Subframe bolts BMW 3 SERIES 1988 E30 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1988, Model line: 3 SERIES, Model: BMW 3 SERIES 1988 E30Pages: 228, PDF Size: 7.04 MB

Page 144 of 228

Torque wrench settingsNm

Front suspension

Strut damper rod nut

Rod with external hexagon . . . . . . . . . . . . . . . . . . . . . . 65

Rod with internal hexagon . . . . . . . . . . . . . . . . . . . . . . 44

Strut cartridge threaded collar . . . . . . . . . . . . . . . . . . . . . . . 130

Strut upper mounting nuts . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Front control arm (3-Series)

Control arm-to-steering knuckle balljoint nut . . . . . . . . . . 64

Control arm-to-subframe balljoint nut . . . . . . . . . . . . . . . 83

Control arm bush bracket bolts . . . . . . . . . . . . . . . . . . . . 41

Lower control arm (5-Series)

Control arm-to-steering arm balljoint stud nut . . . . . . . . . 85

Control arm pivot bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Thrust arm (5-Series)

Thrust arm-to-steering arm balljoint stud nut . . . . . . . . . . 85

Thrust arm through-bolt . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Front hub (wheel bearing) nut . . . . . . . . . . . . . . . . . . . . . . . . 290

Steering arm-to-strut bolts (5-Series) . . . . . . . . . . . . . . . . . . 65

Anti-roll bar (3-Series)

Anti-roll bar-to-connecting link bolt . . . . . . . . . . . . . . . . . 41

Anti-roll bar mounting brackets-to-subframe . . . . . . . . . . 22

Connecting link-to-bracket . . . . . . . . . . . . . . . . . . . . . . . . 22

Connecting link bracket-to-control arm . . . . . . . . . . . . . . 41

Anti-roll bar (5-Series)

Anti-roll bar mounting brackets . . . . . . . . . . . . . . . . . . . . 22

Anti-roll bar link-to-strut housing locknut

Yellow chrome . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

White chrome . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Yellow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

10•2 Suspension and steering systems

Torque wrench settingsNm

Rear suspension

Rear shock absorber (3-Series)

Shock absorber-to-upper mounting bracket . . . . . . . . . . 12 to 15

Shock absorber-to-trailing arm . . . . . . . . . . . . . . . . . . . . 71 to 85

Rear shock absorber (5-Series)

Lower mounting bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125 to 142

Upper mounting nut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 to 24

Upper spring mounting-to-shock absorber locknut . . . . . 22 to 24

Trailing arms (3-Series)

Trailing arm-to-lower mounting . . . . . . . . . . . . . . . . . . . . 71 to 85

Trailing arm-to-anti-roll bar . . . . . . . . . . . . . . . . . . . . . . . . 22 to 23

Trailing arms (5-Series)

Trailing arm-to-rear axle carrier (rubber bush

through-bolt and nut) . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Trailing arm-to-axle carrier connecting link (1983-on) . . . 126

Rear wheel bearing drive flange axle nut (5-Series)

M22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175 to 210

M27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235 to 260

Steering system

Steering wheel retaining nut . . . . . . . . . . . . . . . . . . . . . . . . . 79

Steering column universal joint pinch-bolt . . . . . . . . . . . . . . 22

Steering gear-to-subframe mounting bolts (3-Series) . . . . . 41

Steering box-to-front suspension subframe bolts (5-Series) 42

Track rod end-to-steering arm nut . . . . . . . . . . . . . . . . . . . . 37

Track rod end clamping bolt . . . . . . . . . . . . . . . . . . . . . . . . . 14

Pitman arm-to-steering box (5-Series) . . . . . . . . . . . . . . . . . 140

Steering linkage balljoints (all) . . . . . . . . . . . . . . . . . . . . . . . 37

1 General information

Warning: Whenever any of the

suspension or steering fasteners

are loosened or removed, they

must be inspected and if

necessary, new ones fitted, of the same

part number or of original-equipment

quality and design. Torque specifications

must be followed for proper reassembly

and component retention. Never attempt

to heat, straighten or weld any suspension

or steering component. Any bent or

damaged parts must be renewed.

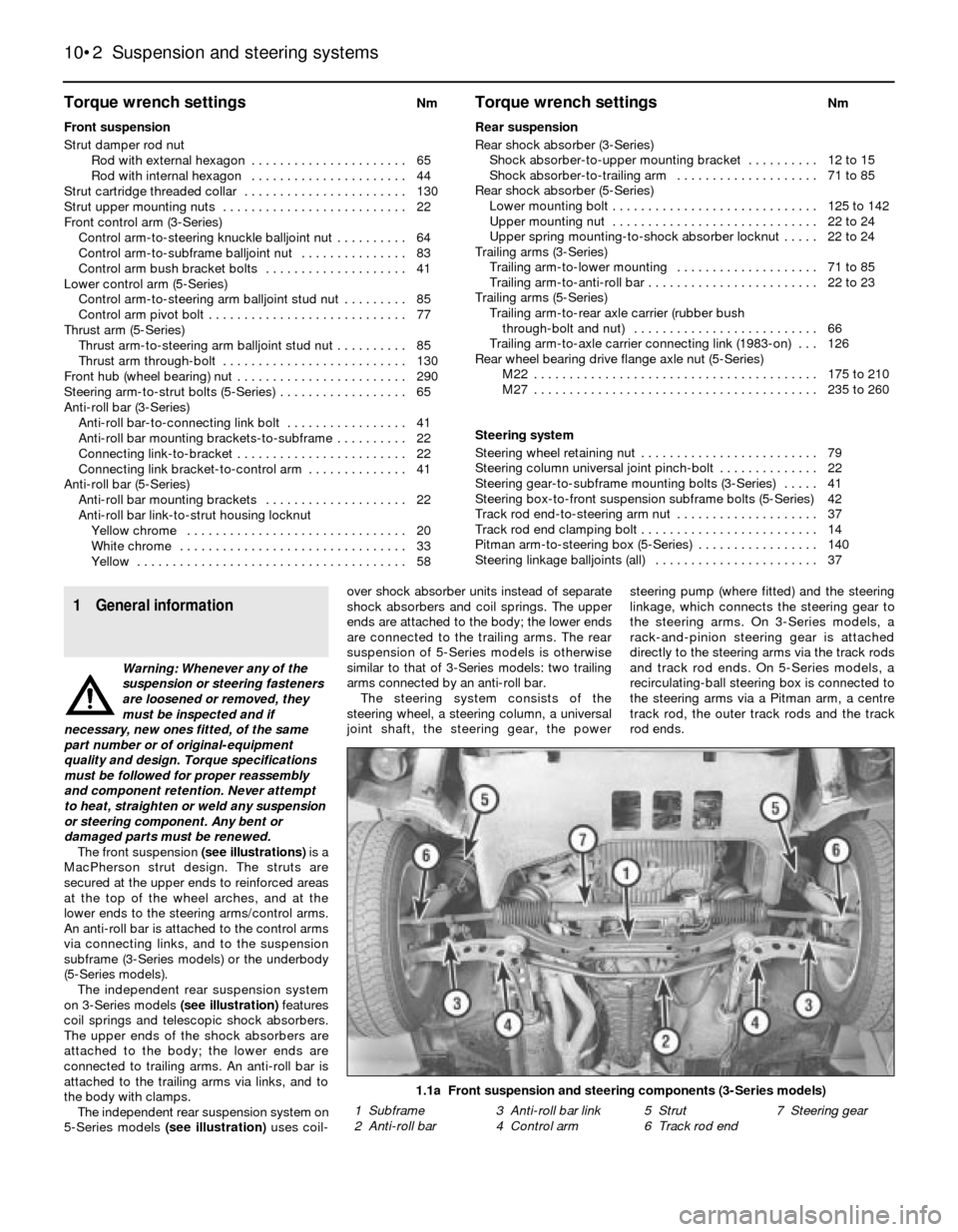

The front suspension (see illustrations)is a

MacPherson strut design. The struts are

secured at the upper ends to reinforced areas

at the top of the wheel arches, and at the

lower ends to the steering arms/control arms.

An anti-roll bar is attached to the control arms

via connecting links, and to the suspension

subframe (3-Series models) or the underbody

(5-Series models).

The independent rear suspension system

on 3-Series models (see illustration)features

coil springs and telescopic shock absorbers.

The upper ends of the shock absorbers are

attached to the body; the lower ends are

connected to trailing arms. An anti-roll bar is

attached to the trailing arms via links, and to

the body with clamps.

The independent rear suspension system on

5-Series models (see illustration)uses coil-over shock absorber units instead of separate

shock absorbers and coil springs. The upper

ends are attached to the body; the lower ends

are connected to the trailing arms. The rear

suspension of 5-Series models is otherwise

similar to that of 3-Series models: two trailing

arms connected by an anti-roll bar.

The steering system consists of the

steering wheel, a steering column, a universal

joint shaft, the steering gear, the powersteering pump (where fitted) and the steering

linkage, which connects the steering gear to

the steering arms. On 3-Series models, a

rack-and-pinion steering gear is attached

directly to the steering arms via the track rods

and track rod ends. On 5-Series models, a

recirculating-ball steering box is connected to

the steering arms via a Pitman arm, a centre

track rod, the outer track rods and the track

rod ends.

1.1a Front suspension and steering components (3-Series models)

1 Subframe 3 Anti-roll bar link 5 Strut 7 Steering gear

2 Anti-roll bar 4 Control arm 6 Track rod end

Page 146 of 228

2 Front anti-roll bar-

removal and refitting

2

Removal

1Raise the front of the vehicle, and support it

securely on axle stands.

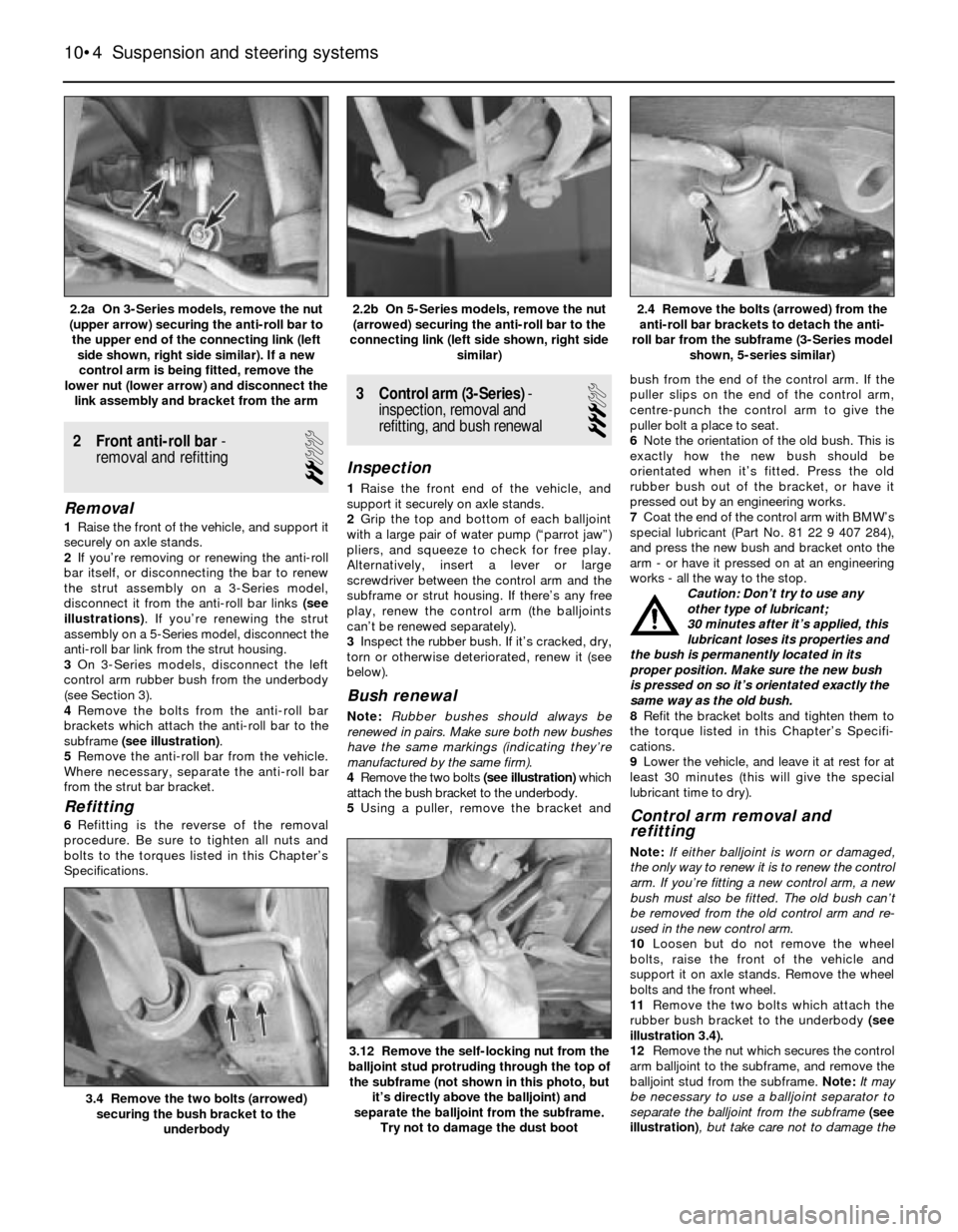

2If you’re removing or renewing the anti-roll

bar itself, or disconnecting the bar to renew

the strut assembly on a 3-Series model,

disconnect it from the anti-roll bar links (see

illustrations). If you’re renewing the strut

assembly on a 5-Series model, disconnect the

anti-roll bar link from the strut housing.

3On 3-Series models, disconnect the left

control arm rubber bush from the underbody

(see Section 3).

4Remove the bolts from the anti-roll bar

brackets which attach the anti-roll bar to the

subframe (see illustration).

5Remove the anti-roll bar from the vehicle.

Where necessary, separate the anti-roll bar

from the strut bar bracket.

Refitting

6Refitting is the reverse of the removal

procedure. Be sure to tighten all nuts and

bolts to the torques listed in this Chapter’s

Specifications.

3 Control arm (3-Series)-

inspection, removal and

refitting, and bush renewal

3

Inspection

1Raise the front end of the vehicle, and

support it securely on axle stands.

2Grip the top and bottom of each balljoint

with a large pair of water pump (“parrot jaw”)

pliers, and squeeze to check for free play.

Alternatively, insert a lever or large

screwdriver between the control arm and the

subframe or strut housing. If there’s any free

play, renew the control arm (the balljoints

can’t be renewed separately).

3Inspect the rubber bush. If it’s cracked, dry,

torn or otherwise deteriorated, renew it (see

below).

Bush renewal

Note:Rubber bushes should always be

renewed in pairs. Make sure both new bushes

have the same markings (indicating they’re

manufactured by the same firm).

4Remove the two bolts (see illustration)which

attach the bush bracket to the underbody.

5Using a puller, remove the bracket andbush from the end of the control arm. If the

puller slips on the end of the control arm,

centre-punch the control arm to give the

puller bolt a place to seat.

6Note the orientation of the old bush. This is

exactly how the new bush should be

orientated when it’s fitted. Press the old

rubber bush out of the bracket, or have it

pressed out by an engineering works.

7Coat the end of the control arm with BMW’s

special lubricant (Part No. 81 22 9 407 284),

and press the new bush and bracket onto the

arm - or have it pressed on at an engineering

works - all the way to the stop.

Caution: Don’t try to use any

other type of lubricant;

30 minutes after it’s applied, this

lubricant loses its properties and

the bush is permanently located in its

proper position. Make sure the new bush

is pressed on so it’s orientated exactly the

same way as the old bush.

