Brake system BMW 3 SERIES 1988 E30 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1988, Model line: 3 SERIES, Model: BMW 3 SERIES 1988 E30Pages: 228, PDF Size: 7.04 MB

Page 22 of 228

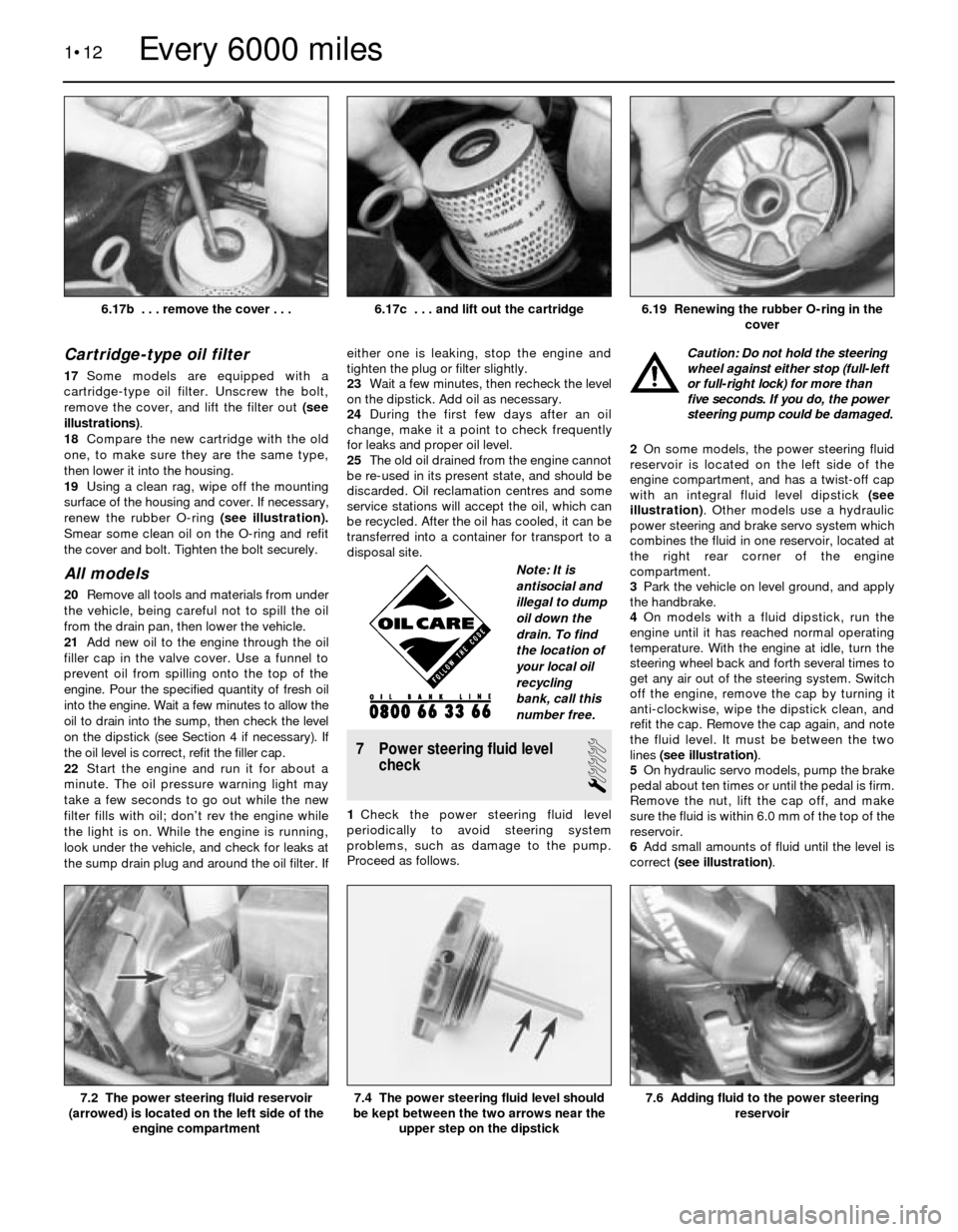

Cartridge-type oil filter

17Some models are equipped with a

cartridge-type oil filter. Unscrew the bolt,

remove the cover, and lift the filter out (see

illustrations).

18Compare the new cartridge with the old

one, to make sure they are the same type,

then lower it into the housing.

19Using a clean rag, wipe off the mounting

surface of the housing and cover. If necessary,

renew the rubber O-ring (see illustration).

Smear some clean oil on the O-ring and refit

the cover and bolt. Tighten the bolt securely.

All models

20Remove all tools and materials from under

the vehicle, being careful not to spill the oil

from the drain pan, then lower the vehicle.

21Add new oil to the engine through the oil

filler cap in the valve cover. Use a funnel to

prevent oil from spilling onto the top of the

engine. Pour the specified quantity of fresh oil

into the engine. Wait a few minutes to allow the

oil to drain into the sump, then check the level

on the dipstick (see Section 4 if necessary). If

the oil level is correct, refit the filler cap.

22Start the engine and run it for about a

minute. The oil pressure warning light may

take a few seconds to go out while the new

filter fills with oil; don’t rev the engine while

the light is on. While the engine is running,

look under the vehicle, and check for leaks at

the sump drain plug and around the oil filter. Ifeither one is leaking, stop the engine and

tighten the plug or filter slightly.

23Wait a few minutes, then recheck the level

on the dipstick. Add oil as necessary.

24During the first few days after an oil

change, make it a point to check frequently

for leaks and proper oil level.

25The old oil drained from the engine cannot

be re-used in its present state, and should be

discarded. Oil reclamation centres and some

service stations will accept the oil, which can

be recycled. After the oil has cooled, it can be

transferred into a container for transport to a

disposal site.

7 Power steering fluid level

check

1

1Check the power steering fluid level

periodically to avoid steering system

problems, such as damage to the pump.

Proceed as follows.Caution: Do not hold the steering

wheel against either stop (full-left

or full-right lock) for more than

five seconds. If you do, the power

steering pump could be damaged.

2On some models, the power steering fluid

reservoir is located on the left side of the

engine compartment, and has a twist-off cap

with an integral fluid level dipstick (see

illustration). Other models use a hydraulic

power steering and brake servo system which

combines the fluid in one reservoir, located at

the right rear corner of the engine

compartment.

3Park the vehicle on level ground, and apply

the handbrake.

4On models with a fluid dipstick, run the

engine until it has reached normal operating

temperature. With the engine at idle, turn the

steering wheel back and forth several times to

get any air out of the steering system. Switch

off the engine, remove the cap by turning it

anti-clockwise, wipe the dipstick clean, and

refit the cap. Remove the cap again, and note

the fluid level. It must be between the two

lines (see illustration).

5On hydraulic servo models, pump the brake

pedal about ten times or until the pedal is firm.

Remove the nut, lift the cap off, and make

sure the fluid is within 6.0 mm of the top of the

reservoir.

6Add small amounts of fluid until the level is

correct (see illustration).

1•12

7.6 Adding fluid to the power steering

reservoir7.4 The power steering fluid level should

be kept between the two arrows near the

upper step on the dipstick7.2 The power steering fluid reservoir

(arrowed) is located on the left side of the

engine compartment

6.19 Renewing the rubber O-ring in the

cover6.17c . . . and lift out the cartridge

Every 6000 miles

6.17b . . . remove the cover . . .

Note: It is

antisocial and

illegal to dump

oil down the

drain. To find

the location of

your local oil

recycling

bank, call this

number free.

Page 23 of 228

Caution: Do not overfill the

reservoir. If too much fluid is

added, remove the excess with a

clean syringe. Refit the cap.

7If frequent topping-up is needed, check the

power steering hoses and connections for

leaks and wear (see Section 10).

8Check the condition and tension of the

drivebelt (see Section 11).

8 Automatic transmission fluid

level check

1

Caution: The use of transmission

fluid other than the type listed in

this Chapter’s Specifications

could result in transmission

malfunctions or failure.

1The automatic transmission fluid should be

carefully maintained. Low fluid level can lead

to slipping or loss of drive, while overfilling

can cause foaming and loss of fluid. Either

condition can cause transmission damage.

2Since transmission fluid expands as it heats

up, the fluid level should only be checked

when the transmission is warm (at normal

operating temperature). If the vehicle has just

been driven over 20 miles (32 km), the

transmission can be considered warm. You

can also check the fluid level when the

transmission is cold. If the vehicle has not

been driven for over five hours and the fluid is

about room temperature (20°C), the

transmission is cold. However, the fluid level

is normally checked with the transmission

warm, to ensure accurate results.

Caution: If the vehicle has just

been driven for a long time at

high speed or in city traffic, in hot

weather, or if it has been pulling

a trailer, an accurate fluid level reading

cannot be obtained. Allow the trans-

mission to cool down for about 30 minutes.

3Immediately after driving the vehicle, park it

on a level surface, apply the handbrake and

start the engine. While the engine is idling,

depress the brake pedal and move theselector lever through all the gear ranges,

beginning and ending in Park.

4The automatic transmission dipstick tube is

located in the left rear corner of the engine

compartment.

5With the engine still idling, pull the dipstick

out of the tube (see illustration), wipe it off

with a clean rag, push it all the way back into

the tube and withdraw it again, then note the

fluid level.

6The level should be between the two marks

(see illustration). If the level is low, add the

specified automatic transmission fluid through

the dipstick tube - use a clean funnel,

preferably equipped with a fine mesh filter, to

prevent spills.

Caution: Be careful not to

introduce dirt into the

transmission when topping up.

7Add just enough of the recommended fluid

to fill the transmission to the proper level. It

takes about half a litre to raise the level from

the low mark to the high mark when the fluid

is hot, so add the fluid a little at a time, and

keep checking the level until it’s correct.

8The condition of the fluid should also be

checked along with the level. If the fluid is

black or a dark reddish-brown colour, or if it

smells burned, it should be changed (see

Section 28). If you are in doubt about its

condition, purchase some new fluid, and

compare the two for colour and smell.

