not starting BMW 3 SERIES 1986 E30 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1986, Model line: 3 SERIES, Model: BMW 3 SERIES 1986 E30Pages: 228, PDF Size: 7.04 MB

Page 9 of 228

0•9Roadside Repairs

When jump-starting a car using a

booster battery, observe the following

precautions:

4Before connecting the booster

battery, make sure that the ignition is

switched off.

4Ensure that all electrical equipment

(lights, heater, wipers, etc) is

switched off.

4Make sure that the booster battery is

the same voltage as the discharged

one in the vehicle.

4If the battery is being jump-started

from the battery in another vehicle,

the two vehcles MUST NOT TOUCH

each other.

4Make sure that the transmission is in

neutral (or PARK, in the case of

automatic transmission).

Jump starting will get you out

of trouble, but you must correct

whatever made the battery go

flat in the first place. There are

three possibilities:

1The battery has been drained by

repeated attempts to start, or by

leaving the lights on.

2The charging system is not working

properly (alternator drivebelt slack

or broken, alternator wiring fault or

alternator itself faulty).

3The battery itself is at fault

(electrolyte low, or battery worn out).

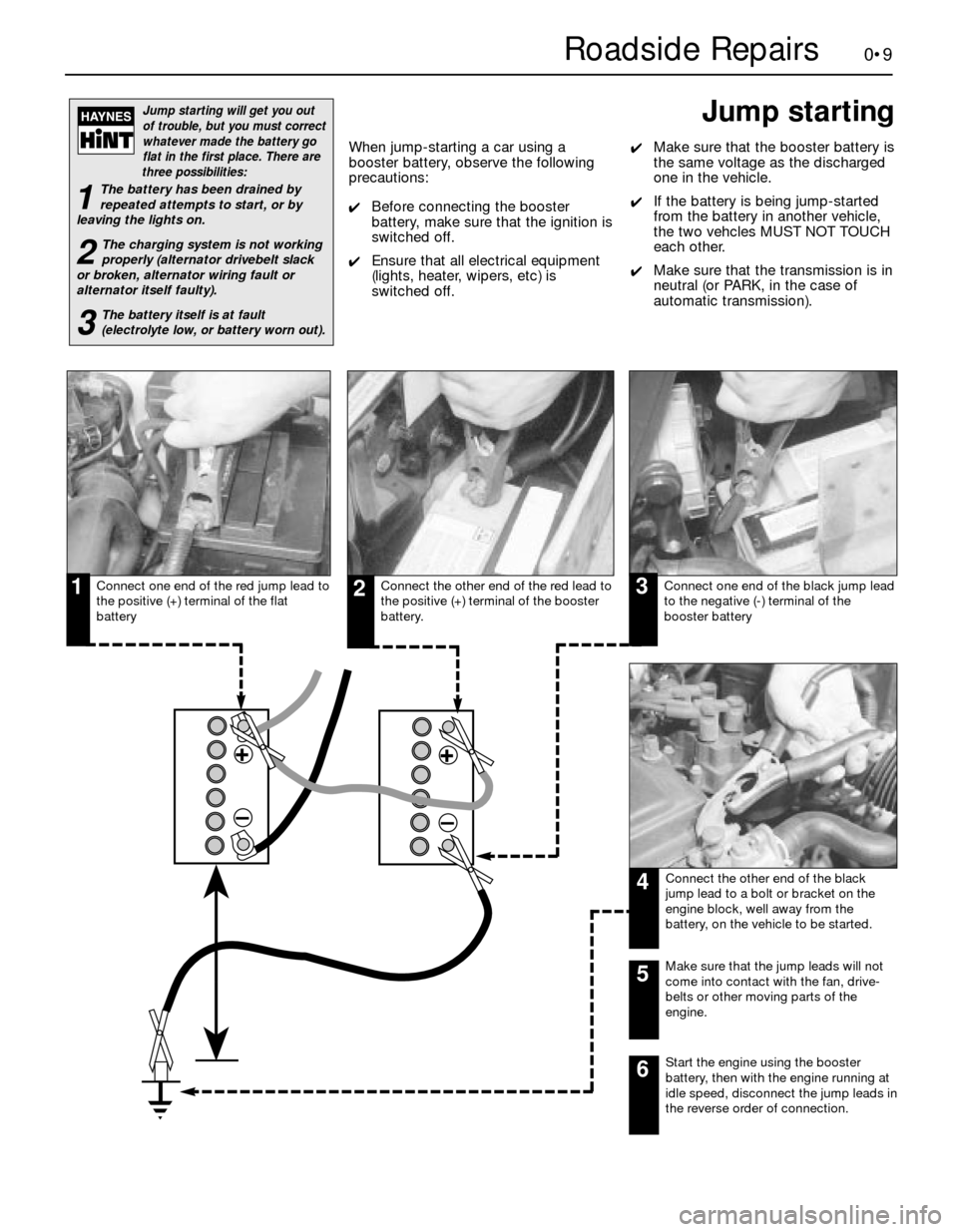

Connect one end of the red jump lead to

the positive (+) terminal of the flat

batteryConnect the other end of the red lead to

the positive (+) terminal of the booster

battery.Connect one end of the black jump lead

to the negative (-) terminal of the

booster battery

Connect the other end of the black

jump lead to a bolt or bracket on the

engine block, well away from the

battery, on the vehicle to be started.

123

4

Make sure that the jump leads will not

come into contact with the fan, drive-

belts or other moving parts of the

engine.5

Start the engine using the booster

battery, then with the engine running at

idle speed, disconnect the jump leads in

the reverse order of connection.6

Jump starting

Page 27 of 228

terminals and cable clamps after they are

assembled.

9Make sure that the battery carrier is in good

condition, and that the hold-down clamp bolt

is tight. If the battery is removed (see Chap-

ter 5 for the removal and refitting procedure),

make sure that no parts remain in the bottom

of the carrier when it’s refitted. When refitting

the hold-down clamp, don’t overtighten the

bolt.

10Corrosion on the carrier, battery case and

surrounding areas can be removed with a

solution of water and baking soda. Apply the

mixture with a small brush, let it work, then

rinse it off with plenty of clean water.

11Any metal parts of the vehicle damaged

by corrosion should be coated with a zinc-

based primer, then painted.

12Additional information on the battery and

jump starting can be found in Chapter 5 and

the front of this manual.

Charging

Note: The manufacturer recommends the

battery be removed from the vehicle for

charging, because the gas which escapes

during this procedure can damage the paint or

interior, depending on the location of the

battery. Fast charging with the battery cables

connected can result in damage to the

electrical system.

13Remove all of the cell caps (if applicable),

and cover the holes with a clean cloth to

prevent spattering electrolyte. Disconnect thebattery negative cable, and connect the

battery charger leads to the battery posts

(positive to positive, negative to negative),

then plug in the charger. Make sure it is set at

12 volts if it has a selector switch.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you have

the correct activation code

before disconnecting the battery. Note: If,

after connecting the battery, the wrong

language appears on the instrument panel

display, refer to page 0-7 for the language

resetting procedure.

14If you’re using a charger with a rate higher

than two amps, check the battery regularly

during charging to make sure it doesn’t

overheat. If you’re using a trickle charger, you

can safely let the battery charge overnight

after you’ve checked it regularly for the first

couple of hours. Where a maintenance-free

battery is fitted, special precautions may be

necessary when charging it (for example, the

charge rate is normally very low). There may

be a warning label on the battery, but if not,

consult a BMW dealer or auto-electrician.

15If the battery has removable cell caps,

measure the specific gravity with a

hydrometer every hour during the last few

hours of the charging cycle. Hydrometers are

available inexpensively from car accessory

shops - follow the instructions that come with

the hydrometer. Consider the battery charged

when there’s no change in the specific gravity

reading for two hours, and the electrolyte in

the cells is gassing (bubbling) freely. The

specific gravity reading from each cell should

be very close to the others. If not, the battery

probably has a bad cell(s), and a new one

should be fitted.

16Some maintenance-free (sealed) batteries

have built-in hydrometers on the top,

indicating the state of charge by the colour

displayed in the hydrometer window.

Normally, a bright-coloured hydrometer

indicates a full charge, and a dark hydrometer

indicates the battery still needs charging.

Check the battery manufacturer’s instructions

to be sure you know what the colours mean.17If the battery is sealed and has no built-in

hydrometer, you can connect a digital

voltmeter across the battery terminals to

check the charge. A fully-charged battery

should read 12.6 volts or higher.

18Further information on the battery and

jump starting can be found in Chapter 5 and

at the front of this manual.

