fuel gauge BMW 318i 1992 E36 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1992, Model line: 318i, Model: BMW 318i 1992 E36Pages: 759

Page 192 of 759

160-

8

FUEL

TANK

AND

FUEL

PUMP

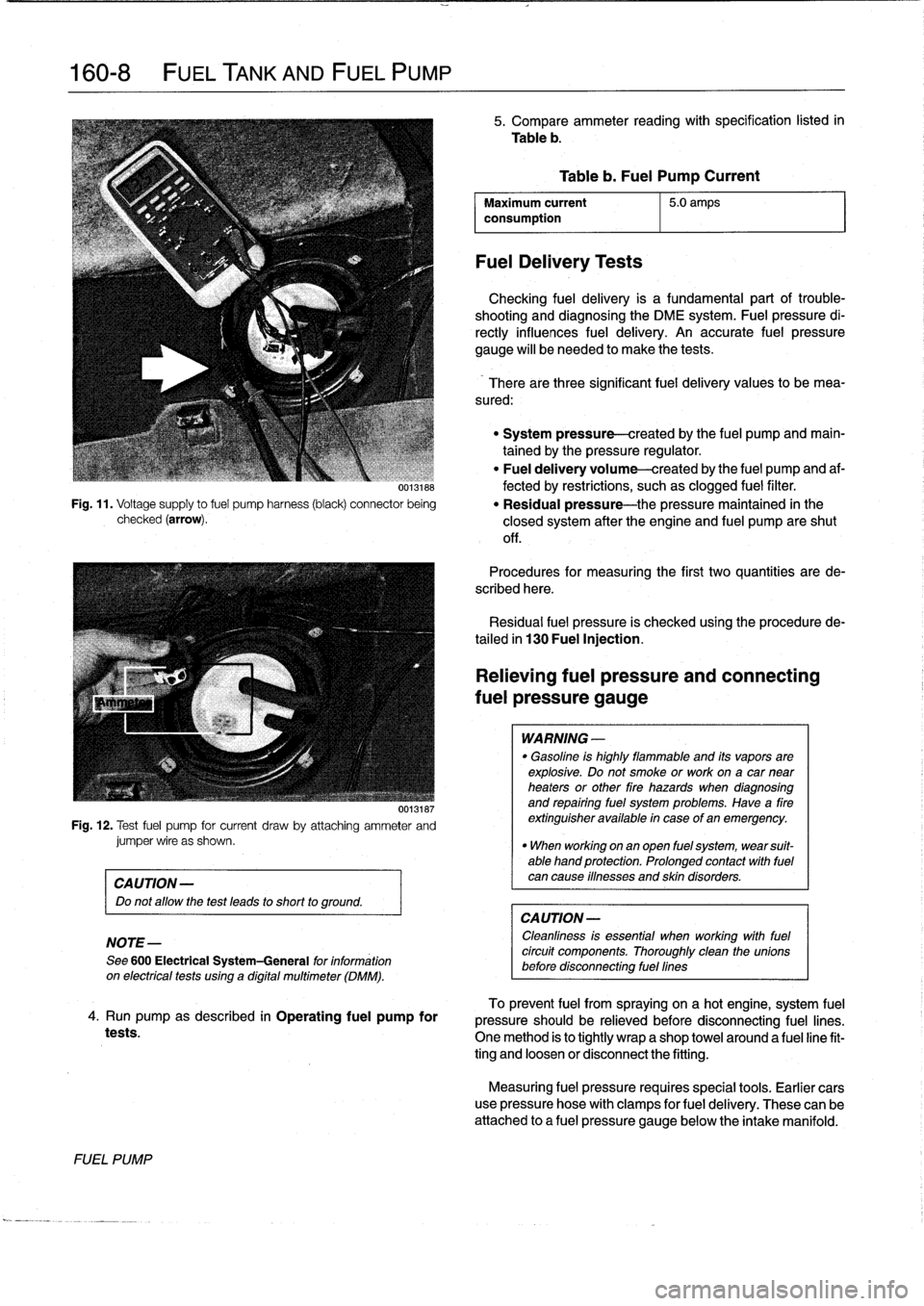

UU131

tst5

Fig

.

11

.

Voltage

supply

to

fuel

pump

harness

(black)

connector

being

checked

(arrow)

.

00131ts7

Fig

.

12

.

Test

fuel

pump

for

current

draw

by

attadhing

ammeter

andjumper

wire

as

shown

.

CAUTION-

Do

not

allow

the

test

leads

to

short

to

ground

.

NOTE-

See

600

Electrical

System-General

for

information

on

electricaltests

using

a

digital

multimeter

(DMM)

.

4

.

Run

pump

as

described

in

Operating

fuel

pump

for

tests

.

FUEL

PUMP

5

.

Compare

ammeter

reading

with

specification

listed

in

Table

b

.

Maximum

current

5

.0

amps

consumption

FuelDelivery

Tests

Table

b

.

Fuel

Pump

Current

Checking

fuel

delivery

is

a

fundamental

part

of

trouble-

shooting

and

diagnosing

the

DME

system

.

Fuelpressure

di-

rectly

influences

fuel

delivery

.

An

accurate

fuel

pressure

gauge

will

be

needed

to

make

the

tests

.

There

arethree

significant

fuel

delivery

values

to

bemea-

sured

:

"

System

pressure-created

by

the

fuel

pump

and

main-

tained

by

the

pressure

regulator

.

"

Fuel

delivery

volume-created

by

the

fuel

pump

and

af-

fected

by

restrictions,

suchas

clogged

fuel

filter

.

"

Residual

pressure-the

pressure

maintained

in

the

closed

system

after

the

engine

and

fuel

pump

areshut

off

.

Procedures

for

measuring

the

first

two

quantities

arede-

scribed

here

.

Residual

fuel

pressure

is

checked

using

the

procedurede-

tailed

in

130

Fuel

Injection

.

Relieving

fuel

pressure

and

connecting

fuel

pressure

gauge

WARNING

-

"

Gasoline

is

highly

flammable

and

its

vaporsare

explosive

.

Do

not

smoke

or

work

ona

car

near

heaters

or

other

fire

hazards

when

diagnosing

and

repairing

fuel

system

problems

.

Have

a

fire

extinguisher

available

in

case

of

an

emergency

.

"

When

working

onan

open

fuel

system,

wear

suit-

able

hand

protection

.

Prolonged

contact

with

fuel

can

cause

iflnesses

and

skin

disorders

.

CA

UTION-

Cleanliness

is

essential

when

working

withfuel

circuit

components

.

Thoroughly

clean

the

unionsbefore

disconnecting

fuel

fines

To

prevent

fuel

from

spraying

on

a

hotengine,

system

fuel

pressure

should

be

relieved

before

disconnecting

fuel

lines

.

One

method

is

to

tightly

wrap

a

shop

towel

around

a

fuel

line

fit-

ting

and

loosen

or

disconnect

the

fitting

.

Measuring

fuel

pressure

requires

special

tools

.

Earlier

cars

use

pressure

hose

with

clamps

for

fuel

delivery

.

These

can

be

attached

to

a

fuel

pressure

gauge

below

the

intake

manifold

.

Page 193 of 759

NOTE-

NOTE

-

On

1996

and

later

4-cylinder

cars,

use

BMW

special

"

Use

BMW

pressure

gauge

Part

No

.

133

060,or

an

tool

13

6051

(hose

with

quick

release

coupling)

toat-

equivalent

.

The

fuel

pressure

gauge

should

have

a

tach

pressure

gauge

to

Shraeder

valve

fitting

on

top

of

rangeof

0

to

5bar

(0

to

75

psi)

and

mustbe

securely

the

M44

fuel

rail

.

See

Fig

.

13

.

connected

to

prevent

it

from

coming

loose

under

pres-

sure

.

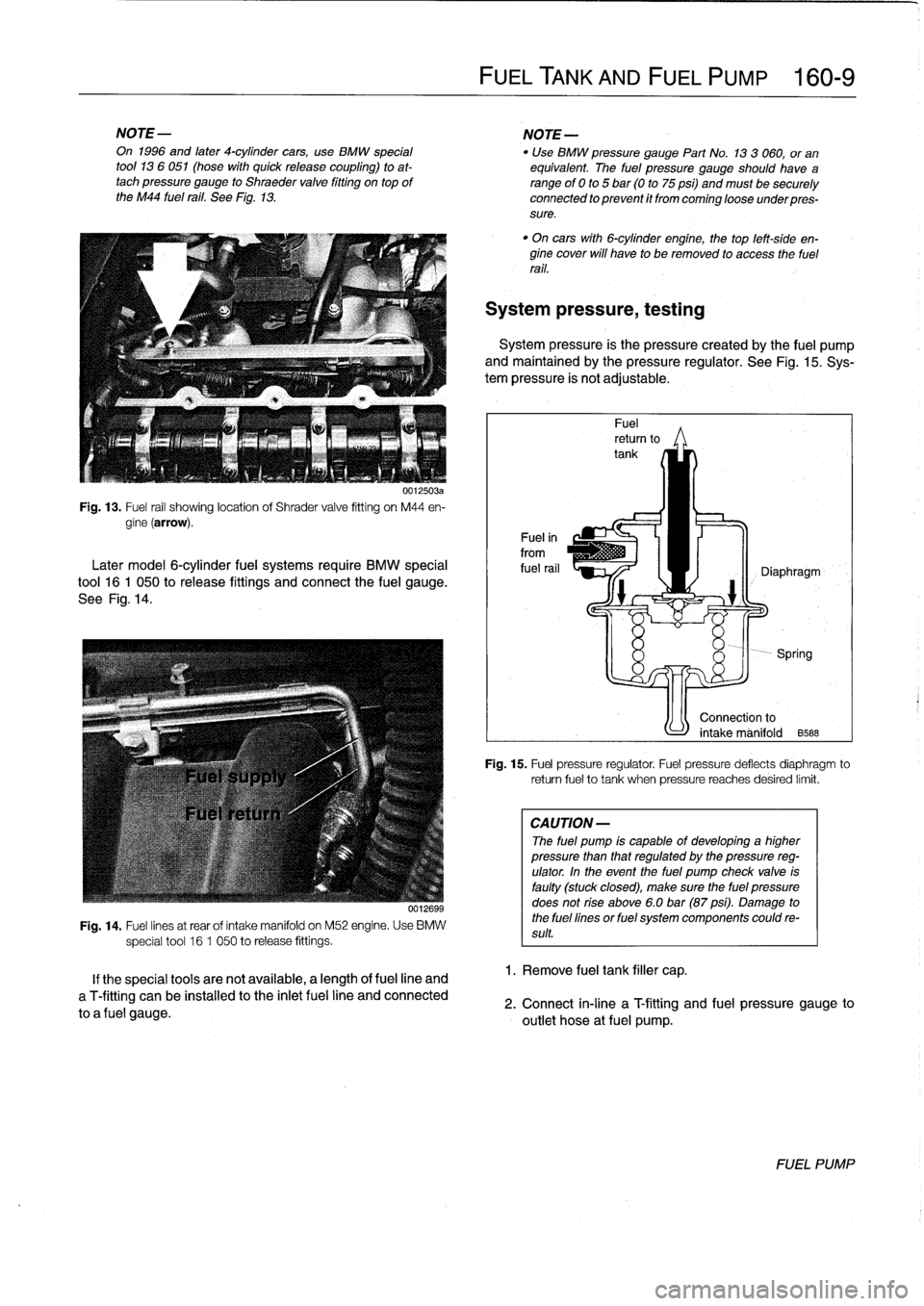

u012503a

Fig

.

13

.

Fuel

rail

showing

location

of

Shrader

valve

fitting

on

M44

en-

gine

(arrow)

.

Later

model

6-cylinder

fuel

systems

require

BMW

specíal

tool

16

1

050

to

release

fittings

and

connect

the

fuel

gauge

.

See

Fig

.

14

.

0012699

Fig

.

14

.

Fuel

lines

at

rear

of

íntake

manifold

on

M52

engine

.

Use

BMW

special

tool

16

1

050

to

release

fittings

.

If

the

special

tools

arenot

available,

a

length

offuel

line

and

a

T-fitting

can

be

installed

tothe

inlet

fuel

line

and

connected

to

a

fuel

gauge

.

FUEL

TANK

AND

FUEL

PUMP

160-

9

"

On

cars

with

6-cylinder

engine,

thetop

left-side

en-

Bine

cover

will

have

to

be

removed

to

access

the

fuel

rail

.

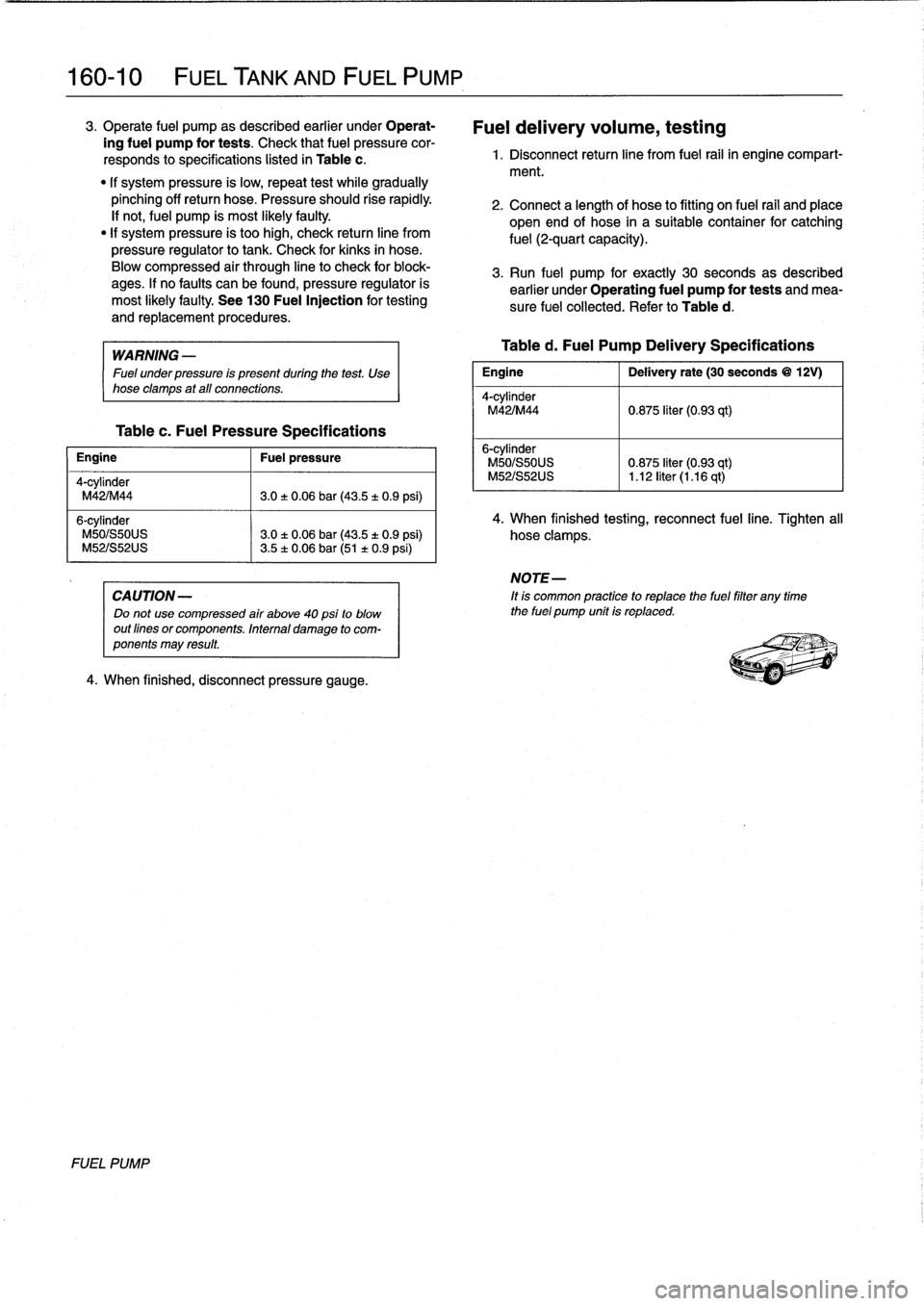

System

pressure,

testing

System

pressure

is

the

pressure

created

by

the

fuel

pump

and

maintained

by

the

pressure

regulator

.

See

Fig

.

15

.

Sys-

tem

pressure

is

not

adjustable

.

1

.

Remove

fuel

tank

filler

cap

.

Fig

.

15

.

Fuel

pressure

regulator

.

Fuel

pressure

deflects

diaphragm

to

retum

fuel

to

tank

when

pressure

reaches

desired

limit

.

CA

UTION-

The

fuel

pump

is

capable

of

developing

a

higher

pressure

than

that

regulated

by

the

pressure

reg-

ulator

.

In

the

event

the

fuel

pump

check

valve

is

faulty

(stuck

closed),

make

sure

the

fuel

pressure

does

not

rise

aboye

6

.0

bar(87

psi)

.

Damage

to

the

fuel

fines

or

fuel

system

components

could

re-

sult

.

2

.

Connect

in-fine

a

Tfitting

and

fuel

pressure

gauge

to

outlet

hose

atfuel

pump

.

FUEL

PUMP

Page 194 of 759

160-

1

0

FUEL

TANK

AND

FUEL

PUMP

3

.

Operate

fuel

pump

as

described

earlier

under

Operat-

ing

fuel

pump

for

tests

.

Check

that

fuel

pressure

cor-

responds

to

specifications

listed

in

Table

c

.

"

If

system

pressure

is

low,

repeat

test

whilegradually

pinching

off

return

hose

.

Pressure

should

rise

rapidly

.

If

not,fuel

pump

is

most

likely

faulty

.

"

If

system

pressure

is

too

high,

check

return

line

from

pressure

regulator

to

tank

.

Check

for

kinks

in

hose

.

Blow

compressed

air

through

line

to

check

for

block-

ages

.

If

no

faulty

canbe

found,

pressure

regulator

is

most

likely

faulty

.

See

130

Fuel

Injection

for

testing

and

replacementprocedures

.

Table

c

.

Fuel

Pressure

Specifications

Engine

1

Fuel

pressure

4-cylinder

M42/M44

3

.0

:e

0

.06

bar(43

.5

±0

.9

psi)

6-cylinder

M50/S50US

3

.0

:j-

0

.06bar(43

.5

t0

.9

psi)

M52/S52US

3

.5

t

0

.06

bar

(51

t0

.9psi)

CA

UTION-

Do

not

use

compressed

air

above

40

psi

to

blow

out

fines

or

components

.

Interna¡

damage

to

com-

ponents

may

result

.

4

.

When

finished,

disconnect

pressure

gauge

.

FUEL

PUMP

Fuel

delivery

volume,

testing

1

.

Disconnect

return

line

from

fuel

rail

in

engine

compart-

ment

.

2

.

Connect

a

length

of

hose

to

fitting

on

fuel

rail

and

place

open

end

of

hose

in

a

suitable

container

for

catching

fuel

(2-quart

capacity)

.

3

.

Run

fuel

pump

for

exactly

30

seconds

as

described

earlier

under

Operating

fuel

pump

for

tests

and

mea-

sure

fuel

collected

.

Refer

to

Table

d

.

WARNING-

Table

d

.

Fuel

Pump

Delivery

Specifications

Fuel

under

pressure

is

present

duringthe

test

.

Use

I

Engine

Delivery

rate

(30

seconds

@

12V)

hose

clamps

at

all

connections

.

4-cylinder

M42/M44

0

.875

fter

(0

.93

qt)

6-cylinder

M50/S50US

0

.875

fter(0

.93

qt)

M52/S52US

~

1

.12

liter

(1

.16

qt)

4

.

When

finished

testing,

reconnect

fuel

line

.

Tighten

all

hose

clamps

.

NOTE-

It

is

common

practice

to

replace

the

fuel

filter

any

time

the

fuel

pump

unit

is

replaced

.

Page 197 of 759

Cooling

System

Pressure

Test

If

the

engine

overheats

and

no

other

cooling

system

testsindicate

trouble,

the

radiator

may

have

some

pluggedpassag-

A

cooling

system

pressure

test

is

used

to

check

for

internal

es

that

are

restricting

coolant

flow

.

leaks

.

Some

of

the

common

sources

ofinternal

leaks

are

a

faulty

cylinder

head

gasket,

a

cracked

cylinder

head,

or

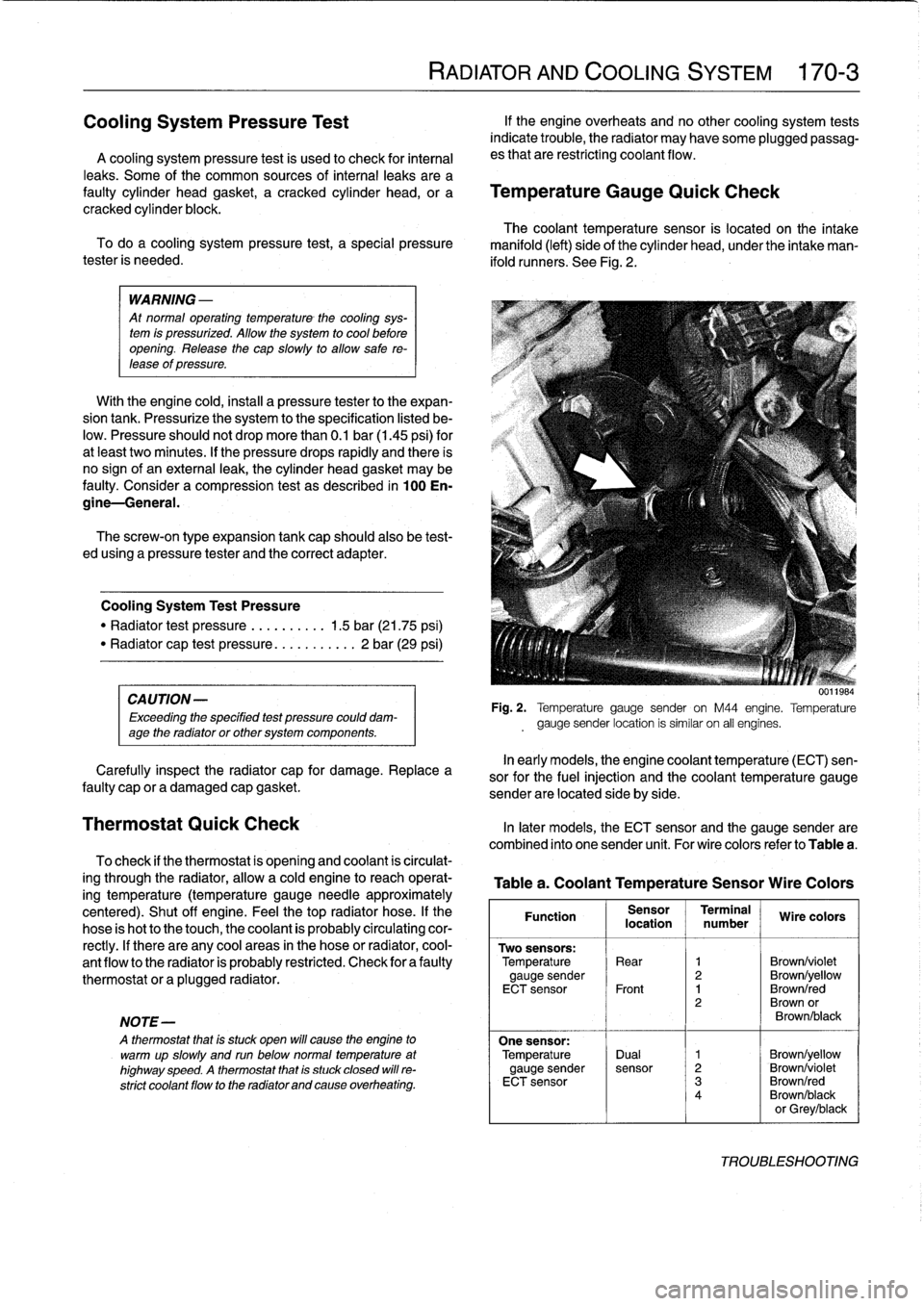

a

Temperature

Gauge

Quick

Check

cracked

cylinder

block

.

The

coolant

temperature

sensor

is

located

on

the

intake

To

doa

cooling

system

pressure

test,

a

special

pressure

manifold

(left)

side

of

the

cylinder

head,

under

the

intake

man-

tester

is

needed

.

ifold

runners

.

See

Fig

.

2

.

WARNING

-

At

normal

operating

temperature

-

the

cooling

sys-

tem

is

pressurized

.

Allow

the

system

to

cool

before

opening

.

Release

the

cap

slowly

to

allow

sale

re-

tease

of

pressure

.

With

the

engine

cold,instan

a

pressure

tester

to

the

expan-

sion

tank

.

Pressurize

thesystem

to

the

specification

listed

be-

low

.

Pressure

should

not

drop

more

than

0

.1

bar

(1

.45

psi)

for

at

leakt

two

minutes

.

If

the

pressure

drops

rapidly

and

there

is

no

sign

of

an

externa¡

leak,

the

cylinder

head

gasket

may

be

faulty

.

Considera

compression

test

as

described

in

100

En-

gine-General

.

The

screw-on

type

expansion

tank

cap

should

also

be

test-

ed

using

a

pressure

tester

and

the

correct

adapter

.

Cooling

System

Test

Pressure

"

Radiator

test

pressure

.........

.

1

.5

bar

(21

.75

psi)

"

Radiator

cap

test

pressure

..

.

........

2

bar

(29

psi)

CA

UTION-

Exceeding

the

speclfied

test

pressure

could

dam-

age

the

radiatoror

other

system

components

.

Carefully

inspect

the

radiator

cap

for

damage

.

Replace

a

faulty

cap

or

a

damaged

cap

gasket

.

Thermostat

Quick

Check

In

later

models,

the

ECT

sensor

and

the

gauge

sender

are

combined

into

one

sender

unit

.

