steering rack BMW 3 SERIES 1983 E30 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1983, Model line: 3 SERIES, Model: BMW 3 SERIES 1983 E30Pages: 228, PDF Size: 7.04 MB

Page 152 of 228

4Inspect and, if necessary, renew any worn

or defective bolts, washers, bushes or links.

Refitting

5Refitting is the reverse of removal. Tighten

all fasteners securely.

13 Rear trailing arms (3-Series)

- removal and refitting

3

Removal

1Loosen the wheel bolts, then chock the

front wheels. Raise the rear of the vehicle, and

support it securely on axle stands. Remove

the wheel(s).

2Remove the driveshaft (see Chapter 8), or

disconnect it from the final drive output

flange.

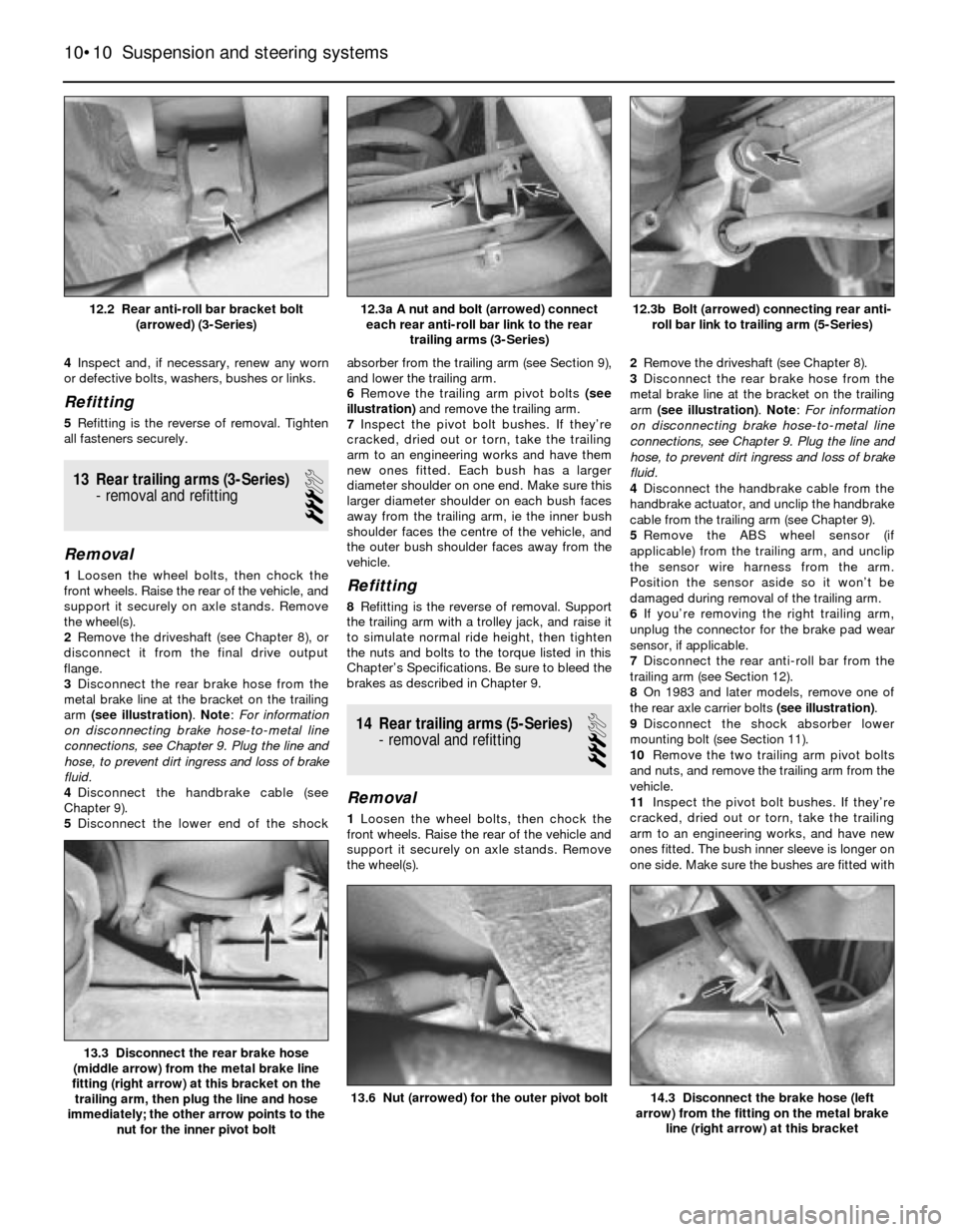

3Disconnect the rear brake hose from the

metal brake line at the bracket on the trailing

arm (see illustration). Note: For information

on disconnecting brake hose-to-metal line

connections, see Chapter 9. Plug the line and

hose, to prevent dirt ingress and loss of brake

fluid.

4Disconnect the handbrake cable (see

Chapter 9).

5Disconnect the lower end of the shockabsorber from the trailing arm (see Section 9),

and lower the trailing arm.

6Remove the trailing arm pivot bolts (see

illustration)and remove the trailing arm.

7Inspect the pivot bolt bushes. If they’re

cracked, dried out or torn, take the trailing

arm to an engineering works and have them

new ones fitted. Each bush has a larger

diameter shoulder on one end. Make sure this

larger diameter shoulder on each bush faces

away from the trailing arm, ie the inner bush

shoulder faces the centre of the vehicle, and

the outer bush shoulder faces away from the

vehicle.Refitting

8Refitting is the reverse of removal. Support

the trailing arm with a trolley jack, and raise it

to simulate normal ride height, then tighten

the nuts and bolts to the torque listed in this

Chapter’s Specifications. Be sure to bleed the

brakes as described in Chapter 9.

14 Rear trailing arms (5-Series)

- removal and refitting

3

Removal

1Loosen the wheel bolts, then chock the

front wheels. Raise the rear of the vehicle and

support it securely on axle stands. Remove

the wheel(s).2Remove the driveshaft (see Chapter 8).

3Disconnect the rear brake hose from the

metal brake line at the bracket on the trailing

arm (see illustration). Note: For information

on disconnecting brake hose-to-metal line

connections, see Chapter 9. Plug the line and

hose, to prevent dirt ingress and loss of brake

fluid.

4Disconnect the handbrake cable from the

handbrake actuator, and unclip the handbrake

cable from the trailing arm (see Chapter 9).

5Remove the ABS wheel sensor (if

applicable) from the trailing arm, and unclip

the sensor wire harness from the arm.

Position the sensor aside so it won’t be

damaged during removal of the trailing arm.

6If you’re removing the right trailing arm,

unplug the connector for the brake pad wear

sensor, if applicable.

7Disconnect the rear anti-roll bar from the

trailing arm (see Section 12).

