m42 BMW 318i 1992 E36 Owner's Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1992, Model line: 318i, Model: BMW 318i 1992 E36Pages: 759

Page 162 of 759

130-

1

6

FUEL

INJECTION

Throttie

position

sensor

(TPS),

Idie

speed

control

valve,

testing

and

replacing

testing

and

replacing

The

throttie

position

sensor

(TPS)

is

mounted

on

the

side

of

¡die

speed

is

maintained

by

the

ECM

via

the

¡die

speed

con-

the

throttie

housing

and

is

directly

connected

to

the

throttie

trol

valve

.

See

Fig

.

24

.

¡die

speed

is

adaptive

through

the

valve

shaft

.

The

ECM

sends

a

voltage

signal

to

the

potentiom-

ECM

and

no

¡die

speed

adjustments

can

be

made

.

Before

eter-type

sensor

and

monitors

the

voltage

that

comes

back

.

testing

the

valve,

confirm

that

the

throttie

position

sensor(TPS)

is

working

correctly

.

Check

TPS

function

by

disconnecting

the

harnessconnec-

tor

and

checking

reference

voltage

and

sensor

resistance

.

See

Table

e

and

Fig

.

23

.

If

voltage

is

not

present,

check

the

output

voltage

signal

from

the

ECM

and

check

the

wiring

be-

tween

the

sensor

and

the

ECM

.

If

the

sensor

resistance

is

in-

correct,

replace

the

throttie

position

sensor

.

NOTE

-

The

throttie

position

sensor

is

not

adjustable

.

If

test

re-

sults

are

íncorrect,

the

sensor

should

be

replaced

.

Table

e

.

Throttle

Position

Sensor

Tests

(DME

1

.7)

Testconditions

1

Terminais

1

Test

value

Harness

connec-

(

1

and

ground

in

15

VDC

(approx

.)

tor

disconnected,

harness

connector

ignition

on

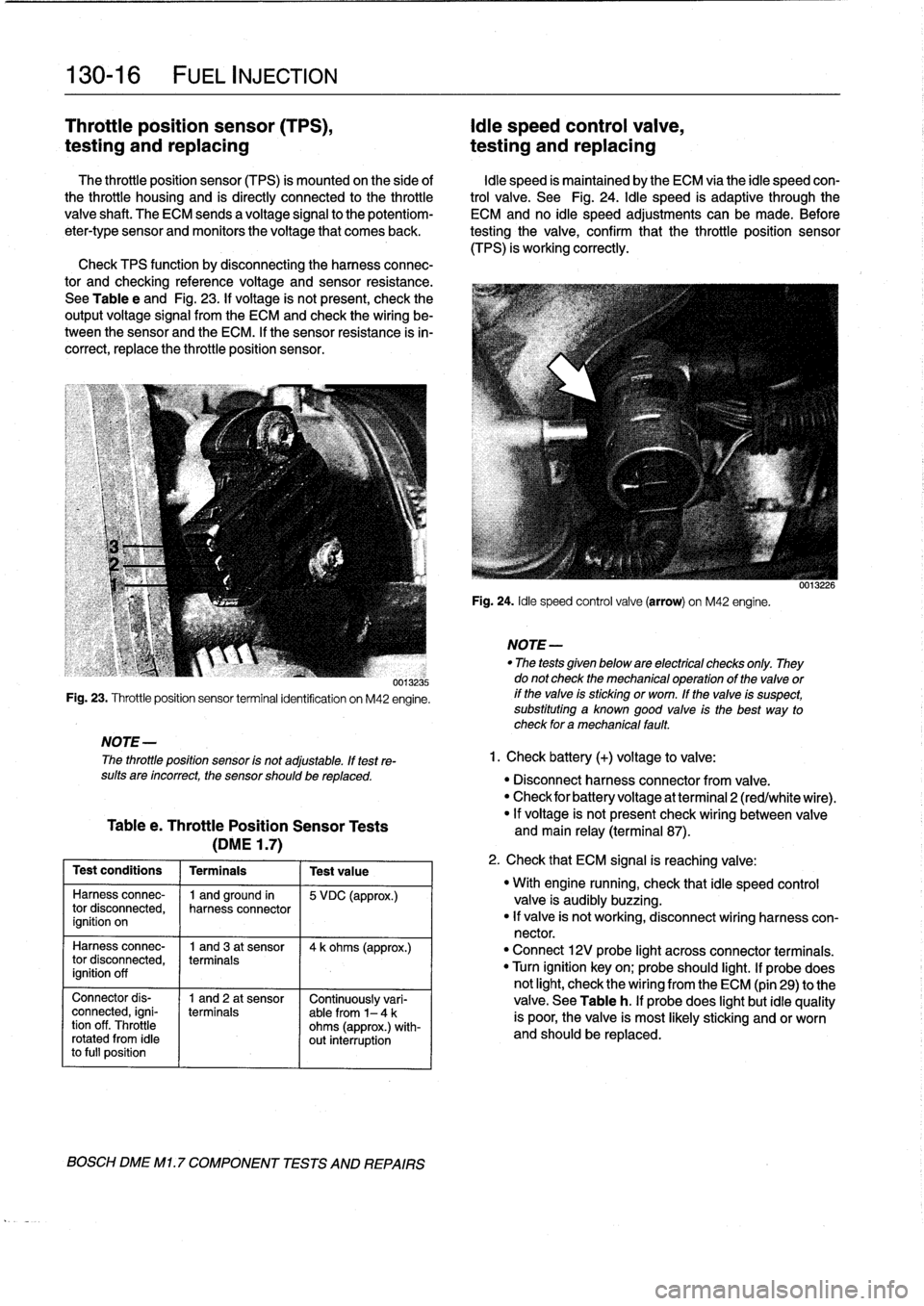

0013235

Fig

.

23

.

Throttieposition

sensor

terminal

identification

on

M42

engine

.

Harnessconnec-

I

1

and

3

at

sensor

(

4k

ohms

(approx

.)

tor

disconnected,

terminais

ignition

off

Connector

dis-

1

and

2

at

sensor

Continuously

vari-

connected,

igni-

terminais

able

from

1-4

k

tion

off

.

Throttle

ohms

(approx

.)

with

rotated

from

¡die

out

interruption

to

fui]

position

BOSCH

DME

Ml

.

7

COMPONENT

TESTS

AND

REPAIRS

Fig

.

24

.

¡die

speed

control

valve

(arrow)

on

M42

engine

.

NOTE

-

"

The

tests

given

below

are

electrical

checks

only

.

They

do

not

check

the

mechanical

operation

of

the

valve

or

if

the

valve

is

sticking

or

worn

.

If

the

valve

is

suspect,

substituting

a

known

good

valve

is

the

best

way

to

check

for

amechanical

fault

.

1

.

Check

battery

(+)

voltage

to

valve

:

0013226

"

Disconnect

harness

connector

from

valve

.

"

Check

for

battery

voltage

at

terminal

2

(red/white

wire)

.

"

If

voltage

is

not

present

check

wiring

between

valve

and

main

relay

(terminal

87)

.

2

.

Check

that

ECM

signal

is

reaching

valve

:

"

With

engine

running,

check

that

¡die

speed

control

valve

is

audibly

buzzing

.

"

If

valve

is

not

working,

disconnect

wiring

harness

con-

nector

.

"

Connect

12V

probe

light

across

connector

terminais

.

"

Turn

ignition

key

on

;

probe

should

light

.

lf

probe

does

nof

light,

check

the

wiring

from

the

ECM

(pin

29)

to

the

valve

.