14 Spark plug check and

renewal

1

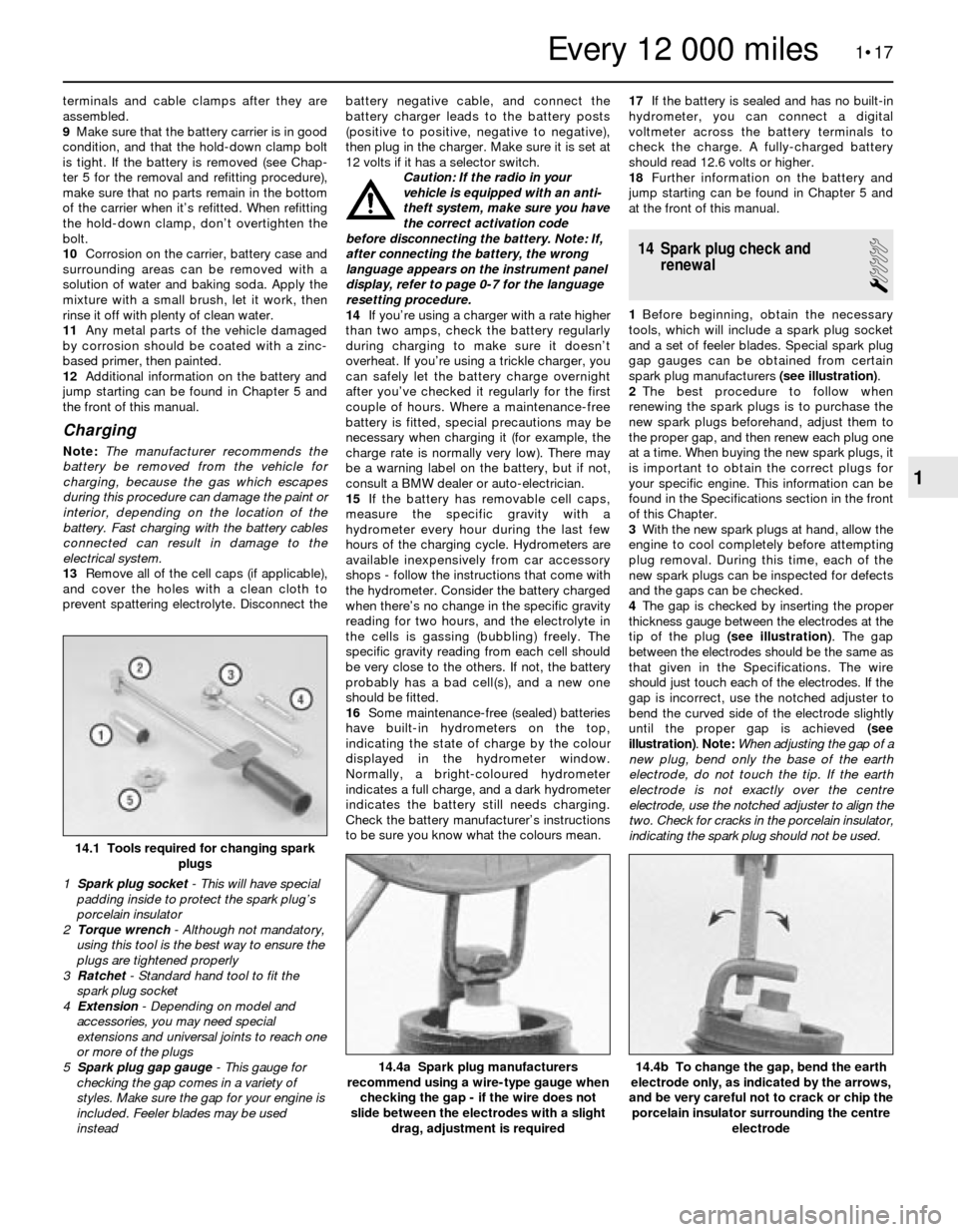

1Before beginning, obtain the necessary

tools, which will include a spark plug socket

and a set of feeler blades. Special spark plug

gap gauges can be obtained from certain

spark plug manufacturers (see illustration).

2The best procedure to follow when

renewing the spark plugs is to purchase the

new spark plugs beforehand, adjust them to

the proper gap, and then renew each plug one

at a time. When buying the new spark plugs, it

is important to obtain the correct plugs for

your specific engine. This information can be

found in the Specifications section in the front

of this Chapter.

3With the new spark plugs at hand, allow the

engine to cool completely before attempting

plug removal. During this time, each of the

new spark plugs can be inspected for defects

and the gaps can be checked.

4The gap is checked by inserting the proper

thickness gauge between the electrodes at the

tip of the plug (see illustration). The gap

between the electrodes should be the same as

that given in the Specifications. The wire

should just touch each of the electrodes. If the

gap is incorrect, use the notched adjuster to

bend the curved side of the electrode slightly

until the proper gap is achieved (see

illustration). Note: When adjusting the gap of a

new plug, bend only the base of the earth

electrode, do not touch the tip. If the earth

electrode is not exactly over the centre

electrode, use the notched adjuster to align the

two. Check for cracks in the porcelain insulator,

indicating the spark plug should not be used.

1•17

14.4b To change the gap, bend the earth

electrode only, as indicated by the arrows,

and be very careful not to crack or chip the

porcelain insulator surrounding the centre

electrode14.4a Spark plug manufacturers

recommend using a wire-type gauge when

checking the gap - if the wire does not

slide between the electrodes with a slight

drag, adjustment is required

14.1 Tools required for changing spark

plugs

1 Spark plug socket- This will have special

padding inside to protect the spark plug’s

porcelain insulator

2 Torque wrench - Although not mandatory,

using this tool is the best way to ensure the

plugs are tightened properly

3 Ratchet - Standard hand tool to fit the

spark plug socket

4 Extension - Depending on model and

accessories, you may need special

extensions and universal joints to reach one

or more of the plugs

5 Spark plug gap gauge- This gauge for

checking the gap comes in a variety of

styles. Make sure the gap for your engine is

included. Feeler blades may be used

instead

1

Every 12 000 miles

Page 42 of 228

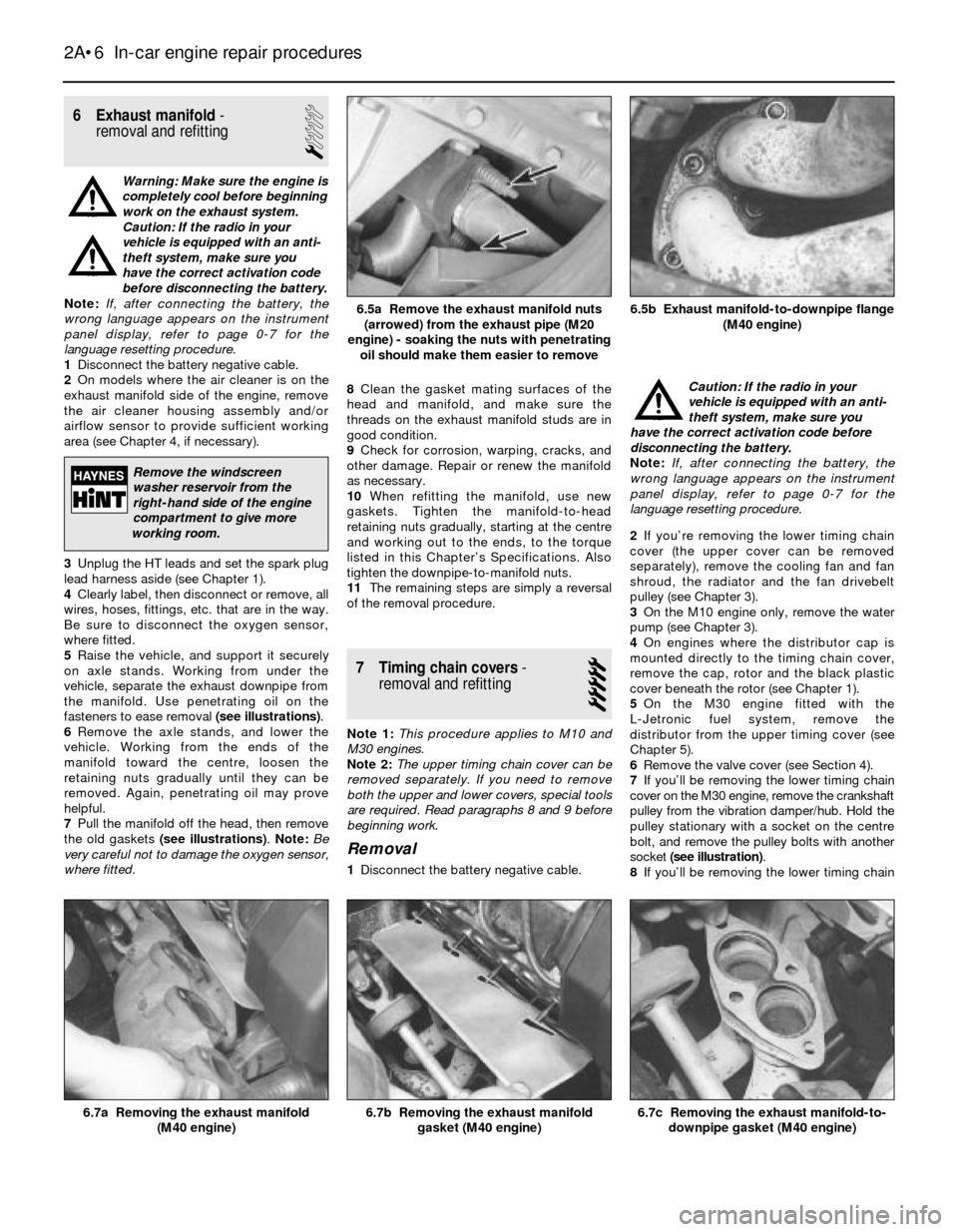

6 Exhaust manifold-

removal and refitting

1

Warning: Make sure the engine is

completely cool before beginning

work on the exhaust system.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

1Disconnect the battery negative cable.

2On models where the air cleaner is on the

exhaust manifold side of the engine, remove

the air cleaner housing assembly and/or

airflow sensor to provide sufficient working

area (see Chapter 4, if necessary).

3Unplug the HT leads and set the spark plug

lead harness aside (see Chapter 1).

4Clearly label, then disconnect or remove, all

wires, hoses, fittings, etc. that are in the way.

Be sure to disconnect the oxygen sensor,

where fitted.

5Raise the vehicle, and support it securely

on axle stands. Working from under the

vehicle, separate the exhaust downpipe from

the manifold. Use penetrating oil on the

fasteners to ease removal (see illustrations).

6Remove the axle stands, and lower the

vehicle. Working from the ends of the

manifold toward the centre, loosen the

retaining nuts gradually until they can be

removed. Again, penetrating oil may prove

helpful.