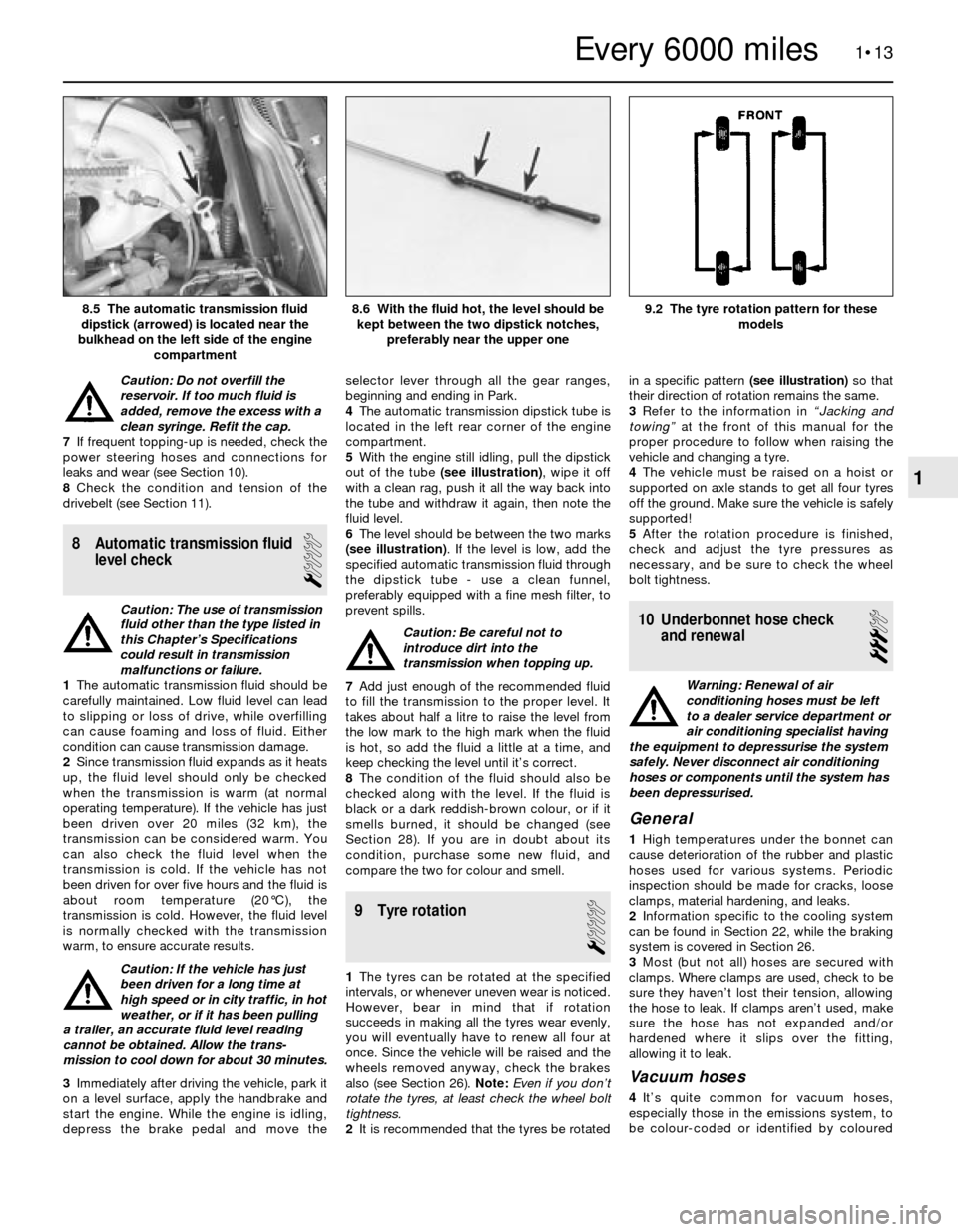

9 Tyre rotation

1

1The tyres can be rotated at the specified

intervals, or whenever uneven wear is noticed.

However, bear in mind that if rotation

succeeds in making all the tyres wear evenly,

you will eventually have to renew all four at

once. Since the vehicle will be raised and the

wheels removed anyway, check the brakes

also (see Section 26). Note: Even if you don’t

rotate the tyres, at least check the wheel bolt

tightness.

2It is recommended that the tyres be rotatedin a specific pattern (see illustration)so that

their direction of rotation remains the same.

3Refer to the information in “Jacking and

towing”at the front of this manual for the

proper procedure to follow when raising the

vehicle and changing a tyre.

4The vehicle must be raised on a hoist or

supported on axle stands to get all four tyres

off the ground. Make sure the vehicle is safely

supported!

5After the rotation procedure is finished,

check and adjust the tyre pressures as

necessary, and be sure to check the wheel

bolt tightness.

10 Underbonnet hose check

and renewal

3

Warning: Renewal of air

conditioning hoses must be left

to a dealer service department or

air conditioning specialist having

the equipment to depressurise the system

safely. Never disconnect air conditioning

hoses or components until the system has

been depressurised.

General

1High temperatures under the bonnet can

cause deterioration of the rubber and plastic

hoses used for various systems. Periodic

inspection should be made for cracks, loose

clamps, material hardening, and leaks.

2Information specific to the cooling system

can be found in Section 22, while the braking

system is covered in Section 26.

3Most (but not all) hoses are secured with

clamps. Where clamps are used, check to be

sure they haven’t lost their tension, allowing

the hose to leak. If clamps aren’t used, make

sure the hose has not expanded and/or

hardened where it slips over the fitting,

allowing it to leak.

Vacuum hoses

4It’s quite common for vacuum hoses,

especially those in the emissions system, to

be colour-coded or identified by coloured

1•13

9.2 The tyre rotation pattern for these

models8.6 With the fluid hot, the level should be

kept between the two dipstick notches,

preferably near the upper one8.5 The automatic transmission fluid

dipstick (arrowed) is located near the

bulkhead on the left side of the engine

compartment

1

Every 6000 miles

Page 24 of 228

stripes moulded into them. Various systems

require hoses with different wall thicknesses,

collapse resistance and temperature

resistance. When fitting new hoses, be sure

the new ones are made of the same material.

5Often the only effective way to check a

hose is to remove it completely from the

vehicle. If more than one hose is removed, be

sure to label the hoses and fittings to ensure

correct refitting.

6When checking vacuum hoses, be sure to

include any plastic T-fittings in the check.

Inspect the connections for cracks which

could cause leakage.

7A small piece of vacuum hose can be used

as a stethoscope to detect vacuum leaks.

Hold one end of the hose to your ear and

probe around vacuum hoses and fittings,

listening for the “hissing” sound characteristic

of a vacuum leak.

Warning: When probing with the

vacuum hose stethoscope, be

careful not to touch moving

engine components such as the

drivebelt, cooling fan, etc.

Fuel hoses

Warning: There are certain

precautions which must be taken

when servicing or inspecting fuel

system components. Work in a

well-ventilated area, and do not allow open

flames (cigarettes, appliance pilot lights,

etc.) or bare light bulbs near the work

area. Mop up any spills immediately, and

do not store fuel-soaked rags where they

could ignite. If you spill any fuel on your

skin, rinse it off immediately with soap and

water. When you perform any kind of work

on the fuel system, wear safety glasses,

and have a fire extinguisher on hand.

8The fuel hoses are usually under pressure,

so if any fuel hoses are to be disconnected,

be prepared to catch spilled fuel.

Warning: On vehicles equipped

with fuel injection, you must

depressurise the fuel system

before servicing the fuel hoses.

Refer to Chapter 4 for details.9Check all rubber fuel hoses for deterioration

and chafing. Check especially for cracks in

areas where the hose bends, and just before

connectors, such as where a hose attaches to

the fuel pump or fuel filter, for example.

10Only high-quality fuel hose should be

used. Never, under any circumstances, use

unreinforced vacuum hose, clear plastic

tubing or water hose for fuel hoses.

11Band-type clamps are commonly used on

fuel hoses. These clamps often lose their

tension over a period of time, and can be

“sprung” during removal. Renew all band-type

clamps with screw clamps whenever a hose is

renewed.

Metal lines

12Sections of metal line are often used

between the fuel pump and fuel injection

system. Check carefully to make sure the line

isn’t bent, crimped or cracked.

13If a section of metal line must be renewed,

use seamless steel tubing only, since copper

and aluminium tubing do not have the

strength necessary to withstand the vibration

caused by the engine.

14Check the metal brake lines where they

enter the master cylinder and brake

proportioning or ABS unit (if used) for cracks

in the lines and loose fittings. Any sign of

brake fluid leakage calls for an immediate

thorough inspection of the braking system.

Power steering hoses

15Check the power steering hoses for leaks,

loose connections and worn clamps. Tighten

loose connections. Worn clamps or leaky

hoses should be renewed.