See

Table

h

.

lf

probe

does

light

but

¡die

quality

is

poor,

the

valve

is

most

likely

sticking

and

or

worn

and

should

be

replaced

.

Page 194 of 759

160-

1

0

FUEL

TANK

AND

FUEL

PUMP

3

.

Operate

fuel

pump

as

described

earlier

under

Operat-

ing

fuel

pump

for

tests

.

Check

that

fuel

pressure

cor-

responds

to

specifications

listed

in

Table

c

.

"

If

system

pressure

is

low,

repeat

test

whilegradually

pinching

off

return

hose

.

Pressure

should

rise

rapidly

.

If

not,fuel

pump

is

most

likely

faulty

.

"

If

system

pressure

is

too

high,

check

return

line

from

pressure

regulator

to

tank

.

Check

for

kinks

in

hose

.

Blow

compressed

air

through

line

to

check

for

block-

ages

.

If

no

faulty

canbe

found,

pressure

regulator

is

most

likely

faulty

.

See

130

Fuel

Injection

for

testing

and

replacementprocedures

.

Table

c

.

Fuel

Pressure

Specifications

Engine

1

Fuel

pressure

4-cylinder

M42/M44

3

.0

:e

0

.06

bar(43

.5

±0

.9

psi)

6-cylinder

M50/S50US

3

.0

:j-

0

.06bar(43

.5

t0

.9

psi)

M52/S52US

3

.5

t

0

.06

bar

(51

t0

.9psi)

CA

UTION-

Do

not

use

compressed

air

above

40

psi

to

blow

out

fines

or

components

.

Interna¡

damage

to

com-

ponents

may

result

.

4

.

When

finished,

disconnect

pressure

gauge

.

FUEL

PUMP

Fuel

delivery

volume,

testing

1

.

Disconnect

return

line

from

fuel

rail

in

engine

compart-

ment

.

2

.

Connect

a

length

of

hose

to

fitting

on

fuel

rail

and

place

open

end

of

hose

in

a

suitable

container

for

catching

fuel

(2-quart

capacity)

.

3

.

Run

fuel

pump

for

exactly

30

seconds

as

described

earlier

under

Operating

fuel

pump

for

tests

and

mea-

sure

fuel

collected

.

Refer

to

Table

d

.

WARNING-

Table

d

.

Fuel

Pump

Delivery

Specifications

Fuel

under

pressure

is

present

duringthe

test

.

Use

I

Engine

Delivery

rate

(30

seconds

@

12V)

hose

clamps

at

all

connections

.

4-cylinder

M42/M44

0

.875

fter

(0

.93

qt)

6-cylinder

M50/S50US

0

.875

fter(0

.93

qt)

M52/S52US

~

1

.12

liter

(1

.16

qt)

4

.

When

finished

testing,

reconnect

fuel

line

.

Tighten

all

hose

clamps

.

NOTE-

It

is

common

practice

to

replace

the

fuel

filter

any

time

the

fuel

pump

unit

is

replaced

.

Page 213 of 759

GENERAL

..

.

......

.

.

.

.....

.

...

.

.

.

.

.

.

.

.

200-1

Manual

Transmission

.

.

.....

.

.

.

.'

.

.

.

.

.

.

.

.

200-1

Automatic

Transmission

.........

.

.

.

.

.

.

.

.

200-1

Transmission

ID

Codes

..........

.

.

.

.

.

.

.

.

200-2

GENERAL

E36

models

areequipped

with

a

longitudinal

drivetrain

.

The

transmission

is

bolted

directly

to

the

rear

of

the

engine

.

A

driveshaft

connects

the

output

shaft

of

thetransmission

to

the

final

drive

.

The

final

drive

is

mounted

lo

the

rear

suspension

and

the

body

.

Individual

drive

axles

with

integrated

constant

velocity

joints

transfer

rotational

power

to

the

rear

wheels

.

Manual

Transmission

Due

to

different

power

characteristics

and

performance

re-

quirements,

four

different

manual

transmissions

are

used

in

the

models

coveredby

this

manual

.

Manual

transmission

ap-

plications

are

given

in

Table

a

.

TRANSMISSION-GENERAL

200-1

200

Transmission-General

TABLES

a

.

Manual

Transmission

Applications

..

...........

200-1

b

.

Automatic

Transmission

Applications

...........

200-1

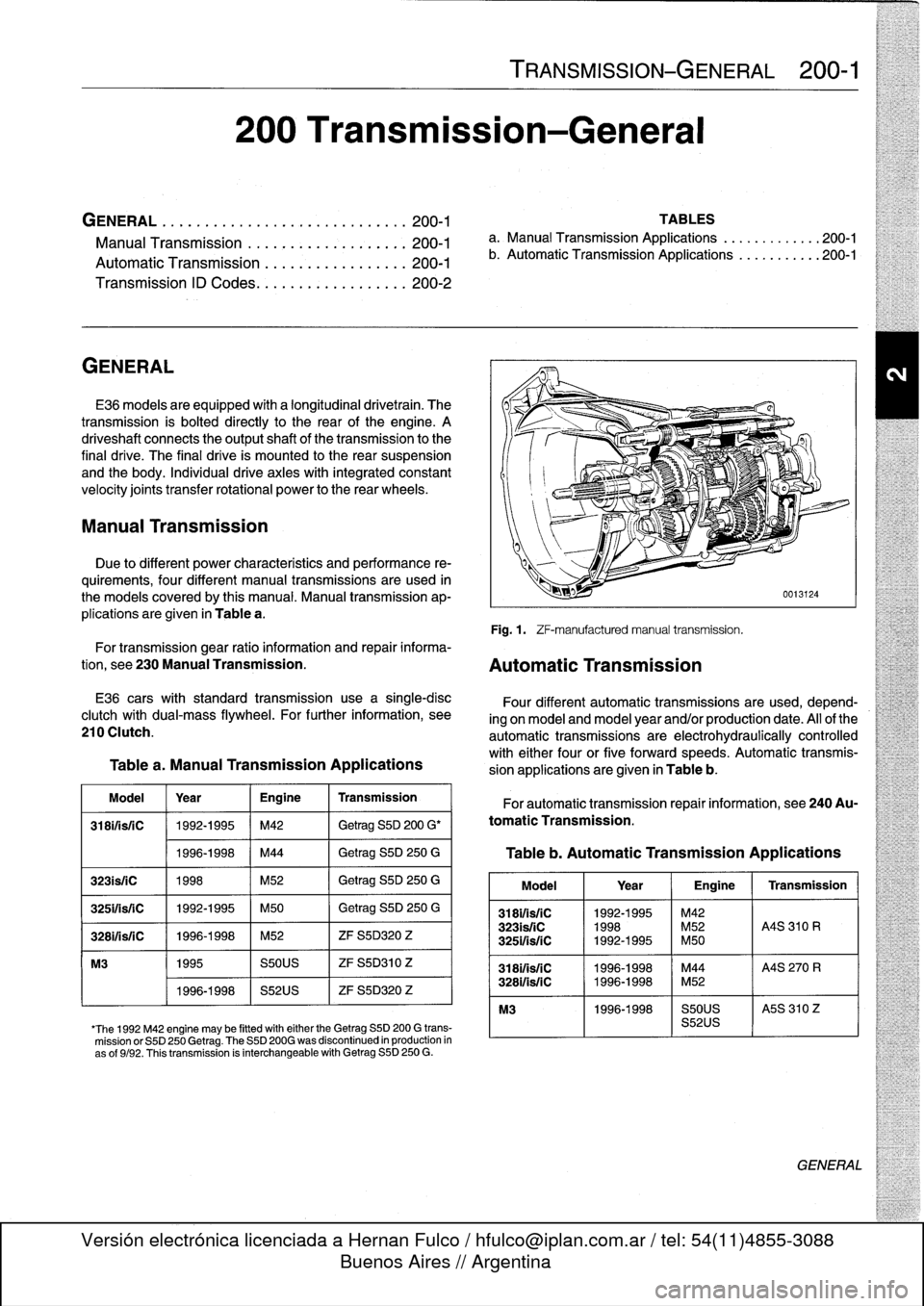

Fig

.

