Timing belt renewal BMW 3 SERIES 1988 E30 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1988, Model line: 3 SERIES, Model: BMW 3 SERIES 1988 E30Pages: 228, PDF Size: 7.04 MB

Page 111 of 228

5GeneralApplication

Models with carburettor or L-Jetronic fuel injection . . . . . . . . . . . . . . Transistorised Coil Ignition (TCI) system

Models with Motronic fuel injection . . . . . . . . . . . . . . . . . . . . . . . . . . Ignition functions controlled by Motronic system

Ignition coil

Primary resistance

TCI system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.82 ohms

Motronic system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.50 ohms

Secondary resistance

TCI system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8250 ohms

Motronic system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5000 to 6000 ohms

Distributor(models with TCI system)

Air gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.3 mm to 0.7 mm

Pick-up coil/impulse generator resistance . . . . . . . . . . . . . . . . . . . . . . . 900 to 1200 ohms

Ignition timing(models with TCI system)

(Vacuum line disconnected at distributor)

316 with M10/B18 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25º BTDC at 2500 rpm (2900 rpm from 9/83)

318i with M10/B18 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30º BTDC at 3000 rpm

320i with M20/B20 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23º BTDC at 5000 ±50 rpm

518 with M10/B18 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25º BTDC at 2900 ±50 rpm

518i with M10/B18 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30º BTDC at 3000 ±50 rpm

525i with M30/B25 engine (except distributor

237 302 033) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22º BTDC at 1800 ±50 rpm

525i with M30/B25 engine (distributor 237 302 033) . . . . . . . . . . . . . . . 22º BTDC at 2150 ±50 rpm

528i with M30/B28 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22º BTDC at 2150 ±50 rpm

Chapter 5 Engine electrical systems

Air gap (TCI system) – check and adjustment . . . . . . . . . . . . . . . . . . 11

Alternator – removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Alternator brushes – check and renewal . . . . . . . . . . . . . . . . . . . . . . 17

Battery – emergency jump starting . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Battery – removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Battery cables – check and renewal . . . . . . . . . . . . . . . . . . . . . . . . . 4

Battery check and maintenance . . . . . . . . . . . . . . . . See Chapter 1

Charging system – check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Charging system – general information and precautions . . . . . . . . . 13

Distributor – removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Drivebelt check, adjustment and renewal . . . . . . . . . See Chapter 1

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Ignition coil – check and renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . 9Ignition sensors (Motronic system) – check and renewal . . . . . . . . . 12

Ignition system – check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Ignition system – general information and precautions . . . . . . . . . . 5

Ignition timing (TCI system) – check and adjustment . . . . . . . . . . . . 7

Impulse generator and ignition control unit – check and

renewal (TCI system) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Spark plug HT lead check and renewal . . . . . . . . . . . See Chapter 1

Spark plug renewal . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Starter motor – in-vehicle check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Starter motor – removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 20

Starter solenoid – removal and refitting . . . . . . . . . . . . . . . . . . . . . . 21

Starting system – general information and precautions . . . . . . . . . . 18

Voltage regulator – renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Specifications Contents

Page 118 of 228

and down - you should feel a slight drag on

the feeler gauge as it is moved if the gap is

correct. The gap must be as given in this

Chapter’s Specifications.

3To adjust the gap, it is necessary to remove

the impulse generator and the baseplate

assembly from the distributor (see illus-

tration 10.1).

4Follow paragraphs 17 to 24 in Section 10

and loosen the screws that retain the impulse

generator to the baseplate assembly.

5Carefully insert the feeler gauge and tighten

the screws.

6Refit the assembly back into the distributor

and recheck the adjustment.12 Ignition sensors (Motronic

system)- check and renewal

2

Note:Some models are equipped with a TDC

sensor mounted on the front of the engine.

This sensor is strictly for the BMW service test

unit, and is not part of the Motronic ignition

system.