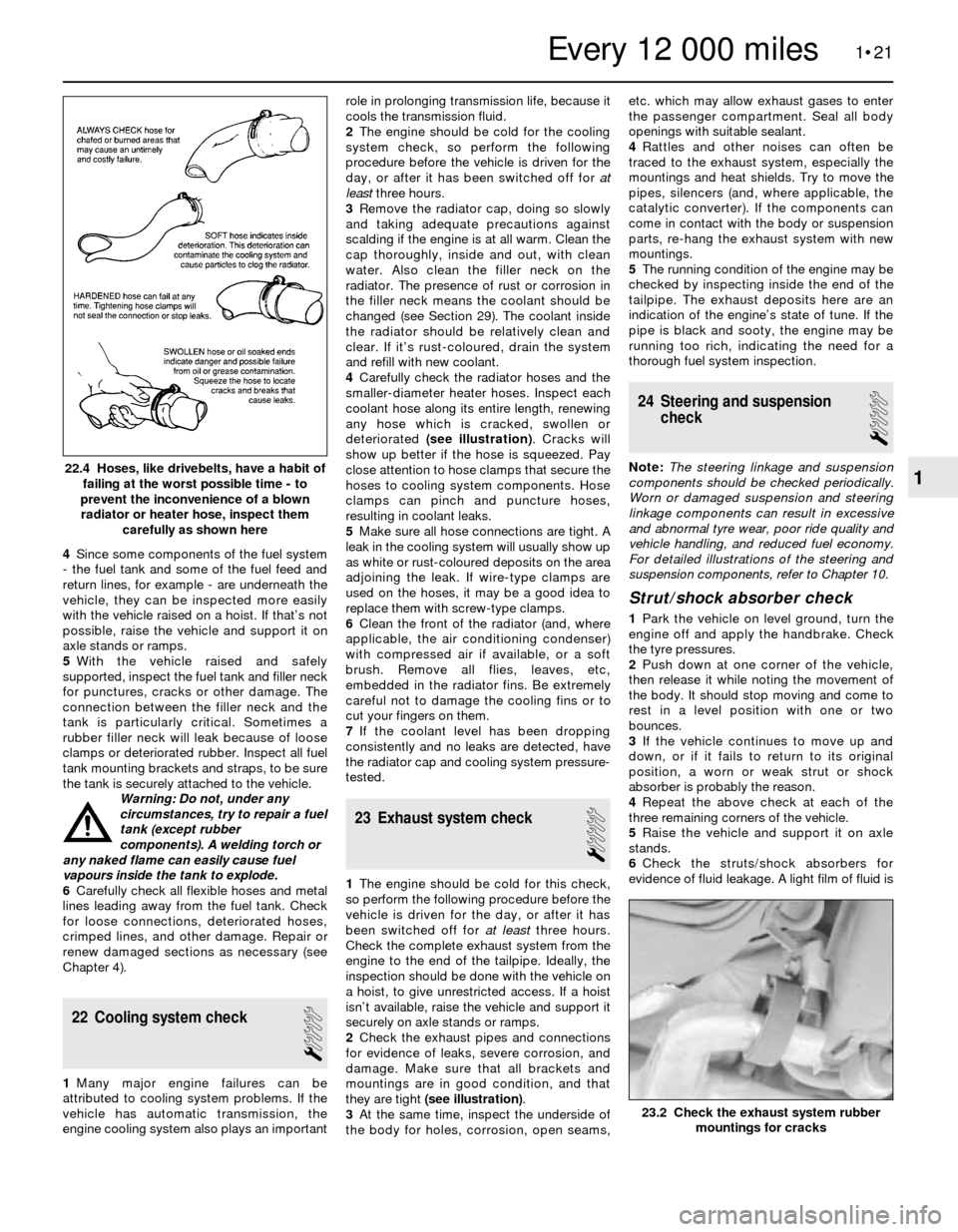

11 Drivebelt check, adjustment

and renewal

1

Check

1The drivebelts, sometimes called V-belts or

simply “fan” belts, are located at the front of

the engine, and play an important role in the

overall operation of the vehicle and itscomponents. Due to their function and

material make-up, the belts are prone to

failure after a period of time, and should be

inspected and adjusted periodically to prevent

major engine damage.

2The number of belts used on a particular

vehicle depends on the accessories fitted.

Drivebelts are used to turn the alternator,

power steering pump, water pump, and air

conditioning compressor. Depending on the

pulley arrangement, a single belt may be used

to drive more than one of these components.

3With the engine switched off, open the

bonnet and locate the various belts at the

front of the engine. Using your fingers (and a

torch, if necessary), move along the belts,

checking for cracks and separation of the belt

plies. Also check for fraying and glazing,

which gives the belt a shiny appearance (see

illustration). Both sides of the belts should be

inspected, which means you will have to twist

each belt to check the underside.

4The tension of each belt is checked by

pushing firmly with your thumb and seeing

how much the belt moves (deflects). Measure

the deflection with a ruler (see illustration). A

good rule of thumb is that the belt should

deflect 6 mm if the distance from pulley

centre-to-pulley centre is between 180 and

280 mm. The belt should deflect 13 mm if the

distance from pulley centre-to-pulley centre is

between 300 and 400 mm.

Adjustment

5If it is necessary to adjust the belt tension,

either to make the belt tighter or looser, it is

done by moving a belt-driven accessory on its

bracket. (When the same belt drives more

than one accessory, normally only one

accessory is moved when making

adjustment.)

6For each component, there will be an

adjusting bolt and a pivot bolt. Both bolts

must be loosened slightly to enable you to

move the component. On some components,

the drivebelt tension can be adjusted by

turning an adjusting bolt after loosening the

lockbolt (see illustration).

7After the two bolts have been loosened,

1•14

11.6 Loosen the nut on the other end of

the adjuster bolt (arrowed) and turn the

bolt to increase or decrease tension on the

drivebelt11.4 Measuring drivebelt deflection with a

straightedge and ruler11.3 Here are some of the more common

problems associated with drivebelts

(check the belts very carefully to prevent

an untimely breakdown)

Every 6000 miles

Page 31 of 228

4Since some components of the fuel system

- the fuel tank and some of the fuel feed and

return lines, for example - are underneath the

vehicle, they can be inspected more easily

with the vehicle raised on a hoist. If that’s not

possible, raise the vehicle and support it on

axle stands or ramps.

5With the vehicle raised and safely

supported, inspect the fuel tank and filler neck

for punctures, cracks or other damage. The

connection between the filler neck and the

tank is particularly critical. Sometimes a

rubber filler neck will leak because of loose

clamps or deteriorated rubber. Inspect all fuel

tank mounting brackets and straps, to be sure

the tank is securely attached to the vehicle.

Warning: Do not, under any

circumstances, try to repair a fuel

tank (except rubber

components). A welding torch or

any naked flame can easily cause fuel

vapours inside the tank to explode.

6Carefully check all flexible hoses and metal

lines leading away from the fuel tank. Check

for loose connections, deteriorated hoses,

crimped lines, and other damage. Repair or

renew damaged sections as necessary (see

Chapter 4).

22 Cooling system check

1

1Many major engine failures can be

attributed to cooling system problems. If the

vehicle has automatic transmission, the

engine cooling system also plays an importantrole in prolonging transmission life, because it

cools the transmission fluid.

2The engine should be cold for the cooling

system check, so perform the following

procedure before the vehicle is driven for the

day, or after it has been switched off for at

leastthree hours.

3Remove the radiator cap, doing so slowly

and taking adequate precautions against

scalding if the engine is at all warm. Clean the

cap thoroughly, inside and out, with clean

water. Also clean the filler neck on the

radiator. The presence of rust or corrosion in

the filler neck means the coolant should be

changed (see Section 29). The coolant inside

the radiator should be relatively clean and

clear. If it’s rust-coloured, drain the system

and refill with new coolant.

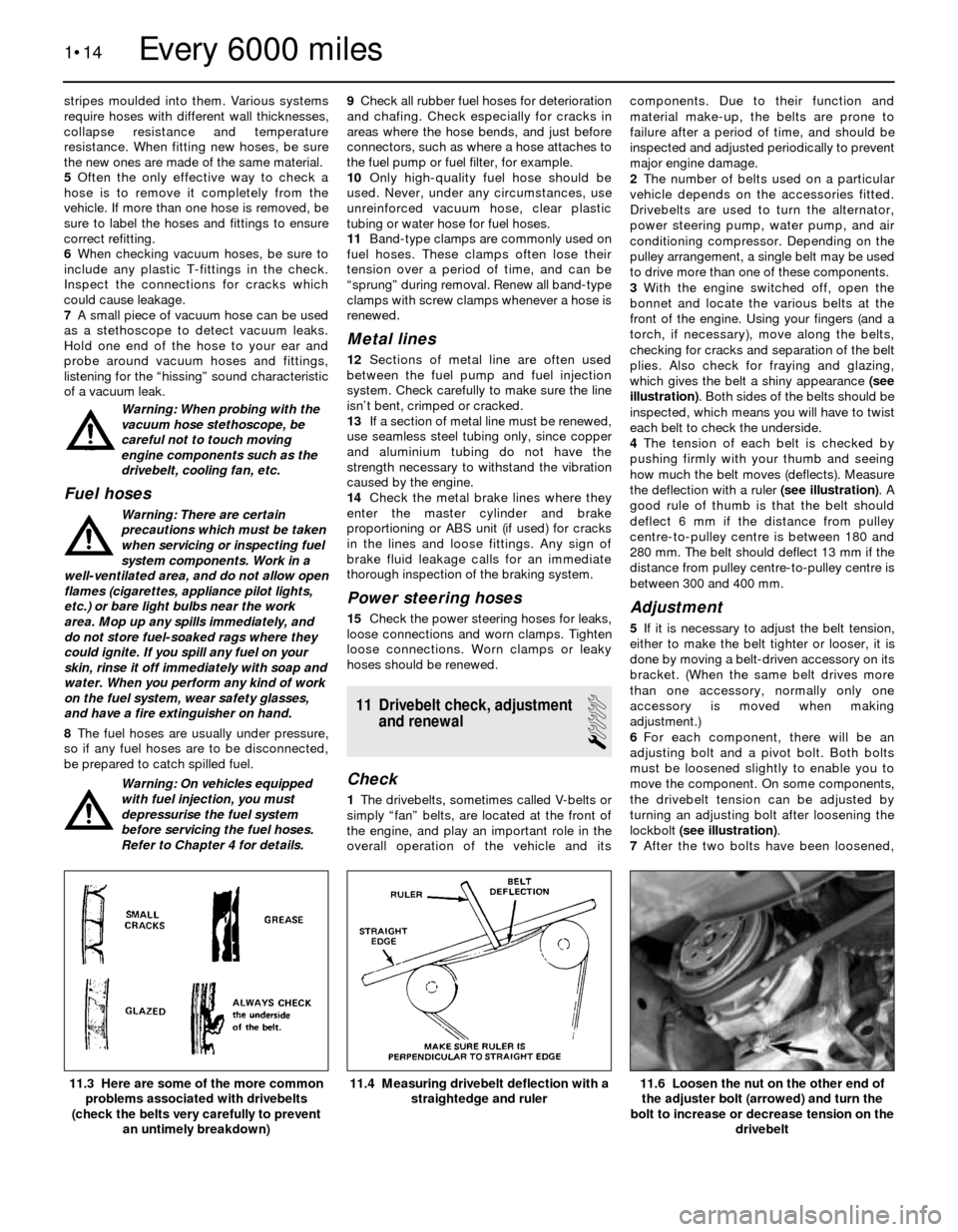

4Carefully check the radiator hoses and the

smaller-diameter heater hoses. Inspect each

coolant hose along its entire length, renewing

any hose which is cracked, swollen or

deteriorated (see illustration). Cracks will

show up better if the hose is squeezed. Pay

close attention to hose clamps that secure the

hoses to cooling system components. Hose

clamps can pinch and puncture hoses,

resulting in coolant leaks.

5Make sure all hose connections are tight. A

leak in the cooling system will usually show up

as white or rust-coloured deposits on the area

adjoining the leak. If wire-type clamps are

used on the hoses, it may be a good idea to

replace them with screw-type clamps.

6Clean the front of the radiator (and, where

applicable, the air conditioning condenser)

with compressed air if available, or a soft

brush. Remove all flies, leaves, etc,

embedded in the radiator fins. Be extremely

careful not to damage the cooling fins or to

cut your fingers on them.

7If the coolant level has been dropping

consistently and no leaks are detected, have

the radiator cap and cooling system pressure-

tested.