8Refit the bracket bolts and tighten them to

the torque listed in this Chapter’s Specifi-

cations.

9Lower the vehicle, and leave it at rest for at

least 30 minutes (this will give the special

lubricant time to dry).

Control arm removal and

refitting

Note:If either balljoint is worn or damaged,

the only way to renew it is to renew the control

arm. If you’re fitting a new control arm, a new

bush must also be fitted. The old bush can’t

be removed from the old control arm and re-

used in the new control arm.

10Loosen but do not remove the wheel

bolts, raise the front of the vehicle and

support it on axle stands. Remove the wheel

bolts and the front wheel.

11Remove the two bolts which attach the

rubber bush bracket to the underbody (see

illustration 3.4).

12Remove the nut which secures the control

arm balljoint to the subframe, and remove the

balljoint stud from the subframe. Note:It may

be necessary to use a balljoint separator to

separate the balljoint from the subframe (see

illustration), but take care not to damage the

10•4 Suspension and steering systems

3.12 Remove the self-locking nut from the

balljoint stud protruding through the top of

the subframe (not shown in this photo, but

it’s directly above the balljoint) and

separate the balljoint from the subframe.

Try not to damage the dust boot

3.4 Remove the two bolts (arrowed)

securing the bush bracket to the

underbody

2.4 Remove the bolts (arrowed) from the

anti-roll bar brackets to detach the anti-

roll bar from the subframe (3-Series model

shown, 5-series similar)2.2b On 5-Series models, remove the nut

(arrowed) securing the anti-roll bar to the

connecting link (left side shown, right side

similar)2.2a On 3-Series models, remove the nut

(upper arrow) securing the anti-roll bar to

the upper end of the connecting link (left

side shown, right side similar). If a new

control arm is being fitted, remove the

lower nut (lower arrow) and disconnect the

link assembly and bracket from the arm

Page 150 of 228

problem exists, a new subframe or steering

arm (5-Series) or steering knuckle (3-Series),

which is integral with the strut housing, should

be fitted as well as the new balljoint.

Renewal

Note: None of these balljoints can be serviced

or renewed individually. If one of them is worn,

a complete new arm must be fitted.

8 Front hub and wheel bearing

assembly-

removal and refitting

3

Note:Removing the front hub/bearing

assembly renders it unfit for re-use. A new

assembly will be required for refitting.

Removal

1Loosen the wheel bolts, then raise the front

of the vehicle, and support it securely on axle

stands. Remove the wheel bolts and the

wheel.