For

wire

colors

refer

to

Table

a

.

To

check

if

the

thermostat

is

opening

and

coolant

is

circulat-

ing

through

the

radiator,

allow

a

cold

engine

to

reach

operat-

ing

temperature

(temperature

gauge

needieapproximately

centered)

.

Shut

off

engine

.

Feel

the

top

radiator

hose

.

If

the

hose

is

hot

to

the

touch,

the

coolant

is

probably

circulating

cor-

rectly

.

If

there

are

any

cool

areas

in

the

hose

or

radiator,

cool-

ant

flow

to

the

radiator

is

probably

restricted

.

Check

for

a

faulty

thermostat

or

aplugged

radiator

.

NOTE-

A

thermostat

that

is

stuck

open

will

cause

the

engine

to

warmup

slowly

and

run

belownormal

temperature

at

highway

speed

.

A

thermostat

that

is

stuck

closed

will

re-

strict

coolant

flow

to

the

radiator

and

cause

overheating

.

RADIATOR

AND

COOLING

SYSTEM

170-

3

U

.¡ig

.v

Fig

.

2

.

Temperature

gauge

sender

on

M44

engine

.

Temperature

gauge

sender

location

is

similar

on

al]

engines

.

In

early

models,

the

engine

coolant

temperature

(ECT)

sen-

sor

for

the

fuel

injection

and

the

coolant

temperature

gauge

sender

are

located

side

by

side

.

Table

a

.

Coolant

Temperature

Sensor

Wire

Colors

Function

Sensor

Terminal

Wire

colors

location

number

Two

sensors

:

Temperature

Rear

1

Brown/violet

gauge

sender

2

Brown/yellow

ECT

sensor

Front

1

Brown/red

2

Brown

or

Brown/black

One

sensor

:

Temperature

Dual

1

Brown/yellow

gauge

sender

sensor

2

Brown/violet

ECT

sensor

3

Brown/red

4

Brown/black

or

Grey/black

TROUBLESHOOTING

Page 648 of 759

8299

1

/~

EXCEPT

BRAKE

~J

1997

FLUID

IND

A23

~

.

A16

I

I

SRS

IND

A17

81

18

B

B24

J,

CHARGE

PARK

IND

BRAKE

IND

CHECK

ENGINE

IN.

LEFT

TURN

IND

RIGHT

TURN

IND

1997

ONLY

FUEL

CONSUMPTION

METER

CHECK

IND

SEAT

FRONT

BELT

10

.

LT

INDIND

HIGH

BEAM

IND

FUEL

RESERVE

IND

FUEL

GAUGE

ILL

UM

A22

25

~

(3

USED)

EXCEPT

y

28

7992

TEMPGAUGE

INSTRUMENT

CLUSTER

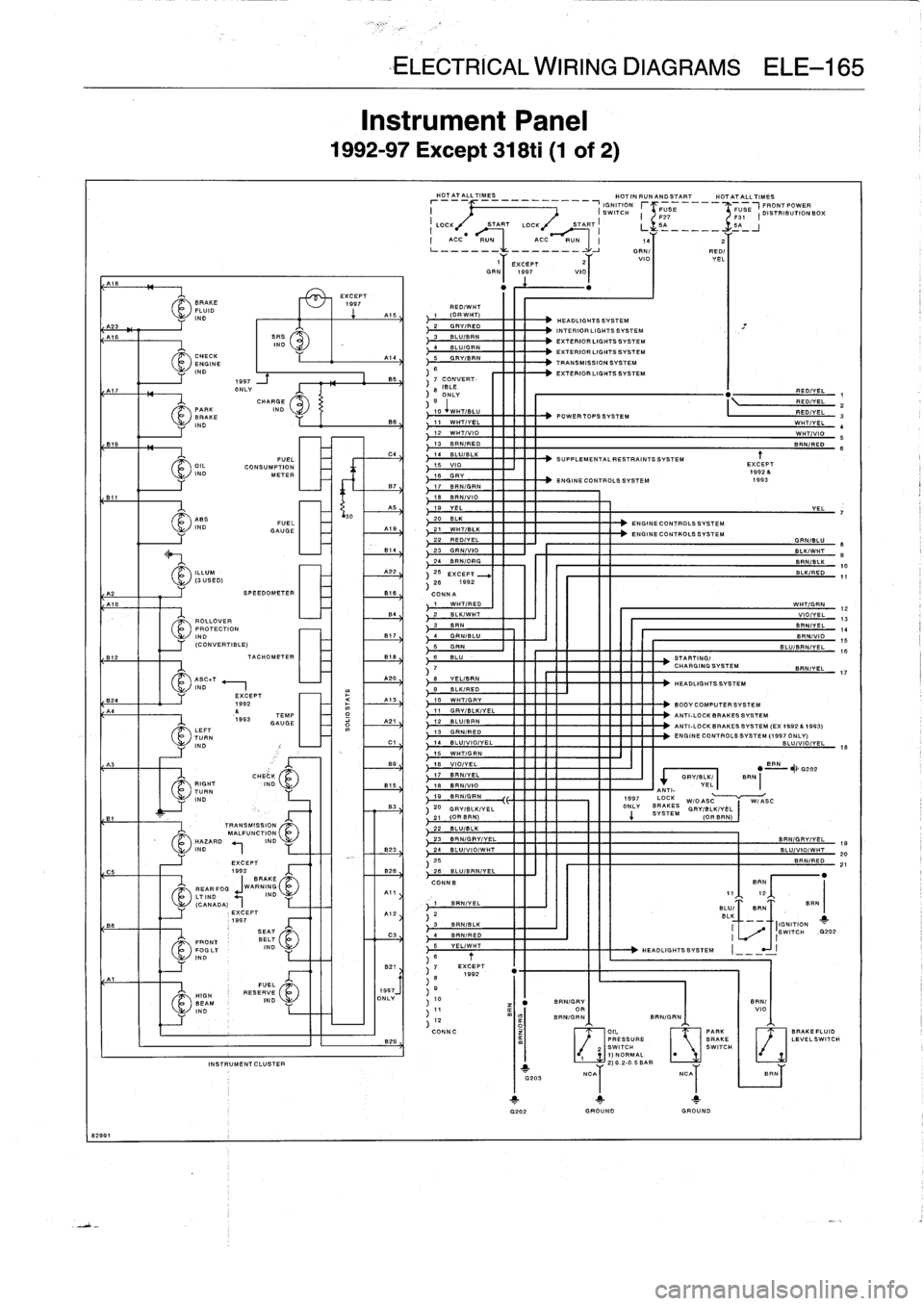

InstrumentPanel

1992-97

Except

318ti

(1

of

2)

B

-ELECTRICAL

WIRING

DIAGRAMS

ELE-165

HOTATALLTIMES

________

HOT

IN

RUNAND

START

HOTATALLTIMES

IGNITION

r

FUSE

FUSE

I

FRONT

UTION

I

(SWITCH

F21

~F31

DISTRIB1000%

LOCK

START

LOCK

START

LL

I

5

_A

_-__-

ACC

RUN

ACC

RUN

14

2

L---

-------

-

-

OR

N1

RED/

T

V

YEL

11

EXCEPT

2

lo

GRN

1997

VIO

RED/WHT

1

(ORWHT)

2

GRYIRED

3

BLU/BRN

4

BLU/GRN

5

GRVIBRN

BS

7

CONVERT-

8

ISLE

ONLY

HEADLIGHTS

SYSTEM

INTERIOR

LIGHTS

SYSTEM

EXTERIOR

LIGHTS

SYSTEM

EXTERIOR

LIGHTS

SYSTEM

TRANSMISSION

SYSTEM

EXTERIOR

LIGHTS

SYSTEM

9

I

iw

.TIBLU

POWERTOPSSYSTEM

11

WHT/YEL

12

WHT/VIO

13

BRN/RED

14

BLU/BLK

15

VIO

16

GRY

-

ENGINE

CONTROLS

SYSTEM

17

BRN/GRN

18

BAN

/Vlo19

YEL

20

BLK

ENGINE

CONTROLS

SYSTEM

A79

21

WHT/BLK

22

RED/YEL

814

23

GRNIVIO

24

BRNIORG

SUPPLEMENTAL

RESTRAINTS

SYSTEM

SPEEDOMETER

816

CONNA

1

WHTIRED

B4

~2

BLK/WHT

ROLLOVER

33

8R~N

PROTECTION

IND

B17

4

GRN/BLU

(CONVERTIBLE)

5

GRIN

TACHOMETER

B18

6

BLU

STARTING/

7

CHARGINGSYSTEM

A20

8

YELIBRN

B

-K/FED

10

WHTIGRY

11

GRYIBLK/YEL

12

BL

LISP

N13

GRN/PED

14

BLU/VIO/YEL

15

WHT/GRN

89

16

VIO/YEL

BRN

"

~I

G202

17

BRNIYEL

GRY/BLK,

BFN

15

18

BN/VIO

VEL

B

ANT

19

BRNIGRN

1997

LOCK

~`r~i

j

W/OASCW/ASO

83

20

GRYIBLK/VEL

ONLY

SYES

4

STEM

GRV/BLK/VEL

21

(ORBRN)

(ORBRN)

22

BLU/BLK

23

BRN/GRV/VEL

BRNIGRVIVEL

19

BRN/GRV

OR

BRN/GRN

HEADLIGHTS

SYSTEM

BODYCOMPUTER

SYSTEM

ANTI-LOCK

BRAKESSYSTEM

ANTI-LOCK

BRAKESSYSTEM

(EX

1992

A1993)

ENGINE

CONTROLS

SYSTEM

(1997

ONLY)

BLU/VIO/YEL

J

EXCEPT

1

.92

.

1993

BIN/

VIO

BRN/GRN

11

OIL

[

._~]

PARK

RA11FL11

AL.^

SWITCH

I

PRESSURE

BRAKE

LEVELSW

U

ITCH

SWITCH

111

G202

GROUND

GROUND

REDIYELRED/YELRED/YEL

WHTIYEL

WHT/VIO

BRN/RED

YEL

GRN/BLU

BLKIWHTBRN/BLK

BLK/RED

WHTIGRN

VIO/YEL

BRNIYELBRN/VIO

BLU/BRNIYEL

BRN/YEL

e9

0

11

1213

141516

Page 751 of 759

2

INDEX

Brakes

(cont

.)

pressure

bleeding

brakes

(except

cars

wíth

AST)

340-3

troubleshooting

340-1

Brushes,

alternator

See

Battery,

starter,

alternator

Bulbs

See

Exterior

lighting

See

also

Instruments

Bumpers

See

Exterior

trim,

bumpers

C

CamberSee

Steering

and

wheel

alignment

Camshaft

See

Cylinder

head

and

valvetrain

Camshaft

position

sensor

See

Ignition

system

Camshaft

timing

chain

general

information

117-1

camshaft

timingchain,

4-cylinder

117-

2

camshaft

timing

chains,6-cylinder

117-6

camshaft

timing

chain,

removing

(4-cylinder

engines)

117-2

camshaft

timing

chains,

removing

(6-cylinder

engines)

117-7vanos

(variable

valve

timing)

117-14

control

unit,

removing

117-16system

operation,

testing

117-14

Caster

See

Steering

andwheel

alignment

Catalytic

convertor

See

Exhaustsystem

Cautions

viü

Center

bearing

See

Driveshaft

Center

console

See

interior

trim

Central

body

electronics

(ZKE

IV)

515-8

Central

locking

system

(ZVM)

515-7

Centrallocking

and

anti-theft

general

information

515-1

door

handles

and

Iocks

515-1

door

striker,

replacing

515-6

front

door

handle,

removing/

installing

515-3

front

door

lock,

removing/installing

515-1

rear

door

handle,

removing/installing

515-5

rear

door

lock,

removing/installing

515-4

EWS

II

control

module,

replacing

515-10

EWS

II

ring

antenna,

replacing

515-10

EWS

II

transmitter/receiver

module,

replacing

515-11

locking

system

and

electronic

immobilization

515-7

luggage

compartment

locking

actuator,

removing/installing

515-6

Clutch

general

information210-1

clutch

hydraulic

system,

bleeding

and

flushing

210-2

clutch,

inspecting

and

installing

210-5

clutch

master

cylinder,

replacing

210-2

clutch,

removing

210-4

clutch

slave

cylinder,

replacing

210-3

transmission

pilot

bearing,

replacing

210-6

Clutch

fluid

See

Maintenance

program

Coil

See

Ignition

system

Coilspring

See

Rear

suspension

Component

locations

See

Electrical

component

locations

Compressor

See

Air

conditioning

Compressor

clutch

See

Air

conditioning

Condenser

See

Air

conditioningControl

arms

See

Front

suspension

See

also

Rear

suspension

Convertible

top

general

information

541-1

manual

convertible

top

541-1

lid

release

mechanism

541-2

replacing

541-2

visor

latch

541-1

visor

latch

píate

541-1

power

convertible

top

541-2

drive

motor,

replacing

541-7

emergency

operation

541-7

front

latching

mechanism

541-4

lid

541-9

replacing

541-5

visor

latch

541-4

visor

latch

motor541-5

visor

latch

plate

541-4

rollover

protection

system

541-9

Coolant

(Anti-freeze)

