fuel level BMW 318i 1992 E36 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1992, Model line: 318i, Model: BMW 318i 1992 E36Pages: 759

Page 185 of 759

160

Fuel

Tank

and

Fuel

Pump

GENERAL

.

.

.

.

.

.

...........

.

....

.

.

.

.

.

.

160-1

Operating

fuel

pump

for

tests

.

.

.

.

.

.

.......

.160-6

Fuel

Pump

Electrical

Tests

.

.

.

.

.

.

.

...

.

.

.

.

.

160-7

FUEL

TANK

AND

LINES

..

.

.

.

..........

160-2

Fuel

pump

electrical

circuit,

testing.

...

.

.

.

.

.

160-7

Fuel

tank,

draining

..

.

.

.

.

.

.

.

.

.

..........

160-2

Fuel

pump

power

consumption,

testing

.

.

.

.

.

.

160-7

Fuel

tank,

removing

and

installing

.........

160-3

Fuel

Delivery

Tests

....

.

.

.

...

.

.....

.

.

.

..

160-8

Fuel

Tank

Evaporative

Control

System

.....

160-4

Relieving

fuel

pressure

and

connecting

fuel

pressure

gauge

..

.

...........

.

.

.

..

160-8

FUEL

LEVEL

SENDERS

.

.

.

.

.

.......

.

.

.

160-4

System

pressure,

testing

.................

160-9

Fuel

level

senders,

testing

.

.

.

.

.

.......

.

.

.

160-5

Fuel

delivery

volume,

testing

.............

160-10

Fuel

leve¡

sender

and

fuel

pump

(right

side),

emoving

and

installing

.

.

.

.

.

.

160-5

TABLES

Fuel

leve¡

sender

(left

side),

a

.

FuelLeve¡

Sender

Resistances

...........

.

.

..

.160-5

removing

and

installing

.........

.

.

.

.

.

.

.

160-6

b

.

Fuel

Pump

Current

...

.................

..

...

160-8

c

.

Fuel

Pressure

Specifications

..............

.

..

160-10

FUEL

PUMP

.

.

.

................

.

.

.

.

.

.

.

160-6

d

.

Fuel

Pump

Delivery

Specifications

.........

.

..

160-10

Fuel

Pump

Fuse

and

Relay

.

.

.

....

.

.

.

.

.

.

.

160-6

GENERAL

This

repair

group

covers

service

information

specifically

for

The

cautions

and

warnings

on

this

page

should

beob

the

fuel

supply

system

.

Information

on

the

fue¡

injection

sys-

served

when

servicing

the

fuel

system

.

tem

is

covered

in

130

Fuel

Injection

.

NOTE-

Fue¡

filter

replacement

is

covered

in

020

Maintenance

Program

.

WARNING

-

"

The

fuel

system

is

designed

to

retain

pressure

even

when

the

ignition

isoff

.

When

working

with

the

fuel

system,

loosen

the

fuel

lines

slowly

toal-

low

residual

fuel

pressure

to

dissipate

gradually

.

Avoid

spraying

fuel

.

"

Before

beginning

any

work

on

the

fuel

system,

place

a

tire

extinguisher

in

the

vicinity

of

the

work

area

.

"

Fuel

is

highly

flammable

.

When

working

around

fuel,

do

not

disconnect

any

wires

that

could

cause

electrical

sparks

.

Do

not

smoke

or

work

near

heaters

or

other

tire

hazards

.

"

Always

unscrew

the

fuel

tank

cap

to

release

pres-

sure

in

the

tank

before

working

on

the

tank

or

fines

.

"

Do

not

use

a

work

light

near

any

fuel

.

Fuel

may

spray

onto

the

hot

bulb

causing

a

tire

.

"

Make

sure

the

work

area

is

properly

ventifated

.

FUEL

TANK

AND

FUEL

PUMP

160-1

CAUTION-

"

Prior

to

disconnecting

the

battery,

read

the

bat-tery

disconnection

cautions

given

at

the

front

of

this

manual

onpage

viü

.

"

Before

making

any

electrical

tests

with

the

ignition

tumed

on,

disable

the

ignition

system

as

de-

scribed

in

120

Ignition

System

.

Be

sure

the

bat-tery

is

disconnected

when

replacing

components

.

"

To

prevent

damage

to

the

ignition

system

or

the

electronic

fuel

system

components,

including

the

control

unit,

aiways

connect

and

disconnect

wires

and

test

equipment

with

the

ignition

off

.

"

Cleanliness

is

essential

when

working

with

the

fuel

system

.

Thoroughly

clean

the

fuel

fine

unionsbefore

disconnecting

any

of

the

fines

.

"

Use

only

clean

tools

.

Keep

removed

parts

clean

and

sealed

or

covered

with

a

clean,

lint-free

cloth,

especially

if

completion

of

the

repair

is

delayed

.

"

Do

not

move

the

car

while

the

fuel

system

is

open

.

"

Avoid

using

high

pressure

compressed

air

to

blow

out

fines

and

componente

.

High

pressure

can

rupture

infernal

seals

and

gaskets

.

"

Always

replace

seals

and

O-rings

.

GENERAL

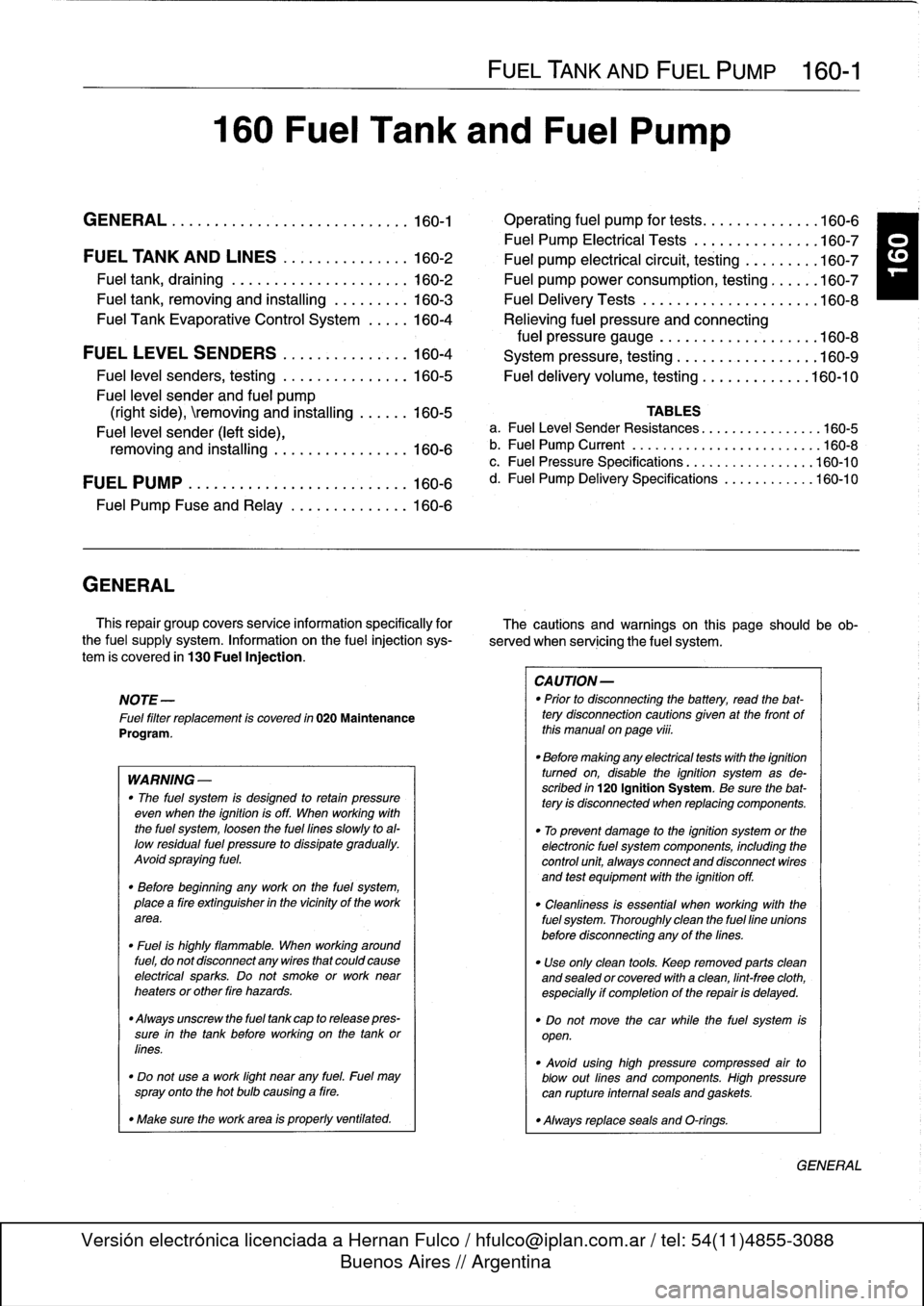

Page 187 of 759

2

.

Remove

fuel

tank

filler

cap

.

3

.

Remove

rearseat

cushion

and

pull

back

insulation

mats

to

expose

fuel

tank

access

covers

.

See

Fig

.

2

.

uui3140

Fig

.

2

.

Right

side

fuel

tank

access

cover

under

rear

seat

cushion

.

4

.

Remove

right

and

left

access

covers

to

expose

fuel

hoses

and

electrical

connections

at

tank

.