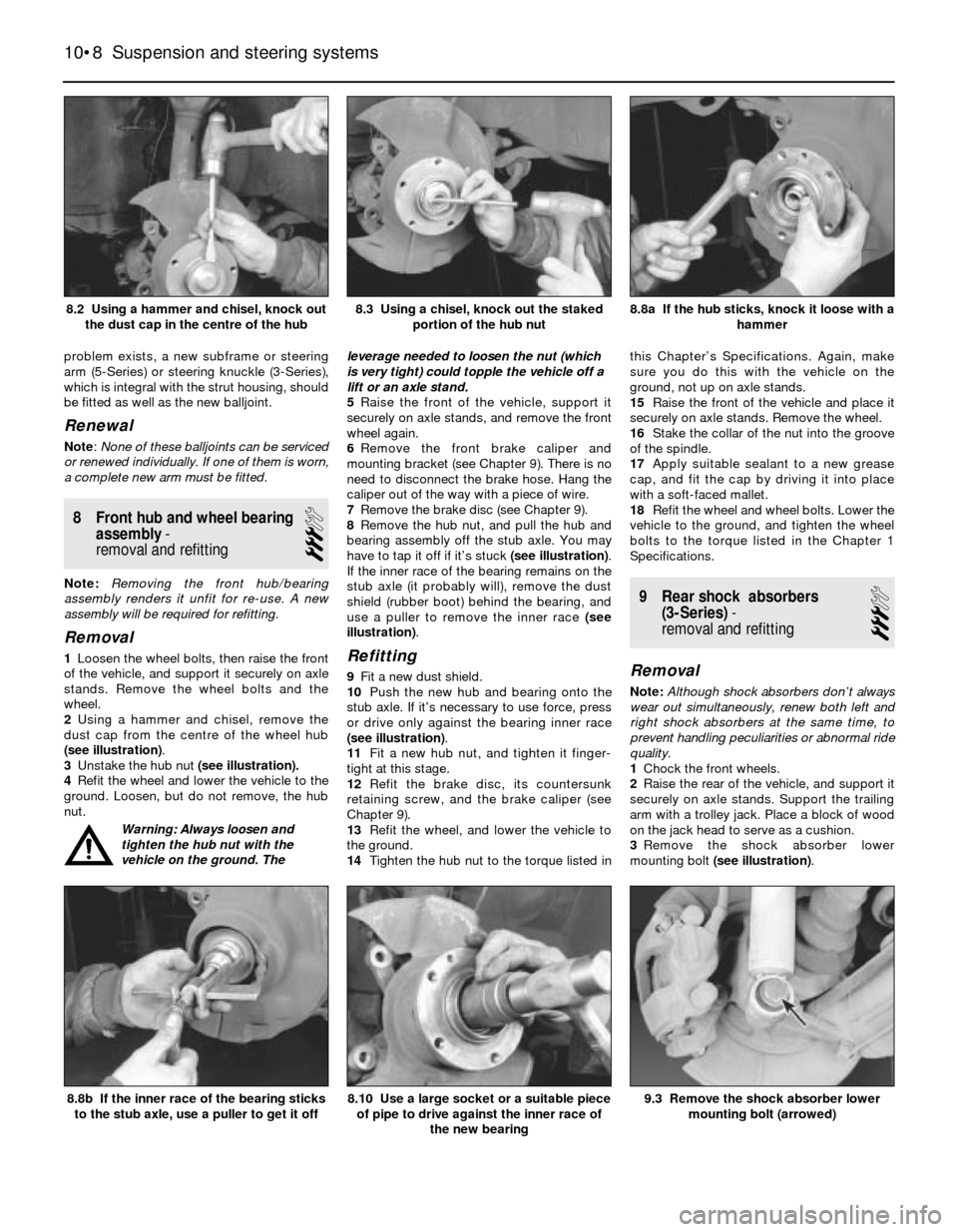

2Using a hammer and chisel, remove the

dust cap from the centre of the wheel hub

(see illustration).

3Unstake the hub nut (see illustration).

4Refit the wheel and lower the vehicle to the

ground. Loosen, but do not remove, the hub

nut.

Warning: Always loosen and

tighten the hub nut with the

vehicle on the ground. Theleverage needed to loosen the nut (which

is very tight) could topple the vehicle off a

lift or an axle stand.

5Raise the front of the vehicle, support it

securely on axle stands, and remove the front

wheel again.

6Remove the front brake caliper and

mounting bracket (see Chapter 9). There is no

need to disconnect the brake hose. Hang the

caliper out of the way with a piece of wire.

7Remove the brake disc (see Chapter 9).

8Remove the hub nut, and pull the hub and

bearing assembly off the stub axle. You may

have to tap it off if it’s stuck (see illustration).

If the inner race of the bearing remains on the

stub axle (it probably will), remove the dust

shield (rubber boot) behind the bearing, and

use a puller to remove the inner race (see

illustration).Refitting

9Fit a new dust shield.

10Push the new hub and bearing onto the

stub axle. If it’s necessary to use force, press

or drive only against the bearing inner race

(see illustration).

11Fit a new hub nut, and tighten it finger-

tight at this stage.

12Refit the brake disc, its countersunk

retaining screw, and the brake caliper (see

Chapter 9).

13Refit the wheel, and lower the vehicle to

the ground.

14Tighten the hub nut to the torque listed inthis Chapter’s Specifications. Again, make

sure you do this with the vehicle on the

ground, not up on axle stands.

15Raise the front of the vehicle and place it

securely on axle stands. Remove the wheel.

16Stake the collar of the nut into the groove

of the spindle.

17Apply suitable sealant to a new grease

cap, and fit the cap by driving it into place

with a soft-faced mallet.

18Refit the wheel and wheel bolts. Lower the

vehicle to the ground, and tighten the wheel

bolts to the torque listed in the Chapter 1

Specifications.

9 Rear shock absorbers

(3-Series)-

removal and refitting

3

Removal

Note:Although shock absorbers don’t always

wear out simultaneously, renew both left and

right shock absorbers at the same time, to

prevent handling peculiarities or abnormal ride

quality.

1Chock the front wheels.

2Raise the rear of the vehicle, and support it

securely on axle stands. Support the trailing

arm with a trolley jack. Place a block of wood

on the jack head to serve as a cushion.

3Remove the shock absorber lower

mounting bolt (see illustration).

10•8 Suspension and steering systems

9.3 Remove the shock absorber lower

mounting bolt (arrowed)8.10 Use a large socket or a suitable piece

of pipe to drive against the inner race of

the new bearing8.8b If the inner race of the bearing sticks

to the stub axle, use a puller to get it off

8.8a If the hub sticks, knock it loose with a

hammer8.3 Using a chisel, knock out the staked

portion of the hub nut8.2 Using a hammer and chisel, knock out

the dust cap in the centre of the hub

Page 156 of 228

syringe or hand pump, empty the power

steering fluid reservoir.

4On power steering models, remove the

banjo bolts and disconnect the power

steering pressure and return lines from the

steering gear. Place a container under the

lines to catch spilled fluid. Plug the lines to

prevent excessive fluid loss and

contamination. Discard the sealing washers

(new ones should be used when

reassembling).