See

Maintenance

program

Coolant

pump

See

Cooling

system

Cooling

system

general

information

170-1

cooling

fan,

replacing

170-8

coolant

pump,

replacing

170-10

coolant

pump

and

thermostat170-1

coolant,

draining/filling

170-5

cooling

fans

170-2

cooling

fan,

testing

170-4

cooling

system

service

170-5

cooling

system,

bleeding

(radiator

with

integral

expansion

tank)

170-6

cooling

system

pressure

test

170-3

electric

cooling

fan,

replacing

170-8

radiator,

removing/installing

170-11

Cooling

system

(cont

.)

radiator

and

expansion

tank

170-1

radiator

service

170-11

temperature

gauge

quick

check170-3

thermostat

quick

check

170-3

thermostat,

replacing

170-9

troubleshooting

170-2

warnings

and

cautions

170-2Crankshaft

position/rpm

sensor

See

Ignition

system

Crash

sensor

See

Airbag

system

(SRS)

CV

joint

See

Maintenance

program

See

also

Rear

suspension

Cylinder

head

and

valvetrain

general

information

116-1

camshaft116-7

camshafts,

removing/installing

(M42

engine)

116-1camshafts,

removing/installing

(M44

engine)

116-3

camshafts,

removing/installing

(6-cylinder

engine)

116-4

cylinder

head,

disassembly/assembly

116-1

cylinder

head

and

valvetrain,

reconditioning

116-7

cylinder

head

116-7

hydraulic

cam

followers,

checking

and

replacing

(M42

and

al]

6-cylinder

engines)

116-9

hydraulic

valve

adjusters,

checking

and

replacing

(M44

Engine)

116-8

valve

guides

116-10

valveseats

116-12

valve

springs

116-12

valve

stem

oil

seals

116-11

valves

116-11

valves,

leak

test

116-11

valves,removing/installing

116-6

Cylinder

head

removal

and

installation

general

information

113-1

cylinder

head,

removing/installing

(4-

cylinder

engine)

113-1

cylinder

head

(6-cylinder

engine),

removing/installing

113-10

Dashboard

See

Interior

trim

Deck

lid

See

Trunk

lid

Defogger

See

Heating

Differential

See

Final

drive

DISA

(dual

resonance

intake

system)

See

Fuel

injection

See

also

Engine-general

DME

(digital

motor

electronics)

See

Ignition

system

See

alsoFuel

injection

Page 753 of 759

4

INDEX

Evaporator

See

Air

conditioning

EWS

(Electronic

immobilization

system)

515-8

Exhaust

system

See

also

Maintenance

program

general

information

180-1

exhaust

manifolds,

removingAnstalling

180-5

exhaustsystem,

removing/installing

180-3

Expansion

valve

See

Air

conditioning

Exterior

lighting

general

information

630-1

center

brake

light

housing,

replacing

(4-door

and

coupe

models)

630-5

foglight

assembly,

removing/installing

630-3

front

turn

signal

assembly,

removing/

installing

630-4

headlight

assembly,removing/

installing

630-2

headlight

bulb,

replacing

630-1

license

plate

light,

removing/installing

630-6

side

marker

lights

630-4

taillight

assembly,

removing/installing

630-5

taillight

bulbs,

replacing

630-4

Exterior

trim,

bumpers

general

information

510-1

BMW

embiem,

removing/installing

510-7

body

side

molding,

replacing

-7

bumper

height,

adjusting

510-6

front

bumper,

removing/installing

510-3

front

bumper

impact

absorber,

replacing

510-4

front

panel,

removing/installing

510-7

outside

rear

view

mirrors

510-1

mirror

housing,

removing/installing

510-1

mírror,

removing/installing

510-2

mirror

glass,

replacing

510-1

radiator

grille,

removing/installing

510-7

rear

bumper,

removingfinstalling

510-

4

rear

bumper

impact

absorber,

replacing

510-4

F

Fenders,

engine

hood

general

information

410-1

front

fenders

410-1

front

fender,

removing/installing

410-1

hood

aligning

410-4

hood,

raising

to

service

position

410-2

hood

release

cable

and

latches,

adjusting

410-4

hood,

removing/installing

410-3

Finaldrive

general

information

331-1

final

drive

se

rvice

331-1

flange

oil

sea¡,

replacing

331-2

inputshaft

oil

sea¡,

replacing

331-3

oil,

draining/filling

331-1

oil

seals331-1

removing/installing

331-3

Final

drive

carrier

See

Rear

suspension

Firing

order

See

Ignition

system

Flexdisc

See

DriveshaftFluids

and

lubricants

See

Maintenance

program

Foglight

See

Exterior

lighting

Front

suspension

general

information

310-1

ball

joint

See

outer

control

arm

ball

joint

control

arm,

removing/installing

310-5

control

arm

bushing,

replacing

310-7

control

arms

310-5

front

wheel

bearing,

replacing

310-8

front

wheel

bearings

310-8

outer

control

arm

ball

joint,

replacing

(except

M3)310-6

ride

height

310-4shock

absorbers

and

springs

310-2

stabilizer

bar

310-9

stabilizer

bar,

removing/installing

310-9

strut

assembly,disassembling/

assembling310-4

strut

assembly,

removing/installing

310-2subframe

crossmember

310-9subframe

crossmember,

removing/

installing

310-9

Fuel

injection

general

information

130-2

basic

engine

settings

130-2

principies

of

operatínn

130-2

Bosch

DME

Ml

.7

component

tests

and

repairs

130-14

air

floiv

sensor,testing/replacing

130-14

engine

coolant

temperature

(ECT)

sensor,

testing/replacing

130-15

¡dle

speed

control

valve,

testing/

replacing

130-16

throttle

position

sensor

(TPS),

testing/replacing

130-16

Bosch

DME

M3

.1

and

M3

.3

.1

component

tests

and

repairs

130-17

engine

coolant

temperature

(ECT)

sensor,

testing/replacing

130-18

¡dle

speed

control

valve,

replacing

130-21

¡dle

speed

control

valve,

testing

130-

20

intake

air

temperature

(IAT)

sensor,

testing/replacing

130-19

mass

air

flow

sensor130-17

Bosch

DME

M3

.1

and

M3

.3.1

(cont)

mass

air

flow

sensor

(hot

film)

testing/replacing

130-18

mass

air

flow

sensor

(hot

wire)

testing/replacing

130-17

throttle

position

sensor

(TPS),

testing/replacing

130-19

Bosch

DME

M5

.2

component

replacement

130-21engine

coolant

temperature

(ECT)

sensor,

replacing

130-22

ldle

speed

control

valve,

replacing

130-23

intake

air

temperature

(IAT)

sensor,

replacing

130-22

mass

air

flow

sensor,

replacing

130-

22

throttle

position

sensor

(TPS),

replacing

130-22

DISA

(dual

resonance

intake

system)

