fuel pressure BMW 3 SERIES 1990 E30 Owner's Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1990, Model line: 3 SERIES, Model: BMW 3 SERIES 1990 E30Pages: 228, PDF Size: 7.04 MB

Page 124 of 228

4 Information sensors

2

Note:Refer to Chapters 4 and 5 for additional

information on the location and diagnosis of

the information sensors that are not covered in

this Section.

Coolant temperature sensor

General description

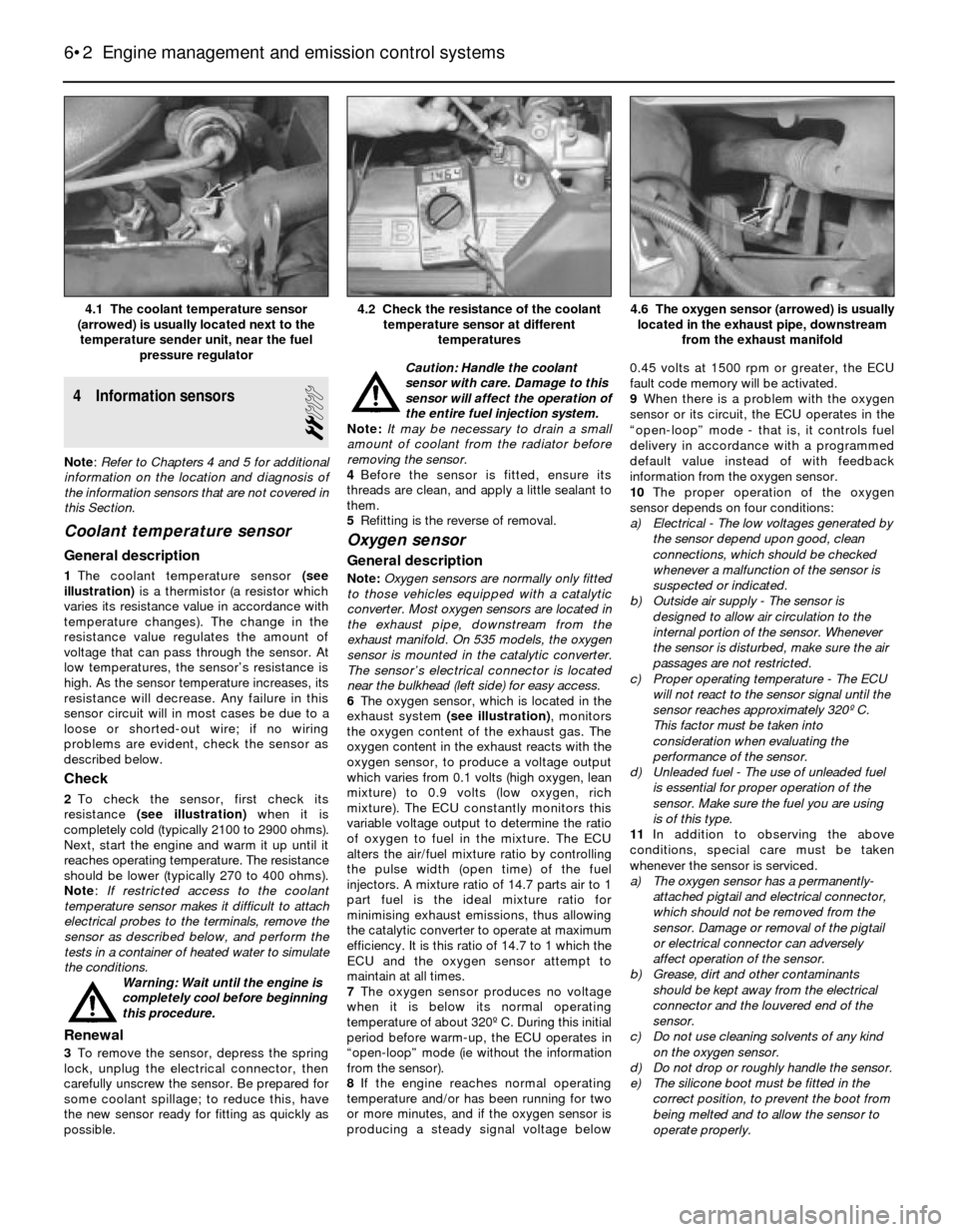

1The coolant temperature sensor (see

illustration)is a thermistor (a resistor which

varies its resistance value in accordance with

temperature changes). The change in the

resistance value regulates the amount of

voltage that can pass through the sensor. At

low temperatures, the sensor’s resistance is

high. As the sensor temperature increases, its

resistance will decrease. Any failure in this

sensor circuit will in most cases be due to a

loose or shorted-out wire; if no wiring

problems are evident, check the sensor as

described below.

Check

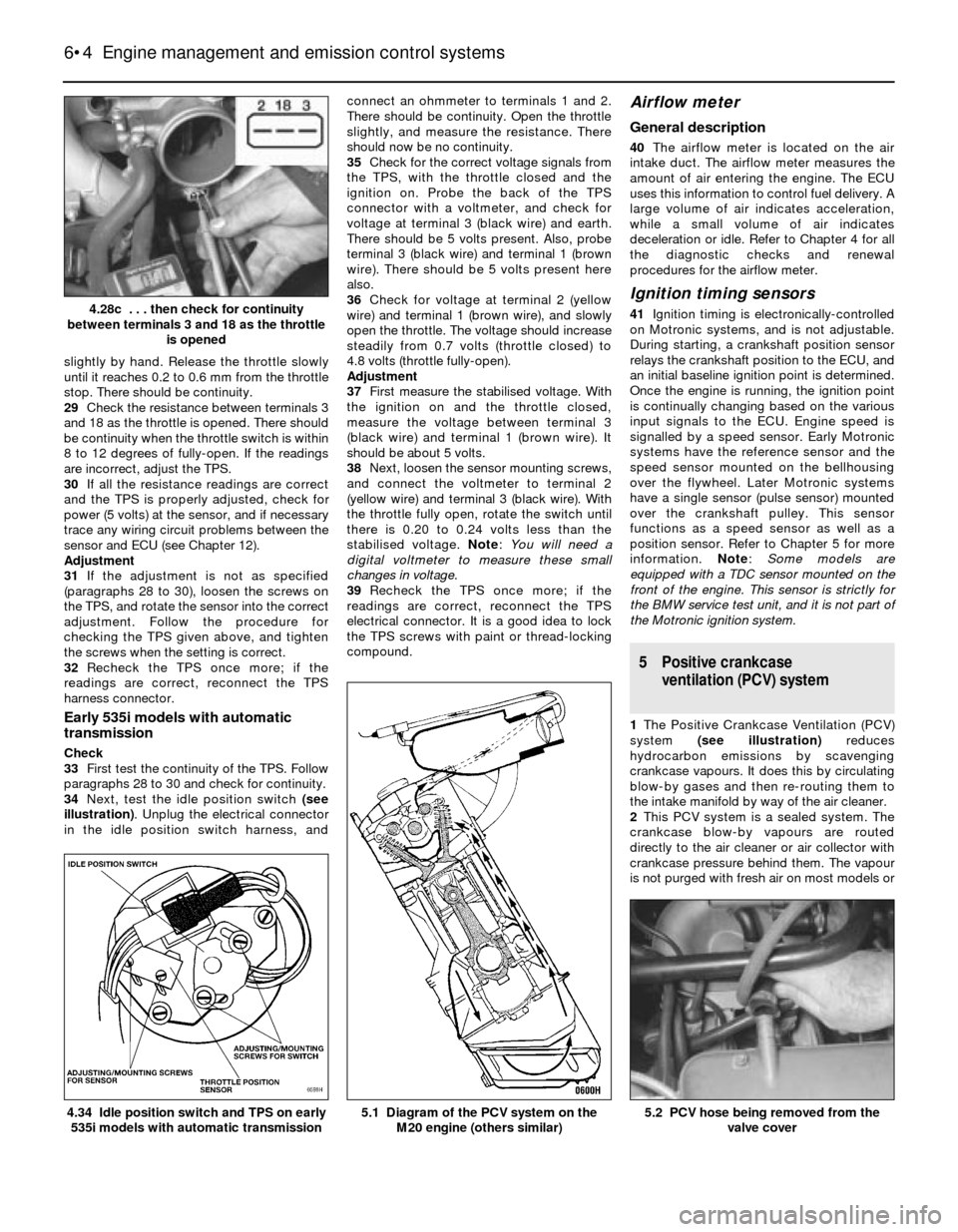

2To check the sensor, first check its

resistance (see illustration)when it is

completely cold (typically 2100 to 2900 ohms).

Next, start the engine and warm it up until it

reaches operating temperature. The resistance

should be lower (typically 270 to 400 ohms).

Note: If restricted access to the coolant

temperature sensor makes it difficult to attach

electrical probes to the terminals, remove the

sensor as described below, and perform the

tests in a container of heated water to simulate

the conditions.

Warning: Wait until the engine is

completely cool before beginning

this procedure.

Renewal

3To remove the sensor, depress the spring

lock, unplug the electrical connector, then

carefully unscrew the sensor. Be prepared for

some coolant spillage; to reduce this, have

the new sensor ready for fitting as quickly as

possible.Caution: Handle the coolant

sensor with care. Damage to this

sensor will affect the operation of

the entire fuel injection system.

Note: It may be necessary to drain a small

amount of coolant from the radiator before

removing the sensor.

4Before the sensor is fitted, ensure its

threads are clean, and apply a little sealant to

them.

5Refitting is the reverse of removal.