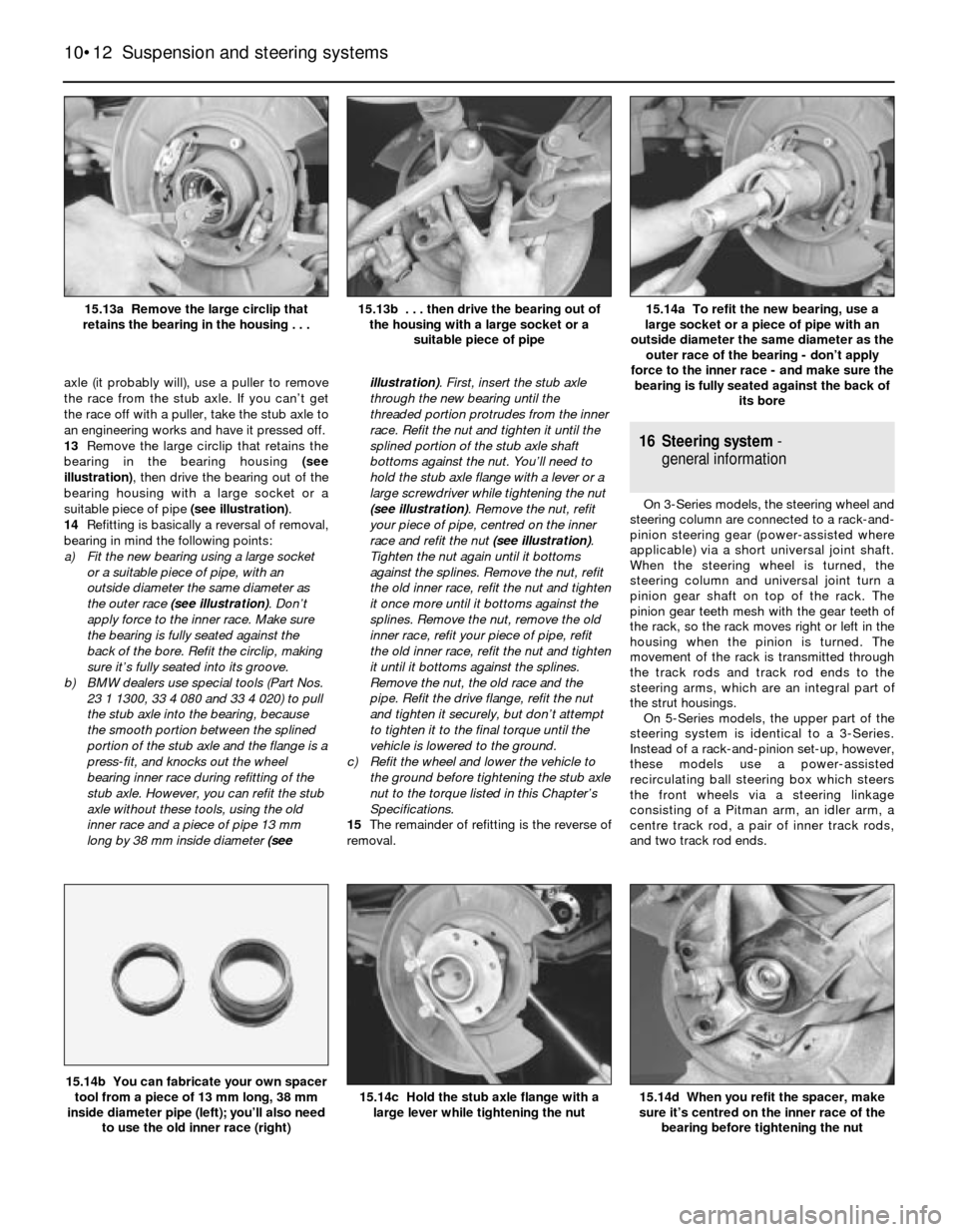

8On 1983 and later models, remove one of

the rear axle carrier bolts (see illustration).

9Disconnect the shock absorber lower

mounting bolt (see Section 11).

10Remove the two trailing arm pivot bolts

and nuts, and remove the trailing arm from the

vehicle.

11Inspect the pivot bolt bushes. If they’re

cracked, dried out or torn, take the trailing

arm to an engineering works, and have new

ones fitted. The bush inner sleeve is longer on

one side. Make sure the bushes are fitted with

10•10 Suspension and steering systems

14.3 Disconnect the brake hose (left

arrow) from the fitting on the metal brake

line (right arrow) at this bracket13.6 Nut (arrowed) for the outer pivot bolt

13.3 Disconnect the rear brake hose

(middle arrow) from the metal brake line

fitting (right arrow) at this bracket on the

trailing arm, then plug the line and hose

immediately; the other arrow points to the

nut for the inner pivot bolt

12.3b Bolt (arrowed) connecting rear anti-

roll bar link to trailing arm (5-Series)12.3a A nut and bolt (arrowed) connect

each rear anti-roll bar link to the rear

trailing arms (3-Series)12.2 Rear anti-roll bar bracket bolt

(arrowed) (3-Series)

Page 153 of 228

the longer side of the sleeve facing towards

the centre of the vehicle.

Refitting

12Refitting is the reverse of removal. Refit

the inner pivot bolt first. Don’t fully tighten the

nuts on the pivot bolts or the shock absorber

yet.

13Bleed the brakes as described in Chap-

ter 9.

14Support the trailing arm with a trolley jack,

and raise it to simulate normal ride height.

Tighten the bolts and nuts to the torques

listed in this Chapter’s Specifications.

15 Rear wheel bearings-

renewal

4

3-Series models

1Loosen the driveshaft nut and the rear

wheel bolts, then chock the front wheels.

Raise the rear of the vehicle and place it

securely on axle stands. Remove the rear

wheel. Note: Depending on the type of rear

wheel, it may be necessary to remove the

wheel first, remove the hubcap, then refit the

wheel and loosen the driveshaft nut.

2Remove the driveshaft (see Chapter 8).3On models with rear brake drums, remove

the drum. On models with rear disc brakes,

remove the brake caliper and mounting

bracket. Don’t disconnect the hose. Hang the

caliper out of the way with a piece of wire.

Remove the brake disc (see Chapter 9).

Working from behind, drive the wheel hub out

of the wheel bearing with a large socket or a

piece of pipe.

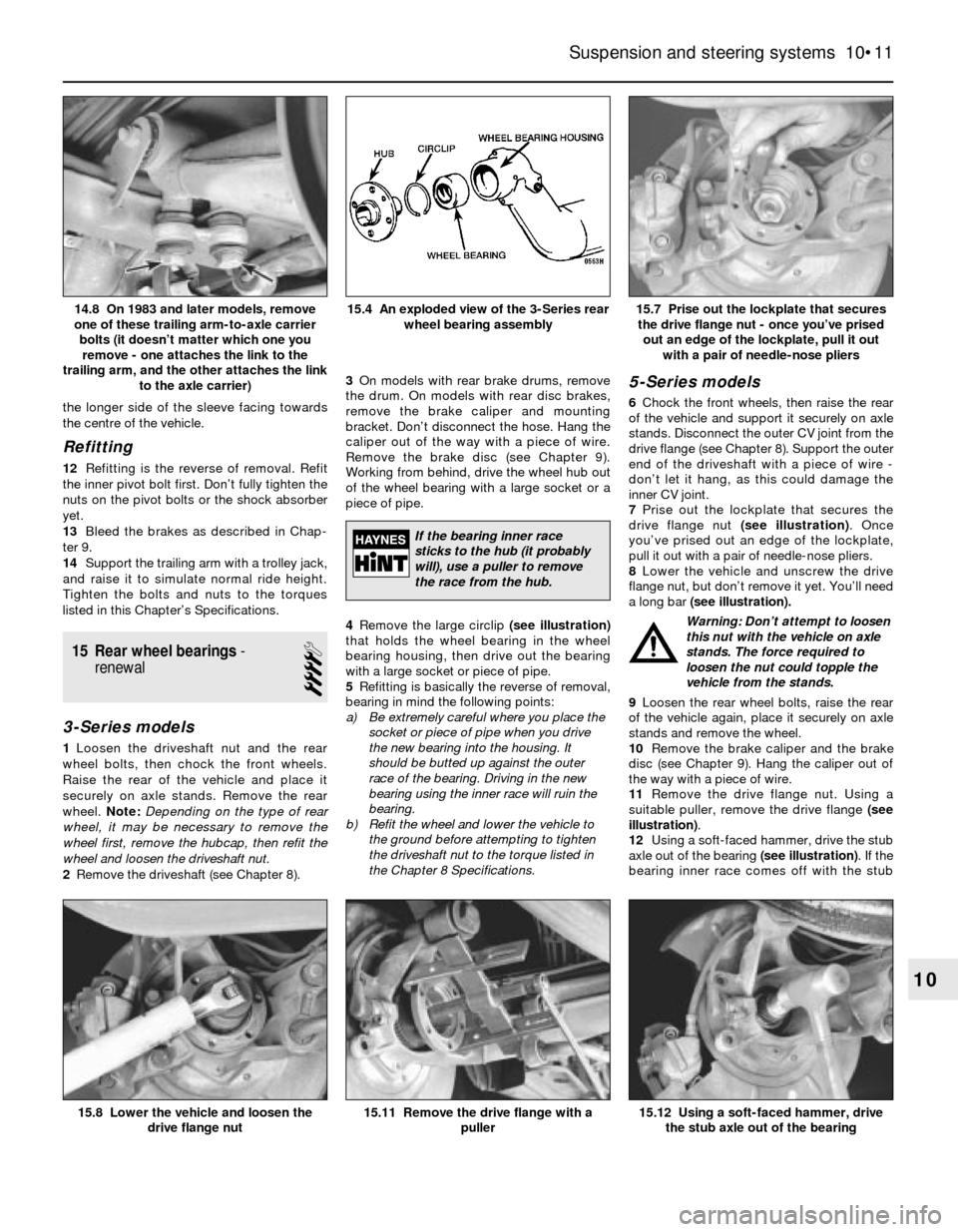

4Remove the large circlip (see illustration)

that holds the wheel bearing in the wheel

bearing housing, then drive out the bearing

with a large socket or piece of pipe.

5Refitting is basically the reverse of removal,

bearing in mind the following points:

a) Be extremely careful where you place the

socket or piece of pipe when you drive

the new bearing into the housing. It

should be butted up against the outer

race of the bearing. Driving in the new

bearing using the inner race will ruin the

bearing.

b) Refit the wheel and lower the vehicle to

the ground before attempting to tighten

the driveshaft nut to the torque listed in

the Chapter 8 Specifications.

5-Series models

6Chock the front wheels, then raise the rear

of the vehicle and support it securely on axle

stands. Disconnect the outer CV joint from the

drive flange (see Chapter 8). Support the outer

end of the driveshaft with a piece of wire -

don’t let it hang, as this could damage the

inner CV joint.

7Prise out the lockplate that secures the

drive flange nut (see illustration). Once

you’ve prised out an edge of the lockplate,

pull it out with a pair of needle-nose pliers.

8Lower the vehicle and unscrew the drive

flange nut, but don’t remove it yet. You’ll need

a long bar (see illustration).