1

.

ZF-manufacturedmanual

transmission

.

For

transmission

gear

ratio

information

and

repair

informa-

tion,

see

230

Manual

Transmission

.

Automatic

Transmission

E36

carswith

standard

transmission

use

a

single-disc

clutch

with

dual-mass

flywheel

.

For

further

information,

see

210

Clutch

.

Table

a

.

Manual

Transmission

Applications

Model

Year

Engine

Transmission

318ifisfC

1992-1995

M42

Getrag

S5D

200

G'

1996-1998

M44

Getrag

S5D

250

G

323is/iC

1998

M52

Getrag

S5D

250

G

325ifsriC

1992-1995

M50

Getrag

S5D

250

G

3281/isfC

1996-1998

M52

ZF

S5D320

Z

M3

1995

S50US

ZF

S5D310

Z

1996-1998

S52US

ZF

S5D320

Z

'The

1992

M42

engine

may

be

fitted

witheither

the

Getrag

SSD

200

G

trans-

mission

or

S5D

250

Getrag

.

The

S5D

200G

was

discontinued

in

production

in

as

of

9/92

.

Thistransmission

is

interchangeable

with

Getrag

S5D

250

G

.

Four

different

automatic

transmissions

are

used,

depend-

ing

on

model

and

model

year

and/or

production

date

.

All

of

the

automatic

transmissions

are

electrohydraulically

controlled

with

either

four

or

five

forward

speeds

.

Automatic

transmis-

sion

applications

are

given

in

Table

b

.

For

automatic

transmission

repair

information,

see

240Au-

tomatic

Transmission

.

Table

b

.

Automatic

Transmission

Applications

Model

1

Year

1

Engine

1

Transmission

318i1is/1C

1992-1995

~

M42

323isfiC

1998

M52

A4S

310

R

3251/is/1C

1992-1995

M50

3181/isfC

11996-1998

M44

A4S

270

R

328i/is/1C

1996-1998

M52

M3

1996-1998

S50US

I

A5S

310

Z

S52US

GENERAL

Page 220 of 759

210-

6

CLUTCH

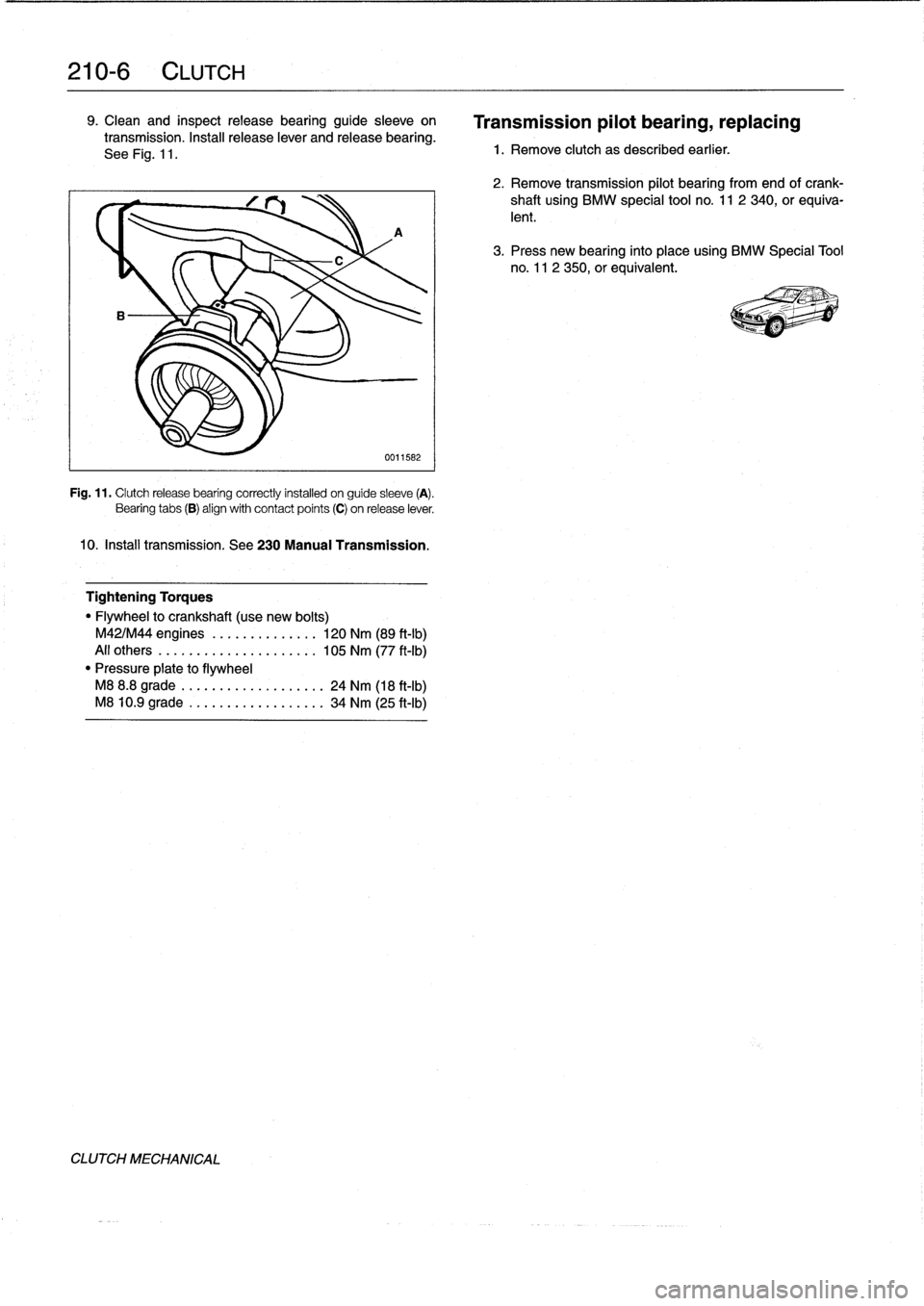

9

.

Clean

and

inspectrelease

bearing

guide

sleeve

on

transmission

.

Install

release

lever

and

release

bearing

.

See

Fig

.

11

.

A

0011582

Fig

.

11

.

Clutchrelease

bearing

correctly

installed

on

guide

sleeve

(A)

.

Bearing

tabs

(B)

align

with

contact

points

(C)

on

release

lever

.

10

.

Insta¡¡

transmission

.

See230

Manual

Transmission

.

Tightening

Torques

"

Flywheel

to

crankshaft

(use

new

bolts)

M42/M44

engines

....

.

..

...

....

120

Nm

(89

ft-Ib)

All

others

..........

..

.

..

......

105

Nm

(77

ft-Ib)

"

Pressure

píate

to

flywheel

M8

8

.8

grade

......

...

.

.

........

24

Nm

(18

ft-Ib)

M8

10

.9

grade

.....

..

..

..

.......

34

Nm

(25

ft-Ib)

CLUTCH

MECHANICAL

Transmission

pilot

bearing,

replacing

1

.

Remove

clutch

as

described

earlier

.

2

.

Remove

transmission

pilot

bearing

from

end

ofcrank-

shaft

using

BMW

special

tool

no

.

