lower intake BMW 318i 1992 E36 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1992, Model line: 318i, Model: BMW 318i 1992 E36Pages: 759

Page 100 of 759

117-

4

CAMSHAFT

TIMING

CHAIN

15

.

Remove

mounting

bolts

from

left

and

right

camshaft

4

.

Insta¡¡

and

hand-tighten

sprocket

mounting

bolts

.

sprockets

.

16

.

On

M42

engines,

remove

upper

bolt

on

right

side

chainguide

and

unbolt

lower

timing

chainguide

below

crank-

shaft

.

17

.

Remove

camshaft

sprockets

from

camshafts

together

with

chain

and

crankshaft

sprocket

.

NoteWoodruffkey

when

removing

crankshaftsprocket

.

CA

UTION-

The

crankshaft

must

not

be

allowed

to

rotate

when

the

timing

chaín

is

removed

.

The

pistons

can

contact

the

valves

.

Camshaft

timing

chain,

installing

(4-cylinder

engines)

Inspectal¡

sprockets

for

wear

or

damage

.

Inspect

the

chain

guide

and

tensioner

rails

for

grooves

caused

by

chain

contact

.

Replace

any

partthat

is

worn

.

If

any

of

the

sprockets

are

worn,

the

chain

and

sprocketsare

replaced

asan

assembly

.

The

procedure

outlined

below

assumes

that

the

camshafts

and

the

crankshaft

arelocked

in

the

TDC

installation

positionwithspecial

tools

(shown

earlier

in

Fig

.

5

and

Fig

.

6)

.

1

.

Install

timing

chain

to

crankshaft

sprocket,

then

slide

sprocket

on

crankshaft

whílealigníng

woodruff

key

.

2

.

Place

camshaft

sprockets

on

chain,

then

place

sprock-

ets

oncamshafts

so

that

arrows

on

sprockets

point

up

and

elongatedholes

in

sprockets

are

centered

lo

tapped

holes

in

camshafts

.

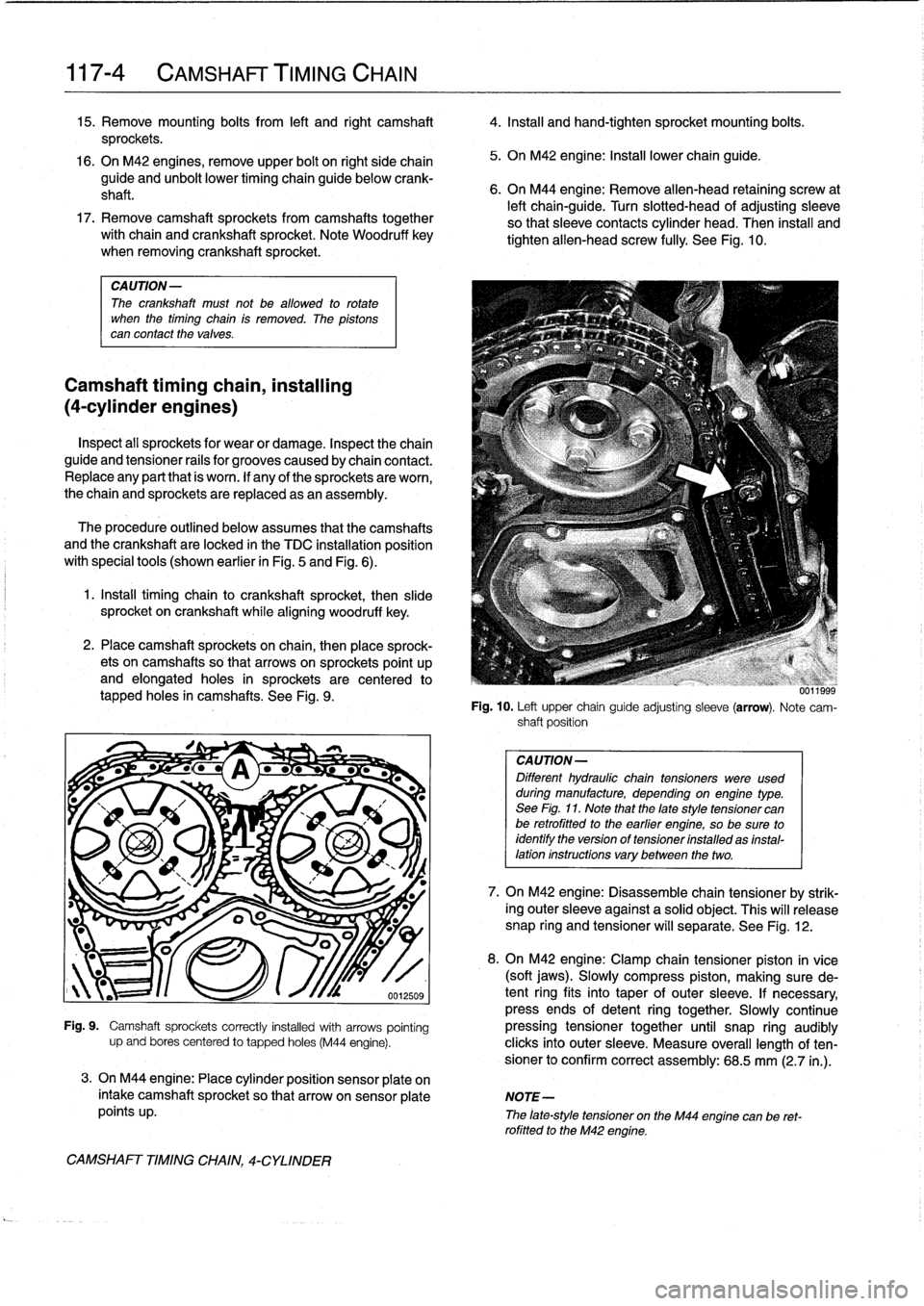

See

Fig

.

9

.

.

I

Pa

-

s

~_

a

Ge

..

.

0012509

5

.

On

M42

engine

:

Install

lowerchainguide

.

6

.

On

M44

engine

:

Remove

allen-head

retaining

screw

at

left

chain-guide

.

Turn

slotted-head

of

adjusting

sleeve

so

that

sleeve

contacts

cylinder

head

.

Then

install

and

tighten'allen-head

screw

fully

.

See

Fig

.

10

.

Fig

.

10

.

Left

upper

chain

guide

adjusting

sleeve

(arrow)

.

Note

cam-

shaft

position

CAUTION-

Different

hydraulic

chaintensioners

were

used

duringmanufacture,

depending

onengíne

type

.

See

Fig

.

11

.

Note

that

the

late

style

tensioner

canbe

retrofitted

to

the

earlier

engíne,

so

be

sure

to

identify

the

versíon

of

tensioner

ínstalled

as

ínstal-

lation

instructions

vary

between

the

two

.

7

.

On

M42

engine

:

Disassemble

chain

tensioner

by

strik-

ing

outer

sleeve

against

a

solid

object

.

This

will

release

snap

ring

and

tensioner

will

separate

.

See

Fig

.

12

.

8

.

On

M42

engine

:

Clamp

chain

tensioner

piston

in

vice

(soft

jaws)

.

Slowly

compress

piston,

making

sure

de-

tent

ring

fits

into

taper

of

outer

sleeve

.

If

necessary,

press

ends

of

detent

ring

together

.

Slowly

continueFig

.

9

.

Camshaft

sprockets

correctly

installed

with

arrows

pointing

pressing

tensioner

together

until

snap

ring

audibly

upand

bores

centered

to

tapped

holes

(M44

engine)

.

clicks

into

outer

sleeve

.

Measure

overall

length

of

ten-

sionerto

confirm

correct

assembly

:

68

.5

mm

(2

.7

in

.)

.

3

.

On

M44

engine

:

Place

cylinder

position

sensor

plate

on

intake

camshaft

sprocket

so

that

arrowonsensor

plate

NOTE-

points

up

.

The

¡ate-style

tensioner

on

the

M44

engine

can

be

ret-rofittedto

the

M42

engíne

.

CAMSHAFT

TIMING

CHAIN,

4-CYLINDER

Page 103 of 759

Camshaft

timing

chains,

removing

(6-cylinder

engines)

1

.

Disconnect

negative

(-)

cable

from

battery

.

CA

UTION-

Disconnecting

the

battery

may

erase

fault

codes)

stored

in

control

module

memory

.

Check

for

fault

codes

using

special

BMW

diagnostic

equipment

.

2

.

Drain

engine

coolant

.

Drain

engine

block

by

removing

block

drain

.

Remove

radiator

cooling

fan

shroud

and

cooling

fan

.

See170

Radiator

and

Cooling

System

.

.

WARNING

-

Allow

the

engine

to

cool

before

openingor

draining

the

system

.

CAUTION-

Radiator

fan

has

left

hand

threads

.

NOTE-

The

block

drain

plug

is

located

on

the

exhaust

side

of

the

engine,

below

cylinder

no

.

4

.

3

.

Drain

engine

oíl

andremove

oil

pan

.

See

119

Lubrica-

tion

System

.

4

.

Remove

alternator

cooling

duct

.

5

.

Remove

two

large

coolant

hoses

from

thermostat

housing

.

Remove

engine

lifting

bracket

and

thermostat

housing

from

front

of

cylinder

head

.

6

.

Loosen

bolts

for

coolant

pump

pulley

.

Then

remove

drive

belts

for

alternator

andA/C

compressor

.

See

020

Maintenance

Program

.

Remove

coolant

pump

pulley

.