Speed and position sensors

Check

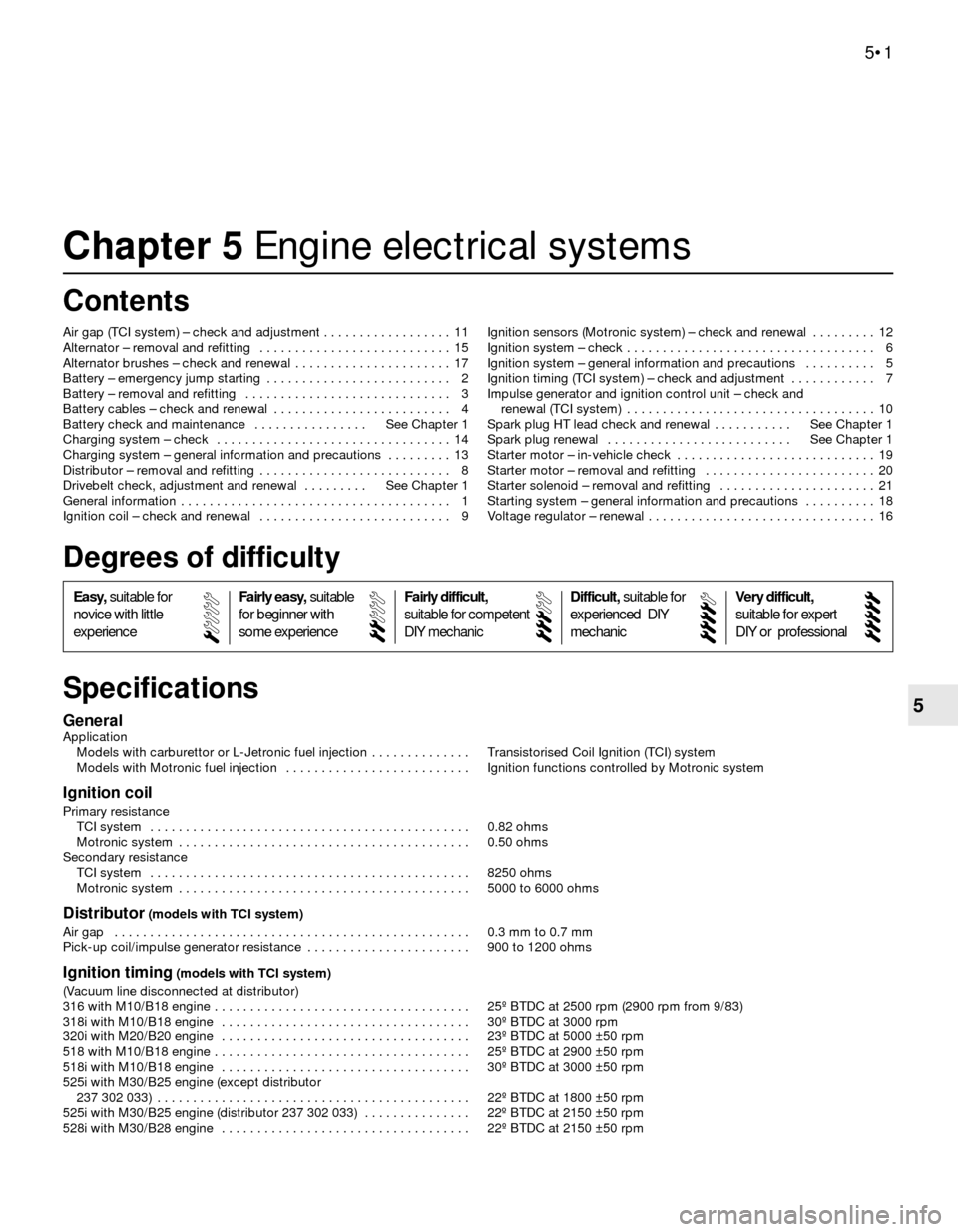

1Locate the two electrical connectors for the

sensors (see illustrations). The grey

connector is for the position sensor, and the

white connector is for the speed sensor.

2Using an ohmmeter, check the resistance

between terminal 1 (yellow wire) and terminal

2 (black wire) on the sensor side of each

connector. The resistance should be 860 to

1,060 ohms.

3Also check the resistance between terminal

3 and either terminal 1 or terminal 2. The

resistance should be approximately 100 000

ohms.

4If the reading(s) are incorrect, renew the

sensor(s).

Renewal

5Remove the sensor mounting screw(s),using an Allen key where necessary, and pull

the sensor(s) from the sockets. Disconnect

the wiring from one sensor at a time - be sure

the connectors are not interchanged when

fitting new sensors. The bellhousing is marked

with a B for the position sensor (grey

connector) and D for the speed sensor (black

connector) (see illustration). Note: It is a

good idea to check the condition of the raised

pin on the flywheel while the sensors are out

of the sockets. Turn the engine by hand as

necessary to bring the pin into view.

6Tighten the sensor mounting screw(s)

securely, but be careful not to overtighten.

