engine coolant BMW 3 SERIES 1987 E30 Owner's Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1987, Model line: 3 SERIES, Model: BMW 3 SERIES 1987 E30Pages: 228, PDF Size: 7.04 MB

Page 108 of 228

reading should be between 400 and 500 mA.

Adjust the valve if the current reading is not as

specified. Note: The idle air stabiliser current

will fluctuate between 400 and 1100 mA if the

engine is too cold, if the coolant temperature

sensor is faulty, if there is an engine vacuum

leak, or if electrical accessories are on.

25If there is no current reading, have the idle

speed control unit (under the facia) checked

by a BMW dealer or other specialist.

26On three-wire valves, check for voltage at

the electrical connector. With the ignition on,

there should be battery voltage present at the

centre terminal (see illustration). There

should be about 10 volts between the centre

terminal and each of the outer terminals.

27If there is no voltage reading, have the idle

speed control unit (early models) or the ECU

(later models) checked by a dealer service

department or other specialist.

Adjustment (early models only)

28With the ignition switched off, connect a

tachometer in accordance with the equipment

manufacturer’s instructions.

29Make sure the ignition timing is correct

(see Chapter 5).

30Connect an ammeter to the valve as

described in paragraph 13.

31With the engine running, the current draw

should be 450 to 470 mA at 700 to 750 rpm.

32If the control current is not correct, turn

the adjusting screw until it is within the

specified range. Note: Turn the idle air bypass

screw clockwise to increase the current, or

anti-clockwise to decrease the current.

Renewal

33Remove the electrical connector and the

bracket from the idle air stabiliser valve.

Remove the valve, disconnecting the hoses.

34Refitting is the reverse of removal.

22 Exhaust system servicing-

general information

Warning: Inspect or repair

exhaust system components only

when the system is completely

cool. When working under the

vehicle, make sure it is securely

supported.

Silencer and pipes

1The exhaust system consists of the exhaust

manifold, catalytic converter, silencers, and all

connecting pipes, brackets, mountings (see

illustration)and clamps. The exhaust system

is attached to the body with brackets and

rubber mountings. If any of the parts are

improperly fitted, excessive noise and

vibration may be transmitted to the body.

2Inspect the exhaust system regularly. Look

for any damaged or bent parts, open seams,

holes, loose connections, excessive

corrosion, or other defects which could allow

exhaust fumes to enter the vehicle. Generally,

deteriorated exhaust system components

cannot be satisfactorily repaired; they should

be renewed.3If the exhaust system components are

extremely corroded or rusted together, it may

be necessary to cut off the old components

with a hacksaw. Be sure to wear safety

goggles to protect your eyes from metal

chips, and wear work gloves to protect your

hands.

4Here are some simple guidelines to follow

when repairing the exhaust system:

a) Work from the back to the front of the

vehicle when removing exhaust system

components.

b) Apply penetrating oil to the exhaust

system nuts and bolts to make them

easier to remove.

c) Use new gaskets, mountings and clamps

when fitting exhaust system components.

d) Apply anti-seize compound to the threads

of all exhaust system nuts and bolts

during reassembly.

e) Be sure to allow sufficient clearance

between newly-fitted parts and all points

on the underbody, to avoid overheating

the floorpan, and possibly damaging the

interior carpet and insulation. Pay

particularly close attention to the catalytic

converters and heat shields. Also, make

sure that the exhaust will not come into

contact with suspension parts, etc.

Catalytic converter

5Although the catalytic converter is an

emissions-related component, it is discussed

here because, physically, it’s an integral part

of the exhaust system. Always check the

converter whenever you raise the vehicle to

inspect or service the exhaust system.

6Raise and support the vehicle.

7Inspect the catalytic converter for cracks or

damage.

8Check the converter connections for

tightness.

9Check the insulation covers welded onto the

catalytic converter for damage or a loose fit.

Caution: If an insulation cover is

dented so that it touches the

converter housing inside,

excessive heat may be

transferred to the floor.

10Start the engine and run it at idle speed.

Check all converter connections for exhaust

gas leakage.

4•20 Fuel and exhaust systems

22.1 A typical exhaust system rubber

mounting21.26 Check for battery voltage on the

centre terminal

Page 109 of 228

Fuel injection system - fault finding

L-Jetronic fuel injection system

Engine difficult to start, or fails to start (when cold)

Probable cause Corrective action

Cold start injector or thermotime switch faulty Test cold start injector and thermotime switch. Renew faulty components (see Section 19)

Fuel pump inoperative Check fuel pump fuse and fuel pump relay (see Sections 3 and 4)

Airflow meter flap (door) binding or stuck

in open position Inspect the airflow meter for damage (see Section 16)

Fuel pressure incorrect Test system pressure (see Section 3). Test fuel pressure regulator (Section 18)

Intake air leaks Inspect all vacuum lines, air ducts, and oil filler and dipstick seals

Fuel injectors clogged or not operating Check fuel injectors (see Section 20) and wiring harness

Coolant temperature sensor faulty or

wiring problem Test coolant temperature sensor (see Chapter 6, Section 4)

Throttle position sensor (TPS) incorrectly adjusted Check TPS adjustment (see Chapter 6, Section 4)

Incorrect ignition timing Check ignition timing (see Chapter 5). Check vacuum advance system

Dirt or other contaminants in fuel Check the fuel and drain the tank if necessary

Faulty ECU Have the ECU tested at a dealer service department or other specialist

Engine difficult to start, or fails to start (when warm)

Probable cause Corrective action

Cold start injector leaking or operating continuously Test cold start injector and thermotime switch (see Section 19)

Fuel pressure incorrect Test fuel pump(s). Renew if necessary (see Section 3)

Insufficient residual fuel pressure Test residual fuel pressure. Renew fuel pump or fuel accumulator as necessary

(see Section 18)

Fuel leak(s) Inspect fuel lines and fuel injectors for leaks. Correct leaks as required (see Chapter 4)

Coolant temperature sensor faulty or

wiring problem Test coolant temperature sensor (see Chapter 6, Section 4)

Vapour lock (warm weather) Check fuel pressure (see Section 3)

EVAP system faulty (where applicable) Check EVAP system (see Chapter 6, Section 6)

Incorrect ignition timing Check ignition timing (see Chapter 5). Check vacuum advance system

Faulty ECU Have the ECU tested at a dealer service department or other specialist

Idle speed control system faulty Test the idle air stabiliser valve (see Section 21)

Engine misses and hesitates under load

Probable cause Corrective action

Fuel injector clogged or faulty Test fuel injectors. Check for clogged injector lines. Renew faulty injectors (see Section 20)

Fuel pressure incorrect Test fuel system pressure (see Section 3). Test fuel pressure regulator (see Section 18)

Fuel leak(s) Inspect fuel lines and fuel injectors for leaks (see Chapter 4)

Engine maintenance Tune-up engine (see Chapter 1). Check the distributor cap, rotor, HT leads and spark

plugs, and renew any faulty components

Airflow meter flap (door) binding, or

stuck in open position Inspect the airflow meter for damage (see Section 16)

Intake air leaks Inspect all vacuum lines, air ducts and oil filler and dipstick seals

Engine has erratic idle speed

Probable cause Corrective action

Idle air stabiliser valve faulty Check the idle air stabiliser valve (see Section 21)

No power to the idle air stabiliser valve Check the idle air stabiliser relay and wiring circuit (see Chapter 12)

Vacuum advance system faulty Check vacuum advance system and electronic vacuum advance relay

Idle speed control unit faulty Have the idle speed control unit checked by a dealer

Motronic fuel injection system

Note:With this system, when faults occur, the ECU stores a fault code in its memory. These codes can only be read by a BMW dealer, as

specialised equipment is required. It may save time to have at least the initial fault diagnosis carried out by a dealer.

