engine BMW 3 SERIES 2004 E46 Drive Away Protection Syst

[x] Cancel search | Manufacturer: BMW, Model Year: 2004, Model line: 3 SERIES, Model: BMW 3 SERIES 2004 E46Pages: 30, PDF Size: 0.7 MB

Page 18 of 30

18

EWS

Clutch Switch

A Hall-Effect Switch is added to the clutch system to inform the EWS III (3.2) control mod-

ule of clutch status. Input from the switch replaces the signal from the Trans Range Selector

Switch on manual transmission equipped vehicles. High signal status indicates the clutch

is depressed and vehicle starting is allowed.

Principle of Operation

The starting sequence for the EWS III (3.2) is as follows:

• The key is inserted into the lock cylinder and switched “ON”. The EWS III control mod-

ule is powered through KL R and sends a 125kHz AM signal to the ring antenna. The

AM signal induces voltage in the key coil and powers up the transponder.

• Powered up, the key transponder sends the key identification code to the EWS III mod-

ule. The EWS III module verifies the key identification code and checks to see if the key

is enabled. If the key is correct and enabled, a password is sent to the transponder over

the 125kHz AM signal through the ring antenna.

• When the transponders accepts the password, it releases the changing code, which it

received from the EWS III module during the last start-up operation, to the EWS III mod-

ule via the ring antenna.

• The EWS III module compares the changing code received from the transponder with

the code stored in its memory and if they match the process is allowed to continue.

The EWS III module looks at the other inputs for correct status (e.g. Code function not

active, Transmission in P or N or clutch depressed, engine speed below specified RPM)

and energizes the the internal relay to begin starter operation.

• As the starter begins to operate, the EWS III module sends the ISN to the DME and if

verified as correct by the DME, drive away protection is cancelled and injection and igni-

tion is enabled. The EWS III module also sends a new changing code to the key

transponder through the ring antenna.

Replacement Procedures

Keys

Up to 6 additional keys may be ordered as replacement keys. The EWS III (3.2) module is

codeable for only 10 keys (4 delivered with vehicle and 6 replacement). The keys are

mechanically matched to the vehicle with the lock tumblers and electronically matched to

the EWS III (3.2) through unalterable coding.

Page 21 of 30

21

EWS

DME Control Module

The DME Control Module has changed in that it is not the source of the ISN but now only

stores the “Rolling Code”. It compares the “Codes” to those sent to it by the EWS III (3.3)

control module. The “Rolling Code Table” assigned to the DME must match the table in the

EWS III (3.3) module. The “Rolling Code Table is “burned” into the DME during the pro-

gramming of the DME and cannot be change once “burned”.

Transmission Range Selection Input

With the introduction of the SKE type connectors on Transmission Control Modules the

direct input from the Transmission Range Selector Switch is eliminated. The input for range

selection is now received from the AGS Control Module.

On manual transmission vehicles clutch status is input directly into the DME.

Principle of Operation

The starting sequence of the EWS III (3.3) is as follows:

(Same as EWS III (3.2)

• The key is inserted into the lock cylinder and switched “ON”. The EWS III (3.3) control

module is powered through KL R and sends a 125kHz AM signal to the ring antenna.

The AM signal induces voltage in the key coil and powers up the transponder.

• Powered up, the key transponder sends the key identification code to the EWS III (3.3)

module. The EWS III (3.3) module verifies the key identification code and checks to see

if the key is enabled. If the key is correct and enabled, a password is sent to the

transponder over the 125kHz AM signal through the ring antenna.

• When the transponders accepts the password, it releases the changing code which it

received from the EWS III (3.3) module during the last start-up operation to the EWS III

(3.3) module via the ring antenna.

• The EWS III (3.3) module compares the changing code received from the transponder

with the code stored in its memory and if they match the process is allowed to contin-

ue. The EWS III (3.3) module looks at the other inputs for correct status (e.g. Code func-

tion not active, Transmission in P or N or clutch depressed, engine speed below spec-

ified RPM) and energizes the the internal relay to begin starter operation.