7Pull the manifold off the head, then remove

the old gaskets (see illustrations). Note:Be

very careful not to damage the oxygen sensor,

where fitted.8Clean the gasket mating surfaces of the

head and manifold, and make sure the

threads on the exhaust manifold studs are in

good condition.

9Check for corrosion, warping, cracks, and

other damage. Repair or renew the manifold

as necessary.

10When refitting the manifold, use new

gaskets. Tighten the manifold-to-head

retaining nuts gradually, starting at the centre

and working out to the ends, to the torque

listed in this Chapter’s Specifications. Also

tighten the downpipe-to-manifold nuts.

11The remaining steps are simply a reversal

of the removal procedure.

7 Timing chain covers-

removal and refitting

5

Note 1:This procedure applies to M10 and

M30 engines.

Note 2:The upper timing chain cover can be

removed separately. If you need to remove

both the upper and lower covers, special tools

are required. Read paragraphs 8 and 9 before

beginning work.

Removal

1Disconnect the battery negative cable.Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code before

disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

2If you’re removing the lower timing chain

cover (the upper cover can be removed

separately), remove the cooling fan and fan

shroud, the radiator and the fan drivebelt

pulley (see Chapter 3).

3On the M10 engine only, remove the water

pump (see Chapter 3).

4On engines where the distributor cap is

mounted directly to the timing chain cover,

remove the cap, rotor and the black plastic

cover beneath the rotor (see Chapter 1).

5On the M30 engine fitted with the

L-Jetronic fuel system, remove the

distributor from the upper timing cover (see

Chapter 5).

6Remove the valve cover (see Section 4).

7If you’ll be removing the lower timing chain

cover on the M30 engine, remove the crankshaft

pulley from the vibration damper/hub. Hold the

pulley stationary with a socket on the centre

bolt, and remove the pulley bolts with another

socket (see illustration).

8If you’ll be removing the lower timing chain

2A•6 In-car engine repair procedures

6.7c Removing the exhaust manifold-to-

downpipe gasket (M40 engine)6.7b Removing the exhaust manifold

gasket (M40 engine)6.7a Removing the exhaust manifold

(M40 engine)

6.5b Exhaust manifold-to-downpipe flange

(M40 engine)6.5a Remove the exhaust manifold nuts

(arrowed) from the exhaust pipe (M20

engine) - soaking the nuts with penetrating

oil should make them easier to remove

Remove the windscreen

washer reservoir from the

right-hand side of the engine

compartment to give more

working room.

Page 68 of 228

6If coarse grinding compound is being used,

work only until a dull, matt even surface is

produced on both the valve seat and the

valve, then wipe off the used compound and

repeat the process with fine compound. When

a smooth, unbroken ring of light grey matt

finish is produced on both the valve and seat,

the grinding operation is complete. Do not

grind in the valves any further than absolutely

necessary.

7When all the valves have been ground-in,

carefully wash off all traces of grinding

compound using paraffin or a suitable solvent

before reassembly of the cylinder head.

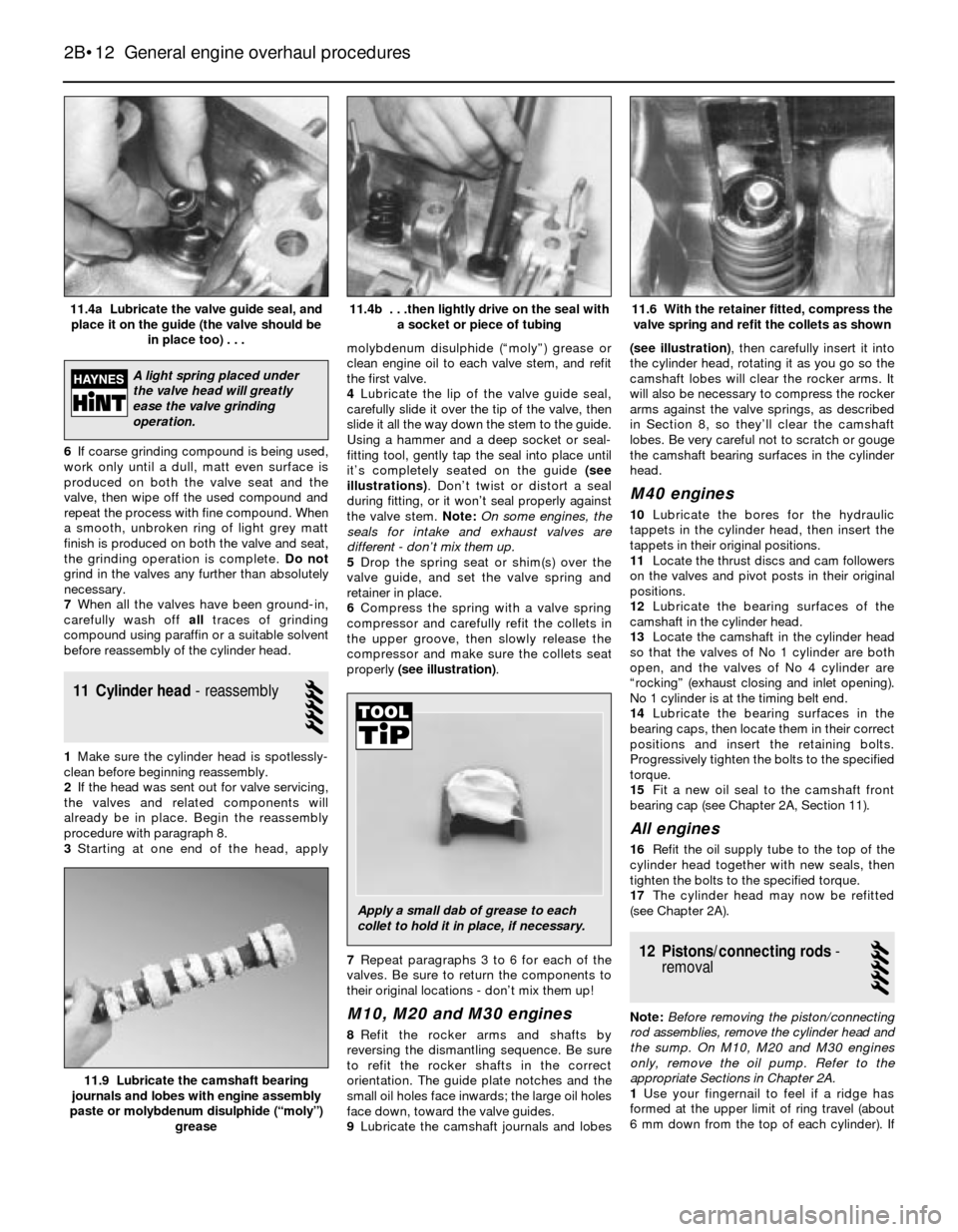

11 Cylinder head- reassembly

5

1Make sure the cylinder head is spotlessly-

clean before beginning reassembly.

2If the head was sent out for valve servicing,

the valves and related components will

already be in place. Begin the reassembly

procedure with paragraph 8.

3Starting at one end of the head, applymolybdenum disulphide (“moly”) grease or

clean engine oil to each valve stem, and refit

the first valve.

4Lubricate the lip of the valve guide seal,

carefully slide it over the tip of the valve, then

slide it all the way down the stem to the guide.

Using a hammer and a deep socket or seal-

fitting tool, gently tap the seal into place until

it’s completely seated on the guide (see

illustrations). Don’t twist or distort a seal

during fitting, or it won’t seal properly against

the valve stem. Note:On some engines, the

seals for intake and exhaust valves are

different - don’t mix them up.

5Drop the spring seat or shim(s) over the

valve guide, and set the valve spring and

retainer in place.

6Compress the spring with a valve spring

compressor and carefully refit the collets in

the upper groove, then slowly release the

compressor and make sure the collets seat

properly (see illustration).

7Repeat paragraphs 3 to 6 for each of the

valves. Be sure to return the components to

their original locations - don’t mix them up!

M10, M20 and M30 engines

8Refit the rocker arms and shafts by

reversing the dismantling sequence. Be sure

to refit the rocker shafts in the correct

orientation. The guide plate notches and the

small oil holes face inwards; the large oil holes

face down, toward the valve guides.

9Lubricate the camshaft journals and lobes(see illustration), then carefully insert it into

the cylinder head, rotating it as you go so the

camshaft lobes will clear the rocker arms. It

will also be necessary to compress the rocker

arms against the valve springs, as described

in Section 8, so they’ll clear the camshaft

lobes. Be very careful not to scratch or gouge

the camshaft bearing surfaces in the cylinder

head.

M40 engines

10Lubricate the bores for the hydraulic

tappets in the cylinder head, then insert the

tappets in their original positions.

11Locate the thrust discs and cam followers

on the valves and pivot posts in their original

positions.

12Lubricate the bearing surfaces of the

camshaft in the cylinder head.

13Locate the camshaft in the cylinder head

so that the valves of No 1 cylinder are both

open, and the valves of No 4 cylinder are

“rocking” (exhaust closing and inlet opening).

No 1 cylinder is at the timing belt end.

14Lubricate the bearing surfaces in the

bearing caps, then locate them in their correct

positions and insert the retaining bolts.

Progressively tighten the bolts to the specified

torque.

15Fit a new oil seal to the camshaft front

bearing cap (see Chapter 2A, Section 11).

All engines

16Refit the oil supply tube to the top of the

cylinder head together with new seals, then

tighten the bolts to the specified torque.

17The cylinder head may now be refitted

(see Chapter 2A).

12 Pistons/connecting rods-

removal

5

Note:Before removing the piston/connecting

rod assemblies, remove the cylinder head and

the sump. On M10, M20 and M30 engines

only, remove the oil pump. Refer to the

appropriate Sections in Chapter 2A.