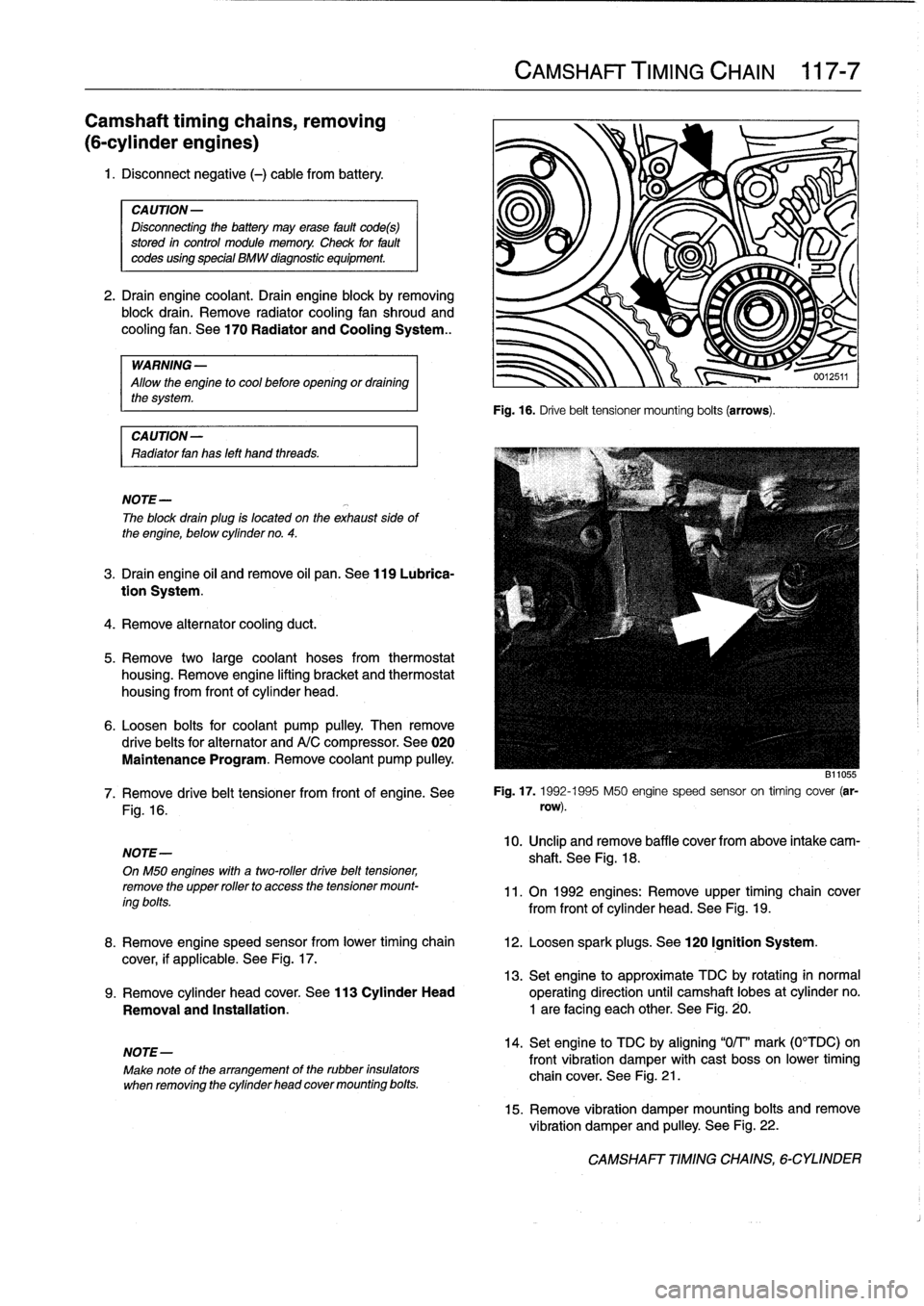

Fig

.

16

.

NOTE-

OnM50

engines

with

a

two-roller

drive

belt

tensioner,

remove

the

upper

rollerto

access

thetensioner

mount-

ing

bolts

.

NOTE-

Make

note

of

the

arrangement

of

the

rubber

insulators

when

removing

the

cylinder

head

cover

mounting

bolts

.

CAMSHAFT

TIMING

CHAIN

117-

7

Fig

.

16

.

Drive

belt

tensioner

mounting

bolts

(arrows)

.

B11055

7

.

Remove

drive

belt

tensioner

from

front

of

engine

.

See

Fig

.

17

.

1992-1995

M50

engine

speed

sensor

on

timing

cover

(ar-

row)

.

10

.

Unclip

andremove

baffle

cover

from

above

intake

cam-

shaft

.

See

Fig

.

18

.

11

.

On

1992

engines

:

Remove

upper

timing

chain

cover

from

front

of

cylinder

head

.

See

Fig

.

19

.

8

.

Remove

engine

speed

sensor

from

lower

timing

chain

12

.

Loosen

spark

plugs

.

See

120

Ignition

System

.

cover,

if

applicable

.

See

Fig

.

17

.

13

.

Set

engine

to

approximate

TDC

by

rotating

in

normal

9

.

Remove

cylinder

head

cover

.

See

113

Cylinder

Head

operating

direction

until

camshaft

lobes

at

cylinder

no

.

Removal

and

Installatíon

.

1

are

facing

each

other

.

See

Fig

.

20

.

14

.

Set

engine

to

TDC

by

aligning

"0/T'

mark

(0°TDC)on

front

vibration

damper

with

cast

bosson

lower

timing

chain

cover

.

See

Fig

.

21

.

15

.

Remove

vibration

damper

mounting

bolts

and

remove

vibration

damper

and

pulley

.

See

Fig

.

22

.

CAMSHAFT

TIMING

CHAINS,

6-CYLINDER

Page 106 of 759

117-

1

0

CAMSHAFT

TIMING

CHAIN

21

.

On

1993

and

lates

engines

:

Remove

access

plugs

from

24

.

On

1993

and

later

engines

:

VANOS

control

unit

in

front

of

exhaust

camshaft

"

Remove

VANOS

control

unit

as

described

laterinthis

sprocket

.

Remove

4

bolts

from

exhaust

camshaft

repair

group

.

sprocket

(useTono

El0

socket)

.

See

Fig

.

26

.

"

Remove

intake

camshaft

sprocket

mounting

nuts

.

"

Remove

intake

and

exhaust

sprockets

together

with

secondary

chain

.

Note

location

of

thrust

washers

and

spring

plate

(where

applicable)

on

intake

sprocket

.

Fig

.

26

.

Exhaust

camshaftmounting

bolts

(arrows)

.

CAMSHAFT

TIMING

CHAINS,

6-CYLINDER

0013056

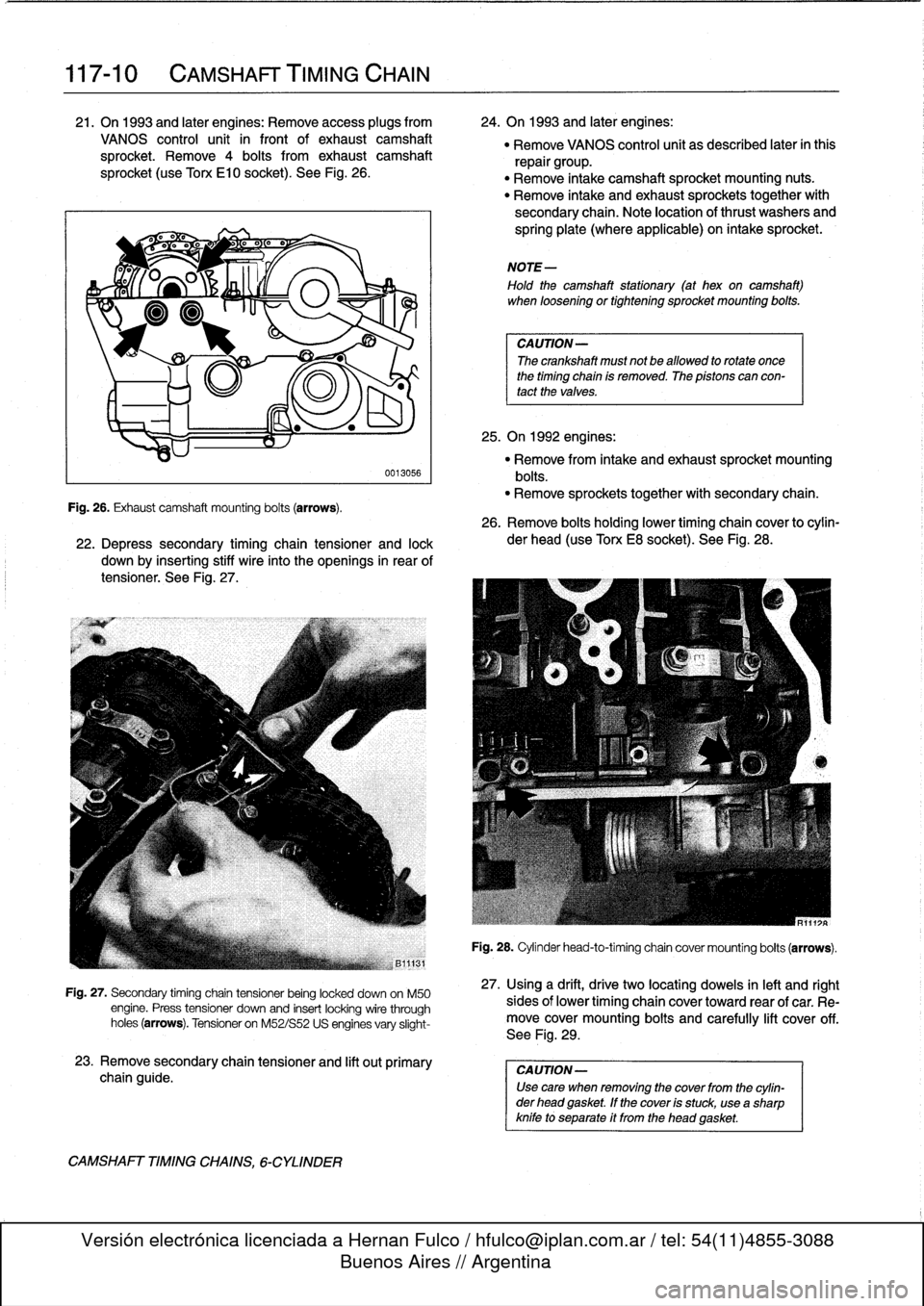

22

.