Lack of power

Probable cause Corrective action

Coolant temperature sensor faulty, Test coolant temperature sensor and wiring. Repair wiring or renew sensor if

or wire to sensor broken faulty (see Chapter 6)

Fuel pressure incorrect Check fuel pressure from main pump and transfer pump, as applicable (see Section 3)

Throttle plate not opening fully Check accelerator cable adjustment to make sure throttle is opening fully. Adjust cable if

necessary (see Section 9)

Fuel and exhaust systems 4•21

4

Page 110 of 228

Engine difficult to start, or fails to start (when cold)

Probable cause Corrective action

Cold start injector or thermotime switch

faulty (early Motronic system only) Test cold start injector and thermotime switch. Renew faulty components (see Section 19)

Fuel pump not running Check fuel pump fuse and fuel pump relay (see Sections 2 and 3)

Airflow meter flap (door) binding, or

stuck in open position Inspect the airflow meter for damage (see Section 16)

Fuel pressure incorrect Test system pressure (see Section 3)

Intake air leaks Inspect all vacuum lines, air ducts and oil filler and dipstick seals

Fuel injectors clogged or not operating Check fuel injectors (see Section 20) and wiring harness

Coolant temperature sensor faulty or Test coolant temperature sensor (see Chapter 6, Section 4)

wiring problem

TPS (throttle position sensor) incorrectly adjusted Check TPS adjustment (see Chapter 6, Section 4)

Dirt or other contaminants in fuel Check the fuel and drain the tank if necessary

Faulty ECU Have the ECU tested at a dealer service department or other specialist

Crankshaft position signal missing Faulty position sensor or flywheel, or reference pin missing (see Chapter 5)

Engine difficult to start, or fails to start (when warm)

Probable cause Corrective action

Cold start injector leaking or operating

continuously (early Motronic system only) Test cold start injector and thermotime switch (see Section 19)

Fuel pressure incorrect Test fuel pressure (see Section 3)

Insufficient residual fuel pressure Test fuel system hold pressure (see Section 3)

Fuel leak(s) Inspect fuel lines and fuel injectors for leaks. Correct leaks as necessary

Coolant temperature sensor faulty

or wiring problem Test coolant temperature sensor (see Chapter 6, Section 4)

Vapour lock (in warm weather) Check fuel pressure (see Section 3)

EVAP system faulty Check EVAP system (see Chapter 6, Section 6)

Faulty ECU Have the ECU tested at a dealer service department or other specialist

Idle speed control system faulty Test the idle air stabiliser valve (see Section 21)

Oxygen sensor faulty (where applicable) Check the oxygen sensor (see Chapter 6, Section 4)

Engine misses and hesitates under load

Probable cause Corrective action

Fuel injector clogged Test fuel injectors. Check for clogged injector lines. Renew faulty injectors (see Section 20)

Fuel pressure incorrect Test fuel system pressure (see Section 3). Test fuel pressure regulator (see Section 18)

Fuel leak(s) Inspect fuel lines and fuel injectors for leaks (see Chapter 4)

Engine maintenance Tune-up engine (see Chapter 1). Check the distributor cap, rotor, HT leads and spark

plugs, and renew any faulty components

Airflow meter flap (door) binding, or Inspect the airflow meter for damage (see Section 16)

stuck in open position

Intake air leaks Inspect all vacuum lines, air ducts, and oil filler and dipstick seals

Throttle position sensor (TPS) incorrectly adjusted Check TPS adjustment (see Chapter 6)

Engine idles too fast

Probable cause Corrective action

Accelerator pedal, cable or throttle valve binding Check for worn or broken components, kinked cable, or other damage. Renew faulty

components

Air leaking past throttle valve Inspect throttle valve, and adjust or renew as required

Engine has erratic idle speed

Probable cause Corrective action

Idle air stabiliser valve faulty Check the idle air stabiliser valve (see Section 21)

No power to the idle air stabiliser valve Check the idle air stabiliser relay and wiring circuit (see Chapter 12)

Idle speed control unit faulty Have the idle speed control unit checked by a dealer

Poor fuel economy

Probable cause Corrective action

Cold start injector leaking

(early Motronic system only) Test and, if necessary, renew cold start injector (see Section 19)

Oxygen sensor faulty (where applicable) Test the oxygen sensor (see Chapter 6, Section 4))

Sticking handbrake/binding brakes Check the handbrake/braking system (see Chapter 9)

Tyre pressures low Check tyre pressures (Chapter 1)

4•22 Fuel and exhaust systems

Page 113 of 228

5 Ignition system- general

information and precautions

The ignition system includes the ignition

switch, the battery, the distributor, the primary

(low-voltage/low-tension or LT) and

secondary (high-voltage/high-tension or HT)

wiring circuits, the spark plugs and the spark

plug leads. Models fitted with a carburettor or

L-Jetronic fuel injection are equipped with a

Transistorised Coil Ignition (TCI) system.

Models fitted with the Motronic fuel injection

system have the ignition system incorporated

within the Motronic system (Digital Motor

Electronics or DME).

Transistorised Coil Ignition (TCI)

system

This system is has four major components;

the impulse generator, the ignition control

unit, the coil, and the spark plugs. The

impulse generator provides a timing signal for

the ignition system. Equivalent to cam-

actuated breaker points in a standard

distributor, the impulse generator creates an

A/C voltage signal every time the trigger

wheel tabs pass the impulse generator tabs.

When the ignition control unit (capacitive

discharge unit) receives the voltage signal, it

triggers a spark discharge from the coil by

interrupting the primary coil circuit. The

ignition dwell (coil charging time) is adjusted

by the ignition control unit for the most

intense spark. Note: The air gap (distance

between the impulse generator and trigger

wheel tabs) can be adjusted (see Section 11).

Ignition timing is mechanically adjusted

(see Section 7). A centrifugal advance unit

that consists of spring-loaded rotating

weights advances ignition timing as engine

speed increases. The vacuum advance

adjusts ignition timing to compensate for

changes in engine load.

Motronic ignition system

This system, also known as Digital Motor

Electronics (DME), incorporates all ignition

and fuel injection functions into one central

control unit or ECU (computer). The ignition

timing is based on inputs the ECU receives for

engine load, engine speed, coolant

temperature and intake air temperature. The

only function the distributor performs is the

distribution of the high voltage signal to the

individual spark plugs. The distributor is

attached directly to the cylinder head. There is

no mechanical spark advance system used on

these systems.

Ignition timing is electronically-controlled,

and is not adjustable on Motronic systems.

During starting, a crankshaft position sensor

(reference sensor) relays the crankshaft

position to the ECU, and an initial baseline

ignition point is determined. Once the engineis running, the ignition timing is continually

changing, based on the various input signals

to the ECU. Engine speed is signalled by a

speed sensor. Early Motronic systems have

the position reference sensor and the speed

sensor mounted on the bellhousing over the

flywheel on the left-hand side. Later Motronic

systems have a single sensor (pulse sensor)

mounted over the crankshaft pulley. This

sensor functions as a speed sensor as well as

a position reference sensor. Refer to Sec-

tion 12 for checking and renewing the ignition

sensors. Note: Some models are equipped

with a TDC sensor mounted on the front of the

engine. This sensor is strictly for the BMW

service test unit, and it is not part of the

Motronic ignition system.

Precautions

Certain precautions must be observed

when working on a transistorised ignition

system.

a) Do not disconnect the battery cables

when the engine is running

b) Make sure the ignition control unit (TCI

ignition system) is always well earthed

(see Section 10).

c) Keep water away from the distributor and

HT leads.

d) If a tachometer is to be connected to the

engine, always connect the tachometer

positive (+) lead to the ignition coil

negative terminal (-) and never to the

distributor.

e) Do not allow the coil terminals to be

earthed, as the impulse generator or coil

could be damaged.

f) Do not leave the ignition switch on for

more than ten minutes with the engine

off, or if the engine will not start.

6 Ignition system- check

2

Warning: Because of the high

voltage generated by the ignition

system, extreme care should be

taken whenever an operation is

performed involving ignition components.

This not only includes the impulse

generator (electronic ignition), coil,

distributor and spark plug HT leads, but

related components such as spark plug

connectors, tachometer and other test

equipment.