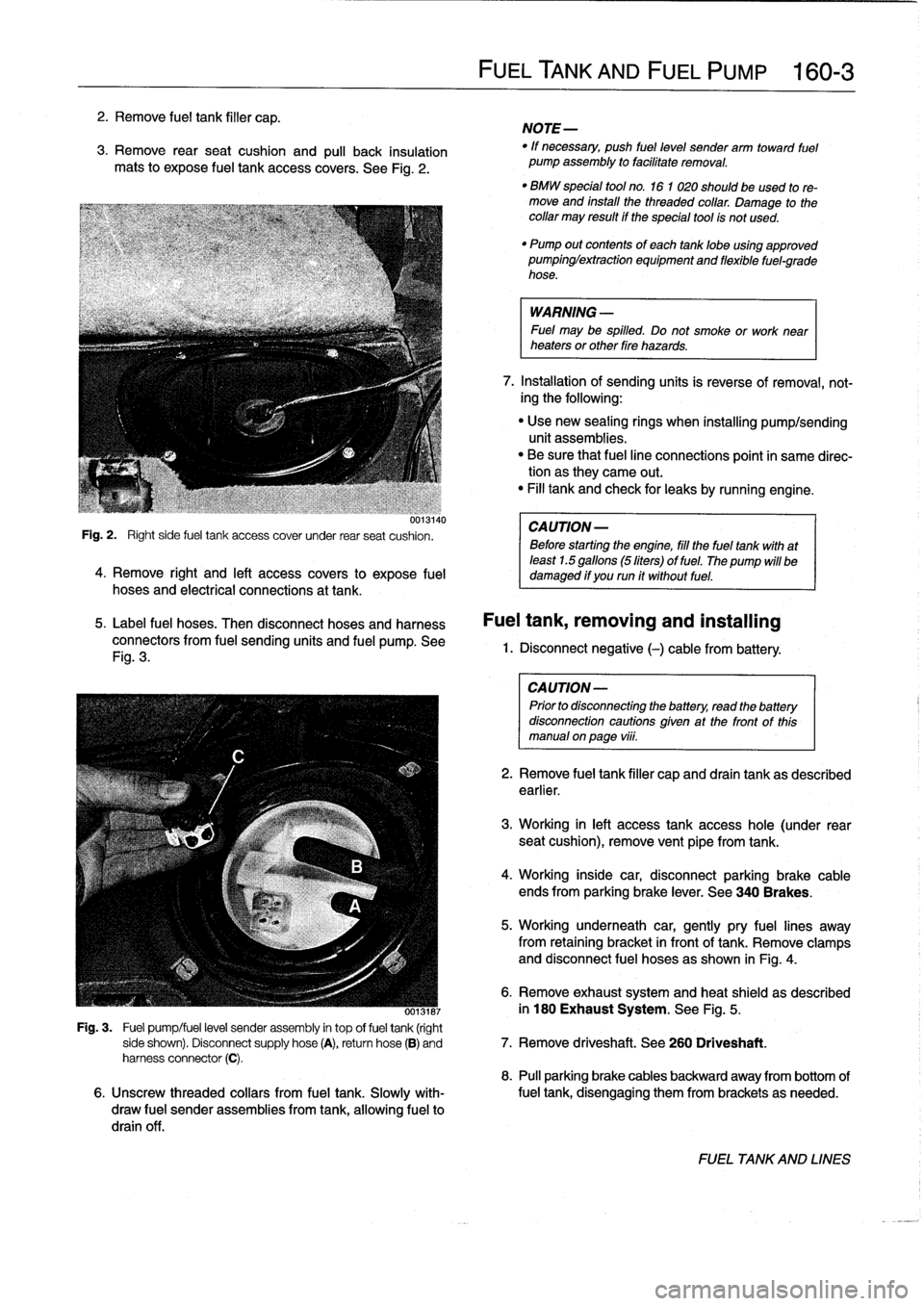

5

.

Label

fuel

hoses

.

Then

disconnect

hoses

and

harness

connectors

from

fuel

sending

units

and

fuel

pump

.

See

Fig

.

3

.

FUELTANK

AND

FUEL

PUMP

160-

3

NOTE-

"

If

necessary,

push

fuel

level

sender

arm

toward

fuel

pump

assembly

to

facilitate

removal

.

"

BMW

special

tool

no

.

16

1

020

should

beused

tore-

move

and

install

the

threaded

collar

.

Damage

to

thecollar

may

result

if

the

special

tool

is

not

used

.

"

Pump

out

contents

of

each

tanklobe

using

approved

pumpinglextraction

equipment

and

flexible

fuel-grade

hose

.

WARNING

-

Fuel

may

be

spilled

.

Do

not

smoke

or

work

near

heaters

or

other

fire

hazards

.

7

.

Installation

of

sending

units

is

reverse

of

removal,

not-

ing

the

following

:

"

Use

new

sealing

rings

when

installing

pump/sending

unit

assemblies

.

"

Be

sure

that

fuel

line

connections

point

in

same

direc-tion

as

they

carne

out

.

"

Fill

tank

and

check

for

leaks

by

running

engine

.

CA

UTION-

Before

starting

the

engine,

fill

the

fuel

tank

with

at

least

1.5

gallons

(5liters)

of

fuel

.

The

pump

will

be

damaged

if

you

run

it

without

fuel

.

Fuel

tank,

removing

and

installing

1.

Disconnect

negative

(-)cablefrom

battery

:

CAUTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manual

onpage

viii

.

2

.

Remove

fuel

tank

filler

capand

drain

tank

as

described

earlier

.

3

.

Working

in

left

access

tank

access

hole

(under

rear

seat

cushion),

remove

vent

pipe

fromtank

.

4

.

Working

inside

car,

disconnectparking

brake

cable

ends

from

parking

brake

lever

.

See

340

Brakes

.

5

.

Working

underneath

car,

gently

pry

fuel

lines

away

from

retaining

bracket

in

front

of

tank

.

Remove

clamps

and

disconnect

fuel

hoses

as

shown

in

Fig

.

4

.

6

.

Remove

exhaust

system

and

heat

shield

as

described

ooisiai

in

180

Exhaust

System

.

See

Fig

.

5

.

Fig

.

3

.

Fuel

pump/fuel

level

sender

assembly

in

top

offuel

tank

(right

side

shown)

.

Disconnect

supply

hose

(A),

return

hose

(B)

and

7

.

Remove

driveshaft

.

See

260

Driveshaft

.

harness

connector

(C)

.

8

.

Pull

parking

brake

cables

backward

away

from

bottom

of

6

.

Unscrew

threaded

collars

from

fuel

tank

.

Slowly

with-

fuel

tank,

disengaging

them

from

brackets

as

needed

.

draw

fuel

sender

assemblies

from

tank,allowing

fuel

to

drain

off

.

FUEL

TANKAND

LINES

Page 188 of 759

160-

4

FUEL

TANK

AND

FUEL

PUMP

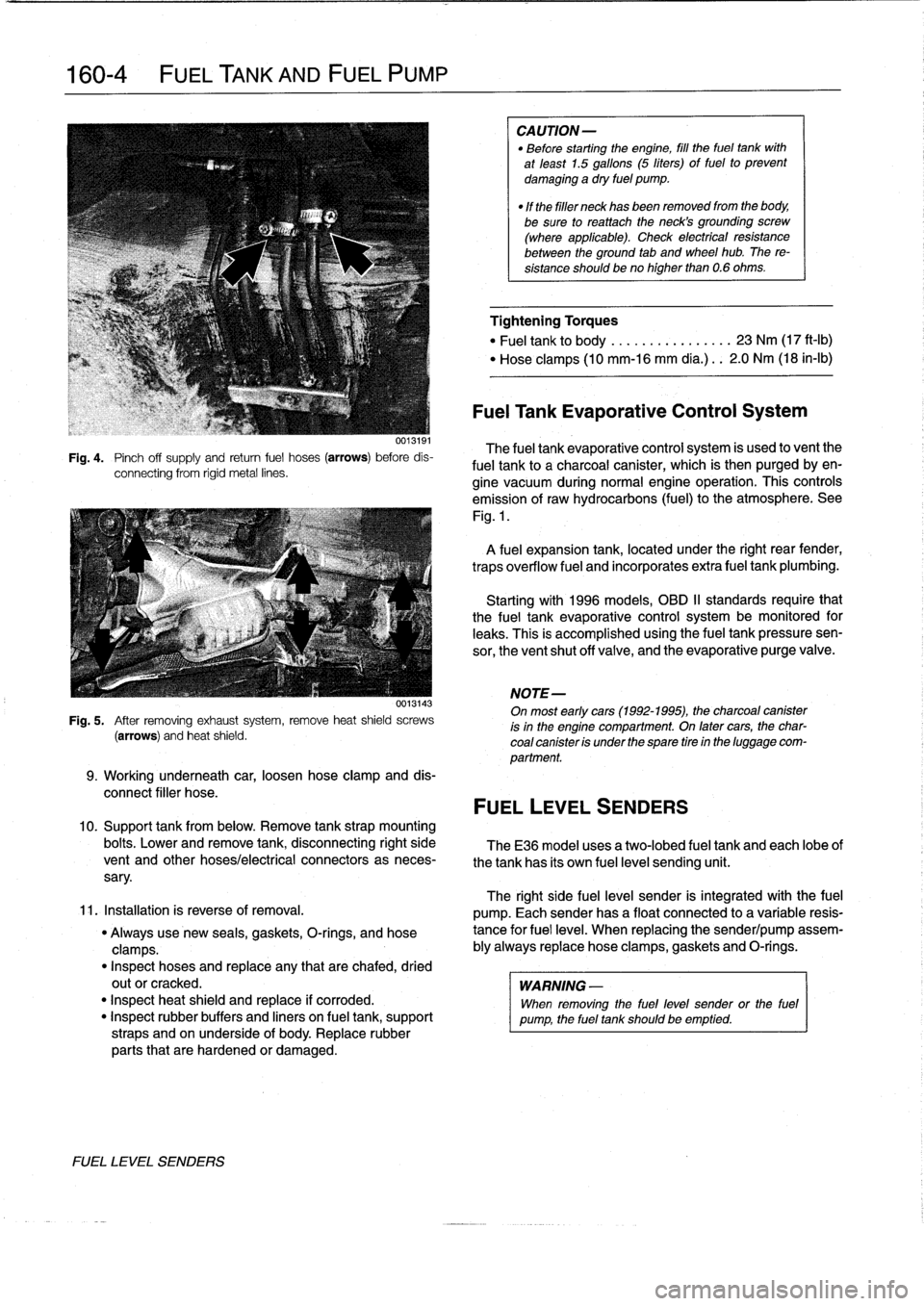

Fig

.

4

.

Pinch

off

supply

and

retum

fuel

hoses

(arrows)

before

dis-

connecting

from

rigid

metal

lines

.

0013143

Fig

.

5

.

After

removing

exhaustsystem,

remove

heat

shield

screws

(arrows)

and

heat

shield

.

9

.

Working

underneath

car,

loosen

hose

clamp

and

dis-

connect

filler

hose

.

10

.

Support

tank

from

below

.

Remove

tank

strap

mounting

bolts

.

Lower

and

remove

tank,

disconnecting

right

side

TheE36

model

uses

a

two-lobed

fuel

tank

and

each

lobeof

vent

and

other

hoses/electrical

connectors

as

neces-

the

tank

has

its

own

fuel

level

sending

unit

.

sary

.

11

.

Installation

is

reverse

of

removal

.

"

Always

use

new

seals,

gaskets,

O-rings,

and

hose

clamps

.

"

Inspect

hoses

and

replace

any

that

are

chafed,

dried

outor

cracked

.

"

Inspect

heat

shield

and

replace

if

corroded

.

"

Inspect

rubber

buffers

and

liners

on

fuel

tank,

support

straps

and

on

underside

of

body

.

Replace

rubber

parts

that

are

hardened

or

damaged

.

FUEL

LEVEL

SENDERS

CAUTION-

"

Before

starting

the

engine,

fill

the

fuel

tank

with

at

least

1.5

gallons

(5

liters)

of

fuel

to

prevent

damaging

a

dry

fuel

pump

.

"

If

the

filler

neck

has

been

removed

from

the

body,

be

sure

toreattach

theneck's

grounding

screw

(where

applicable)

.

Check

electrical

resistance

between

the

ground

tab

and

wheel

hub

.

The

re-

sistance

shouldbeno

higher

than

0

.6

ohms

.

Tightening

Torques

"

Fuel

tank

to

body

.............

...

23

Nm

(17

ft-Ib)

"

Hose

clamps

(10

mm-16

mm

día

.)

..

2

.0

Nm

(18

in-lb)

Fuel

Tank

Evaporative

Control

System

The

fuel

tank

evaporative

control

system

is

used

to

vent

the

fuel

tank

to

a

charcoal

canister,

which

is

then

purgedby

en-

gine

vacuum

during

normal

engine

operatíon

.

This

controls

emission

of

raw

hydrocarbons

(fuel)

to

the

atmosphere

.

See

Fig

.

1

.

A

fuel

expansion

tank,

located

under

the

right

rear

fender,

traps

overflow

fuel

and

incorporates

extra

fuel

tank

plumbing

.

Startingwith

1996

models,

OBD

II

standards

require

that

the

fuel

tank

evaporative

control

system

be

monitored

for

leaks

.

This

is

accomplished

usingthe

fuel

tankpressuresen-

sor,

the

ventshut

off

valve,

and

the

evaporative

purge

valve

.

NOTE-

On

most

early

cars(1992-1995),

the

charcoal

canister

is

in

the

engine

compartment

.

On

latercars,

the

char-

coal

canister

is

under

the

spare

tire

in

the

luggage

com-

partment

.

FUEL

LEVEL

SENDERS

The

right

side

fuel

leve¡

sender

is

integrated

with

the

fuel

pump

.

Each

senderhas

a

float

connected

to

a

variable

resis-

tance

for

fuel

leve¡

.

When

replacing

the

sender/pump

assem-

bly

always

replace

hose

clamps,gaskets

and

O-rings

.

WARNING

-

When

removing

the

fuel

level

sender

or

the

fuel

pump,

the

fuel

tank

should

be

emptied

.

Page 189 of 759

Fuel

leve¡

senders,

testing

Fuel

leve¡

sender

(right

side)

The

left

and

right

fuelleve¡

sending

units

are

wired

in

series

.

and

fuel

pump,

removing

and

installing

The

fuel

gauge

receives

a

signal

that

is

the

average

of

the

two

1

.

Disconnect

negative

(-)

cable

from

battery

.

input

values

.

1

.

Remove

rear

seat

cushion,

lift

up

insulation

mats,

andremove

both

fuel

tank

access

covers

.

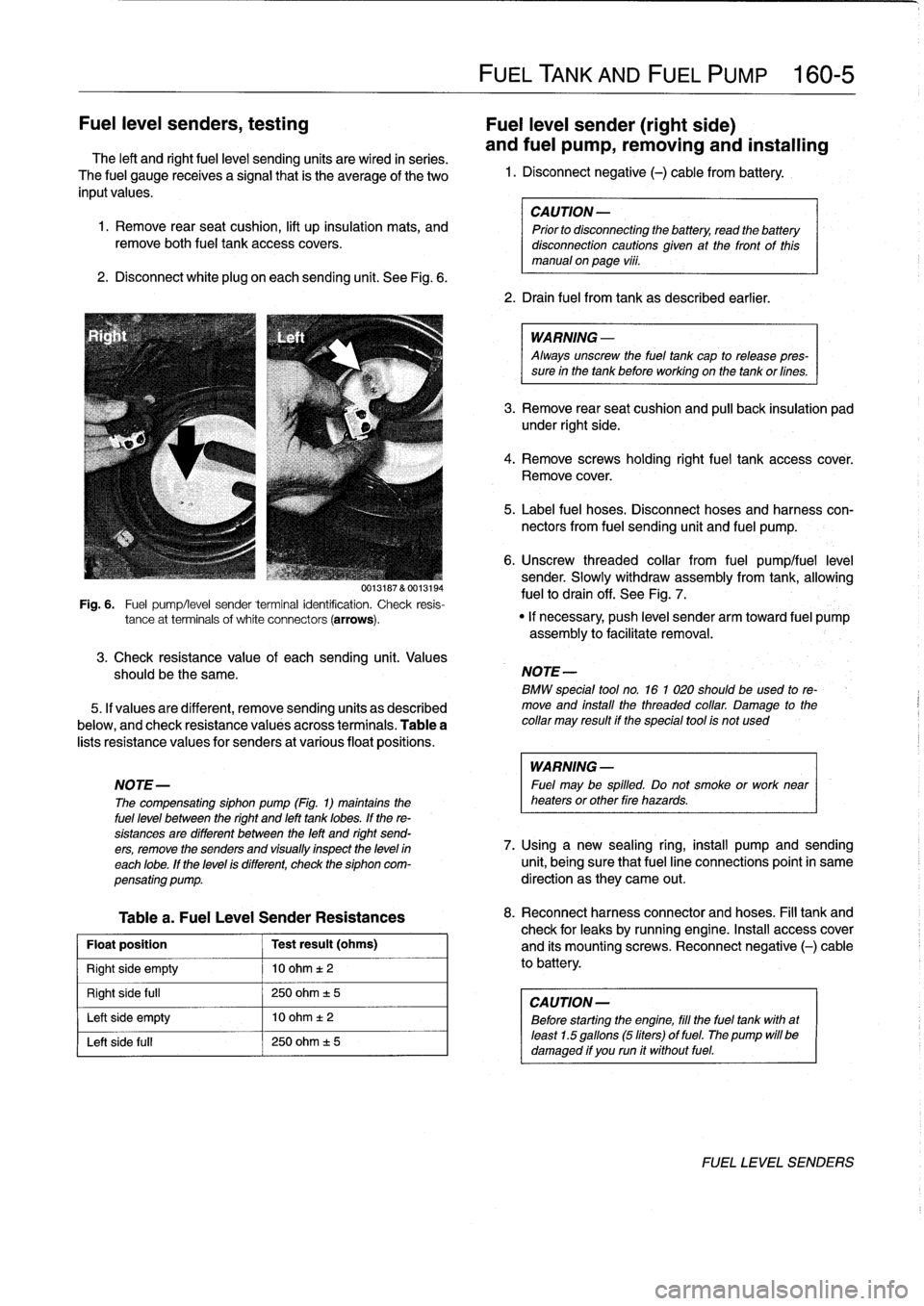

2

.

Disconnect

white

plug

on

each

sending

unit

.

See

Fig

.

6

.

3

.

Check

resistance

value

of

eachsending

unit

.

Values

should

be

the

same

.

5

.

If

valuesare

different,

remove

sending

units

as

described

below,

and

check

resistance

valuésacross

terminals

.

Table

a

lists

resistance

values

for

senders

at

various

float

positions

.

Table

a

.

Fuel

Leve¡

Sender

Resistances

Float

position

Test

result

(ohms)

Right

side

empty

10

ohm

t2

Right

side

full

250

ohm

±

5

Left

side

empty

10

ohm

t

2

Left

side

fui¡

250

ohm

±

5

FUEL

TANK

AND

FUEL

PUMP

160-

5

CAUTION

-

Prior

to

disconnecting

the

battery,

read

the

battery

disconnection

cautionsglven

at

the

front

of

this

manual

onpage

viii

.

2

.

Drain

fuel

from

tank

as

described

earlier

.

WARNING

-

Always

unscrew

the

fuel

tank

cap

to

release

pres-

sure

in

the

tank

before

working

on

the

tank

or

fines

.

3

.

Remove

rear

seat

cushion

and

pull

back

insulation

pad

under

right

side

.

4

.

Remove

screws

holding

rightfuel

tank

accesscover

.

Remove

cover

.

5

.

Label

fuel

hoses

.

Disconnect

hoses

and

harness

con-

nectors

from

fuel

sending

unit

and

fuel

pump

.

6

.

Unscrew

threaded

collar

from

fuel

pumplfuel

leve¡

sender

.

Slowly

withdraw

assembly

from

tank,allowing

fuelto

drain

off

.

See

Fig

.

7

.

0013187

&

0013194

Fig

.

6

.

Fuel

pump/leve¡

sender

terminal

identification

.

Check

resis-

tance

at

terminals

of

white

connectors

(arrows)

.

"

If

necessary,

push

leve¡

sender

arm

toward

fuel

pump

assembly

to

facilitate

removal

.

NOTE

-

BMW

special

tool

no

.

16

1

020

should

beused

to

re-

move

and

install

the

threaded

collar

.

Damage

to

the

collar

may

result

if

the

special

tool

is

not

used

WARNING

-

NOTE-

Fuel

may

be

spilled

.

Do

not

smoke

or

work

near

The

compensating

siphon

pump

(Fig

.

1)

maintains

the

heaters

or

other

fire

hazards

.

fuel

leve¡

between

the

right

and

left

tank

lobes

.

If

the

re-

sistances

are

different

between

the

left

and

right

send-

ers,

remove

the

senders

and

visually

inspect

the

leve)

in

7

.

Using

a

new

sealing

ring,

install

pump

and

sending

each

lobe

.

If

the

leve¡

is

different,

check

the

siphon

com-

unit,

being

sure

that

fuel

line

connections

point

in

same

pensating

pump

.

direction

as

they

carne

out

.

8

.

Reconnect

harnessconnector

and

hoses

.

Fill

tank

and

check

for

leaks

by

running

engine

.

Insta¡¡

access

cover

and

its

mountingscrews

.

Reconnect

negative

(-)

cable

to

battery

.

CAUTION

-

Before

starting

the

engine,

fill

the

fuel

tank

with

at

least

1

.5

gallons

(5liters)

of

fuel

.

The

pump

will

be

damaged

if

you

run

it

without

fuel

.

FUEL

LEVEL

SENDERS

Page 523 of 759

LEFT

-

LEFT

I

I

-

RIGHT

-

RIGHT

I

(

)

TAIL

(

)

TAIL

I

I

(

)

TAIL

(

)

TAIL

I

-

LIGHT

-

LIGHT

I

I

LIGHT

-

LIGHT

I

I

II

I

II

I

I

_

I

(

)

BACK-

LEFTUP

(

^

)

BRAKE

I

I

(

^

)

BACK

FIGHT

UP

(

_

)

BRAKE

LIGHT

LIGHT

LIGHT

LIGHT

I

I

II

I

I

______________J

______________J

64882

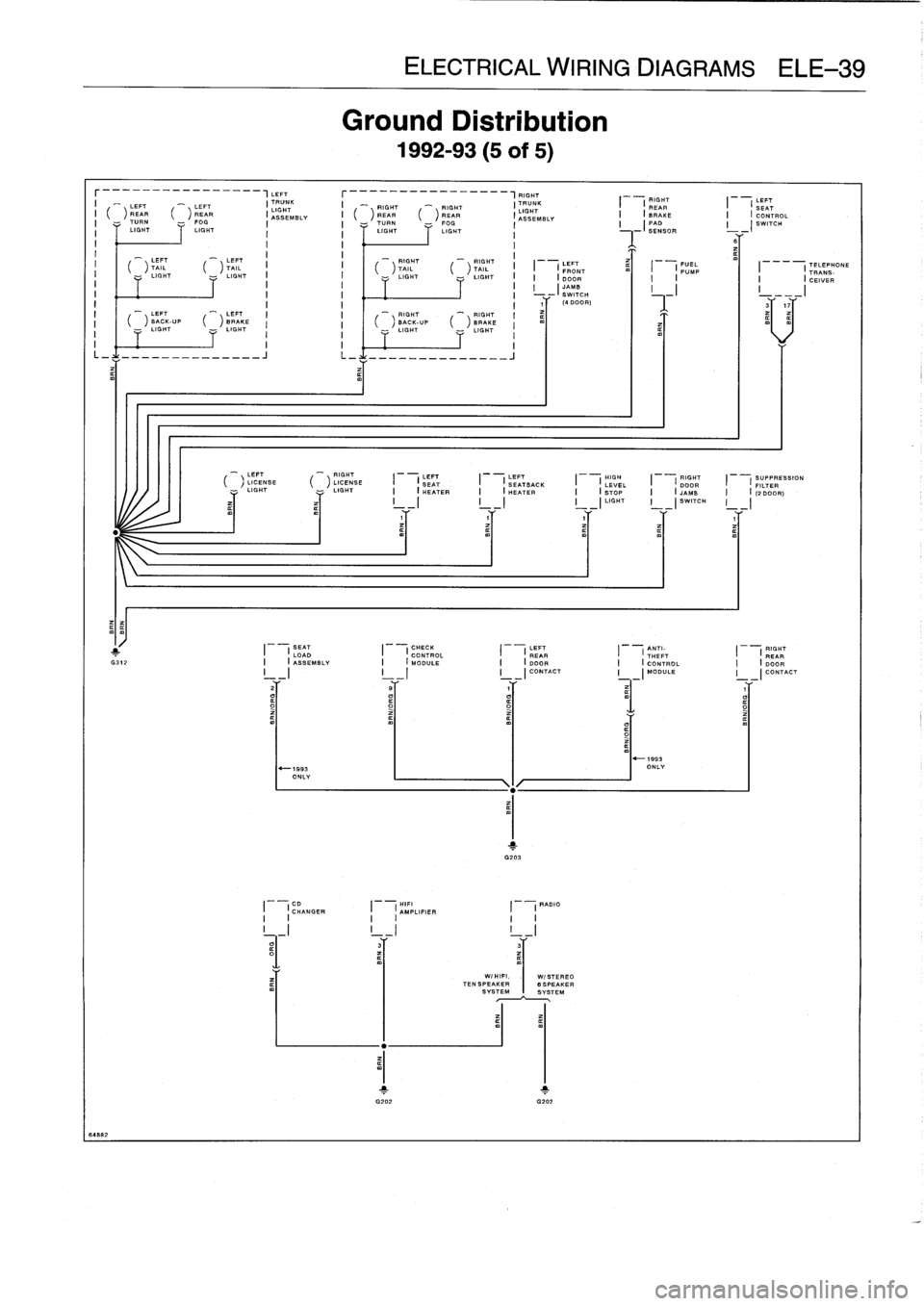

-

7993

ONLY

ELECTRICAL

WIRING

DIAGRAMSELE-39

Ground

Distribution

1992-93

(5

of

5)

,LEFT

rFIGHT

I

_

_

LEFT

"~LEFT

(TRUNK

I

TRUNK

I

RIGHT

LEFT

I

G

LIGHT

REAR

REAR

RIGHT

~'

RIGHT

I

I

REAR

I

(SEAT(ASSEMBLY

I

(

)

REAR

(

)

BEAR_

(ASSEMBLY

I

(BRAKE

I

(CONTROL

I

-

TURN

FOG

I

I

TURN

FOG

I

I

(

PAD

I

(

SWITCH

LIGHT

LIGHT

i

i

LIGHT

LIGHT

i

SENSOR

B

()

LEFT

LICENSE

(

)

LICENSE

I

(

SEAT

I

I

SEATBACK

I

(

LEVEL

I

(

DOOR

I

I

FILTER

ESSION

LIGHT

LIGHT

I

(

HEATER

I

l

HEATER

I

V

(

STOP

I

v

(

JAMB

I

v

I

(2DOOR)

I

I

I

__I

I

_

(

LIGHT

I

-(SWITCH

I__I

Y

Y

SEAT

I

CHECK

LEFT

ANTI-

RIGHT

(

I

LOAD

CONTROL

REAR

I

(

THEFT

I

I

REAR

G312

I

I(

ASSEMBLY

I

(

MODULE

I

(

DOOR

I

(

CONTROL

I

(

DOOR

I

-

I

I

_

I

I

_I

CONTACT

I

_I

MODULE

I

_I

CONTACT

CD

HIFI

RADIO

I

(

CHANGER

I

(

AMPLIFIER

i

II

I

I

I

I

I

WIHIFI

.