1Use your fingernail to feel if a ridge has

formed at the upper limit of ring travel (about

6 mm down from the top of each cylinder). If

2B•12 General engine overhaul procedures

11.9 Lubricate the camshaft bearing

journals and lobes with engine assembly

paste or molybdenum disulphide (“moly”)

grease

11.6 With the retainer fitted, compress the

valve spring and refit the collets as shown 11.4b . . .then lightly drive on the seal with

a socket or piece of tubing11.4a Lubricate the valve guide seal, and

place it on the guide (the valve should be

in place too) . . .

A light spring placed under

the valve head will greatly

ease the valve grinding

operation.

Apply a small dab of grease to each

collet to hold it in place, if necessary.

Page 76 of 228

positions (don’t mix them up) with the arrows

pointing towards the front of the engine. Don’t

disturb the Plastigage.

13Starting with the centre main bearing and

working out toward the ends, progressively

tighten the main bearing cap bolts to the

torque listed in this Chapter’s Specifications.

On M10, M20 and M30 engines, tighten the

bolts in three stages. On the M40 engine,

tighten all the bolts initially to the Stage 1

torque, then angle-tighten them by the angle

given in the Specifications. Carry out the

angle-tightening on each bolt in one

controlled movement. Don’t rotate the

crankshaft at any time during the tightening

operation.

14Remove the bolts and carefully lift off the

main bearing caps. Keep them in order. Don’t

disturb the Plastigage or rotate the

crankshaft. If any of the main bearing caps are

difficult to remove, tap them gently from side-

to-side with a soft-face hammer to loosen

them.

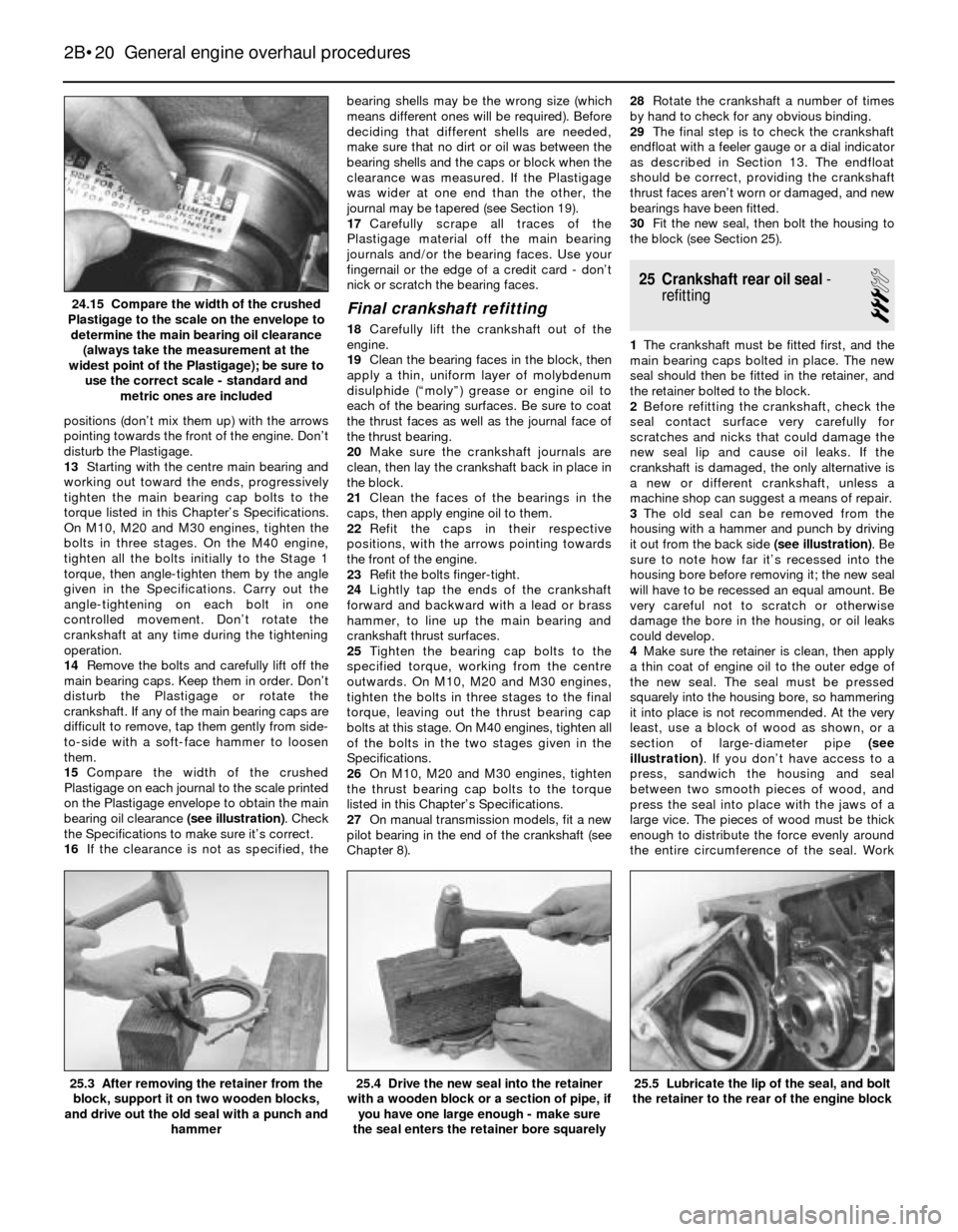

15Compare the width of the crushed

Plastigage on each journal to the scale printed

on the Plastigage envelope to obtain the main

bearing oil clearance (see illustration). Check

the Specifications to make sure it’s correct.

16If the clearance is not as specified, thebearing shells may be the wrong size (which

means different ones will be required). Before

deciding that different shells are needed,

make sure that no dirt or oil was between the

bearing shells and the caps or block when the

clearance was measured. If the Plastigage

was wider at one end than the other, the

journal may be tapered (see Section 19).

17Carefully scrape all traces of the

Plastigage material off the main bearing

journals and/or the bearing faces. Use your

fingernail or the edge of a credit card - don’t

nick or scratch the bearing faces.

Final crankshaft refitting

18Carefully lift the crankshaft out of the

engine.

19Clean the bearing faces in the block, then

apply a thin, uniform layer of molybdenum

disulphide (“moly”) grease or engine oil to

each of the bearing surfaces. Be sure to coat

the thrust faces as well as the journal face of

the thrust bearing.

20Make sure the crankshaft journals are

clean, then lay the crankshaft back in place in

the block.

21Clean the faces of the bearings in the

caps, then apply engine oil to them.

22Refit the caps in their respective

positions, with the arrows pointing towards

the front of the engine.

23Refit the bolts finger-tight.

24Lightly tap the ends of the crankshaft

forward and backward with a lead or brass

hammer, to line up the main bearing and

crankshaft thrust surfaces.

25Tighten the bearing cap bolts to the

specified torque, working from the centre

outwards. On M10, M20 and M30 engines,

tighten the bolts in three stages to the final

torque, leaving out the thrust bearing cap

bolts at this stage. On M40 engines, tighten all

of the bolts in the two stages given in the

Specifications.

26On M10, M20 and M30 engines, tighten

the thrust bearing cap bolts to the torque

listed in this Chapter’s Specifications.

27On manual transmission models, fit a new

pilot bearing in the end of the crankshaft (see

Chapter 8).28Rotate the crankshaft a number of times

by hand to check for any obvious binding.

29The final step is to check the crankshaft

endfloat with a feeler gauge or a dial indicator

as described in Section 13. The endfloat

should be correct, providing the crankshaft

thrust faces aren’t worn or damaged, and new

bearings have been fitted.

30Fit the new seal, then bolt the housing to

the block (see Section 25).

25 Crankshaft rear oil seal-

refitting

3

1The crankshaft must be fitted first, and the

main bearing caps bolted in place. The new

seal should then be fitted in the retainer, and

the retainer bolted to the block.

2Before refitting the crankshaft, check the

seal contact surface very carefully for

scratches and nicks that could damage the

new seal lip and cause oil leaks. If the

crankshaft is damaged, the only alternative is

a new or different crankshaft, unless a

machine shop can suggest a means of repair.