Depress

secondary

timing

chain

tensiones

and

lock

down

by

inserting

stiff

wire

into

the

openings

in

rear

of

tensioner

.

See

Fig

.

27

.

Fig

.

27

.

Secondary

timing

chaintensioner

being

locked

down

on

M50

engine

.

Press

tensioner

downand

insert

locking

wire

through

holes(arrows)

.

Tensioner

on

M52/S52

US

engines

vary

slight-

23

.

Remove

secondary

chain

tensioner

and

lift

out

primary

chain

guide

.

NOTE-

Hold

the

camshaft

stationary

(at

hex

on

camshaft)

when

loosening

ortightening

sprocket

mounting

boits

.

CAUTION-

The

crankshaft

must

not

be

allowed

to

rotate

once

the

timing

chain

is

removed

.

The

pistons

can

con-

tact

the

valves

.

25

.

On

1992

engines

:

"

Remove

from

intake

and

exhaust

sprocket

mounting

bolts

.

"

Remove

sprockets

together

with

secondary

chain

.

26

.

Remove

bolts

holding

lower

timing

chain

cover

to

cylin-

der

head

(use

Torx

E8

socket)

.

See

Fig

.

28

.

MR111:

R

Fig

.

28

.

Cylinderhead-to-timingchain

covermounting

bolts

(arrows)

.

27

.

Using

a

drift,

drive

two

locatiog

dowels

in

left

and

right

sides

of

lower

timing

chaincover

toward

rear

of

car

.

Re-

move

covermounting

boits

and

carefully

lift

cover

off

.

See

Fig

.

29

.

CA

UTION-

Use

care

when

removing

the

cover

from

the

cylin-

der

head

gasket

.

If

the

cover

is

stuck,

useasharp

knife

to

separate

it

from

the

head

gasket

.

Page 110 of 759

117-

1

4

CAMSHAFT

TIMING

CHAIN

22

.

Installation

of

remaining

parts

is

reverse

of

removal,

When

theengine

is

running,

the

piston

housing

is

supplied

noting

the

following

:

with

pressurized

engine

oil

.

At

idie,

the

solenoid

isin

the

off

"

When

installing

thermostat,

make

sure

arrow

or

vent

position

(de-energized)

and

valve

timing

is

maintained

in

the

hole

faces

up,

if

applicable

.

normal

position

:

When

the

solenoid

is

energized,

the

gear

cup

"

Refill

cooling

systemas

described

in

170

Radiator

piston

moves

forward

to

advance

the

camshaftby

a

maximum

and

Coming

System

.

of

12

.5

.

"

Install

oil

pan

as

described

in

119

Lubrication

Sys-

tem

.

"

Fill

engine

with

oil

and

install

a

new

oil

filter

as

de-

scribed

in

020

Maintenance

Program

.

"

Insta¡¡

ground

wires

at

cylinder

head

cover

mounting

studs

and

at

front

of

cylinder

head

and

thermostat

housing,

where

applicable

.

VANOS

system

operation,

testing

Tightening

Torques

There

are3

special

tools

required

to

check

VANOS

opera-

"

Coolant

drain

plugto

cylinder

block

.

.

25

Nm

(18

ft-Ib)

tion

;

an

electricaltest

lead

(BMW

special

tool

no

.

12

6

410),

an

"

Radiator

cooling

fan

to

coolant

pump

.

40

Nm

(30

ft-Ib)

air

line

fitting

(BMW

special

tool

no

.

11

3

450),

and

a

crank-

"

Radiator

drain

screw

to

radiator

...

.

2

.5

Nm

(22

in-Ib)

shaft

TDC

locking

tool

(BMW

special

tool

no

.

112

300)

.

"

Upper

timing

chaincover

to

cylinder

head

The

test

leal

is

used

to

power

the

solenoid,

simulating

the

M6

nut

...

.....

.............

..

.

10

Nm

(89

in-lb)

ground

signal

from

the

DME

control

unit

.

The

air

line

fitting

M8

bolt

.....

....

.

.

.............

22

Nm

(17

ft-Ib)

takes

the

place

of

the

oil

supply

line

fitting

to

simulate

oil

Ares-

"

VANOS

control

unit

to

cylinder

head

sure

.

The

locking

tool

positions

and

locks

the

crankshaft

at

M6

nut

.........

..

..

.

..........

10

Nm

(89

in-lb)

TDC,

cylinder

no

.

l.

M8

bolt

........

...

.............

22

Nm

(17

ft-Ib)

"

VANOS

oil

supply

pipe

to

VANOS

control

unit

1

.

Remove

alternator

cooling

air

duct

.

banjo

bolt

.......

..

..

.

..........

32

Nm

(24

ft-Ib)

VANOS

(VARIABLE

VALVE

TIMING)

3

.

Remove

top

plastic

enginecovers

.

Disconnect

ignition

coil

harness

connectors

fromcofs

.

Remove

ignition

1993

and

later

6-cylinder

engines

are

equipped

with

a

vari-

coils

.

able

valve

timing

system

called

VANOS

.

This

system

is

con-

trolled

by

the

engine

management

system

and

dynamically

4

.

Remove

cylinder

head

cover

mounting

bolts

and

re-

adjusts

intake

camshaft

timing

based

on

engine

load,

engine

move

cylinder

head

cover

.

Unclip

andremove

oil

baffle

speed

and

engine

temperature

.

cover

from

above

intake

camshaft

.

See

113

Cylinder

Head

Removal

and

installation

.

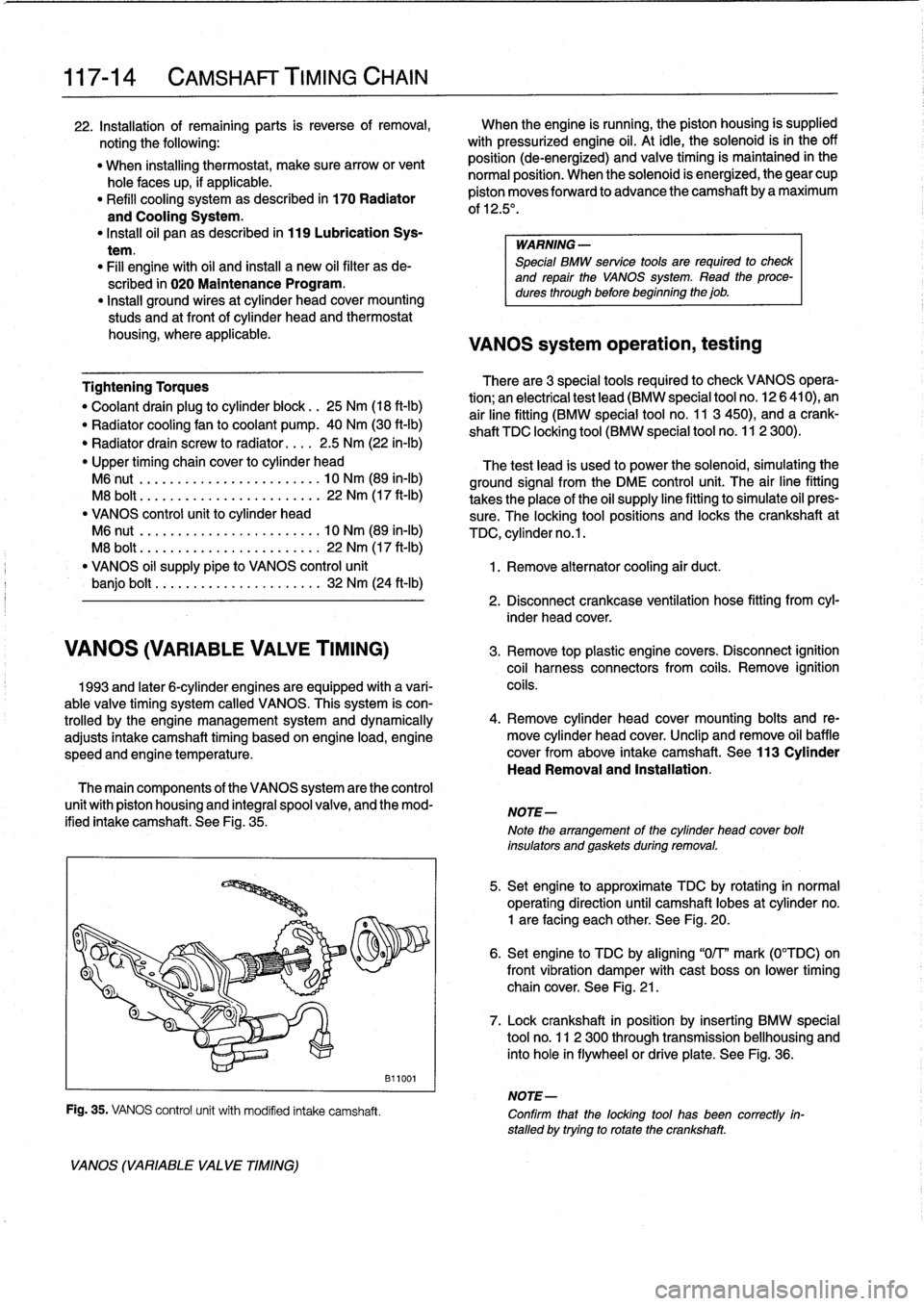

The

main

components

of

the

VANOS

system

are

the

control

unit

with

piston

housing

and

integral

spool

valve,

and

the

mod-

ified

intake

camshaft

.