I

WISTEREO

TENSPEAKER

BSPEAKER

SYSTEMSYSTEM

I

LEFT

FUEL

TELEPHONE

(

FRONT

I

(

PUMP

I---

I

TRANS-

DOOR

I

I

I

I

CEIVER

I

(JAMB

I

I

I

SWITCH

,Y

(4DOOR

I

=

Y

~~Y

Page 527 of 759

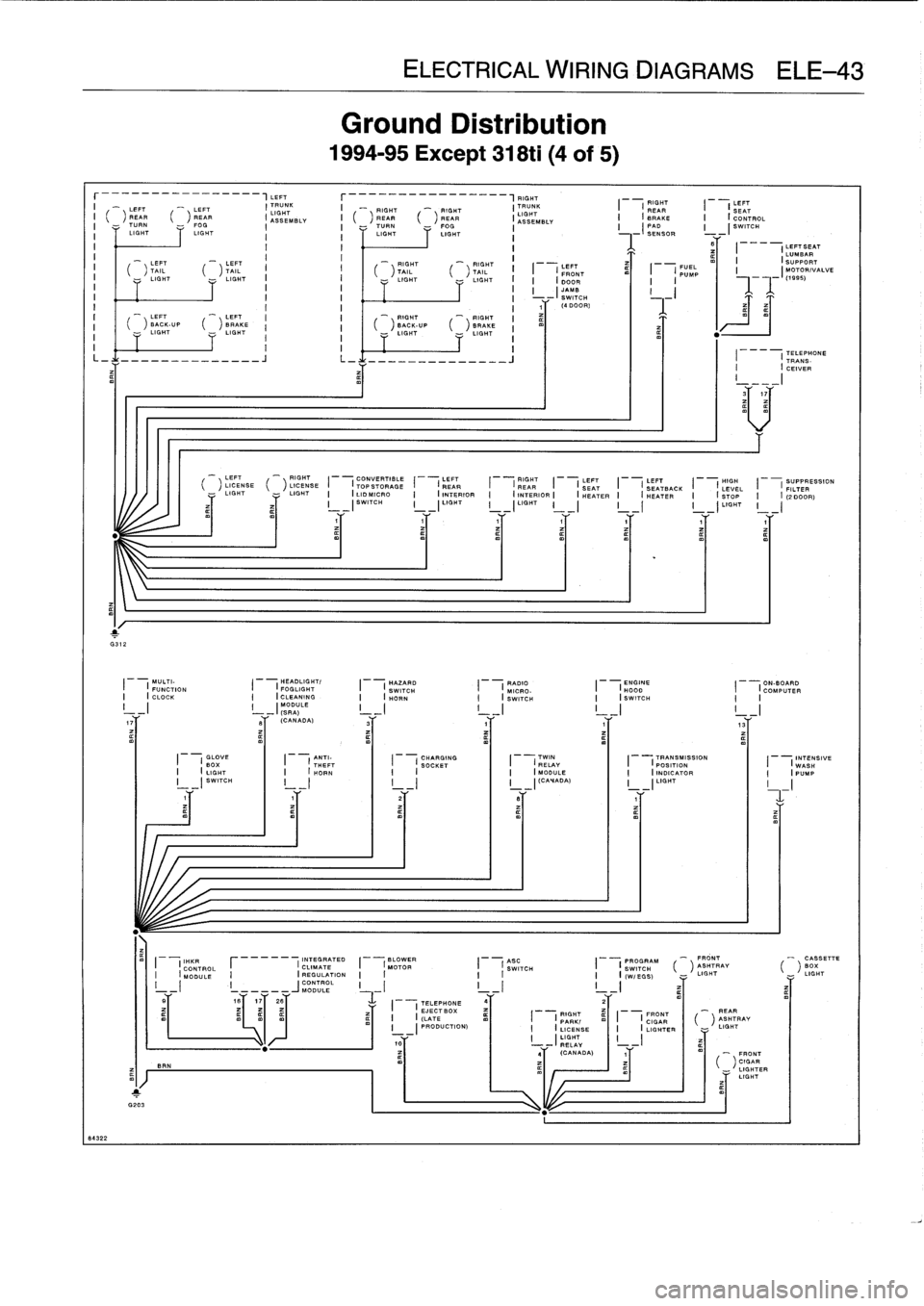

ELECTRICAL

WIRING

DIAGRAMSELE-43

r----------_-__--,LEFT

r---__-------~_--,FIGHT

I

-

RIGHT

LIT

LEFT

"-

LEFT

I

IGHT

K

I

_

RIGHT

'

RIGHT

I

'TRUNK

SEMBLY

I

(

REAR

I

(

SEAT

I

(

)

REAR

(

)

REAR

I

gSSEMBLV

I

(

)

REAR

(

)REAR

I

I

(

BRAKE

I

(

CONTROL

AS

I

-

TURN

-

FOG

I

I

-

TURN

-

FOG

I

I

(

PAD

I

-(

SWITCH

I

LIGHT

LIGHT

I

I

LIGHT

LIGHT

I

SENSOR

I

I

I

I

B

LEFT

SEAT

I

(LUMBAR

I

-

LEFT

-

LEFT

_RIGHT

RIGHT

I

I

(

)

TAIL

(

)

SUPPO

TAIL

I

I

(

)

TAIL

(

)

TAIL

I

I

(

LEFT

I

,

FUEL

I

I

MO70RRVALVE

LIGHT

-

LIGHT

i

i

LIGHT

-~

LIGHT

i

I

I

DRM9T

I

(

PUMP

(I9SB)

I

I

I

I

I

v

I

SWITCH

I

T

T

(4

DOOR)

84322

1

G312

_

LEFT

'

LEFT

>

BACK-UP

(

)

BRAKE

LIGHT

LIGHT

G203

Ground

Distribution

1994-95

Except

318ti

(4

of

5)

'

RIGHT

"'

RIGHT

(

)

BACK-UP

(

>

BRAKE

LIGHT

,,

LIGHT

L_1--------------

J

L-1

--------------

i

I

_I

_I

_I

MODU

(SRA)

LE

I

_I

I

_I

I

_I

I

_I

17T

SY

(CANADA,

3T

Y

IaY

,

1

TELEPHONE

I

---

I

TRANS-CEIVER

I

._I

3T

,

7Y

_LEFT

-

RIGHT

_

CONVERTIBLE

LEFT

_RIGHT

_

LEFT

_

LEFT

_

HIGH

SUPPRESSION

(

)

LICENSE

(

)

LICENSE

I

I

TOPSTORAGE

I

(

REAR

I

(

REAR

I

(

SEAT

I

I

SEATBAIK

I

(

LEVEL

I

(

FILTER

LIGHT

LIGHT

I

I

LID

MICRO

I

(

INTERIOR

I

ANTERIOR

(

Y

(

HEATER

I

Y

(

HEATER

I

v

.

(

STOP

I

v

I

(2

DOOR)

I

I

SWITCH

I

I

LIGHT

I

_

I

LIGHT

_-

I

I

-

I

I

_

I

LIGHT

I-I

Y

YY

MULTI-

HEADLIGHT/

HAZARD

RADIO

ENGINE

ON-BOARD

I

(

FUNCTION

I

I

FOGLIGHT

I

(

SWITCH

I

(

MICRO-

I

I

H000

I

(

COMPUTER

I

I

CLOCK

I

I

CLEANING

I

(

HORN

I

(

SWITCH

I

(

SWITCH

I

I

GLOVE

ANTI-

CHARGING

TWIN

TRANSMISSION

INTENSIVE

I

(

BOX

I

(

THEFT

I

(

SOCKET

I

(

RELAY

I

(

POSITION

I

(

WASH

I

(

LIGHT

I

(

HORN

I

I

I

(

MODULE

I

(

INDICATOR

I

(

PUMP

I

_

(

SWITCH

I

_

I

I

-I

L-1

(CANADA)

I

-(LIGHT_

_

I

I

IT

IT

21'

ST

,Y

IHKR

INTEGRATED

BLOWER

ABC

OGRAM

-

FRONT

-

CASSETTE

CONTROL

I

r

-

CLIMATE

I

(MOTOR

II

I

:PR

ASHTRAY

BOX

SWITCH

SW

I

TCH

(

MODULE

I

(

REGULATION

I

i

I

I

I

(W/EGS)

LIGHT

LIGHT

I

i

-----JMODULE

L

I

I

I

I

I

`7'

I

1617

26

I

(TELEPHONE

4

"I

4

_

4

EJECTBOX

RIGHT

FRONT

REAR

I

(

(LATE

I

(

PARK(

I

(

CIGAR

(

)

ASHTRAY

-(

PRODUCTION)

I

(

LICENSE

I

(

LIGHTER

-

LIGHT

I

I

LIGHT

-

I

RELAY

4

(CANADA)

1

FRONT

BRN

(

^

)

CIGAR

LIGHTER

LIGHT

Page 533 of 759

TELEPHONE

CONVERTIBLE

RIGHT

REAR

CENTRAL

RIGHT

DRIVERS

___

I

I

_

__

_

_

___

_7RAN5-

I

I

TOpSTORAGE

I

I

BRAKEPAD

I

(

LOCKING

(

)LICENSE

I

II

I

CEIVER

I

LID

MICRO

I

I

SENSOR

I

(

SWITCH

LIGHT

SEAT

[-

,

RIGHT

-(

(1996)

I

(

__

I

I

I

_I__

I

(

SWATCH

SWITCH

31'

17Y

LUGGAGE

COMPARTMENT

TELEPHONECONNECTOR

(1997)

DRIVERS

1

-

1

FUEL

I

IJAMB

I

I

IPUMP

I

_I

SWITCH

I

I

_I

F__

f

____

_

_-_---

------

1997WITH

m

I

ALL

CONVERTIBLE

OTHERS

CONVERTIBLE

LEFT

I

I

REAR

I

I

TOP

I

I

REAR

WINDOW

I

(CONTROL

i

(INTERIOR

I

(BLOWER

-

I

MODULE_

I

-

I

LIGHT

I

-I

SWITCH

Y

V

1

SUPPRESSION

RIGHT

LEFT

-

LEFT

I

I

RAR

I

I

(

FILTER

I

(

REAR

~

i

h

)

TAIL

(

)

TAIL

I

(

REAR

I

(

WINDOW

I

I

(2

DOOR)

I

(

I

LIGHT

LIGHT

(

INTERIOR

m

I

(

BLOWER

LIGHT

I

I

LIGHT

INTERIOR

-

-I

1

2

_

(

HARD

1

2

I

DRIVERS

LEFT

I

-

LEFT

^'