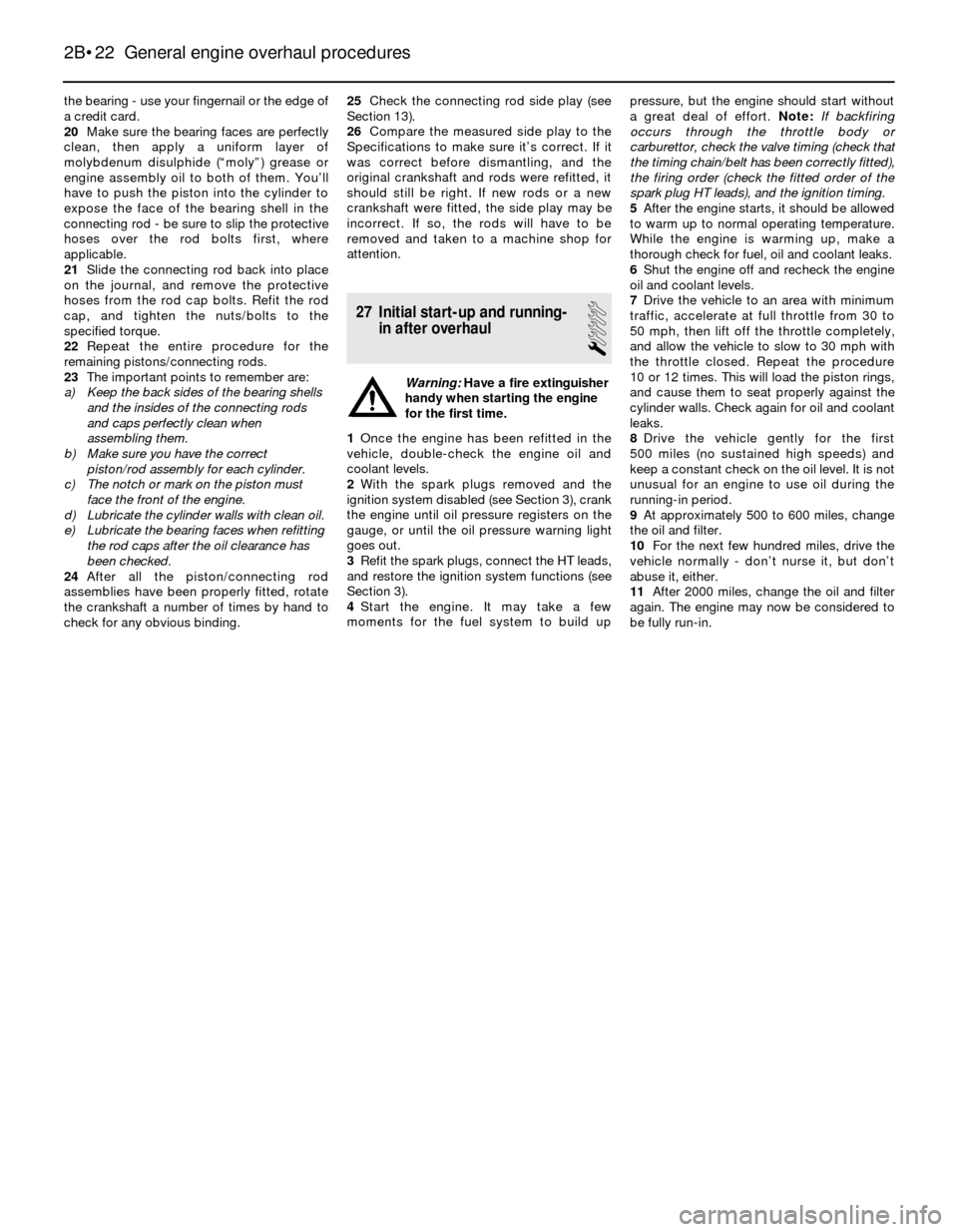

3The old seal can be removed from the

housing with a hammer and punch by driving

it out from the back side (see illustration). Be

sure to note how far it’s recessed into the

housing bore before removing it; the new seal

will have to be recessed an equal amount. Be

very careful not to scratch or otherwise

damage the bore in the housing, or oil leaks

could develop.

4Make sure the retainer is clean, then apply

a thin coat of engine oil to the outer edge of

the new seal. The seal must be pressed

squarely into the housing bore, so hammering

it into place is not recommended. At the very

least, use a block of wood as shown, or a

section of large-diameter pipe (see

illustration). If you don’t have access to a

press, sandwich the housing and seal

between two smooth pieces of wood, and

press the seal into place with the jaws of a

large vice. The pieces of wood must be thick

enough to distribute the force evenly around

the entire circumference of the seal. Work

2B•20 General engine overhaul procedures

25.5 Lubricate the lip of the seal, and bolt

the retainer to the rear of the engine block25.4 Drive the new seal into the retainer

with a wooden block or a section of pipe, if

you have one large enough - make sure

the seal enters the retainer bore squarely25.3 After removing the retainer from the

block, support it on two wooden blocks,

and drive out the old seal with a punch and

hammer

24.15 Compare the width of the crushed

Plastigage to the scale on the envelope to

determine the main bearing oil clearance

(always take the measurement at the

widest point of the Plastigage); be sure to

use the correct scale - standard and

metric ones are included

Page 78 of 228

the bearing - use your fingernail or the edge of

a credit card.

20Make sure the bearing faces are perfectly

clean, then apply a uniform layer of

molybdenum disulphide (“moly”) grease or

engine assembly oil to both of them. You’ll

have to push the piston into the cylinder to

expose the face of the bearing shell in the

connecting rod - be sure to slip the protective

hoses over the rod bolts first, where

applicable.

21Slide the connecting rod back into place

on the journal, and remove the protective

hoses from the rod cap bolts. Refit the rod

cap, and tighten the nuts/bolts to the

specified torque.

22Repeat the entire procedure for the

remaining pistons/connecting rods.

23The important points to remember are:

a) Keep the back sides of the bearing shells

and the insides of the connecting rods

and caps perfectly clean when

assembling them.

b) Make sure you have the correct

piston/rod assembly for each cylinder.

c) The notch or mark on the piston must

face the front of the engine.

d) Lubricate the cylinder walls with clean oil.

e) Lubricate the bearing faces when refitting

the rod caps after the oil clearance has

been checked.

24After all the piston/connecting rod

assemblies have been properly fitted, rotate

the crankshaft a number of times by hand to

check for any obvious binding.25Check the connecting rod side play (see

Section 13).

26Compare the measured side play to the

Specifications to make sure it’s correct. If it

was correct before dismantling, and the

original crankshaft and rods were refitted, it

should still be right. If new rods or a new

crankshaft were fitted, the side play may be

incorrect. If so, the rods will have to be

removed and taken to a machine shop for

attention.

27 Initial start-up and running-

in after overhaul

1

Warning:Have a fire extinguisher

handy when starting the engine

for the first time.

1Once the engine has been refitted in the

vehicle, double-check the engine oil and

coolant levels.

2With the spark plugs removed and the

ignition system disabled (see Section 3), crank

the engine until oil pressure registers on the

gauge, or until the oil pressure warning light

goes out.

3Refit the spark plugs, connect the HT leads,

and restore the ignition system functions (see

Section 3).

4Start the engine. It may take a few

moments for the fuel system to build uppressure, but the engine should start without

a great deal of effort. Note: If backfiring

occurs through the throttle body or

carburettor, check the valve timing (check that

the timing chain/belt has been correctly fitted),

the firing order (check the fitted order of the

spark plug HT leads), and the ignition timing.

5After the engine starts, it should be allowed

to warm up to normal operating temperature.

While the engine is warming up, make a

thorough check for fuel, oil and coolant leaks.

6Shut the engine off and recheck the engine

oil and coolant levels.

7Drive the vehicle to an area with minimum

traffic, accelerate at full throttle from 30 to

50 mph, then lift off the throttle completely,

and allow the vehicle to slow to 30 mph with

the throttle closed. Repeat the procedure

10 or 12 times. This will load the piston rings,

and cause them to seat properly against the

cylinder walls. Check again for oil and coolant

leaks.

8Drive the vehicle gently for the first

500 miles (no sustained high speeds) and

keep a constant check on the oil level. It is not

unusual for an engine to use oil during the

running-in period.

9At approximately 500 to 600 miles, change

the oil and filter.

10For the next few hundred miles, drive the

vehicle normally - don’t nurse it, but don’t

abuse it, either.

11After 2000 miles, change the oil and filter

again. The engine may now be considered to

be fully run-in.

2B•22 General engine overhaul procedures

Page 106 of 228

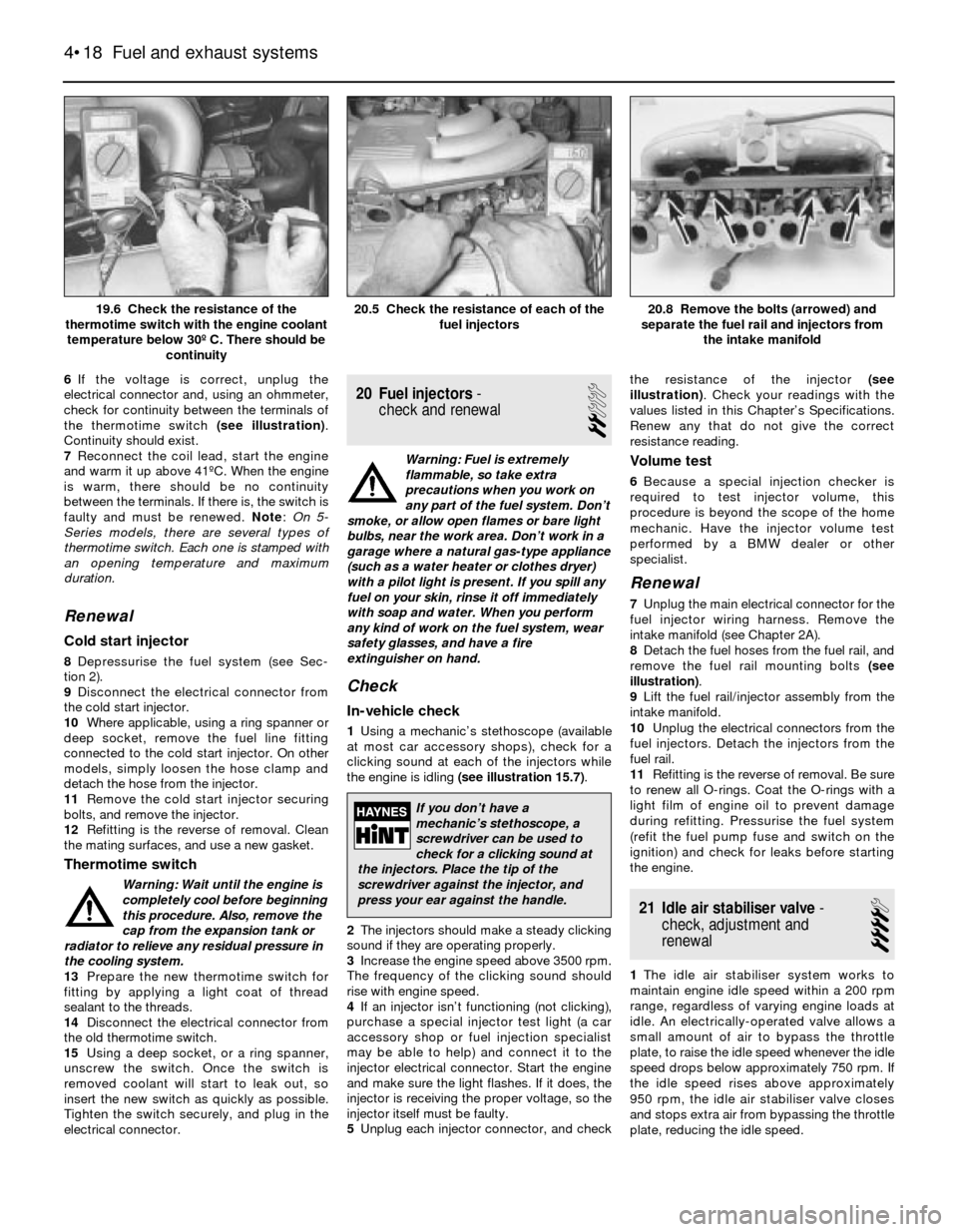

6If the voltage is correct, unplug the

electrical connector and, using an ohmmeter,

check for continuity between the terminals of

the thermotime switch (see illustration).