11

2

340,

or

equiva-

lent

.

3

.

Press

new

bearing

finto

placeusing

BMW

Specíal

Tool

no

.

11

2

350,or

equivalent

.

Page 390 of 759

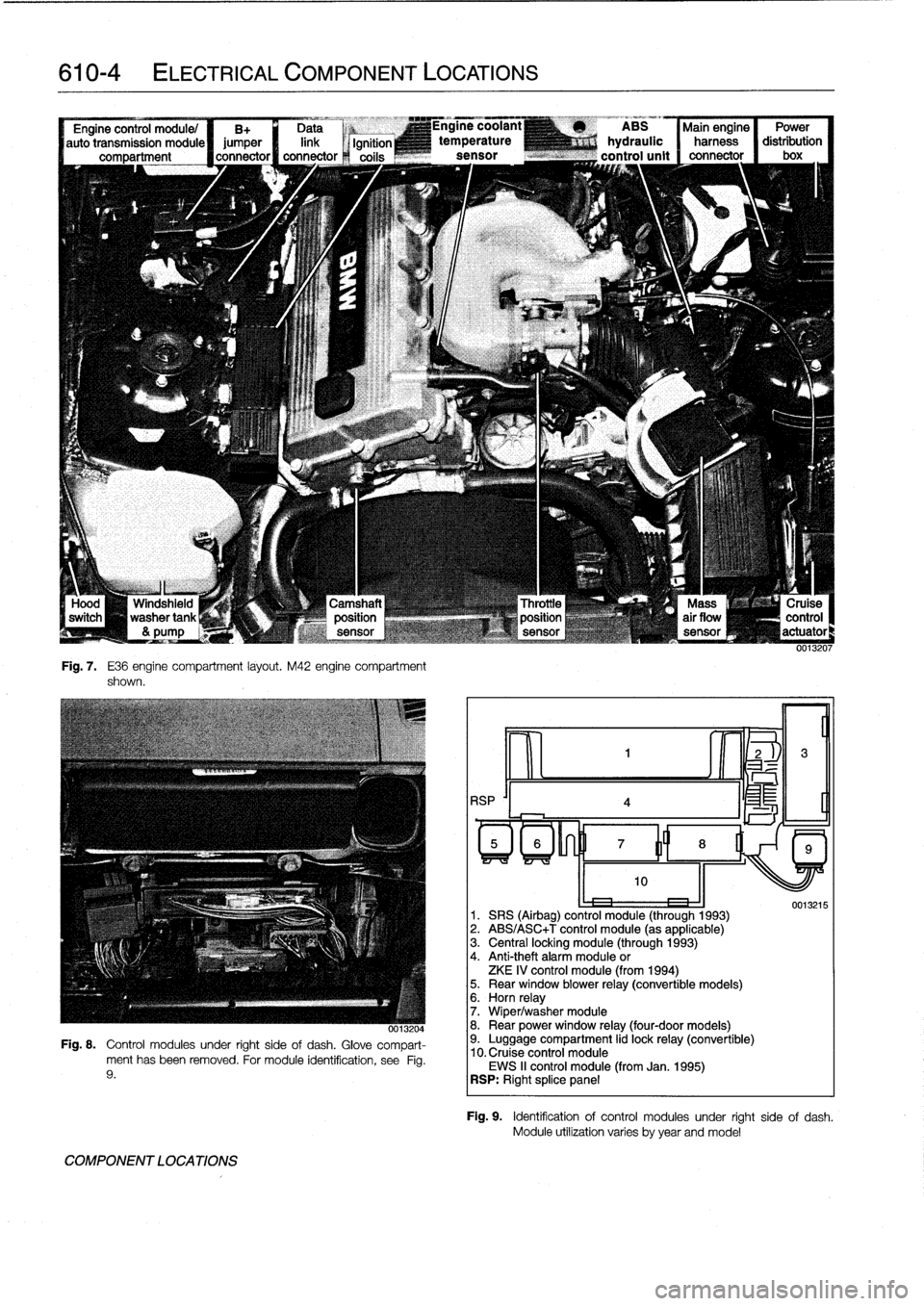

610-4

ELECTRICAL

COMPONENT

LOCATIONS

--J

L

Windshield

washertank

&

pump

Fig

.

7

.

E36

engine

compartment

layout

.

M42

engine

compartment

shown

.

-,x

0013204

Fig

.

8

.

Control

modules

under

right

sideof

dash

.

Glove

compart-

ment

has

been

removed

.

For

module

identification,

see

Fig

.

9

.

COMPONENT

LOCATIONS

RSP

'I

4

ABS

Main

engine

Power

hydraulic

harness

distribution

control

unit

connector

I

box

oe

1

.

SRS

(Airbag)

control

module

(through

1993)

2

.

ABS/ASC+T

control

module

(as

applicable)

3

.

Central

locking

module

(through

1993)

4

.

Anti-theft

alarm

module

or

ZKE

IV

control

module

(from

1994)5

.

Rear

window

blower

relay

(convertible

models)6

.

Horn

relay

7

.

Wiper/washer

module

8

.

Rear

power

window

relay

(four-door

models)9

.

Luggage

compartment

lid

lock

relay

(convertible)

10

.

Cruise

control

module

EWS

II

control

module

(from

Jan

.

1995)

RSP

:

Right

splice

panel

0013215

Fig

.

9

.

Identificationof

control

modules

under

right

side

of

dash

.

