considerable force. Hold the

tensioner plug securely as it’s beingunscrewed, and release the spring tension

slowly.

11On the M30 engine, if you’re removing the

upper timing cover, unbolt the thermostat cover

and remove the thermostat (see Chapter 3).

12On the M30 engine, if you’re removing the

lower timing cover, loosen the alternator

mounting bolts, and swing the alternator to

one side. Remove the front lower mounting

bracket bolt, and loosen the other bolts. Also

unbolt the power steering pump mounting

bracket, and move it to one side.

13Remove the bolts and nuts securing the

upper timing chain cover to the engine block,

and remove the cover. Draw a simple diagram

showing the location of the bolts, so they can

be returned to the same holes from which

they’re removed. Remove the upper timing

chain cover. If it sticks to the engine block, tap

it gently with a rubber mallet, or place a piece

of wood against the cover and hit the wood

with a hammer. On the M30 engine fitted with

the L-Jetronic fuel system, remove the

distributor driveshaft.

14Remove the bolts and nuts attaching the

lower timing chain cover to the engine block.

Be sure to remove the three bolts from

underneath that connect the front of the sump

to the bottom of the front cover (see

illustration). Loosen the remaining sump bolts.

15Run a sharp, thin knife between the sump

gasket and lower timing chain cover, cutting

the cover free from the gasket. Be very careful

not to damage or dirty the gasket, so you can

re-use it.

16Break the lower timing chain cover-to-

block gasket seal by tapping the cover with a

rubber mallet, or with a hammer and block of

wood. Do not prise between the cover and the

engine block, as damage to the gasket sealing

surfaces will result.

17Using a scraper, remove all traces of old

gasket material from the sealing surfaces of

the covers and engine block.

Caution: Be very careful not to

scratch or gouge the delicate

aluminium surfaces. Also, do not

damage the sump gasket, and

keep it clean. Gasket removal solvents are

available at motor factors, and may prove

helpful. After all gasket material has beenremoved, the gasket surfaces can be

degreased by wiping them with a rag

dampened with a suitable solvent.Refitting

18Renew the front oil seals (see Section 11).

It’s not wise to take a chance on an old seal,

since renewal with the covers removed is very

easy. Be sure to apply a little oil to the front oil

seal lips.

19Apply a film of RTV-type gasket sealant to

the surface of the sump gasket that mates

with the lower timing chain cover. Apply extra

beads of RTV sealant to the edges where the

gasket meets the engine block. Note:If the

sump gasket is damaged, instead of fitting a

whole new gasket, you might try trimming the

front portion of the gasket off at the point

where it meets the engine block, then trim off

the front portion of a new sump gasket so it’s

exactly the same size. Cover the exposed

inside area of the sump with a rag, then clean

all traces of old gasket material off the area

where the gasket was removed. Attach the

new gasket piece to the sump with contact-

cement-type gasket adhesive, then apply

RTV-type sealant as described at the

beginning of this paragraph.

20Coat both sides of the new gasket with

RTV-type gasket sealant, then attach the

lower timing chain cover to the front of the

engine. Refit the bolts, and tighten them

evenly to the torque listed in this Chapter’s

Specifications. Work from bolt-to-bolt in a

criss-cross pattern to be sure they’re

tightened evenly.Note 1:Tighten the lower

cover-to-block bolts first, then tighten the

sump-to-cover bolts. If the gasket protrudes

above the cover-to-block joint, or bunches up

at the cover-to-sump joint, trim the gasket so

it fits correctly.Note 2:After applying RTV-

type sealant, reassembly must be completed

in about 10 minutes so the RTV won’t

prematurely harden.

21Refit the upper timing chain cover in the

same way as the lower cover. If the gasket

protrudes beyond the top of the cover and the

engine block, trim off the excess with a razor

blade.

22Refitting is otherwise the reverse of

removal.

In-car engine repair procedures 2A•7

7.14 From underneath the vehicle, remove

the three bolts (arrowed) that connect the

cover and the sump7.10 Unscrew the plug from the timing

chain cover, and remove the tensioner

spring and plunger7.7 Place a socket and ratchet on the

centre bolt to keep the pulley stationary,

and use another socket and ratchet to

remove the smaller bolts attaching the

pulley to the vibration damper

2A

If the pulley seems to be

sticking on the crankshaft, it

may help to spray the hub

area with some penetrating

oil, and to gently tap on the hub area

with a hammer.