See

Fig

.

35

.

VANOS

(VARIABLE

VA

LVE

TIMING)

Fig

.

35

.

VANOS

control

unit

with

modified

intake

camshaft

.

B11001

WARNING

-

Special

BMW

service

tools

are

required

to

check

and

repair

the

VANOS

System

.

Read

theproce-

dures

through

before

beginning

the

job

.

2

.

Disconnect

crankcase

ventilation

hose

fitting

from

cyl-

inder

head

cover

.

NOTE-

Note

the

arrangement

of

the

cylinder

head

cover

bolt

insulators

and

gaskets

during

removal

.

5

.

Set

engine

to

approximate

TDC

by

rotating

in

normal

operating

direction

until

camshaft

lobes

at

cylinder

no

.

1

are

facing

each

other

.

See

Fig

.

20

.

6

.

Set

engine

to

TDC

by

aligning

"0/T"

mark

(0°TDC)on

front

vibration

damper

withcast

boss

on

lower

timing

chain

cover

.

See

Fig

.

21

.

7

.

Lock

crankshaft

in

position

by

inserting

BMW

special

tool

no

.

11

2

300

through

transmission

bellhousing

and

into

hole

in

flywheelor

driveplate

.

See

Fig

.

36

.

NOTE-

Confirm

that

the

locking

tool

has

been

correctly

in-

stalled

by

trying

to

rotatethe

crankshaft

.

Page 112 of 759

117-

1

6

CAMSHAFT

TIMING

CHAIN

15

.

Remove

crankshaft

locking

tool

.

Remove

special

test

equipment

.

Insta¡¡

oil

supply

line

using

new

seals

and

reconnect

solenoid

connector

.

Remainder

of

installa-

tion

is

reverse

of

removal

.

Tightening

Torque

"

Cylinder

head

cover

to

cylinder

head

.

10

Nm

(89

in-lb)

"

VANOS

oil

supply

line

to

VANOS

control

unit

(banjo

bolt)

..

.........

32

Nm

(24

ft-Ib)

"

VANOS

solenoidlo

VANOS

control

unit

........

.

.

.

..

........

30

Nm

(22

ft-Ib)

VANOS

control

unit,

removing

Special

BMW

service

tools

are

required

lo

remove

and

in-

stall

the

VANOS

control

unit

.

Read

the

procedure

through

be-

forestarting

the

job

.

1

.

Remove

radiator

cooling

fan

shroud

and

cooling

fan

.

See

170

Radiator

and

Cooling

System

.

CAUTION-

Radiator

fan

has

left

hand

threads

.

2

.

Remove

top

plastic

engine

covers

.

Disconnect

ignition

coil

harness

connectors

from

coils

.

Remove

ignition

coils

.

Remove

cylinder

head

cover

.

Unclip

andremove

oil

baffle

cover

from

above

intake

camshaft

.See

113

Cylinder

Head

Removal

and

Installation

.

NOTE-

Make

note

of

the

mounting

bolt

insulator

arrangement

during

removal

of

the

cylinder

head

cover

.

3

.

Set

engine

lo

TDC

by

rotating

engine

in

normal

operat-

ing

direction

until

camshaft

lobes

at

cylinder

no

.

1

are

facing

each

other

and

"0/T"

mark

(0°TDC)

on

vibration

damper

lines

up

with

cast

boss

on

lower

timing

chain

cover

.

See

Fig

.

38

.

4

.

Lock

crankshaft

at

TDC

by

inserting

BMW

special

tool

no

.

11

2

300

through

transmission

bellhousing

and

finto

flywheel

or

drive

plate

.

Refer

to

Fig

.

36

given

earlier

.

NOTE-

Confirm

that

the

locking

tool

has

been

correctly

in-

stalled

by

trying

to

rotatethe

crankshaft

.

5

.

Remove

three

cylinder

head

cover

mounting

studs

from

rear

of

head

.

Lockcamshafts

at

TDC

bymounting

BMW

special

tool

no

.

11

3

240

at

ends

of

camshafts

.

Check

that

tool

is

squarely

seated

on

cylinder

head

gasket

surface

.

If

necessary,

rotate

camshafts

slightly

using

a24

mm

wrench

.

Refer

to

Fig

.

24

given

earlier

.

VANOS

(VARIABLE

VALVE

TIMING)

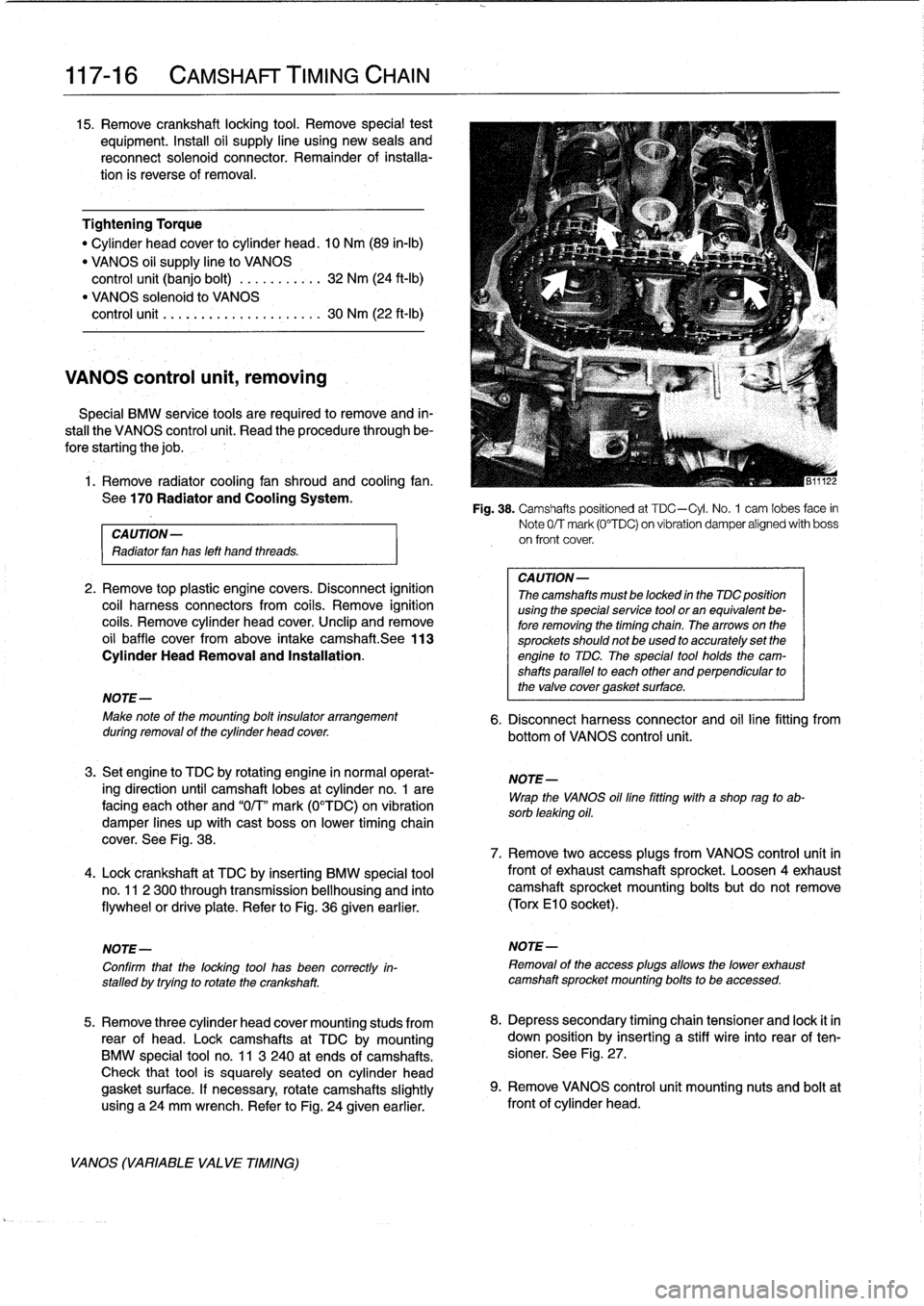

Fig

.

38

.

Camshafts

positioned

at

TDC-Cyl

.

No

.

1

cam

lobes

face

in

Note

0/T

mark

(0°TDC)

on

vibration

damper

alígned

with

boss

on

front

cover

.

CA

UTION-

Thecamshafts

mustbe

locked

in

the

TDC

position

using

the

specialservice

tool

or

an

equivalent

be-

fore

removing

the

timing

chain

.

Thearrows

on

the

sprockets

should

not

be

used

to

accurately

set

the

engine

to

TDC

The

special

tool

holds

the

cam-

shafts

parallel

to

each

other

and

perpendicular

to

the

valve

cover

gasket

surface

.

6

.

Disconnect

harness

connector

and

oil

line

fitting

from

bottom

of

VANOS

control

unit

.

NOTE-

Wrap

the

VANOS

oilfine

fitting

with

a

shop

rag

to

ab-

sorb

leaking

oil

.

7

.

Remove

two

access

plugs

from

VANOS

control

unit

in

frontof

exhaustcamshaft

sprocket

.

Loosen

4exhaustcamshaft

sprocket

mounting

bolts

but

do

not

remove

(Torx

El

0

socket)

.

NOTE-

Removal

of

the

access

plugs

allows

the

lower

exhaust

camshaft

sprocket

mounting

bolts

to

be

accessed

.

8

.

Depress

secondary

timing

chain

tensioner

and

lock

it

in

down

position

by

inserting

a

stiff

wire

into

rear

of

ten-

sioner

.

See

Fig

.

27

.

9

.

Remove

VANOS

control

unít

mounting

nuts

and

boltat

front

of

cylinder

head

.

Page 120 of 759

119-

6

LUBRICATION

SYSTEM

17

.

Raise

engine

as

much

as

possible

.

Check

carefully

for

22

.

Installation

is

reverse

of

removal

.

obstructions,

wiring

harness

clearance

and

pinched

hoses

or

lines

as

engine

is

raised

.

"

When

installing

oil

pan,

apply

a

b

d

of

non-hardening

sealing

compound

(3-Bond

1209

0

or

equivalent)

to

18

.

Remove

oil

pan

mounting

bolts

and

lower

oil

pan

to

front

and

rear

end

cover

seam

areas

on

block

.

subframe

crossmember

.

"

Position

oil

pump

pickup

tube

and

oil

pan

onto

block

and

install

pickup

tube

using

a

new

gasket

.

"

Be

sure

tab

on

gasket

faces

down

towards

intake

of

NOTE-

pickup

tube

.

If

the

oil

pan

does

not

separate

easily

from

the

engine

"

Tightenforward

oil

pan

screws

first,

then

tighten

rear

.

cylinder

block,

afew

taps

with

arubber

mallet

should

"

Fill

engine

with

oil

as

described

in

020

Maintenance

break

it

free

.

Do

not

pry

the

oil

pan

loose

.

Program

.

"

After

adding

engine

oil,

start

and

run

engine

.

Raise

en-

19

.

Remove

oil

pump

sprocket

mounting

nut

.

See

Fig

.

9

.

gine

speed

to

2,500

rpm

until

oil

pressure

warning

Lift

sprocket

off

together

with

drive

chain

.

lampgoes

out(about

5seconds)

.

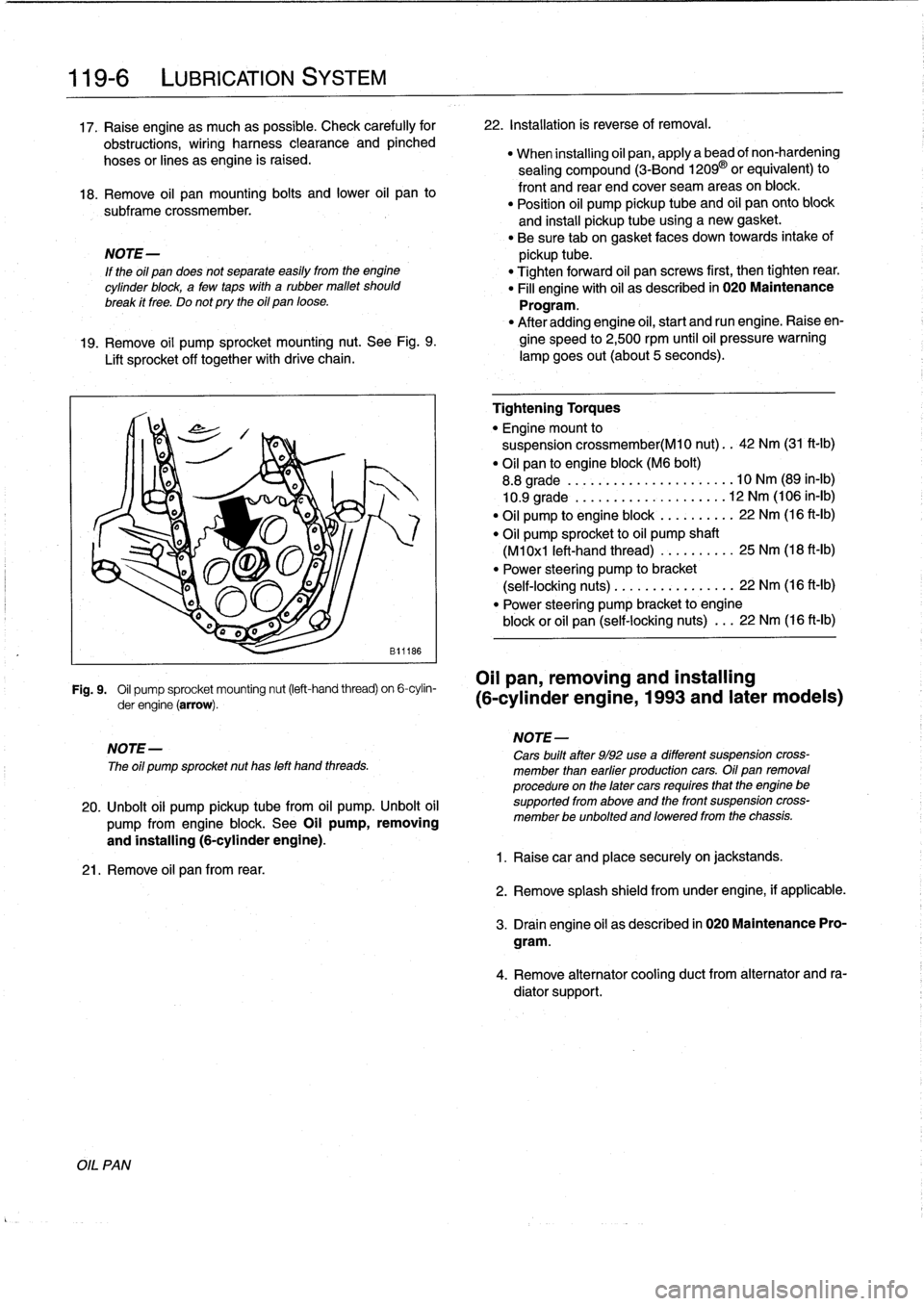

Fig

.

9

.

Oil

pump

sprocket

mounting

nut

(left-hand

thread)

on

6-cylin-

OII

pan,

removing

and

installing

derengine(arrow)

.

(6-cylinder

engine,

1993

and

later

modeis)

NOTE-

The

oíl

pump

sprocket

nut

has

left

hand

threads

.

20

.

Unbolt

oil

pump

pickup

tubefrom

oil

pump

.

Unbolt

oil

pump

from

engine

block

.

See

Oil

pump,

removing

and

installing

(6-cylinder

engine)

.

21

.

Remove

oil

pan

from

rear

.

Tightening

Torques

"

Engine

mount

to

suspension

crossmember(M10

nut)

..

42

Nm

(31

ft-Ib)

"

Oil

pan

to

engine

block

(M6

bolt)

8

.8

grade

....

..

.

...

...

.

........

10

Nm

(89

in-lb)

10

.9

grade

.

.

..

.

..

...

.

.

.

.

.

.....

12

Nm

(106

in-lb)

"

Oil

pump

to

engine

block

.

...

...

.

..

22

Nm

(16

ft-Ib)

"

Oil

pump

sprocket

to

oil

pump

shaft

(M1

0x1

left-hand

thread)

...

..

.

.

..

.

25

Nm

(18

ft-Ib)

"

Power

steering

pump

to

bracket

(self-locking

nuts)

.....

.

....

..

.

...

22

Nm

(16

ft-lb)

"

Power

steering

pump

bracket

to

engine

block

or

oil

pan

(self-locking

nuts)

.

..

22

Nm

(16

ft-Ib)

NOTE-

Cars

built

after

9/92

use

a

different

suspension

cross-

member

¡han

earfier

productíon

cars

.

Oil

pan

removal

procedure

on

the

later

cars

requíres

that

the

engine

be

supported

from

aboye

and

the

front

suspension

cross-

member

be

unbolted

and

loweredfrom

the

chassis

.

1

.

Raisecar

and

place

securely

on

jackstands

.

2

.

Remove

splash

shield

fromunder

engine,

if

applicable

.

3

.

Drain

engine

oil

as

descríbed

in

020

Maintenance

Pro-

gram

.

4

.

Remove

alternator

cooling

duct

from

alternator

and

ra-

diator

support

.

Page 148 of 759

130-2

FUEL

INJECTION

GENERAL

This

repair

group

covers

fuel

injection

system

component

testing

and

repair

.

Special

equipment

is

necessary

for

some

of

the

procedures

given

in

this

repair

group

.

If

you

do

not

have

the

equipment

required

to

do

the

job,

it

is

recommended

that

these

repairs

be

left

to

an

authorized

BMW

dealer

.

The

BMW

dealer

is

equipped

with

sophisticated

diagnostic

test

equip-

ment

that

is

capable

of

quicklypinpointing

hard-to-find

fuel

in-

jection

problems

.

NOTE-

"

Wiring

diagrams

for

the

engine

management

system,

can

be

found

at

the

rear

of

the

manual

under

Electri-

cal

Wiring

Diagrams

.

"

For

ignition

system

repairinformation,

see120

Igni-

tion

System

.

"

For

fuel

supply

system

testing

and

repair,

see160

The

engine

control

module

(ECM)

uses

electrical

signals

Fuel

Tank

and

Fuel

Pump

.

from

the

mass

air

flow

sensor,

the

air

and

coolant

temperature

sensors,

the

crankshaft

position/rpm

sensor,

the

knock

sen

Principies

Of

Operation

sors

and

the

oxygen

sensorsas

the

primary

inputs

to

electron-

ically

control

fuel

delivery

and

ignition

timing

.

There

are

five

versions

of

engine

management

systems

usedon

the

E36

cars

.

Each

has

the

same

basic

components

and

operating

principles

.

The

most

notable

difference

is

that

1996

and

later

cars

use

a

sophisticated

OBD

II-compliant

sys-

tem

.

See

Table

a

.

Table

a

.

Engine

Management

System

Variants

Engine

code/year

1

System

4-cy1inder

M42

(1

.8

I)

1992-1995

Bosch

DME

Ml

.7

M44

(1

.91)

1996-1998

~

Bosch

DME

M5

.2

(OBD

II)

6-cylinder

M50

1992

(2.5

I)

Bosch

DME

M3

.1

1993-1995

(2.5

I)

Bosch

DME

M3

.3.1

(VANOS)

M52

1996-1998

(3281-

2

.8

I)

Siemens

MS

41

.1

(OBD

II)

1998

(3231

-

2

.5

I)

Siemens

MS

41

.1

(OBD

II)

M-Power

S50US

(M3

-

3

.01)

1995

Bosch

DME

M3

.3

.1

S52US

(M3

-

3

.21)

1997-1998

Siemens

MS

41

.1

(0131)

11)

NOTE-

-

Descriptions

and

procedures

in

the

first

partof

this

re-

pairgroup

refer

to

all

the

various

engine

management

systems

.

"

Particulars

of

each

fuel

injection

system

are

treated

in

separate

sections

in

the

second

part

of

this

repair

group

.

GENERAL

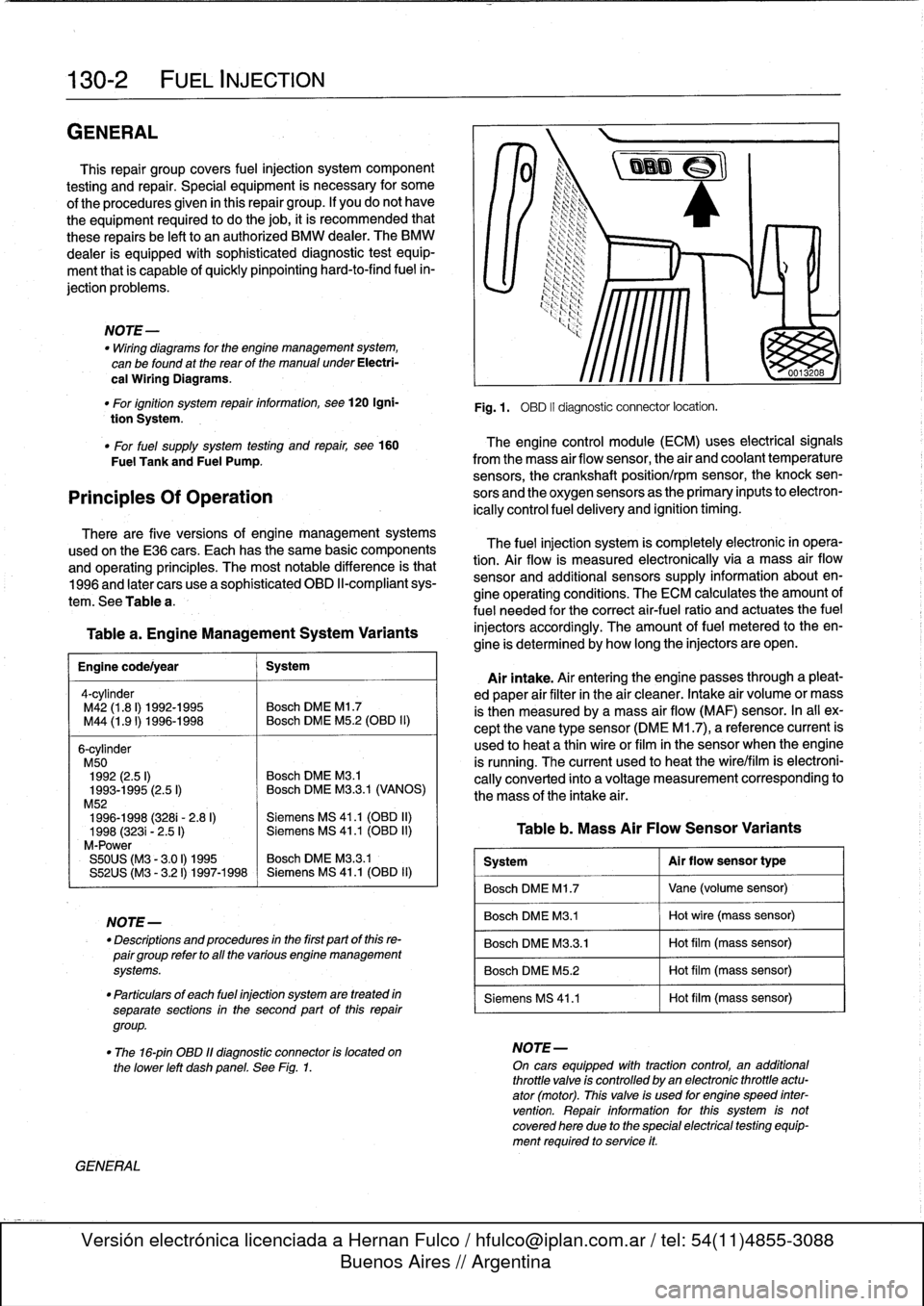

Fig

.1

.

OBD

II

diagnostic

connector

locatíon

.

The

fuel

injection

system

is

completely

electronic

in

opera-

tion

.

Air

flow

is

measured

electronically

via

a

mass

air

flow

sensor

and

additional

sensors

supply

information

about

en-

gine

operating

conditions

.

The

ECM

calculates

the

amount

of

fuel

needed

for

the

correct

air-fuel

ratio

and

actuates

the

fuel

injectors

accordingly

.

The

amount

offuel

metered

to

theen-

gine

is

determined

by

how

long

the

injectors

are

open

.

Airintake

.

Air

entering

the

engine

passes

through

a

pleat-

ed

paper

air

filter

in

the

air

cleaner

.

Intake

air

volume

or

mass

is

then

measured

bya

mass

air

flow

(MAF)

sensor

.

In

al¡

ex-

cept

the

vane

type

sensor

(DME

M1

.7),

a

reference

current

is

used

to

heat

a

thin

wireor

film

in

the

sensor

when

the

engine

is

running

.

The

current

used

to

heat

the

wire/film

is

electroni-

cally

converted

into

a

voltage

measurement

corresponding

to

the

mass

of

the

intake

air

.

Table

b

.

Mass

Air

Flow

Sensor

Variants

System

Al

r

flow

sensor

type

Bosch

DME

M1

.7

Vane

(volume

sensor)

Bosch

DME

M3

.1

Hot

wire

(mass

sensor)

Bosch

DME

M3

.3

.1

Hot

film

(mass

sensor)

Bosch

DME

M5

.2

Hot

film

(mass

sensor)

Siemens

MS

41

.1

Hot

film

(mass

sensor)

"

The

16-pin

OBD

11

diagnostic

connector

is

located

on

NOTE-

the

lower

left

dashpanel

.

See

Fig

.

1

.

On

cars

equipped

wíth

tractioncontrol,

an

additional

throttle

valve

is

controlled

by

an

electronic

throttle

actu-

ator

(motor)

.

This

valve

is

used

for

engine

speed

inter

vention

.

Repair

information

forthis

system

is

notcovered

here

due

to

the

special

electrical

testing

equip-

ment

required

to

service

it

.

Page 149 of 759

FUEL

INJECTION

130-

3

Fuel

metering

.

The

ECM

meters

fuel

bychanging

the

The

engine

management

system

compensates

automatical-

opening

time

(pulsewidth)

of

the

fuel

injectors

.

To

ensure

that

ly

for

changes

in

the

engine

due

to

age,

minor

wear

or

small

injector

pulsewídth

is

the

only

factor

that

determines

fuel

me-

problems,

such

as

a

disconnected

vacuum

hose

.

Asa

result,

tering,fuel

pressure

is

maintained

bya

fuel

pressure

regula-

idle

speed

and

mixture

do

not

need

lo

be

adjustedas

partof

tor

.

The

injectors

are

mounted

lo

a

common

fuel

supply

called

routine

maintenance

.

the

fuel

rail

.

The

ECM

monitors

engine

speed

to

determine

the

duration

NOTE-

ofinjector

openings

.

Other

signals

to

the

ECM

help

determine

Poordriveabilitymaybe

encountered

when

the

batteryis

injector

pulse

time

for

different

operating

conditions

.

A

tem-

disconnected

and

reconnected

.

when

the

battery

is

dis-

connected,

the

adaptive

memory

is

lost

The

system

will

perature

sensor

signals

engine

temperature

for

mixture

adap-

readaptafterabout

ten

minutes

of

drfving

.

tion

.

A

throttle

position

sensor

signals

throttle

position

.

The

exhaust

oxygen

sensor(s)

signal

information

about

combus-

tion

efficiency

for

control

of

the

air-fuel

mixture

.

1992

to

1995

DISA

(Dual

Resonance

Intake

System)

engines

are

equipped

with

a

single

sensor

.