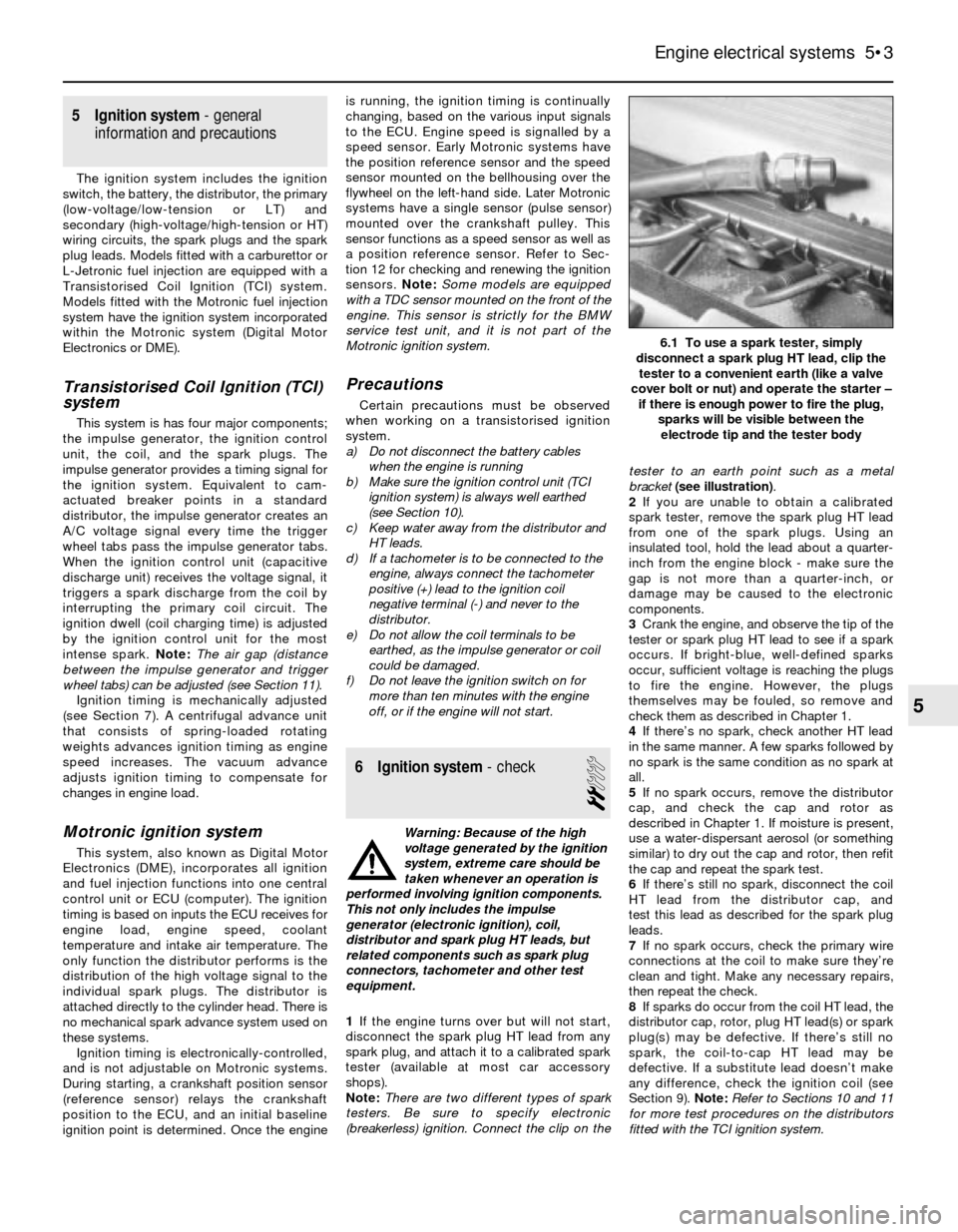

1If the engine turns over but will not start,

disconnect the spark plug HT lead from any

spark plug, and attach it to a calibrated spark

tester (available at most car accessory

shops).

Note:There are two different types of spark

testers. Be sure to specify electronic

(breakerless) ignition. Connect the clip on thetester to an earth point such as a metal

bracket (see illustration).

2If you are unable to obtain a calibrated

spark tester, remove the spark plug HT lead

from one of the spark plugs. Using an

insulated tool, hold the lead about a quarter-

inch from the engine block - make sure the

gap is not more than a quarter-inch, or

damage may be caused to the electronic

components.

3Crank the engine, and observe the tip of the

tester or spark plug HT lead to see if a spark

occurs. If bright-blue, well-defined sparks

occur, sufficient voltage is reaching the plugs

to fire the engine. However, the plugs

themselves may be fouled, so remove and

check them as described in Chapter 1.

4If there’s no spark, check another HT lead

in the same manner. A few sparks followed by

no spark is the same condition as no spark at

all.

5If no spark occurs, remove the distributor

cap, and check the cap and rotor as

described in Chapter 1. If moisture is present,

use a water-dispersant aerosol (or something

similar) to dry out the cap and rotor, then refit

the cap and repeat the spark test.

6If there’s still no spark, disconnect the coil

HT lead from the distributor cap, and

test this lead as described for the spark plug

leads.

7If no spark occurs, check the primary wire

connections at the coil to make sure they’re

clean and tight. Make any necessary repairs,

then repeat the check.

8If sparks do occur from the coil HT lead, the

distributor cap, rotor, plug HT lead(s) or spark

plug(s) may be defective. If there’s still no

spark, the coil-to-cap HT lead may be

defective. If a substitute lead doesn’t make

any difference, check the ignition coil (see

Section 9). Note:Refer to Sections 10 and 11

for more test procedures on the distributors

fitted with the TCI ignition system.

Engine electrical systems 5•3

6.1 To use a spark tester, simply

disconnect a spark plug HT lead, clip the

tester to a convenient earth (like a valve

cover bolt or nut) and operate the starter –

if there is enough power to fire the plug,

sparks will be visible between the

electrode tip and the tester body

5

Page 122 of 228

when the transmission selector lever is in Park

or Neutral.

Always detach the battery negative cable

before working on the starting system.

19 Starter motor-

in-vehicle check

2

Note:Before diagnosing starter problems,

make sure the battery is fully charged.

1If the starter motor does not turn at all when

the switch is operated, make sure that the

gear lever is in Neutral or Park (automatic

transmission) or, where applicable, that the

clutch pedal is depressed (manual

transmission).

2Make sure that the battery is charged, and

that all cables, both at the battery and starter

solenoid terminals, are clean and secure.

3If the starter motor spins but the engine is

not cranking, the overrun clutch in the starter

motor is slipping, and the starter motor must

be renewed.

4If, when the switch is actuated, the starter

motor does not operate at all but the solenoid

clicks, then the problem lies either in the

battery, the main solenoid contacts, or the

starter motor itself (or the engine is seized).

5If the solenoid plunger cannot be heard

when the switch is actuated, the battery is

faulty, the switch is defective, the fusible link

is burned-out (the circuit is open), or the

solenoid itself is defective.

6To check the solenoid, connect a jumper

lead between the battery (+) and the ignition

switch wire terminal (the small terminal) on the

solenoid. If the starter motor now operates,

the solenoid is OK and the problem is in the

ignition switch, starter inhibitor switch

(automatic transmission models), clutch

switch (some manual transmission models), or

the wiring.

7If the starter motor still does not operate,

remove the starter/solenoid assembly for

dismantling, testing and repair.

8If the starter motor cranks the engine at an

abnormally-slow speed, first make sure that

the battery is charged, and that all terminal

connections are tight. If the engine is partially-

seized, or has the wrong viscosity oil in it, it

will crank slowly.

9Run the engine until normal operating

temperature is reached, then disconnect the

coil HT lead from the distributor cap and earth

it on the engine.

10Connect a voltmeter positive lead to the

battery positive post, and connect the

negative lead to the negative post.11Crank the engine, and take the voltmeter

readings as soon as a steady figure is

indicated. Do not allow the starter motor to

turn for more than 10 seconds at a time. A

reading of 9 volts or more, with the starter

motor turning at normal cranking speed, is

normal. If the reading is 9 volts or more but

the cranking speed is slow, the solenoid

contacts are burned, there is a bad

connection, or the starter motor itself is faulty.

If the reading is less than 9 volts and the

cranking speed is slow, the starter motor is

faulty or the battery is responsible (defective

or discharged).

20 Starter motor-

removal and refitting

1

Note:If the starter motor is defective, it should

be renewed, or taken to an auto electrical

specialist for repair. Overhaul of the starter

motor is unlikely to be a practical proposition

for the home mechanic, even if spare parts are

available. However, the solenoid can be

renewed separately (see Section 21).

Removal

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery. Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

1Detach the battery negative cable.

2Raise the vehicle and support it securely on

axle stands.