Page 22 of 30

22

EWS

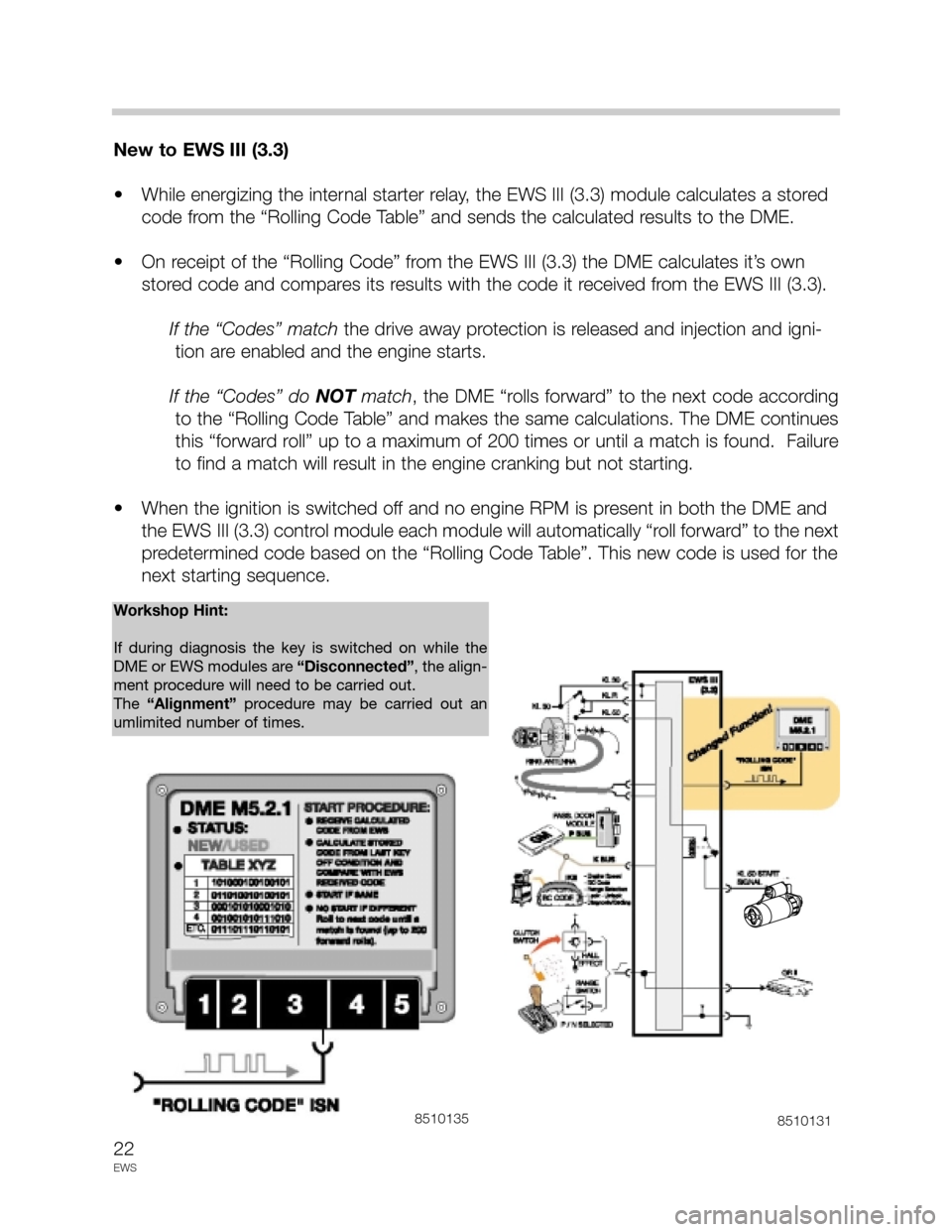

New to EWS III (3.3)

• While energizing the internal starter relay, the EWS III (3.3) module calculates a stored

code from the “Rolling Code Table” and sends the calculated results to the DME.

• On receipt of the “Rolling Code” from the EWS III (3.3) the DME calculates it’s own

stored code and compares its results with the code it received from the EWS III (3.3).

If the “Codes” matchthe drive away protection is released and injection and igni-

tion are enabled and the engine starts.

If the “Codes” do NOTmatch, the DME “rolls forward” to the next code according

to the “Rolling Code Table” and makes the same calculations. The DME continues

this “forward roll” up to a maximum of 200 times or until a match is found. Failure

to find a match will result in the engine cranking but not starting.

• When the ignition is switched off and no engine RPM is present in both the DME and

the EWS III (3.3) control module each module will automatically “roll forward” to the next

predetermined code based on the “Rolling Code Table”. This new code is used for the

next starting sequence.

85101318510135

Workshop Hint:

If during diagnosis the key is switched on while the

DME or EWS modules are “Disconnected”, the align-

ment procedure will need to be carried out.

The“Alignment”procedure may be carried out an

umlimited number of times.