Oxygen sensor

General description

Note:Oxygen sensors are normally only fitted

to those vehicles equipped with a catalytic

converter. Most oxygen sensors are located in

the exhaust pipe, downstream from the

exhaust manifold. On 535 models, the oxygen

sensor is mounted in the catalytic converter.

The sensor’s electrical connector is located

near the bulkhead (left side) for easy access.

6The oxygen sensor, which is located in the

exhaust system (see illustration), monitors

the oxygen content of the exhaust gas. The

oxygen content in the exhaust reacts with the

oxygen sensor, to produce a voltage output

which varies from 0.1 volts (high oxygen, lean

mixture) to 0.9 volts (low oxygen, rich

mixture). The ECU constantly monitors this

variable voltage output to determine the ratio

of oxygen to fuel in the mixture. The ECU

alters the air/fuel mixture ratio by controlling

the pulse width (open time) of the fuel

injectors. A mixture ratio of 14.7 parts air to 1

part fuel is the ideal mixture ratio for

minimising exhaust emissions, thus allowing

the catalytic converter to operate at maximum

efficiency. It is this ratio of 14.7 to 1 which the

ECU and the oxygen sensor attempt to

maintain at all times.

7The oxygen sensor produces no voltage

when it is below its normal operating

temperature of about 320º C. During this initial

period before warm-up, the ECU operates in

“open-loop” mode (ie without the information

from the sensor).

8If the engine reaches normal operating

temperature and/or has been running for two

or more minutes, and if the oxygen sensor is

producing a steady signal voltage below 0.45 volts at 1500 rpm or greater, the ECU

fault code memory will be activated.

9When there is a problem with the oxygen

sensor or its circuit, the ECU operates in the

“open-loop” mode - that is, it controls fuel

delivery in accordance with a programmed

default value instead of with feedback

information from the oxygen sensor.

10The proper operation of the oxygen

sensor depends on four conditions:

a) Electrical - The low voltages generated by

the sensor depend upon good, clean

connections, which should be checked

whenever a malfunction of the sensor is

suspected or indicated.

b) Outside air supply - The sensor is

designed to allow air circulation to the

internal portion of the sensor. Whenever

the sensor is disturbed, make sure the air

passages are not restricted.

c) Proper operating temperature - The ECU

will not react to the sensor signal until the

sensor reaches approximately 320º C.

This factor must be taken into

consideration when evaluating the

performance of the sensor.

d) Unleaded fuel - The use of unleaded fuel

is essential for proper operation of the

sensor. Make sure the fuel you are using

is of this type.

11In addition to observing the above

conditions, special care must be taken

whenever the sensor is serviced.

a) The oxygen sensor has a permanently-

attached pigtail and electrical connector,

which should not be removed from the

sensor. Damage or removal of the pigtail

or electrical connector can adversely

affect operation of the sensor.

b) Grease, dirt and other contaminants

should be kept away from the electrical

connector and the louvered end of the

sensor.

c) Do not use cleaning solvents of any kind

on the oxygen sensor.

d) Do not drop or roughly handle the sensor.

e) The silicone boot must be fitted in the

correct position, to prevent the boot from

being melted and to allow the sensor to

operate properly.

6•2 Engine management and emission control systems

4.6 The oxygen sensor (arrowed) is usually

located in the exhaust pipe, downstream

from the exhaust manifold4.2 Check the resistance of the coolant

temperature sensor at different

temperatures4.1 The coolant temperature sensor

(arrowed) is usually located next to the

temperature sender unit, near the fuel

pressure regulator

Page 126 of 228

slightly by hand. Release the throttle slowly

until it reaches 0.2 to 0.6 mm from the throttle

stop. There should be continuity.

29Check the resistance between terminals 3

and 18 as the throttle is opened. There should

be continuity when the throttle switch is within

8 to 12 degrees of fully-open. If the readings

are incorrect, adjust the TPS.

30If all the resistance readings are correct

and the TPS is properly adjusted, check for

power (5 volts) at the sensor, and if necessary

trace any wiring circuit problems between the

sensor and ECU (see Chapter 12).

Adjustment

31If the adjustment is not as specified

(paragraphs 28 to 30), loosen the screws on

the TPS, and rotate the sensor into the correct

adjustment. Follow the procedure for

checking the TPS given above, and tighten

the screws when the setting is correct.

32Recheck the TPS once more; if the

readings are correct, reconnect the TPS

harness connector.

Early 535i models with automatic

transmission

Check

33First test the continuity of the TPS. Follow

paragraphs 28 to 30 and check for continuity.

34Next, test the idle position switch (see

illustration). Unplug the electrical connector

in the idle position switch harness, andconnect an ohmmeter to terminals 1 and 2.

There should be continuity. Open the throttle

slightly, and measure the resistance. There

should now be no continuity.

35Check for the correct voltage signals from

the TPS, with the throttle closed and the

ignition on. Probe the back of the TPS

connector with a voltmeter, and check for

voltage at terminal 3 (black wire) and earth.

There should be 5 volts present. Also, probe

terminal 3 (black wire) and terminal 1 (brown

wire). There should be 5 volts present here

also.

36Check for voltage at terminal 2 (yellow

wire) and terminal 1 (brown wire), and slowly

open the throttle. The voltage should increase

steadily from 0.7 volts (throttle closed) to

4.8 volts (throttle fully-open).

Adjustment

37First measure the stabilised voltage. With

the ignition on and the throttle closed,

measure the voltage between terminal 3

(black wire) and terminal 1 (brown wire). It

should be about 5 volts.

38Next, loosen the sensor mounting screws,

and connect the voltmeter to terminal 2

(yellow wire) and terminal 3 (black wire). With

the throttle fully open, rotate the switch until

there is 0.20 to 0.24 volts less than the

stabilised voltage. Note: You will need a

digital voltmeter to measure these small

changes in voltage.

39Recheck the TPS once more; if the

readings are correct, reconnect the TPS

electrical connector. It is a good idea to lock

the TPS screws with paint or thread-locking

compound.

Airflow meter

General description

40The airflow meter is located on the air

intake duct. The airflow meter measures the

amount of air entering the engine. The ECU

uses this information to control fuel delivery. A

large volume of air indicates acceleration,

while a small volume of air indicates

deceleration or idle. Refer to Chapter 4 for all

the diagnostic checks and renewal

procedures for the airflow meter.

Ignition timing sensors

41Ignition timing is electronically-controlled

on Motronic systems, and is not adjustable.

During starting, a crankshaft position sensor

relays the crankshaft position to the ECU, and

an initial baseline ignition point is determined.

Once the engine is running, the ignition point

is continually changing based on the various

input signals to the ECU. Engine speed is

signalled by a speed sensor. Early Motronic

systems have the reference sensor and the

speed sensor mounted on the bellhousing

over the flywheel. Later Motronic systems

have a single sensor (pulse sensor) mounted

over the crankshaft pulley. This sensor

functions as a speed sensor as well as a

position sensor. Refer to Chapter 5 for more

information. Note: Some models are

equipped with a TDC sensor mounted on the

front of the engine. This sensor is strictly for

the BMW service test unit, and it is not part of

the Motronic ignition system.

5 Positive crankcase

ventilation (PCV) system

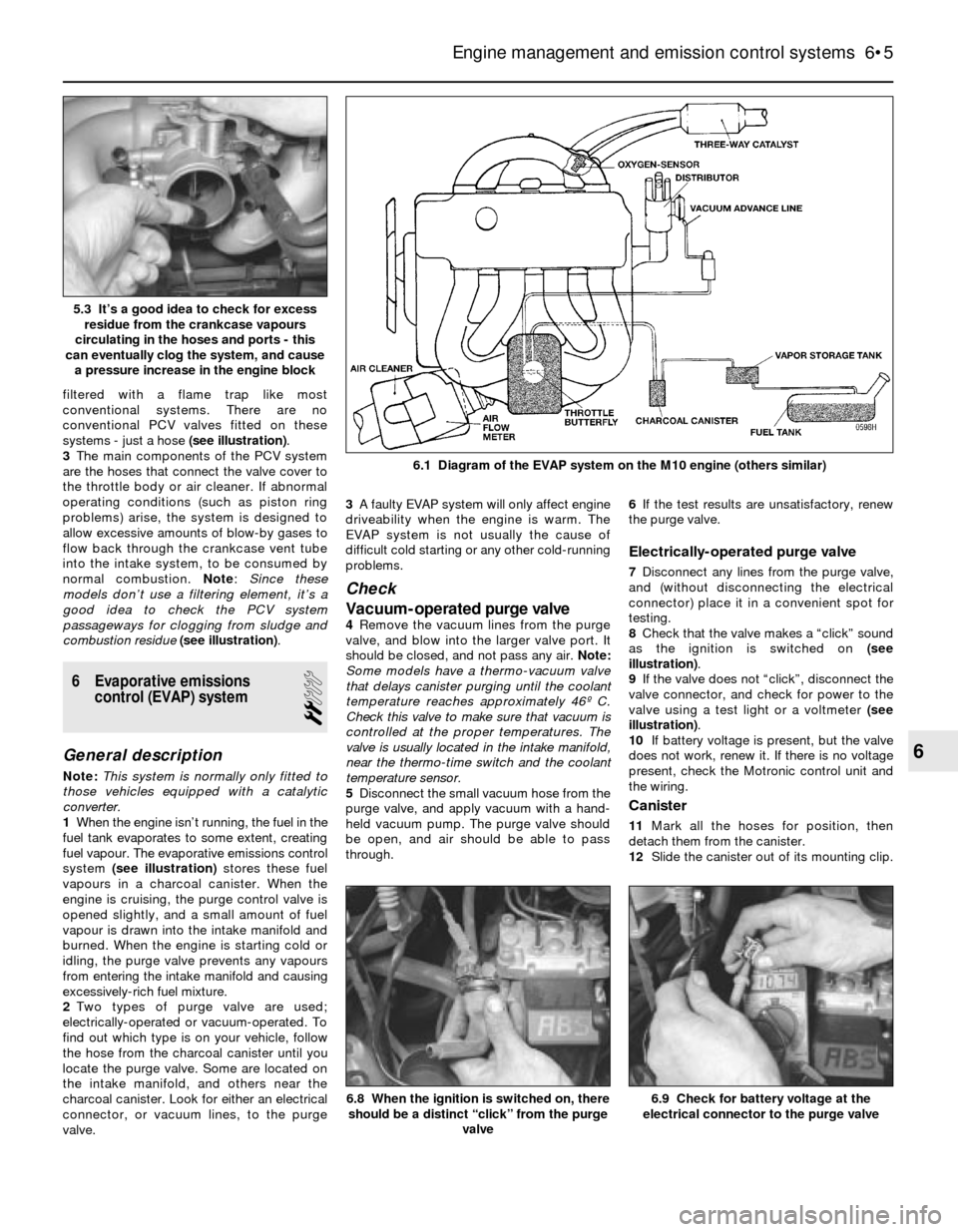

1The Positive Crankcase Ventilation (PCV)