Module

utilízation

varies

byyear

andmodel

Page 391 of 759

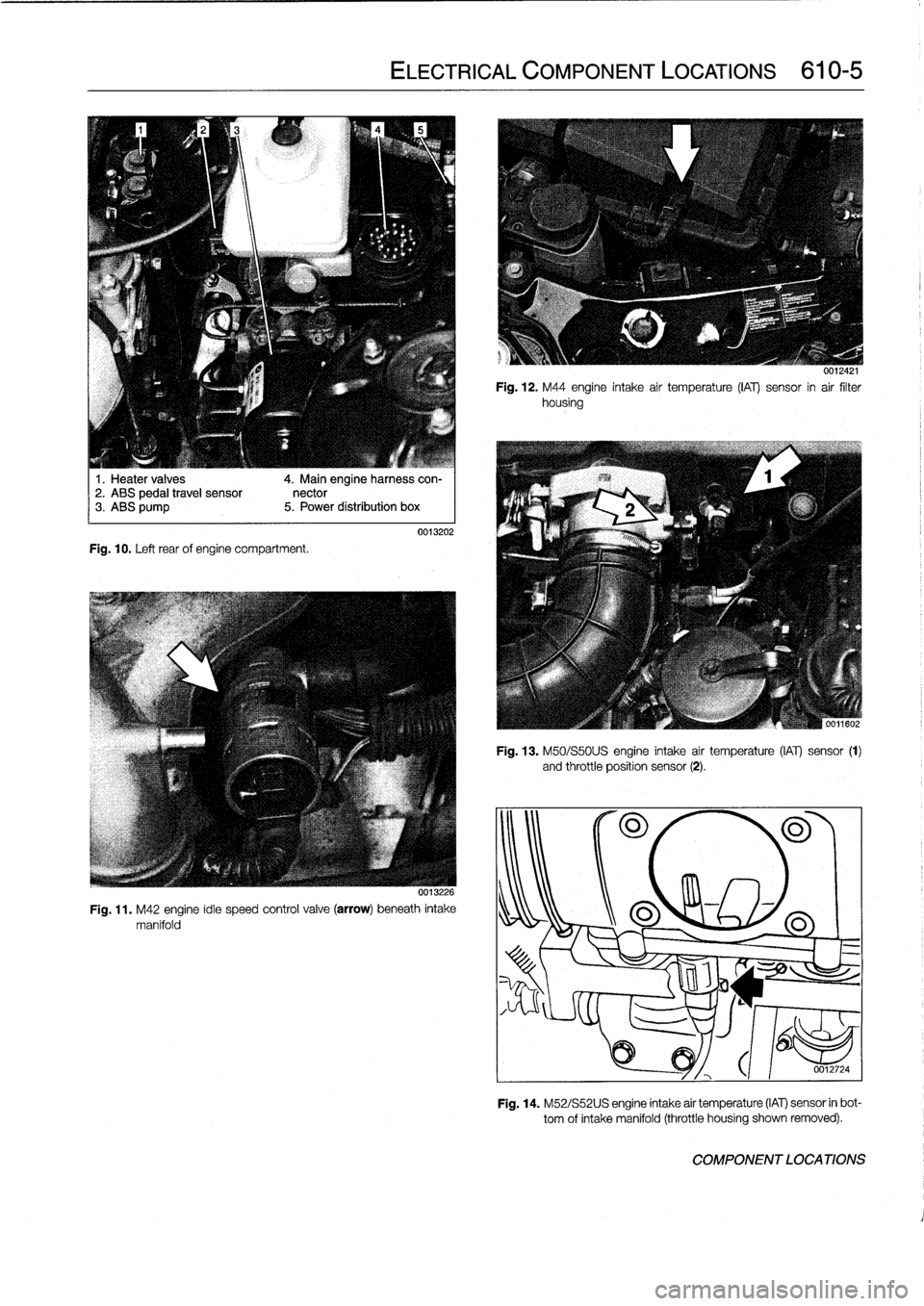

1

.

Heater

valves

2

.

ABS

pedal

travel

sensor3

.

ABS

pump

Fig

.

10

.

Left

rear

of

engine

compartment

.

4

.

Main

engineharness

con-

nector

5

.

Power

distribution

box

ELECTRICAL

COMPONENT

LOCATIONS

610-5

0013202

0013226

Fig

.

11

.

M42

engine

idie

speed

control

valve

(arrow)

beneath

intake

manifold

0012421

Fig

.

12

.

M44

engine

intake

air

temperature

(¡Al)

sensor

in

air

filter

housing

Fig

.

13

.

M50/S50U

S

engine

intake

air

temperature

(IAT)

sensor

(1)

and

throttle

position

sensor

(2)

.

301180

0012724

Fig

.

14

.

M52/S52U

S

engine

intake

air

temperature

(IAT)

sensor

in

bot-

tom

of

intake

manifold

(throttle

housing

shown

removed)

.

COMPONENT

LOCATIONS

Page 401 of 759

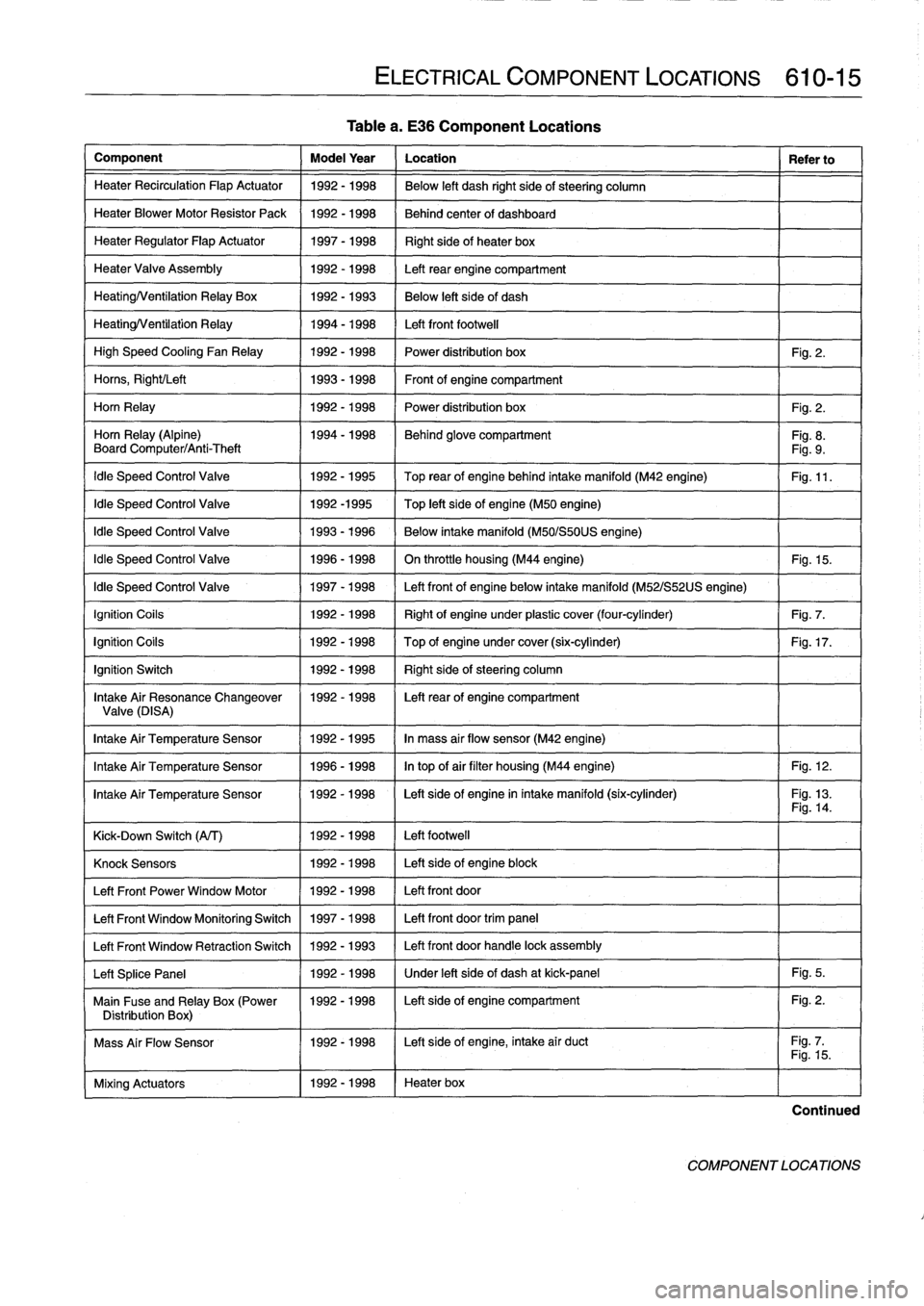

Component

Model

Year

Location

Refer

to

Heater

Recirculation

Flap

Actuator

1992-1998

Below

left

dash

right

side

of

steering

column

HeaterBlowerMotor

Resistor

Pack

1992-1998

Behind

center

of

dashboard

Heater

Regulator

FlapActuator

1997-1998

Right

side

of

heater

box

HeaterValve

Assembly

1992-1998

Left

rear

engine

compartment

HeatingNentilation

Relay

Box

1992-1993

Below

left

side

of

dash

HeatingNentilation

Relay

1994-1998

Left

front

footwell

High

Speed

Cooling

Fan

Relay

1992-1998

Power

distribution

box

Fig

.

2

.

Homs,

Right/Left

1993-1998

Front

of

engine

compartment

Horn

Relay

1992-1998

Power

distribution

box

Fig

.

2

.

Horn

Relay

(Alpine)

1994-1998

Behind

glove

compartment

Fig

.

8

.

Board

Computer/Anti-Theft

Fig

.

9

.

Idle

Speed

Control

Valve

1992-1995

Top

rearof

enginebehind

intake

manifold

(M42

engine)

Fig

.

11

.

Idle

Speed

Control

Valve

1992-1995

Top

left

side

of

engine

(M50

engine)

Idle

Speed

Control

Valve

1993-1996

Below

intake

manifold

(M50/S50US

engine)

Idle

Speed

Control

Valve

1996-1998

On

throttle

housing

(M44

engine)

Fig

.

15

.

Idle

Speed

Control

Valve

1997-1998

Left

front

of

engine

below

intake

manifold

(M52/S52US

engine)

Ignition

Coils

1992-1998

Right

of

engineunder

plastic

cover

(four-cylinder)

Fig

.

7

.

Ignition

Cofs

1992-1998

Top

of

engine

undercover

(six-cylinder)

Fig

.

17

.

Ignition

Switch

1992-1998

Right

sídeofsteering

column

Intake

Air

Resonance

Changeover

1992-1998

Leftrear

of

engine

compartment

Valve(DISA)

Intake

Air

Temperature

Sensor

1992-1995

In

mass

air

flow

sensor

(M42

engine)

Intake

Air

TemperatureSensor

1996-1998

In

top

ofair

filter

housing

(M44

engine)

Fig

.

12

.

Intake

Air

Temperature

Sensor

1992-1998

I

Left

sídeof

engine

in

intake

manifold

(six-cylinder)

-

-

I

Fig

.

13

.

Fig

.

14

.

Kick-Down

Switch

(A/T)

1

1992-1998

1

Left

footwell

Mixing

Actuators

1

1992-1998

1

Heater

box

ELECTRICAL

COMPONENT

LOCATIONS

610-15

Table

a

.

E36

Component

Locations

Knock

Sensors

1

1992-1998

1

Left

side

of

engine

block

Left

Front

Power

Window

Motor

11992-1998

/

Left

front

door

Left

Front

Window

Monitoring

Switch

1

1997-1998

1

Left

front

door

trim

panel

Left

Front

Window

Retraction

Switch

1

1992

-

1993

1

Left

front

door

handle

lock

assembly

Left

Splice

Panel

1

1992-1998

1

Under

left

side

of

dash

at

kick-panel

1

Fig

.

5

.

Main

Fuse

and

Relay

Box

(Power

1992-1998

I

Left

sideof

engine

compartment

Fig

.

2

.

Distribution

Box)

1

I

Mass

Air

Flow

Sensor

1992-1998

I

Left

side

of

engine,

intake

air

duct

Fig

.

7

.1

I

Fig

.

15

.

Continued

COMPONENT

LOCATIONS

Page 402 of 759

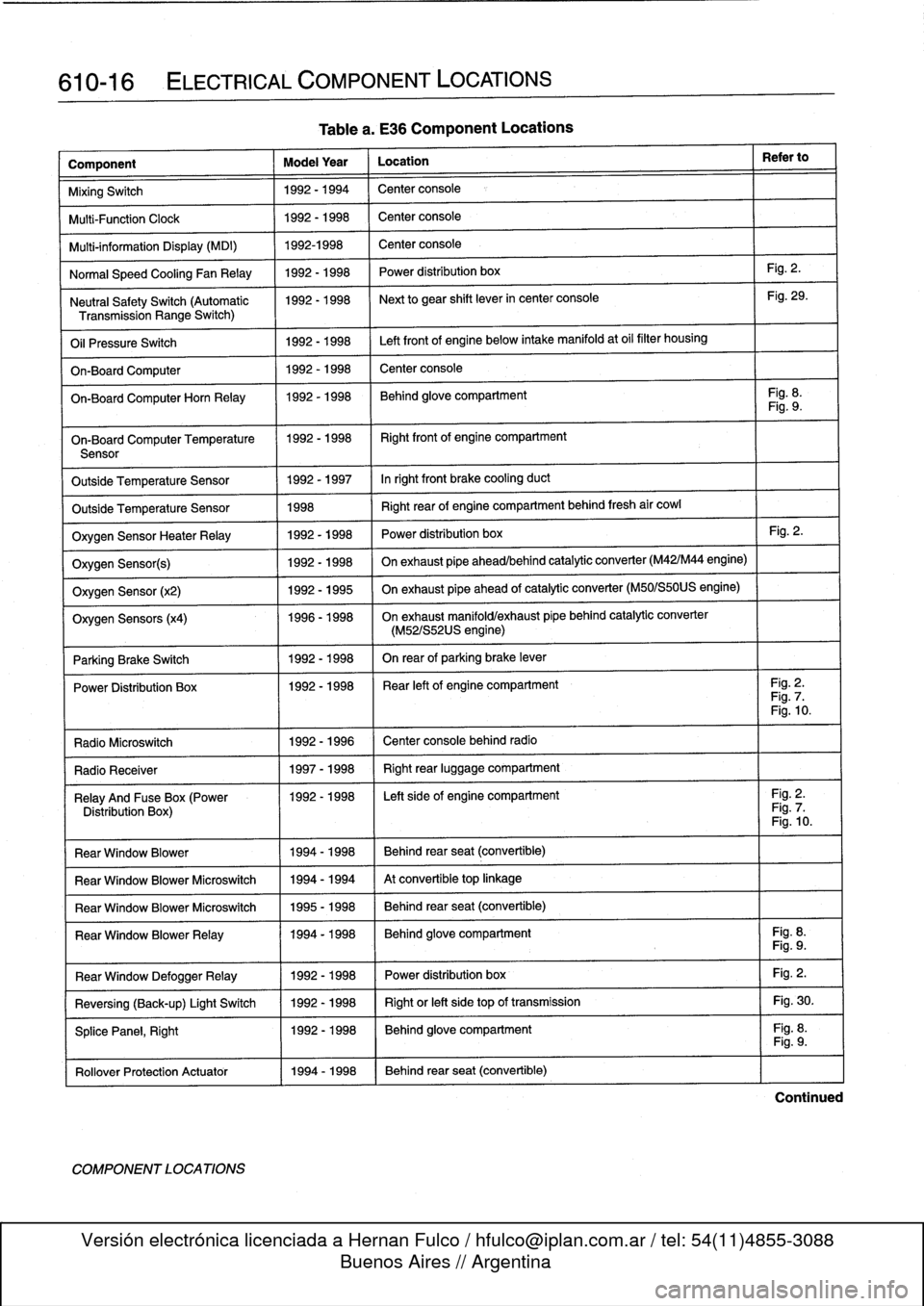

610-16

ELECTRICAL

COMPONENT

LOCATIONS

Component

Model

Year

Location

Refer

to

MixingSwitch

1992-1994

Center

console

Multi-Function

Clock

1992-1998

Center

console

Multi-information

Display

(MDI)

1992-1998

Center

console

Normal

Speed

Cooling

Fan

Relay

1992-1998

Power

distribution

box

Fig

.

2

.

Neutral

SafetySwitch

(Automatic

1992-1998

Next

to

gear

shift

lever

in

center

console

Fig

.

29

.

Transmission

Range

Switch)

Oil

Pressure

Switch

1992-1998

Left

front

of

engine

below

intake

manifold

at

oil

filter

housing

On-Board

Computer

1992-1998

Center

console

On-BoardComputerHorn

Relay

1992-1998

Behind

glove

compartment

Fig

.

8

.

Fig

.

9

.

On-Board

Computer

Temperature

11992-1998

I

Right

front

of

engine

compartment

Sensor

Outside

Temperature

Sensor

1992-1997

Inright

front

brake

cooling

duct

Outside

Temperature

Sensor

1998

Right

rear

of

engine

compartment

behind

fresh

air

cowl

Oxygen

Sensor

HeaterRelay

1992-1998

Power

distribution

box

Fig

.