Page 25 of 30

25

EWS

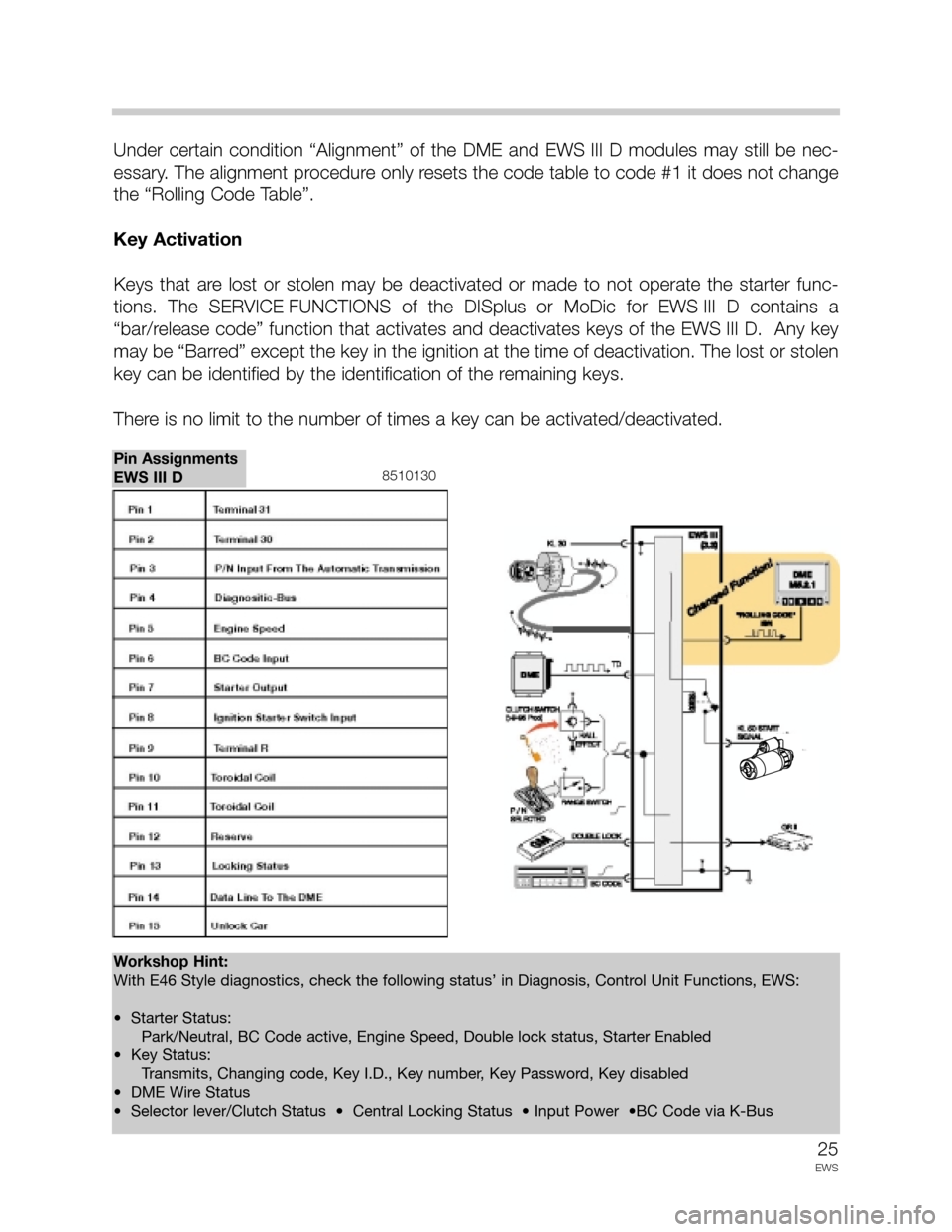

Under certain condition “Alignment” of the DME and EWS III D modules may still be nec-

essary. The alignment procedure only resets the code table to code #1 it does not change

the “Rolling Code Table”.

Key Activation

Keys that are lost or stolen may be deactivated or made to not operate the starter func-

tions. The SERVICE FUNCTIONS of the DISplus or MoDic for EWS III D contains a

“bar/release code” function that activates and deactivates keys of the EWS III D. Any key

may be “Barred” except the key in the ignition at the time of deactivation. The lost or stolen

key can be identified by the identification of the remaining keys.

There is no limit to the number of times a key can be activated/deactivated.

8510130

Pin Assignments

EWS III D

Workshop Hint:

With E46 Style diagnostics, check the following status’ in Diagnosis, Control Unit Functions, EWS:

• Starter Status:

Park/Neutral, BC Code active, Engine Speed, Double lock status, Starter Enabled

• Key Status:

Transmits, Changing code, Key I.D., Key number, Key Password, Key disabled

• DME Wire Status

• Selector lever/Clutch Status • Central Locking Status • Input Power •BC Code via K-Bus

Page 27 of 30

27

EWS

Workshop Exercises

1.

Vehicle Model:

Install EWS “V” cable adapter and 26 pin Breakout Box, perform pin-out.

2.

Vehicle Model:

Display the starter enabled status:

Display the Status, DME wire:

Perform the EWS-DME communication Test Plan:

Display the Date of Manufacture of EWS Control Module:

Print the FN of the EWS Control Module:

Perform “key status” and print:

3.

Vehicle Model:

Display the “key status”:

Bar key #3:

Attempt to start engine with “Barred Key”, display key status in EWS Diagnosis

Requests:

Perform EWS-DME Test plan:

Display locking status in EWS:

Display P/N input at EWS:

Perform Toroidal coil Test Plan:

Page 28 of 30

28

EWS

Diagnostic Exercise Worksheet #1

Vehicle Model:

Customer Complaint: Engine will not start, starter does not engage.

Observations/Symptoms/Faults stored:

Test steps/modules recommended by diagnostic program:

Test steps/modules performed:

Results:

Repair Recommendation:

Notes:

Page 29 of 30

29

EWS

Diagnostic Exercise Worksheet #2

Vehicle Model:

Customer Complaint: Engine will not start, starter engages.

Observations/Symptoms/Faults stored:

Test steps/modules recommended by diagnostic program:

Test steps/modules performed:

Results:

Repair Recommendation:

Notes: