heating BMW 3 SERIES 1986 E30 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1986, Model line: 3 SERIES, Model: BMW 3 SERIES 1986 E30Pages: 228, PDF Size: 7.04 MB

Page 85 of 228

4If a new sender unit is to be fitted, make

sure the engine is completely cool. There will

be some coolant loss when the unit is

unscrewed, so be prepared to catch it, or

have the new unit ready to fit immediately the

old one is removed. Disconnect the wiring,

then unscrew the old unit from the engine,

and fit the new one. Use sealant on the

threads. Reconnect the wiring, and check the

coolant level on completion.

9 Heater and air conditioning

blower motor- removal,

testing and refitting

1

Removal

Note: The 3-Series models covered by this

manual have always used a single blower

motor for ventilation, heating and air

conditioning. “Old-shape” (E28) 5-Series

models use two separate blower motors: one

for ventilation and heating, and another for air

conditioning. “New-shape” (E34) 5-Series

models have a single blower motor, like the 3-

Series. The removal and refitting of the single

blower motor, and the old-shape 5-Series

vent/heat motor, is described below. The

removal and refitting of the old-shape 5-Series

air conditioning blower motor is described in

Section 14 of this Chapter.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you have

the correct activation code

before disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

1Disconnect the battery negative cable.

2The blower motor is located behind the

bulkhead, under an access panel. Remove the

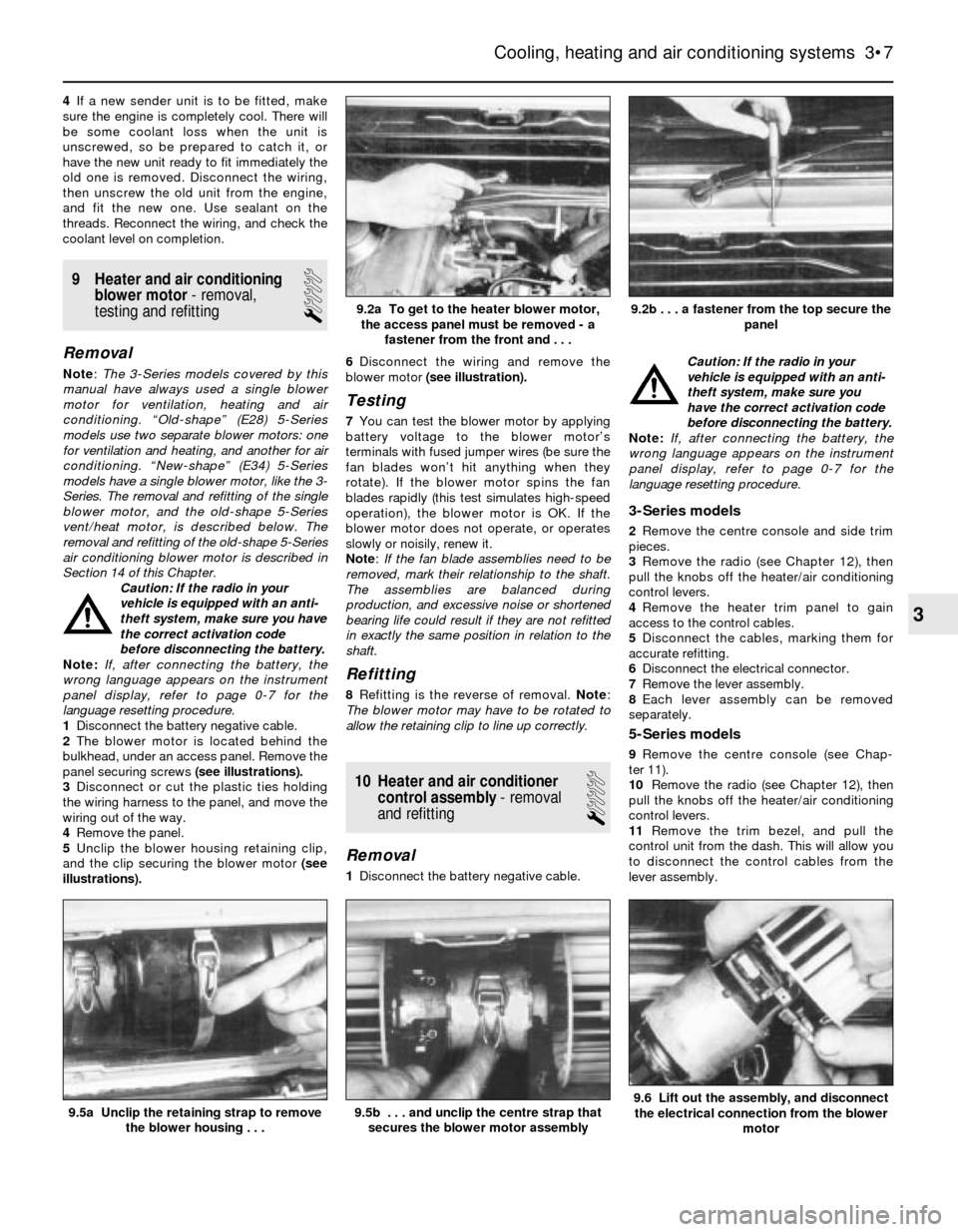

panel securing screws (see illustrations).

3Disconnect or cut the plastic ties holding

the wiring harness to the panel, and move the

wiring out of the way.

4Remove the panel.