Warning: Don’t attempt to loosen

this nut with the vehicle on axle

stands. The force required to

loosen the nut could topple the

vehicle from the stands.

9Loosen the rear wheel bolts, raise the rear

of the vehicle again, place it securely on axle

stands and remove the wheel.

10Remove the brake caliper and the brake

disc (see Chapter 9). Hang the caliper out of

the way with a piece of wire.

11Remove the drive flange nut. Using a

suitable puller, remove the drive flange (see

illustration).

12Using a soft-faced hammer, drive the stub

axle out of the bearing (see illustration). If the

bearing inner race comes off with the stub

Suspension and steering systems 10•11

15.7 Prise out the lockplate that secures

the drive flange nut - once you’ve prised

out an edge of the lockplate, pull it out

with a pair of needle-nose pliers15.4 An exploded view of the 3-Series rear

wheel bearing assembly14.8 On 1983 and later models, remove

one of these trailing arm-to-axle carrier

bolts (it doesn’t matter which one you

remove - one attaches the link to the

trailing arm, and the other attaches the link

to the axle carrier)

15.12 Using a soft-faced hammer, drive

the stub axle out of the bearing15.11 Remove the drive flange with a

puller15.8 Lower the vehicle and loosen the

drive flange nut

10

If the bearing inner race

sticks to the hub (it probably

will), use a puller to remove

the race from the hub.

Page 154 of 228

axle (it probably will), use a puller to remove

the race from the stub axle. If you can’t get

the race off with a puller, take the stub axle to

an engineering works and have it pressed off.

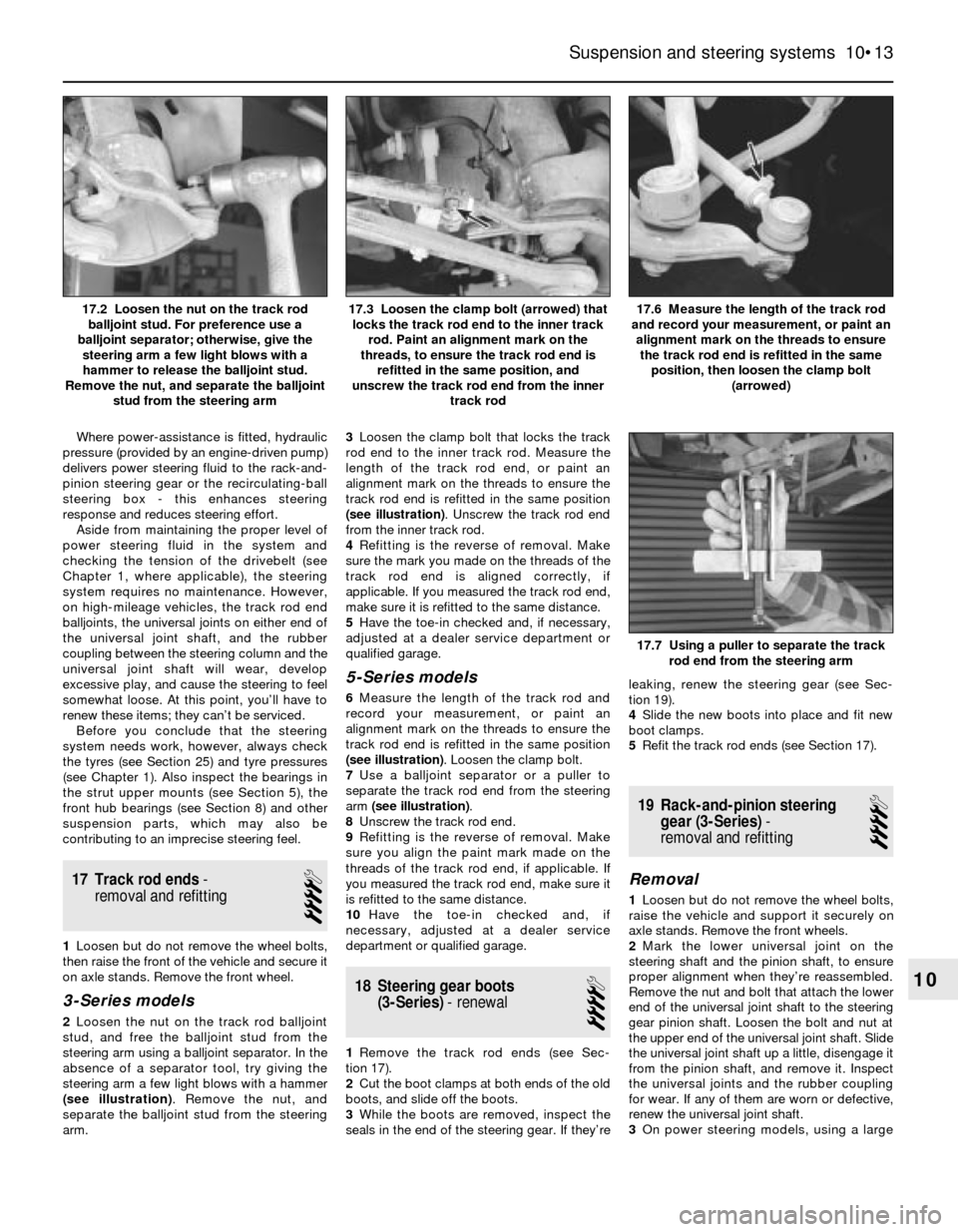

13Remove the large circlip that retains the

bearing in the bearing housing (see

illustration), then drive the bearing out of the

bearing housing with a large socket or a

suitable piece of pipe (see illustration).

14Refitting is basically a reversal of removal,

bearing in mind the following points:

a) Fit the new bearing using a large socket

or a suitable piece of pipe, with an

outside diameter the same diameter as

the outer race (see illustration). Don’t

apply force to the inner race. Make sure

the bearing is fully seated against the

back of the bore. Refit the circlip, making

sure it’s fully seated into its groove.

b) BMW dealers use special tools (Part Nos.

23 1 1300, 33 4 080 and 33 4 020) to pull

the stub axle into the bearing, because

the smooth portion between the splined

portion of the stub axle and the flange is a

press-fit, and knocks out the wheel

bearing inner race during refitting of the

stub axle. However, you can refit the stub

axle without these tools, using the old

inner race and a piece of pipe 13 mm

long by 38 mm inside diameter (seeillustration). First, insert the stub axle

through the new bearing until the

threaded portion protrudes from the inner

race. Refit the nut and tighten it until the

splined portion of the stub axle shaft

bottoms against the nut. You’ll need to

hold the stub axle flange with a lever or a

large screwdriver while tightening the nut

(see illustration). Remove the nut, refit

your piece of pipe, centred on the inner

race and refit the nut (see illustration).

Tighten the nut again until it bottoms

against the splines. Remove the nut, refit

the old inner race, refit the nut and tighten

it once more until it bottoms against the

splines. Remove the nut, remove the old

inner race, refit your piece of pipe, refit

the old inner race, refit the nut and tighten

it until it bottoms against the splines.

Remove the nut, the old race and the

pipe. Refit the drive flange, refit the nut

and tighten it securely, but don’t attempt

to tighten it to the final torque until the

vehicle is lowered to the ground.

c) Refit the wheel and lower the vehicle to

the ground before tightening the stub axle

nut to the torque listed in this Chapter’s

Specifications.

15The remainder of refitting is the reverse of

removal.

16 Steering system-

general information

On 3-Series models, the steering wheel and

steering column are connected to a rack-and-

pinion steering gear (power-assisted where

applicable) via a short universal joint shaft.

When the steering wheel is turned, the

steering column and universal joint turn a

pinion gear shaft on top of the rack. The

pinion gear teeth mesh with the gear teeth of

the rack, so the rack moves right or left in the

housing when the pinion is turned. The

movement of the rack is transmitted through

the track rods and track rod ends to the

steering arms, which are an integral part of

the strut housings.

On 5-Series models, the upper part of the

steering system is identical to a 3-Series.

Instead of a rack-and-pinion set-up, however,

these models use a power-assisted

recirculating ball steering box which steers

the front wheels via a steering linkage

consisting of a Pitman arm, an idler arm, a

centre track rod, a pair of inner track rods,

and two track rod ends.

10•12 Suspension and steering systems

15.14d When you refit the spacer, make

sure it’s centred on the inner race of the

bearing before tightening the nut15.14c Hold the stub axle flange with a

large lever while tightening the nut15.14b You can fabricate your own spacer

tool from a piece of 13 mm long, 38 mm

inside diameter pipe (left); you’ll also need

to use the old inner race (right)

15.14a To refit the new bearing, use a

large socket or a piece of pipe with an

outside diameter the same diameter as the

outer race of the bearing - don’t apply

force to the inner race - and make sure the

bearing is fully seated against the back of

its bore15.13b . . . then drive the bearing out of

the housing with a large socket or a

suitable piece of pipe15.13a Remove the large circlip that

retains the bearing in the housing . . .