system (see illustration)reduces

hydrocarbon emissions by scavenging

crankcase vapours. It does this by circulating

blow-by gases and then re-routing them to

the intake manifold by way of the air cleaner.

2This PCV system is a sealed system. The

crankcase blow-by vapours are routed

directly to the air cleaner or air collector with

crankcase pressure behind them. The vapour

is not purged with fresh air on most models or

6•4 Engine management and emission control systems

5.2 PCV hose being removed from the

valve cover5.1 Diagram of the PCV system on the

M20 engine (others similar)4.34 Idle position switch and TPS on early

535i models with automatic transmission

4.28c . . . then check for continuity

between terminals 3 and 18 as the throttle

is opened

Page 127 of 228

filtered with a flame trap like most

conventional systems. There are no

conventional PCV valves fitted on these

systems - just a hose (see illustration).

3The main components of the PCV system

are the hoses that connect the valve cover to

the throttle body or air cleaner. If abnormal

operating conditions (such as piston ring

problems) arise, the system is designed to

allow excessive amounts of blow-by gases to

flow back through the crankcase vent tube

into the intake system, to be consumed by

normal combustion. Note: Since these

models don’t use a filtering element, it’s a

good idea to check the PCV system

passageways for clogging from sludge and

combustion residue(see illustration).

6 Evaporative emissions

control (EVAP) system

2

General description

Note:This system is normally only fitted to

those vehicles equipped with a catalytic

converter.

1When the engine isn’t running, the fuel in the

fuel tank evaporates to some extent, creating

fuel vapour. The evaporative emissions control

system (see illustration)stores these fuel

vapours in a charcoal canister. When the

engine is cruising, the purge control valve is

opened slightly, and a small amount of fuel

vapour is drawn into the intake manifold and

burned. When the engine is starting cold or

idling, the purge valve prevents any vapours

from entering the intake manifold and causing

excessively-rich fuel mixture.

2Two types of purge valve are used;

electrically-operated or vacuum-operated. To

find out which type is on your vehicle, follow

the hose from the charcoal canister until you

locate the purge valve. Some are located on

the intake manifold, and others near the

charcoal canister. Look for either an electrical

connector, or vacuum lines, to the purge

valve.3A faulty EVAP system will only affect engine

driveability when the engine is warm. The

EVAP system is not usually the cause of

difficult cold starting or any other cold-running

problems.

Check

Vacuum-operated purge valve

4Remove the vacuum lines from the purge

valve, and blow into the larger valve port. It

should be closed, and not pass any air. Note:

Some models have a thermo-vacuum valve

that delays canister purging until the coolant

temperature reaches approximately 46º C.

Check this valve to make sure that vacuum is

controlled at the proper temperatures. The

valve is usually located in the intake manifold,

near the thermo-time switch and the coolant

temperature sensor.

5Disconnect the small vacuum hose from the

purge valve, and apply vacuum with a hand-

held vacuum pump. The purge valve should

be open, and air should be able to pass

through.6If the test results are unsatisfactory, renew

the purge valve.

Electrically-operated purge valve

7Disconnect any lines from the purge valve,

and (without disconnecting the electrical

connector) place it in a convenient spot for

testing.

8Check that the valve makes a “click” sound

as the ignition is switched on (see

illustration).

9If the valve does not “click”, disconnect the

valve connector, and check for power to the

valve using a test light or a voltmeter (see

illustration).

10If battery voltage is present, but the valve

does not work, renew it. If there is no voltage

present, check the Motronic control unit and

the wiring.

Canister

11Mark all the hoses for position, then

detach them from the canister.

12Slide the canister out of its mounting clip.

Engine management and emission control systems 6•5

6.1 Diagram of the EVAP system on the M10 engine (others similar)

6.9 Check for battery voltage at the

electrical connector to the purge valve6.8 When the ignition is switched on, there

should be a distinct “click” from the purge

valve

6

5.3 It’s a good idea to check for excess

residue from the crankcase vapours

circulating in the hoses and ports - this

can eventually clog the system, and cause

a pressure increase in the engine block

Page 205 of 228

REF•4MOT Test Checks

MExamine the handbrake mechanism,

checking for frayed or broken cables,

excessive corrosion, or wear or insecurity of

the linkage. Check that the mechanism works

on each relevant wheel, and releases fully,

without binding.

MIt is not possible to test brake efficiency

without special equipment, but a road test can

be carried out later to check that the vehicle

pulls up in a straight line.

Fuel and exhaust systems

MInspect the fuel tank (including the filler

cap), fuel pipes, hoses and unions. All

components must be secure and free from

leaks.

MExamine the exhaust system over its entire

length, checking for any damaged, broken or

missing mountings, security of the retaining

clamps and rust or corrosion.

Wheels and tyres

MExamine the sidewalls and tread area of

each tyre in turn. Check for cuts, tears, lumps,

bulges, separation of the tread, and exposure

of the ply or cord due to wear or damage.

Check that the tyre bead is correctly seated

on the wheel rim, that the valve is sound andproperly seated, and that the wheel is not

distorted or damaged.

MCheck that the tyres are of the correct size

for the vehicle, that they are of the same size

and type on each axle, and that the pressures

are correct.

MCheck the tyre tread depth. The legal

minimum at the time of writing is 1.6 mm over

at least three-quarters of the tread width.

Abnormal tread wear may indicate incorrect

front wheel alignment.

Body corrosion

MCheck the condition of the entire vehicle

structure for signs of corrosion in load-bearing

areas. (These include chassis box sections,

side sills, cross-members, pillars, and all

suspension, steering, braking system and

seat belt mountings and anchorages.) Any

corrosion which has seriously reduced the

thickness of a load-bearing area is likely to

cause the vehicle to fail. In this case

professional repairs are likely to be needed.

MDamage or corrosion which causes sharp

or otherwise dangerous edges to be exposed

will also cause the vehicle to fail.

Petrol models

MHave the engine at normal operating

temperature, and make sure that it is in good

tune (ignition system in good order, air filter

element clean, etc).

MBefore any measurements are carried out,

raise the engine speed to around 2500 rpm,

and hold it at this speed for 20 seconds. Allowthe engine speed to return to idle, and watch

for smoke emissions from the exhaust

tailpipe. If the idle speed is obviously much

too high, or if dense blue or clearly-visible

black smoke comes from the tailpipe for more

than 5 seconds, the vehicle will fail. As a rule

of thumb, blue smoke signifies oil being burnt

(engine wear) while black smoke signifies

unburnt fuel (dirty air cleaner element, or other

carburettor or fuel system fault).

MAn exhaust gas analyser capable of

measuring carbon monoxide (CO) and

hydrocarbons (HC) is now needed. If such an

instrument cannot be hired or borrowed, a

local garage may agree to perform the check

for a small fee.

CO emissions (mixture)

MAt the time of writing, the maximum CO

level at idle is 3.5% for vehicles first used after

August 1986 and 4.5% for older vehicles.

From January 1996 a much tighter limit

(around 0.5%) applies to catalyst-equipped

vehicles first used from August 1992. If the

CO level cannot be reduced far enough to

pass the test (and the fuel and ignition

systems are otherwise in good condition) then

the carburettor is badly worn, or there is some

problem in the fuel injection system or

catalytic converter (as applicable).

HC emissionsMWith the CO emissions within limits, HC

emissions must be no more than 1200 ppm

(parts per million). If the vehicle fails this test

at idle, it can be re-tested at around 2000 rpm;

if the HC level is then 1200 ppm or less, this

counts as a pass.

MExcessive HC emissions can be caused by

oil being burnt, but they are more likely to be

due to unburnt fuel.

Diesel models

MThe only emission test applicable to Diesel

engines is the measuring of exhaust smoke

density. The test involves accelerating the

engine several times to its maximum

unloaded speed.

Note: It is of the utmost importance that the

engine timing belt is in good condition before

the test is carried out.

M

Excessive smoke can be caused by a dirty

air cleaner element. Otherwise, professional

advice may be needed to find the cause.