2

.

Oxygen

Sensor(s)

1992-1998

On

exhaust

pipe

ahead/behind

catalytic

converter

(M42/M44

engine)

Oxygen

Sensor

(x2)

1992-1995

On

exhaust

pipe

ahead

of

catalytic

converter

(M50/S50US

engine)

Oxygen

Sensors

(x4)

1996-1998

On

exhaust

manifold/exhaust

pípe

behind

catalytic

converter

(M52/S52US

engine)

Parking

Brake

Switch

1

1992-1998

I

On

rear

of

parking

brake

lever

Power

Distribution

Box

11992-1998

I

Rear

left

of

engine

compartment

I

Fig

.

2

.

Fig

.

7

.

Fig

.

10

.

Radio

Microswitch

1992

-

1996

Center

console

behind

radio

Radio

Receíver

1

1997-1998

1

Right

rear

luggage

compartment

Relay

And

Fuse

Box

(Power

1992-1998

I

Left

side

of

engine

compartment

I

Fig

.

2

.

Distribution

Box)

Fig

.

7

.

Fig

.

10

.

Rear

Window

Blower

1994-1998

Behind

rear

seat

(convertible)

Rear

Window

Blower

Microswitch

1994-1994

At

convertible

top

linkage

Rear

Window

Blower

Microswitch

1995-1998

Behind

rear

seat

(convertible)

Rear

Window

BlowerRelay

11994-1998

Behind

glove

compartment

Fig

.

8

.

Fig

.

9

.

Fig

.

2

.

Fig

.

30

.

Fig

.

8

.

Rear

Window

DefoggerRelay

Reversing

(Back-up)

Light

Switch

SplicePanel,

Right

Rollover

Protection

Actuator

11994-1998

COMPONENT

LOCATIONS

Table

a

.

E36

Component

Locations

1992-1998

1992-1998

1992-1998

Power

distribution

box

Right

or

left

side

top

of

transmission

Behind

glove

compartment

Behind

rear

seat

(convertible)

Fig

.

9

.

Continued

Page 404 of 759

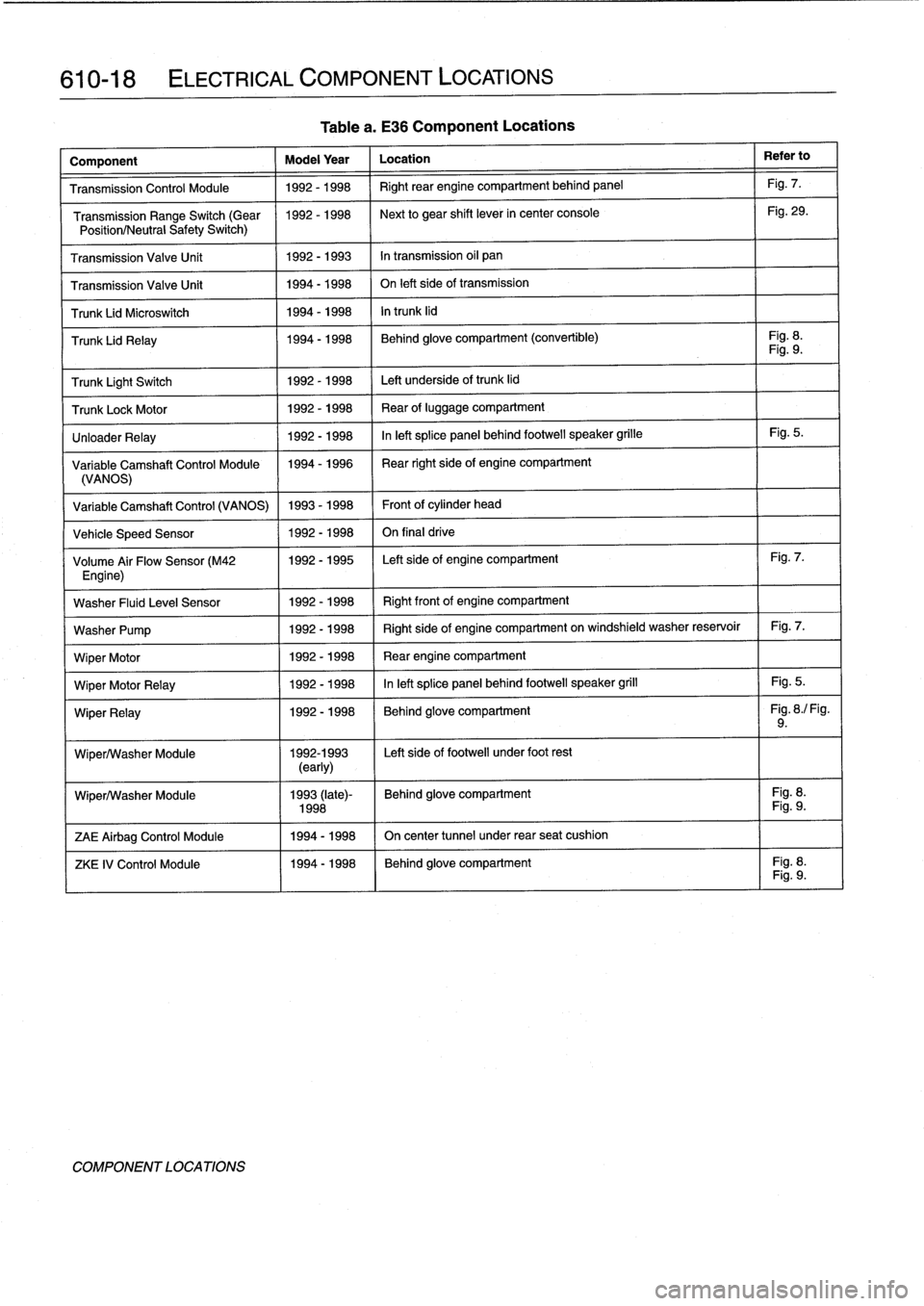

610-18

ELECTRICAL

COMPONENT

LOCATIONS

Tablea

.

E36

Component

Locations

Component

Model

Year

Location

Refer

to

Transmission

Control

Module

1992-1998

Right

rear

engine

compartment

behíndpanel

Fig

.

7

.

Transmission

Range

Switch

(Gear

1992-1998

Next

to

gear

shift

lever

in

center

console

Fig

.

29

.

Position/Neutra

l

Safety

Switch)

Transmission

Valve

Unít

1992-1993

In

transmission

oil

pan

Transmission

Valve

Unit

1994-1998

On

left

side

of

transmission

Trunk

Lid

Microswitch

1994-1998

In

trunk

lid

Trunk

Lid

Relay

1994-1998

Behind

glove

compartment

(convertible)

Fig

.

8

.

Fig

.

9

.

Trunk

Light

Switch

1992-1998

Left

underside

of

trunk

lid

TrunkLockMotor

1992-1998

Rear

of

luggage

compartment

UnloaderRelay

1992-1998

Inleft

splice

panel

behind

footwell

speaker

grille

Fig

.

5

.

Variable

Camshaft

Control

Module

1994-1996

I

Rear

right

side

of

engine

compartment

(VANOS)

Variable

Camshaft

Control

(VANOS)

1993-1998

Front

ofcylinder

head

Veh¡cle

Speed

Sensor

1992-1998

On

final

drive

Volume

Air

Flow

Sensor

(M42

1992-1995

Left

side

of

engine

compartment

Fig

.

7

.