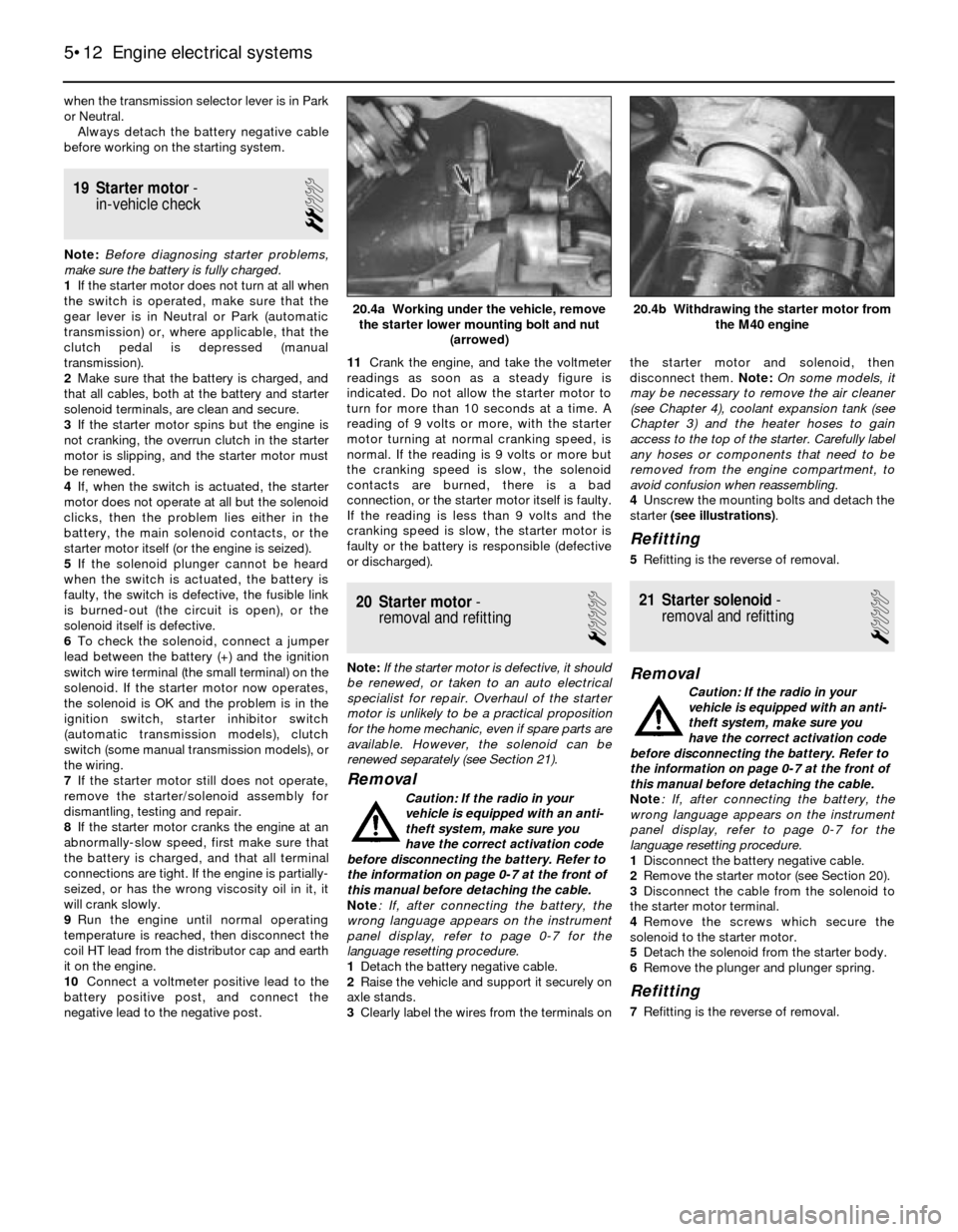

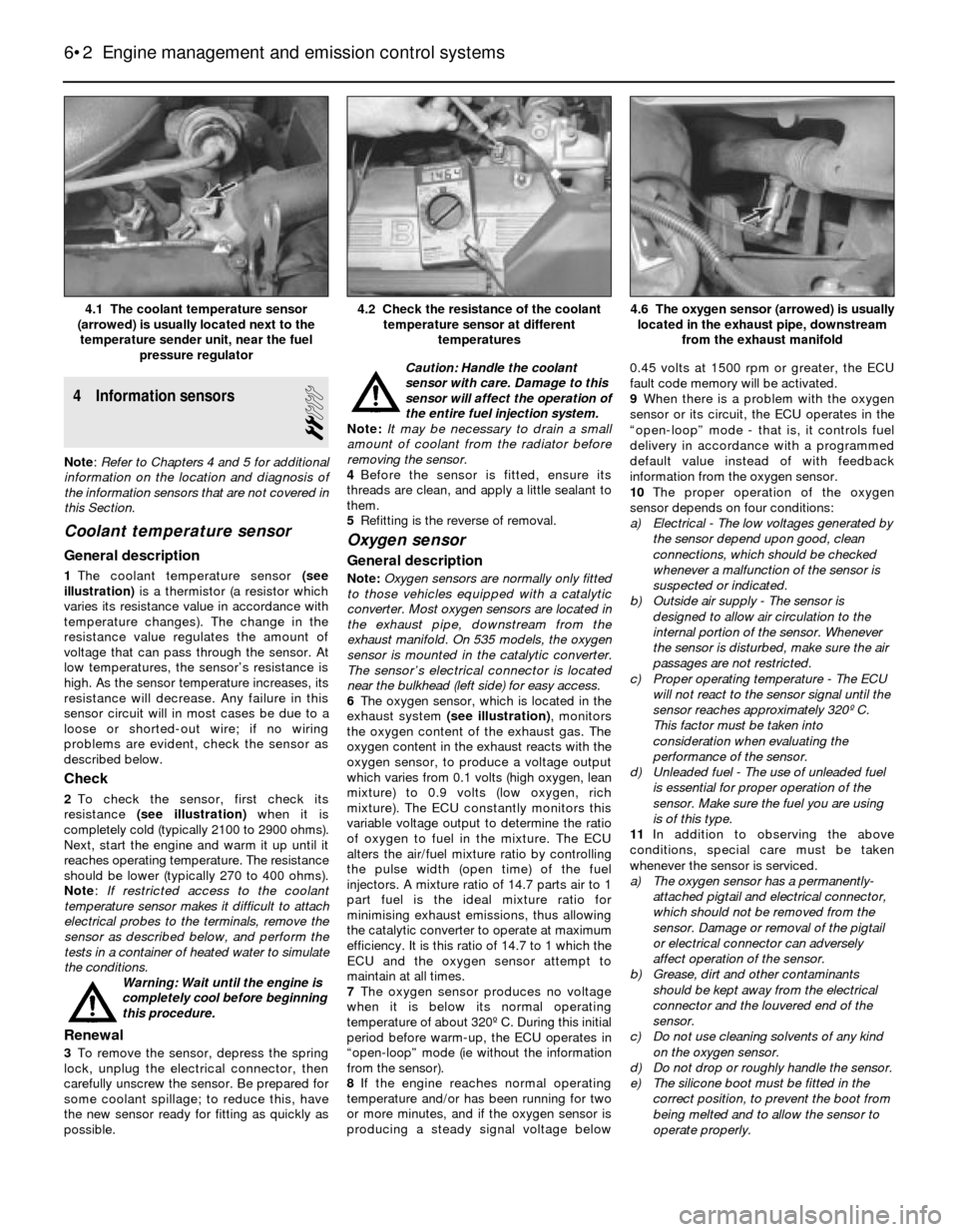

3Clearly label the wires from the terminals onthe starter motor and solenoid, then

disconnect them. Note: On some models, it

may be necessary to remove the air cleaner

(see Chapter 4), coolant expansion tank (see

Chapter 3) and the heater hoses to gain

access to the top of the starter. Carefully label

any hoses or components that need to be

removed from the engine compartment, to

avoid confusion when reassembling.

4Unscrew the mounting bolts and detach the

starter (see illustrations).

Refitting

5Refitting is the reverse of removal.

21 Starter solenoid-

removal and refitting

1

Removal

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery. Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

1Disconnect the battery negative cable.

2Remove the starter motor (see Section 20).

3Disconnect the cable from the solenoid to

the starter motor terminal.

4Remove the screws which secure the

solenoid to the starter motor.

5Detach the solenoid from the starter body.

6Remove the plunger and plunger spring.

Refitting

7Refitting is the reverse of removal.

5•12 Engine electrical systems

20.4b Withdrawing the starter motor from

the M40 engine20.4a Working under the vehicle, remove

the starter lower mounting bolt and nut

(arrowed)

Page 124 of 228

4 Information sensors

2

Note:Refer to Chapters 4 and 5 for additional

information on the location and diagnosis of

the information sensors that are not covered in

this Section.