4Checks carried out on

YOUR VEHICLE’S EXHAUST

EMISSION SYSTEM

Page 210 of 228

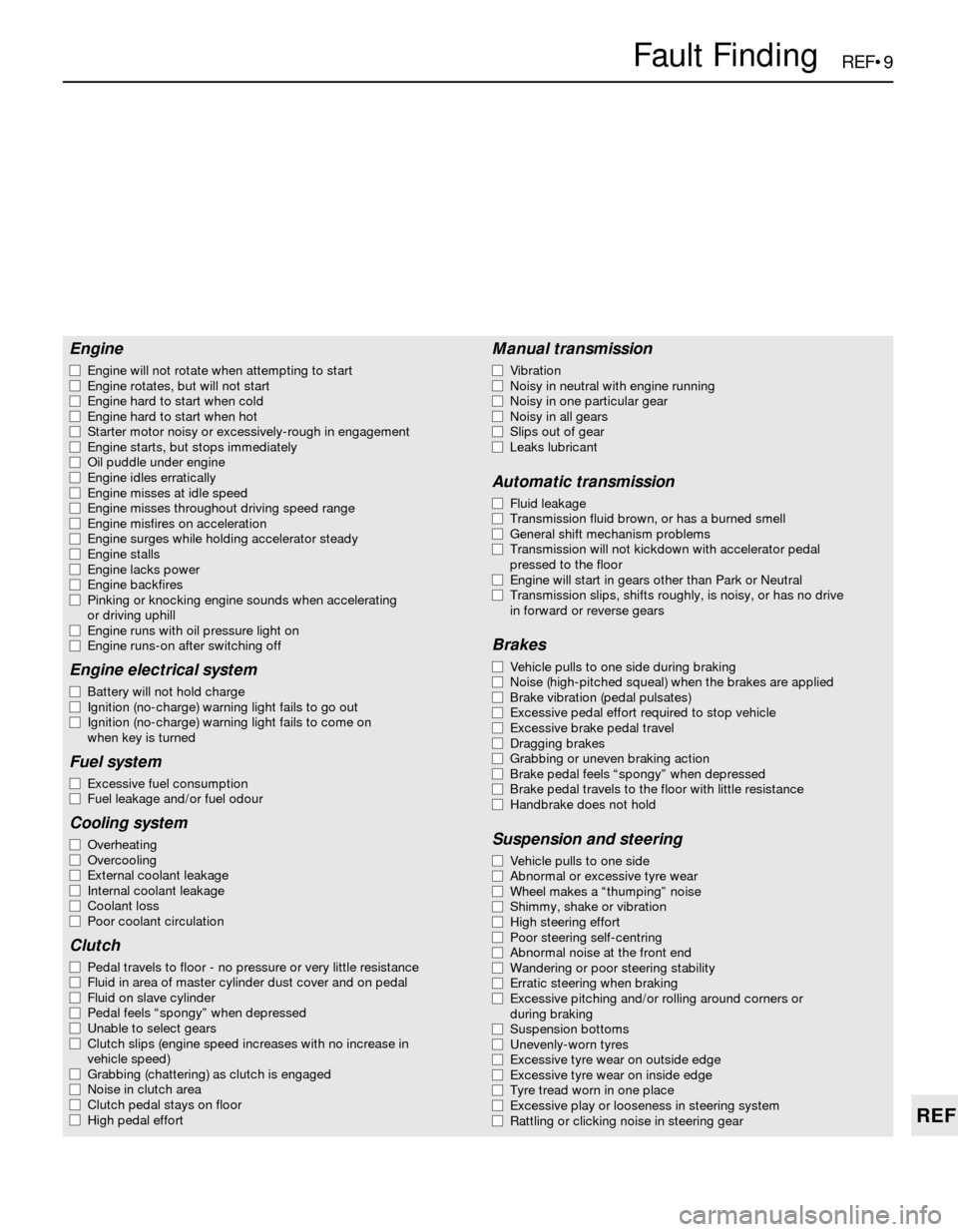

REF•9

REF

Fault Finding

Engine

m mEngine will not rotate when attempting to start

m mEngine rotates, but will not start

m mEngine hard to start when cold

m mEngine hard to start when hot

m mStarter motor noisy or excessively-rough in engagement

m mEngine starts, but stops immediately

m mOil puddle under engine

m mEngine idles erratically

m mEngine misses at idle speed

m mEngine misses throughout driving speed range

m mEngine misfires on acceleration

m mEngine surges while holding accelerator steady

m mEngine stalls

m mEngine lacks power

m mEngine backfires

m mPinking or knocking engine sounds when accelerating

or driving uphill

m mEngine runs with oil pressure light on

m mEngine runs-on after switching off

Engine electrical system

m

mBattery will not hold charge

m mIgnition (no-charge) warning light fails to go out

m mIgnition (no-charge) warning light fails to come on

when key is turned

Fuel system

m mExcessive fuel consumption

m mFuel leakage and/or fuel odour

Cooling system

m

mOverheating

m mOvercooling

m mExternal coolant leakage

m mInternal coolant leakage

m mCoolant loss

m mPoor coolant circulation

Clutch

m

mPedal travels to floor - no pressure or very little resistance

m mFluid in area of master cylinder dust cover and on pedal

m mFluid on slave cylinder

m mPedal feels “spongy” when depressed

m mUnable to select gears

m mClutch slips (engine speed increases with no increase in

vehicle speed)

m mGrabbing (chattering) as clutch is engaged

m mNoise in clutch area

m mClutch pedal stays on floor

m mHigh pedal effort

Manual transmission

m

mVibration

m mNoisy in neutral with engine running

m mNoisy in one particular gear

m mNoisy in all gears

m mSlips out of gear

m mLeaks lubricant

Automatic transmission

m

mFluid leakage

m mTransmission fluid brown, or has a burned smell

m mGeneral shift mechanism problems

m mTransmission will not kickdown with accelerator pedal

pressed to the floor

m mEngine will start in gears other than Park or Neutral

m mTransmission slips, shifts roughly, is noisy, or has no drive

in forward or reverse gears

Brakes

m mVehicle pulls to one side during braking

m mNoise (high-pitched squeal) when the brakes are applied

m mBrake vibration (pedal pulsates)

m mExcessive pedal effort required to stop vehicle

m mExcessive brake pedal travel

m mDragging brakes

m mGrabbing or uneven braking action

m mBrake pedal feels “spongy” when depressed

m mBrake pedal travels to the floor with little resistance

m mHandbrake does not hold

Suspension and steering

m

mVehicle pulls to one side

m mAbnormal or excessive tyre wear

m mWheel makes a “thumping” noise

m mShimmy, shake or vibration

m mHigh steering effort

m mPoor steering self-centring

m mAbnormal noise at the front end

m mWandering or poor steering stability

m mErratic steering when braking

m mExcessive pitching and/or rolling around corners or

during braking

m mSuspension bottoms

m mUnevenly-worn tyres

m mExcessive tyre wear on outside edge

m mExcessive tyre wear on inside edge

m mTyre tread worn in one place

m mExcessive play or looseness in steering system

m mRattling or clicking noise in steering gear

Page 211 of 228

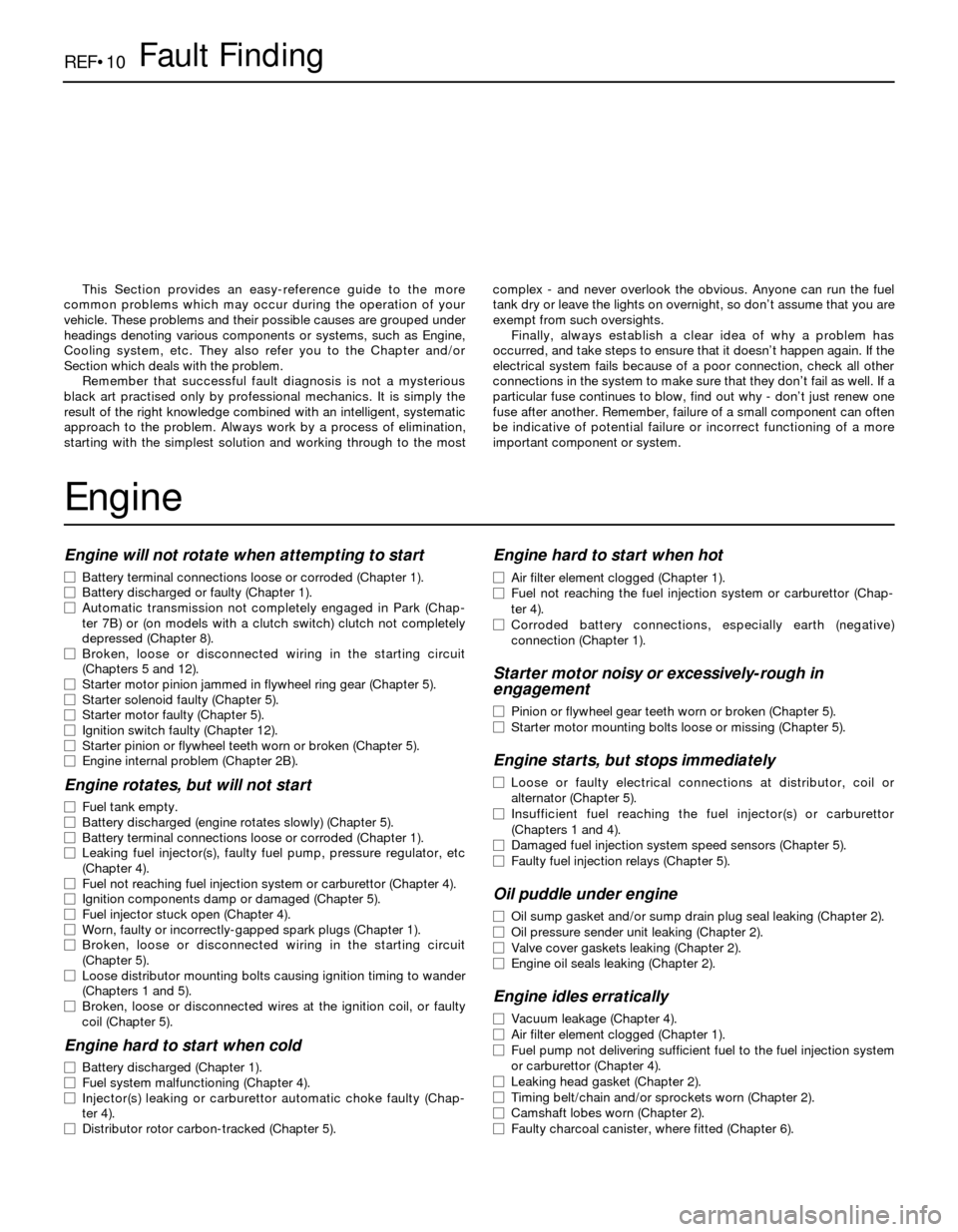

REF•10Fault Finding

Engine will not rotate when attempting to start

m mBattery terminal connections loose or corroded (Chapter 1).