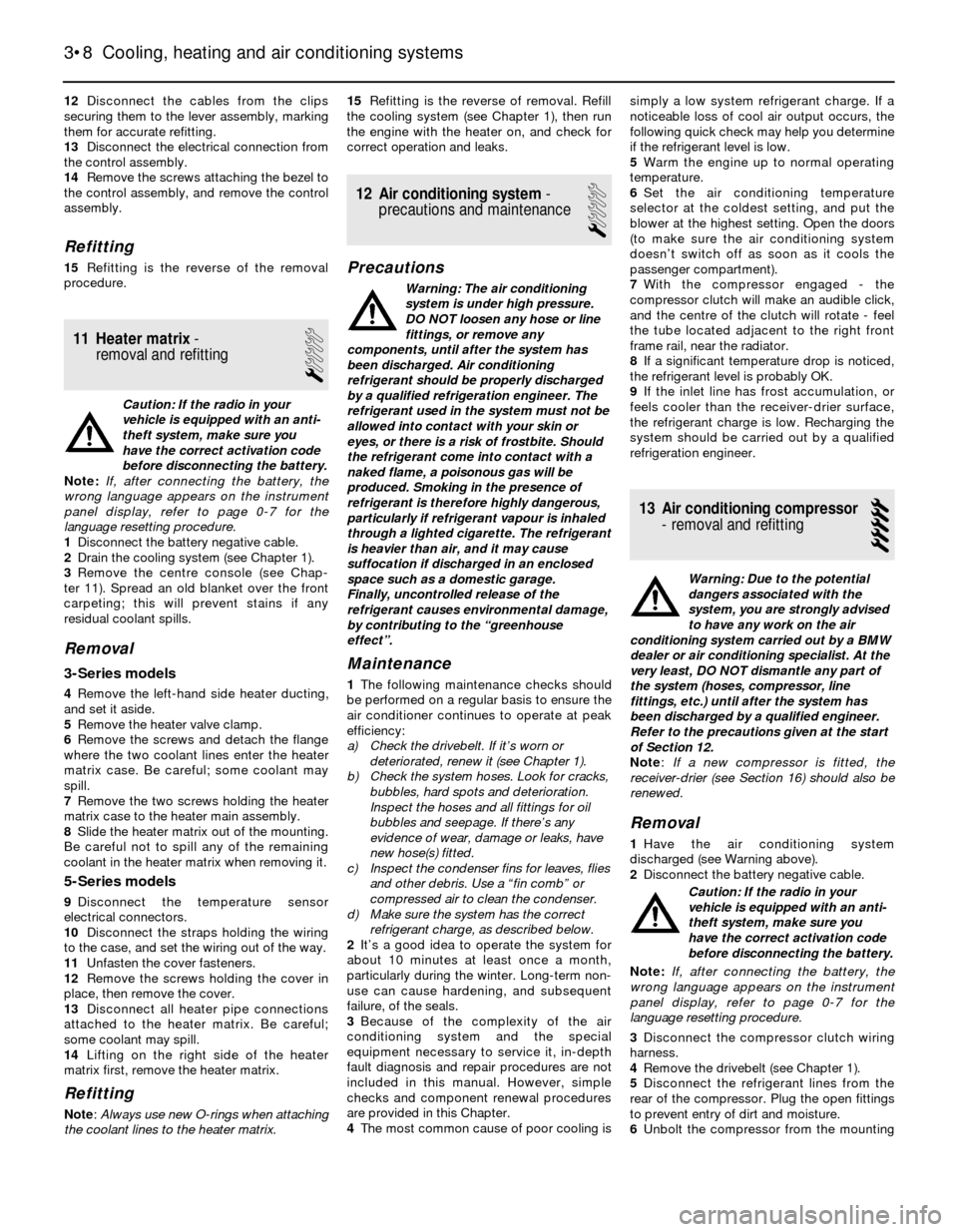

5Unclip the blower housing retaining clip,

and the clip securing the blower motor (see

illustrations).6Disconnect the wiring and remove the

blower motor (see illustration).

Testing

7You can test the blower motor by applying

battery voltage to the blower motor’s

terminals with fused jumper wires (be sure the

fan blades won’t hit anything when they

rotate). If the blower motor spins the fan

blades rapidly (this test simulates high-speed

operation), the blower motor is OK. If the

blower motor does not operate, or operates

slowly or noisily, renew it.

Note: If the fan blade assemblies need to be

removed, mark their relationship to the shaft.

The assemblies are balanced during

production, and excessive noise or shortened

bearing life could result if they are not refitted

in exactly the same position in relation to the

shaft.

Refitting

8Refitting is the reverse of removal. Note:

The blower motor may have to be rotated to

allow the retaining clip to line up correctly.

10 Heater and air conditioner

control assembly- removal

and refitting

1

Removal

1Disconnect the battery negative cable. Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

3-Series models

2Remove the centre console and side trim

pieces.

3Remove the radio (see Chapter 12), then

pull the knobs off the heater/air conditioning

control levers.

4Remove the heater trim panel to gain

access to the control cables.

5Disconnect the cables, marking them for

accurate refitting.

6Disconnect the electrical connector.

7Remove the lever assembly.

8Each lever assembly can be removed

separately.

5-Series models

9Remove the centre console (see Chap-

ter 11).

10Remove the radio (see Chapter 12), then

pull the knobs off the heater/air conditioning

control levers.

11Remove the trim bezel, and pull the

control unit from the dash. This will allow you

to disconnect the control cables from the

lever assembly.

Cooling, heating and air conditioning systems 3•7

9.5a Unclip the retaining strap to remove

the blower housing . . .

9.2b . . . a fastener from the top secure the

panel9.2a To get to the heater blower motor,

the access panel must be removed - a

fastener from the front and . . .

9.6 Lift out the assembly, and disconnect

the electrical connection from the blower

motor9.5b . . . and unclip the centre strap that

secures the blower motor assembly

3

Page 86 of 228

12Disconnect the cables from the clips

securing them to the lever assembly, marking

them for accurate refitting.

13Disconnect the electrical connection from

the control assembly.

14Remove the screws attaching the bezel to

the control assembly, and remove the control

assembly.

Refitting

15Refitting is the reverse of the removal

procedure.

11 Heater matrix-

removal and refitting

1

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

1Disconnect the battery negative cable.

2Drain the cooling system (see Chapter 1).

3Remove the centre console (see Chap-

ter 11). Spread an old blanket over the front

carpeting; this will prevent stains if any

residual coolant spills.

Removal

3-Series models

4Remove the left-hand side heater ducting,

and set it aside.

5Remove the heater valve clamp.

6Remove the screws and detach the flange

where the two coolant lines enter the heater

matrix case. Be careful; some coolant may

spill.

7Remove the two screws holding the heater

matrix case to the heater main assembly.

8Slide the heater matrix out of the mounting.

Be careful not to spill any of the remaining

coolant in the heater matrix when removing it.

5-Series models

9Disconnect the temperature sensor

electrical connectors.

10Disconnect the straps holding the wiring

to the case, and set the wiring out of the way.

11Unfasten the cover fasteners.

12Remove the screws holding the cover in

place, then remove the cover.

13Disconnect all heater pipe connections

attached to the heater matrix. Be careful;

some coolant may spill.

14Lifting on the right side of the heater

matrix first, remove the heater matrix.

Refitting

Note: Always use new O-rings when attaching

the coolant lines to the heater matrix.15Refitting is the reverse of removal. Refill

the cooling system (see Chapter 1), then run

the engine with the heater on, and check for

correct operation and leaks.

12 Air conditioning system-

precautions and maintenance

1

Precautions

Warning: The air conditioning

system is under high pressure.

DO NOT loosen any hose or line

fittings, or remove any

components, until after the system has

been discharged. Air conditioning

refrigerant should be properly discharged

by a qualified refrigeration engineer. The

refrigerant used in the system must not be

allowed into contact with your skin or

eyes, or there is a risk of frostbite. Should

the refrigerant come into contact with a

naked flame, a poisonous gas will be

produced. Smoking in the presence of

refrigerant is therefore highly dangerous,

particularly if refrigerant vapour is inhaled

through a lighted cigarette. The refrigerant

is heavier than air, and it may cause

suffocation if discharged in an enclosed

space such as a domestic garage.

Finally, uncontrolled release of the

refrigerant causes environmental damage,

by contributing to the “greenhouse

effect”.

Maintenance

1The following maintenance checks should

be performed on a regular basis to ensure the

air conditioner continues to operate at peak

efficiency:

a) Check the drivebelt. If it’s worn or

deteriorated, renew it (see Chapter 1).

b) Check the system hoses. Look for cracks,

bubbles, hard spots and deterioration.

Inspect the hoses and all fittings for oil

bubbles and seepage. If there’s any

evidence of wear, damage or leaks, have

new hose(s) fitted.

c) Inspect the condenser fins for leaves, flies

and other debris. Use a “fin comb” or

compressed air to clean the condenser.

d) Make sure the system has the correct

refrigerant charge, as described below.

2It’s a good idea to operate the system for

about 10 minutes at least once a month,

particularly during the winter. Long-term non-

use can cause hardening, and subsequent

failure, of the seals.

3Because of the complexity of the air

conditioning system and the special

equipment necessary to service it, in-depth

fault diagnosis and repair procedures are not

included in this manual. However, simple

checks and component renewal procedures

are provided in this Chapter.

4The most common cause of poor cooling issimply a low system refrigerant charge. If a

noticeable loss of cool air output occurs, the

following quick check may help you determine

if the refrigerant level is low.