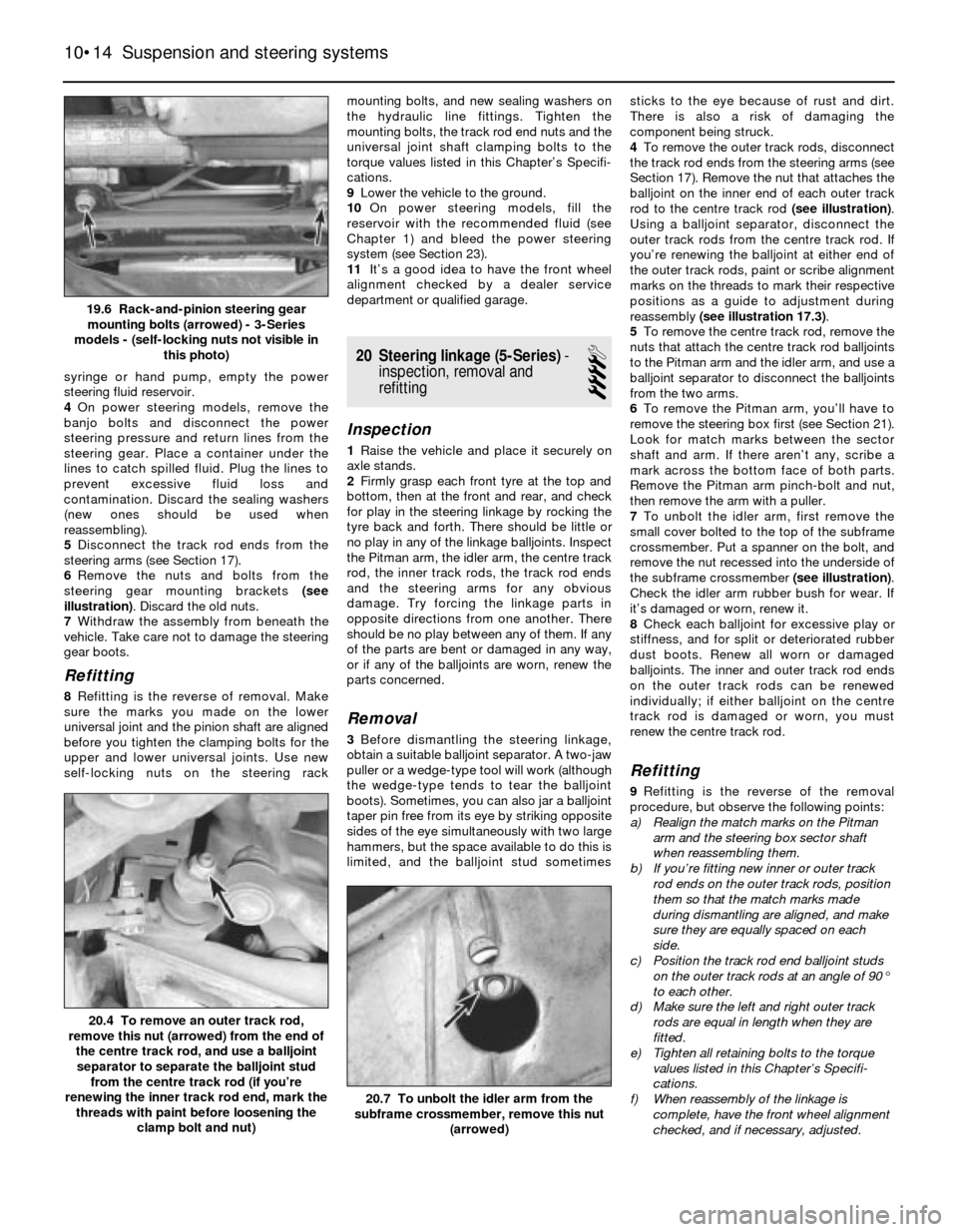

5Disconnect the track rod ends from the

steering arms (see Section 17).

6Remove the nuts and bolts from the

steering gear mounting brackets (see

illustration). Discard the old nuts.

7Withdraw the assembly from beneath the

vehicle. Take care not to damage the steering

gear boots.

Refitting

8Refitting is the reverse of removal. Make

sure the marks you made on the lower

universal joint and the pinion shaft are aligned

before you tighten the clamping bolts for the

upper and lower universal joints. Use new

self-locking nuts on the steering rackmounting bolts, and new sealing washers on

the hydraulic line fittings. Tighten the

mounting bolts, the track rod end nuts and the

universal joint shaft clamping bolts to the

torque values listed in this Chapter’s Specifi-

cations.

9Lower the vehicle to the ground.

10On power steering models, fill the

reservoir with the recommended fluid (see

Chapter 1) and bleed the power steering

system (see Section 23).

11It’s a good idea to have the front wheel

alignment checked by a dealer service

department or qualified garage.

20 Steering linkage (5-Series)-

inspection, removal and

refitting

4

Inspection

1Raise the vehicle and place it securely on

axle stands.

2Firmly grasp each front tyre at the top and

bottom, then at the front and rear, and check

for play in the steering linkage by rocking the

tyre back and forth. There should be little or

no play in any of the linkage balljoints. Inspect

the Pitman arm, the idler arm, the centre track

rod, the inner track rods, the track rod ends

and the steering arms for any obvious

damage. Try forcing the linkage parts in

opposite directions from one another. There

should be no play between any of them. If any

of the parts are bent or damaged in any way,

or if any of the balljoints are worn, renew the

parts concerned.

Removal

3Before dismantling the steering linkage,

obtain a suitable balljoint separator. A two-jaw

puller or a wedge-type tool will work (although

the wedge-type tends to tear the balljoint

boots). Sometimes, you can also jar a balljoint

taper pin free from its eye by striking opposite

sides of the eye simultaneously with two large

hammers, but the space available to do this is

limited, and the balljoint stud sometimessticks to the eye because of rust and dirt.

There is also a risk of damaging the

component being struck.

4To remove the outer track rods, disconnect

the track rod ends from the steering arms (see

Section 17). Remove the nut that attaches the

balljoint on the inner end of each outer track

rod to the centre track rod (see illustration).