23 Exhaust system check

1

1The engine should be cold for this check,

so perform the following procedure before the

vehicle is driven for the day, or after it has

been switched off for at leastthree hours.

Check the complete exhaust system from the

engine to the end of the tailpipe. Ideally, the

inspection should be done with the vehicle on

a hoist, to give unrestricted access. If a hoist

isn’t available, raise the vehicle and support it

securely on axle stands or ramps.

2Check the exhaust pipes and connections

for evidence of leaks, severe corrosion, and

damage. Make sure that all brackets and

mountings are in good condition, and that

they are tight (see illustration).

3At the same time, inspect the underside of

the body for holes, corrosion, open seams,etc. which may allow exhaust gases to enter

the passenger compartment. Seal all body

openings with suitable sealant.

4Rattles and other noises can often be

traced to the exhaust system, especially the

mountings and heat shields. Try to move the

pipes, silencers (and, where applicable, the

catalytic converter). If the components can

come in contact with the body or suspension

parts, re-hang the exhaust system with new

mountings.

5The running condition of the engine may be

checked by inspecting inside the end of the

tailpipe. The exhaust deposits here are an

indication of the engine’s state of tune. If the

pipe is black and sooty, the engine may be

running too rich, indicating the need for a

thorough fuel system inspection.

24 Steering and suspension

check

1

Note: The steering linkage and suspension

components should be checked periodically.

Worn or damaged suspension and steering

linkage components can result in excessive

and abnormal tyre wear, poor ride quality and

vehicle handling, and reduced fuel economy.

For detailed illustrations of the steering and

suspension components, refer to Chapter 10.

Strut/shock absorber check

1Park the vehicle on level ground, turn the

engine off and apply the handbrake. Check

the tyre pressures.

2Push down at one corner of the vehicle,

then release it while noting the movement of

the body. It should stop moving and come to

rest in a level position with one or two

bounces.

3If the vehicle continues to move up and

down, or if it fails to return to its original

position, a worn or weak strut or shock

absorber is probably the reason.

4Repeat the above check at each of the

three remaining corners of the vehicle.

5Raise the vehicle and support it on axle

stands.

6Check the struts/shock absorbers for

evidence of fluid leakage. A light film of fluid is

1•21

22.4 Hoses, like drivebelts, have a habit of

failing at the worst possible time - to

prevent the inconvenience of a blown

radiator or heater hose, inspect them

carefully as shown here

23.2 Check the exhaust system rubber

mountings for cracks

1

Every 12 000 miles

Page 32 of 228

no cause for concern. Make sure that any fluid

noted is from the struts/shocks, and not from

any other source. If leakage is noted, renew

the struts or shock absorbers in axle pairs (or

as a full set).

7Check the struts/shock absorbers to be

sure that they are securely mounted and

undamaged. Check the upper mountings for

damage and wear. If damage or wear is

noted, renew the struts or shock absorbers.

8If the struts or shock absorbers must be

renewed, refer to Chapter 10 for the

procedure. Always renew both units on the

same axle, or the safety of the vehicle may be

compromised. If possible, renew all four as a

set.

Steering and suspension check

9Inspect the steering system components

for damage and distortion. Look for leaks and

damaged seals, boots and fittings.

10Clean the lower end of the steering

knuckle. Have an assistant grasp the lower

edge of the tyre and move the wheel in and

out, while you look for movement at the

steering knuckle-to-axle arm balljoints.

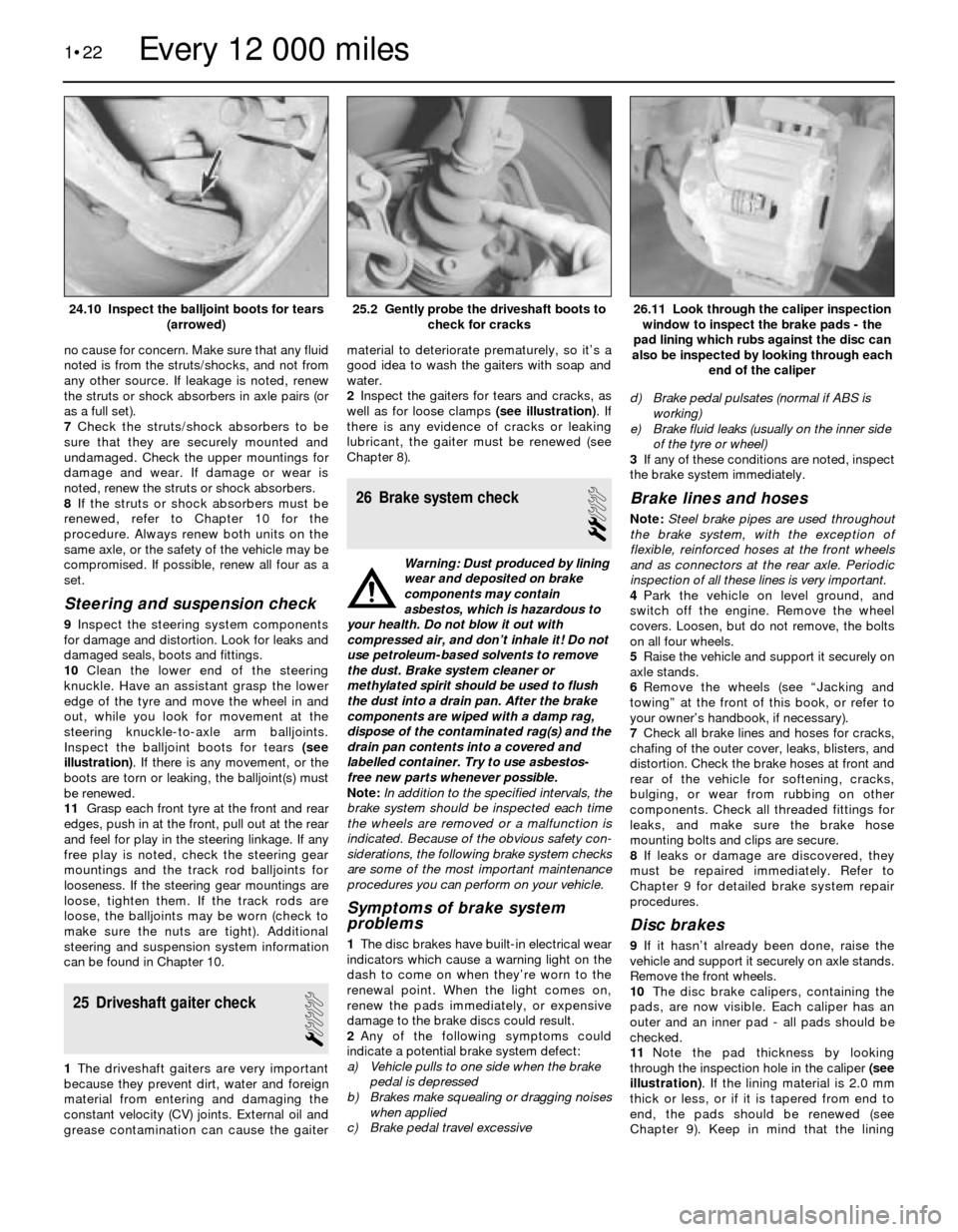

Inspect the balljoint boots for tears (see

illustration). If there is any movement, or the

boots are torn or leaking, the balljoint(s) must

be renewed.

11Grasp each front tyre at the front and rear

edges, push in at the front, pull out at the rear

and feel for play in the steering linkage. If any

free play is noted, check the steering gear

mountings and the track rod balljoints for

looseness. If the steering gear mountings are

loose, tighten them. If the track rods are

loose, the balljoints may be worn (check to

make sure the nuts are tight). Additional

steering and suspension system information

can be found in Chapter 10.

25 Driveshaft gaiter check

1

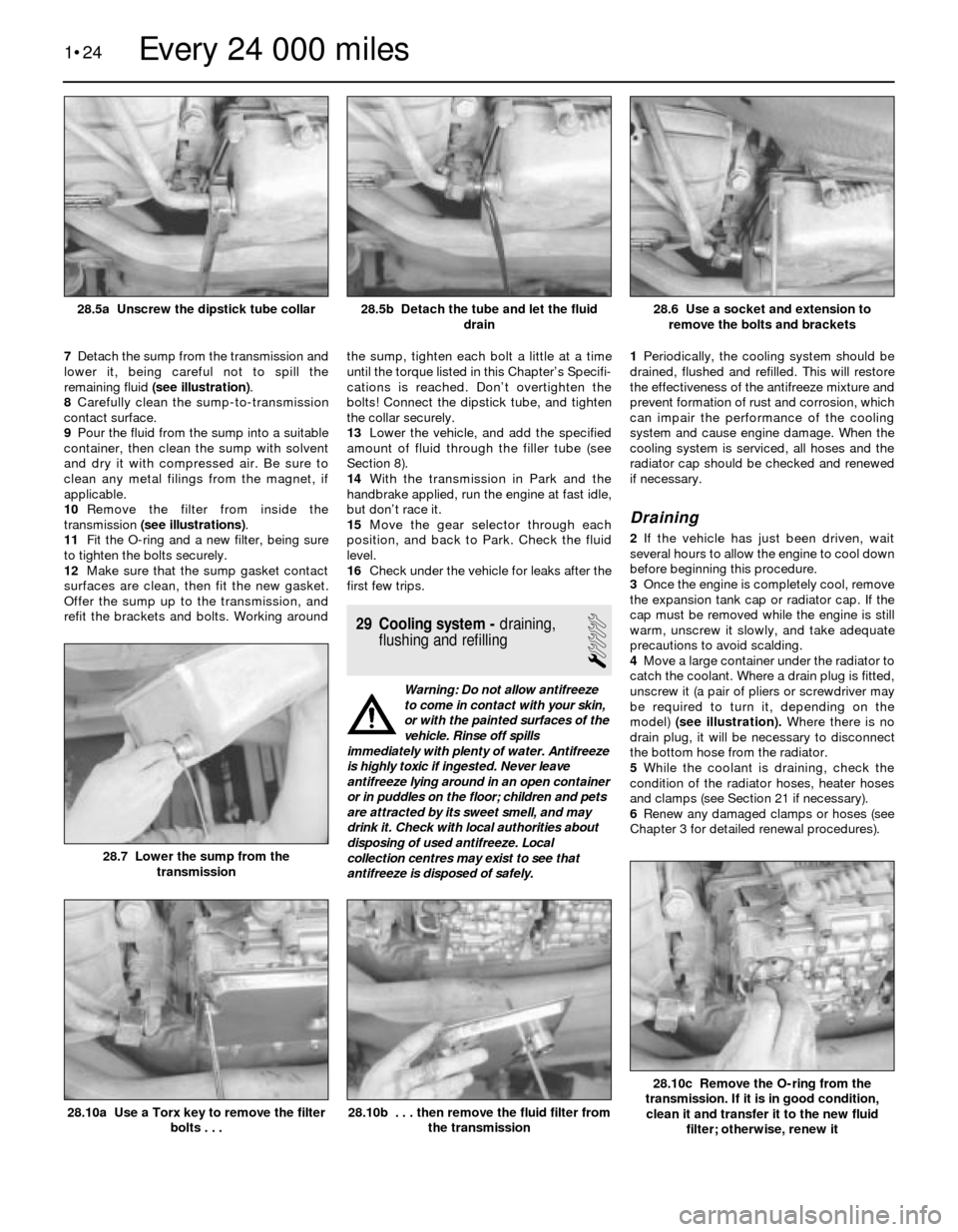

1The driveshaft gaiters are very important

because they prevent dirt, water and foreign

material from entering and damaging the

constant velocity (CV) joints. External oil and

grease contamination can cause the gaitermaterial to deteriorate prematurely, so it’s a

good idea to wash the gaiters with soap and

water.