5Warm the engine up to normal operating

temperature.

6Set the air conditioning temperature

selector at the coldest setting, and put the

blower at the highest setting. Open the doors

(to make sure the air conditioning system

doesn’t switch off as soon as it cools the

passenger compartment).

7With the compressor engaged - the

compressor clutch will make an audible click,

and the centre of the clutch will rotate - feel

the tube located adjacent to the right front

frame rail, near the radiator.

8If a significant temperature drop is noticed,

the refrigerant level is probably OK.

9If the inlet line has frost accumulation, or

feels cooler than the receiver-drier surface,

the refrigerant charge is low. Recharging the

system should be carried out by a qualified

refrigeration engineer.

13 Air conditioning compressor

- removal and refitting

5

Warning: Due to the potential

dangers associated with the

system, you are strongly advised

to have any work on the air

conditioning system carried out by a BMW

dealer or air conditioning specialist. At the

very least, DO NOT dismantle any part of

the system (hoses, compressor, line

fittings, etc.) until after the system has

been discharged by a qualified engineer.

Refer to the precautions given at the start

of Section 12.

Note: If a new compressor is fitted, the

receiver-drier (see Section 16) should also be

renewed.

Removal

1Have the air conditioning system

discharged (see Warning above).

2Disconnect the battery negative cable.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

3Disconnect the compressor clutch wiring

harness.

4Remove the drivebelt (see Chapter 1).

5Disconnect the refrigerant lines from the

rear of the compressor. Plug the open fittings

to prevent entry of dirt and moisture.

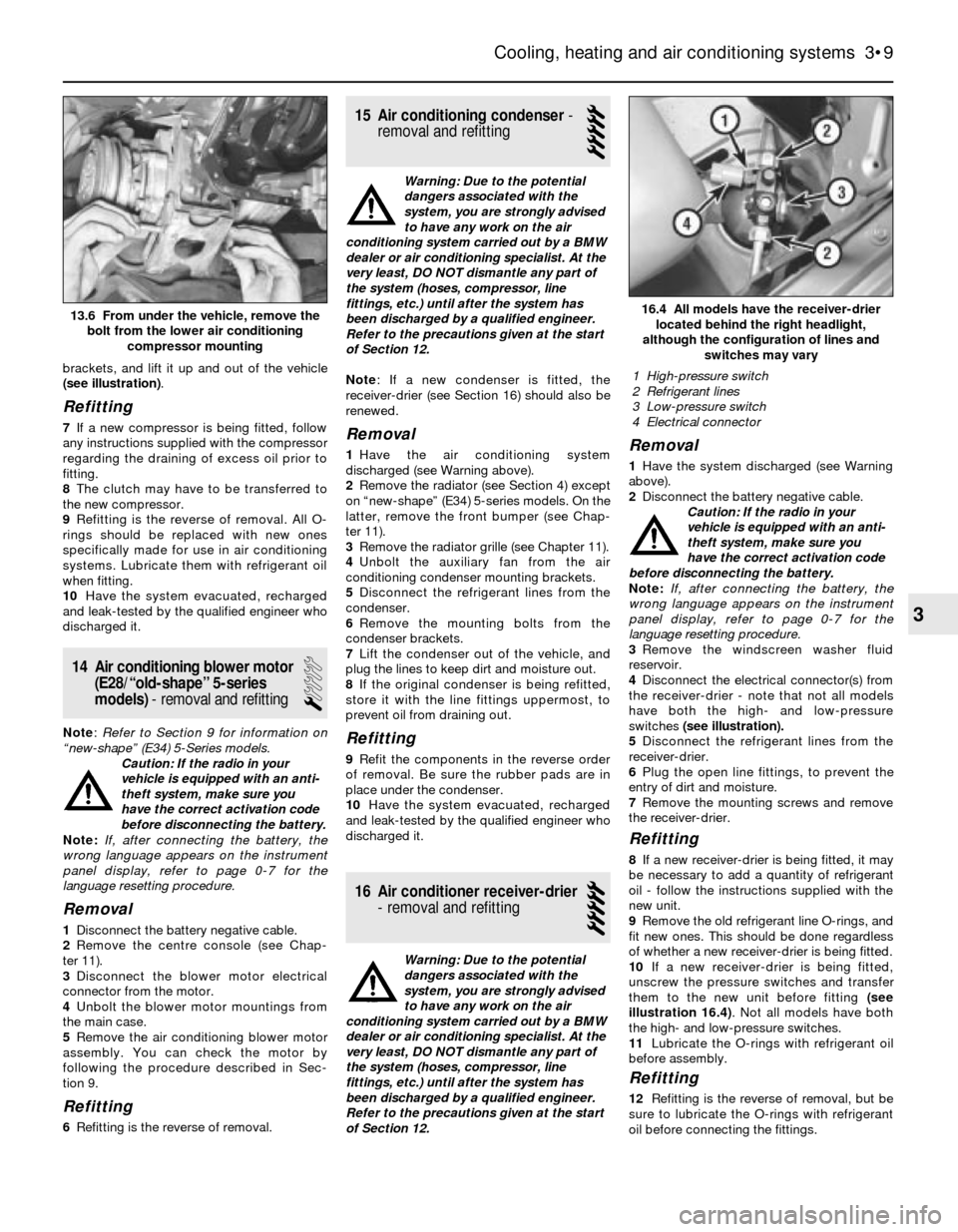

6Unbolt the compressor from the mounting

3•8 Cooling, heating and air conditioning systems

Page 87 of 228

brackets, and lift it up and out of the vehicle

(see illustration).

Refitting

7If a new compressor is being fitted, follow

any instructions supplied with the compressor

regarding the draining of excess oil prior to

fitting.

8The clutch may have to be transferred to

the new compressor.

9Refitting is the reverse of removal. All O-

rings should be replaced with new ones

specifically made for use in air conditioning

systems. Lubricate them with refrigerant oil

when fitting.

10Have the system evacuated, recharged

and leak-tested by the qualified engineer who

discharged it.

14 Air conditioning blower motor

(E28/“old-shape” 5-series

models)- removal and refitting

1

Note: Refer to Section 9 for information on

“new-shape” (E34) 5-Series models.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

Removal

1Disconnect the battery negative cable.

2Remove the centre console (see Chap-

ter 11).

3Disconnect the blower motor electrical

connector from the motor.

4Unbolt the blower motor mountings from

the main case.

5Remove the air conditioning blower motor

assembly. You can check the motor by

following the procedure described in Sec-

tion 9.

Refitting

6Refitting is the reverse of removal.

15 Air conditioning condenser-

removal and refitting

5

Warning: Due to the potential

dangers associated with the

system, you are strongly advised

to have any work on the air

conditioning system carried out by a BMW

dealer or air conditioning specialist. At the

very least, DO NOT dismantle any part of

the system (hoses, compressor, line

fittings, etc.) until after the system has

been discharged by a qualified engineer.

Refer to the precautions given at the start

of Section 12.

Note: If a new condenser is fitted, the

receiver-drier (see Section 16) should also be

renewed.

Removal

1Have the air conditioning system

discharged (see Warning above).

2Remove the radiator (see Section 4) except

on “new-shape” (E34) 5-series models. On the

latter, remove the front bumper (see Chap-

ter 11).

3Remove the radiator grille (see Chapter 11).

4Unbolt the auxiliary fan from the air

conditioning condenser mounting brackets.

5Disconnect the refrigerant lines from the

condenser.

6Remove the mounting bolts from the

condenser brackets.

7Lift the condenser out of the vehicle, and

plug the lines to keep dirt and moisture out.

8If the original condenser is being refitted,

store it with the line fittings uppermost, to

prevent oil from draining out.

Refitting

9Refit the components in the reverse order

of removal. Be sure the rubber pads are in

place under the condenser.

10Have the system evacuated, recharged

and leak-tested by the qualified engineer who

discharged it.

16 Air conditioner receiver-drier

- removal and refitting

5

Warning: Due to the potential

dangers associated with the

system, you are strongly advised

to have any work on the air

conditioning system carried out by a BMW

dealer or air conditioning specialist. At the

very least, DO NOT dismantle any part of

the system (hoses, compressor, line

fittings, etc.) until after the system has

been discharged by a qualified engineer.

Refer to the precautions given at the start

of Section 12.

Removal

1Have the system discharged (see Warning

above).

2Disconnect the battery negative cable.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

3Remove the windscreen washer fluid

reservoir.

4Disconnect the electrical connector(s) from

the receiver-drier - note that not all models

have both the high- and low-pressure

switches (see illustration).

5Disconnect the refrigerant lines from the

receiver-drier.

6Plug the open line fittings, to prevent the

entry of dirt and moisture.

7Remove the mounting screws and remove

the receiver-drier.

Refitting

8If a new receiver-drier is being fitted, it may

be necessary to add a quantity of refrigerant

oil - follow the instructions supplied with the

new unit.

9Remove the old refrigerant line O-rings, and

fit new ones. This should be done regardless

of whether a new receiver-drier is being fitted.

10If a new receiver-drier is being fitted,

unscrew the pressure switches and transfer

them to the new unit before fitting (see

illustration 16.4). Not all models have both

the high- and low-pressure switches.

11Lubricate the O-rings with refrigerant oil

before assembly.

Refitting

12Refitting is the reverse of removal, but be

sure to lubricate the O-rings with refrigerant

oil before connecting the fittings.

Cooling, heating and air conditioning systems 3•9

16.4 All models have the receiver-drier

located behind the right headlight,

although the configuration of lines and

switches may vary

3

13.6 From under the vehicle, remove the

bolt from the lower air conditioning

compressor mounting

1 High-pressure switch

2 Refrigerant lines

3 Low-pressure switch

4 Electrical connector

Page 88 of 228

13Have the system evacuated, recharged

and leak-tested by the qualified engineer who

discharged it.

17 Evaporator matrix-

removal and refitting

5

Warning: Due to the potential

dangers associated with the

system, you are strongly advised

to have any work on the air conditioning

system carried out by a BMW dealer or airconditioning specialist. At the very least,

DO NOT dismantle any part of the system

(hoses, compressor, line fittings, etc.) until

after the system has been discharged by a

qualified engineer. Refer to the pre-

cautions given at the start of Section 12.

Removal

1Have the air conditioning system

discharged (see Warning above).

2Remove the trim panel on the sides of the

centre console (see Chapter 11)

3Disconnect the electrical lead and remove

the evaporator sensor.4Remove the evaporator cover, exposing the

refrigerant lines.

5Disconnect the refrigerant lines from the

evaporator matrix.

6Remove the evaporator matrix from the

case.Refitting

7Refitting is the reverse procedure of the

removal.

8Have the system evacuated, recharged and

leak-tested by the qualified engineer who

discharged it.

3•10 Cooling, heating and air conditioning systems

Page 108 of 228

reading should be between 400 and 500 mA.

Adjust the valve if the current reading is not as

specified. Note: The idle air stabiliser current

will fluctuate between 400 and 1100 mA if the

engine is too cold, if the coolant temperature

sensor is faulty, if there is an engine vacuum

leak, or if electrical accessories are on.

25If there is no current reading, have the idle

speed control unit (under the facia) checked

by a BMW dealer or other specialist.

26On three-wire valves, check for voltage at

the electrical connector. With the ignition on,

there should be battery voltage present at the

centre terminal (see illustration). There

should be about 10 volts between the centre

terminal and each of the outer terminals.

27If there is no voltage reading, have the idle

speed control unit (early models) or the ECU

(later models) checked by a dealer service

department or other specialist.

Adjustment (early models only)

28With the ignition switched off, connect a

tachometer in accordance with the equipment

manufacturer’s instructions.

29Make sure the ignition timing is correct

(see Chapter 5).

30Connect an ammeter to the valve as

described in paragraph 13.

31With the engine running, the current draw

should be 450 to 470 mA at 700 to 750 rpm.

32If the control current is not correct, turn

the adjusting screw until it is within the

specified range. Note: Turn the idle air bypass

screw clockwise to increase the current, or

anti-clockwise to decrease the current.

Renewal

33Remove the electrical connector and the

bracket from the idle air stabiliser valve.

Remove the valve, disconnecting the hoses.

34Refitting is the reverse of removal.

22 Exhaust system servicing-

general information

Warning: Inspect or repair

exhaust system components only

when the system is completely

cool. When working under the

vehicle, make sure it is securely

supported.

Silencer and pipes

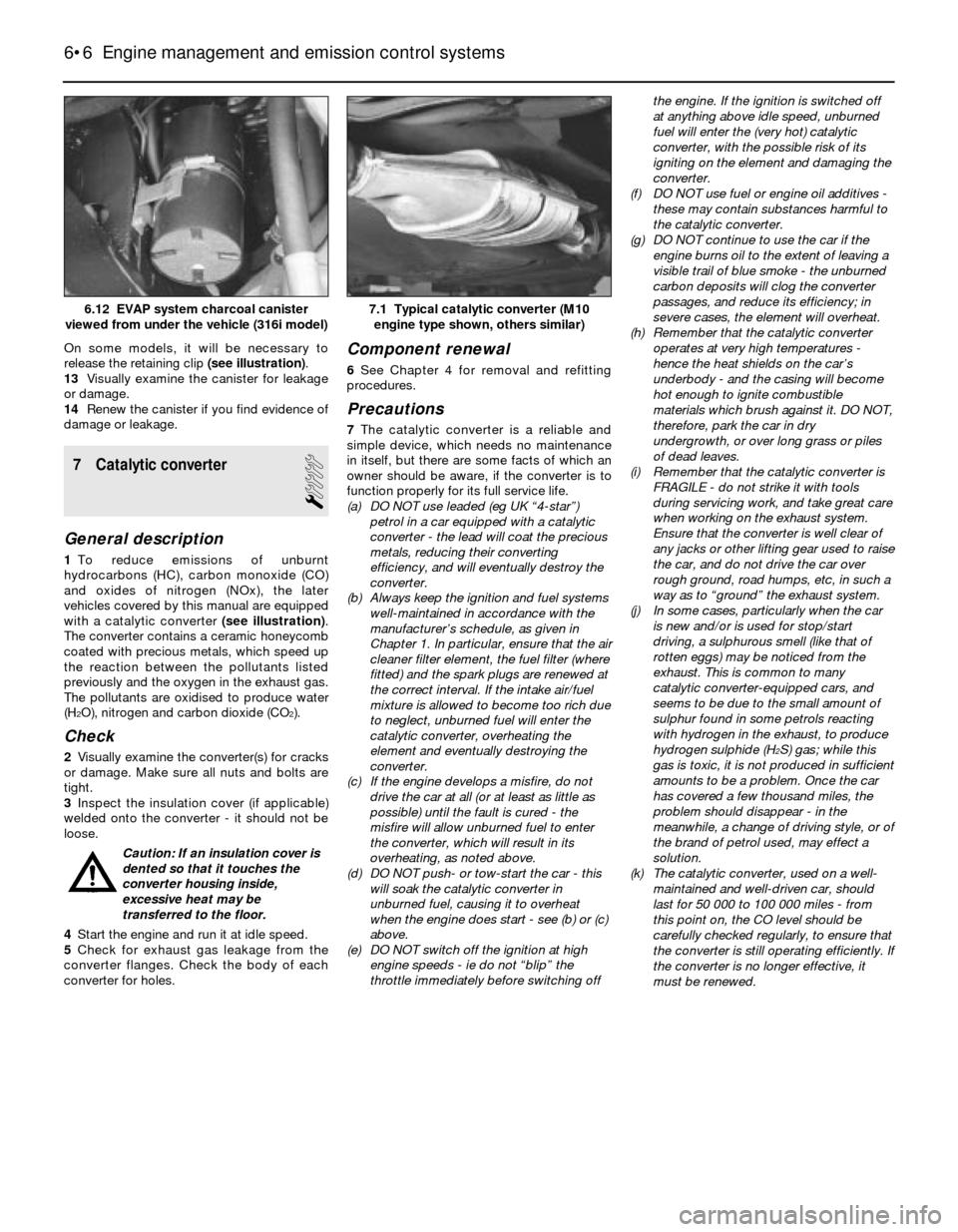

1The exhaust system consists of the exhaust

manifold, catalytic converter, silencers, and all

connecting pipes, brackets, mountings (see

illustration)and clamps. The exhaust system

is attached to the body with brackets and

rubber mountings. If any of the parts are

improperly fitted, excessive noise and

vibration may be transmitted to the body.

2Inspect the exhaust system regularly. Look

for any damaged or bent parts, open seams,

holes, loose connections, excessive

corrosion, or other defects which could allow

exhaust fumes to enter the vehicle. Generally,

deteriorated exhaust system components

cannot be satisfactorily repaired; they should

be renewed.3If the exhaust system components are

extremely corroded or rusted together, it may

be necessary to cut off the old components

with a hacksaw. Be sure to wear safety

goggles to protect your eyes from metal

chips, and wear work gloves to protect your

hands.

4Here are some simple guidelines to follow

when repairing the exhaust system:

a) Work from the back to the front of the

vehicle when removing exhaust system

components.

b) Apply penetrating oil to the exhaust

system nuts and bolts to make them

easier to remove.

c) Use new gaskets, mountings and clamps

when fitting exhaust system components.

d) Apply anti-seize compound to the threads

of all exhaust system nuts and bolts

during reassembly.

e) Be sure to allow sufficient clearance

between newly-fitted parts and all points

on the underbody, to avoid overheating

the floorpan, and possibly damaging the

interior carpet and insulation. Pay

particularly close attention to the catalytic

converters and heat shields. Also, make

sure that the exhaust will not come into

contact with suspension parts, etc.

Catalytic converter

5Although the catalytic converter is an

emissions-related component, it is discussed

here because, physically, it’s an integral part

of the exhaust system. Always check the

converter whenever you raise the vehicle to

inspect or service the exhaust system.

6Raise and support the vehicle.

7Inspect the catalytic converter for cracks or

damage.

8Check the converter connections for

tightness.

9Check the insulation covers welded onto the

catalytic converter for damage or a loose fit.

Caution: If an insulation cover is

dented so that it touches the

converter housing inside,

excessive heat may be

transferred to the floor.

10Start the engine and run it at idle speed.

Check all converter connections for exhaust

gas leakage.

4•20 Fuel and exhaust systems

22.1 A typical exhaust system rubber

mounting21.26 Check for battery voltage on the

centre terminal

Page 128 of 228

On some models, it will be necessary to

release the retaining clip (see illustration).

13Visually examine the canister for leakage

or damage.

14Renew the canister if you find evidence of

damage or leakage.

7 Catalytic converter

1

General description

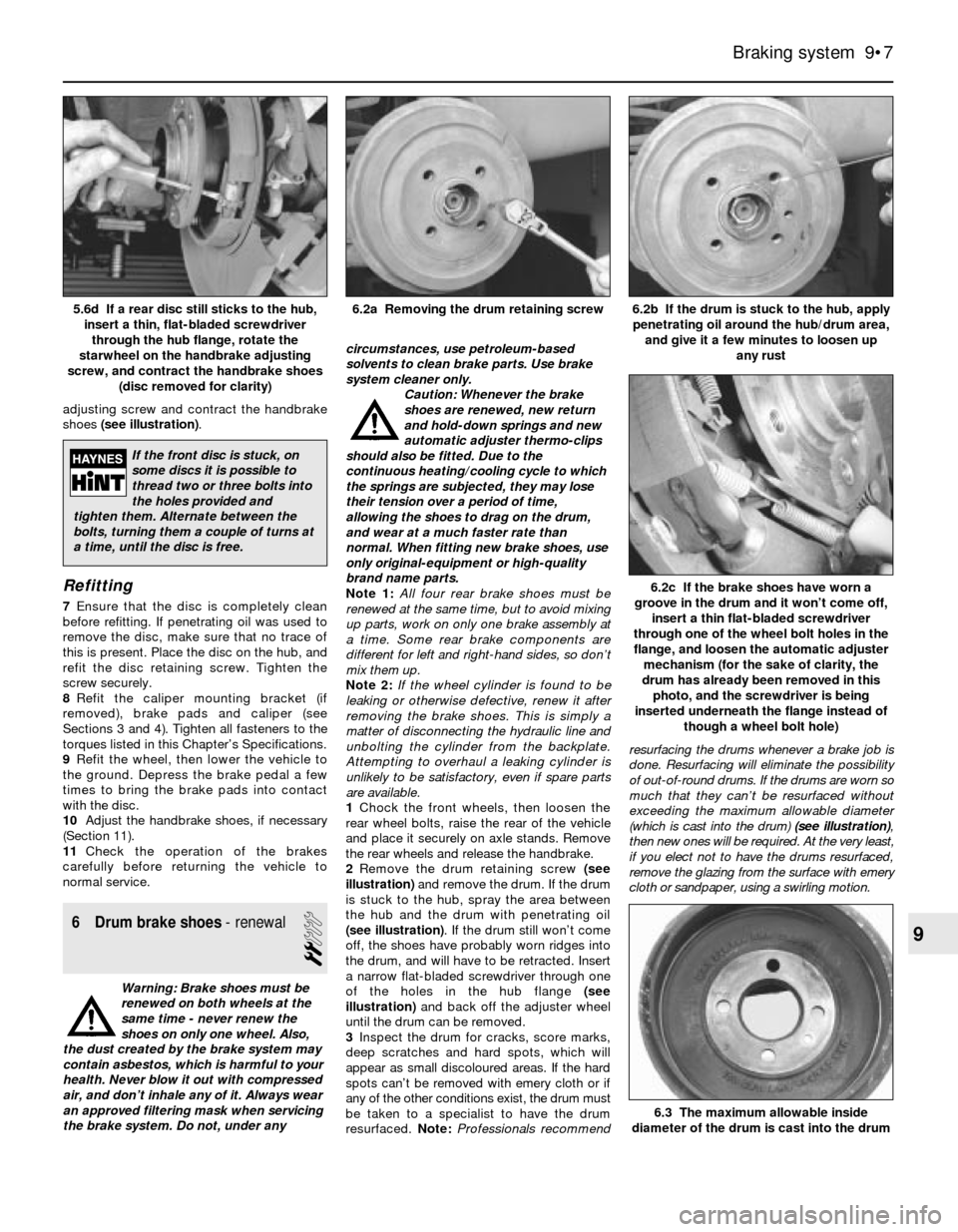

1To reduce emissions of unburnt

hydrocarbons (HC), carbon monoxide (CO)

and oxides of nitrogen (NOx), the later

vehicles covered by this manual are equipped

with a catalytic converter (see illustration).