Using a balljoint separator, disconnect the

outer track rods from the centre track rod. If

you’re renewing the balljoint at either end of

the outer track rods, paint or scribe alignment

marks on the threads to mark their respective

positions as a guide to adjustment during

reassembly (see illustration 17.3).

5To remove the centre track rod, remove the

nuts that attach the centre track rod balljoints

to the Pitman arm and the idler arm, and use a

balljoint separator to disconnect the balljoints

from the two arms.

6To remove the Pitman arm, you’ll have to

remove the steering box first (see Section 21).

Look for match marks between the sector

shaft and arm. If there aren’t any, scribe a

mark across the bottom face of both parts.

Remove the Pitman arm pinch-bolt and nut,

then remove the arm with a puller.

7To unbolt the idler arm, first remove the

small cover bolted to the top of the subframe

crossmember. Put a spanner on the bolt, and

remove the nut recessed into the underside of

the subframe crossmember (see illustration).

Check the idler arm rubber bush for wear. If

it’s damaged or worn, renew it.

8Check each balljoint for excessive play or

stiffness, and for split or deteriorated rubber

dust boots. Renew all worn or damaged

balljoints. The inner and outer track rod ends

on the outer track rods can be renewed

individually; if either balljoint on the centre

track rod is damaged or worn, you must

renew the centre track rod.

Refitting

9Refitting is the reverse of the removal

procedure, but observe the following points:

a) Realign the match marks on the Pitman

arm and the steering box sector shaft

when reassembling them.

b) If you’re fitting new inner or outer track

rod ends on the outer track rods, position

them so that the match marks made

during dismantling are aligned, and make

sure they are equally spaced on each

side.

c) Position the track rod end balljoint studs

on the outer track rods at an angle of 90°

to each other.

d) Make sure the left and right outer track

rods are equal in length when they are

fitted.

e) Tighten all retaining bolts to the torque

values listed in this Chapter’s Specifi-

cations.

f) When reassembly of the linkage is

complete, have the front wheel alignment

checked, and if necessary, adjusted.

10•14 Suspension and steering systems

20.7 To unbolt the idler arm from the

subframe crossmember, remove this nut

(arrowed)

20.4 To remove an outer track rod,

remove this nut (arrowed) from the end of

the centre track rod, and use a balljoint

separator to separate the balljoint stud

from the centre track rod (if you’re

renewing the inner track rod end, mark the

threads with paint before loosening the

clamp bolt and nut)

19.6 Rack-and-pinion steering gear

mounting bolts (arrowed) - 3-Series

models - (self-locking nuts not visible in

this photo)

Page 157 of 228

21 Steering box (5-Series)-

removal and refitting

4

Removal

Note:If you find that the steering box is

defective, it is not recommended that you

overhaul it. Because of the special tools

needed to do the job, it is best to let your

dealer service department overhaul it for you

(otherwise, fit a new unit). Removal and

refitting the steering box is outlined here.

1On 5-Series E28 (“old-shape”) models,

discharge the hydraulic system by depressing

the brake pedal about 20 times.

2Using a large syringe or hand pump, empty

the power steering fluid reservoir (see Chap-

ter 1).

3Raise the front of the vehicle and support it

securely on axle stands.

4Support the front of the engine with a trolley

jack. Place a block of wood between the jack

head and the sump to protect the sump from

damage.

5Remove the pivot bolts from the inner ends

of the front control arms (see Section 4).

6Remove the nuts from the left and right

engine mountings (see Chapter 2).