m mBattery discharged or faulty (Chapter 1).

m mAutomatic transmission not completely engaged in Park (Chap-

ter 7B) or (on models with a clutch switch) clutch not completely

depressed (Chapter 8).

m mBroken, loose or disconnected wiring in the starting circuit

(Chapters 5 and 12).

m mStarter motor pinion jammed in flywheel ring gear (Chapter 5).

m mStarter solenoid faulty (Chapter 5).

m mStarter motor faulty (Chapter 5).

m mIgnition switch faulty (Chapter 12).

m mStarter pinion or flywheel teeth worn or broken (Chapter 5).

m mEngine internal problem (Chapter 2B).

Engine rotates, but will not start

m

mFuel tank empty.

m mBattery discharged (engine rotates slowly) (Chapter 5).

m mBattery terminal connections loose or corroded (Chapter 1).

m mLeaking fuel injector(s), faulty fuel pump, pressure regulator, etc

(Chapter 4).

m mFuel not reaching fuel injection system or carburettor (Chapter 4).

m mIgnition components damp or damaged (Chapter 5).

m mFuel injector stuck open (Chapter 4).

m mWorn, faulty or incorrectly-gapped spark plugs (Chapter 1).

m mBroken, loose or disconnected wiring in the starting circuit

(Chapter 5).

m mLoose distributor mounting bolts causing ignition timing to wander

(Chapters 1 and 5).

m mBroken, loose or disconnected wires at the ignition coil, or faulty

coil (Chapter 5).

Engine hard to start when cold

m mBattery discharged (Chapter 1).

m mFuel system malfunctioning (Chapter 4).

m mInjector(s) leaking or carburettor automatic choke faulty (Chap-

ter 4).

m mDistributor rotor carbon-tracked (Chapter 5).

Engine hard to start when hot

m

mAir filter element clogged (Chapter 1).

m mFuel not reaching the fuel injection system or carburettor (Chap-

ter 4).

m mCorroded battery connections, especially earth (negative)

connection (Chapter 1).

Starter motor noisy or excessively-rough in

engagement

m mPinion or flywheel gear teeth worn or broken (Chapter 5).

m mStarter motor mounting bolts loose or missing (Chapter 5).

Engine starts, but stops immediately

m

mLoose or faulty electrical connections at distributor, coil or

alternator (Chapter 5).

m mInsufficient fuel reaching the fuel injector(s) or carburettor

(Chapters 1 and 4).

m mDamaged fuel injection system speed sensors (Chapter 5).

m mFaulty fuel injection relays (Chapter 5).

Oil puddle under engine

m

mOil sump gasket and/or sump drain plug seal leaking (Chapter 2).

m mOil pressure sender unit leaking (Chapter 2).

m mValve cover gaskets leaking (Chapter 2).

m mEngine oil seals leaking (Chapter 2).

Engine idles erratically

m

mVacuum leakage (Chapter 4).

m mAir filter element clogged (Chapter 1).

m mFuel pump not delivering sufficient fuel to the fuel injection system

or carburettor (Chapter 4).

m mLeaking head gasket (Chapter 2).

m mTiming belt/chain and/or sprockets worn (Chapter 2).

m mCamshaft lobes worn (Chapter 2).

m mFaulty charcoal canister, where fitted (Chapter 6). This Section provides an easy-reference guide to the more

common problems which may occur during the operation of your

vehicle. These problems and their possible causes are grouped under

headings denoting various components or systems, such as Engine,

Cooling system, etc. They also refer you to the Chapter and/or

Section which deals with the problem.

Remember that successful fault diagnosis is not a mysterious

black art practised only by professional mechanics. It is simply the

result of the right knowledge combined with an intelligent, systematic

approach to the problem. Always work by a process of elimination,

starting with the simplest solution and working through to the mostcomplex - and never overlook the obvious. Anyone can run the fuel

tank dry or leave the lights on overnight, so don’t assume that you are

exempt from such oversights.

Finally, always establish a clear idea of why a problem has

occurred, and take steps to ensure that it doesn’t happen again. If the

electrical system fails because of a poor connection, check all other

connections in the system to make sure that they don’t fail as well. If a

particular fuse continues to blow, find out why - don’t just renew one

fuse after another. Remember, failure of a small component can often

be indicative of potential failure or incorrect functioning of a more

important component or system.

Engine

Page 212 of 228

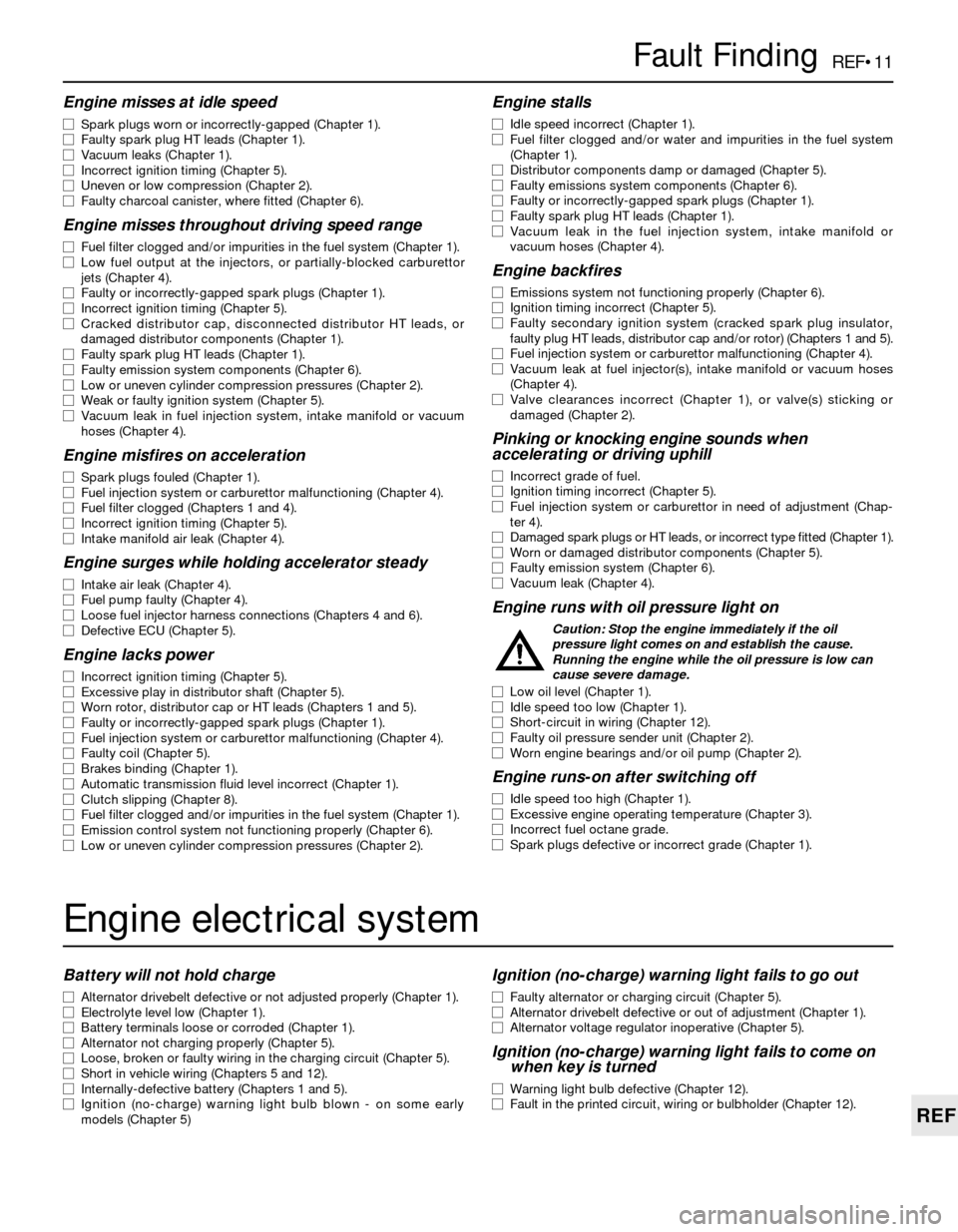

REF•11

REF

Fault Finding

Engine misses at idle speed

m mSpark plugs worn or incorrectly-gapped (Chapter 1).

m mFaulty spark plug HT leads (Chapter 1).

m mVacuum leaks (Chapter 1).

m mIncorrect ignition timing (Chapter 5).

m mUneven or low compression (Chapter 2).

m mFaulty charcoal canister, where fitted (Chapter 6).

Engine misses throughout driving speed range

m

mFuel filter clogged and/or impurities in the fuel system (Chapter 1).

m mLow fuel output at the injectors, or partially-blocked carburettor

jets (Chapter 4).

m mFaulty or incorrectly-gapped spark plugs (Chapter 1).

m mIncorrect ignition timing (Chapter 5).

m mCracked distributor cap, disconnected distributor HT leads, or

damaged distributor components (Chapter 1).

m mFaulty spark plug HT leads (Chapter 1).

m mFaulty emission system components (Chapter 6).

m mLow or uneven cylinder compression pressures (Chapter 2).

m mWeak or faulty ignition system (Chapter 5).

m mVacuum leak in fuel injection system, intake manifold or vacuum

hoses (Chapter 4).

Engine misfires on acceleration

m mSpark plugs fouled (Chapter 1).

m mFuel injection system or carburettor malfunctioning (Chapter 4).

m mFuel filter clogged (Chapters 1 and 4).

m mIncorrect ignition timing (Chapter 5).

m mIntake manifold air leak (Chapter 4).

Engine surges while holding accelerator steady

m

mIntake air leak (Chapter 4).

m mFuel pump faulty (Chapter 4).

m mLoose fuel injector harness connections (Chapters 4 and 6).

m mDefective ECU (Chapter 5).

Engine lacks power

m

mIncorrect ignition timing (Chapter 5).

m mExcessive play in distributor shaft (Chapter 5).

m mWorn rotor, distributor cap or HT leads (Chapters 1 and 5).

m mFaulty or incorrectly-gapped spark plugs (Chapter 1).

m mFuel injection system or carburettor malfunctioning (Chapter 4).

m mFaulty coil (Chapter 5).

m mBrakes binding (Chapter 1).

m mAutomatic transmission fluid level incorrect (Chapter 1).

m mClutch slipping (Chapter 8).

m mFuel filter clogged and/or impurities in the fuel system (Chapter 1).

m mEmission control system not functioning properly (Chapter 6).

m mLow or uneven cylinder compression pressures (Chapter 2).

Engine stalls

m

mIdle speed incorrect (Chapter 1).

m mFuel filter clogged and/or water and impurities in the fuel system

(Chapter 1).

m mDistributor components damp or damaged (Chapter 5).

m mFaulty emissions system components (Chapter 6).

m mFaulty or incorrectly-gapped spark plugs (Chapter 1).

m mFaulty spark plug HT leads (Chapter 1).

m mVacuum leak in the fuel injection system, intake manifold or

vacuum hoses (Chapter 4).

Engine backfires

m mEmissions system not functioning properly (Chapter 6).

m mIgnition timing incorrect (Chapter 5).

m mFaulty secondary ignition system (cracked spark plug insulator,

faulty plug HT leads, distributor cap and/or rotor) (Chapters 1 and 5).

m mFuel injection system or carburettor malfunctioning (Chapter 4).

m mVacuum leak at fuel injector(s), intake manifold or vacuum hoses

(Chapter 4).

m mValve clearances incorrect (Chapter 1), or valve(s) sticking or

damaged (Chapter 2).

Pinking or knocking engine sounds when

accelerating or driving uphill

m mIncorrect grade of fuel.

m mIgnition timing incorrect (Chapter 5).

m mFuel injection system or carburettor in need of adjustment (Chap-

ter 4).

m mDamaged spark plugs or HT leads, or incorrect type fitted (Chapter 1).

m mWorn or damaged distributor components (Chapter 5).

m mFaulty emission system (Chapter 6).

m mVacuum leak (Chapter 4).

Engine runs with oil pressure light on

Caution: Stop the engine immediately if the oil

pressure light comes on and establish the cause.

Running the engine while the oil pressure is low can

cause severe damage.

m mLow oil level (Chapter 1).

m mIdle speed too low (Chapter 1).

m mShort-circuit in wiring (Chapter 12).

m mFaulty oil pressure sender unit (Chapter 2).

m mWorn engine bearings and/or oil pump (Chapter 2).

Engine runs-on after switching off

m

mIdle speed too high (Chapter 1).

m mExcessive engine operating temperature (Chapter 3).

m mIncorrect fuel octane grade.

m mSpark plugs defective or incorrect grade (Chapter 1).

Engine electrical system

Battery will not hold charge

m

mAlternator drivebelt defective or not adjusted properly (Chapter 1).

m mElectrolyte level low (Chapter 1).

m mBattery terminals loose or corroded (Chapter 1).

m mAlternator not charging properly (Chapter 5).

m mLoose, broken or faulty wiring in the charging circuit (Chapter 5).

m mShort in vehicle wiring (Chapters 5 and 12).

m mInternally-defective battery (Chapters 1 and 5).

m mIgnition (no-charge) warning light bulb blown - on some early

models (Chapter 5)

Ignition (no-charge) warning light fails to go out

m mFaulty alternator or charging circuit (Chapter 5).

m mAlternator drivebelt defective or out of adjustment (Chapter 1).

m mAlternator voltage regulator inoperative (Chapter 5).

Ignition (no-charge) warning light fails to come on

when key is turned

m mWarning light bulb defective (Chapter 12).

m mFault in the printed circuit, wiring or bulbholder (Chapter 12).

Page 213 of 228

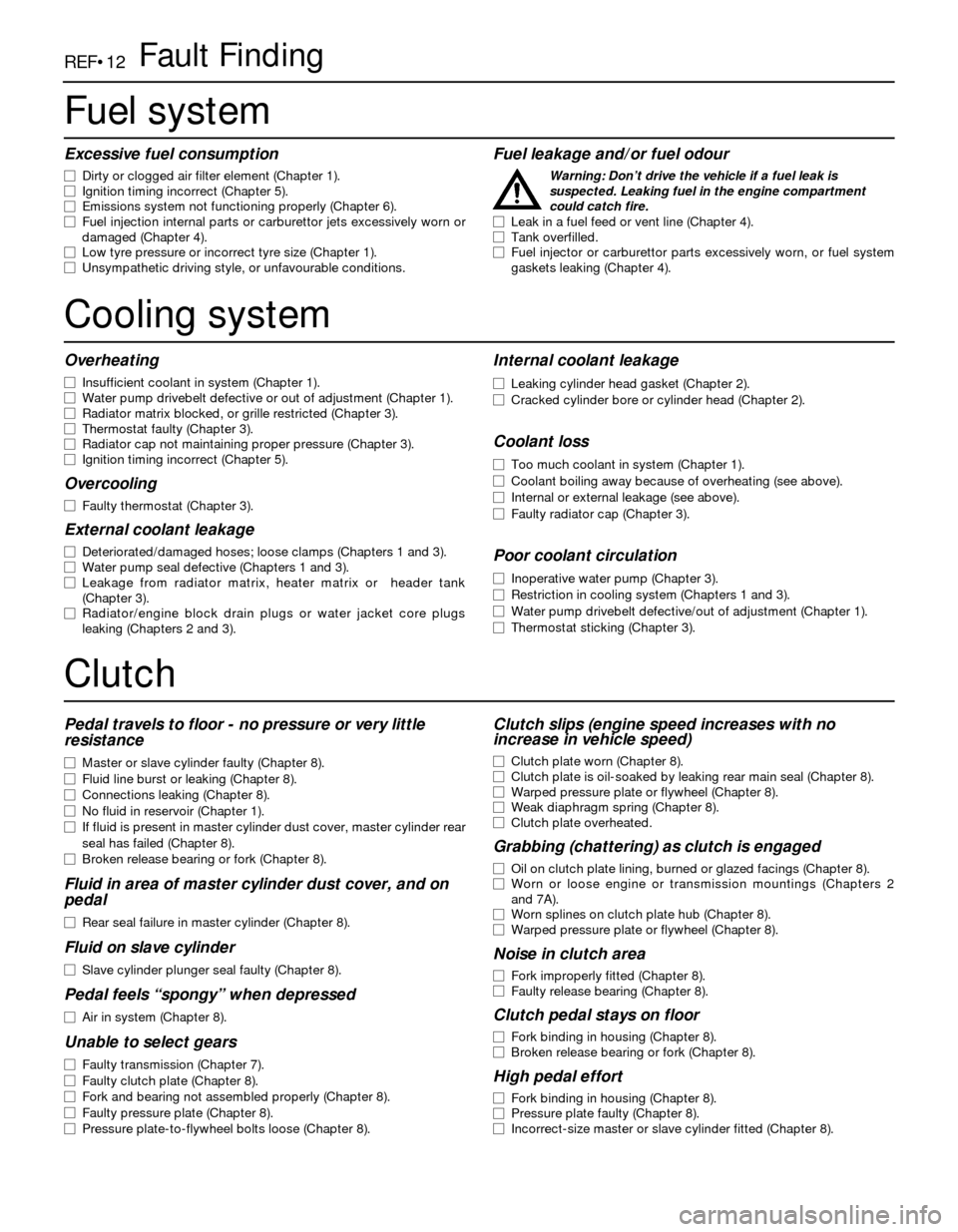

REF•12Fault Finding

Fuel system

Excessive fuel consumption

m mDirty or clogged air filter element (Chapter 1).

m mIgnition timing incorrect (Chapter 5).

m mEmissions system not functioning properly (Chapter 6).

m mFuel injection internal parts or carburettor jets excessively worn or

damaged (Chapter 4).

m mLow tyre pressure or incorrect tyre size (Chapter 1).

m mUnsympathetic driving style, or unfavourable conditions.

Fuel leakage and/or fuel odour

Warning: Don’t drive the vehicle if a fuel leak is

suspected. Leaking fuel in the engine compartment

could catch fire.

m mLeak in a fuel feed or vent line (Chapter 4).

m mTank overfilled.

m mFuel injector or carburettor parts excessively worn, or fuel system

gaskets leaking (Chapter 4).