The converter contains a ceramic honeycomb

coated with precious metals, which speed up

the reaction between the pollutants listed

previously and the oxygen in the exhaust gas.

The pollutants are oxidised to produce water

(H

2O), nitrogen and carbon dioxide (CO2).

Check

2Visually examine the converter(s) for cracks

or damage. Make sure all nuts and bolts are

tight.

3Inspect the insulation cover (if applicable)

welded onto the converter - it should not be

loose.

Caution: If an insulation cover is

dented so that it touches the

converter housing inside,

excessive heat may be

transferred to the floor.

4Start the engine and run it at idle speed.

5Check for exhaust gas leakage from the

converter flanges. Check the body of each

converter for holes.

Component renewal

6See Chapter 4 for removal and refitting

procedures.

Precautions

7The catalytic converter is a reliable and

simple device, which needs no maintenance

in itself, but there are some facts of which an

owner should be aware, if the converter is to

function properly for its full service life.

(a) DO NOT use leaded (eg UK “4-star”)

petrol in a car equipped with a catalytic

converter - the lead will coat the precious

metals, reducing their converting

efficiency, and will eventually destroy the

converter.

(b) Always keep the ignition and fuel systems

well-maintained in accordance with the

manufacturer’s schedule, as given in

Chapter 1. In particular, ensure that the air

cleaner filter element, the fuel filter (where

fitted) and the spark plugs are renewed at

the correct interval. If the intake air/fuel

mixture is allowed to become too rich due

to neglect, unburned fuel will enter the

catalytic converter, overheating the

element and eventually destroying the

converter.

(c) If the engine develops a misfire, do not

drive the car at all (or at least as little as

possible) until the fault is cured - the

misfire will allow unburned fuel to enter

the converter, which will result in its

overheating, as noted above.

(d) DO NOT push- or tow-start the car - this

will soak the catalytic converter in

unburned fuel, causing it to overheat

when the engine does start - see (b) or (c)

above.

(e) DO NOT switch off the ignition at high

engine speeds - ie do not “blip” the

throttle immediately before switching offthe engine. If the ignition is switched off

at anything above idle speed, unburned

fuel will enter the (very hot) catalytic

converter, with the possible risk of its

igniting on the element and damaging the

converter.

(f) DO NOT use fuel or engine oil additives -

these may contain substances harmful to

the catalytic converter.

(g) DO NOT continue to use the car if the

engine burns oil to the extent of leaving a

visible trail of blue smoke - the unburned

carbon deposits will clog the converter

passages, and reduce its efficiency; in

severe cases, the element will overheat.

(h) Remember that the catalytic converter

operates at very high temperatures -

hence the heat shields on the car’s

underbody - and the casing will become

hot enough to ignite combustible

materials which brush against it. DO NOT,

therefore, park the car in dry

undergrowth, or over long grass or piles

of dead leaves.

(i) Remember that the catalytic converter is

FRAGILE - do not strike it with tools

during servicing work, and take great care

when working on the exhaust system.

Ensure that the converter is well clear of

any jacks or other lifting gear used to raise

the car, and do not drive the car over

rough ground, road humps, etc, in such a

way as to “ground” the exhaust system.

(j) In some cases, particularly when the car

is new and/or is used for stop/start

driving, a sulphurous smell (like that of

rotten eggs) may be noticed from the

exhaust. This is common to many

catalytic converter-equipped cars, and

seems to be due to the small amount of

sulphur found in some petrols reacting

with hydrogen in the exhaust, to produce

hydrogen sulphide (H

2S) gas; while this

gas is toxic, it is not produced in sufficient

amounts to be a problem. Once the car

has covered a few thousand miles, the

problem should disappear - in the

meanwhile, a change of driving style, or of

the brand of petrol used, may effect a

solution.

(k) The catalytic converter, used on a well-

maintained and well-driven car, should

last for 50 000 to 100 000 miles - from

this point on, the CO level should be

carefully checked regularly, to ensure that

the converter is still operating efficiently. If

the converter is no longer effective, it

must be renewed.

6•6 Engine management and emission control systems

7.1 Typical catalytic converter (M10

engine type shown, others similar)6.12 EVAP system charcoal canister

viewed from under the vehicle (316i model)

Page 135 of 228

adjusting screw and contract the handbrake

shoes (see illustration).

Refitting

7Ensure that the disc is completely clean

before refitting. If penetrating oil was used to

remove the disc, make sure that no trace of

this is present. Place the disc on the hub, and

refit the disc retaining screw. Tighten the

screw securely.

8Refit the caliper mounting bracket (if

removed), brake pads and caliper (see

Sections 3 and 4). Tighten all fasteners to the

torques listed in this Chapter’s Specifications.

9Refit the wheel, then lower the vehicle to

the ground. Depress the brake pedal a few

times to bring the brake pads into contact

with the disc.

10Adjust the handbrake shoes, if necessary

(Section 11).

11Check the operation of the brakes

carefully before returning the vehicle to

normal service.

6 Drum brake shoes- renewal

2

Warning: Brake shoes must be

renewed on both wheels at the

same time - never renew the

shoes on only one wheel. Also,

the dust created by the brake system may

contain asbestos, which is harmful to your

health. Never blow it out with compressed

air, and don’t inhale any of it. Always wear

an approved filtering mask when servicing

the brake system. Do not, under anycircumstances, use petroleum-based

solvents to clean brake parts. Use brake

system cleaner only.

Caution: Whenever the brake

shoes are renewed, new return

and hold-down springs and new

automatic adjuster thermo-clips

should also be fitted. Due to the

continuous heating/cooling cycle to which

the springs are subjected, they may lose

their tension over a period of time,

allowing the shoes to drag on the drum,

and wear at a much faster rate than

normal. When fitting new brake shoes, use

only original-equipment or high-quality

brand name parts.

Note 1:All four rear brake shoes must be

renewed at the same time, but to avoid mixing

up parts, work on only one brake assembly at

a time. Some rear brake components are

different for left and right-hand sides, so don’t

mix them up.

Note 2:If the wheel cylinder is found to be

leaking or otherwise defective, renew it after

removing the brake shoes. This is simply a

matter of disconnecting the hydraulic line and

unbolting the cylinder from the backplate.

Attempting to overhaul a leaking cylinder is

unlikely to be satisfactory, even if spare parts

are available.

1Chock the front wheels, then loosen the

rear wheel bolts, raise the rear of the vehicle

and place it securely on axle stands. Remove

the rear wheels and release the handbrake.

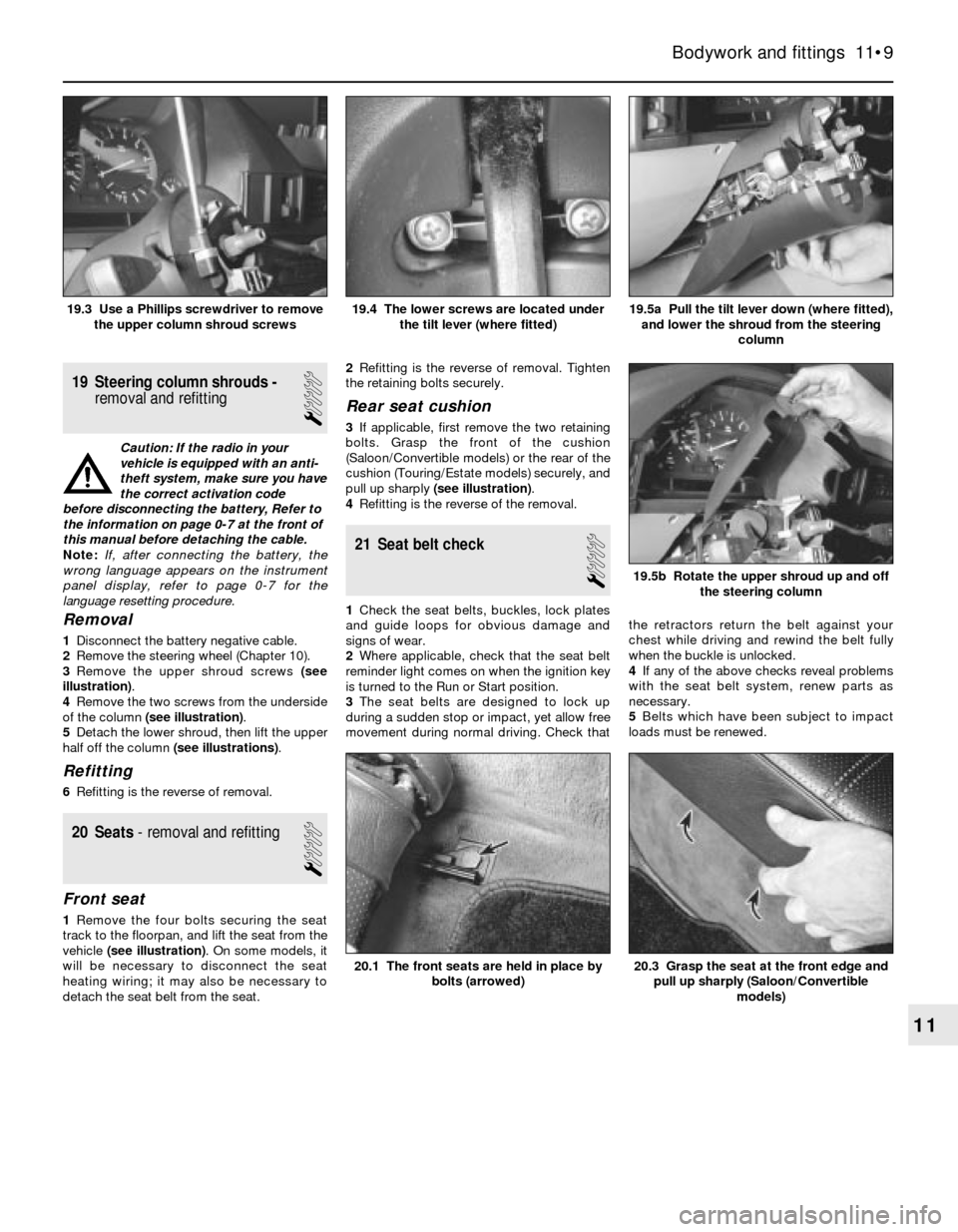

2Remove the drum retaining screw (see

illustration)and remove the drum. If the drum

is stuck to the hub, spray the area between

the hub and the drum with penetrating oil

(see illustration). If the drum still won’t come

off, the shoes have probably worn ridges into

the drum, and will have to be retracted. Insert

a narrow flat-bladed screwdriver through one

of the holes in the hub flange (see

illustration)and back off the adjuster wheel

until the drum can be removed.

3Inspect the drum for cracks, score marks,

deep scratches and hard spots, which will

appear as small discoloured areas. If the hard

spots can’t be removed with emery cloth or if

any of the other conditions exist, the drum must

be taken to a specialist to have the drum

resurfaced. Note:Professionals recommendresurfacing the drums whenever a brake job is

done. Resurfacing will eliminate the possibility

of out-of-round drums. If the drums are worn so

much that they can’t be resurfaced without

exceeding the maximum allowable diameter

(which is cast into the drum) (see illustration),

then new ones will be required. At the very least,

if you elect not to have the drums resurfaced,

remove the glazing from the surface with emery

cloth or sandpaper, using a swirling motion.

Braking system 9•7

6.2b If the drum is stuck to the hub, apply

penetrating oil around the hub/drum area,

and give it a few minutes to loosen up

any rust6.2a Removing the drum retaining screw5.6d If a rear disc still sticks to the hub,

insert a thin, flat-bladed screwdriver

through the hub flange, rotate the

starwheel on the handbrake adjusting

screw, and contract the handbrake shoes

(disc removed for clarity)

6.3 The maximum allowable inside

diameter of the drum is cast into the drum

6.2c If the brake shoes have worn a

groove in the drum and it won’t come off,

insert a thin flat-bladed screwdriver

through one of the wheel bolt holes in the

flange, and loosen the automatic adjuster

mechanism (for the sake of clarity, the

drum has already been removed in this

photo, and the screwdriver is being

inserted underneath the flange instead of

though a wheel bolt hole)

9

If the front disc is stuck, on

some discs it is possible to

thread two or three bolts into

the holes provided and

tighten them. Alternate between the

bolts, turning them a couple of turns at

a time, until the disc is free.

Page 168 of 228

19 Steering column shrouds -

removal and refitting

1

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you have

the correct activation code

before disconnecting the battery, Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

Removal

1Disconnect the battery negative cable.

2Remove the steering wheel (Chapter 10).

3Remove the upper shroud screws (see

illustration).

4Remove the two screws from the underside

of the column (see illustration).

5Detach the lower shroud, then lift the upper

half off the column (see illustrations).

Refitting

6Refitting is the reverse of removal.

20 Seats- removal and refitting

1

Front seat

1Remove the four bolts securing the seat

track to the floorpan, and lift the seat from the

vehicle (see illustration). On some models, it

will be necessary to disconnect the seat

heating wiring; it may also be necessary to

detach the seat belt from the seat.2Refitting is the reverse of removal. Tighten

the retaining bolts securely.

Rear seat cushion

3If applicable, first remove the two retaining

bolts. Grasp the front of the cushion

(Saloon/Convertible models) or the rear of the

cushion (Touring/Estate models) securely, and

pull up sharply (see illustration).

4Refitting is the reverse of the removal.

21 Seat belt check

1

1Check the seat belts, buckles, lock plates

and guide loops for obvious damage and

signs of wear.

2Where applicable, check that the seat belt

reminder light comes on when the ignition key

is turned to the Run or Start position.

3The seat belts are designed to lock up

during a sudden stop or impact, yet allow free

movement during normal driving. Check thatthe retractors return the belt against your

chest while driving and rewind the belt fully

when the buckle is unlocked.

4If any of the above checks reveal problems

with the seat belt system, renew parts as

necessary.

5Belts which have been subject to impact

loads must be renewed.