2Inspect the gaiters for tears and cracks, as

well as for loose clamps (see illustration). If

there is any evidence of cracks or leaking

lubricant, the gaiter must be renewed (see

Chapter 8).

26 Brake system check

2

Warning: Dust produced by lining

wear and deposited on brake

components may contain

asbestos, which is hazardous to

your health. Do not blow it out with

compressed air, and don’t inhale it! Do not

use petroleum-based solvents to remove

the dust. Brake system cleaner or

methylated spirit should be used to flush

the dust into a drain pan. After the brake

components are wiped with a damp rag,

dispose of the contaminated rag(s) and the

drain pan contents into a covered and

labelled container. Try to use asbestos-

free new parts whenever possible.

Note:In addition to the specified intervals, the

brake system should be inspected each time

the wheels are removed or a malfunction is

indicated. Because of the obvious safety con-

siderations, the following brake system checks

are some of the most important maintenance

procedures you can perform on your vehicle.

Symptoms of brake system

problems

1The disc brakes have built-in electrical wear

indicators which cause a warning light on the

dash to come on when they’re worn to the

renewal point. When the light comes on,

renew the pads immediately, or expensive

damage to the brake discs could result.

2Any of the following symptoms could

indicate a potential brake system defect:

a) Vehicle pulls to one side when the brake

pedal is depressed

b) Brakes make squealing or dragging noises

when applied

c) Brake pedal travel excessived) Brake pedal pulsates (normal if ABS is

working)

e) Brake fluid leaks (usually on the inner side

of the tyre or wheel)

3If any of these conditions are noted, inspect

the brake system immediately.

Brake lines and hoses

Note: Steel brake pipes are used throughout

the brake system, with the exception of

flexible, reinforced hoses at the front wheels

and as connectors at the rear axle. Periodic

inspection of all these lines is very important.

4Park the vehicle on level ground, and

switch off the engine. Remove the wheel

covers. Loosen, but do not remove, the bolts

on all four wheels.

5Raise the vehicle and support it securely on

axle stands.

6Remove the wheels (see “Jacking and

towing” at the front of this book, or refer to

your owner’s handbook, if necessary).

7Check all brake lines and hoses for cracks,

chafing of the outer cover, leaks, blisters, and

distortion. Check the brake hoses at front and

rear of the vehicle for softening, cracks,

bulging, or wear from rubbing on other

components. Check all threaded fittings for

leaks, and make sure the brake hose

mounting bolts and clips are secure.

8If leaks or damage are discovered, they

must be repaired immediately. Refer to

Chapter 9 for detailed brake system repair

procedures.

Disc brakes

9If it hasn’t already been done, raise the

vehicle and support it securely on axle stands.

Remove the front wheels.

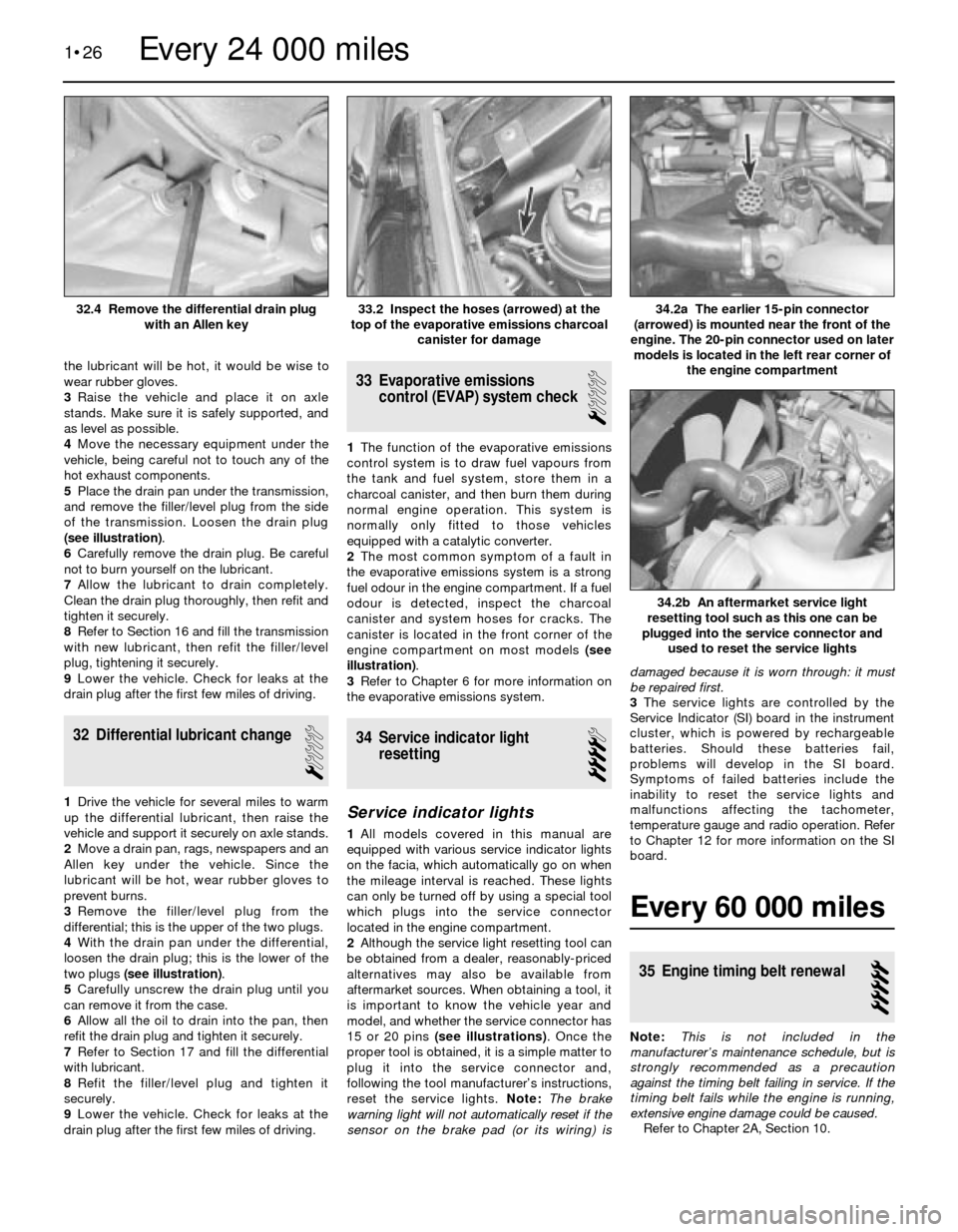

10The disc brake calipers, containing the

pads, are now visible. Each caliper has an

outer and an inner pad - all pads should be

checked.

11Note the pad thickness by looking

through the inspection hole in the caliper (see

illustration). If the lining material is 2.0 mm

thick or less, or if it is tapered from end to

end, the pads should be renewed (see

Chapter 9). Keep in mind that the lining

1•22

26.11 Look through the caliper inspection

window to inspect the brake pads - the

pad lining which rubs against the disc can

also be inspected by looking through each

end of the caliper25.2 Gently probe the driveshaft boots to

check for cracks24.10 Inspect the balljoint boots for tears

(arrowed)

Every 12 000 miles

Page 34 of 228

7Detach the sump from the transmission and

lower it, being careful not to spill the

remaining fluid (see illustration).

8Carefully clean the sump-to-transmission

contact surface.

9Pour the fluid from the sump into a suitable

container, then clean the sump with solvent

and dry it with compressed air. Be sure to

clean any metal filings from the magnet, if

applicable.

10Remove the filter from inside the

transmission (see illustrations).

11Fit the O-ring and a new filter, being sure

to tighten the bolts securely.

12Make sure that the sump gasket contact

surfaces are clean, then fit the new gasket.

Offer the sump up to the transmission, and

refit the brackets and bolts. Working aroundthe sump, tighten each bolt a little at a time

until the torque listed in this Chapter’s Specifi-

cations is reached. Don’t overtighten the

bolts! Connect the dipstick tube, and tighten

the collar securely.

13Lower the vehicle, and add the specified

amount of fluid through the filler tube (see

Section 8).

14With the transmission in Park and the

handbrake applied, run the engine at fast idle,

but don’t race it.

15Move the gear selector through each

position, and back to Park. Check the fluid

level.

16Check under the vehicle for leaks after the

first few trips.

29 Cooling system -draining,

flushing and refilling

1

Warning: Do not allow antifreeze

to come in contact with your skin,

or with the painted surfaces of the

vehicle. Rinse off spills

immediately with plenty of water. Antifreeze

is highly toxic if ingested. Never leave

antifreeze lying around in an open container

or in puddles on the floor; children and pets

are attracted by its sweet smell, and may

drink it. Check with local authorities about

disposing of used antifreeze. Local

collection centres may exist to see that

antifreeze is disposed of safely.1Periodically, the cooling system should be

drained, flushed and refilled. This will restore

the effectiveness of the antifreeze mixture and

prevent formation of rust and corrosion, which

can impair the performance of the cooling

system and cause engine damage. When the

cooling system is serviced, all hoses and the

radiator cap should be checked and renewed

if necessary.

Draining

2If the vehicle has just been driven, wait

several hours to allow the engine to cool down

before beginning this procedure.