Page 155 of 228

Where power-assistance is fitted, hydraulic

pressure (provided by an engine-driven pump)

delivers power steering fluid to the rack-and-

pinion steering gear or the recirculating-ball

steering box - this enhances steering

response and reduces steering effort.

Aside from maintaining the proper level of

power steering fluid in the system and

checking the tension of the drivebelt (see

Chapter 1, where applicable), the steering

system requires no maintenance. However,

on high-mileage vehicles, the track rod end

balljoints, the universal joints on either end of

the universal joint shaft, and the rubber

coupling between the steering column and the

universal joint shaft will wear, develop

excessive play, and cause the steering to feel

somewhat loose. At this point, you’ll have to

renew these items; they can’t be serviced.

Before you conclude that the steering

system needs work, however, always check

the tyres (see Section 25) and tyre pressures

(see Chapter 1). Also inspect the bearings in

the strut upper mounts (see Section 5), the

front hub bearings (see Section 8) and other

suspension parts, which may also be

contributing to an imprecise steering feel.

17 Track rod ends-

removal and refitting

4

1Loosen but do not remove the wheel bolts,

then raise the front of the vehicle and secure it

on axle stands. Remove the front wheel.

3-Series models

2Loosen the nut on the track rod balljoint

stud, and free the balljoint stud from the

steering arm using a balljoint separator. In the

absence of a separator tool, try giving the

steering arm a few light blows with a hammer

(see illustration). Remove the nut, and

separate the balljoint stud from the steering

arm.3Loosen the clamp bolt that locks the track

rod end to the inner track rod. Measure the

length of the track rod end, or paint an

alignment mark on the threads to ensure the

track rod end is refitted in the same position

(see illustration). Unscrew the track rod end

from the inner track rod.

4Refitting is the reverse of removal. Make

sure the mark you made on the threads of the

track rod end is aligned correctly, if

applicable. If you measured the track rod end,

make sure it is refitted to the same distance.

5Have the toe-in checked and, if necessary,

adjusted at a dealer service department or

qualified garage.

5-Series models

6Measure the length of the track rod and

record your measurement, or paint an

alignment mark on the threads to ensure the

track rod end is refitted in the same position

(see illustration). Loosen the clamp bolt.

7Use a balljoint separator or a puller to

separate the track rod end from the steering

arm (see illustration).

8Unscrew the track rod end.

9Refitting is the reverse of removal. Make

sure you align the paint mark made on the

threads of the track rod end, if applicable. If

you measured the track rod end, make sure it

is refitted to the same distance.

10Have the toe-in checked and, if

necessary, adjusted at a dealer service

department or qualified garage.

18 Steering gear boots

(3-Series)- renewal

4

1Remove the track rod ends (see Sec-

tion 17).

2Cut the boot clamps at both ends of the old

boots, and slide off the boots.

3While the boots are removed, inspect the

seals in the end of the steering gear. If they’releaking, renew the steering gear (see Sec-

tion 19).

4Slide the new boots into place and fit new

boot clamps.

5Refit the track rod ends (see Section 17).

19 Rack-and-pinion steering

gear (3-Series)-

removal and refitting

4

Removal

1Loosen but do not remove the wheel bolts,

raise the vehicle and support it securely on

axle stands. Remove the front wheels.

2Mark the lower universal joint on the

steering shaft and the pinion shaft, to ensure

proper alignment when they’re reassembled.

Remove the nut and bolt that attach the lower

end of the universal joint shaft to the steering

gear pinion shaft. Loosen the bolt and nut at

the upper end of the universal joint shaft. Slide

the universal joint shaft up a little, disengage it

from the pinion shaft, and remove it. Inspect

the universal joints and the rubber coupling

for wear. If any of them are worn or defective,

renew the universal joint shaft.

3On power steering models, using a large

Suspension and steering systems 10•13

17.6 Measure the length of the track rod

and record your measurement, or paint an

alignment mark on the threads to ensure

the track rod end is refitted in the same

position, then loosen the clamp bolt

(arrowed)17.3 Loosen the clamp bolt (arrowed) that

locks the track rod end to the inner track

rod. Paint an alignment mark on the

threads, to ensure the track rod end is

refitted in the same position, and

unscrew the track rod end from the inner

track rod17.2 Loosen the nut on the track rod

balljoint stud. For preference use a

balljoint separator; otherwise, give the

steering arm a few light blows with a

hammer to release the balljoint stud.

Remove the nut, and separate the balljoint

stud from the steering arm

17.7 Using a puller to separate the track

rod end from the steering arm

10

Page 156 of 228

syringe or hand pump, empty the power

steering fluid reservoir.

4On power steering models, remove the

banjo bolts and disconnect the power

steering pressure and return lines from the

steering gear. Place a container under the

lines to catch spilled fluid. Plug the lines to

prevent excessive fluid loss and

contamination. Discard the sealing washers

(new ones should be used when

reassembling).

5Disconnect the track rod ends from the

steering arms (see Section 17).

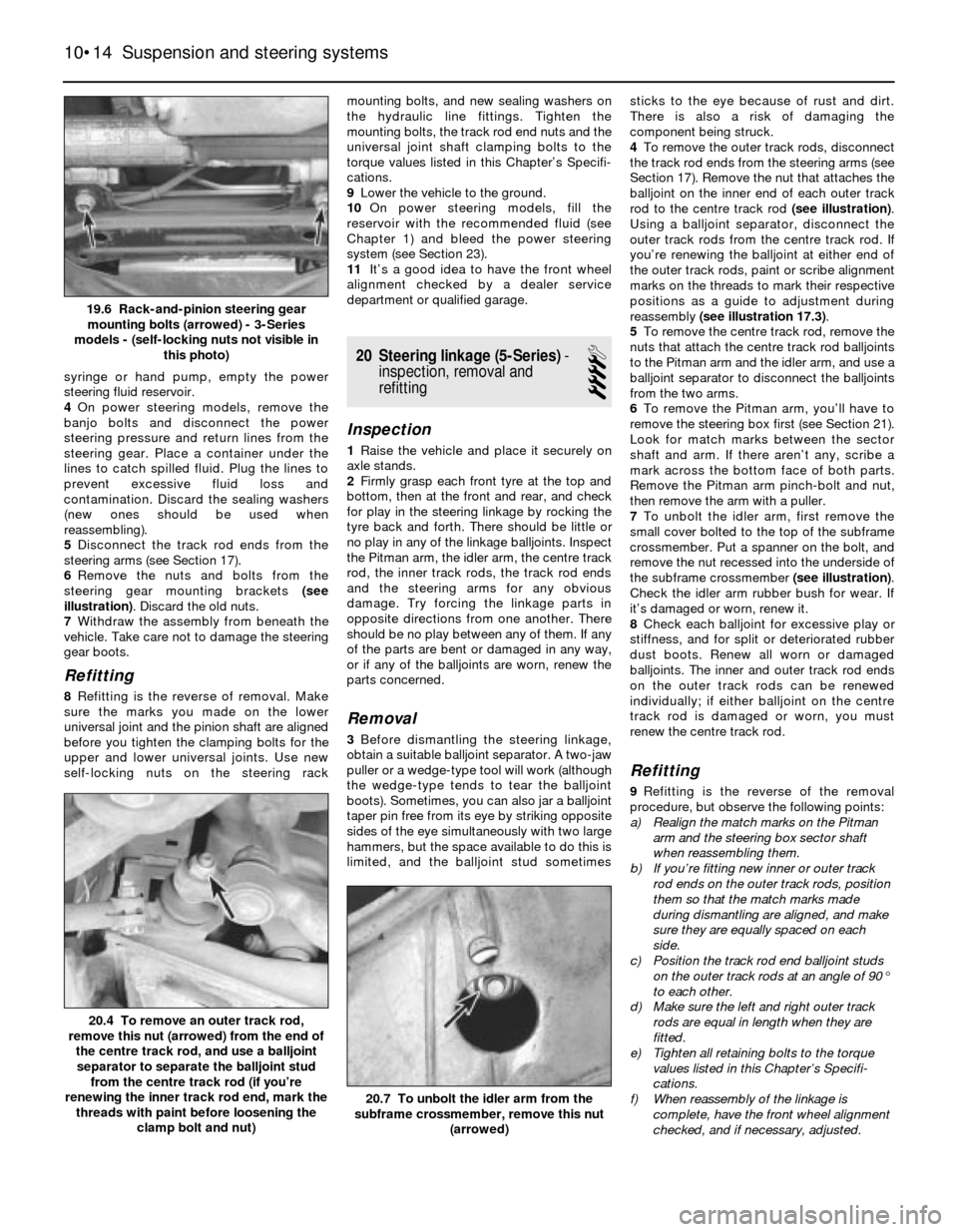

6Remove the nuts and bolts from the

steering gear mounting brackets (see

illustration). Discard the old nuts.

7Withdraw the assembly from beneath the

vehicle. Take care not to damage the steering

gear boots.