Coolant temperature sensor

General description

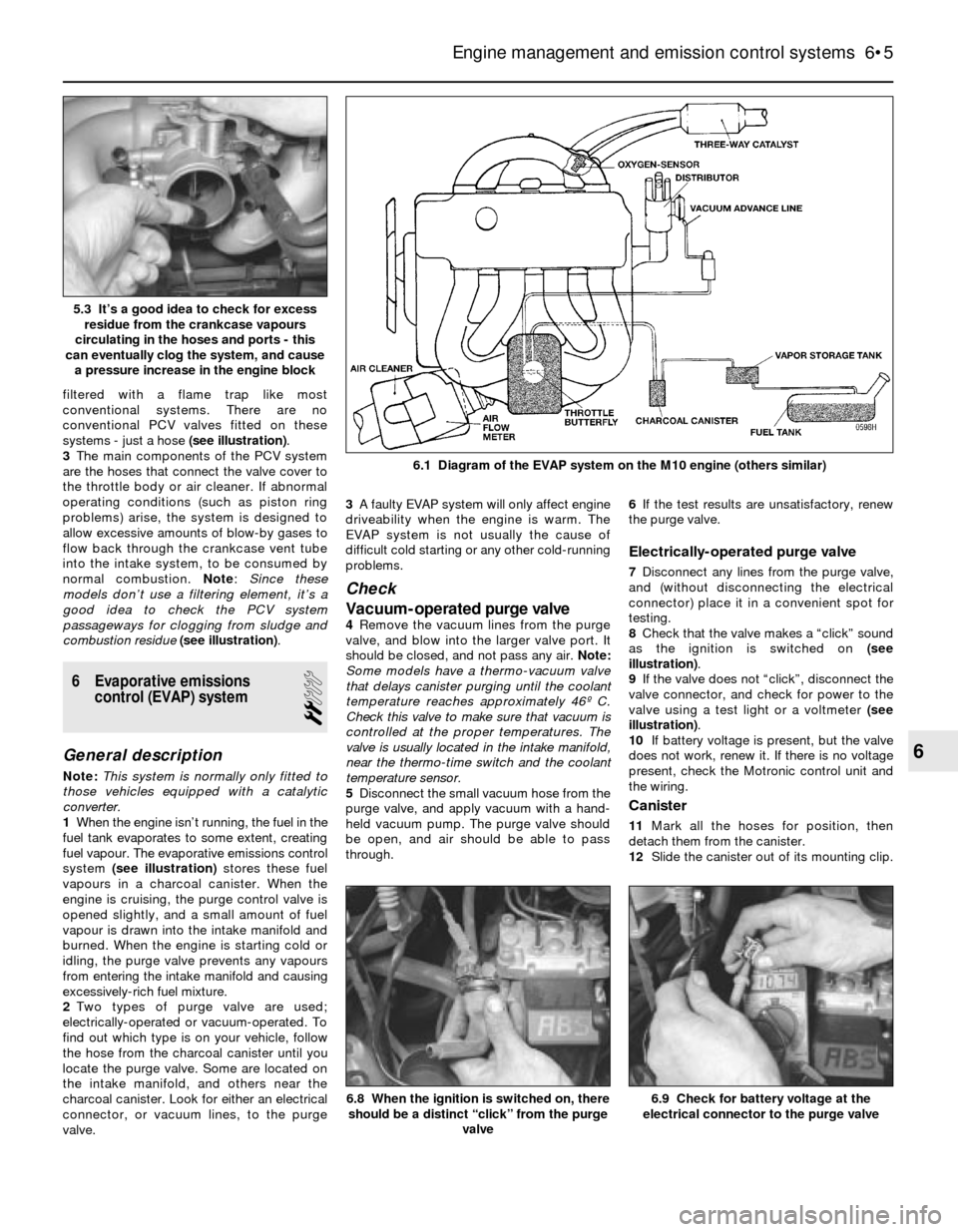

1The coolant temperature sensor (see

illustration)is a thermistor (a resistor which

varies its resistance value in accordance with

temperature changes). The change in the

resistance value regulates the amount of

voltage that can pass through the sensor. At

low temperatures, the sensor’s resistance is

high. As the sensor temperature increases, its

resistance will decrease. Any failure in this

sensor circuit will in most cases be due to a

loose or shorted-out wire; if no wiring

problems are evident, check the sensor as

described below.

Check

2To check the sensor, first check its

resistance (see illustration)when it is

completely cold (typically 2100 to 2900 ohms).

Next, start the engine and warm it up until it

reaches operating temperature. The resistance

should be lower (typically 270 to 400 ohms).

Note: If restricted access to the coolant

temperature sensor makes it difficult to attach

electrical probes to the terminals, remove the

sensor as described below, and perform the

tests in a container of heated water to simulate

the conditions.

Warning: Wait until the engine is

completely cool before beginning

this procedure.

Renewal

3To remove the sensor, depress the spring

lock, unplug the electrical connector, then

carefully unscrew the sensor. Be prepared for

some coolant spillage; to reduce this, have

the new sensor ready for fitting as quickly as

possible.Caution: Handle the coolant

sensor with care. Damage to this

sensor will affect the operation of

the entire fuel injection system.

Note: It may be necessary to drain a small

amount of coolant from the radiator before

removing the sensor.

4Before the sensor is fitted, ensure its

threads are clean, and apply a little sealant to

them.

5Refitting is the reverse of removal.

Oxygen sensor

General description

Note:Oxygen sensors are normally only fitted

to those vehicles equipped with a catalytic

converter. Most oxygen sensors are located in

the exhaust pipe, downstream from the

exhaust manifold. On 535 models, the oxygen

sensor is mounted in the catalytic converter.

The sensor’s electrical connector is located

near the bulkhead (left side) for easy access.

6The oxygen sensor, which is located in the

exhaust system (see illustration), monitors

the oxygen content of the exhaust gas. The

oxygen content in the exhaust reacts with the

oxygen sensor, to produce a voltage output

which varies from 0.1 volts (high oxygen, lean

mixture) to 0.9 volts (low oxygen, rich

mixture). The ECU constantly monitors this

variable voltage output to determine the ratio

of oxygen to fuel in the mixture. The ECU

alters the air/fuel mixture ratio by controlling

the pulse width (open time) of the fuel

injectors. A mixture ratio of 14.7 parts air to 1

part fuel is the ideal mixture ratio for

minimising exhaust emissions, thus allowing

the catalytic converter to operate at maximum

efficiency. It is this ratio of 14.7 to 1 which the

ECU and the oxygen sensor attempt to

maintain at all times.

7The oxygen sensor produces no voltage

when it is below its normal operating

temperature of about 320º C. During this initial

period before warm-up, the ECU operates in

“open-loop” mode (ie without the information

from the sensor).

8If the engine reaches normal operating

temperature and/or has been running for two

or more minutes, and if the oxygen sensor is

producing a steady signal voltage below 0.45 volts at 1500 rpm or greater, the ECU

fault code memory will be activated.

9When there is a problem with the oxygen

sensor or its circuit, the ECU operates in the

“open-loop” mode - that is, it controls fuel

delivery in accordance with a programmed

default value instead of with feedback

information from the oxygen sensor.

10The proper operation of the oxygen

sensor depends on four conditions:

a) Electrical - The low voltages generated by

the sensor depend upon good, clean

connections, which should be checked

whenever a malfunction of the sensor is

suspected or indicated.

b) Outside air supply - The sensor is

designed to allow air circulation to the

internal portion of the sensor. Whenever

the sensor is disturbed, make sure the air

passages are not restricted.

c) Proper operating temperature - The ECU

will not react to the sensor signal until the

sensor reaches approximately 320º C.

This factor must be taken into

consideration when evaluating the

performance of the sensor.

d) Unleaded fuel - The use of unleaded fuel

is essential for proper operation of the

sensor. Make sure the fuel you are using

is of this type.

11In addition to observing the above

conditions, special care must be taken

whenever the sensor is serviced.

a) The oxygen sensor has a permanently-

attached pigtail and electrical connector,

which should not be removed from the

sensor. Damage or removal of the pigtail

or electrical connector can adversely

affect operation of the sensor.

b) Grease, dirt and other contaminants

should be kept away from the electrical

connector and the louvered end of the

sensor.

c) Do not use cleaning solvents of any kind

on the oxygen sensor.

d) Do not drop or roughly handle the sensor.

e) The silicone boot must be fitted in the

correct position, to prevent the boot from

being melted and to allow the sensor to

operate properly.

6•2 Engine management and emission control systems

4.6 The oxygen sensor (arrowed) is usually

located in the exhaust pipe, downstream

from the exhaust manifold4.2 Check the resistance of the coolant

temperature sensor at different

temperatures4.1 The coolant temperature sensor

(arrowed) is usually located next to the

temperature sender unit, near the fuel

pressure regulator

Page 127 of 228

filtered with a flame trap like most

conventional systems. There are no

conventional PCV valves fitted on these

systems - just a hose (see illustration).

3The main components of the PCV system

are the hoses that connect the valve cover to

the throttle body or air cleaner. If abnormal

operating conditions (such as piston ring

problems) arise, the system is designed to

allow excessive amounts of blow-by gases to

flow back through the crankcase vent tube

into the intake system, to be consumed by

normal combustion. Note: Since these

models don’t use a filtering element, it’s a

good idea to check the PCV system

passageways for clogging from sludge and

combustion residue(see illustration).

6 Evaporative emissions

control (EVAP) system

2

General description

Note:This system is normally only fitted to

those vehicles equipped with a catalytic

converter.

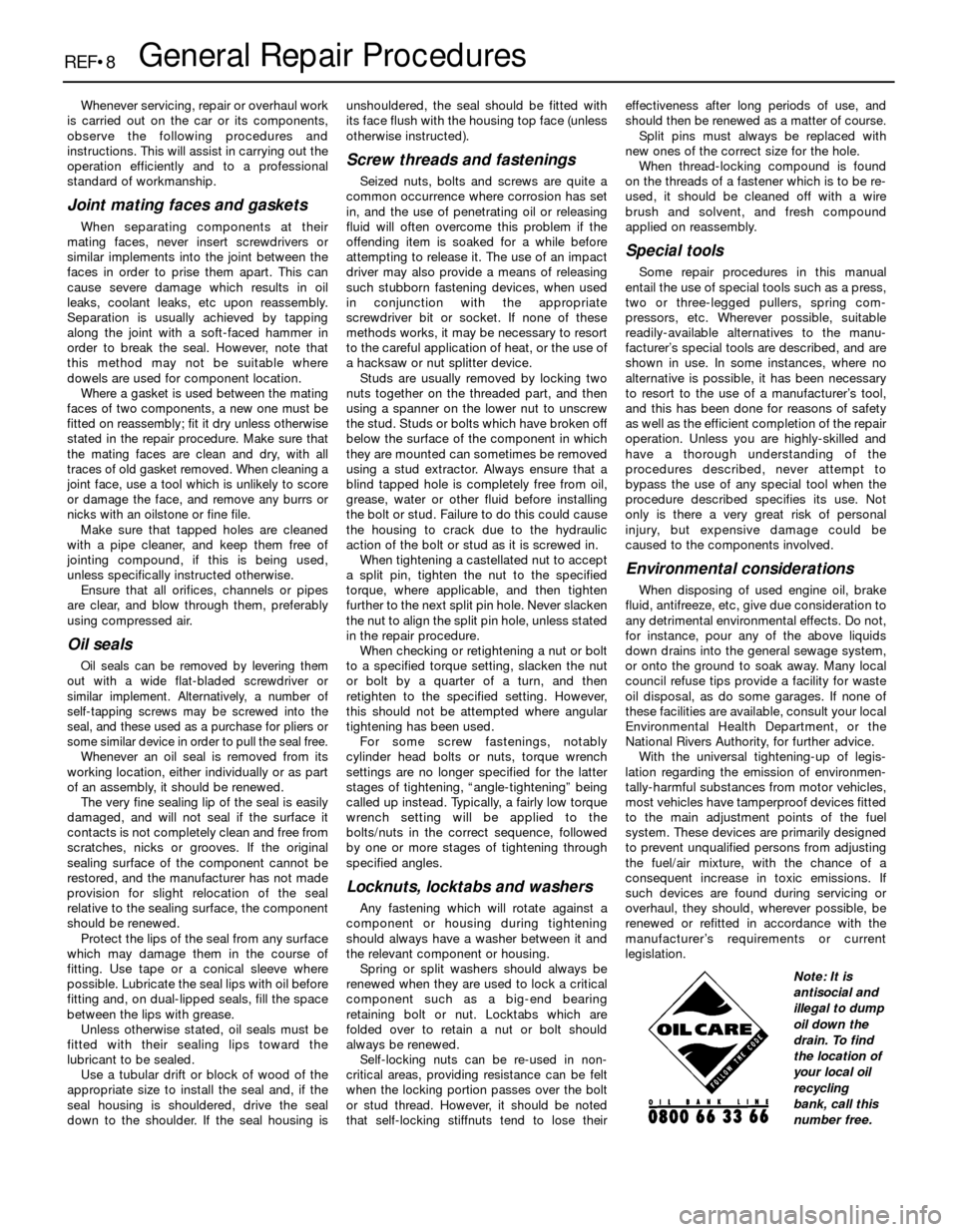

1When the engine isn’t running, the fuel in the

fuel tank evaporates to some extent, creating

fuel vapour. The evaporative emissions control

system (see illustration)stores these fuel

vapours in a charcoal canister. When the

engine is cruising, the purge control valve is

opened slightly, and a small amount of fuel

vapour is drawn into the intake manifold and

burned. When the engine is starting cold or

idling, the purge valve prevents any vapours

from entering the intake manifold and causing

excessively-rich fuel mixture.

2Two types of purge valve are used;

electrically-operated or vacuum-operated. To

find out which type is on your vehicle, follow

the hose from the charcoal canister until you

locate the purge valve. Some are located on

the intake manifold, and others near the

charcoal canister. Look for either an electrical

connector, or vacuum lines, to the purge

valve.3A faulty EVAP system will only affect engine

driveability when the engine is warm. The

EVAP system is not usually the cause of

difficult cold starting or any other cold-running

problems.

Check

Vacuum-operated purge valve

4Remove the vacuum lines from the purge

valve, and blow into the larger valve port. It

should be closed, and not pass any air. Note:

Some models have a thermo-vacuum valve

that delays canister purging until the coolant

temperature reaches approximately 46º C.

Check this valve to make sure that vacuum is

controlled at the proper temperatures. The

valve is usually located in the intake manifold,

near the thermo-time switch and the coolant

temperature sensor.

5Disconnect the small vacuum hose from the

purge valve, and apply vacuum with a hand-

held vacuum pump. The purge valve should

be open, and air should be able to pass

through.6If the test results are unsatisfactory, renew

the purge valve.

Electrically-operated purge valve

7Disconnect any lines from the purge valve,

and (without disconnecting the electrical

connector) place it in a convenient spot for

testing.

8Check that the valve makes a “click” sound

as the ignition is switched on (see

illustration).

9If the valve does not “click”, disconnect the

valve connector, and check for power to the

valve using a test light or a voltmeter (see

illustration).

10If battery voltage is present, but the valve

does not work, renew it. If there is no voltage

present, check the Motronic control unit and

the wiring.

Canister

11Mark all the hoses for position, then

detach them from the canister.

12Slide the canister out of its mounting clip.

Engine management and emission control systems 6•5

6.1 Diagram of the EVAP system on the M10 engine (others similar)

6.9 Check for battery voltage at the

electrical connector to the purge valve6.8 When the ignition is switched on, there

should be a distinct “click” from the purge

valve

6

5.3 It’s a good idea to check for excess

residue from the crankcase vapours

circulating in the hoses and ports - this

can eventually clog the system, and cause

a pressure increase in the engine block

Page 209 of 228

REF•8General Repair Procedures

Whenever servicing, repair or overhaul work

is carried out on the car or its components,

observe the following procedures and

instructions. This will assist in carrying out the

operation efficiently and to a professional

standard of workmanship.

Joint mating faces and gaskets

When separating components at their

mating faces, never insert screwdrivers or

similar implements into the joint between the

faces in order to prise them apart. This can

cause severe damage which results in oil

leaks, coolant leaks, etc upon reassembly.

Separation is usually achieved by tapping

along the joint with a soft-faced hammer in

order to break the seal. However, note that

this method may not be suitable where

dowels are used for component location.

Where a gasket is used between the mating

faces of two components, a new one must be

fitted on reassembly; fit it dry unless otherwise

stated in the repair procedure. Make sure that

the mating faces are clean and dry, with all

traces of old gasket removed. When cleaning a

joint face, use a tool which is unlikely to score

or damage the face, and remove any burrs or

nicks with an oilstone or fine file.

Make sure that tapped holes are cleaned

with a pipe cleaner, and keep them free of

jointing compound, if this is being used,

unless specifically instructed otherwise.

Ensure that all orifices, channels or pipes

are clear, and blow through them, preferably

using compressed air.

Oil seals

Oil seals can be removed by levering them

out with a wide flat-bladed screwdriver or

similar implement. Alternatively, a number of

self-tapping screws may be screwed into the

seal, and these used as a purchase for pliers or

some similar device in order to pull the seal free.

Whenever an oil seal is removed from its

working location, either individually or as part

of an assembly, it should be renewed.

The very fine sealing lip of the seal is easily

damaged, and will not seal if the surface it

contacts is not completely clean and free from

scratches, nicks or grooves. If the original

sealing surface of the component cannot be

restored, and the manufacturer has not made

provision for slight relocation of the seal

relative to the sealing surface, the component

should be renewed.

Protect the lips of the seal from any surface

which may damage them in the course of

fitting. Use tape or a conical sleeve where

possible. Lubricate the seal lips with oil before

fitting and, on dual-lipped seals, fill the space

between the lips with grease.

Unless otherwise stated, oil seals must be

fitted with their sealing lips toward the

lubricant to be sealed.

Use a tubular drift or block of wood of the

appropriate size to install the seal and, if the

seal housing is shouldered, drive the seal

down to the shoulder. If the seal housing isunshouldered, the seal should be fitted with

its face flush with the housing top face (unless

otherwise instructed).

Screw threads and fastenings

Seized nuts, bolts and screws are quite a

common occurrence where corrosion has set

in, and the use of penetrating oil or releasing

fluid will often overcome this problem if the

offending item is soaked for a while before

attempting to release it. The use of an impact

driver may also provide a means of releasing

such stubborn fastening devices, when used

in conjunction with the appropriate

screwdriver bit or socket. If none of these

methods works, it may be necessary to resort

to the careful application of heat, or the use of

a hacksaw or nut splitter device.

Studs are usually removed by locking two

nuts together on the threaded part, and then

using a spanner on the lower nut to unscrew

the stud. Studs or bolts which have broken off

below the surface of the component in which

they are mounted can sometimes be removed

using a stud extractor. Always ensure that a

blind tapped hole is completely free from oil,

grease, water or other fluid before installing

the bolt or stud. Failure to do this could cause

the housing to crack due to the hydraulic

action of the bolt or stud as it is screwed in.

When tightening a castellated nut to accept

a split pin, tighten the nut to the specified

torque, where applicable, and then tighten

further to the next split pin hole. Never slacken

the nut to align the split pin hole, unless stated

in the repair procedure.

When checking or retightening a nut or bolt

to a specified torque setting, slacken the nut

or bolt by a quarter of a turn, and then

retighten to the specified setting. However,

this should not be attempted where angular

tightening has been used.