Cooling system

Overheating

m mInsufficient coolant in system (Chapter 1).

m mWater pump drivebelt defective or out of adjustment (Chapter 1).

m mRadiator matrix blocked, or grille restricted (Chapter 3).

m mThermostat faulty (Chapter 3).

m mRadiator cap not maintaining proper pressure (Chapter 3).

m mIgnition timing incorrect (Chapter 5).

Overcooling

m

mFaulty thermostat (Chapter 3).

External coolant leakage

m

mDeteriorated/damaged hoses; loose clamps (Chapters 1 and 3).

m mWater pump seal defective (Chapters 1 and 3).

m mLeakage from radiator matrix, heater matrix or header tank

(Chapter 3).

m mRadiator/engine block drain plugs or water jacket core plugs

leaking (Chapters 2 and 3).

Internal coolant leakage

m mLeaking cylinder head gasket (Chapter 2).

m mCracked cylinder bore or cylinder head (Chapter 2).

Coolant loss

m

mToo much coolant in system (Chapter 1).

m mCoolant boiling away because of overheating (see above).

m mInternal or external leakage (see above).

m mFaulty radiator cap (Chapter 3).

Poor coolant circulation

m

mInoperative water pump (Chapter 3).

m mRestriction in cooling system (Chapters 1 and 3).

m mWater pump drivebelt defective/out of adjustment (Chapter 1).

m mThermostat sticking (Chapter 3).

Clutch

Pedal travels to floor - no pressure or very little

resistance

m mMaster or slave cylinder faulty (Chapter 8).

m mFluid line burst or leaking (Chapter 8).

m mConnections leaking (Chapter 8).

m mNo fluid in reservoir (Chapter 1).

m mIf fluid is present in master cylinder dust cover, master cylinder rear

seal has failed (Chapter 8).

m mBroken release bearing or fork (Chapter 8).

Fluid in area of master cylinder dust cover, and on

pedal

m mRear seal failure in master cylinder (Chapter 8).

Fluid on slave cylinder

m

mSlave cylinder plunger seal faulty (Chapter 8).

Pedal feels “spongy” when depressed

m

mAir in system (Chapter 8).

Unable to select gears

m

mFaulty transmission (Chapter 7).

m mFaulty clutch plate (Chapter 8).

m mFork and bearing not assembled properly (Chapter 8).

m mFaulty pressure plate (Chapter 8).

m mPressure plate-to-flywheel bolts loose (Chapter 8).

Clutch slips (engine speed increases with no

increase in vehicle speed)

m mClutch plate worn (Chapter 8).

m mClutch plate is oil-soaked by leaking rear main seal (Chapter 8).

m mWarped pressure plate or flywheel (Chapter 8).

m mWeak diaphragm spring (Chapter 8).

m mClutch plate overheated.

Grabbing (chattering) as clutch is engaged

m

mOil on clutch plate lining, burned or glazed facings (Chapter 8).

m mWorn or loose engine or transmission mountings (Chapters 2

and 7A).

m mWorn splines on clutch plate hub (Chapter 8).

m mWarped pressure plate or flywheel (Chapter 8).

Noise in clutch area

m

mFork improperly fitted (Chapter 8).

m mFaulty release bearing (Chapter 8).

Clutch pedal stays on floor

m

mFork binding in housing (Chapter 8).

m mBroken release bearing or fork (Chapter 8).

High pedal effort

m

mFork binding in housing (Chapter 8).

m mPressure plate faulty (Chapter 8).

m mIncorrect-size master or slave cylinder fitted (Chapter 8).

Page 217 of 228

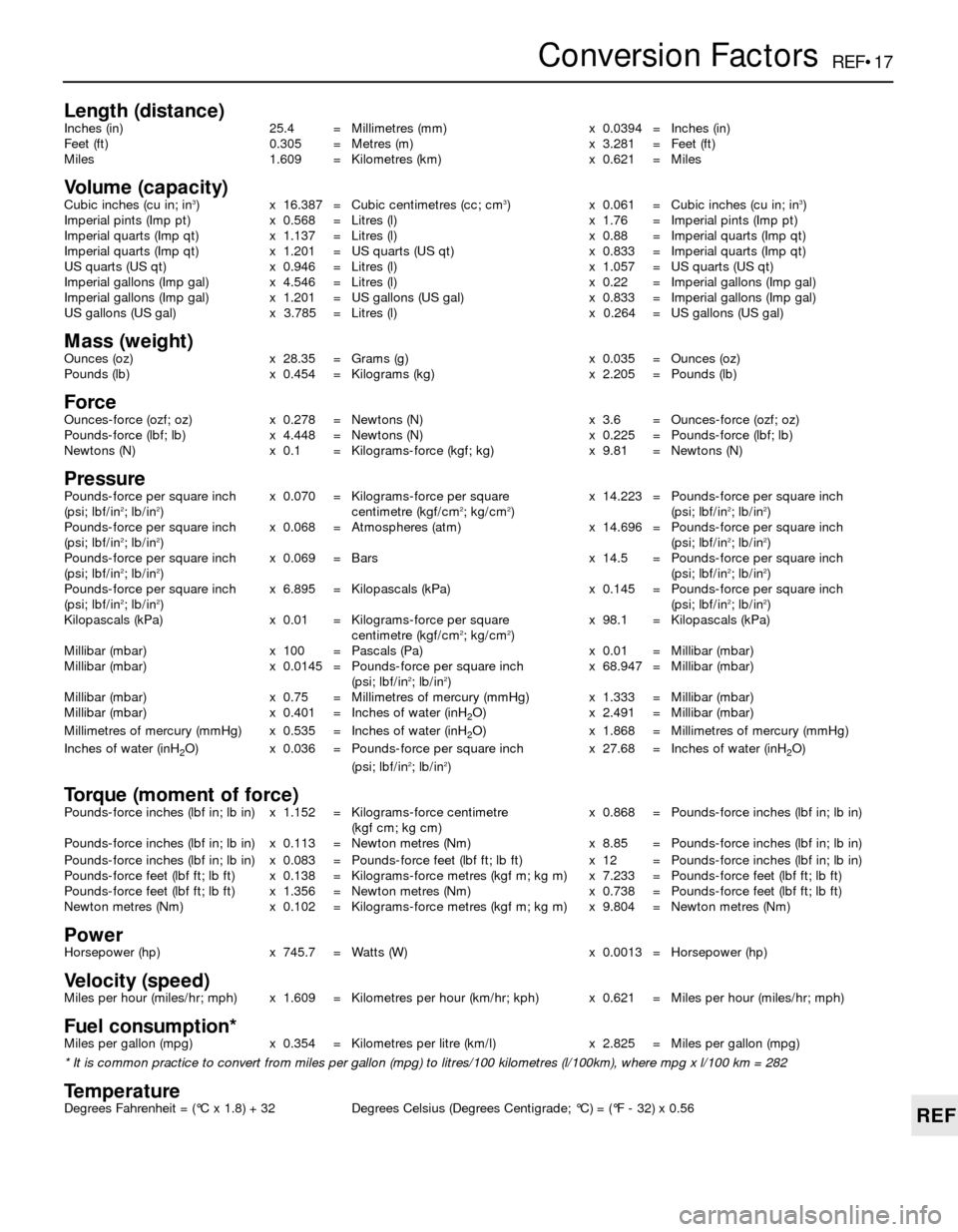

REF•17

REF

Conversion Factors

Length (distance)Inches (in) 25.4 = Millimetres (mm) x 0.0394 = Inches (in)

Feet (ft) 0.305 = Metres (m) x 3.281 = Feet (ft)

Miles 1.609 = Kilometres (km) x 0.621 = Miles

Volume (capacity)Cubic inches (cu in; in3) x 16.387 = Cubic centimetres (cc; cm3) x 0.061 = Cubic inches (cu in; in3)

Imperial pints (Imp pt) x 0.568 = Litres (l) x 1.76 = Imperial pints (Imp pt)

Imperial quarts (Imp qt) x 1.137 = Litres (l) x 0.88 = Imperial quarts (Imp qt)

Imperial quarts (Imp qt) x 1.201 = US quarts (US qt) x 0.833 = Imperial quarts (Imp qt)

US quarts (US qt) x 0.946 = Litres (l) x 1.057 = US quarts (US qt)

Imperial gallons (Imp gal) x 4.546 = Litres (l) x 0.22 = Imperial gallons (Imp gal)

Imperial gallons (Imp gal) x 1.201 = US gallons (US gal) x 0.833 = Imperial gallons (Imp gal)

US gallons (US gal) x 3.785 = Litres (l) x 0.264 = US gallons (US gal)

Mass (weight)Ounces (oz) x 28.35 = Grams (g) x 0.035 = Ounces (oz)

Pounds (lb) x 0.454 = Kilograms (kg) x 2.205 = Pounds (lb)

ForceOunces-force (ozf; oz) x 0.278 = Newtons (N) x 3.6 = Ounces-force (ozf; oz)

Pounds-force (lbf; lb) x 4.448 = Newtons (N) x 0.225 = Pounds-force (lbf; lb)

Newtons (N) x 0.1 = Kilograms-force (kgf; kg) x 9.81 = Newtons (N)

PressurePounds-force per square inch x 0.070 = Kilograms-force per square x 14.223 = Pounds-force per square inch

(psi; lbf/in2; lb/in2) centimetre (kgf/cm2; kg/cm2) (psi; lbf/in2; lb/in2)

Pounds-force per square inch x 0.068 = Atmospheres (atm) x 14.696 = Pounds-force per square inch

(psi; lbf/in

2; lb/in2)(psi; lbf/in2; lb/in2)