Refitting

8Refitting is the reverse of removal. Make

sure the marks you made on the lower

universal joint and the pinion shaft are aligned

before you tighten the clamping bolts for the

upper and lower universal joints. Use new

self-locking nuts on the steering rackmounting bolts, and new sealing washers on

the hydraulic line fittings. Tighten the

mounting bolts, the track rod end nuts and the

universal joint shaft clamping bolts to the

torque values listed in this Chapter’s Specifi-

cations.

9Lower the vehicle to the ground.

10On power steering models, fill the

reservoir with the recommended fluid (see

Chapter 1) and bleed the power steering

system (see Section 23).

11It’s a good idea to have the front wheel

alignment checked by a dealer service

department or qualified garage.

20 Steering linkage (5-Series)-

inspection, removal and

refitting

4

Inspection

1Raise the vehicle and place it securely on

axle stands.

2Firmly grasp each front tyre at the top and

bottom, then at the front and rear, and check

for play in the steering linkage by rocking the

tyre back and forth. There should be little or

no play in any of the linkage balljoints. Inspect

the Pitman arm, the idler arm, the centre track

rod, the inner track rods, the track rod ends

and the steering arms for any obvious

damage. Try forcing the linkage parts in

opposite directions from one another. There

should be no play between any of them. If any

of the parts are bent or damaged in any way,

or if any of the balljoints are worn, renew the

parts concerned.

Removal

3Before dismantling the steering linkage,

obtain a suitable balljoint separator. A two-jaw

puller or a wedge-type tool will work (although

the wedge-type tends to tear the balljoint

boots). Sometimes, you can also jar a balljoint

taper pin free from its eye by striking opposite

sides of the eye simultaneously with two large

hammers, but the space available to do this is

limited, and the balljoint stud sometimessticks to the eye because of rust and dirt.

There is also a risk of damaging the

component being struck.

4To remove the outer track rods, disconnect

the track rod ends from the steering arms (see

Section 17). Remove the nut that attaches the

balljoint on the inner end of each outer track

rod to the centre track rod (see illustration).

Using a balljoint separator, disconnect the

outer track rods from the centre track rod. If

you’re renewing the balljoint at either end of

the outer track rods, paint or scribe alignment

marks on the threads to mark their respective

positions as a guide to adjustment during

reassembly (see illustration 17.3).

5To remove the centre track rod, remove the

nuts that attach the centre track rod balljoints

to the Pitman arm and the idler arm, and use a

balljoint separator to disconnect the balljoints

from the two arms.

6To remove the Pitman arm, you’ll have to

remove the steering box first (see Section 21).

Look for match marks between the sector

shaft and arm. If there aren’t any, scribe a

mark across the bottom face of both parts.

Remove the Pitman arm pinch-bolt and nut,

then remove the arm with a puller.

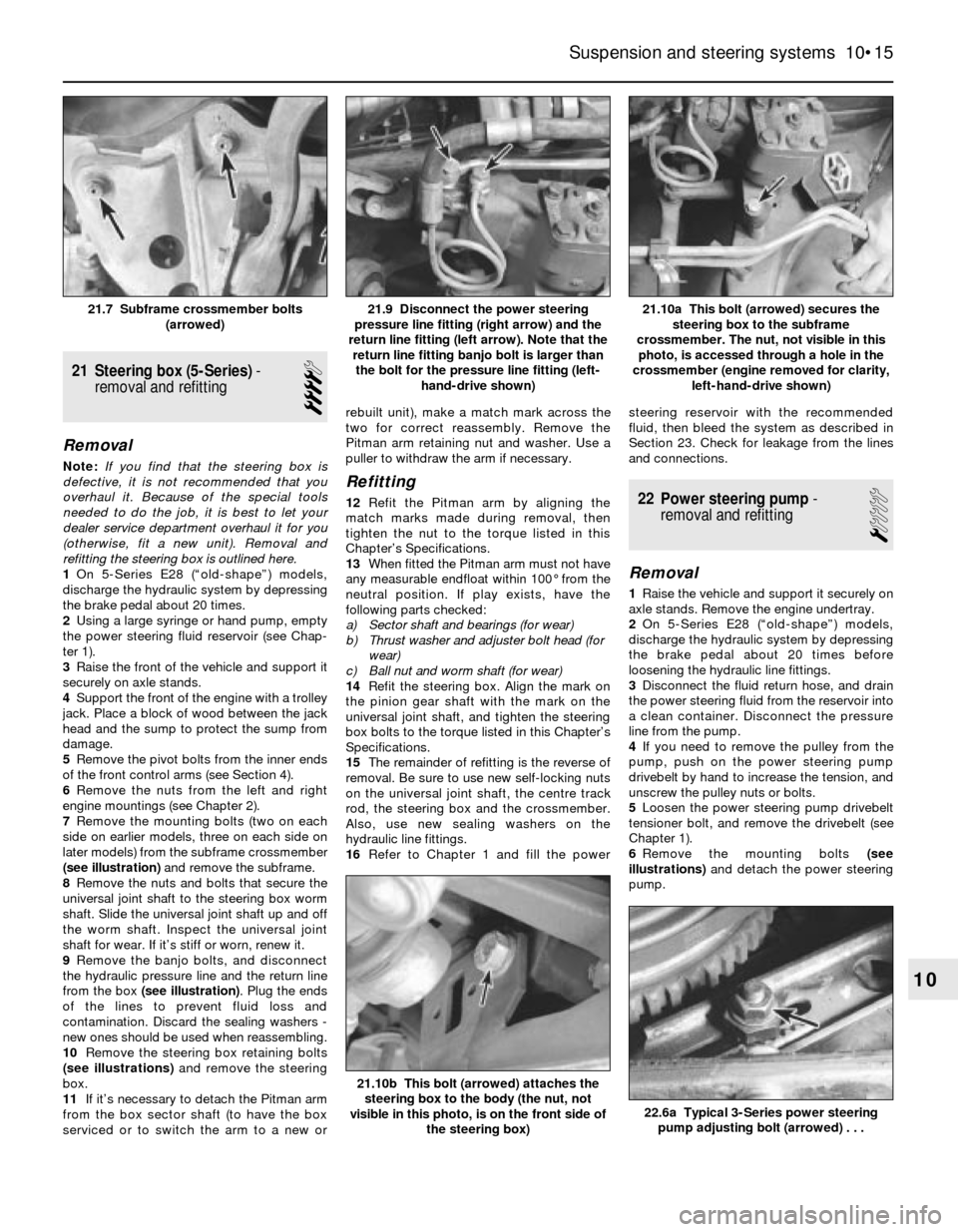

7To unbolt the idler arm, first remove the

small cover bolted to the top of the subframe

crossmember. Put a spanner on the bolt, and

remove the nut recessed into the underside of

the subframe crossmember (see illustration).

Check the idler arm rubber bush for wear. If

it’s damaged or worn, renew it.

8Check each balljoint for excessive play or

stiffness, and for split or deteriorated rubber

dust boots. Renew all worn or damaged

balljoints. The inner and outer track rod ends

on the outer track rods can be renewed

individually; if either balljoint on the centre

track rod is damaged or worn, you must

renew the centre track rod.

Refitting

9Refitting is the reverse of the removal

procedure, but observe the following points:

a) Realign the match marks on the Pitman

arm and the steering box sector shaft

when reassembling them.

b) If you’re fitting new inner or outer track

rod ends on the outer track rods, position

them so that the match marks made

during dismantling are aligned, and make

sure they are equally spaced on each

side.

c) Position the track rod end balljoint studs

on the outer track rods at an angle of 90°

to each other.

d) Make sure the left and right outer track

rods are equal in length when they are

fitted.

e) Tighten all retaining bolts to the torque

values listed in this Chapter’s Specifi-

cations.

f) When reassembly of the linkage is

complete, have the front wheel alignment

checked, and if necessary, adjusted.

10•14 Suspension and steering systems

20.7 To unbolt the idler arm from the

subframe crossmember, remove this nut

(arrowed)

20.4 To remove an outer track rod,

remove this nut (arrowed) from the end of

the centre track rod, and use a balljoint

separator to separate the balljoint stud

from the centre track rod (if you’re

renewing the inner track rod end, mark the

threads with paint before loosening the

clamp bolt and nut)

19.6 Rack-and-pinion steering gear

mounting bolts (arrowed) - 3-Series

models - (self-locking nuts not visible in

this photo)

Page 157 of 228

21 Steering box (5-Series)-

removal and refitting

4

Removal

Note:If you find that the steering box is

defective, it is not recommended that you

overhaul it. Because of the special tools

needed to do the job, it is best to let your

dealer service department overhaul it for you

(otherwise, fit a new unit). Removal and

refitting the steering box is outlined here.

1On 5-Series E28 (“old-shape”) models,

discharge the hydraulic system by depressing

the brake pedal about 20 times.

2Using a large syringe or hand pump, empty

the power steering fluid reservoir (see Chap-

ter 1).

3Raise the front of the vehicle and support it

securely on axle stands.

4Support the front of the engine with a trolley

jack. Place a block of wood between the jack

head and the sump to protect the sump from

damage.

5Remove the pivot bolts from the inner ends

of the front control arms (see Section 4).

6Remove the nuts from the left and right

engine mountings (see Chapter 2).

7Remove the mounting bolts (two on each

side on earlier models, three on each side on

later models) from the subframe crossmember

(see illustration)and remove the subframe.

8Remove the nuts and bolts that secure the

universal joint shaft to the steering box worm

shaft. Slide the universal joint shaft up and off

the worm shaft. Inspect the universal joint

shaft for wear. If it’s stiff or worn, renew it.

9Remove the banjo bolts, and disconnect

the hydraulic pressure line and the return line

from the box (see illustration). Plug the ends

of the lines to prevent fluid loss and

contamination. Discard the sealing washers -

new ones should be used when reassembling.

10Remove the steering box retaining bolts

(see illustrations)and remove the steering

box.

11If it’s necessary to detach the Pitman arm

from the box sector shaft (to have the box

serviced or to switch the arm to a new orrebuilt unit), make a match mark across the

two for correct reassembly. Remove the

Pitman arm retaining nut and washer. Use a

puller to withdraw the arm if necessary.

Refitting

12Refit the Pitman arm by aligning the

match marks made during removal, then

tighten the nut to the torque listed in this

Chapter’s Specifications.

13When fitted the Pitman arm must not have

any measurable endfloat within 100° from the

neutral position. If play exists, have the

following parts checked:

a) Sector shaft and bearings (for wear)

b) Thrust washer and adjuster bolt head (for

wear)

c) Ball nut and worm shaft (for wear)

14Refit the steering box. Align the mark on

the pinion gear shaft with the mark on the

universal joint shaft, and tighten the steering

box bolts to the torque listed in this Chapter’s

Specifications.

15The remainder of refitting is the reverse of

removal. Be sure to use new self-locking nuts

on the universal joint shaft, the centre track

rod, the steering box and the crossmember.

Also, use new sealing washers on the

hydraulic line fittings.

16Refer to Chapter 1 and fill the powersteering reservoir with the recommended

fluid, then bleed the system as described in

Section 23. Check for leakage from the lines

and connections.22 Power steering pump-

removal and refitting

1

Removal

1Raise the vehicle and support it securely on

axle stands. Remove the engine undertray.

2On 5-Series E28 (“old-shape”) models,

discharge the hydraulic system by depressing

the brake pedal about 20 times before

loosening the hydraulic line fittings.

3Disconnect the fluid return hose, and drain

the power steering fluid from the reservoir into

a clean container. Disconnect the pressure

line from the pump.

4If you need to remove the pulley from the

pump, push on the power steering pump

drivebelt by hand to increase the tension, and

unscrew the pulley nuts or bolts.

5Loosen the power steering pump drivebelt

tensioner bolt, and remove the drivebelt (see

Chapter 1).

6Remove the mounting bolts (see

illustrations)and detach the power steering

pump.

Suspension and steering systems 10•15

21.10a This bolt (arrowed) secures the

steering box to the subframe

crossmember. The nut, not visible in this

photo, is accessed through a hole in the

crossmember (engine removed for clarity,

left-hand-drive shown)21.9 Disconnect the power steering

pressure line fitting (right arrow) and the

return line fitting (left arrow). Note that the

return line fitting banjo bolt is larger than

the bolt for the pressure line fitting (left-

hand-drive shown)21.7 Subframe crossmember bolts

(arrowed)

22.6a Typical 3-Series power steering

pump adjusting bolt (arrowed) . . .

21.10b This bolt (arrowed) attaches the

steering box to the body (the nut, not

visible in this photo, is on the front side of

the steering box)

10

Page 159 of 228

26 Wheel alignment-

general information

4

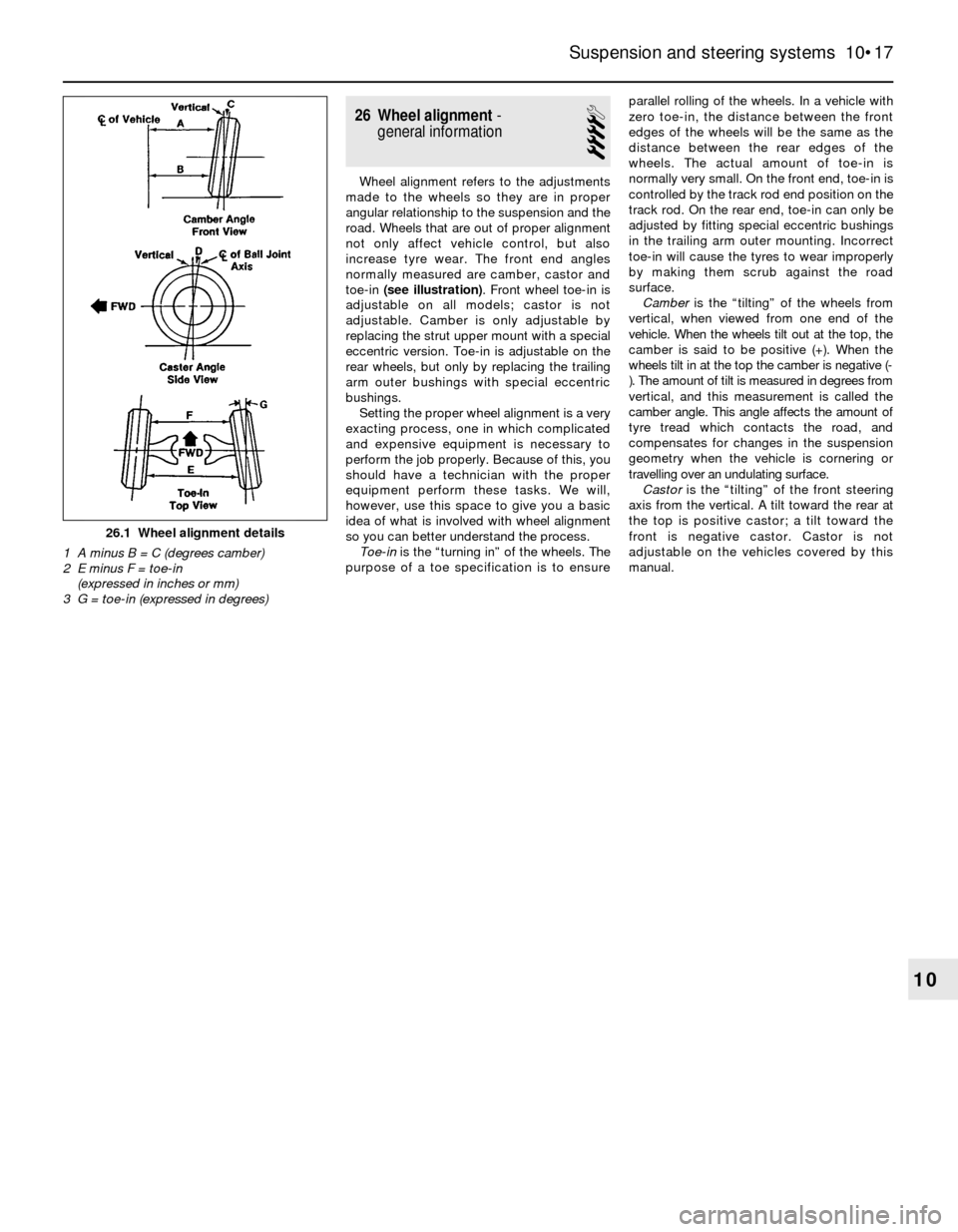

Wheel alignment refers to the adjustments

made to the wheels so they are in proper

angular relationship to the suspension and the

road. Wheels that are out of proper alignment

not only affect vehicle control, but also

increase tyre wear. The front end angles

normally measured are camber, castor and

toe-in (see illustration). Front wheel toe-in is

adjustable on all models; castor is not

adjustable. Camber is only adjustable by

replacing the strut upper mount with a special

eccentric version. Toe-in is adjustable on the

rear wheels, but only by replacing the trailing

arm outer bushings with special eccentric

bushings.

Setting the proper wheel alignment is a very

exacting process, one in which complicated

and expensive equipment is necessary to

perform the job properly. Because of this, you

should have a technician with the proper

equipment perform these tasks. We will,

however, use this space to give you a basic

idea of what is involved with wheel alignment

so you can better understand the process.

Toe-inis the “turning in” of the wheels. The

purpose of a toe specification is to ensureparallel rolling of the wheels. In a vehicle with

zero toe-in, the distance between the front

edges of the wheels will be the same as the

distance between the rear edges of the

wheels. The actual amount of toe-in is

normally very small. On the front end, toe-in is

controlled by the track rod end position on the

track rod. On the rear end, toe-in can only be

adjusted by fitting special eccentric bushings

in the trailing arm outer mounting. Incorrect

toe-in will cause the tyres to wear improperly

by making them scrub against the road

surface.

Camberis the “tilting” of the wheels from

vertical, when viewed from one end of the

vehicle. When the wheels tilt out at the top, the

camber is said to be positive (+). When the

wheels tilt in at the top the camber is negative (-

). The amount of tilt is measured in degrees from

vertical, and this measurement is called the

camber angle. This angle affects the amount of

tyre tread which contacts the road, and

compensates for changes in the suspension

geometry when the vehicle is cornering or

travelling over an undulating surface.

Castoris the “tilting” of the front steering

axis from the vertical. A tilt toward the rear at

the top is positive castor; a tilt toward the

front is negative castor. Castor is not

adjustable on the vehicles covered by this

manual.

Suspension and steering systems 10•17

10

26.1 Wheel alignment details

1 A minus B = C (degrees camber)

2 E minus F = toe-in

(expressed in inches or mm)

3 G = toe-in (expressed in degrees)

Page 168 of 228

19 Steering column shrouds -

removal and refitting

1

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you have

the correct activation code

before disconnecting the battery, Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

Removal

1Disconnect the battery negative cable.

2Remove the steering wheel (Chapter 10).

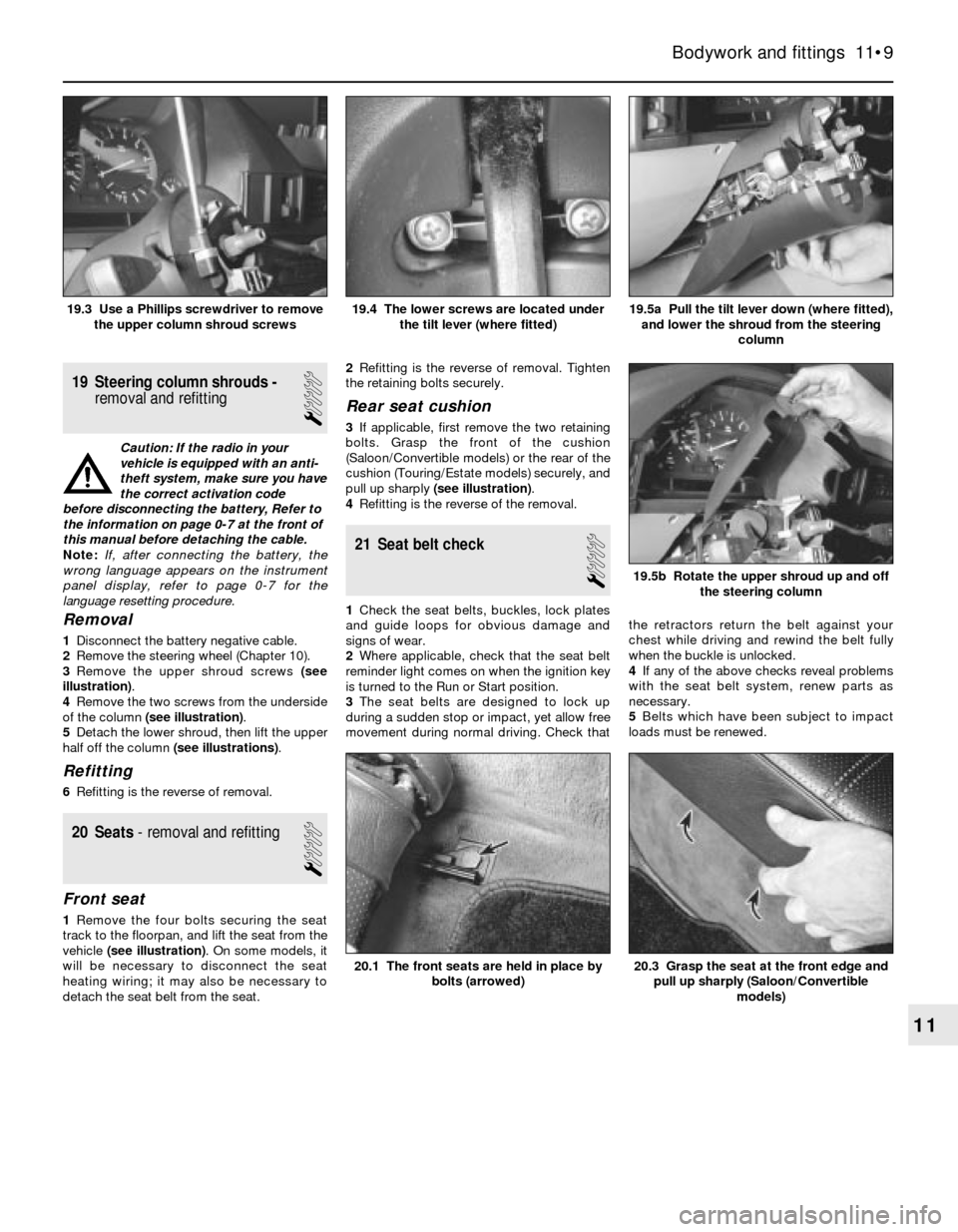

3Remove the upper shroud screws (see

illustration).

4Remove the two screws from the underside

of the column (see illustration).

5Detach the lower shroud, then lift the upper

half off the column (see illustrations).

Refitting

6Refitting is the reverse of removal.

20 Seats- removal and refitting

1

Front seat

1Remove the four bolts securing the seat

track to the floorpan, and lift the seat from the

vehicle (see illustration). On some models, it

will be necessary to disconnect the seat

heating wiring; it may also be necessary to

detach the seat belt from the seat.2Refitting is the reverse of removal. Tighten

the retaining bolts securely.

Rear seat cushion

3If applicable, first remove the two retaining

bolts. Grasp the front of the cushion

(Saloon/Convertible models) or the rear of the

cushion (Touring/Estate models) securely, and

pull up sharply (see illustration).

4Refitting is the reverse of the removal.

21 Seat belt check

1

1Check the seat belts, buckles, lock plates

and guide loops for obvious damage and

signs of wear.

2Where applicable, check that the seat belt

reminder light comes on when the ignition key

is turned to the Run or Start position.

3The seat belts are designed to lock up

during a sudden stop or impact, yet allow free

movement during normal driving. Check thatthe retractors return the belt against your

chest while driving and rewind the belt fully

when the buckle is unlocked.

4If any of the above checks reveal problems

with the seat belt system, renew parts as

necessary.

5Belts which have been subject to impact

loads must be renewed.

Bodywork and fittings 11•9

19.5a Pull the tilt lever down (where fitted),

and lower the shroud from the steering

column19.4 The lower screws are located under

the tilt lever (where fitted)19.3 Use a Phillips screwdriver to remove

the upper column shroud screws

20.3 Grasp the seat at the front edge and

pull up sharply (Saloon/Convertible

models)20.1 The front seats are held in place by

bolts (arrowed)

19.5b Rotate the upper shroud up and off

the steering column

11

Page 176 of 228

12Refitting is a reversal of removal. When

fitting the motor, if necessary plug in the

connector and run the motor briefly until it is

in the “neutral” (wiper parked) position.

17 Heated rear window-

check and repair

2

1The heated rear window consists of a

number of horizontal elements on the glass

surface.

2Small breaks in the element can be repaired

without removing the rear window.

Check

3Switch on the ignition and the heated rear

window.

4Place the positive lead of a voltmeter to the

heater element nearest to the incoming power

source.

5Wrap a piece of aluminium foil around the

negative lead of the voltmeter on the positive

side of the suspected broken element, and

slide it slowly towards the negative side.

Watch the voltmeter needle - when it moves

from zero, you have located the break.

Repair

6Repair the break in the line using a repair kit

recommended specifically for this purpose,

such as BMW repair kit No. 81 22 9 (or

equivalent). Included in this kit is plastic

conductive epoxy. The following paragraphs

give general instructions for this type of repair;

follow the instructions supplied with the repair

kit if they are different.

7Prior to repairing a break, switch off the

circuit and allow it to cool down for a few

minutes.

8Lightly buff the element area with fine steel

wool, then clean it thoroughly.

9Use masking tape to mask off the area of

repair, leaving a slit to which the epoxy can be

applied.

10Mix the epoxy thoroughly, according to

the instructions on the package.

11Apply the epoxy material to the slit in the

masking tape, overlapping the undamaged

area about 20 mm on each end.12Allow the repair to cure for 24 hours

before removing the tape and using the

heated rear window.

18 Supplemental Restraint

System (SRS)- general

information

Later models are equipped with a

Supplemental Restraint System (SRS),

incorporating an airbag. This system is

designed to protect the driver from serious

injury in the event of a head-on or frontal

collision. It consists of an airbag module in the

centre of the steering wheel, two crash

sensors mounted on the front inner wing

panels, and a crash safety switch located

inside the passenger compartment.

The airbag module contains a housing

incorporating the airbag and the inflator units.

The inflator assembly is mounted on the back

of the housing over a hole through which gas

is expelled, inflating the bag almost instanta-

neously when an electrical signal is sent from

the system. This signal is carried by a wire

which is specially wound with several turns,

so the signal will be transmitted regardless of

the steering wheel position.