LEFT

I(

SEAT

m

I

(

REAR

BACK-UP

BRAKE(CONNECTOR(

I

I

DRIGHT

Z

EFOGGEfl

I

(REAR

I

(

HEATER

I

(

INTERIOR

I

-

LIGHT

-

LIGHT

II

_I

I

I

I

(DOOR

I

_

I

I

-

(

LIGHT

I

I

I

m

I

y,

-I

(1

BR~1

cT

1

2

L_

I

IT-PD

ml

-

iCONNECTOR1

I

I

1

G312

0312

(CONVERTIBLE)

MULTI-

HEADLIGHT/

HAZARD

RADIO

ENGINE

TRANSMISSION

I

(

FUNCTION

I

I

FOGLIGHT

I

I

I

I

FINAL

B

LOWER

I

I

CLOCK

I

(

CLEANING

SWITCH

SWITCH

I

(

SHOWIODTC

I

(

INDICATOR

I

I

I

I

I

I

I

(

I

(

H

I

(

I

(

STAGE

MOTOR

UNIT

III

I

I

I

MO

1996)

LE

_

_

_

_

__

_

I_

_

I

I

I

_

_(1996)

I

I

I

(

LIGHT

I

-I

I

I

17

g~

(CANADA)

gY

17

1T

tY

Gy

I

I

~j

AUTOMATIC

I

(CLIMATE

CENTER

I

(CONTROL

GLOVE

SERVOTRONIC

CHARGING

ON-BOARD

INTENSIVE

-

I

MODULE

I

(

BOX

I

(

CONTROL

I

(

SOCKET

CONSOLE

m

I

(COMPUTER

m

I

IWgSH

I

_

I

(LIGHT

mI

I

(

MODULE

mI

I

I

MI

TELEPHONE

II

(()

II

I

1996

PUMP

1997

W/IHKA

InOR

ALL1996

_-__41,

_

-F_---_-0-9-_----f--f----0--0_----_f-f--_----___-----

I

-

(

(1997)

I

-(

(1997)

I

_

I

AS

C

FRONT

I

I

SWITCH

I

I

CIGAR

I

I

I

I

LIGHTER

I

_I

_I

I

_I

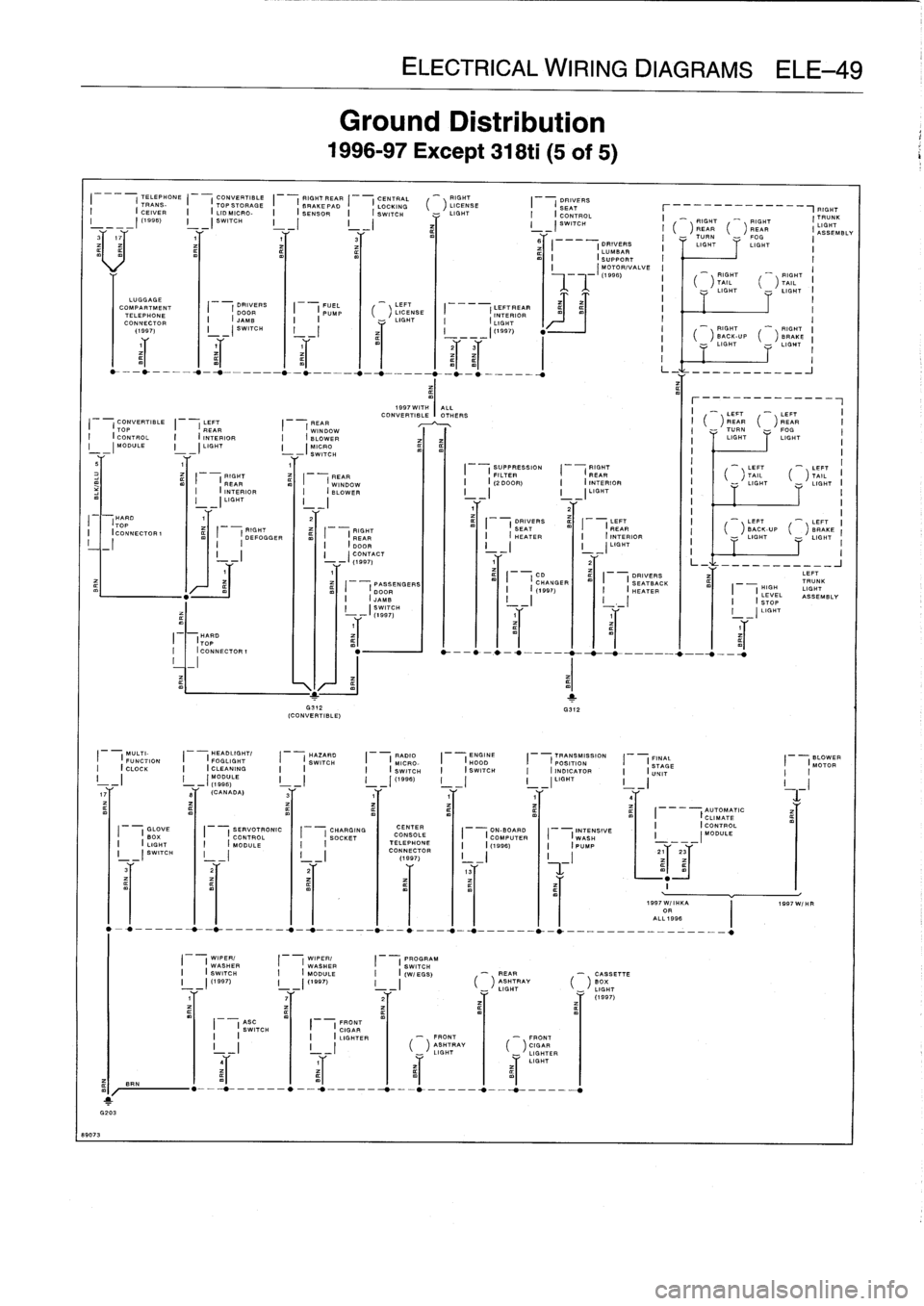

Ground

Distribution

1996-97

Except

318ti

(5

of

5)

-

LEFT

LICENSE

-

LIGHT

ELECTRICAL

WIRING

DIAGRAMS

ELE-49

I

DRIVERS

LEFT

PASSENGERS

I

OHANGER

I

ISEATBACK

HIGH

TRUNK

I

(

DOOR

I

(

(1997)

I

(

HEATER

I

I

LIGHT

I

i

I

I

I

II

I

LEVEL

JAMB

ASSEMBLY

I

SWITCH

I

I

LIGHT

WIPER/

WIPER/

PROGRAM

I

(

WASHER

I

(

WASHER

I

(

SWITCH

I

(

SWITCH

I

(

MODULE

I

I

(W/EGS)

-

FIGHT

"'

RIGHT

ITRUNK

REARTURN

-

~FOGR

iASSEMBLY

~I

I

I

DRIVERS

I

LIGHT

LIGHT

LUMBAR

II

(SUPPORT

I

II

MOTOR/VALVE

I

_

I

\

(1996)

i

-~

RIGHT

~--'

T

A

IL

I

\

FRONT

-,

FRONT

LGGAF

HTAY

I

-'LIGHTER

LIGHT

-

REAR

-

CASSETTE

_

LIGHT

RAY

6

GHT

Y

Y

(1997)

mI

SRN

1

G203

69073

-

RIGHT

RIGHT

BACK-UP

(

)

BRAKE

LIGHT

-

LIGHT

L_-~

-

___________J

r

-

Y

I

(

)

REAR

(

)

REAR

I

-

TURN

FOG

I

LIGHTLIGHT

I

Page 537 of 759

RIGHT

FUEL

RIGHTREAR

CENTRAL

LEFTREAR

DRIVER'S

---

(

FEAR

I

(

PUMP

I

I

BRAKE

PAD

I

(

LOCKING

I---

(

INTERIOR

I---

(

SEAT

INTERIOR

(

I

I

(

SENSOR

I

(

SWITCH

I

(

LIGHT

I

(

LUMBAR

(

LIGHT

I

I

I

I

I_

_

_

I

_

_

I

I

(

SUPPORT

v

o

I

~

~

eT

,T

,T

3/~

MOTORIVALVE

LUGGAGE

COMPARTMENT

TELEPHONE

CONNECTOR

I

I

DRIVER'S

DOOR

I

(JAMB

I

_I

SWITCH

I

-

LEFT

-

LEFT

CONVERTIBLE

LEFT

FEAR

CONVE

WIT

R

H

TIBLE

OT

A

HLEL

RS

_

_

CD

I

(

)

FEAR

(

)

REAR

I

(

TOP

I

FEAR

I

(

WINDOW

I

(CHANGER

I

T

TURN

--

FOG

I

CONTROL

I

(

INTERIOR

I

(

BLOWER

I

I

LIGHT

LIGHT

I

(

MODULE

I(

LIGHT

I

I

WORD

m

m

_

_

SW

-

H

I

I

-

LEFT

_

LEFT

I1

REAR

CONVERTIBLE

RIGHT_

_

_

_

_

_

I

(

)

TAIL

(

)

TAIL

II

I

(

DEFOGGER

I

I

TOP

STORAGE

I

(REAR

I

-

LIGHT

-

LIGHT

I

I

I

v

(LID

MICRO

I

v

(INTERIOR

I

I

SWITCH

I

_(

LIGHT

I

I

-

-

-

I

I1

1

2

I

-

LEFT

UP

-

LEFT

HARD

RIGHT

PASSENGER'S

FILTER

SID

.