Continuity should exist.

7Reconnect the coil lead, start the engine

and warm it up above 41ºC. When the engine

is warm, there should be no continuity

between the terminals. If there is, the switch is

faulty and must be renewed. Note: On 5-

Series models, there are several types of

thermotime switch. Each one is stamped with

an opening temperature and maximum

duration.

Renewal

Cold start injector

8Depressurise the fuel system (see Sec-

tion 2).

9Disconnect the electrical connector from

the cold start injector.

10Where applicable, using a ring spanner or

deep socket, remove the fuel line fitting

connected to the cold start injector. On other

models, simply loosen the hose clamp and

detach the hose from the injector.

11Remove the cold start injector securing

bolts, and remove the injector.

12Refitting is the reverse of removal. Clean

the mating surfaces, and use a new gasket.

Thermotime switch

Warning: Wait until the engine is

completely cool before beginning

this procedure. Also, remove the

cap from the expansion tank or

radiator to relieve any residual pressure in

the cooling system.

13Prepare the new thermotime switch for

fitting by applying a light coat of thread

sealant to the threads.

14Disconnect the electrical connector from

the old thermotime switch.

15Using a deep socket, or a ring spanner,

unscrew the switch. Once the switch is

removed coolant will start to leak out, so

insert the new switch as quickly as possible.

Tighten the switch securely, and plug in the

electrical connector.

20 Fuel injectors-

check and renewal

2

Warning: Fuel is extremely

flammable, so take extra

precautions when you work on

any part of the fuel system. Don’t

smoke, or allow open flames or bare light

bulbs, near the work area. Don’t work in a

garage where a natural gas-type appliance

(such as a water heater or clothes dryer)

with a pilot light is present. If you spill any

fuel on your skin, rinse it off immediately

with soap and water. When you perform

any kind of work on the fuel system, wear

safety glasses, and have a fire

extinguisher on hand.

Check

In-vehicle check

1Using a mechanic’s stethoscope (available

at most car accessory shops), check for a

clicking sound at each of the injectors while

the engine is idling (see illustration 15.7).

2The injectors should make a steady clicking

sound if they are operating properly.

3Increase the engine speed above 3500 rpm.

The frequency of the clicking sound should

rise with engine speed.

4If an injector isn’t functioning (not clicking),

purchase a special injector test light (a car

accessory shop or fuel injection specialist

may be able to help) and connect it to the

injector electrical connector. Start the engine

and make sure the light flashes. If it does, the

injector is receiving the proper voltage, so the

injector itself must be faulty.

5Unplug each injector connector, and checkthe resistance of the injector (see

illustration). Check your readings with the

values listed in this Chapter’s Specifications.

Renew any that do not give the correct

resistance reading.

Volume test

6Because a special injection checker is

required to test injector volume, this

procedure is beyond the scope of the home

mechanic. Have the injector volume test

performed by a BMW dealer or other

specialist.

Renewal

7Unplug the main electrical connector for the

fuel injector wiring harness. Remove the

intake manifold (see Chapter 2A).

8Detach the fuel hoses from the fuel rail, and

remove the fuel rail mounting bolts (see

illustration).

9Lift the fuel rail/injector assembly from the

intake manifold.

10Unplug the electrical connectors from the

fuel injectors. Detach the injectors from the

fuel rail.

11Refitting is the reverse of removal. Be sure

to renew all O-rings. Coat the O-rings with a

light film of engine oil to prevent damage

during refitting. Pressurise the fuel system

(refit the fuel pump fuse and switch on the

ignition) and check for leaks before starting

the engine.

21 Idle air stabiliser valve-

check, adjustment and

renewal

4

1The idle air stabiliser system works to

maintain engine idle speed within a 200 rpm

range, regardless of varying engine loads at

idle. An electrically-operated valve allows a

small amount of air to bypass the throttle

plate, to raise the idle speed whenever the idle

speed drops below approximately 750 rpm. If

the idle speed rises above approximately

950 rpm, the idle air stabiliser valve closes

and stops extra air from bypassing the throttle

plate, reducing the idle speed.

4•18 Fuel and exhaust systems

20.8 Remove the bolts (arrowed) and

separate the fuel rail and injectors from

the intake manifold20.5 Check the resistance of each of the

fuel injectors19.6 Check the resistance of the

thermotime switch with the engine coolant

temperature below 30º C. There should be

continuity

If you don’t have a

mechanic’s stethoscope, a

screwdriver can be used to

check for a clicking sound at

the injectors. Place the tip of the

screwdriver against the injector, and

press your ear against the handle.

Page 112 of 228

1 General information

The engine electrical systems include all

ignition, charging and starting components.

Because of their engine-related functions,

these components are discussed separately

from body-related electrical devices such as

the lights, the instruments, etc. (which are

included in Chapter 12).

Always observe the following precautions

when working on the electrical systems:

a) Be extremely careful when servicing

engine electrical components. They are

easily damaged if improperly checked,

connected or handled.

b) Never leave the ignition switched on for

long periods of time with the engine off.

c) Don’t disconnect the battery cables while

the engine is running.

d) Observe the rules when jump-starting

your vehicle. Read the precautions at the

front of this manual.

e) Always disconnect the battery negative

cable first, and connect it last, to reduce

the risk of accidental short-circuits.

f) Don’t charge the battery with the cables

connected to the terminals.

It’s also a good idea to review the safety-

related information regarding the engine

electrical systems in the “Safety first”section

near the front of this manual before beginning

any operation included in this Chapter.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery. Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

2 Battery-

emergency jump starting

1

Refer to the “Jump starting”procedure at

the front of this manual.

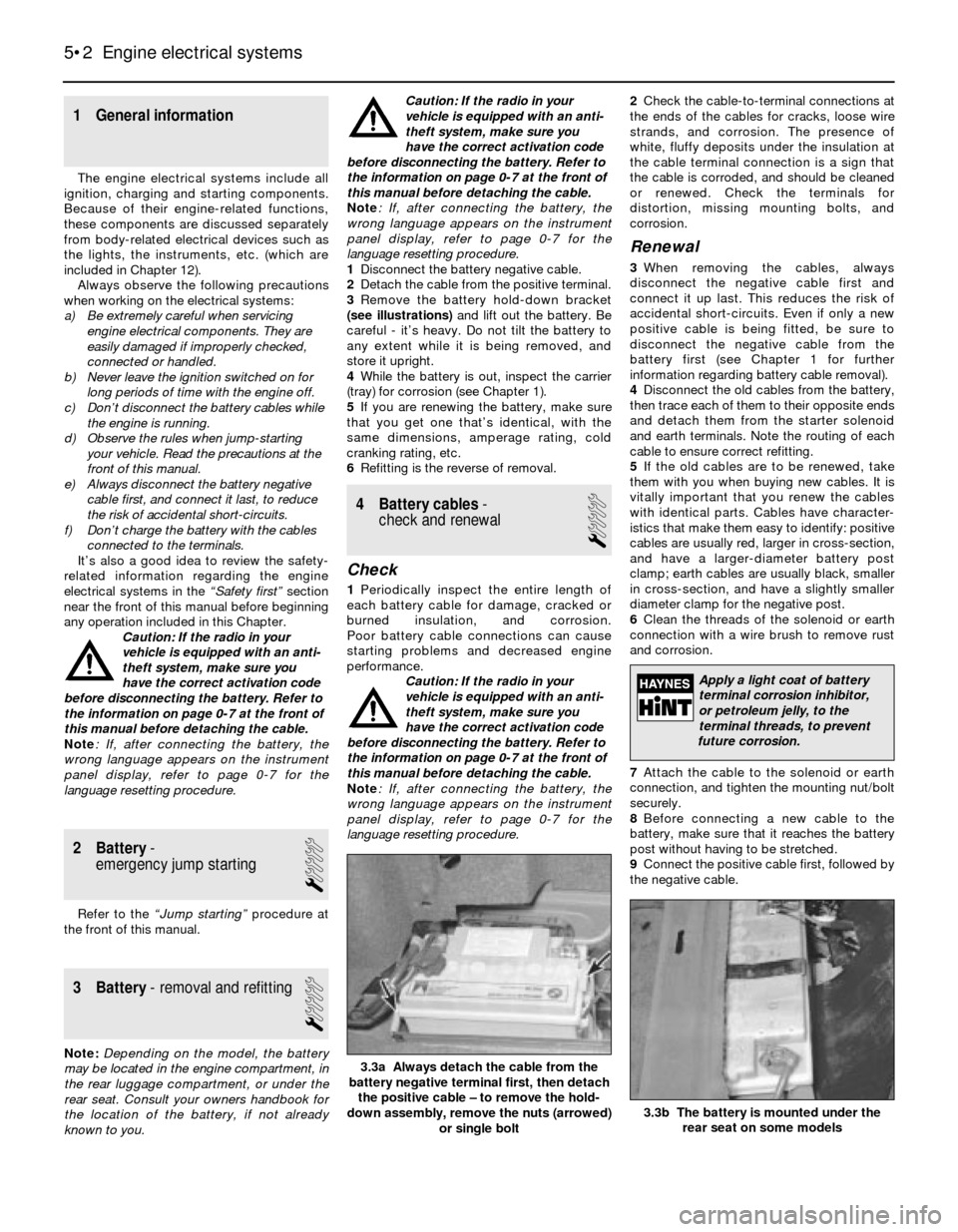

3 Battery- removal and refitting

1

Note:Depending on the model, the battery

may be located in the engine compartment, in

the rear luggage compartment, or under the

rear seat. Consult your owners handbook for

the location of the battery, if not already

known to you.Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery. Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

1Disconnect the battery negative cable.