For some screw fastenings, notably

cylinder head bolts or nuts, torque wrench

settings are no longer specified for the latter

stages of tightening, “angle-tightening” being

called up instead. Typically, a fairly low torque

wrench setting will be applied to the

bolts/nuts in the correct sequence, followed

by one or more stages of tightening through

specified angles.

Locknuts, locktabs and washers

Any fastening which will rotate against a

component or housing during tightening

should always have a washer between it and

the relevant component or housing.

Spring or split washers should always be

renewed when they are used to lock a critical

component such as a big-end bearing

retaining bolt or nut. Locktabs which are

folded over to retain a nut or bolt should

always be renewed.

Self-locking nuts can be re-used in non-

critical areas, providing resistance can be felt

when the locking portion passes over the bolt

or stud thread. However, it should be noted

that self-locking stiffnuts tend to lose theireffectiveness after long periods of use, and

should then be renewed as a matter of course.

Split pins must always be replaced with

new ones of the correct size for the hole.

When thread-locking compound is found

on the threads of a fastener which is to be re-

used, it should be cleaned off with a wire

brush and solvent, and fresh compound

applied on reassembly.

Special tools

Some repair procedures in this manual

entail the use of special tools such as a press,

two or three-legged pullers, spring com-

pressors, etc. Wherever possible, suitable

readily-available alternatives to the manu-

facturer’s special tools are described, and are

shown in use. In some instances, where no

alternative is possible, it has been necessary

to resort to the use of a manufacturer’s tool,

and this has been done for reasons of safety

as well as the efficient completion of the repair

operation. Unless you are highly-skilled and

have a thorough understanding of the

procedures described, never attempt to

bypass the use of any special tool when the

procedure described specifies its use. Not

only is there a very great risk of personal

injury, but expensive damage could be

caused to the components involved.

Environmental considerations

When disposing of used engine oil, brake

fluid, antifreeze, etc, give due consideration to

any detrimental environmental effects. Do not,

for instance, pour any of the above liquids

down drains into the general sewage system,

or onto the ground to soak away. Many local

council refuse tips provide a facility for waste

oil disposal, as do some garages. If none of

these facilities are available, consult your local

Environmental Health Department, or the

National Rivers Authority, for further advice.

With the universal tightening-up of legis-

lation regarding the emission of environmen-

tally-harmful substances from motor vehicles,

most vehicles have tamperproof devices fitted

to the main adjustment points of the fuel

system. These devices are primarily designed

to prevent unqualified persons from adjusting

the fuel/air mixture, with the chance of a

consequent increase in toxic emissions. If

such devices are found during servicing or

overhaul, they should, wherever possible, be

renewed or refitted in accordance with the

manufacturer’s requirements or current

legislation.

Note: It is

antisocial and

illegal to dump

oil down the

drain. To find

the location of

your local oil

recycling

bank, call this

number free.

Page 210 of 228

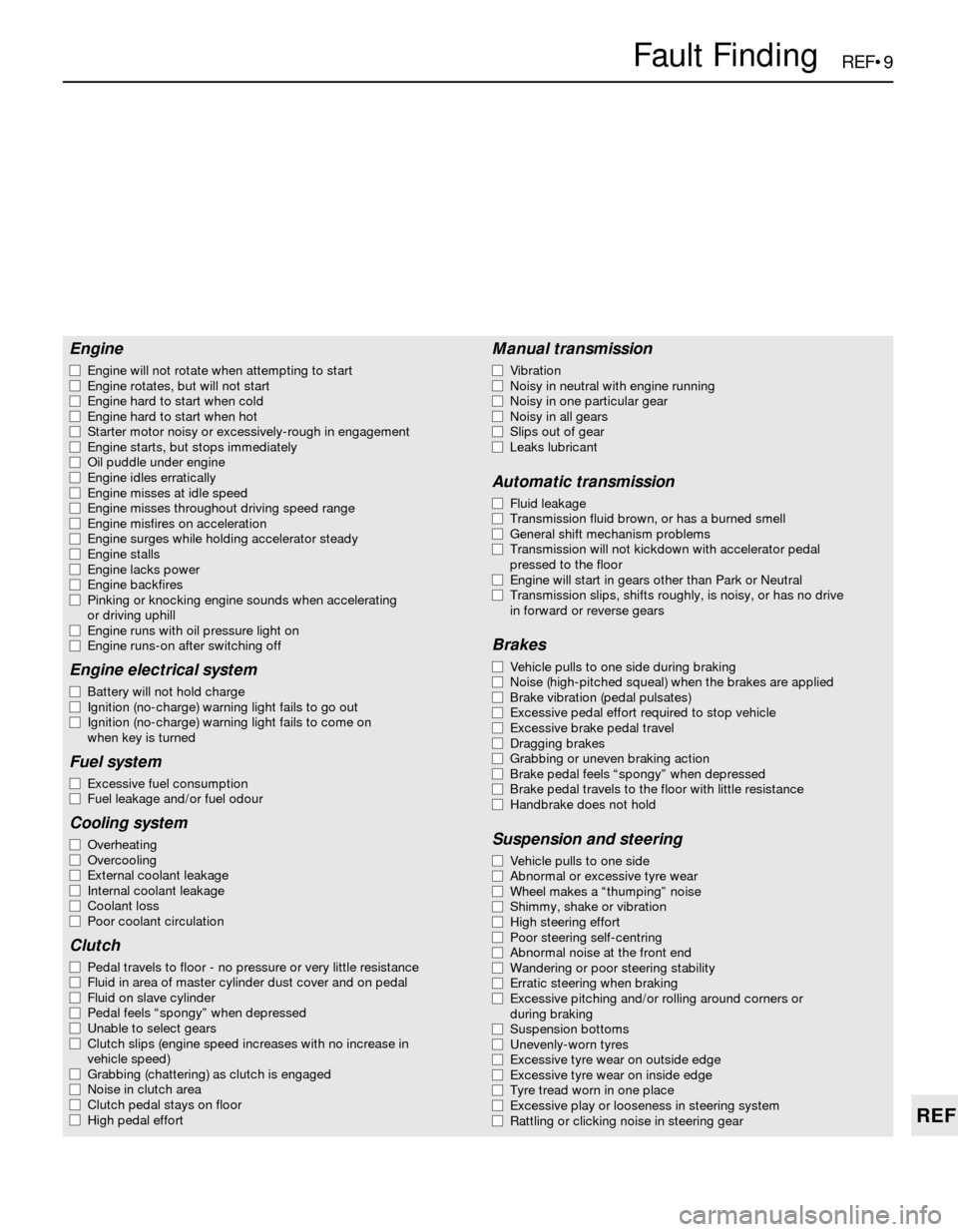

REF•9

REF

Fault Finding

Engine

m mEngine will not rotate when attempting to start

m mEngine rotates, but will not start

m mEngine hard to start when cold

m mEngine hard to start when hot

m mStarter motor noisy or excessively-rough in engagement

m mEngine starts, but stops immediately

m mOil puddle under engine

m mEngine idles erratically

m mEngine misses at idle speed

m mEngine misses throughout driving speed range

m mEngine misfires on acceleration

m mEngine surges while holding accelerator steady

m mEngine stalls

m mEngine lacks power

m mEngine backfires

m mPinking or knocking engine sounds when accelerating

or driving uphill

m mEngine runs with oil pressure light on

m mEngine runs-on after switching off

Engine electrical system

m

mBattery will not hold charge

m mIgnition (no-charge) warning light fails to go out

m mIgnition (no-charge) warning light fails to come on

when key is turned

Fuel system

m mExcessive fuel consumption

m mFuel leakage and/or fuel odour

Cooling system

m

mOverheating

m mOvercooling

m mExternal coolant leakage

m mInternal coolant leakage

m mCoolant loss

m mPoor coolant circulation

Clutch

m

mPedal travels to floor - no pressure or very little resistance

m mFluid in area of master cylinder dust cover and on pedal

m mFluid on slave cylinder

m mPedal feels “spongy” when depressed

m mUnable to select gears

m mClutch slips (engine speed increases with no increase in

vehicle speed)

m mGrabbing (chattering) as clutch is engaged

m mNoise in clutch area

m mClutch pedal stays on floor

m mHigh pedal effort

Manual transmission

m

mVibration

m mNoisy in neutral with engine running

m mNoisy in one particular gear

m mNoisy in all gears

m mSlips out of gear

m mLeaks lubricant

Automatic transmission

m

mFluid leakage

m mTransmission fluid brown, or has a burned smell

m mGeneral shift mechanism problems

m mTransmission will not kickdown with accelerator pedal

pressed to the floor

m mEngine will start in gears other than Park or Neutral

m mTransmission slips, shifts roughly, is noisy, or has no drive

in forward or reverse gears

Brakes

m mVehicle pulls to one side during braking

m mNoise (high-pitched squeal) when the brakes are applied

m mBrake vibration (pedal pulsates)