130-3

ECM

pin

assignments130-26

electrical

checks

andcomponent

testing

130-7engine

control

module(ECM),

accessing

130-26

fuel

delivery

tests

130-9

fuel

pressure

regulator

response

to

engine

load,

testing

130-11

fuel

pressure

regulator

130-13

fuel

pressure

regulator,

replacing

(fuel

rail

mount)130-13

fuel

pressure

regulator,

replacing

(under

car

mount)130-14

fuel

pump

relay,

testing

130-7

fuel

rail

and

injectors,

checking

130-11

fuel

rail

and

injectors,

replacing

130-

12

fuel

delivery

tests

(cont

.)

operatíng

fuel

pump

for

tests

130-9

relieving

fuel

pressure

and

connecting

fuel

pressure

gauge

130-10

residual

fuel

pressure,

testing

130-10

main

relay,

testing

130-7on-board

diagnostics

(OBD)

and

fault

diagnosis

130-4

oxygen

sensor,

testing

(Bosch

systems

only)

130-8

secondary

air

injection

130-5

Siemens

MS

41

.1

component

replacement

130-23

engine

coolant

temperature

(ECT)

sensor,

replacing

130-25

¡dle

speed

control

valve,

replacing

130-26

lntake

air

temperature

(IAT)

sensor,

replacing

130-25

mass

air

flow

sensor,

replacing

130-

25

throttle

position

sensor

(TPS),

replacing

130-26warnings

and

cautions

130-6

Fuel

filter

See

Maintenance

program

Page 754 of 759

WARNING

Your

common

sense,

good

judge-

ment,

and

general

alertness

are

cru-

cial

tosafe

and

successful

service

work

.

Before

attempting

any

work

on

your

BMW,

read

the

warnings

and

cautions

on

page

vi¡

and

the

copyright

page

at

the

frontof

the

manual

.

Review

these

warnings

and

cautions

each

time

you

prepare

to

work

on

your

BMW

.

Please

also

read

any

warnings

and

cautions

that

accom-

pany

the

procedures

in

the

manual

.

Fuel

pressure

regulator

See

Fuel

injection

Fue]

pump

general

information

160-1

electrical

tests

160-7

power

consumption,

testing

160-7

delivery

tests160-8

delivery

volume,

testing

g

160-9

electrical

circuit,

checking

160-7

fuse

and

relay

160-6

level

sender

See

pump/fuel

leve¡

sender

operating

fuel

pump

for

tests

160-6

pump/fuel

level

sender

(left

side),

removing/installing

160-6

pump/fuel

leve¡

sender

(right

side),

removing/installing

160-5

relieving

fuel

pressure

and

connecting

fue¡

pressure

gauge

160-8

Fueltank

and

lines

general

information

160-1

draining

160-2

evaporative

control

system

160-4

leve¡

senders,

testing

160-5

removing/installing

160-3

Fundamentals

for

the

do-it-yourself

owner

general

information

010-1

advice

for

the

beginner

010-4

cleanliness

010-4

electrical

testing

010-6

gaskets

and

seals

010-5

non-reusable

fasteners

010-5

planning

ahead

010-4

tightening

fasteners

010-5

wire

repairs

010-6

buying

parts

010-6

genuine

BMW

parts

010-6

information

you

need

to

know

010-7

non-returnable

parts

010-7

emergencies

010-11brake

fluid

leve¡

010-13

car

will

not

start

010-11

changinga

tire

010-11

check

enginewarning

light

010-13

dim

Iights

010-13

jump

starting

car

010-12

low

o]I

pressure

010-13

overheating

010-12

Emergencies

(cont

.)

spare

parts

kit

010-14

towing

010-13

gettingstarted

010-2

lifting

thecar

010-3

raising

car

safely

010-3

safety

010-2

working

under

car

safely

010-4

how

to

use

this

manual

010-2

warnings,

cautions

and

notes

010-2

service

010-7

tools

010-7

basic

tool

requirements010-8

BMW

specialtools

010-11

feeler

gauges

010-10

jack

stands

010-9

oil

change

equipment

010-9

torque

wrench

010-10

volt-ohm

meter

(VOM)

or

Multi-

meter010-10

Fuses

See

Electrical

component

locations

G

Gaskets

See

Fundamentals

for

the

do-it-

yourself

owner

Gearshift

See

Gearshift

linkage

Gearshift

linkagegeneral

information

250-1

automatic

shiftlock,

checking

function

250-5

automatic

transmission

gearshift

250-

3

gear

position/neutral

safety

switch,

replacing

(automatic

transmission)

250-4

gearshift

lever,

installing

(manual

transmission)

250-2

gearshift

lever,

removing

(manual

transmission)

250-1

gearshift

mechanism,

adjusting

(automatictransmission)

250-3

manual

transmission

gearshift

250-1

shift

interlock,

checking

function

(automatic

transmission)

250-6Glass

See

Door

windows

Glove

compartment

See

Interior

trim

Grille

See

Exterior

trim,

bumpers

Guibo

(flex

disc)

See

Driveshaft

Handle,

door

See

Doors

Hardtop

See

Body-general

Headlight

See

Exterior

lighting

Headlight

switch

See

Switches

and

electrical

accessoriesHeater

box

See

Heating

Heater

core

See

Heating

Heater

valve

See

Heating

Heating

general

information

640-1

air

distribution

motors

640-9

air

distribution

motor,

replacing

(rotary

knob)

640-10

blower

motor,

removing/installing

640-1blower

motor

resistor

pack,

replacing

640-3

control

head

640-7

removing/installing

(digital-display)

640-8

removing/installing

(rotary

knob)

640-7

control

module

removing/installing

(digital-display)

640-8

removing/installing

(rotary

knob)

640-8

heater

box,

removing640-4

heater

core,

replacing

640-6

heater

core

temperature

sensor,

replacing

640-7

heater

valve,

replacing

640-3

rear

window

blower

(convertible

models)

640-10

reas

window

defogger

640-10sensor

fan

forinterior

temperature,

replacing

640-9warnings

and

cautions

640-11

Hood

See

Fenders,

engine

hood

Idle

speed

See

Maintenance

program

Idle

speed

control

valve

See

Fuel

injection

Ignition

switch

See

Switches

and

electrical

accessories

INDEX

5