The SRS system has three sensors: two at

the front, mounted on the inner wing panels

(see illustration), and a safety switch located

inside the passenger compartment. The crash

sensors are basically pressure-sensitive

switches, which complete an electrical circuit

during an impact of sufficient force. The

electrical signal from the crash sensors is sent

to a third sensor, which then completes the

circuit and inflates the airbag.

The module containing the safety switch

monitors the system operation. It checks the

system every time the vehicle is started,

causing the AIRBAG warning light to come on,

then go out if the system is operating

correctly. If there is a fault in the system, the

light will stay on. If the AIRBAG warning light

does stay on, or if it comes on while driving,

take the vehicle to your dealer immediately.

19 Cruise control system-

description and check

1

The cruise control system maintains vehicle

speed using a vacuum-actuated servo motor

located in the engine compartment, which is

connected to the throttle linkage by a cable.

The system consists of the servo motor,

clutch switch, brake switch, control switches,

a relay, and associated vacuum hoses.

Because of the complexity of the cruise

control system, repair should be left to a

dealer service department. However, it is

possible for the home mechanic to make

simple checks of the wiring and vacuum

connections for minor faults which can be

easily repaired. These include:

a) Inspect the cruise control actuating switches

for broken wires and loose connections.

b) Check the cruise control fuse.

c) The cruise control system is operated by

vacuum, so it’s critical that all vacuum

switches, hoses and connections are

secure. Check the hoses in the engine

compartment for loose connections,

cracks, or obvious vacuum leaks.

20 Central locking system-

description and check

2

The central door locking system operates

the door lock actuators mounted in each

door. The system consists of the switches,

actuators and associated wiring. Diagnosis is

limited to simple checks of the wiring

connections and actuators for minor faults

which can be easily repaired. These include:

a) Check the system fuse and/or circuit

breaker (where applicable).

b) Check the switch wires for damage and

loose connections. Check the switches

for continuity.

c) Remove the door trim panel(s), and check

the actuator wiring connections to see if

they’re loose or damaged. Inspect the

actuator rods to make sure they aren’t

12•8 Body electrical systems

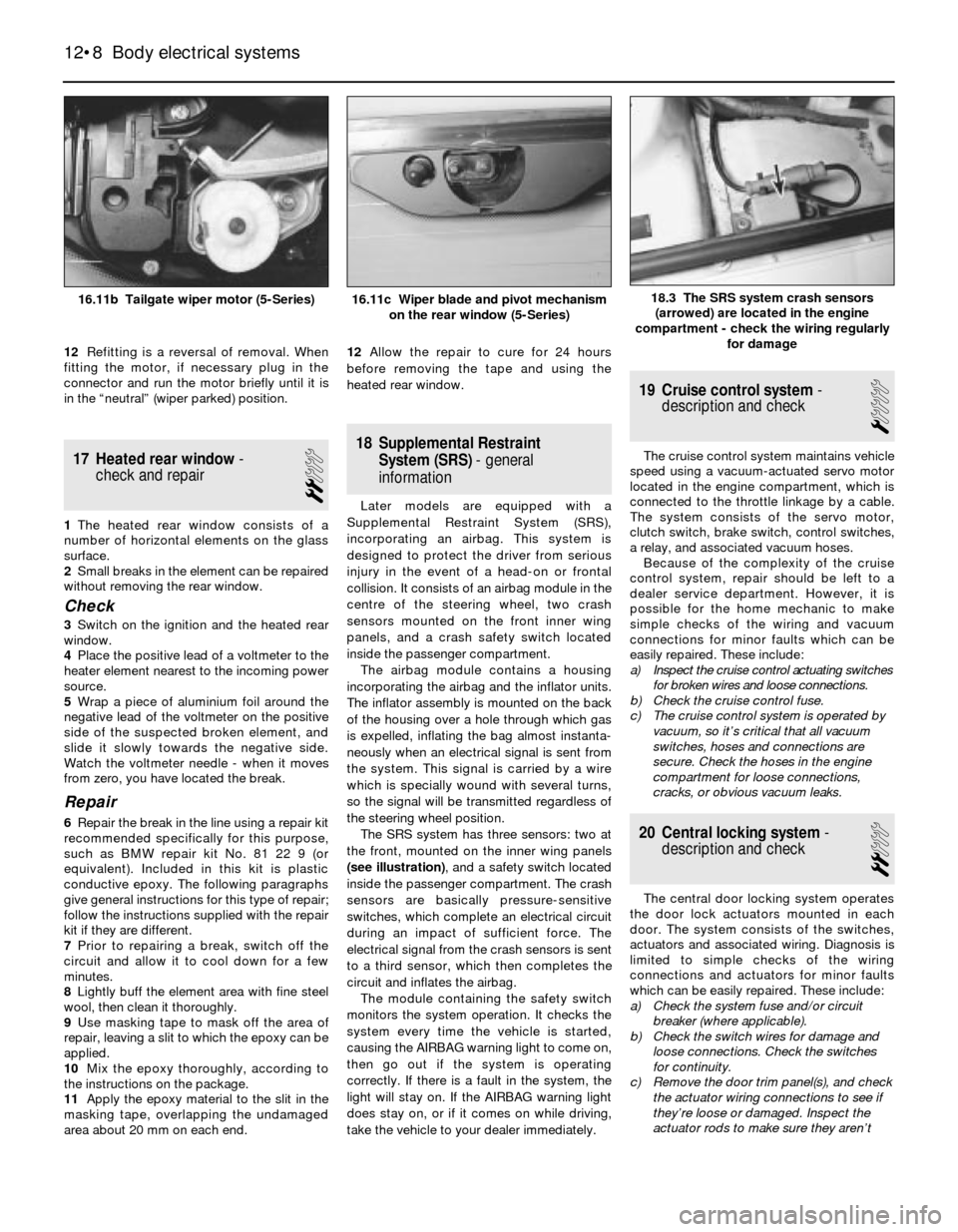

18.3 The SRS system crash sensors

(arrowed) are located in the engine

compartment - check the wiring regularly

for damage16.11b Tailgate wiper motor (5-Series)16.11c Wiper blade and pivot mechanism

on the rear window (5-Series)

Page 202 of 228

REF•1

REF

MOT Test Checks

This is a guide to getting your vehicle through the MOT test.

Obviously it will not be possible to examine the vehicle to the same

standard as the professional MOT tester. However, working through

the following checks will enable you to identify any problem areas

before submitting the vehicle for the test.

Where a testable component is in borderline condition, the tester

has discretion in deciding whether to pass or fail it. The basis of such

discretion is whether the tester would be happy for a close relative or

friend to use the vehicle with the component in that condition. If the

vehicle presented is clean and evidently well cared for, the tester may

be more inclined to pass a borderline component than if the vehicle is

scruffy and apparently neglected.

It has only been possible to summarise the test requirements here,

based on the regulations in force at the time of printing. Test standards

are becoming increasingly stringent, although there are some

exemptions for older vehicles. For full details obtain a copy of the Haynes

publication Pass the MOT! (available from stockists of Haynes manuals).

An assistant will be needed to help carry out some of these checks.

The checks have been sub-divided into four categories, as follows:

HandbrakeMTest the operation of the handbrake.

Excessive travel (too many clicks) indicates

incorrect brake or cable adjustment.

MCheck that the handbrake cannot be

released by tapping the lever sideways. Check

the security of the lever mountings.

Footbrake

MDepress the brake pedal and check that it

does not creep down to the floor, indicating a

master cylinder fault. Release the pedal, wait

a few seconds, then depress it again. If the

pedal travels nearly to the floor before firm

resistance is felt, brake adjustment or repair is

necessary. If the pedal feels spongy, there is

air in the hydraulic system which must be

removed by bleeding.MCheck that the brake pedal is secure and in

good condition. Check also for signs of fluid

leaks on the pedal, floor or carpets, which

would indicate failed seals in the brake master

cylinder.

MCheck the servo unit (when applicable) by

operating the brake pedal several times, then

keeping the pedal depressed and starting the

engine. As the engine starts, the pedal will

move down slightly. If not, the vacuum hose or

the servo itself may be faulty.

Steering wheel and column

MExamine the steering wheel for fractures or

looseness of the hub, spokes or rim.

MMove the steering wheel from side to side

and then up and down. Check that the

steering wheel is not loose on the column,

indicating wear or a loose retaining nut.

Continue moving the steering wheel as before,

but also turn it slightly from left to right.

MCheck that the steering wheel is not loose

on the column, and that there is no abnormalmovement of the steering wheel, indicating

wear in the column support bearings or

couplings.

Windscreen and mirrors

MThe windscreen must be free of cracks or

other significant damage within the driver’s

field of view. (Small stone chips are

acceptable.) Rear view mirrors must be

secure, intact, and capable of being adjusted.

1Checks carried out

FROM THE DRIVER’S SEAT

1Checks carried out

FROM THE DRIVER’S

SEAT2Checks carried out

WITH THE VEHICLE

ON THE GROUND3Checks carried out

WITH THE VEHICLE

RAISED AND THE

WHEELS FREE TO

TURN4Checks carried out on

YOUR VEHICLE’S

EXHAUST EMISSION

SYSTEM