001 BMW 318i 1992 E36 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1992, Model line: 318i, Model: BMW 318i 1992 E36Pages: 759

Page 231 of 759

2

.

On

MS

270R/A4S

310R

transmissions

:

Remove

front

5

.

Installation

is

reverse

of

Rmoval

.

and

rear

oil

sump

mounting

bolts

andremove

sumps

"

Always

replace

sea¡

for

drain

plug

and

al¡

gasket(s)

andand

sump

gaskets

.

O-rings

.

"

Clean

sump

and

sump

magnet(s)

using

a

lint-free

NOTE-

cloth

.

The

MS

270

R/A4S

310

R

transmissions

may

be

fitted

"

On

MS

270R/A4S310R

transmissions

:

Use

new

bolts

with

ASE

(inch)

bolts

.

at

sump

and

tighten

bolts

in-line,

one

after

other

(do

nottighten

bolts

in

a

cross-wise

pattern)

.

3

.

On

A5S

310Z

transmission

:

Remove

oil

sump

mount-

"

On

MS

310Z

transmission,

be

sureto

instan

rounded

ing

bolts

and

brackets,

noting

position

of

brackets

.

Re-

sump

clamping

brackets

at

corners

of

sump

.

move

"

Fill

transmission

with

approved

fluid

.

sump

and

sump

gasket

.

"

Check

fluid

level

as

described

under

ATF

leve¡,

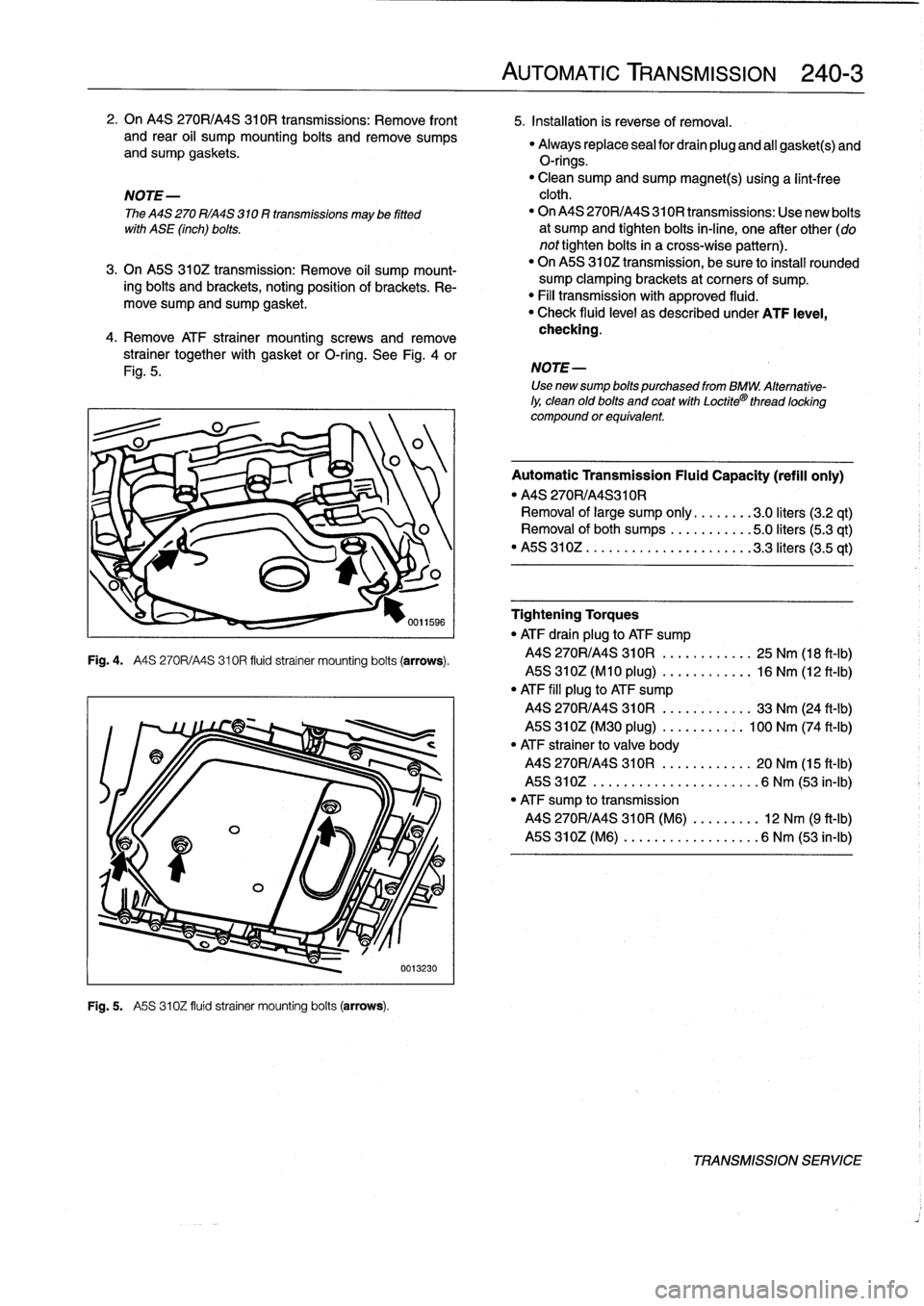

4

.

Remove

ATF

otra¡ner

mount¡ng

screws

and

remove

checking

.

strainer

together

with

gasket

orO-ring

.

See

Fig

.

4

or

Fig

.

5

.

Fig

.

4

.

A4S

270R/A4S310R

fluid

strainer

mounting

boits

(arrows)

.

Fig

.

5

.

A5S

310Z

fluid

strainer

mounting

boits

(arrows)

.

0013230

AUTOMATIC

TRANSMISSION

240-

3

NOTE-

Use

newsump

bolts

purchased

from

BMW

.

Alternative-

ly,

clean

old

bolts

and

coat

with

Loctite®

thread

locking

compound

or

equivalent

Automatic

Transmission

Fluid

Capacity

(refill

only)

"

MS

270R/A4S310R

Removal

of

large

sump

only

........

3

.0liters

(3.2

qt)

Removal

ofboth

sumps

...........

5

.0liters(5

.3

qt)

"

MS

310Z

..

..

..................

3

.3liters

(3.5

qt)

Tightening

Torques

"

ATF

drain

plug

to

ATF

sump

MS

270R/A4S

310R

..........

..

25

Nm

(18

ft-Ib)

MS

310Z(M10

plug)

..........

..

16

Nm

(12

ft-Ib)

"

ATF

fill

plug

to

ATF

sump

MS

270R/A4S

310R

..........

..

33

Nm

(24

ft-Ib)

MS

310Z(M30

plug)

.....

..

..

:.

100

Nm

(74

ft-Ib)

"

ATF

strainer

to

valve

body

MS

270R/A4S

310R

.....

..

.

...

.

20

Nm

(15

ft-Ib)

MS

310Z

..............

..

.

...

..

6

Nm

(53

in-lb)

"

ATF

sump

to

transmission

MS

270R/A4S

310R

(M6)

.

..

.

..

...

12

Nm

(9

ft-¡b)

MS

310Z

(M6)

..........

..

.

..

...

6

Nm

(53

in-¡b)

TRANSMISSION

SERVICE

Page 233 of 759

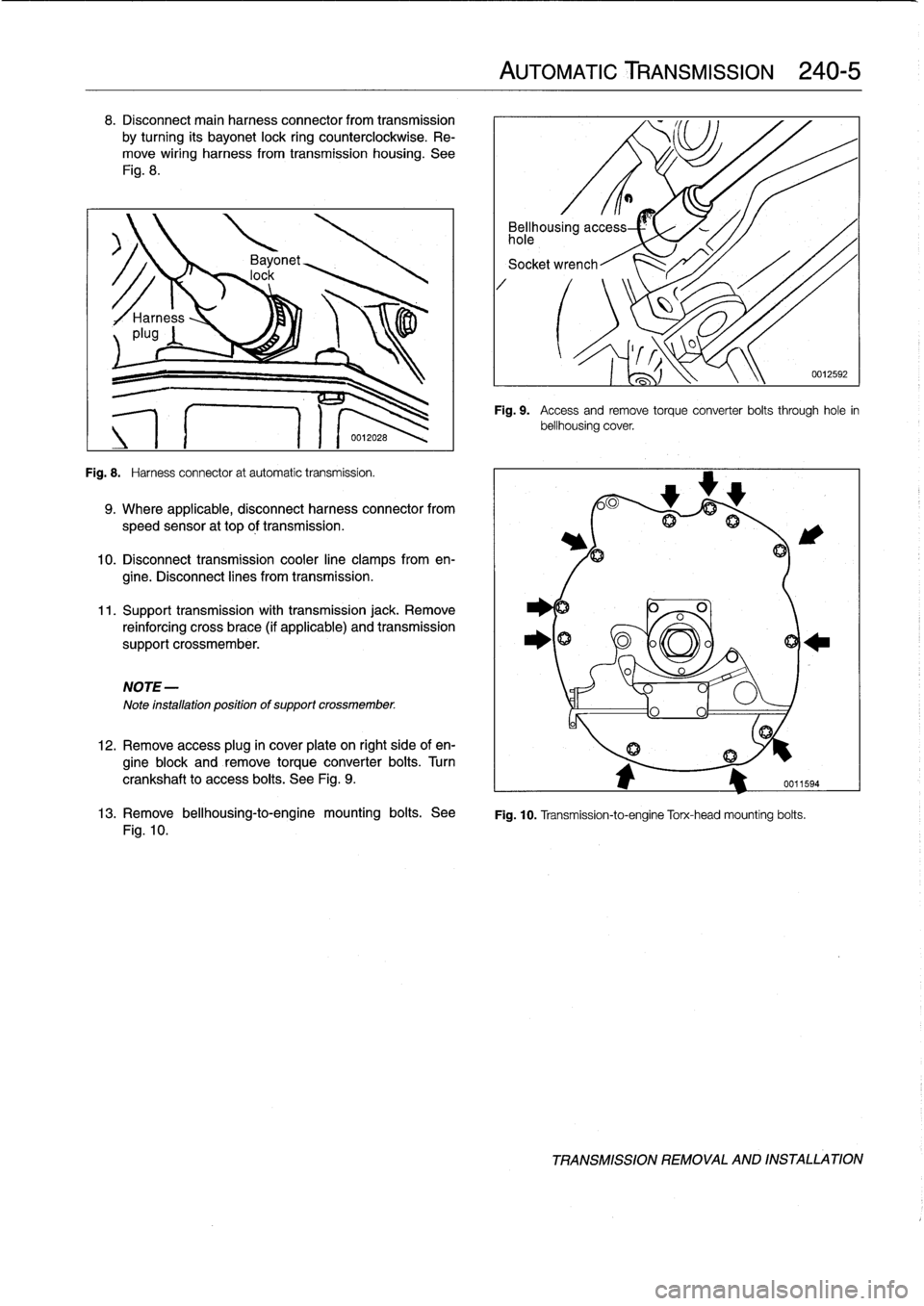

8

.

Disconnect

main

harness

connector

from

transmission

by

turning

its

bayonet

lock

ring

counterclockwise

.

Re-

move

wiring

harness

from

transmission

housing

.

See

Fig

.

8

.

Fig

.

8

.

Harness

connector

at

automatic

transmission

.

9

.

Where

applicable,

disconnect

harness

connector

from

speed

sensor

at

top

óf

transmission

.

10

.

Disconnect

transmission

cooler

line

clamps

from

en-

gine

.

Disconnect

lines

from

transmission

.

11

.

Support

transmission

with

transmission

jack

.

Remove

reinforcing

cross

brace

(if

applicable)

and

transmission

support

crossmember

.

NOTE-

Note

installation

positionof

support

crossmember

.

12

.

Remove

access

plug

in

cover

plate

on

right

side

of

en-

gine

block

and

remove

torqueconverter

bolts

.

Turn

crankshaft

to

access

boits

.

See

Fig

.

9

.

AUTOMATIC

TRANSMISSION

240-

5

Bellhousing

access

hole

Socket

wrench

Fig

.

9

.

Access

andremove

torque

converter

boits

through

hole

in

bellhousing

cover

.

0

A

fij

13

.

Remove

bellhousing-to-engine

mounting

bolts

.

See

Fig

.

10

.

Transmission-to-engine

Torx-head

mounting

bolts

.

Fig

.

10

.

0012592

TRANSMISSION

REMOVAL

AND

INSTALLATION

Page 236 of 759

250-2

GEARSHIFT

LINKAGE

5

.

Remove

driveshaft

.

See260

Driveshaft

.

9

.

Release

gearshift

lever

retaining

ring

from

below

by

turningspecial

tool

90°(

1

/4

turn)

counterclockwise

.

See

6

.

Support

transmission

with

transmission

jack

.

Remove

Fig

.

4

.

crossmember

from

rear

of

transmission

.

See

Fig

.

2

.

Fig

.

2

.

Rear

transmission

crossmember

(arrow)

.

7

.

Lower

rear

of

transmission

to

access

gearshift

linkage

.

CAUTION-

Tilting

the

engine

to

lower

thetransmission

can

lead

to

damage

to

various

componente

due

to

lackof

clearance

.

-On

cars

with

AST

remove

throttle

body

.

-Remove

brake

fluid

reservoir

if

necessary

.

0013135

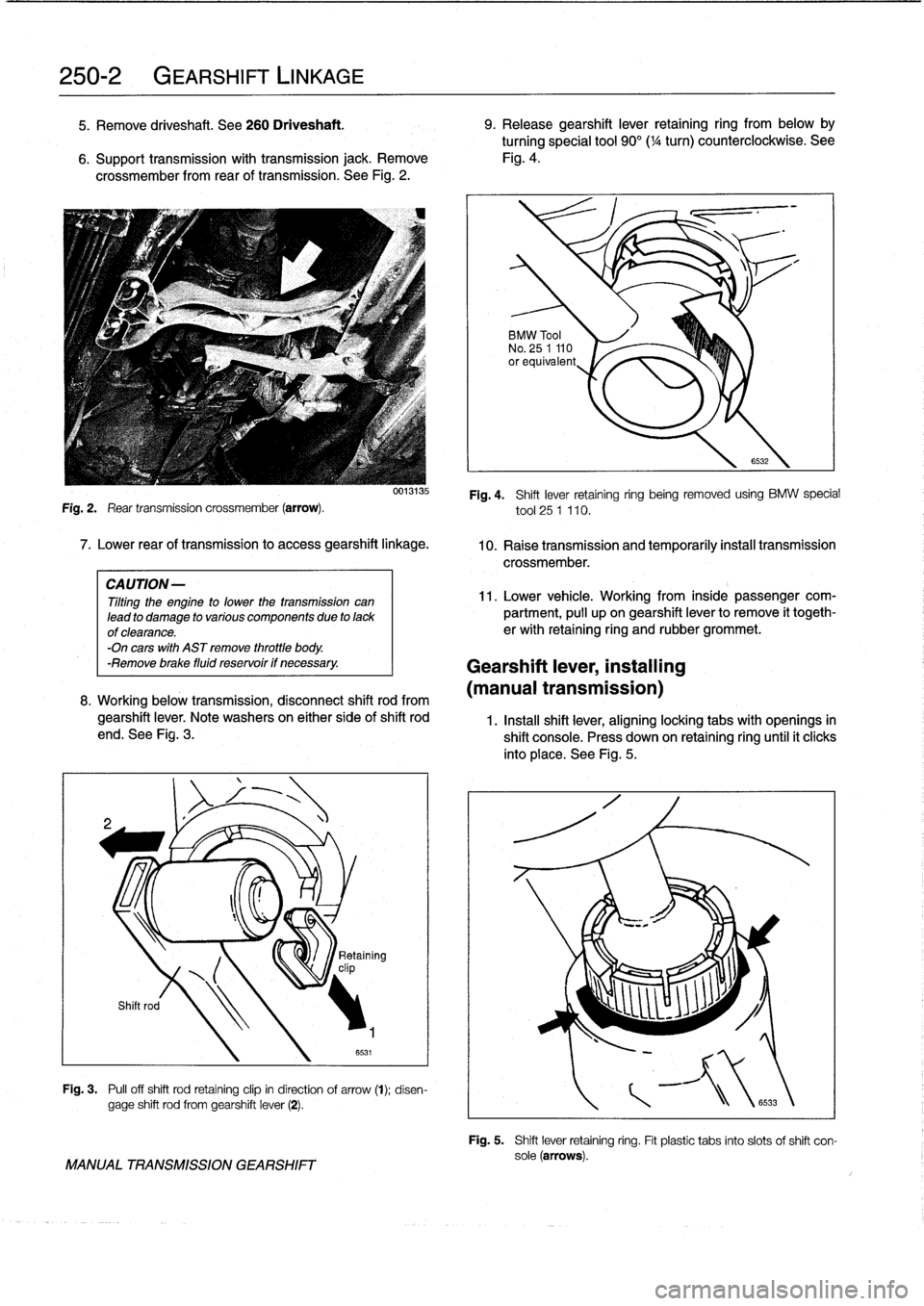

8

.

Working

below

transmission,

disconnect

shift

rod

from

gearshift

lever

.

Note

washers

on

either

side

of

shift

rod

end

.

See

Fig

.

3

.

v

clip

Shift

rod

Fig

.

3

.

Pull

off

shift

rod

retaining

clip

in

direction

of

arrow

(t)

;

disen-

gage

shift

rod

from

gearshift

lever

(2)

.

MANUAL

TRANSMISSION

GEARSHIFT

BMW

Tool

No

.

25

1

110

orequivalent

Fig

.

4

.

Shift

lever

retaining

ring

being

removed

using

BMW

special

tool

25

1

110

.

10

.

Raise

transmission

and

temporarily

instan

transmission

crossmember

.

11

.

Lower

vehicle

.

Working

from

inside

passengercom-

partment,

pull

upon

gearshift

lever

to

remove

it

togeth-

erwith

retaining

ring

and

rubber

grommet

.

Gearshift

lever,

installing

(manual

transmission)

6532

1

.

Instan

shift

lever,

aligninglocking

tabs

with

openings

in

shift

console

.

Press

down

on

retaining

ring

until

it

clicks

into

place

.

See

Fig

.

5

.

\

Retaining

Fig

.

5

.

Shift

lever

retaining

ring

.

Fit

plastic

tabs

into

slots

of

shift

con-

sole(arrows)

.

Page 240 of 759

250-

6

GEARSHIFT

LINKAGE

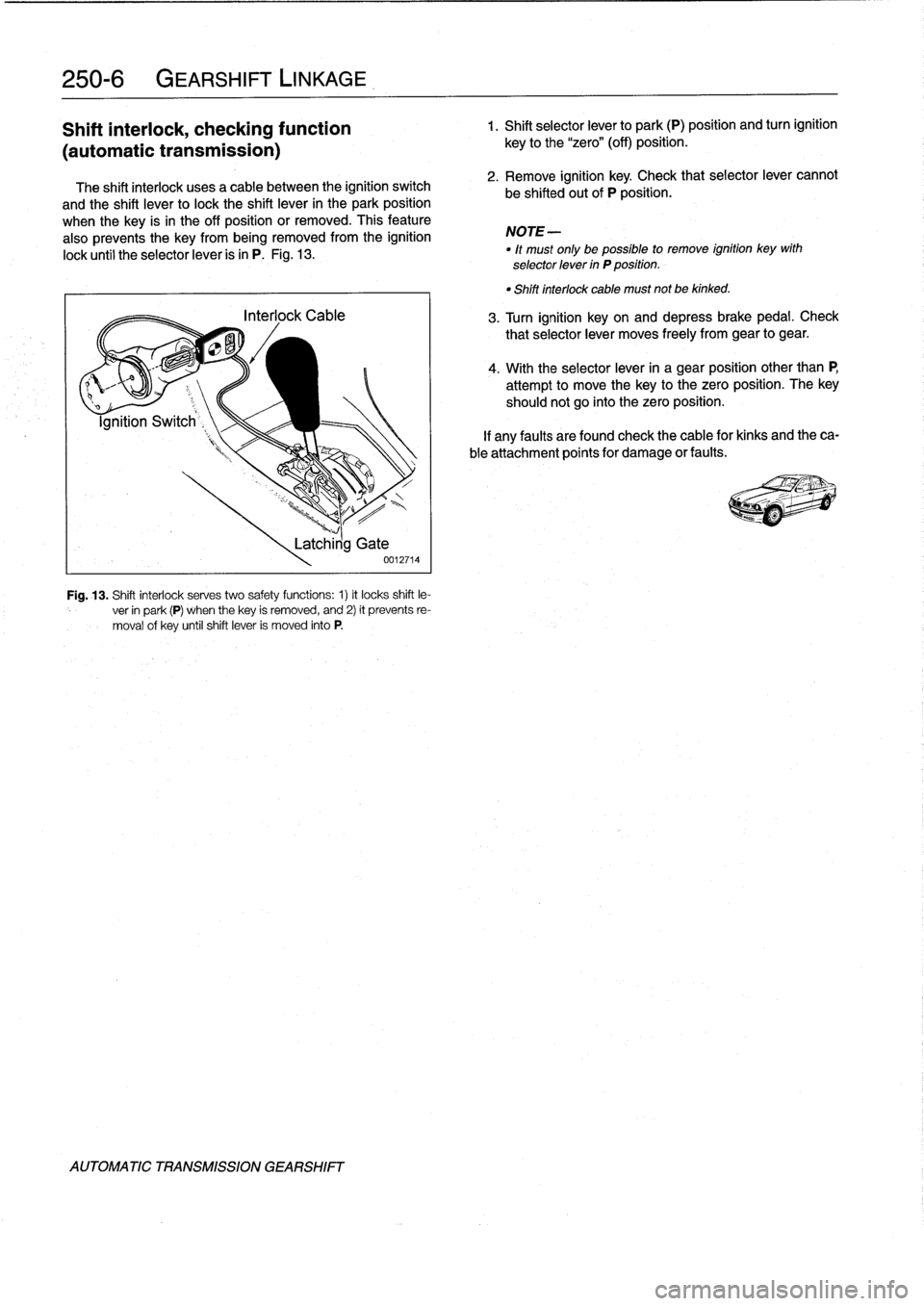

Shift

interlock,

checking

function

1

.

Shift

selectorlever

to

park

(P)

position

and

turn

ignition

(automatic

transmission)

The

shift

interlock

usesa

cable

between

the

ignition

switch

and

the

shift

lever

to

lock

the

shift

lever

in

the

park

position

when

the

key

is

in

the

off

position

or

removed

.

This

feature

also

prevents

the

key

from

being

removed

from

the

ignition

lock

until

the

selectorlever

is

in

P

.

Fig

.

13

.

Fig

.

13

.

Shift

interlock

serves

two

safety

functions

:

1)

it

locks

shift

le-

ver

in

park

(P)

when

thekey

is

removed,

and

2)

it

prevents

re-

moval

of

key

untilshift

lever

is

moved

into

P

.

AUTOMATIC

TRANSMISSION

GEARSHIFT

Latchirig

Gate

0012714

key

to

the

"zero"

(off)

position

.

2

.

Remove

ignition

key

.

Check

that

selectorlever

cannot

be

shifted

out

of

P

position

.

NOTE-

"

lt

must

only

be

possible

to

remove

ignition

key

with

selector

lever

in

P

position

.

"

Shiftinterlock

cable

must

not

be

kinked

.

3

.

Turn

ignition

keyon

and

depressbrakepedal

.

Check

that

selectorlever

moves

freely

from

gear

to

gear

.

4

.

With

the

selectorlever

in

a

gear

position

other

than

P,

attempt

to

move

thekey

to

the

zero

position

.

The

key

shouldnot

go

into

the

zero

position

.

If

any

faults

arefound

check

the

cable

for

kinks

and

theca-

ble

attachment

points

for

damage

or

faults

.

Page 241 of 759

DRIVESHAFT

SERVICE

.

...

.

.

.

...

.

..

.

.

.260-3

Driveshaft,

aligning

...............

.

...

.

.

260-3

Driveshaft,

removing

..............

.

.

.

.

.

.

260-4

260

Driveshaft

DRIVESHAFT

260-1

GENERAL

.

.

.

.

.

.

.

.....

.

.

.

........

.

...

.

260-1

Driveshaft,

installing

.

....

.

..

.

............

260-4

Flex-disc,

replacing

.....

.

.

.

.............

260-5

TROUBLESHOOTING

..

.

.

.

...

.

.........

260-1

Center

bearing

assembly,

replacing

.

......

.260-6

Frontcentering

guide,

replacing

..

.

.......

.

260-7

TABLE

a

.

Driveshaft

Troubleshooting

.

.

...

......

.

....

..

.

.

260-2

GENERAL

NOTE-

For

rear

drive

axlerepair

information,

see330

Rear

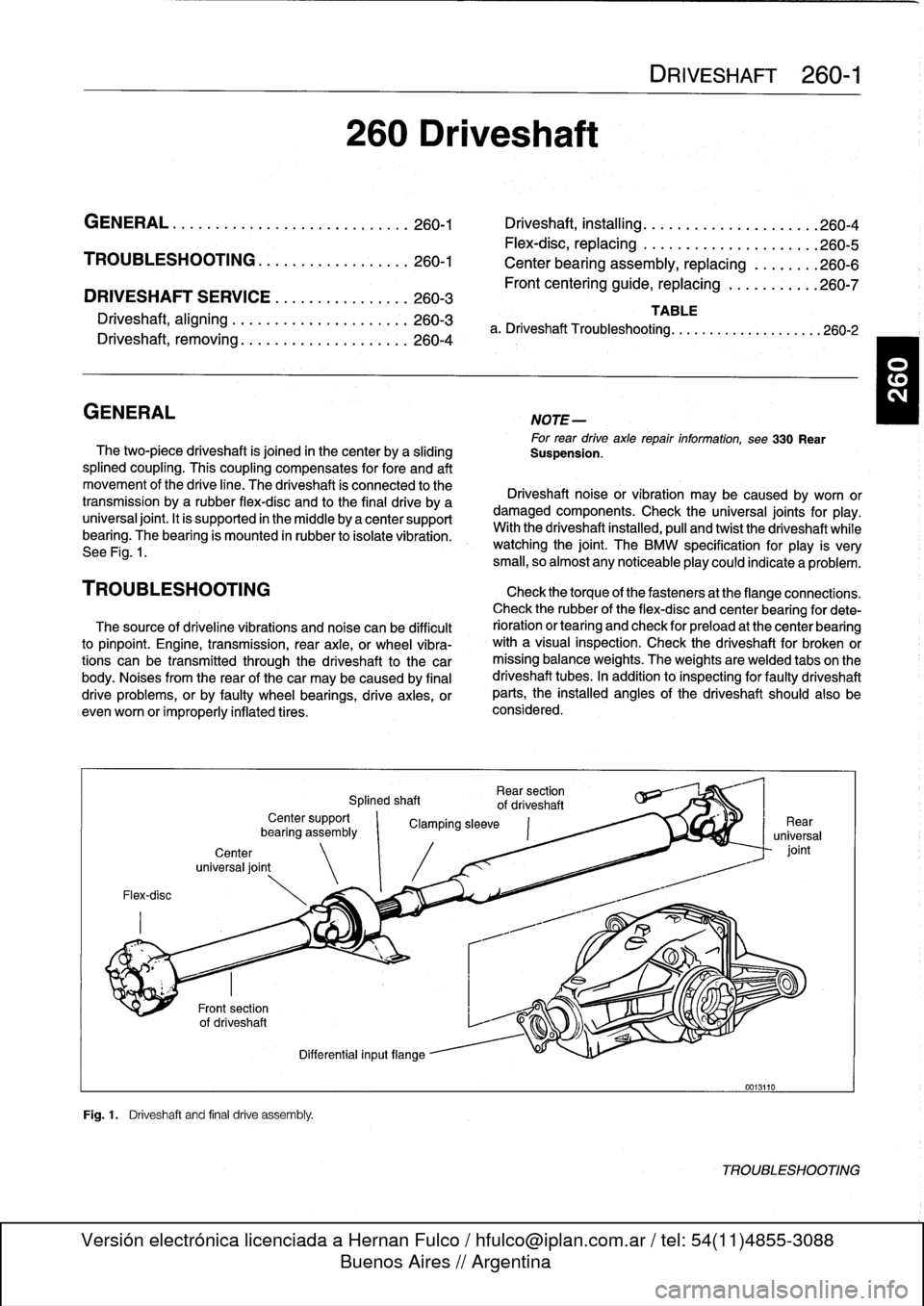

The

two-piece

driveshaft

is

joined

in

thecenter

by

a

sliding

Suspension

.

splined

coupling

.

This

coupling

compensates

for

fore

and

aft

movement

of

the

drive

line

.

The

driveshaft

ís

connected

to

the

Driveshaft

noise

or

vibration

may

be

caused

by

worn

or

transmission

bya

rubber

flex-disc

and

to

the

final

drive

by

a

damaged

components

.

Check

the

universal

joints

for

play

.

universal

joint

.

It

is

supported

in

the

micidle

by

a

center

support

With

the

driveshaft

installed,

pull

and

twist

the

driveshaft

while

bearing

.

The

bearing

is

mounted

in

rubber

to

isolate

vibration

.

watching

the

joint

.

The

BMW

specificationfor

play

is

very

See

Fig

.

1

.

small,

so

almost

any

noticeableplay

could

indicate

a

problem

.

TROU

BLESHOOTING

Check

thetorque

of

thefasteners

at

the

flange

connections

.

Check

therubber

of

the

flex-disc

and

center

bearing

for

dete

The

source

of

driveline

vibrations

and

noise

can

be

difficult

rioration

or

tearíng

and

check

for

preload

at

the

center

bearing

to

pinpoint

.

Engine,

transmission,

rear

axle,

or

wheel

vibra-

with

a

visual

inspection

.

Check

the

driveshaft

for

broken

or

tions

can

be

transmitted

through

the

driveshaft

to

the

car

missing

balance

weights

.

The

weights

are

welded

tabs

on

the

body

.

Noises

from

the

rear

of

thecar

may

be

caused

by

final

driveshaft

tubes

.

In

addition

to

inspecting

for

faulty

driveshaft

drive

problems,

orby

faulty

wheel

bearings,

drive

axies,

or

parts,

the

installed

angles

of

the

driveshaft

should

also

be

evenworn

or

improperly

inflatedtires

.

considered

.

Flex-disc

Center

universal

joint

Fig

.1

.

Driveshaft

and

final

drive

assembly

.

Rear

section

Splined

shaft

of

driveshaft

Center

support

`

Clamping

sleeve

bearíng

assembly

Differential

inputflange

0013110

TROUBLESHOOTING

Page 244 of 759

260-

4

DRIVESHAFT

CAUTION

-

The

maximum

allowable

change

in

height

of

the

center

bearing

or

transmission

support

using

shims

is

3

mm

(0

.12

in

.)

.

Driveshaft,

removing

WARNING

-

"

Be

sure

the

wheels

are

off

the

ground

before

re-

moving

the

driveshaft

.

Set

the

parking

brake

be-

fore

removing

the

driveshaft

.

"

Once

the

driveshaft

has

been

removed,

the

vehi-

cle

can

roll

regardless

of

whether

the

transmis-

sion

isin

gear

or

not

.

"

The

driveshaft

fs

mounted

to

thetransmission

and

final

drive

with

self-locking

nuts

.

These

nuts

are

designed

to

be

used

only

once

and

should

be

replaced

during

reassembly

.

1.

Disconnect

oxygen

sensor

electrical

connectors

and

remove

complete

exhaustsystem

.

See

180

Exhaust

System

.

4

.

Remove

driveshaft

mounting

bolts

.

See

Fig

.

3

.

Discard

old

nuts

.

JG

Fig

.

3

.

Front

driveshaft

totransmission

mounting

bolt

being

re-

moved

.

Note

open-end

wrench

(arrow)

being

used

to

coun-

terhold

bolt

.

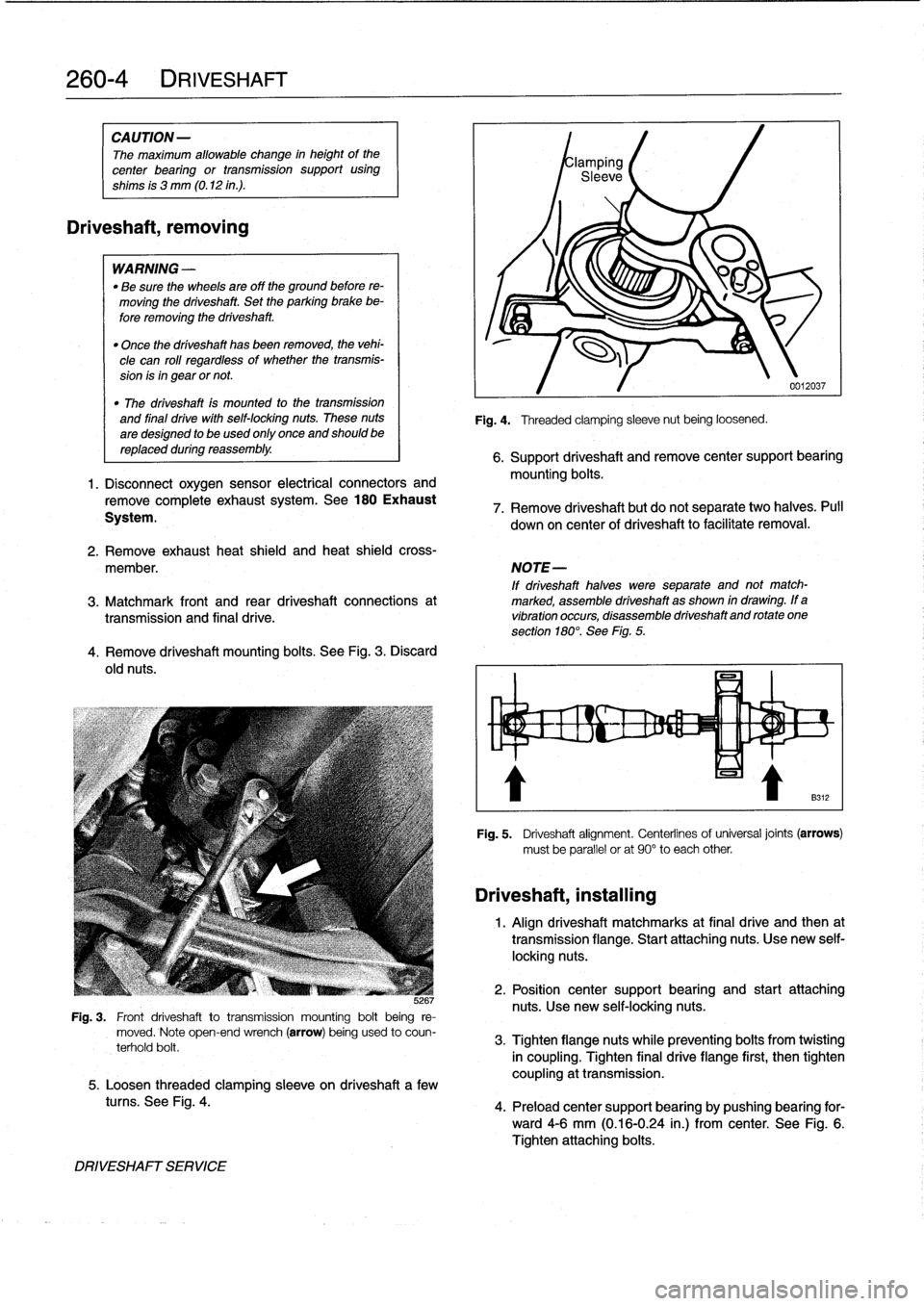

5

.

Loosen

threaded

clamping

sleeve

on

driveshaft

a

few

tucos

.

See

Fig

.

4

.

DRIVESHAFT

SERVICE

Fig

.

4

.

Threaded

clamping

sleeve

nut

being

loosened

.

0012037

6

.

Support

driveshaft

andremove

center

support

bearing

mounting

bolts

.

7

.

Remove

driveshaft

but

do

not

separate

two

halves

.

Pull

down

on

center

of

driveshaft

to

facilitate

removal

.

2

.

Remove

exhaust

heat

shield

and

heat

shieldcross-

member

.

NOTE-

If

driveshaft

halves

were

separate

and

not

match-

3

.

Matchmark

front

and

rear

driveshaft

connections

at

marked,

assemble

driveshaft

as

shown

in

drawing

.

If

a

transmissíon

and

final

drive

.

vibration

occurs,

disassemble

driveshaftand

rotate

one

section

180°

.

See

Fig

.

5

.

Driveshaft,

installing

Fig

.

5

.

Driveshaft

alignment

.

Centerlinesof

universal

joints

(arrows)

must

be

parallel

or

at

90°

to

each

other

1

.

Align

driveshaft

matchmarks

at

final

drive

and

then

at

transmission

flange

.

Start

attaching

nuts

.

Use

new

self-

locking

nuts

.

2

.

Position

center

support

bearing

and

start

attaching

nuts

.

Use

new

self-locking

nuts

.

3

.

Tighten

flangenuts

while

preventing

bolts

from

twisting

in

coupling

.

Tighten

final

drive

flange

first,

then

tighten

coupling

at

transmission

.

4

.

Preload

center

support

bearing

by

pushing

bearing

for-

ward4-6

mm

(0

.16-0

.24

in

.)

from

center

.

See

Fig

.

6

.

Tighten

attaching

bolts

.

Page 246 of 759

260-

6

DRIVESHAFT

4

.

Insta¡¡

driveshaft

as

described

in

Driveshaft,

install-

ing

.

Tightening

Torques

"

Driveshaft

center

mount

to

body

.

...

21

Nm

(16

ft-Ib)

"

Driveshaft

clamping

sleeve

.....

...

10

Nm

(89

in-lb)

"

Driveshaft

to

final

drive

flange

With

CV

joint

(M8)

............

...

32

Nm

(23

ft-Ib)

Wth

U-joint

(M10

ribbed

nut)

......

.

80

Nm

(59

ft-Ib)

With

U-joint

(M10

compressed

nut)

.

.

60

Nm

(44

ft-Ib)

"

Flex-disc

to

driveshaft

or

transmission

flange

M10

(8

.8

grade)

.

...

.............

48

Nm

(35

ft-Ib)

M10

(10

.9

grade

.

...

.............

64

Nm

(47

ft-Ib)

M12

(8

.8

grade)

..

..

.............

81

Nm

(60

ft-Ib)

M12

(10

.9

grade)

.

..

............

100

Nm

(74

ft-Ib)

M12

(10

.9

grade)

(M3

models)

.....

115

Nm

(85

ft-Ib)

"

Transmission

crossmember

to

body

(M8)

......

...

.

..

........

21

Nm

(16

ft-Ib)

5

.

Remove

center

bearing

circlip

and

dust

guard

.

See

Fig

.

Center

bearing

assembly,

replacing

10

.

Remove

bearing

from

driveshaft

using

puller

.

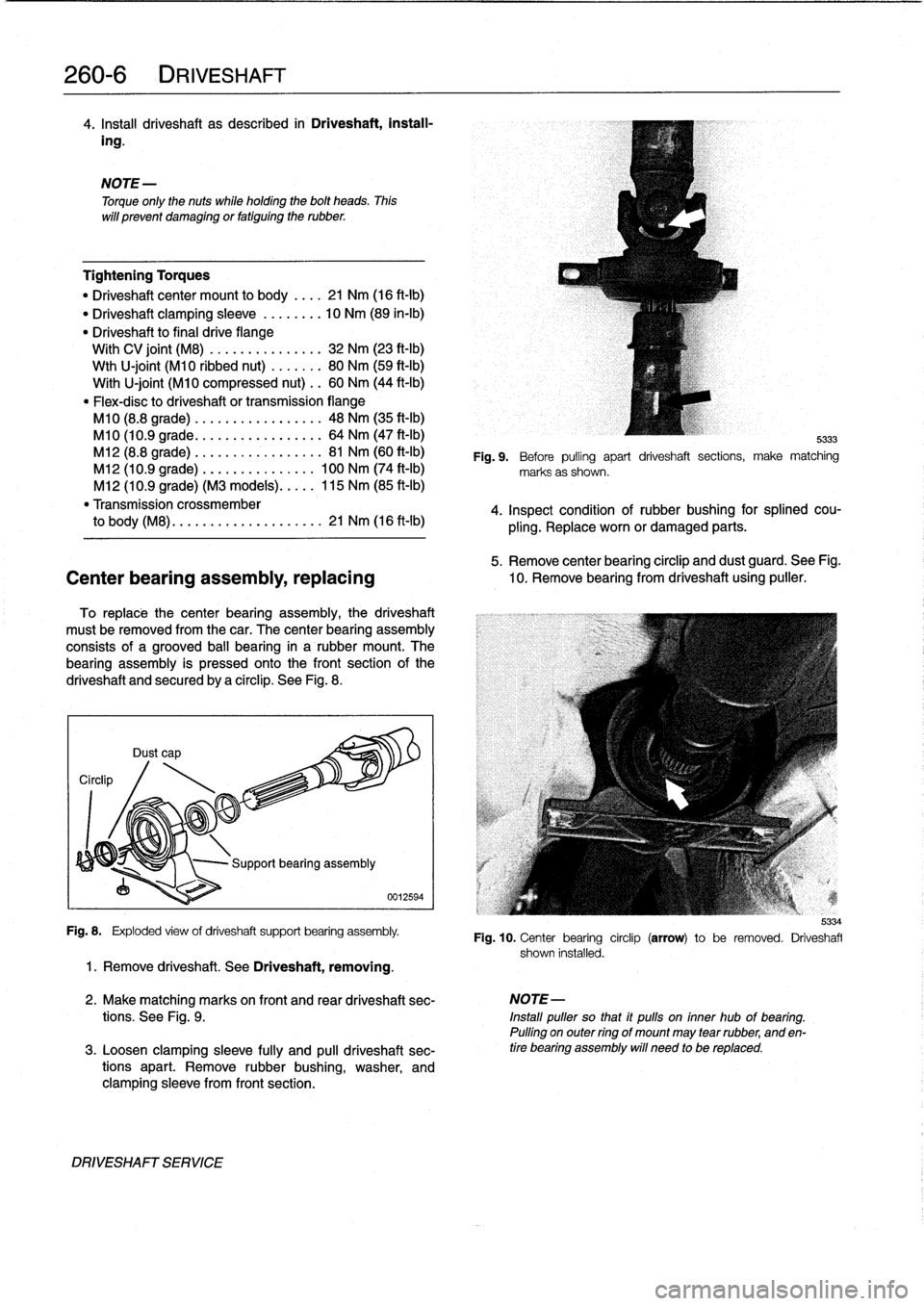

To

replace

thecenter

bearing

assembly,

the

driveshaft

must

be

removed

from

thecar

.

The

center

bearing

assembly

consists

of

a

grooved

ball

bearing

in

a

rubber

mount

.

The

bearing

assembly

is

pressed

onto

the

front

section

of

the

driveshaft

and

securedby

a

circlip

.

See

Fig

.

8

.

Circlip

NOTE

-

Torque

only

the

nuts

while

holding

the

bolt

heads

.

Thís

will

prevent

damaging

or

fatiguing

the

rubber

.

Dust

cap

Fig

.

8

.

Exploded

view

of

driveshaft

support

bearing

assembly

.

1

.

Remove

driveshaft

.

See

Driveshaft,

removing

.

DRIVESHAFT

SERVICE

0012594

5333

Fig

.

9

.

Before

pulling

apart

driveshaft

sections,

make

matching

marks

as

shown

.

4

.

Inspect

condition

of

rubber

bushing

for

splined

cou-

pling

.

Replace

worn

or

damaged

parts

.

2

.

Make

matching

marks

on

front

and

rear

driveshaft

sec-

NOTE-

tions

.

See

Fig

.

9

.

Install

puller

so

that

it

pulls

on

inner

hub

of

bearing

.

Pulling

on

outer

ring

of

mount

may

tear

rubber,

and

en

3

.

Loosen

clamping

sleeve

fully

and

pull

driveshaft

sec-

tire

bearing

assembly

will

need

to

be

replaced

.

tions

apart

.

Remove

rubber

bushing,

washer,

and

clamping

sleeve

from

front

section

.

5334

Fig

.

10

.

Center

bearing

circlip

(arrow)

to

be

removed

.

Driveshafl

shown

installed

.

Page 249 of 759

SUSPENSION,

STEERING

ANDBRAKES-GENERAL

300-1

300

Suspension,

Steering

and

Brakes-General

GENERAL

.....

.

....

.

.....

.

.

.

........

.300-1

M3

SUSPENSION

AND

BRAKES

.......

.

...

300-7

Front

Suspension

..........

.

.

.

...

.

.....

300-1

Steering

...

.

.

.

.

.

....

.

.

.

...

.

.

.

...

.

...

.

.

300-2

SUSPENSION

AND

STEERING

Rear

Suspension

....

.

.

.

...

.

.

.

...

.

.....

300-2

TROUBLESHOOTING

..

.

.

.

.............

300-7

Brakes

.

.

.

.

.

.

.

.

....

.

...........

.

.

.

.

.

.

300-2

Tires

and

wheeis

.

................

.

.

.

.

.

.

300-2

TABLE

a

.

AST

Indicator

Lamp

Function

..

..

.

..

.

.........

300-5

INTEGRATED

SYSTEMS

.........

.

.

.

.

.

.

300-2

b

.

Suspension

and

Steering

Troubleshooting

......

.300-8

Antilock

Brake

System

(ABS)

.......

.

.

.

.

.

.

300-2

Al¡

Season

Traction

(AST)

.........

.

.

.

.

.

.

300-4

GENERAL

Front

Suspension

This

section

covers

general

information

for

front

and

rear

The

lower

control

arms

connect

the

front

suspension

struts

suspension,

the

steering

system,

and

the

brakíng

and

traction

to

mounting

points

on

the

subframe

crossmember

and

the

control

systems

.

body

.

See

Fig

.

2

.

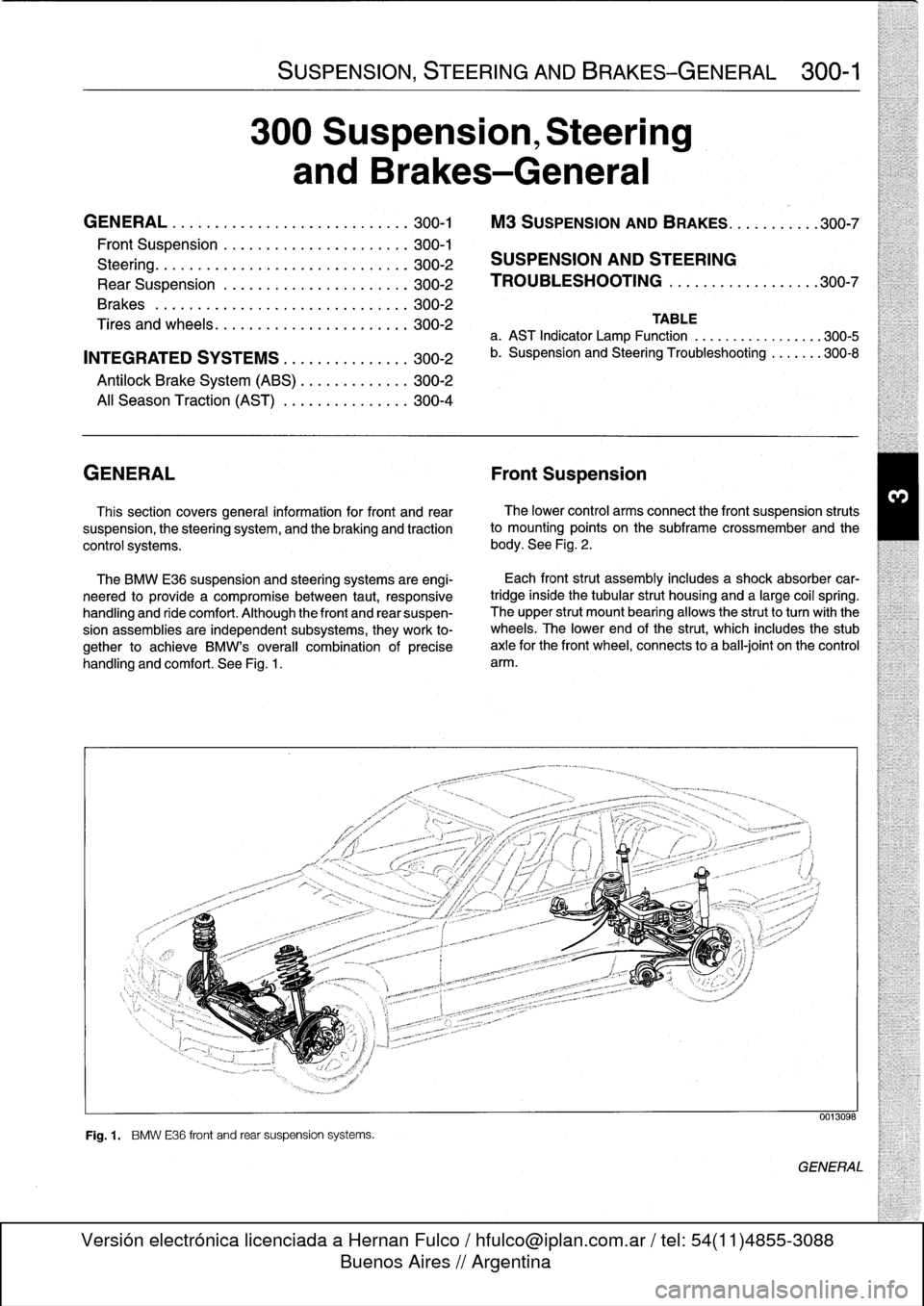

The

BMW

E36

suspension

and

steering

systems

are

engi-

neered

to

provide

a

compromise

between

taut,

responsive

handling

and

ride

comfort

.

Although

the

front

and

rear

suspen-

sion

assemblies

are

independent

subsystems,

they

work

to-

gether

to

achieve

BMW's

overall

combination

of

precise

handling

and

comfort

.

See

Fig

.

1

.

Fig

.

1

.

BMW

E36

front

and

rear

suspension

systems

.

Each

front

strut

assembly

includes

a

shock

absorber

car-

tridgeinside

the

tubular

strut

housing

and

a

large

coil

spring

.

The

upper

strut

mount

bearing

allows

the

strutto

turnwith

the

wheels

.

The

lower

end

of

the

strut,

which

includes

the

stub

axle

for

the

front

wheel,

connects

to

a

ball-joint

on

the

control

arm

.

0013098

GENERAL

Page 250 of 759

300-2

SUSPENSION,

STEERING

AND

BRAKES-GENERAL

Steering

INTEGRATED

SYSTEMS

The

steering

linkage

connects

the

rack-and-pinion

unit

through

tie

rodsto

the

steering

arms

.

The

tie

rod

ends

allow

the

wheels

to

pivot

and

react

to

suspension

travel

.

Rear

Suspension

The

rear

axle

carrier

is

the

main

mounting

point

for

the

final

drive

housing

and

the

rear

suspension

components

.

Trailing

arms

locatethe

rear

wheels

and

anchorthe

springs,

shocks

and

stabilizer

bar

.

Driveaxies

with

constant-velocity

(CV)

joints

at

both

ends

transfer

power

from

the

differential

to

the

road

wheels

.

The

differential

is

mounted

to

the

rearaxle

carrier

through

rubber

mountsand

bushings

to

hele

isolate

drivetrain

noise

and

vibration

.

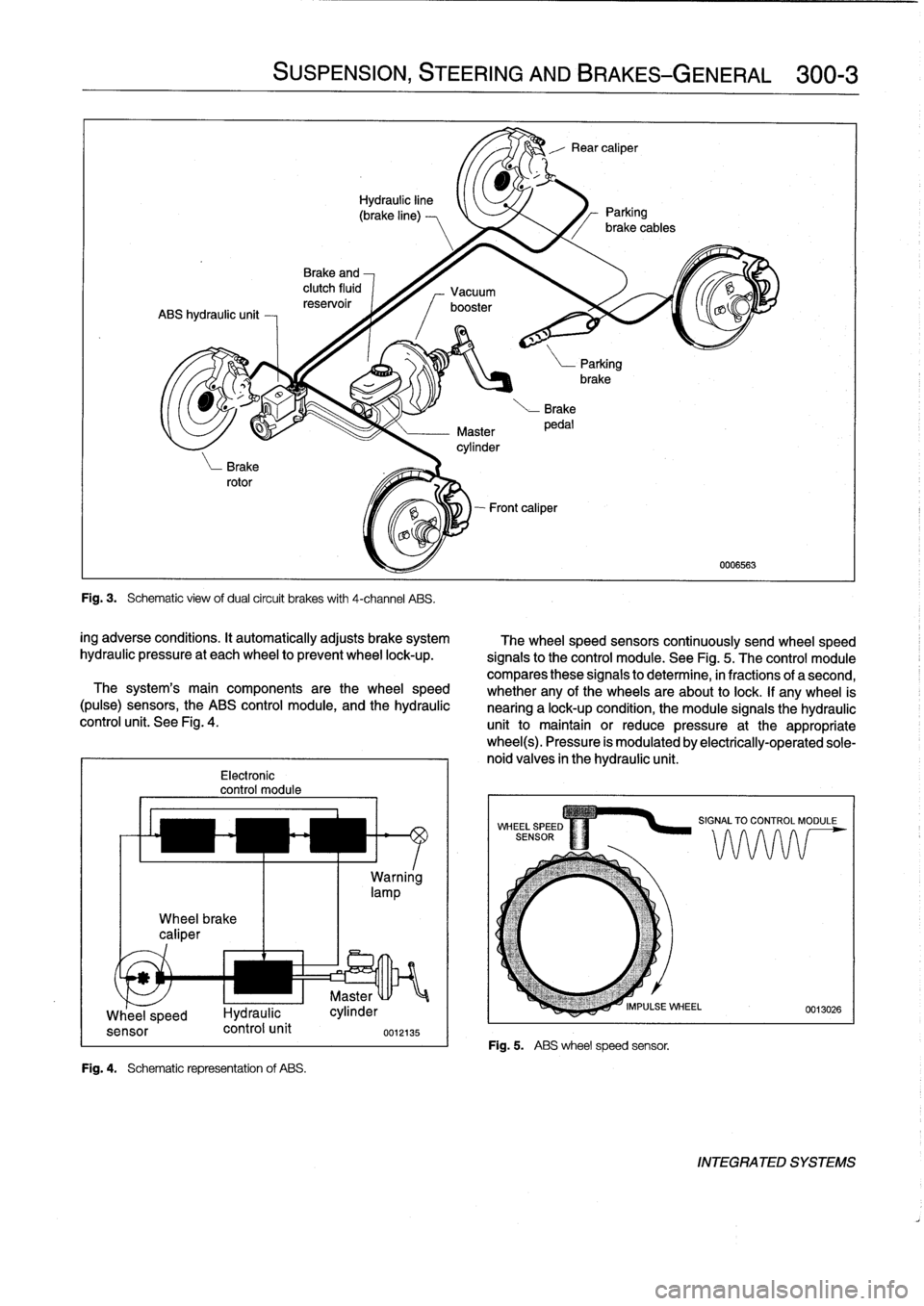

Brakes

E36

cars

areequipped

with

power

disc

brakes

with

an

inte-

gral

antilock

brakes

(ABS)

.

The

parking

brake

is

a

dual-drum

system

integrated

with

the

rear

brake

rotors

.

See

Fig

.

3

.

Power

assist

is

provided

by

a

vacuum

booster

when

the

en-

gine

is

running

.

The

brakepedal

pushrod

is

connected

directly

to

the

master

cylinder,

so

failure

of

the

vacuum

booster

does

not

normally

result

in

total

brake

failure

.

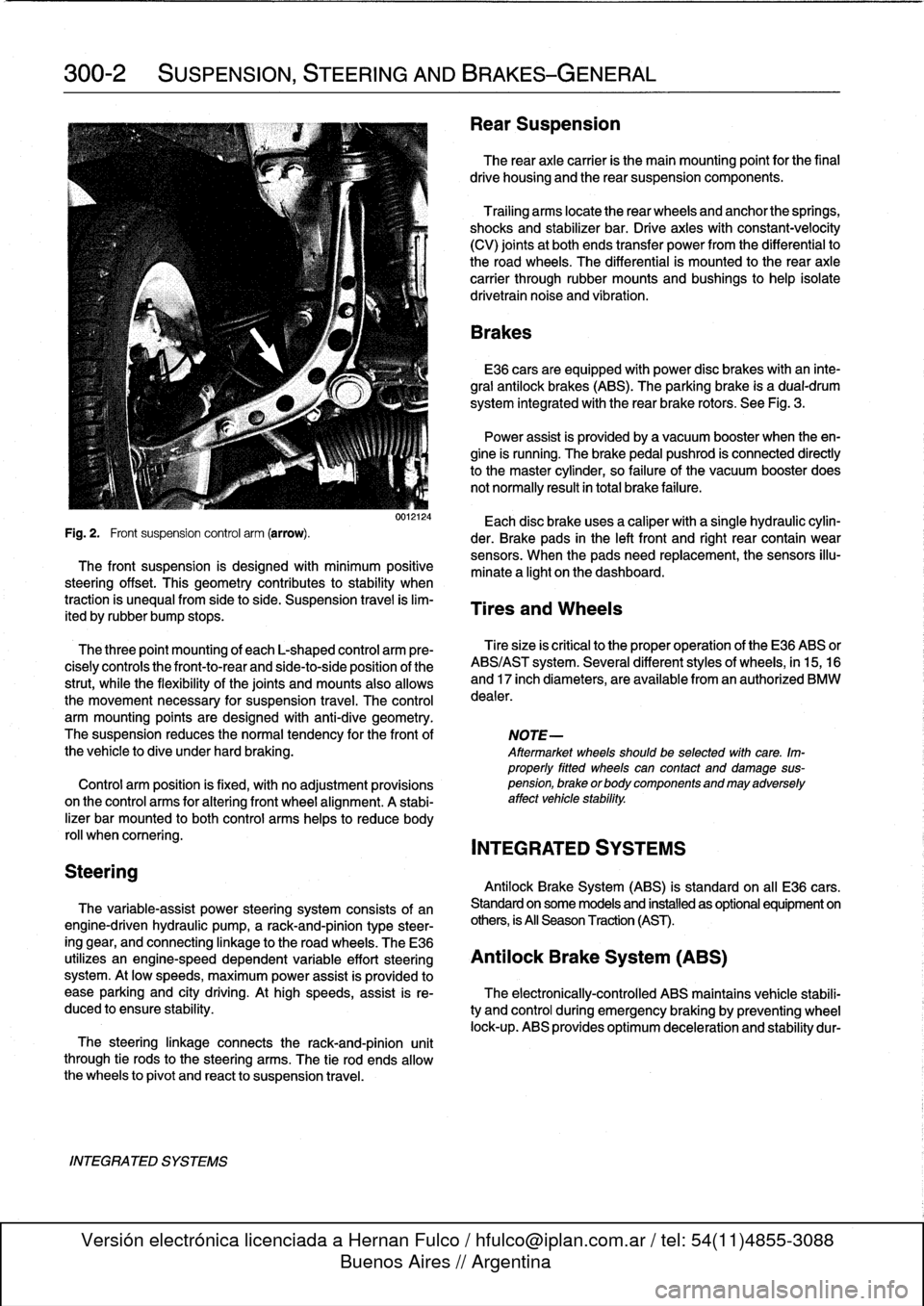

0012124

Each

disc

brakeuses

a

caliper

with

a

single

hydraulic

cylin-

Fig

.

2

.

Front

suspension

control

arm

(arrow)

.

der

.

Brake

pads

in

the

left

front

and

right

rear

contain

wear

sensors

.

When

the

padsneed

replacement,the

sensors

illu-

The

front

suspension

is

designed

with

minimum

positive

minate

a

light

on

the

dashboard

.

steering

offset

.

This

geometry

contributes

to

stability

when

traction

is

unequalfrom

side

to

side

.

Suspension

travel

is

lim-

Tires

and

Wheels

ited

by

rubber

bump

stops

.

The

three

point

mounting

of

each

L-shaped

control

arm

ere-

Tiresize

is

critica¡

to

the

proper

operatíon

of

the

E36

ABS

or

cisely

controls

the

front-to-rear

and

side-to-side

position

of

the

ABS/AST

system

.

Severa¡

different

styles

of

wheels,

in

15,16

strut,

while

the

flexibility

of

the

joints

and

mounts

alsoallows

and

17

inch

diameters,

are

available

from

an

authorized

BMW

the

movement

necessary

for

suspension

travel

.

The

control

dealer

.

arm

mounting

points

are

designed

with

anti-dive

geometry

.

The

suspension

reduces

the

normaltendency

for

the

front

of

NOTE-

the

vehicle

to

dive

under

hard

braking

.

Aftermarket

wheelsshould

be

selected

wlth

care

.

Im-

properly

fitted

wheels

can

contact

anddamage

sus

Control

arm

position

is

fixed,

with

no

adjustment

provisions

pension,

brakeorbodycomponentsandmayadversely

on

the

control

arms

for

alter¡ng

front

wheel

al

ignment

.

A

stabi-

affect

vehicle

stability

.

lizer

bar

mounted

to

both

control

arms

heles

to

reduce

body

rol¡

whencomering

.

INTEGRATED

SYSTEMS

Antilock

Brake

System

(ABS)

is

standard

on

all

E36

cars

.

The

variable-assist

power

steering

system

consists

of

an

Standard

on

some

models

and

installed

as

optional

equipment

on

engine-driven

hydraulic

pump,

a

rack-and-pinion

type

steer-

others,

is

All

Season

Traction

(AST)

.

ing

gear,

and

connecting

linkage

to

the

road

wheels

.

TheE36

utilizes

an

engine-speed

dependent

variable

effort

steering

Antilock

Brake

System

(ABS)

system

.

At

low

speeds,

maximum

power

assist

is

provided

to

ease

parking

and

city

driving

.

Athigh

speeds,

assist

is

re-

The

electronically-controlled

ABS

maintains

vehícle

stabili

duced

to

ensure

stability

.

ty

and

control

during

emergency

braking

by

preventing

wheel

lock-up

.

ABS

provides

optimum

deceleration

and

stability

dur-

Page 251 of 759

Wheel

brake

caliper

Electronic

control

module

Fig

.

4

.

Schematic

representation

of

ABS

.

SUSPENSION,

STEERING

ANDBRAKES-GENERAL

300-3

Fig

.

3

.

Schematic

view

ofdual

circuit

brakes

with

4-channel

ABS

.

ing

adverse

conditions

.

It

automatically

adjusts

brake

system

hydraulic

pressure

at

each

wheel

to

prevent

wheel

lock-up

.

The

system's

main

components

arethe

wheel

speed

(pulse)

sensors,

the

ABS

control

module,

and

the

hydraulic

control

unit

.

See

Fig

.

4

.

Warning

lamp

u

Master

Whee

_

l

speed

I-lydraulic

cylinder

sensor

control

unit

0012135

UNI

The

wheel

speed

sensors

continuously

send

wheel

speed

signals

to

the

control

module

.

See

Fig

.

5

.

The

control

module

compares

these

signals

to

determine,

in

fractions

of

a

second,

whether

any

of

the

wheels

areabout

to

lock

.

If

any

wheel

is

nearing

a

lock-up

condition,

the

module

signals

the

hydraulic

unit

to

maintain

or

reduce

pressure

at

the

appropriatewheel(s)

.

Pressure

is

modulated

by

electrically-operated

sole-

noid

valves

in

the

hydraulic

unit

.

Fig

.

5

.

ABS

wheelspeed

sensor

.

0006563

INTEGRATED

SYSTEMS