1996

and

later

(OBD

II)

engines

are

equipped

with

an

oxygen

sensor

before

TheE36

4-cylinder

engine

is

equipped

with

a

dual

intake

andone

after

each

catalytic

converter

.

Forexample,the

M52

runner

system,

termed

DISA

.

DISA

offers

the

advantages

of

engine

is

equipped

withfour

oxygen

sensors

.

both

short

and

long

intake

pipes

.

Long

intake

runners

are

most

useful

at

low

to

medium

engine

rpm

for

producing

good

Idle

speed

control

.

ldle

speed

is

electronically

controlled

torque

characteristics

.

Short

intake

runners

produce

hígherviathe

idle

speed

control

valve,

which

maintains

idle

speed

by

horsepower

at

hígher

engine

speeds

.

bypassing

varying

amounts

of

air

around

theclosed

throttle

valve

.

Idle

speed

is

not

adjustable

.

NOTE-

Knock

(detonation)

control

.

Knock

sensors

monitor

and

The

term

DISA

comes

from

the

German

words

Differen-

control

ignition

knock

through

the

ECM

.

The

knock

sensors

zierte

Sauganlage,

and

can

roughlybe

translated

as

"dif-

fering

intake

manifold

configuration

."

See

100

Engine-

function

like

microphones

and

are

able

to

convert

mechanical

General

foradditional

information

on

DISA

operation

.

vibration

(knock)

into

electrical

signals

.

The

ECM

is

pro-

grammed

to

react

to

frequencies

that

are

characteristic

of

en-

Manifold

construction

:

The

intake

manifold

is

a

two-piece

gine

knock

and

adapt

the

ignition

timing

point

accordingly

.

metal

construction,

with

a

pair

of

runners

in

thetop

section

See120

Ignition

System

for

further

details

.

and

four

runners

in

the

lower

section

.

A

butterfly

valve

is

in-

stalled

in

the

lower

section,

enabling

the

DISA

solenoid

toiso-

NOTE-

late

one

pair

of

runners

from

the

other

pair

.

See

Fig

.

2

.

The

1992

M50

engine

is

not

equipped

with

knock

sen-

Operation

.

With

the

DISA

butterfly

valve

closed,

the

pipes

sors

.

All

other

engines

are

equipped

with

two

knock

in

thetop

half

of

the

manifold

act

together

with

the

ram

air

sensors

.

pipes

in

the

lower

halfto

producea

single,

long

air

intake

pipe

for

each

cylinder

.

See

Fig

.

3

.

The

column

of

aír

oscíllating

in

Basic

Engine

Settings

this

combined

pipe

significantly

increases

engine

torque

in

the

medium

rpm

range

.

Idle

speed,

idle

mixture

(%CO),

and

ignition

timing

arenot

adjustable

.

The

adaptive

engine

management

system

is

de-

signed

to

automatically

compensate

for

changes

in

engine

op-

eratingconditions,

although

the

adaptive

range

is

limited

.

Once

these

limits

are

exceeded,

driveability

problems

usually

be-

come

noticeable

.

Above

approximately

4,800

rpm,

the

butterfly

valve

between

the

intake

air

pipes

for

the

two

cylinder

groups

is

opened

.

The

shorter

pipes

in

the

lower

manifold

section

now

become

the

main

suppliers

of

ram

air

to

the

cylinders,yielding

greater

pow-

er

at

the

upper

end

of

the

engine

rpm

range

.

See

Fig

.

4

.

Control

components

.

The

DISA

butterfly

valve

is

actuated

NOTE-

electro-pneumatically

via

the

engine

control

module

(ECM)

.

lf

the

system

adaptive

limits

are

exceeded,

the

Check

The

valve

begins

to

open

as

engine

speed

rises

aboye

4,840

Engine

light

will

most

likely

come

on,

indicating

an

rpmand

closes

below

4,760

rpm

.

The

action

of

the

valve

is

de-

emissions-

related

fault

For

Check

Engine

light

diag-

liberately

delayed

to

prevent

it

from

opening

and

closing

repeat-

nostics,

see100

Engine-General

.

edly

within

a

short

time

.

GENERAL

Page 151 of 759

The

fuel

injection

systems

used

on

the

1996

and

later

cars

covered

bythis

manual

are

OBD

II

compliant

.

This

system

is

in-

corporated

into

both

the

Bosch

M5

.2

(M44

engine)

and

the

Si-

emens

MS

41

.1

(M52/S52US

engine)

engine

management

systems

.

OBD

II

systems

use

sophisticateddiagnostic

soft-

ware

capable

of

recognizing

and

electronically

storing

hun-

dreds

of

DTCs

in

the

system

ECM

.

DTCs

can

only

be

accessed

using

special

scan

tooltest

equipment

.

The

BMW

dealer

is

equipped

with

the

specialized

OBD

II

scan

toolto

quickly

and

efficiently

locate

engine

management

problems

.

Alternately,

a

"generic"

scan

tool

can

be

used

to

access

OBD

II

fault

informa-

tion

.

NOTE-

"

At

the

time

this

manual

went

to

press,

generic

scan

tools

were

notwidely

available

for

BMW

vehicles

.

The

generic

sean

tool

is

a

specialized

toolthat

plugs

into

a

standardized

OBD

11

connector

on

1996

and

later

pas-senger

vehícles

built

for

sale

in

the

US

.

"

The

OBD

11

fault

memory

(including

an

illuminated

Check

Engine

light)

can

only

be

reset

using

the

spe-

cial

scan

tool

.

Removing

the

connector

trom

the

ECM

or

disconnecting

the

battery

will

not

erase

the

fault

memory

.

"

The

16-pin

OBD

11

diagnostic

connector

is

located

on

the

lower

left

dash

panel

.

Refer

to

Fig

.

1

.

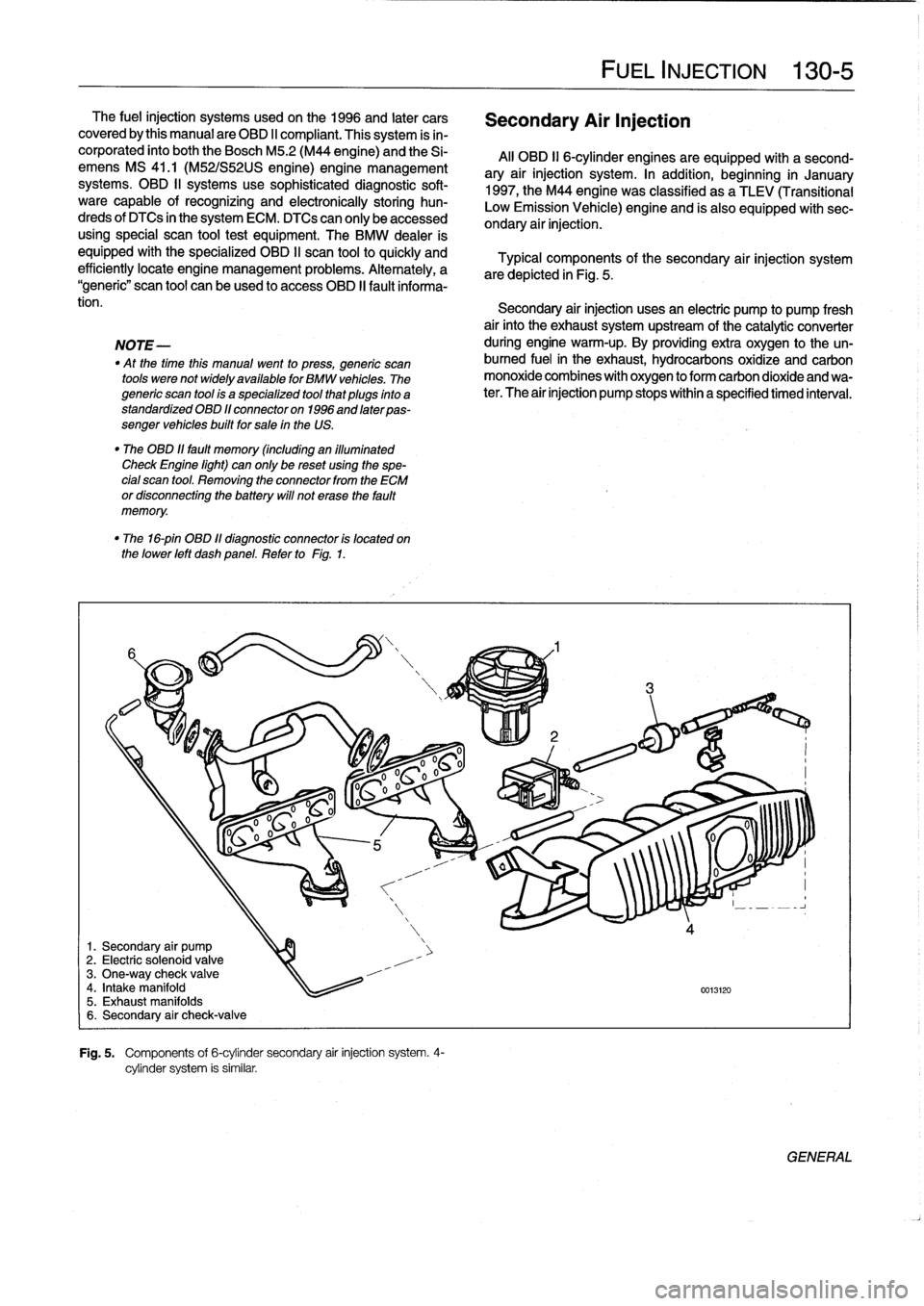

6

1

.