Pounds-force per square inch x 0.069 = Bars x 14.5 = Pounds-force per square inch

(psi; lbf/in

2; lb/in2)(psi; lbf/in2; lb/in2)

Pounds-force per square inch x 6.895 = Kilopascals (kPa) x 0.145 = Pounds-force per square inch

(psi; lbf/in

2; lb/in2)(psi; lbf/in2; lb/in2)

Kilopascals (kPa) x 0.01 = Kilograms-force per square x 98.1 = Kilopascals (kPa)

centimetre (kgf/cm

2; kg/cm2)

Millibar (mbar) x 100 = Pascals (Pa) x 0.01 = Millibar (mbar)

Millibar (mbar) x 0.0145 = Pounds-force per square inch x 68.947 = Millibar (mbar)

(psi; lbf/in

2; lb/in2)

Millibar (mbar) x 0.75 = Millimetres of mercury (mmHg) x 1.333 = Millibar (mbar)

Millibar (mbar) x 0.401 = Inches of water (inH

2O) x 2.491 = Millibar (mbar)

Millimetres of mercury (mmHg) x 0.535 = Inches of water (inH

2O) x 1.868 = Millimetres of mercury (mmHg)

Inches of water (inH

2O) x 0.036 = Pounds-force per square inch x 27.68 = Inches of water (inH2O)

(psi; lbf/in2; lb/in2)

Torque (moment of force)Pounds-force inches (lbf in; lb in) x 1.152 = Kilograms-force centimetre x 0.868 = Pounds-force inches (lbf in; lb in)

(kgf cm; kg cm)

Pounds-force inches (lbf in; lb in) x 0.113 = Newton metres (Nm) x 8.85 = Pounds-force inches (lbf in; lb in)

Pounds-force inches (lbf in; lb in) x 0.083 = Pounds-force feet (lbf ft; lb ft) x 12 = Pounds-force inches (lbf in; lb in)

Pounds-force feet (lbf ft; lb ft) x 0.138 = Kilograms-force metres (kgf m; kg m) x 7.233 = Pounds-force feet (lbf ft; lb ft)

Pounds-force feet (lbf ft; lb ft) x 1.356 = Newton metres (Nm) x 0.738 = Pounds-force feet (lbf ft; lb ft)

Newton metres (Nm) x 0.102 = Kilograms-force metres (kgf m; kg m) x 9.804 = Newton metres (Nm)

PowerHorsepower (hp) x 745.7 = Watts (W) x 0.0013 = Horsepower (hp)

Velocity (speed)Miles per hour (miles/hr; mph) x 1.609 = Kilometres per hour (km/hr; kph) x 0.621 = Miles per hour (miles/hr; mph)

Fuel consumption*Miles per gallon (mpg) x 0.354 = Kilometres per litre (km/l) x 2.825 = Miles per gallon (mpg)

* It is common practice to convert from miles per gallon (mpg) to litres/100 kilometres (l/100km), where mpg x l/100 km = 282

TemperatureDegrees Fahrenheit = (°C x 1.8) + 32 Degrees Celsius (Degrees Centigrade; °C) = (°F - 32) x 0.56

Page 218 of 228

REF•18Automotive chemicals and lubricants

A number of automotive chemicals and

lubricants are available for use during vehicle

maintenance and repair. They include a wide

variety of products ranging from cleaning

solvents and degreasers to lubricants and

protective sprays for rubber, plastic and

vinyl.

Cleaners

Carburettor cleaner and choke cleaner

is a strong solvent for gum, varnish and

carbon. Most carburettor cleaners leave a

dry-type lubricant film which will not harden or

gum up. Because of this film, it is not

recommended for use on electrical

components.

Brake system cleaneris used to remove

grease and brake fluid from the brake system,

where clean surfaces are absolutely

necessary. It leaves no residue, and often

eliminates brake squeal caused by

contaminants.

Electrical cleaner removes oxidation,

corrosion and carbon deposits from electrical

contacts, restoring full current flow. It can also

be used to clean spark plugs, carburettor jets,

voltage regulators and other parts where an

oil-free surface is desired.

Moisture dispersantsremove water and

moisture from electrical components such as

alternators, voltage regulators, electrical

connectors and fuse blocks. They are non-

conductive and non-corrosive.

Degreasersare heavy-duty solvents used

to remove grease from the outside of the

engine and from chassis components. They

can be sprayed or brushed on, and are usually

rinsed off with water.

Lubricants

Engine oilis the lubricant formulated for

use in engines. It normally contains a wide

variety of additives to prevent corrosion and

reduce foaming and wear. Engine oil comes in

various weights (viscosity ratings) from 5 to

60. The recommended weight of the oil

depends on the season, temperature and the

demands on the engine. Light oil is used in

cold climates and under light load conditions.

Heavy oil is used in hot climates, and where

high loads are encountered. Multi-viscosity

(multigrade) oils are designed to have

characteristics of both light and heavy oils,

and are available in a number of weights from

5W-20 to 20W-50.

Gear oilis designed to be used in

differentials, manual transmissions and other

areas where high-temperature lubrication is

required.

Chassis and wheel bearing greaseis a

heavy grease used where increased loads and

friction are encountered, such as for wheel

bearings, balljoints, tie-rod ends and universal

joints.High-temperature wheel bearing grease

is designed to withstand the extreme

temperatures encountered by wheel bearings

in disc brake-equipped vehicles. It usually

contains molybdenum disulphide (moly),

which is a dry-type lubricant.

White greaseis a heavy grease for metal-

to-metal applications where water is a

problem. White grease stays soft at both low

and high temperatures, and will not wash off

or dilute in the presence of water.

Assembly lubeis a special extreme-

pressure lubricant, usually containing moly,

used to lubricate high-load parts (such as

main and rod bearings and cam lobes) for

initial start-up of a new engine. The assembly

lube lubricates the parts without being

squeezed out or washed away until the engine

oiling system begins to function.

Silicone lubricants are used to protect

rubber, plastic, vinyl and nylon parts.

Graphite lubricantsare used where oils

cannot be used due to contamination

problems, such as in locks. The dry graphite

will lubricate metal parts while remaining

uncontaminated by dirt, water, oil or acids. It

is electrically conductive, and will not foul

electrical contacts in locks such as the

ignition switch.

Penetrating oilsloosen and lubricate

frozen, rusted and corroded fasteners and

prevent future rusting or freezing.

Heat-sink greaseis a special electrically

non-conductive grease that is used for

mounting electronic ignition modules where it

is essential that heat is transferred away from

the module.

Sealants

RTV sealantis one of the most widely-

used gasket compounds. Made from silicone,

RTV is air-curing; it seals, bonds, waterproofs,

fills surface irregularities, remains flexible,

doesn’t shrink, is relatively easy to remove,

and is used as a supplementary sealer with

almost all low- and medium-temperature

gaskets.

Anaerobic sealantis much like RTV in that

it can be used either to seal gaskets or to form

gaskets by itself. It remains flexible, is solvent-

resistant, and fills surface imperfections. The

difference between an anaerobic sealant and

an RTV-type sealant is in the curing. RTV

cures when exposed to air, while an anaerobic

sealant cures only in the absence of air. This

means that an anaerobic sealant cures only

after the assembly of parts, sealing them

together.

Thread and pipe sealant is used for

sealing hydraulic and pneumatic fittings and

vacuum lines. It is usually made from a Teflon

compound, and comes in a spray, a paint-on

liquid and as a wrap-around tape.

Chemicals

Anti-seize compoundprevents seizing,

chafing, cold welding, rust and corrosion in

fasteners. High-temperature anti-seize,

usually made with copper and graphite

lubricants, is used for exhaust system and

exhaust manifold bolts.

Anaerobic locking compoundsare used

to keep fasteners from vibrating or working

loose, and cure only after installation, in the

absence of air. Medium-strength locking

compound is used for small nuts, bolts and

screws that may be removed later. High-

strength locking compound is for large nuts,

bolts and studs which aren’t removed on a

regular basis.

Oil additivesrange from viscosity index

improvers to chemical treatments that claim

to reduce internal engine friction. It should be

noted that most oil manufacturers caution

against using additives with their oils.

Fuel additivesperform several functions,

depending on their chemical make-up. They

usually contain solvents that help dissolve

gum and varnish that build up on carburettor,

fuel injection and intake parts. They also serve

to break down carbon deposits that form on

the inside surfaces of the combustion

chambers. Some additives contain upper

cylinder lubricants for valves and piston rings,

and others contain chemicals to remove

condensation from the fuel tank.

Miscellaneous

Brake fluidis specially-formulated

hydraulic fluid that can withstand the heat and

pressure encountered in brake systems. It is

poisonous and inflammable. Care must be

taken so this fluid does not come in contact

with painted surfaces or plastics. An opened

container should always be resealed, to

prevent contamination by water or dirt. Brake

fluid absorbs moisture from the air, if left in an

unsealed container.

Weatherstrip adhesiveis used to bond

weatherstripping around doors, windows and

boot lids. It is sometimes used to attach trim

pieces.

Undersealis a petroleum-based, tar-like

substance that is designed to protect metal

surfaces on the underside of the vehicle from

corrosion. It also acts as a sound-deadening

agent by insulating the bottom of the vehicle.

Waxes and polishesare used to help

protect painted and plated surfaces from the

weather. Different types of paint may require

the use of different types of wax and polish.

Some polishes utilise a chemical or abrasive

cleaner to help remove the top layer of

oxidised (dull) paint on older vehicles. In

recent years, many non-wax polishes

containing a wide variety of chemicals such as

polymers and silicones have been introduced.

These non-wax polishes are usually easier to

apply, and last longer than conventional

waxes and polishes.