DRIVER'

ACK-

BRAKE

S

I

(

(

I

I

(

TOP

I

(

REAR

I

(

DOOR

I

(

m

I

I

EATBACK

I

LIGHT

LIGHT

II

ICONNECTORI

I

I

(INTERIOR(

ml

I

IJgMB

I

I(2DOOR)

HI

(EATER

I

I

I_

I

I

I

(

LIGHT

I

I

I

_(

SWITCH

I

_I

I

I

-I

I

L_1

---J

10441

5

(HARD

TOP

ICONNECTOR1

_1

MULTI-

HAZARD

ENGINE

TRANSMISSION

FINAL

AUTOMATIC

BLOWER

(

FUNCTION

I

(

SWITCH

I

(

HOOD

I

(

POSITION

(

STAGE

I

(

CLIMATE

I

(

MOTOR

(

CLOCK

I

I

I

(

SWITCH

I

(

INDICATOR

I

(

UNIT

I

(

CONTROL

I

I

mI

/

1

G203

BRN

GLOVE

I

CHARGING

BIGHT

I

'

SOCKET

I-_I

I

_I

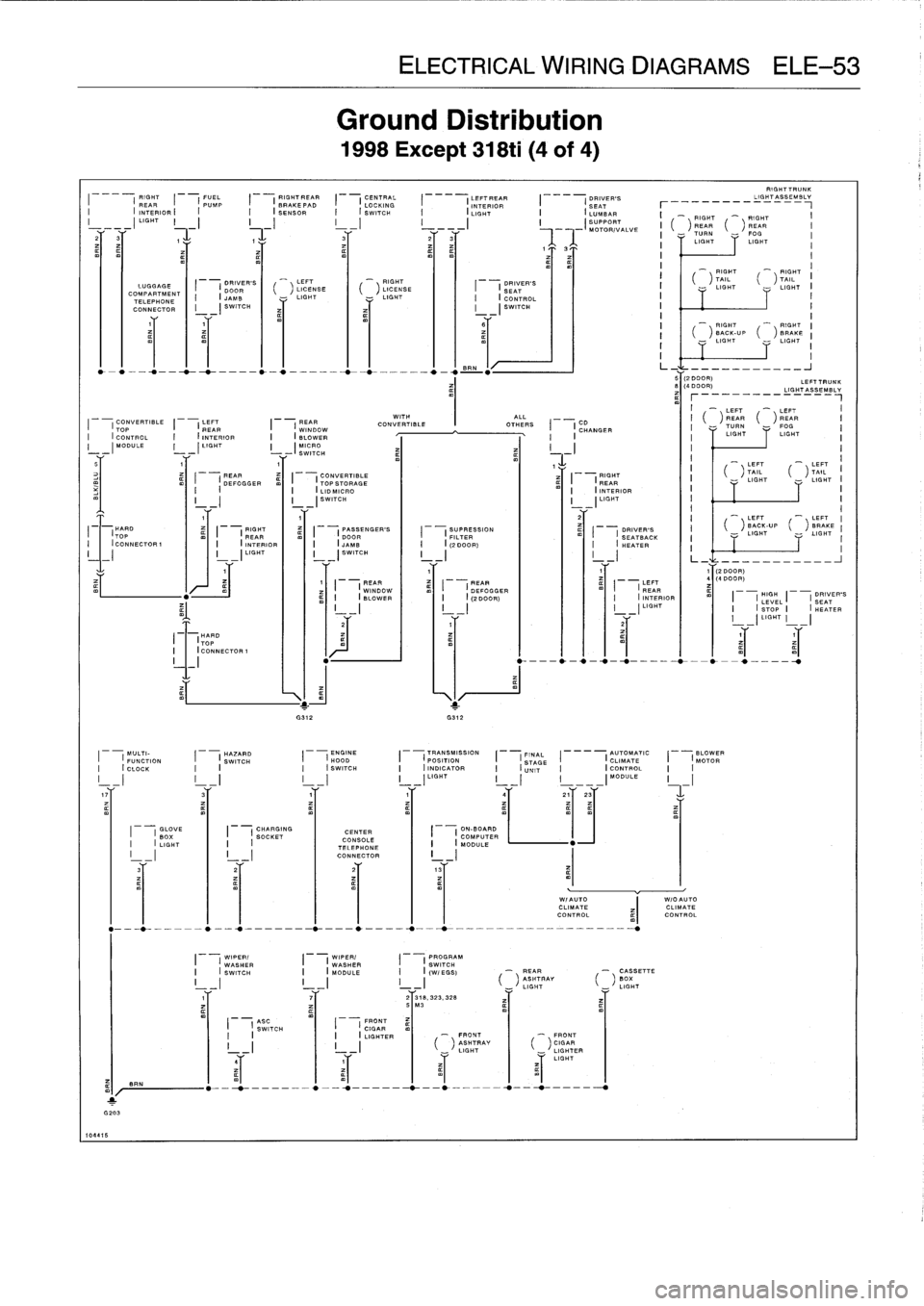

Ground

Distribution

1998Except

318ti

(4

of

4)

LEFT

-

RIGHT

LICENSE

(

)

LICENSE

LIGHT

-

LIGHT

1

FEAR

PEAR

I

I

WINDOW

I

I

DEFOGGER

I

I

BLOWER

I

I

(2

DOOR)

~%___'j

__\I/

G312

G312

CENTER

CONSOLE

TELEPHONE

CONNECTOR

I

I

WIPER/

I

(

WIPER/

I

(

PROGRAMWASHER

WASHER

SWITCH

I

(SWITCH

I

(

MODULE

I

I(WIEGS)

-

REAR

-

CASSETTE

II

II

II

('T

RAV

(B

_

__

LIGH_'IGHT

71

521

318,

323,

328

v3

ELECTRICAL

WIRING

DIAGRAMS

ELE-53

I

I

DRIVER'S

SEAT

I

(CONTROL

_I

SWITCH

ASO

FRONT

I

I

SWITCH

I

I

CIGAR

I

I

I

(

LIGHTER

-

FRONT

FRONT

ASHTRAY

CGAR

L

GHT

LIGHTER

LIGHT

I-

LEFT

FEAR

I

INTERIOR

I

-

I

LIGHT

RIGHTTRUNK

-_------_IGH-T_SSE=BL=

I

-

RIGHT

"~

RIGHT

I

(

)

REAR

(

)REAR

I

TURN

FOG

I

LIGHTLIGHT

RIGHT

~'

gIGHT

I

TAIL

(

)

TAIL

LIGHT

-

LIGHT

I

I

_

RIGHT

-

RIGHT

(

)

BACK-UP

(

)BRAKE

I

I

LIGHT

I

I

I

L_

___J

"T2

DEEP)

LEFTTRUNK

LIGHT

_

__

_

_

_

_

__

¢~

LIGHTASSEMBLV

a

r__

(2

DOOR)

(4

DOOR)

I

I

1

I

HIGH

DRIVER'S

I

LEVEL

1

SEAT

I

I

STOP

I

HEATER

I

-)

LIGHT

I

-

I

Page 543 of 759

RIGHT

DRIVER'S

DRIVER'S

REAR

HIGH

REAR

LEFT

RIGHT

LEFT

RIGHT

DOOR

SEAT-

DRIVER'S

BRAKE

LEVEL

CENTERTRUNK

TRUNK

CENTRAL

LICENSELICENSE

TRUNK

JAMB

BACK

FUEL

SEAT

PAD

CD

STOP

TELEPHONE

INTERIOR

LIGHT

LIGHT

LOCKING

PLATEPLATE

LIGHT

SUPPRESSION

REAR

SWITCHHEATER

PUMP

HEATER

SENSOR

CHANGER

LIGHT

CONNECTOR

LIGHT

ASSEMBLYASSEMBLY

SWITCH

LIGHTLIGHT

SWITCH

FILTER

DEFOGGER

I

--,

I

i

F-

I

I

_-

I

1

-

7

1

-

7

F

-

,

I

--

,

F

-,

1

--,

I

1

--,

1

-

7

I

-

i

I

-

i

I

i

I

i

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

II

!

_I

!

_I

!

_I

I

_I

!

_I

!

_I

L-1

L-1

L

-I

L

-I

L-1

L-1

L-1

L-1

!