Secondary

air

pump

2

.

Electric

solenoid

valve

3

.

One-way

check

valve

4

.

Intake

manifold

5

.

Exhaust

manifolds

6

.

Secondary

air

check-valve

®

G~

i

o

o

0

0

G

0000

o

,-

00

~

1111111

in

,,

0

1--

a

Fig

.

5

.

Components

of

6-cylinder

secondary

air

injection

system

.

4-

cylinder

system

is

similar

.

Secondary

AirInjection

FUEL

INJECTION

130-

5

All

OBD

II

6-cylinder

engines

are

equípped

with

asecond-

ary

air

injection

system

.

In

addition,

beginning

in

January

1997,

the

M44

engine

was

classified

as

a

TLEV

(Transitional

Low

Emission

Vehicle)

engine

and

is

also

equipped

with

sec-

ondary

air

injection

.

Typical

components

of

the

secondary

air

injection

system

are

depicted

in

Fig

.

5

.

Secondary

air

injection

usesan

electric

pump

to

pump

fresh

air

finto

the

exhaust

systemupstream

of

the

catalytic

converter

during

engine

warm-up

.

By

providing

extra

oxygen

to

the

un-

burned

fuel

in

the

exhaust,

hydrocarbons

oxidize

and

carbon

monoxide

combines

with

oxygen

to

form

carbon

dioxide

andwa-

ter

.

The

air

injection

pump

stops

within

a

specified

timed

intenral

.

4

0013120

GENERAL

Page 157 of 759

3

.

Observe

fuel

pressure

gauge

after

20

minutes

.

The

pressure

shouldnot

drop

off

more

than

0

.5

bar

from

system

pressure

listed

in

Tablec

.

4

.

When

finished

testing,

disconnect

pressure

gauge

and

reconnect

fuel

line

.

If

the

fuel

system

does

not

maintain

pressure,

check

visual-

¡y

for

leaks

in

fuel

lines

orat

unions

.

Leaks

can

also

be

due

to

a

leaking

injector

or

a

faulty

fuel

pump

check

valve

.

Check

the

pump

check

valve

by

repeating

the

test,

butbefore

turning

the

fuel

pump

off,

pinch

off

theretum

line

at

the

fuel

rail

.

If

the

pressure

is

now

maintained,

the

fault

is

most

likely

the

fuel

pump

check

valva

.

Tabla

c

.

Fuel

Pressure

Specifications

Engine

1

Fuel

pressure

4-cytinder

1

3

.0

t

0

.2

bar

(43

.5

t

2

.9psi)

6-cytinder

M50/S50US

engine

3

.0

t

0

.2

bar

(43

.5

±2

.9psi)

M52/S52US

engine

3

.5

f

0

.2

bar

(51

t

2.9psi)

Fuel

pressure

regulator

response

to

engine

load,

testing

1

.

With

fuel

pressure

gauge

connected,

reinstallfuel

pump

relay

.

Start

engine

and

allow

it

to

idle

.

NOTE-

The

fuel

pressure

should

be

lower

by0

.4-0.7

bar

from

the

specifications

listed

in

Table

c

.

Engine

vacuum

act-

ing

on

the

fuel

pressure

regulator

diaphragm

reduces

the

fuel

pressure

.

2

.

With

engine

idling,

remove

vacuum

hose

from

regula-

tor

.

Pressure

should

increase

.

3

.

Reconnecthose

and

check

that

pressure

decreases

.

4

.

When

finished

testing,

disconnect

pressure

gauge

and

reconnect

fuelline

.

Tighten

hose

clamp

.

0013190

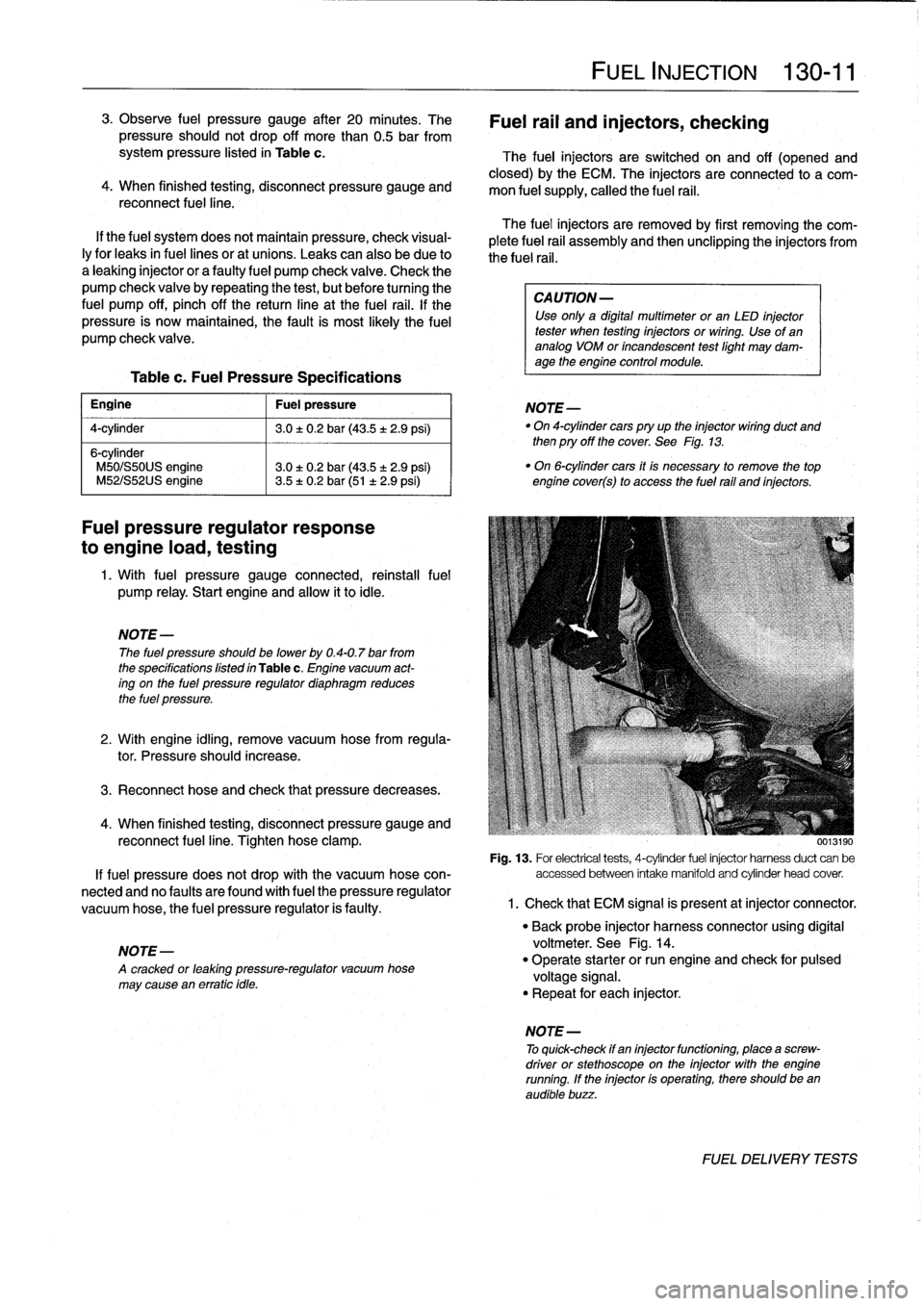

Fig

.

13

.

For

electrical

tests,

4-cytinder

fuel

injector

harnessduct

can

be

If

fuel

pressure

does

not

drop

with

the

vacuum

hose

con-

accessed

between

intake

manifold

and

cytinder

head

cover

.

nected

and

no

faulty

are

found

with

fuel

the

pressure

regulator

vacuum

hose,

the

fuel

pressure

regulator

is

faulty

.

1

.

Check

that

ECM

signal

is

present

atinjector

connector

.

NOTE-

A

cracked

or

leaktng

pressure-regulator

vacuum

hose

may

cause

en

erratic

tdle

.

FUEL

INJECTION

130-

11

Fuel

rail

and

injectors,

checking

The

fuel

injectors

are

switched

on

and

off

(opened

and

closed)

by

the

ECM

.

The

injectors

are

connected

to

a

com-

mon

fuel

supply,

callad

the

fuel

rail

.

The

fuel

injectors

are

removed

by

first

removing

the

com-

plete

fuel

rail

assembly

and

then

unclipping

the

injectors

from

the

fuel

rail

.

CA

UTION-

Use

only

a

digital

multimeter

or

an

LED

injector

tester

when

testing

injectors

or

wiring

.

Use

of

ananalog

VOM

or

incandescent

testlight

may

dam-

age

the

engine

control

module

.

NOTE-

"

On

4-cytindercars

pry

up

the

injector

wiring

duct

and

then

pry

off

the

cover

.

See

Fig

.

13

.

"

On

6-cytinder

cars

it

is

necessary

to

remove

the

top

engine

cover(s)

to

access

the

fuel

rail

and

injectors

.

"

Back

probe

injector

harness

connector

using

digital

voltmeter

.

See

Fig

.

14

.

"

Operate

starter

or

run

engine

and

check

for

pulsad

voltage

signal

.

"

Repeat

for

each

injector

.

NOTE

-

To

quick-check

if

en

injectorfunctioning,

place

a

screw-

driver

or

stethoscope

on

the

injector

with

the

engine

running

.

If

the

injector

is

operating,there

should

been

audible

buzz

.

FUEL

DELIVERYTESTS