3Once the engine is completely cool, remove

the expansion tank cap or radiator cap. If the

cap must be removed while the engine is still

warm, unscrew it slowly, and take adequate

precautions to avoid scalding.

4Move a large container under the radiator to

catch the coolant. Where a drain plug is fitted,

unscrew it (a pair of pliers or screwdriver may

be required to turn it, depending on the

model) (see illustration). Where there is no

drain plug, it will be necessary to disconnect

the bottom hose from the radiator.

5While the coolant is draining, check the

condition of the radiator hoses, heater hoses

and clamps (see Section 21 if necessary).

6Renew any damaged clamps or hoses (see

Chapter 3 for detailed renewal procedures).

1•24

28.10c Remove the O-ring from the

transmission. If it is in good condition,

clean it and transfer it to the new fluid

filter; otherwise, renew it

28.10b . . . then remove the fluid filter from

the transmission28.10a Use a Torx key to remove the filter

bolts . . .

28.7 Lower the sump from the

transmission

28.6 Use a socket and extension to

remove the bolts and brackets28.5b Detach the tube and let the fluid

drain28.5a Unscrew the dipstick tube collar

Every 24 000 miles

Page 36 of 228

the lubricant will be hot, it would be wise to

wear rubber gloves.

3Raise the vehicle and place it on axle

stands. Make sure it is safely supported, and

as level as possible.

4Move the necessary equipment under the

vehicle, being careful not to touch any of the

hot exhaust components.

5Place the drain pan under the transmission,

and remove the filler/level plug from the side

of the transmission. Loosen the drain plug

(see illustration).

6Carefully remove the drain plug. Be careful

not to burn yourself on the lubricant.

7Allow the lubricant to drain completely.

Clean the drain plug thoroughly, then refit and

tighten it securely.

8Refer to Section 16 and fill the transmission

with new lubricant, then refit the filler/level

plug, tightening it securely.

9Lower the vehicle. Check for leaks at the

drain plug after the first few miles of driving.

32 Differential lubricant change

1

1Drive the vehicle for several miles to warm

up the differential lubricant, then raise the

vehicle and support it securely on axle stands.

2Move a drain pan, rags, newspapers and an

Allen key under the vehicle. Since the

lubricant will be hot, wear rubber gloves to

prevent burns.

3Remove the filler/level plug from the

differential; this is the upper of the two plugs.

4With the drain pan under the differential,

loosen the drain plug; this is the lower of the

two plugs (see illustration).

5Carefully unscrew the drain plug until you

can remove it from the case.

6Allow all the oil to drain into the pan, then

refit the drain plug and tighten it securely.

7Refer to Section 17 and fill the differential

with lubricant.

8Refit the filler/level plug and tighten it

securely.

9Lower the vehicle. Check for leaks at the

drain plug after the first few miles of driving.

33 Evaporative emissions

control (EVAP) system check

1

1The function of the evaporative emissions

control system is to draw fuel vapours from

the tank and fuel system, store them in a

charcoal canister, and then burn them during

normal engine operation. This system is

normally only fitted to those vehicles

equipped with a catalytic converter.

2The most common symptom of a fault in

the evaporative emissions system is a strong

fuel odour in the engine compartment. If a fuel

odour is detected, inspect the charcoal

canister and system hoses for cracks. The

canister is located in the front corner of the

engine compartment on most models (see

illustration).

3Refer to Chapter 6 for more information on

the evaporative emissions system.

34 Service indicator light

resetting

4

Service indicator lights

1All models covered in this manual are

equipped with various service indicator lights

on the facia, which automatically go on when

the mileage interval is reached. These lights

can only be turned off by using a special tool

which plugs into the service connector

located in the engine compartment.

2Although the service light resetting tool can

be obtained from a dealer, reasonably-priced

alternatives may also be available from

aftermarket sources. When obtaining a tool, it

is important to know the vehicle year and

model, and whether the service connector has

15 or 20 pins (see illustrations). Once the

proper tool is obtained, it is a simple matter to

plug it into the service connector and,

following the tool manufacturer’s instructions,

reset the service lights. Note: The brake

warning light will not automatically reset if the

sensor on the brake pad (or its wiring) isdamaged because it is worn through: it must

be repaired first.

3The service lights are controlled by the

Service Indicator (SI) board in the instrument

cluster, which is powered by rechargeable

batteries. Should these batteries fail,

problems will develop in the SI board.

Symptoms of failed batteries include the

inability to reset the service lights and

malfunctions affecting the tachometer,

temperature gauge and radio operation. Refer

to Chapter 12 for more information on the SI

board.

Every 60 000 miles

35 Engine timing belt renewal

5

Note:This is not included in the

manufacturer’s maintenance schedule, but is

strongly recommended as a precaution

against the timing belt failing in service. If the

timing belt fails while the engine is running,

extensive engine damage could be caused.

Refer to Chapter 2A, Section 10.

1•26

34.2b An aftermarket service light

resetting tool such as this one can be

plugged into the service connector and

used to reset the service lights

34.2a The earlier 15-pin connector

(arrowed) is mounted near the front of the

engine. The 20-pin connector used on later

models is located in the left rear corner of

the engine compartment33.2 Inspect the hoses (arrowed) at the

top of the evaporative emissions charcoal

canister for damage32.4 Remove the differential drain plug

with an Allen key

Every 24 000 miles

Page 39 of 228

1 General information

This Part of Chapter 2 is devoted to in-

vehicle engine repair procedures. All

information concerning engine removal and

refitting and engine block and cylinder head

overhaul can be found in Chapter 2B.

The following repair procedures are based

on the assumption that the engine is still fitted

in the vehicle. If the engine has been removed

from the vehicle and mounted on a stand,

many of the steps outlined in this Part of

Chapter 2 will not apply.

The Specifications included in this Part of

Chapter 2 apply only to the procedures

contained in this Part. Chapter 2B contains

the Specifications necessary for cylinder head

and engine block rebuilding.

The single overhead camshaft four- and

six-cylinder engines covered in this manual

are very similar in design. Where there are

differences, they will be pointed out.

The means by which the overhead

camshaft is driven varies according to engine

type; M10 and M30 engines use a timing

chain, while M20 and M40 engines have a

timing belt.

2 Repair operations possible

with the engine in the vehicle

Many major repair operations can be

accomplished without removing the engine

from the vehicle.

Clean the engine compartment and the

exterior of the engine with some type of

degreaser before any work is done. It will

make the job easier, and help keep dirt out of

the internal areas of the engine.

Depending on the components involved, it

may be helpful to remove the bonnet to

improve access to the engine as repairs are

performed (see Chapter 11 if necessary).

Cover the wings to prevent damage to the

paint. Special pads are available, but an old

bedspread or blanket will also work.

If vacuum, exhaust, oil or coolant leaks

develop, indicating a need for gasket or seal

renewal, the repairs can generally be made

with the engine in the vehicle. The intake and

exhaust manifold gaskets, sump gasket,

crankshaft oil seals and cylinder head gasket

are all accessible with the engine in place.

Exterior components, such as the intake

and exhaust manifolds, the sump, the oil

pump, the water pump, the starter motor, the

alternator, the distributor and the fuel system

components, can be removed for repair with

the engine in place.

The cylinder head can be removed without

removing the engine, so this procedure is

covered in this Part of Chapter 2. Camshaft,

rocker arm and valve component servicing ismost easily accomplished with the cylinder

head removed; these procedures are covered

in Part B of this Chapter. Note, however, that

the camshaft on the M40 engine may be

removed with the engine in the vehicle since it

is retained by bearing caps.

In extreme cases caused by a lack of

necessary equipment, repair or renewal of

piston rings, pistons, connecting rods and

big-end bearings is possible with the engine in

the vehicle. However, this practice is not

recommended, because of the cleaning and

preparation work that must be done to the

components involved.

3 Top Dead Centre (TDC) for

No 1 piston- locating

2

Note 1:The following procedure is based on

the assumption that the distributor (if

applicable) is correctly fitted. If you are trying

to locate TDC to refit the distributor correctly,

piston position must be determined by feeling

for compression at the No 1 spark plug hole,

then aligning the ignition timing marks or

inserting the timing tool in the flywheel, as

applicable.

Note 2:The No 1 cylinder is the one closest to

the radiator.

1Top Dead Centre (TDC) is the highest point

in the cylinder that each piston reaches as it

travels up and down when the crankshaft

turns. Each piston reaches TDC on the

compression stroke and again on the exhaust

stroke, but TDC generally refers to piston

position on the compression stroke.

2Positioning the piston at TDC is an essential

part of many procedures, such as timing belt

or chain removal and distributor removal.

3Before beginning this procedure, be sure to

place the transmission in Neutral, and apply

the handbrake or chock the rear wheels. Also,

disable the ignition system by detaching the

coil wire from the centre terminal of the

distributor cap, and earthing it on the engine

block with a jumper wire. Remove the spark

plugs (see Chapter 1).

4In order to bring any piston to TDC, the

crankshaft must be turned using one of the

methods outlined below. When looking at the

front of the engine, normal crankshaft rotation

is clockwise.

(a) The preferred method is to turn the

crankshaft with a socket and ratchet

attached to the bolt threaded into the

front of the crankshaft.

(b) A remote starter switch, which may save

some time, can also be used. Follow the

instructions included with the switch.

Once the piston is close to TDC, use a

socket and ratchet as described in the

previous paragraph.

(c) If an assistant is available to turn the

ignition switch to the Start position in

short bursts, you can get the piston close

to TDC without a remote starter switch.Make sure your assistant is out of the

vehicle, away from the ignition switch,

then use a socket and ratchet as

described in (a) to complete the

procedure.

5Note the position of the terminal for the

No 1 spark plug lead on the distributor cap. If

the terminal isn’t marked, follow the plug lead

from the No 1 cylinder spark plug to the cap

(No 1 cylinder is nearest the radiator).

6Use a felt-tip pen or chalk to make a mark

directly below the No 1 terminal on the

distributor body or timing cover.

7Detach the distributor cap, and set it aside

(see Chapter 1 if necessary).