Bodywork and fittings 11•9

19.5a Pull the tilt lever down (where fitted),

and lower the shroud from the steering

column19.4 The lower screws are located under

the tilt lever (where fitted)19.3 Use a Phillips screwdriver to remove

the upper column shroud screws

20.3 Grasp the seat at the front edge and

pull up sharply (Saloon/Convertible

models)20.1 The front seats are held in place by

bolts (arrowed)

19.5b Rotate the upper shroud up and off

the steering column

11

Page 192 of 228

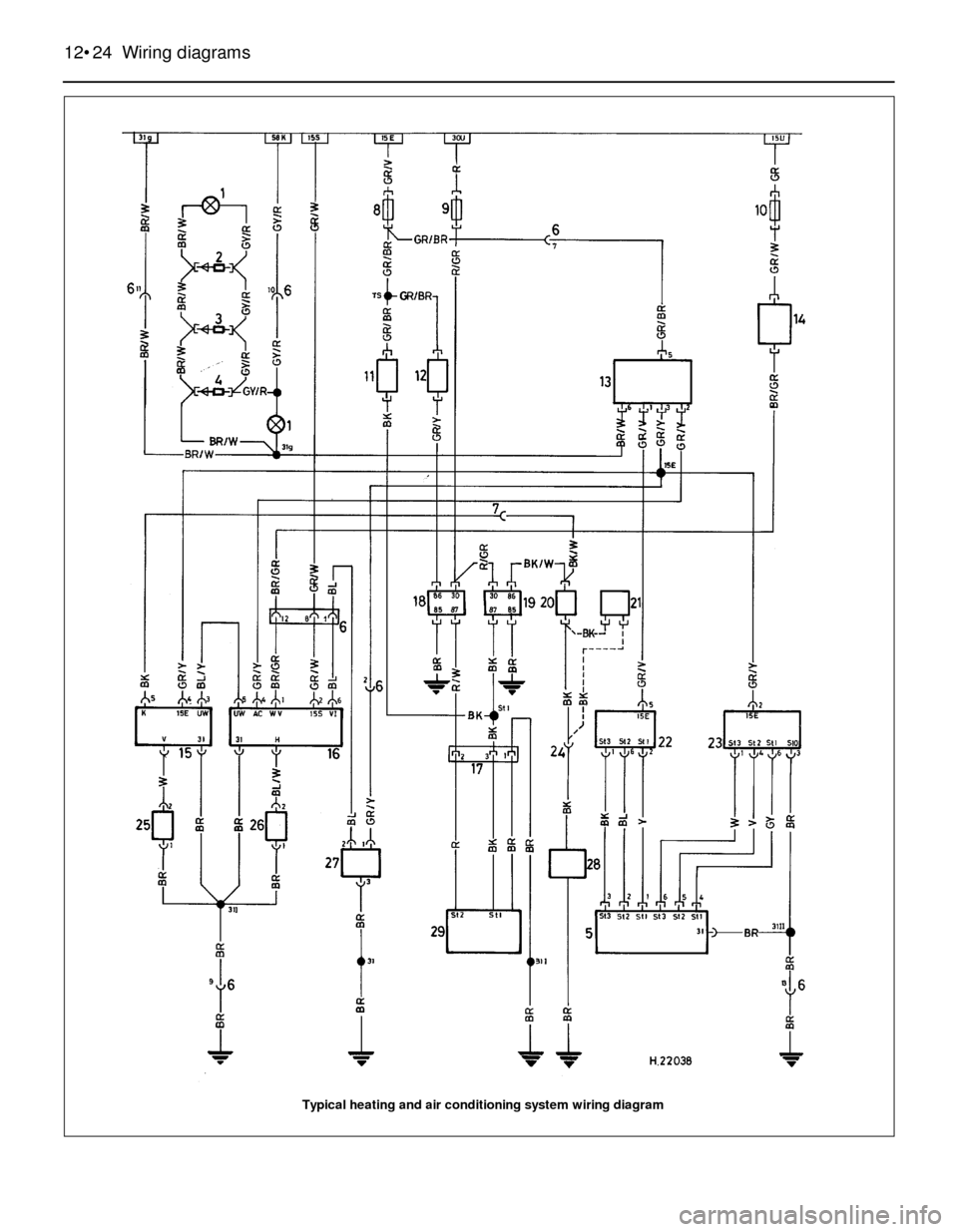

12•24 Wiring diagrams

Typical heating and air conditioning system wiring diagram

Page 210 of 228

REF•9

REF

Fault Finding

Engine

m mEngine will not rotate when attempting to start

m mEngine rotates, but will not start

m mEngine hard to start when cold

m mEngine hard to start when hot

m mStarter motor noisy or excessively-rough in engagement

m mEngine starts, but stops immediately

m mOil puddle under engine

m mEngine idles erratically

m mEngine misses at idle speed

m mEngine misses throughout driving speed range

m mEngine misfires on acceleration

m mEngine surges while holding accelerator steady

m mEngine stalls

m mEngine lacks power

m mEngine backfires

m mPinking or knocking engine sounds when accelerating

or driving uphill

m mEngine runs with oil pressure light on

m mEngine runs-on after switching off

Engine electrical system

m

mBattery will not hold charge

m mIgnition (no-charge) warning light fails to go out

m mIgnition (no-charge) warning light fails to come on

when key is turned

Fuel system

m mExcessive fuel consumption

m mFuel leakage and/or fuel odour

Cooling system

m

mOverheating

m mOvercooling

m mExternal coolant leakage

m mInternal coolant leakage

m mCoolant loss

m mPoor coolant circulation

Clutch

m

mPedal travels to floor - no pressure or very little resistance

m mFluid in area of master cylinder dust cover and on pedal

m mFluid on slave cylinder

m mPedal feels “spongy” when depressed

m mUnable to select gears

m mClutch slips (engine speed increases with no increase in

vehicle speed)

m mGrabbing (chattering) as clutch is engaged

m mNoise in clutch area

m mClutch pedal stays on floor

m mHigh pedal effort

Manual transmission

m

mVibration

m mNoisy in neutral with engine running

m mNoisy in one particular gear

m mNoisy in all gears

m mSlips out of gear

m mLeaks lubricant

Automatic transmission

m

mFluid leakage

m mTransmission fluid brown, or has a burned smell

m mGeneral shift mechanism problems

m mTransmission will not kickdown with accelerator pedal

pressed to the floor

m mEngine will start in gears other than Park or Neutral

m mTransmission slips, shifts roughly, is noisy, or has no drive

in forward or reverse gears

Brakes

m mVehicle pulls to one side during braking

m mNoise (high-pitched squeal) when the brakes are applied

m mBrake vibration (pedal pulsates)

m mExcessive pedal effort required to stop vehicle

m mExcessive brake pedal travel

m mDragging brakes

m mGrabbing or uneven braking action

m mBrake pedal feels “spongy” when depressed

m mBrake pedal travels to the floor with little resistance

m mHandbrake does not hold

Suspension and steering

m

mVehicle pulls to one side

m mAbnormal or excessive tyre wear

m mWheel makes a “thumping” noise

m mShimmy, shake or vibration

m mHigh steering effort

m mPoor steering self-centring

m mAbnormal noise at the front end

m mWandering or poor steering stability

m mErratic steering when braking

m mExcessive pitching and/or rolling around corners or

during braking

m mSuspension bottoms

m mUnevenly-worn tyres

m mExcessive tyre wear on outside edge

m mExcessive tyre wear on inside edge

m mTyre tread worn in one place

m mExcessive play or looseness in steering system

m mRattling or clicking noise in steering gear