m mExcessive pedal effort required to stop vehicle

m mExcessive brake pedal travel

m mDragging brakes

m mGrabbing or uneven braking action

m mBrake pedal feels “spongy” when depressed

m mBrake pedal travels to the floor with little resistance

m mHandbrake does not hold

Suspension and steering

m

mVehicle pulls to one side

m mAbnormal or excessive tyre wear

m mWheel makes a “thumping” noise

m mShimmy, shake or vibration

m mHigh steering effort

m mPoor steering self-centring

m mAbnormal noise at the front end

m mWandering or poor steering stability

m mErratic steering when braking

m mExcessive pitching and/or rolling around corners or

during braking

m mSuspension bottoms

m mUnevenly-worn tyres

m mExcessive tyre wear on outside edge

m mExcessive tyre wear on inside edge

m mTyre tread worn in one place

m mExcessive play or looseness in steering system

m mRattling or clicking noise in steering gear

Page 213 of 228

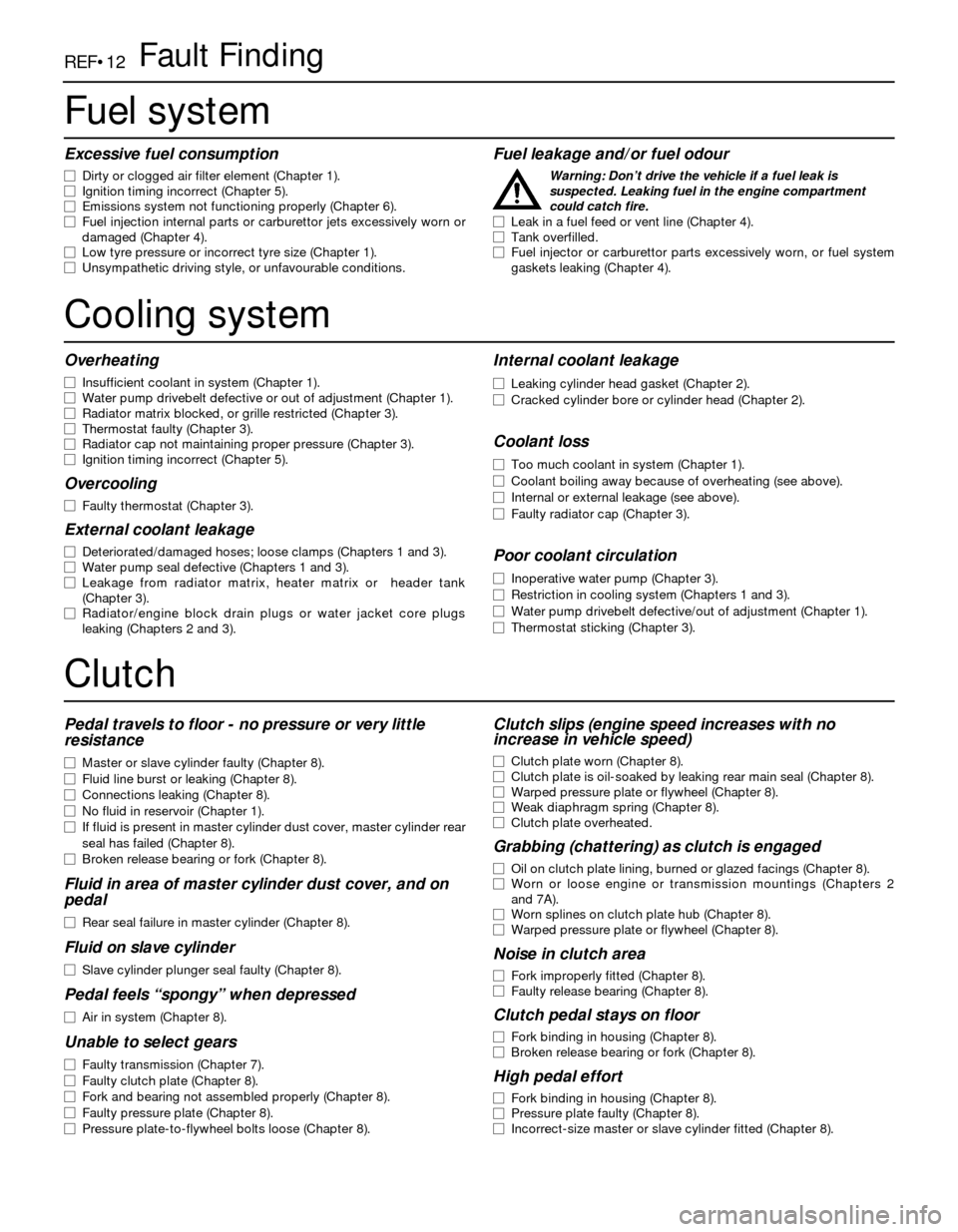

REF•12Fault Finding

Fuel system

Excessive fuel consumption

m mDirty or clogged air filter element (Chapter 1).

m mIgnition timing incorrect (Chapter 5).

m mEmissions system not functioning properly (Chapter 6).

m mFuel injection internal parts or carburettor jets excessively worn or

damaged (Chapter 4).

m mLow tyre pressure or incorrect tyre size (Chapter 1).

m mUnsympathetic driving style, or unfavourable conditions.

Fuel leakage and/or fuel odour

Warning: Don’t drive the vehicle if a fuel leak is

suspected. Leaking fuel in the engine compartment

could catch fire.

m mLeak in a fuel feed or vent line (Chapter 4).

m mTank overfilled.

m mFuel injector or carburettor parts excessively worn, or fuel system

gaskets leaking (Chapter 4).

Cooling system

Overheating

m mInsufficient coolant in system (Chapter 1).

m mWater pump drivebelt defective or out of adjustment (Chapter 1).

m mRadiator matrix blocked, or grille restricted (Chapter 3).

m mThermostat faulty (Chapter 3).

m mRadiator cap not maintaining proper pressure (Chapter 3).

m mIgnition timing incorrect (Chapter 5).

Overcooling

m

mFaulty thermostat (Chapter 3).

External coolant leakage

m

mDeteriorated/damaged hoses; loose clamps (Chapters 1 and 3).

m mWater pump seal defective (Chapters 1 and 3).

m mLeakage from radiator matrix, heater matrix or header tank

(Chapter 3).

m mRadiator/engine block drain plugs or water jacket core plugs

leaking (Chapters 2 and 3).

Internal coolant leakage

m mLeaking cylinder head gasket (Chapter 2).

m mCracked cylinder bore or cylinder head (Chapter 2).

Coolant loss

m

mToo much coolant in system (Chapter 1).

m mCoolant boiling away because of overheating (see above).

m mInternal or external leakage (see above).

m mFaulty radiator cap (Chapter 3).

Poor coolant circulation

m

mInoperative water pump (Chapter 3).

m mRestriction in cooling system (Chapters 1 and 3).

m mWater pump drivebelt defective/out of adjustment (Chapter 1).

m mThermostat sticking (Chapter 3).

Clutch

Pedal travels to floor - no pressure or very little

resistance

m mMaster or slave cylinder faulty (Chapter 8).

m mFluid line burst or leaking (Chapter 8).

m mConnections leaking (Chapter 8).

m mNo fluid in reservoir (Chapter 1).

m mIf fluid is present in master cylinder dust cover, master cylinder rear

seal has failed (Chapter 8).

m mBroken release bearing or fork (Chapter 8).

Fluid in area of master cylinder dust cover, and on

pedal

m mRear seal failure in master cylinder (Chapter 8).

Fluid on slave cylinder

m

mSlave cylinder plunger seal faulty (Chapter 8).

Pedal feels “spongy” when depressed

m

mAir in system (Chapter 8).

Unable to select gears

m

mFaulty transmission (Chapter 7).

m mFaulty clutch plate (Chapter 8).

m mFork and bearing not assembled properly (Chapter 8).

m mFaulty pressure plate (Chapter 8).

m mPressure plate-to-flywheel bolts loose (Chapter 8).

Clutch slips (engine speed increases with no

increase in vehicle speed)

m mClutch plate worn (Chapter 8).

m mClutch plate is oil-soaked by leaking rear main seal (Chapter 8).

m mWarped pressure plate or flywheel (Chapter 8).

m mWeak diaphragm spring (Chapter 8).

m mClutch plate overheated.

Grabbing (chattering) as clutch is engaged

m

mOil on clutch plate lining, burned or glazed facings (Chapter 8).

m mWorn or loose engine or transmission mountings (Chapters 2

and 7A).

m mWorn splines on clutch plate hub (Chapter 8).

m mWarped pressure plate or flywheel (Chapter 8).

Noise in clutch area

m

mFork improperly fitted (Chapter 8).

m mFaulty release bearing (Chapter 8).

Clutch pedal stays on floor

m

mFork binding in housing (Chapter 8).

m mBroken release bearing or fork (Chapter 8).

High pedal effort

m

mFork binding in housing (Chapter 8).

m mPressure plate faulty (Chapter 8).

m mIncorrect-size master or slave cylinder fitted (Chapter 8).