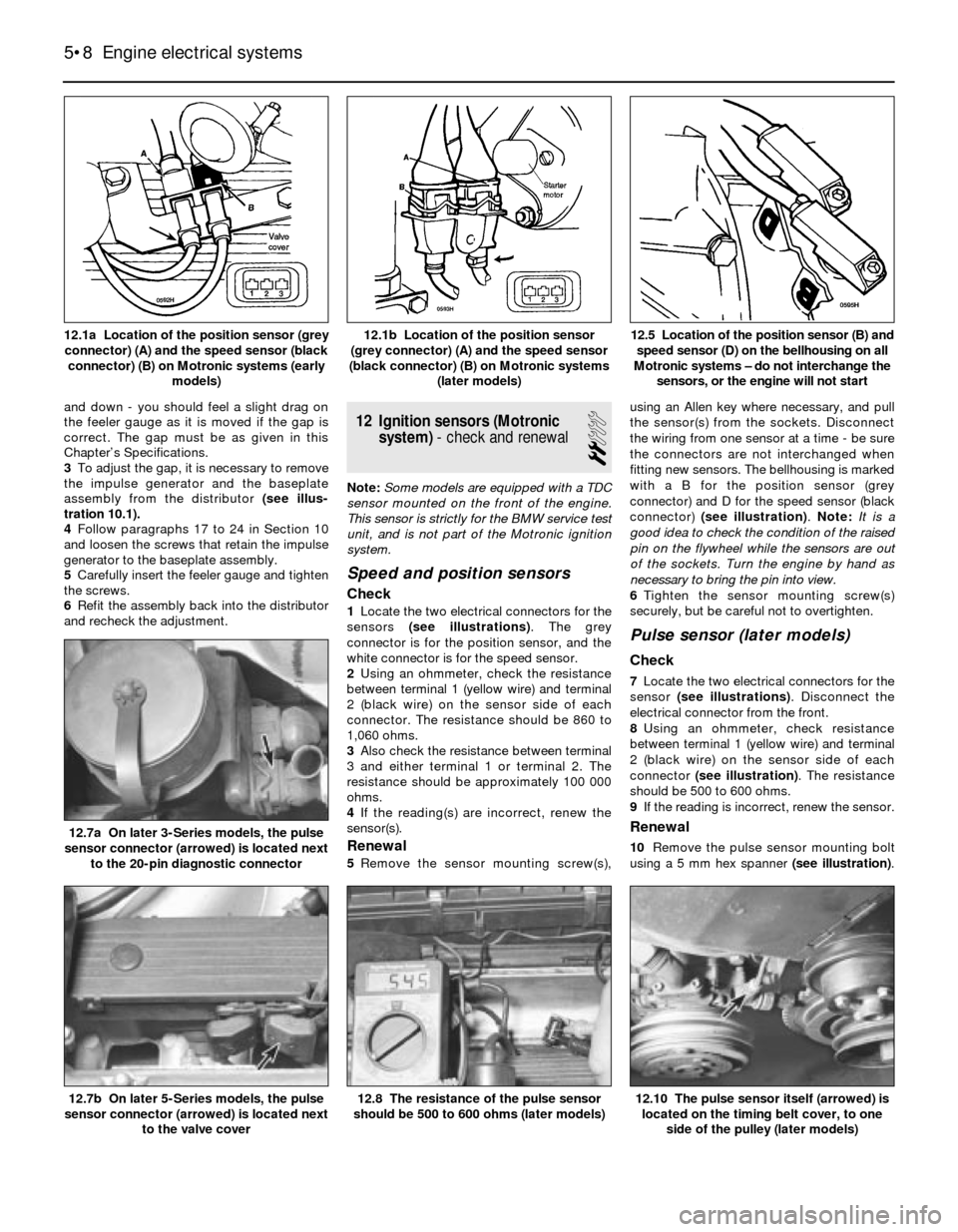

Pulse sensor (later models)

Check

7Locate the two electrical connectors for the

sensor (see illustrations). Disconnect the

electrical connector from the front.

8Using an ohmmeter, check resistance

between terminal 1 (yellow wire) and terminal

2 (black wire) on the sensor side of each

connector (see illustration). The resistance

should be 500 to 600 ohms.

9If the reading is incorrect, renew the sensor.

Renewal

10Remove the pulse sensor mounting bolt

using a 5 mm hex spanner (see illustration).

5•8 Engine electrical systems

12.10 The pulse sensor itself (arrowed) is

located on the timing belt cover, to one

side of the pulley (later models)12.8 The resistance of the pulse sensor

should be 500 to 600 ohms (later models)12.7b On later 5-Series models, the pulse

sensor connector (arrowed) is located next

to the valve cover

12.7a On later 3-Series models, the pulse

sensor connector (arrowed) is located next

to the 20-pin diagnostic connector

12.5 Location of the position sensor (B) and

speed sensor (D) on the bellhousing on all

Motronic systems – do not interchange the

sensors, or the engine will not start12.1b Location of the position sensor

(grey connector) (A) and the speed sensor

(black connector) (B) on Motronic systems

(later models)12.1a Location of the position sensor (grey

connector) (A) and the speed sensor (black

connector) (B) on Motronic systems (early

models)