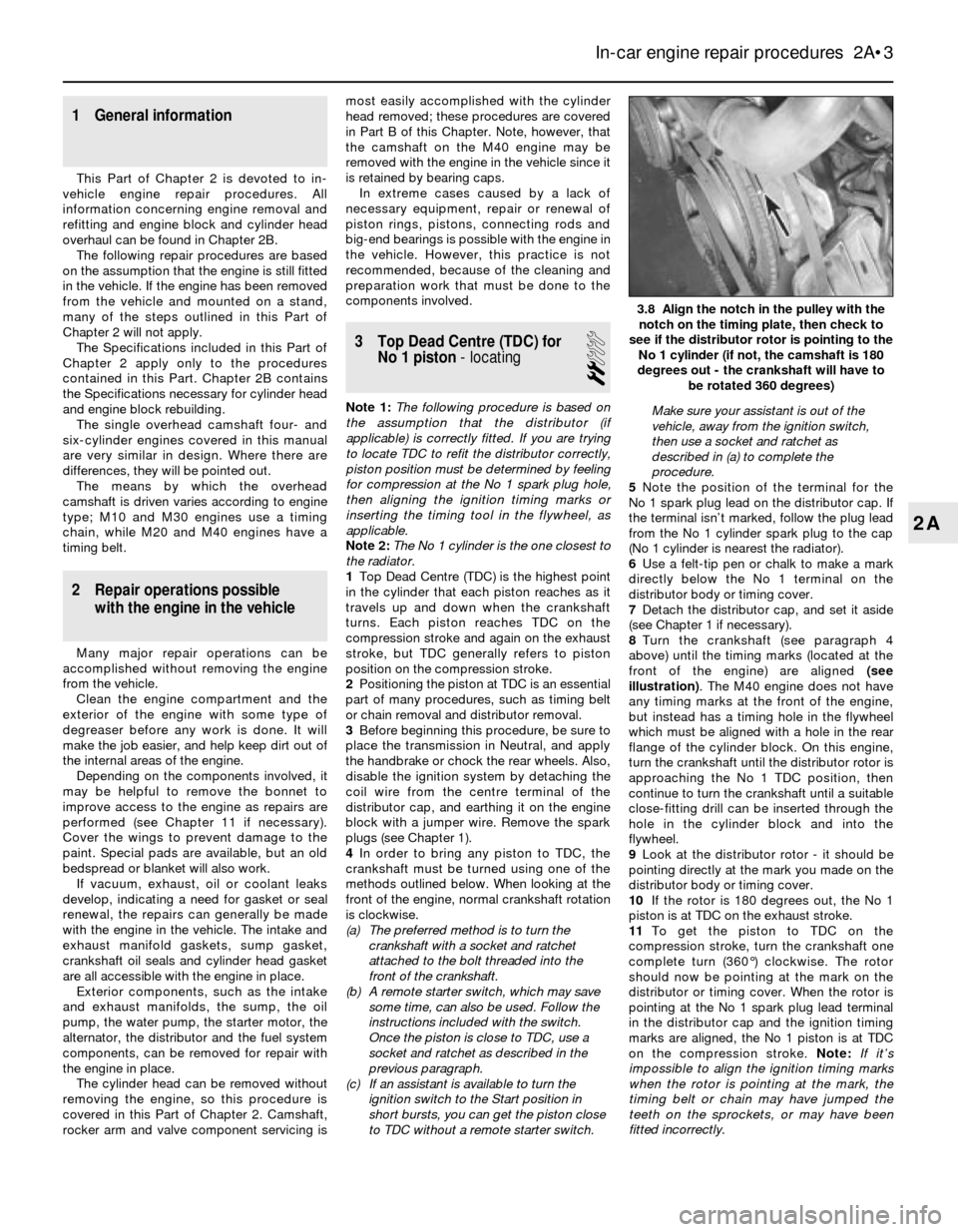

8Turn the crankshaft (see paragraph 4

above) until the timing marks (located at the

front of the engine) are aligned (see

illustration). The M40 engine does not have

any timing marks at the front of the engine,

but instead has a timing hole in the flywheel

which must be aligned with a hole in the rear

flange of the cylinder block. On this engine,

turn the crankshaft until the distributor rotor is

approaching the No 1 TDC position, then

continue to turn the crankshaft until a suitable

close-fitting drill can be inserted through the

hole in the cylinder block and into the

flywheel.

9Look at the distributor rotor - it should be

pointing directly at the mark you made on the

distributor body or timing cover.

10If the rotor is 180 degrees out, the No 1

piston is at TDC on the exhaust stroke.

11To get the piston to TDC on the

compression stroke, turn the crankshaft one

complete turn (360°) clockwise. The rotor

should now be pointing at the mark on the

distributor or timing cover. When the rotor is

pointing at the No 1 spark plug lead terminal

in the distributor cap and the ignition timing

marks are aligned, the No 1 piston is at TDC

on the compression stroke. Note:If it’s

impossible to align the ignition timing marks

when the rotor is pointing at the mark, the

timing belt or chain may have jumped the

teeth on the sprockets, or may have been

fitted incorrectly.

In-car engine repair procedures 2A•3

3.8 Align the notch in the pulley with the

notch on the timing plate, then check to

see if the distributor rotor is pointing to the

No 1 cylinder (if not, the camshaft is 180

degrees out - the crankshaft will have to

be rotated 360 degrees)

2A

Page 110 of 228

Engine difficult to start, or fails to start (when cold)

Probable cause Corrective action

Cold start injector or thermotime switch

faulty (early Motronic system only) Test cold start injector and thermotime switch. Renew faulty components (see Section 19)

Fuel pump not running Check fuel pump fuse and fuel pump relay (see Sections 2 and 3)

Airflow meter flap (door) binding, or

stuck in open position Inspect the airflow meter for damage (see Section 16)

Fuel pressure incorrect Test system pressure (see Section 3)

Intake air leaks Inspect all vacuum lines, air ducts and oil filler and dipstick seals

Fuel injectors clogged or not operating Check fuel injectors (see Section 20) and wiring harness

Coolant temperature sensor faulty or Test coolant temperature sensor (see Chapter 6, Section 4)

wiring problem

TPS (throttle position sensor) incorrectly adjusted Check TPS adjustment (see Chapter 6, Section 4)

Dirt or other contaminants in fuel Check the fuel and drain the tank if necessary

Faulty ECU Have the ECU tested at a dealer service department or other specialist

Crankshaft position signal missing Faulty position sensor or flywheel, or reference pin missing (see Chapter 5)

Engine difficult to start, or fails to start (when warm)

Probable cause Corrective action

Cold start injector leaking or operating

continuously (early Motronic system only) Test cold start injector and thermotime switch (see Section 19)

Fuel pressure incorrect Test fuel pressure (see Section 3)

Insufficient residual fuel pressure Test fuel system hold pressure (see Section 3)

Fuel leak(s) Inspect fuel lines and fuel injectors for leaks. Correct leaks as necessary

Coolant temperature sensor faulty

or wiring problem Test coolant temperature sensor (see Chapter 6, Section 4)

Vapour lock (in warm weather) Check fuel pressure (see Section 3)

EVAP system faulty Check EVAP system (see Chapter 6, Section 6)

Faulty ECU Have the ECU tested at a dealer service department or other specialist

Idle speed control system faulty Test the idle air stabiliser valve (see Section 21)

Oxygen sensor faulty (where applicable) Check the oxygen sensor (see Chapter 6, Section 4)

Engine misses and hesitates under load

Probable cause Corrective action

Fuel injector clogged Test fuel injectors. Check for clogged injector lines. Renew faulty injectors (see Section 20)

Fuel pressure incorrect Test fuel system pressure (see Section 3). Test fuel pressure regulator (see Section 18)

Fuel leak(s) Inspect fuel lines and fuel injectors for leaks (see Chapter 4)

Engine maintenance Tune-up engine (see Chapter 1). Check the distributor cap, rotor, HT leads and spark

plugs, and renew any faulty components

Airflow meter flap (door) binding, or Inspect the airflow meter for damage (see Section 16)

stuck in open position

Intake air leaks Inspect all vacuum lines, air ducts, and oil filler and dipstick seals

Throttle position sensor (TPS) incorrectly adjusted Check TPS adjustment (see Chapter 6)

Engine idles too fast

Probable cause Corrective action

Accelerator pedal, cable or throttle valve binding Check for worn or broken components, kinked cable, or other damage. Renew faulty

components

Air leaking past throttle valve Inspect throttle valve, and adjust or renew as required

Engine has erratic idle speed

Probable cause Corrective action

Idle air stabiliser valve faulty Check the idle air stabiliser valve (see Section 21)

No power to the idle air stabiliser valve Check the idle air stabiliser relay and wiring circuit (see Chapter 12)

Idle speed control unit faulty Have the idle speed control unit checked by a dealer

Poor fuel economy

Probable cause Corrective action

Cold start injector leaking

(early Motronic system only) Test and, if necessary, renew cold start injector (see Section 19)

Oxygen sensor faulty (where applicable) Test the oxygen sensor (see Chapter 6, Section 4))

Sticking handbrake/binding brakes Check the handbrake/braking system (see Chapter 9)

Tyre pressures low Check tyre pressures (Chapter 1)

4•22 Fuel and exhaust systems

Page 114 of 228

7 Ignition timing (TCI system)-

check and adjustment

4

Warning: Keep hands, equipment

and wires well clear of the

viscous cooling fan during

adjustment of the ignition timing.

Note:This Section describes the procedure

for checking and adjusting the ignition timing

on engines fitted with the TCI system. On

engines fitted with the Motronic engine

management system, the ignition timing is

controlled by the electronic control unit, and

no adjustment is possible. The timing can be

checked using the following procedure, but no

ignition timing values were available at the

time of writing. If the timing is thought to be

incorrect, refer to a BMW dealer.