_I

L-1

Y

Y

-T

r

-r

-T

Y

Y

Y

rY

-T-T

r

Y

=r

ANTI-

PASSENGER'SPASSENGER'S

DRIVER'S

DRIVER'S

ASS

LEFT

RIGHT

SEAT

THEFT

SIDE

SEAT

SEAT

SIDE

A

BS

SLIP

PUMP

FRONT

FRONT

ASSOCCUPANCY

CONTROL

IMPACT

I

BELT

BELT

IMPACT

HYDRAULIC

CONTROL

MOTOR

SPEED

SPEED

CONTROL

DETECTOR

MODULESENSOR

SWITCH

SWITCH

SENSOR

UNIT

MODULE

RELAY

SENSOR

SENSORMODULE

F

-,

I

I

I

I

F

-

I

F-

I

F

-

II

I

I

I

I

I

1

I

I

I

I

II

_I

Y

=1

-T-T

Y

=f

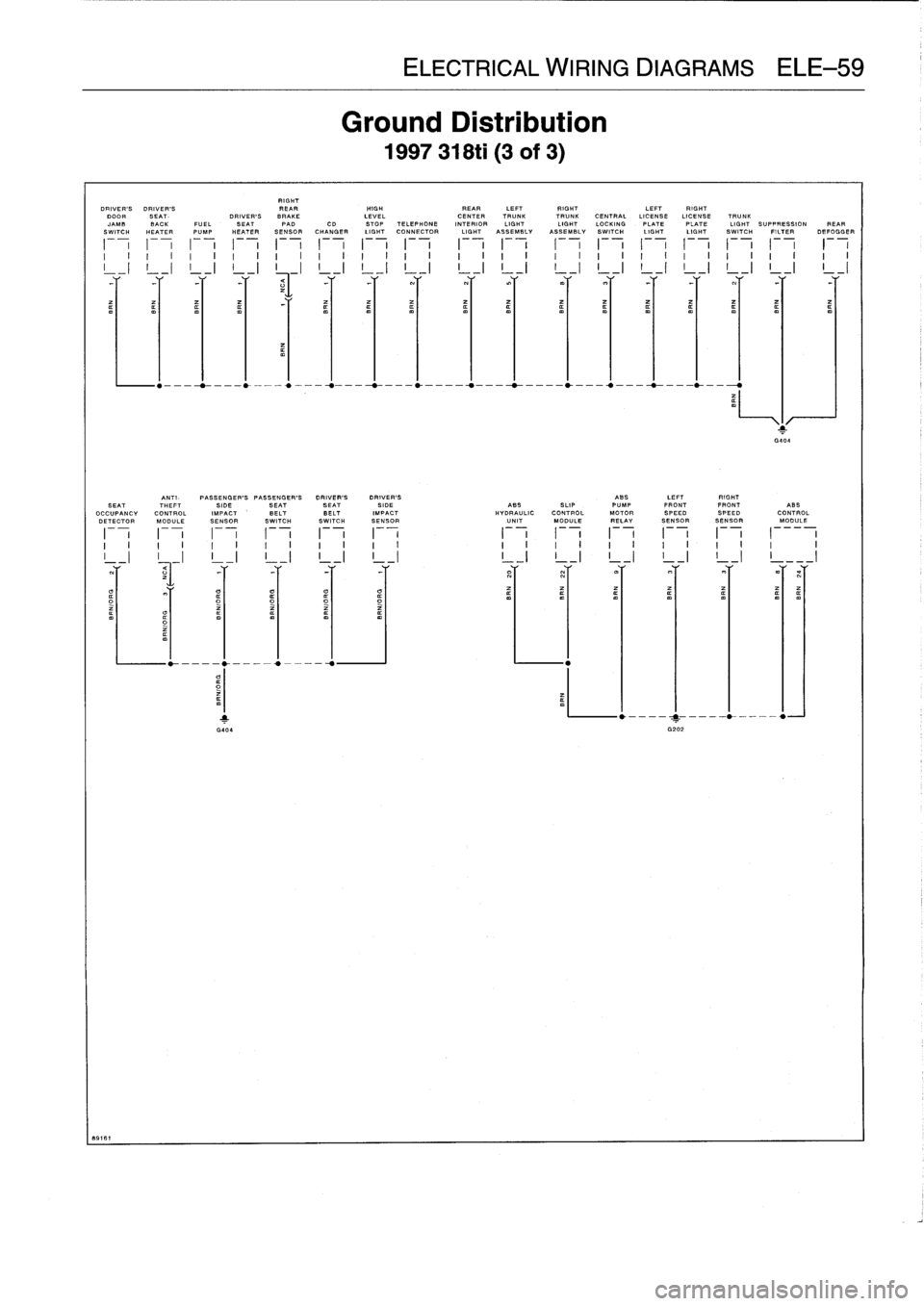

ELECTRICAL

WIRING

DIAGRAMS

ELE-59

Ground

Distribution

1997

318ti

(3of

3)

IIII

F

-,

F

-,

F

-,

I

II

I

I

I

I

I

I

I

I

I

I

I

Page 546 of 759

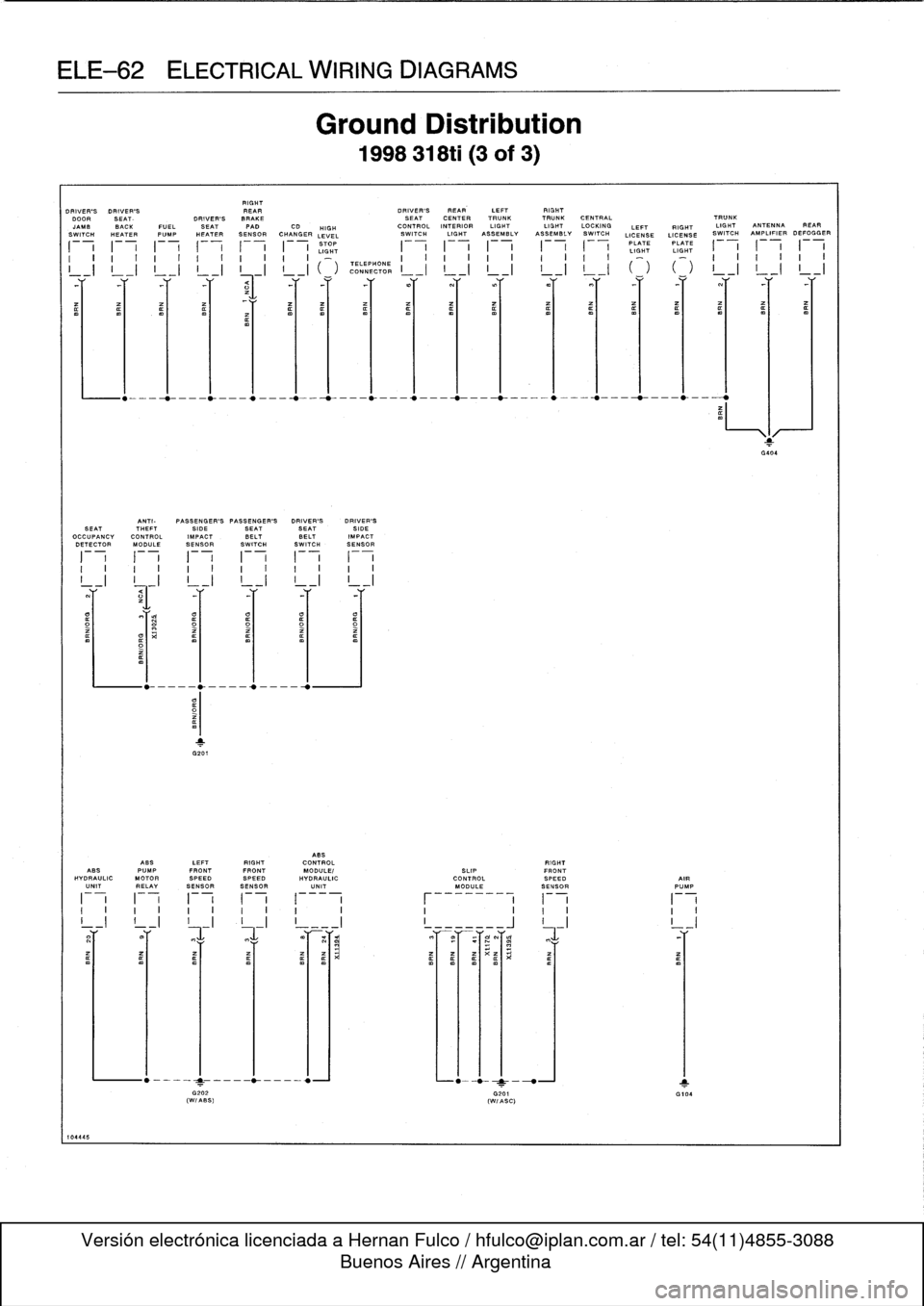

ELE-62

ELECTRICAL

WIRING

DIAGRAMS

ANTI-

PASSENGER'SPASSENGER'S

DRIVER'S

DRIVER'S

SEAT

THEFT

SIDE

SEATSEAT

SIDE

OCCUPANCY

CONTROL

IMPACT

BELT

BELT

IMPACT

DETECTOR

MODULESENSOR

SWITCHSWITCH

SENSOR

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I~I

I=~I

I

_r

I

I

r

I

I

r

II

'T

I

Ground

Distribution

1998

318ti

(3

of

3)

RIGHT

DRIVER'SDRIVER'S

REAR

DRIVER'S

REAR

LEFT

RIGHT

DOOR

SEAT-

DRIVER'S

BRAKE

SEAT

CENTER

TRUNK

TRUNK

CENTRAL

TRUNK

JAMB

BACKFUELSEAT

PAD

CDHIGH

CONTROL

INTERIOR

LIGHT

LIGHT

LOCKING

LEFT

RIGHT

LIGHT

ANTENNA

REAR

SWITCH

HEATER

PUMP

HEATER

SENSORCHANGER

LEVEL

SWITCH

LIGHT

ASSEMBLY

ASSEMBLY

SWITCH

LICENSE

LICENSE

SWITCH

AMPLIFIER

DEFOGGER

STOP

PLATE

PLATE

I

I

I

I

I

I(

I

I

II

I

LIGHT

I

I

I

I

I

I

I

I

(

I

LIGHT

LIGHT

I

II

II

II

I

I

I

I

I

I

I

I

I

I

I

-

I

I

I

I

I

I

I

I

I

I

-

I

I

I

I

I

II

_I_

I_

__I

I

_I

I

_I

I

_I

I

_I

(

)

CONNECTOR

L-1

L-1

!

_I

vvVVV

Y

VY

ASSABS

LEFT

RIGHT

CONTROL

RIGHT

ASS

PUMPFRONT

FRONT

MODULE/

SLIP

FRONT

HYDRAULIC

MOTOR

SPEEDSPEED

HYDRAULIC

CONTROL

SPEED

AIR

UNIT

RELAY

SENSOR

SENSOR

UNIT

MODULE

SENSOR

PUMP

104445

F

-,

F

-,

F

-,

IIII

r

I

I

--

,

I

I

I

I

I

1

1

1

1

1

1

1

1

1

1

1

1

II

_I

1

_I

I

I

I

I

__J

_I

I

_I

r

-r

?~

m~

rY

-rr

-

Y~Yg

G202

(W/ASS)

0201

(WIASC)

G704

G404