2Detach the cable from the positive terminal.

3Remove the battery hold-down bracket

(see illustrations)and lift out the battery. Be

careful - it’s heavy. Do not tilt the battery to

any extent while it is being removed, and

store it upright.

4While the battery is out, inspect the carrier

(tray) for corrosion (see Chapter 1).

5If you are renewing the battery, make sure

that you get one that’s identical, with the

same dimensions, amperage rating, cold

cranking rating, etc.

6Refitting is the reverse of removal.

4 Battery cables-

check and renewal

1

Check

1Periodically inspect the entire length of

each battery cable for damage, cracked or

burned insulation, and corrosion.

Poor battery cable connections can cause

starting problems and decreased engine

performance.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery. Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.2Check the cable-to-terminal connections at

the ends of the cables for cracks, loose wire

strands, and corrosion. The presence of

white, fluffy deposits under the insulation at

the cable terminal connection is a sign that

the cable is corroded, and should be cleaned

or renewed. Check the terminals for

distortion, missing mounting bolts, and

corrosion.

Renewal

3When removing the cables, always

disconnect the negative cable first and

connect it up last. This reduces the risk of

accidental short-circuits. Even if only a new

positive cable is being fitted, be sure to

disconnect the negative cable from the

battery first (see Chapter 1 for further

information regarding battery cable removal).

4Disconnect the old cables from the battery,

then trace each of them to their opposite ends

and detach them from the starter solenoid

and earth terminals. Note the routing of each

cable to ensure correct refitting.

5If the old cables are to be renewed, take

them with you when buying new cables. It is

vitally important that you renew the cables

with identical parts. Cables have character-

istics that make them easy to identify: positive

cables are usually red, larger in cross-section,

and have a larger-diameter battery post

clamp; earth cables are usually black, smaller

in cross-section, and have a slightly smaller

diameter clamp for the negative post.

6Clean the threads of the solenoid or earth

connection with a wire brush to remove rust

and corrosion.

7Attach the cable to the solenoid or earth

connection, and tighten the mounting nut/bolt

securely.

8Before connecting a new cable to the

battery, make sure that it reaches the battery

post without having to be stretched.

9Connect the positive cable first, followed by

the negative cable.

5•2 Engine electrical systems

3.3b The battery is mounted under the

rear seat on some models

3.3a Always detach the cable from the

battery negative terminal first, then detach

the positive cable – to remove the hold-

down assembly, remove the nuts (arrowed)

or single bolt

Apply a light coat of battery

terminal corrosion inhibitor,

or petroleum jelly, to the

terminal threads, to prevent

future corrosion.

Page 113 of 228

5 Ignition system- general

information and precautions

The ignition system includes the ignition

switch, the battery, the distributor, the primary

(low-voltage/low-tension or LT) and

secondary (high-voltage/high-tension or HT)

wiring circuits, the spark plugs and the spark

plug leads. Models fitted with a carburettor or

L-Jetronic fuel injection are equipped with a

Transistorised Coil Ignition (TCI) system.

Models fitted with the Motronic fuel injection

system have the ignition system incorporated

within the Motronic system (Digital Motor

Electronics or DME).

Transistorised Coil Ignition (TCI)

system

This system is has four major components;

the impulse generator, the ignition control

unit, the coil, and the spark plugs. The

impulse generator provides a timing signal for

the ignition system. Equivalent to cam-

actuated breaker points in a standard

distributor, the impulse generator creates an

A/C voltage signal every time the trigger

wheel tabs pass the impulse generator tabs.

When the ignition control unit (capacitive

discharge unit) receives the voltage signal, it

triggers a spark discharge from the coil by

interrupting the primary coil circuit. The

ignition dwell (coil charging time) is adjusted

by the ignition control unit for the most

intense spark. Note: The air gap (distance

between the impulse generator and trigger

wheel tabs) can be adjusted (see Section 11).

Ignition timing is mechanically adjusted

(see Section 7). A centrifugal advance unit

that consists of spring-loaded rotating

weights advances ignition timing as engine

speed increases. The vacuum advance

adjusts ignition timing to compensate for

changes in engine load.

Motronic ignition system

This system, also known as Digital Motor

Electronics (DME), incorporates all ignition

and fuel injection functions into one central

control unit or ECU (computer). The ignition

timing is based on inputs the ECU receives for

engine load, engine speed, coolant

temperature and intake air temperature. The

only function the distributor performs is the

distribution of the high voltage signal to the

individual spark plugs. The distributor is

attached directly to the cylinder head. There is

no mechanical spark advance system used on

these systems.

Ignition timing is electronically-controlled,

and is not adjustable on Motronic systems.

During starting, a crankshaft position sensor

(reference sensor) relays the crankshaft

position to the ECU, and an initial baseline

ignition point is determined. Once the engineis running, the ignition timing is continually

changing, based on the various input signals

to the ECU. Engine speed is signalled by a

speed sensor. Early Motronic systems have

the position reference sensor and the speed

sensor mounted on the bellhousing over the

flywheel on the left-hand side. Later Motronic

systems have a single sensor (pulse sensor)

mounted over the crankshaft pulley. This

sensor functions as a speed sensor as well as

a position reference sensor. Refer to Sec-

tion 12 for checking and renewing the ignition

sensors. Note: Some models are equipped

with a TDC sensor mounted on the front of the

engine. This sensor is strictly for the BMW

service test unit, and it is not part of the

Motronic ignition system.

Precautions

Certain precautions must be observed

when working on a transistorised ignition

system.

a) Do not disconnect the battery cables

when the engine is running

b) Make sure the ignition control unit (TCI

ignition system) is always well earthed

(see Section 10).

c) Keep water away from the distributor and

HT leads.

d) If a tachometer is to be connected to the

engine, always connect the tachometer

positive (+) lead to the ignition coil

negative terminal (-) and never to the

distributor.

e) Do not allow the coil terminals to be

earthed, as the impulse generator or coil

could be damaged.

f) Do not leave the ignition switch on for

more than ten minutes with the engine

off, or if the engine will not start.

6 Ignition system- check

2

Warning: Because of the high

voltage generated by the ignition

system, extreme care should be

taken whenever an operation is

performed involving ignition components.

This not only includes the impulse

generator (electronic ignition), coil,

distributor and spark plug HT leads, but

related components such as spark plug

connectors, tachometer and other test

equipment.

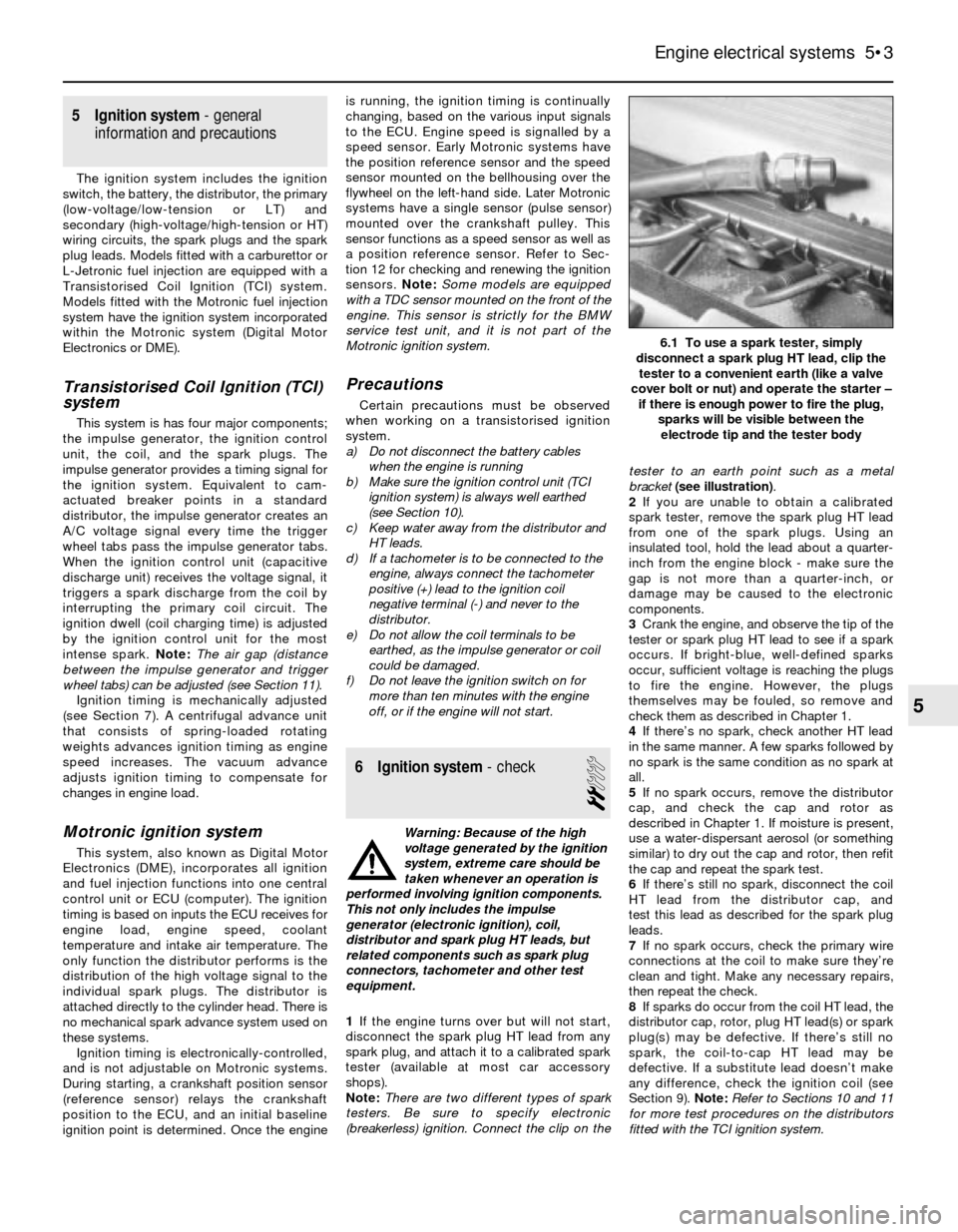

1If the engine turns over but will not start,

disconnect the spark plug HT lead from any

spark plug, and attach it to a calibrated spark

tester (available at most car accessory

shops).