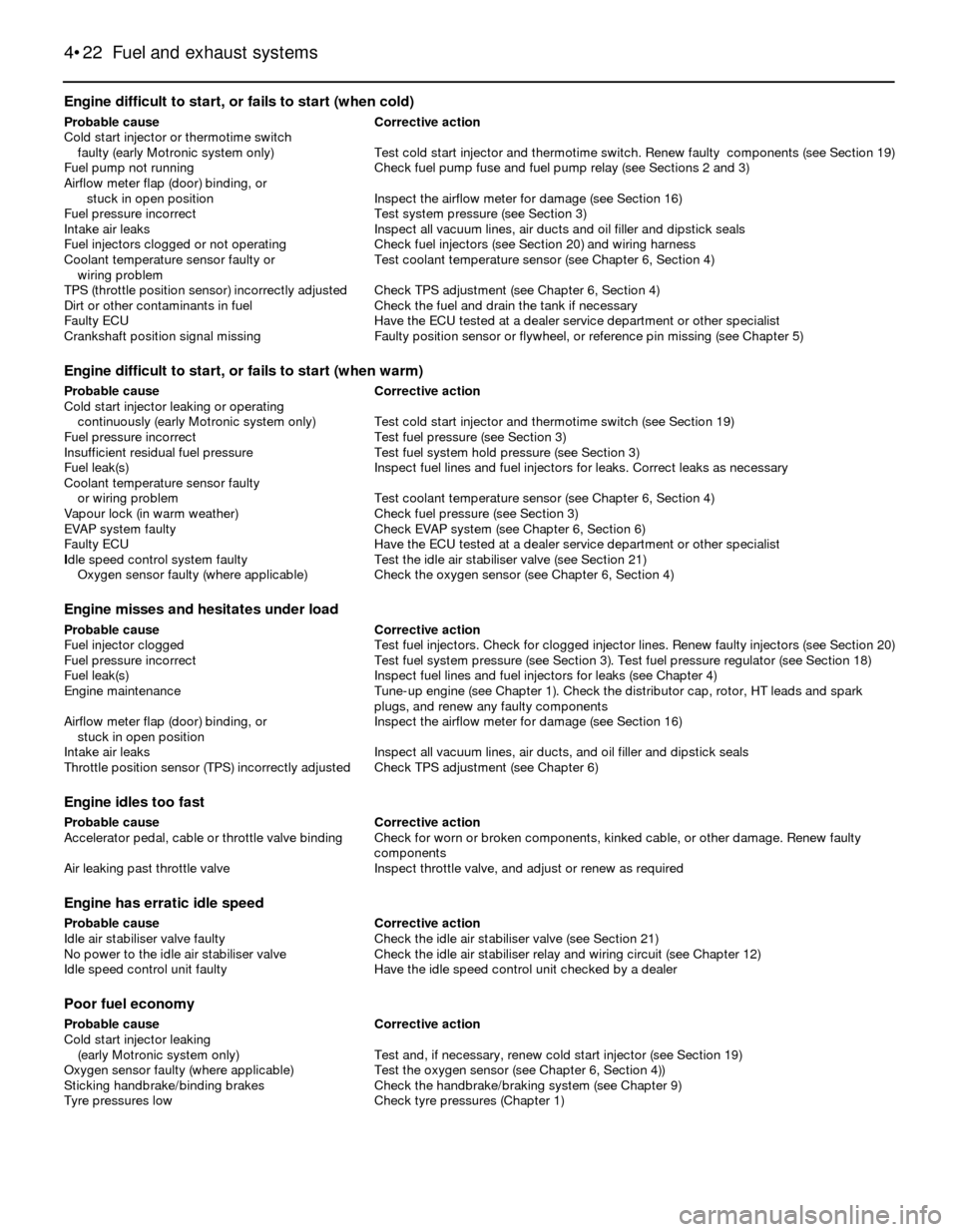

1Some special tools are required for this

procedure (see illustration). The engine must

be at normal operating temperature, and the

air conditioning (where fitted) must be

switched off. Make sure the idle speed is

correct.

2Apply the handbrake, and chock the wheels

to prevent movement of the vehicle. The

transmission must be in neutral (manual) or

Park (automatic).

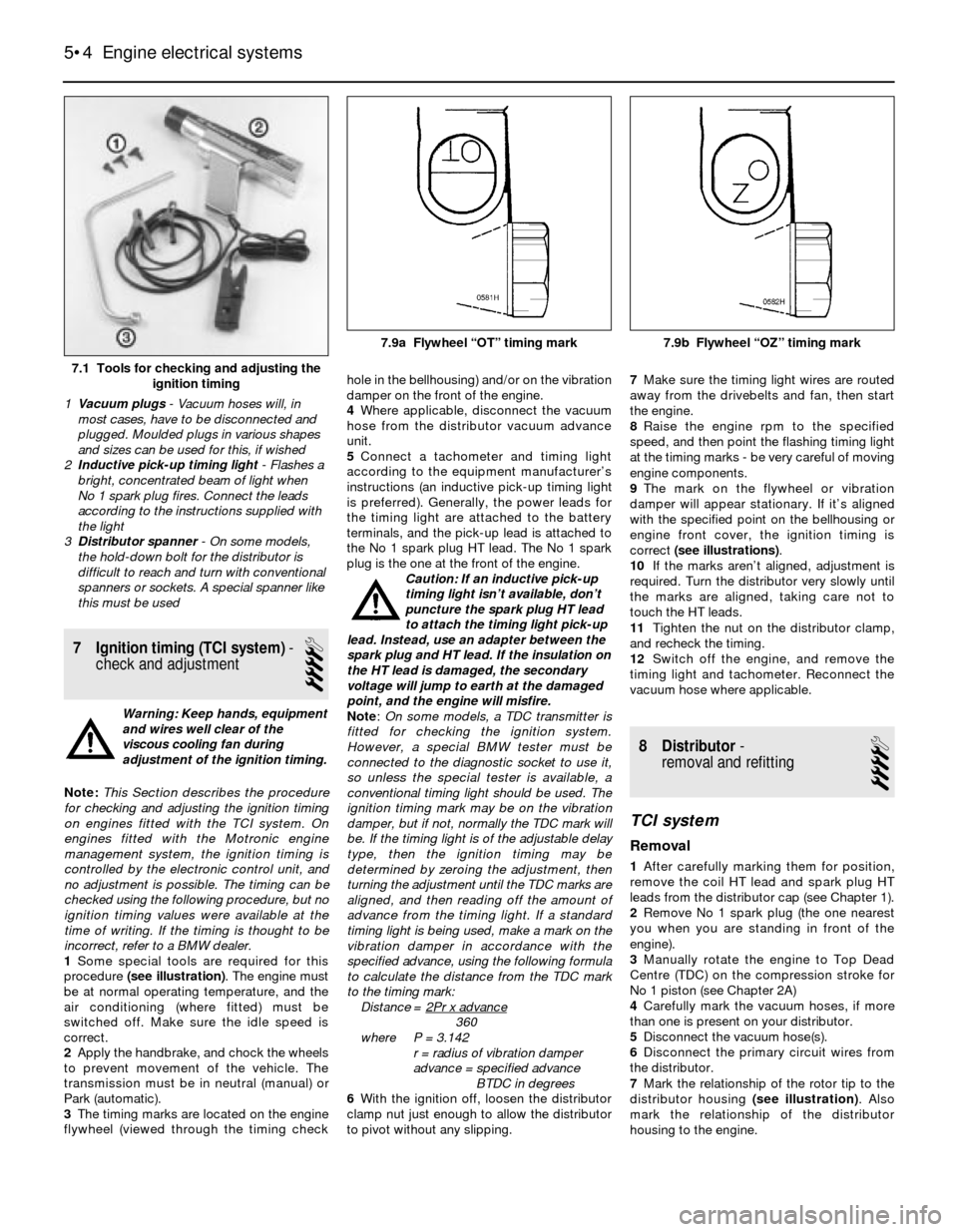

3The timing marks are located on the engine

flywheel (viewed through the timing checkhole in the bellhousing) and/or on the vibration

damper on the front of the engine.

4Where applicable, disconnect the vacuum

hose from the distributor vacuum advance

unit.

5Connect a tachometer and timing light

according to the equipment manufacturer’s

instructions (an inductive pick-up timing light

is preferred). Generally, the power leads for

the timing light are attached to the battery

terminals, and the pick-up lead is attached to

the No 1 spark plug HT lead. The No 1 spark

plug is the one at the front of the engine.

Caution: If an inductive pick-up

timing light isn’t available, don’t

puncture the spark plug HT lead

to attach the timing light pick-up

lead. Instead, use an adapter between the

spark plug and HT lead. If the insulation on

the HT lead is damaged, the secondary

voltage will jump to earth at the damaged

point, and the engine will misfire.

Note:On some models, a TDC transmitter is

fitted for checking the ignition system.

However, a special BMW tester must be

connected to the diagnostic socket to use it,

so unless the special tester is available, a

conventional timing light should be used. The

ignition timing mark may be on the vibration

damper, but if not, normally the TDC mark will

be. If the timing light is of the adjustable delay

type, then the ignition timing may be

determined by zeroing the adjustment, then

turning the adjustment until the TDC marks are

aligned, and then reading off the amount of

advance from the timing light. If a standard

timing light is being used, make a mark on the

vibration damper in accordance with the

specified advance, using the following formula

to calculate the distance from the TDC mark

to the timing mark:

Distance = 2Pr x advance

360

where P = 3.142

r = radius of vibration damper

advance = specified advance

BTDC in degrees

6With the ignition off, loosen the distributor

clamp nut just enough to allow the distributor

to pivot without any slipping.7Make sure the timing light wires are routed

away from the drivebelts and fan, then start

the engine.

8Raise the engine rpm to the specified

speed, and then point the flashing timing light

at the timing marks - be very careful of moving

engine components.

9The mark on the flywheel or vibration

damper will appear stationary. If it’s aligned

with the specified point on the bellhousing or

engine front cover, the ignition timing is

correct (see illustrations).

10If the marks aren’t aligned, adjustment is

required. Turn the distributor very slowly until

the marks are aligned, taking care not to

touch the HT leads.

11Tighten the nut on the distributor clamp,

and recheck the timing.

12Switch off the engine, and remove the

timing light and tachometer. Reconnect the

vacuum hose where applicable.

8 Distributor-

removal and refitting

4

TCI system

Removal

1After carefully marking them for position,

remove the coil HT lead and spark plug HT

leads from the distributor cap (see Chapter 1).

2Remove No 1 spark plug (the one nearest

you when you are standing in front of the

engine).

3Manually rotate the engine to Top Dead

Centre (TDC) on the compression stroke for

No 1 piston (see Chapter 2A)

4Carefully mark the vacuum hoses, if more

than one is present on your distributor.

5Disconnect the vacuum hose(s).

6Disconnect the primary circuit wires from

the distributor.

7Mark the relationship of the rotor tip to the

distributor housing (see illustration). Also

mark the relationship of the distributor

housing to the engine.

5•4 Engine electrical systems

7.1 Tools for checking and adjusting the

ignition timing

1Vacuum plugs- Vacuum hoses will, in

most cases, have to be disconnected and

plugged. Moulded plugs in various shapes

and sizes can be used for this, if wished

2Inductive pick-up timing light- Flashes a

bright, concentrated beam of light when

No 1 spark plug fires. Connect the leads

according to the instructions supplied with

the light

3Distributor spanner - On some models,

the hold-down bolt for the distributor is

difficult to reach and turn with conventional

spanners or sockets. A special spanner like

this must be used

7.9a Flywheel “OT” timing mark 7.9b Flywheel “OZ” timing mark