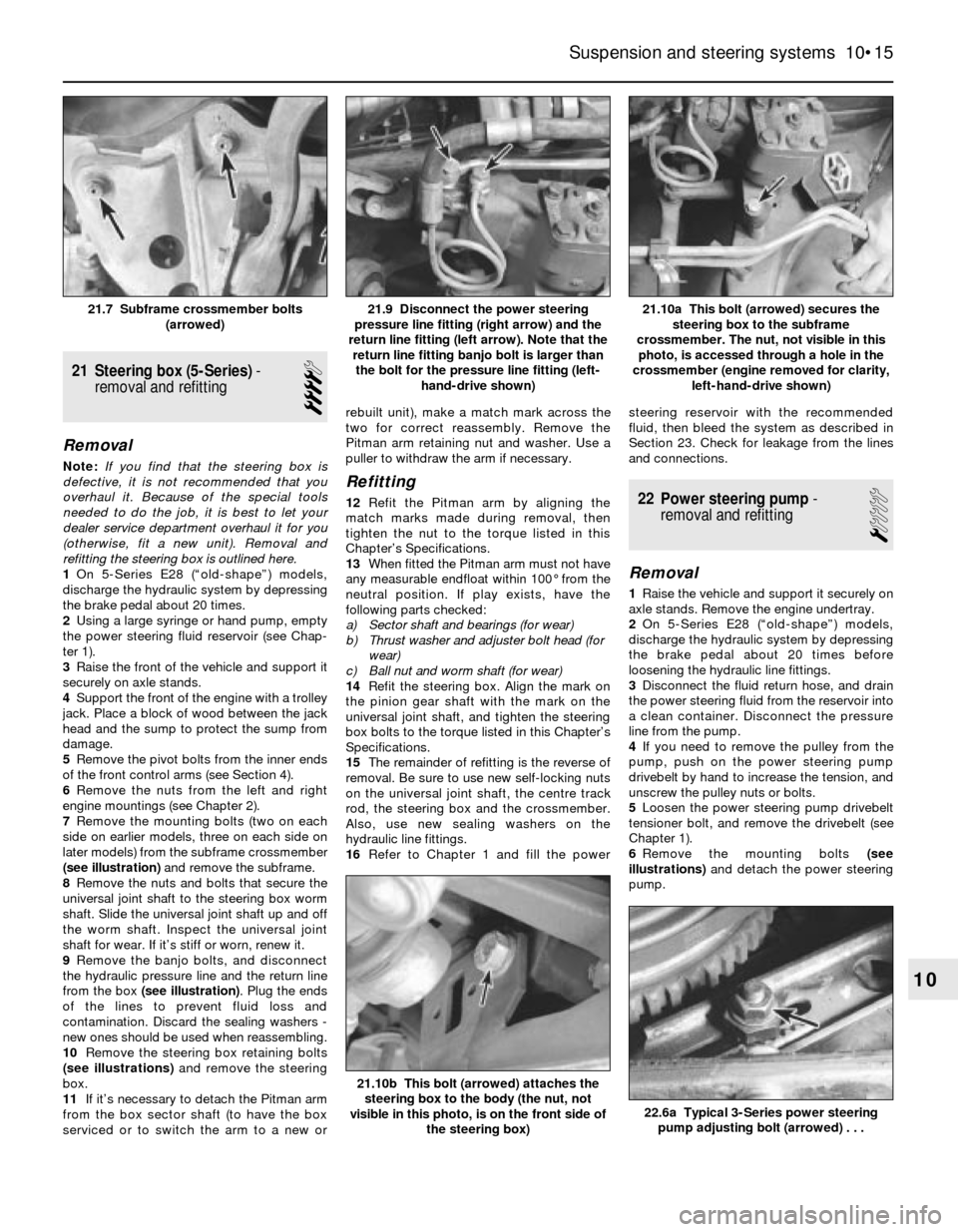

7Remove the mounting bolts (two on each

side on earlier models, three on each side on

later models) from the subframe crossmember

(see illustration)and remove the subframe.

8Remove the nuts and bolts that secure the

universal joint shaft to the steering box worm

shaft. Slide the universal joint shaft up and off

the worm shaft. Inspect the universal joint

shaft for wear. If it’s stiff or worn, renew it.

9Remove the banjo bolts, and disconnect

the hydraulic pressure line and the return line

from the box (see illustration). Plug the ends

of the lines to prevent fluid loss and

contamination. Discard the sealing washers -

new ones should be used when reassembling.

10Remove the steering box retaining bolts

(see illustrations)and remove the steering

box.

11If it’s necessary to detach the Pitman arm

from the box sector shaft (to have the box

serviced or to switch the arm to a new orrebuilt unit), make a match mark across the

two for correct reassembly. Remove the

Pitman arm retaining nut and washer. Use a

puller to withdraw the arm if necessary.

Refitting

12Refit the Pitman arm by aligning the

match marks made during removal, then

tighten the nut to the torque listed in this

Chapter’s Specifications.

13When fitted the Pitman arm must not have

any measurable endfloat within 100° from the

neutral position. If play exists, have the

following parts checked:

a) Sector shaft and bearings (for wear)

b) Thrust washer and adjuster bolt head (for

wear)

c) Ball nut and worm shaft (for wear)

14Refit the steering box. Align the mark on

the pinion gear shaft with the mark on the

universal joint shaft, and tighten the steering

box bolts to the torque listed in this Chapter’s

Specifications.

15The remainder of refitting is the reverse of

removal. Be sure to use new self-locking nuts

on the universal joint shaft, the centre track

rod, the steering box and the crossmember.

Also, use new sealing washers on the

hydraulic line fittings.

16Refer to Chapter 1 and fill the powersteering reservoir with the recommended

fluid, then bleed the system as described in

Section 23. Check for leakage from the lines

and connections.22 Power steering pump-

removal and refitting

1

Removal

1Raise the vehicle and support it securely on

axle stands. Remove the engine undertray.

2On 5-Series E28 (“old-shape”) models,

discharge the hydraulic system by depressing

the brake pedal about 20 times before

loosening the hydraulic line fittings.

3Disconnect the fluid return hose, and drain

the power steering fluid from the reservoir into

a clean container. Disconnect the pressure

line from the pump.

4If you need to remove the pulley from the

pump, push on the power steering pump

drivebelt by hand to increase the tension, and

unscrew the pulley nuts or bolts.

5Loosen the power steering pump drivebelt

tensioner bolt, and remove the drivebelt (see

Chapter 1).

6Remove the mounting bolts (see

illustrations)and detach the power steering

pump.

Suspension and steering systems 10•15

21.10a This bolt (arrowed) secures the

steering box to the subframe

crossmember. The nut, not visible in this

photo, is accessed through a hole in the

crossmember (engine removed for clarity,

left-hand-drive shown)21.9 Disconnect the power steering

pressure line fitting (right arrow) and the

return line fitting (left arrow). Note that the

return line fitting banjo bolt is larger than

the bolt for the pressure line fitting (left-

hand-drive shown)21.7 Subframe crossmember bolts

(arrowed)

22.6a Typical 3-Series power steering

pump adjusting bolt (arrowed) . . .

21.10b This bolt (arrowed) attaches the

steering box to the body (the nut, not

visible in this photo, is on the front side of

the steering box)

10