Note:There are two different types of spark

testers. Be sure to specify electronic

(breakerless) ignition. Connect the clip on thetester to an earth point such as a metal

bracket (see illustration).

2If you are unable to obtain a calibrated

spark tester, remove the spark plug HT lead

from one of the spark plugs. Using an

insulated tool, hold the lead about a quarter-

inch from the engine block - make sure the

gap is not more than a quarter-inch, or

damage may be caused to the electronic

components.

3Crank the engine, and observe the tip of the

tester or spark plug HT lead to see if a spark

occurs. If bright-blue, well-defined sparks

occur, sufficient voltage is reaching the plugs

to fire the engine. However, the plugs

themselves may be fouled, so remove and

check them as described in Chapter 1.

4If there’s no spark, check another HT lead

in the same manner. A few sparks followed by

no spark is the same condition as no spark at

all.

5If no spark occurs, remove the distributor

cap, and check the cap and rotor as

described in Chapter 1. If moisture is present,

use a water-dispersant aerosol (or something

similar) to dry out the cap and rotor, then refit

the cap and repeat the spark test.

6If there’s still no spark, disconnect the coil

HT lead from the distributor cap, and

test this lead as described for the spark plug

leads.

7If no spark occurs, check the primary wire

connections at the coil to make sure they’re

clean and tight. Make any necessary repairs,

then repeat the check.

8If sparks do occur from the coil HT lead, the

distributor cap, rotor, plug HT lead(s) or spark

plug(s) may be defective. If there’s still no

spark, the coil-to-cap HT lead may be

defective. If a substitute lead doesn’t make

any difference, check the ignition coil (see

Section 9). Note:Refer to Sections 10 and 11

for more test procedures on the distributors

fitted with the TCI ignition system.

Engine electrical systems 5•3

6.1 To use a spark tester, simply

disconnect a spark plug HT lead, clip the

tester to a convenient earth (like a valve

cover bolt or nut) and operate the starter –

if there is enough power to fire the plug,

sparks will be visible between the

electrode tip and the tester body

5

Page 121 of 228

Refer to the information on page 0-7 at the

front of this manual before detaching the

cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

1Disconnect the battery negative cable.

Bosch alternator

2Remove the voltage regulator from the back

of the alternator (see Section 16).

3Measure the length of the brushes (see

illustration). They should not be less than

6.0 mm. If any are worn past this point, renew

them all as a set. 4Also check for excessively worn slip rings

(see illustration 16.5).

5The brushes are retained either by set

screws or by solder. If you are not skilled at

soldering, it may be best to have an auto

electrician fit the new brushes. Note: Be

careful not to apply heat to the solder joint for

more than 5 seconds. If necessary, use a heat

sink to capture the excess heat. This can be

accomplished by clamping a pair of needle-

nose pliers next to the solder joint.

6On the screw type, hold the assembly in

place and refit the screws. Tighten them

evenly, a little at a time, so the holder isn’t

distorted.

7Refit the regulator assembly to the

alternator.8Reconnect the battery negative cable.

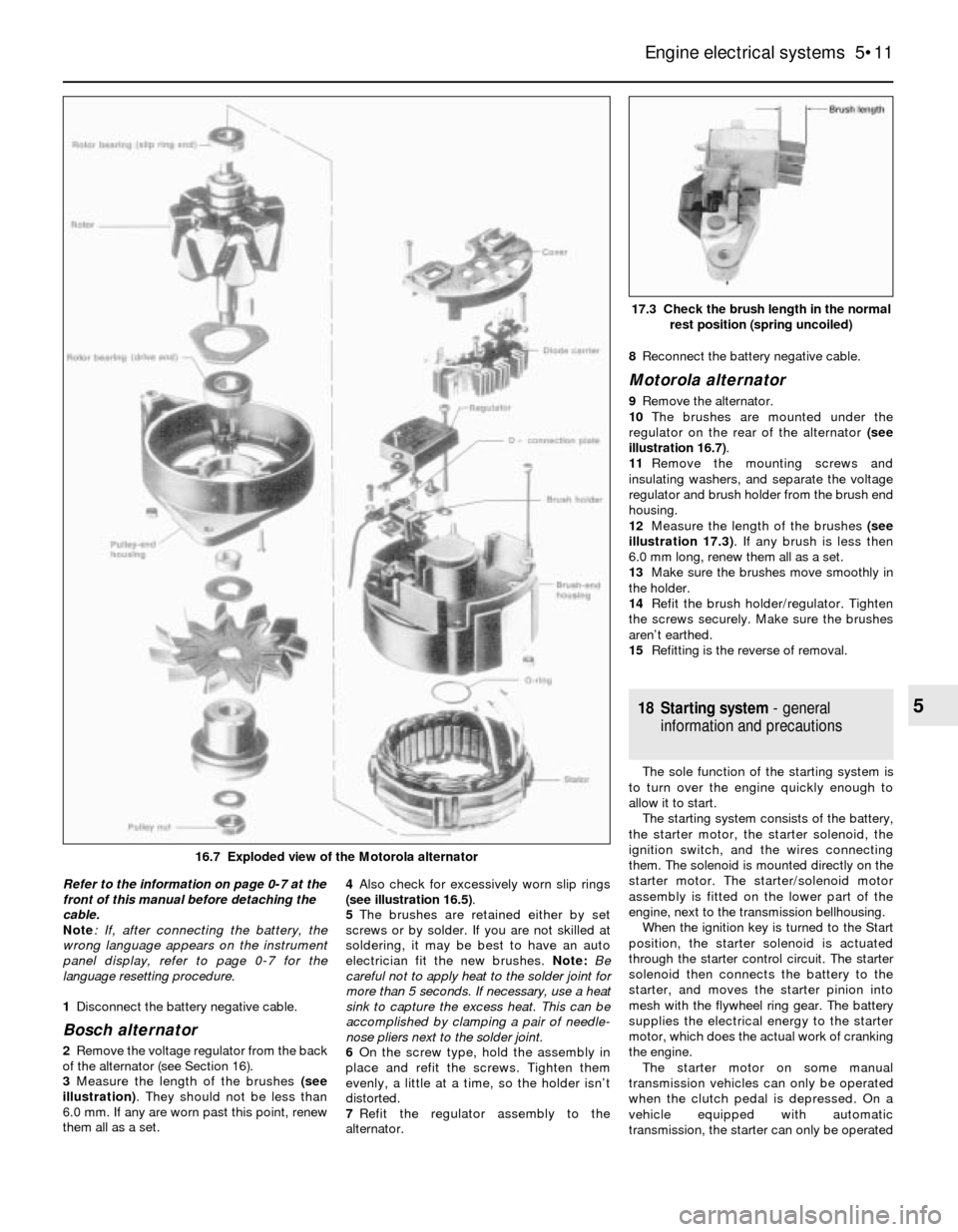

Motorola alternator

9Remove the alternator.

10The brushes are mounted under the

regulator on the rear of the alternator (see

illustration 16.7).

11Remove the mounting screws and

insulating washers, and separate the voltage

regulator and brush holder from the brush end

housing.

12Measure the length of the brushes (see

illustration 17.3). If any brush is less then

6.0 mm long, renew them all as a set.

13Make sure the brushes move smoothly in

the holder.

14Refit the brush holder/regulator. Tighten

the screws securely. Make sure the brushes

aren’t earthed.

15Refitting is the reverse of removal.

18 Starting system- general

information and precautions

The sole function of the starting system is

to turn over the engine quickly enough to

allow it to start.

The starting system consists of the battery,

the starter motor, the starter solenoid, the

ignition switch, and the wires connecting

them. The solenoid is mounted directly on the

starter motor. The starter/solenoid motor

assembly is fitted on the lower part of the

engine, next to the transmission bellhousing.

When the ignition key is turned to the Start

position, the starter solenoid is actuated

through the starter control circuit. The starter

solenoid then connects the battery to the

starter, and moves the starter pinion into

mesh with the flywheel ring gear. The battery

supplies the electrical energy to the starter

motor, which does the actual work of cranking

the engine.

The starter motor on some manual

transmission vehicles can only be operated

when the clutch pedal is depressed. On a

vehicle equipped with automatic

transmission, the starter can only be operated

Engine electrical systems 5•11

17.3 Check the brush length in the normal

rest position (spring uncoiled)

5

16.7 Exploded view of the Motorola alternator