Engine)

Washer

Fluid

Leve¡

Sensor

1992-1998

Right

frontof

engine

compartment

Washer

Pump

1992-1998

Right

side

of

engine

compartment

on

windshield

washer

reservoir

Fig

.

7

.

Wiper

Motor

1992-1998

Rear

engine

compartment

Wiper

Motor

Relay

1992-1998

Inleft

splice

panel

behind

footwell

speaker

grill

Fig

.

5

.

Wiper

Relay

1992-1998

(

Behind

glove

compartment

I

Fig

.

8

./

Fig

.

9

.

Wiper/Washer

Module

1992-1993

Left

side

of

footwell

under

foot

rest

(early)

Wiper/Washer

Module

1993

(late)-

Behind

glove

compartment

Fig

.

8

.

1998

1

Fig

.

9

.

ZAE

Airbag

Control

Module

1

1994-1998

1

On

center

tunnel

under

rear

seat

cushion

ZKE

IV

Control

Module

1994-1998

I

Behind

glove

compartment

Fig

.

8

.I

Fig

.

9

.

COMPONENT

LOCATIONS

Page 751 of 759

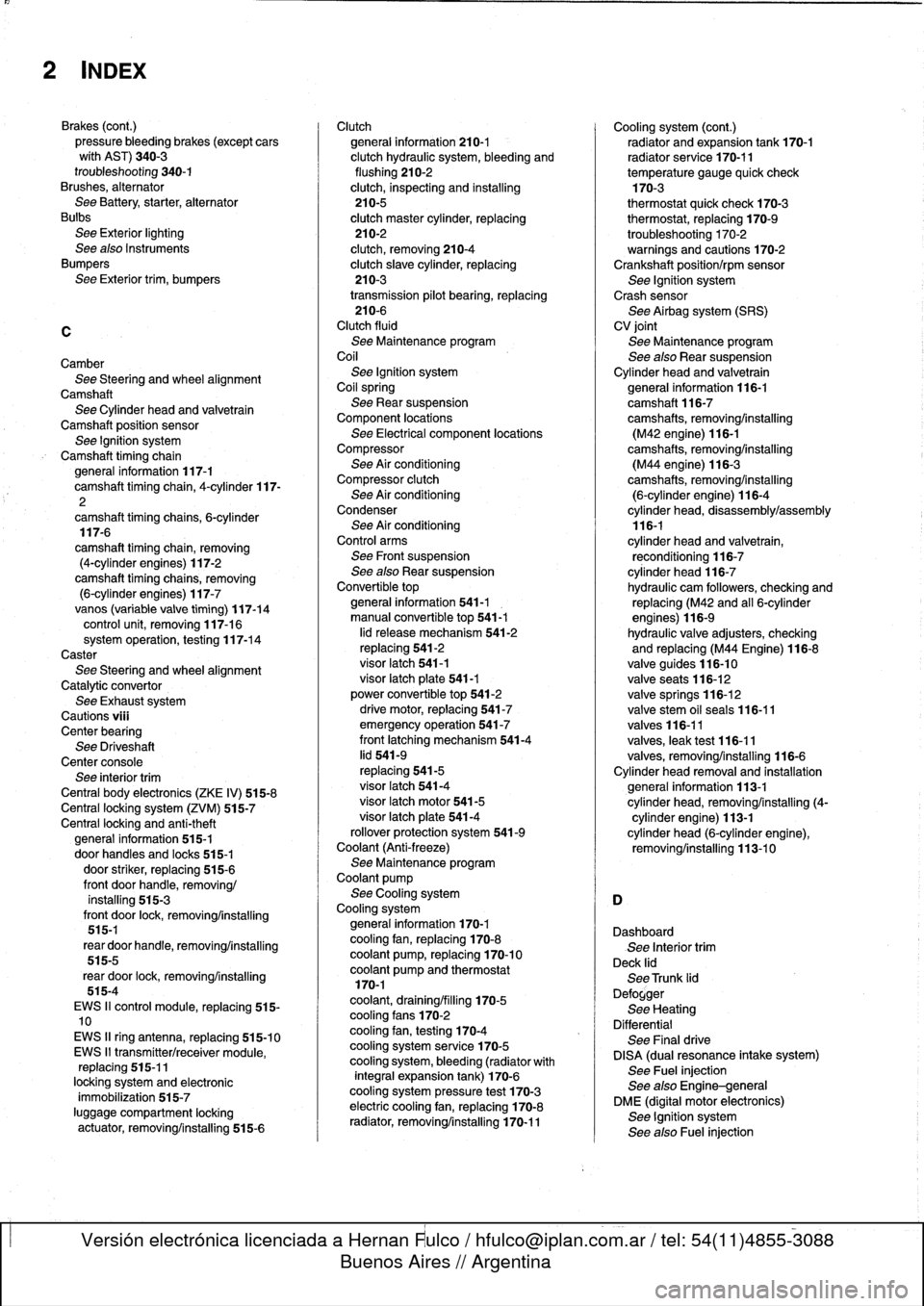

2

INDEX

Brakes

(cont

.)

pressure

bleeding

brakes

(except

cars

wíth

AST)

340-3

troubleshooting

340-1

Brushes,

alternator

See

Battery,

starter,

alternator

Bulbs

See

Exterior

lighting

See

also

Instruments

Bumpers

See

Exterior

trim,

bumpers

C

CamberSee

Steering

and

wheel

alignment

Camshaft

See

Cylinder

head

and

valvetrain

Camshaft

position

sensor

See

Ignition

system

Camshaft

timing

chain

general

information

117-1

camshaft

timingchain,

4-cylinder

117-

2

camshaft

timing

chains,6-cylinder

117-6

camshaft

timing

chain,

removing

(4-cylinder

engines)

117-2

camshaft

timing

chains,

removing

(6-cylinder

engines)

117-7vanos

(variable

valve

timing)

117-14

control

unit,

removing

117-16system

operation,

testing

117-14

Caster

See

Steering

andwheel

alignment

Catalytic

convertor

See

Exhaustsystem

Cautions

viü

Center

bearing

See

Driveshaft

Center

console

See

interior

trim

Central

body

electronics

(ZKE

IV)

515-8

Central

locking

system

(ZVM)

515-7

Centrallocking

and

anti-theft

general

information

515-1

door

handles

and

Iocks

515-1

door

striker,

replacing

515-6

front

door

handle,

removing/

installing

515-3

front

door

lock,

removing/installing

515-1

rear

door

handle,

removing/installing

515-5

rear

door

lock,

removing/installing

515-4

EWS

II

control

module,

replacing

515-10

EWS

II

ring

antenna,

replacing

515-10

EWS

II

transmitter/receiver

module,

replacing

515-11

locking

system

and

electronic

immobilization

515-7

luggage

compartment

locking

actuator,

removing/installing

515-6

Clutch

general

information210-1

clutch

hydraulic

system,

bleeding

and

flushing

210-2

clutch,

inspecting

and

installing

210-5

clutch

master

cylinder,

replacing

210-2

clutch,

removing

210-4

clutch

slave

cylinder,

replacing

210-3

transmission

pilot

bearing,

replacing

210-6

Clutch

fluid

See

Maintenance

program

Coil

See

Ignition

system

Coilspring

See

Rear

suspension

Component

locations

See

Electrical

component

locations

Compressor

See

Air

conditioning

Compressor

clutch

See

Air

conditioning

Condenser

See

Air

conditioningControl

arms

See

Front

suspension

See

also

Rear

suspension

Convertible

top

general

information

541-1

manual

convertible

top

541-1

lid

release

mechanism

541-2

replacing

541-2

visor

latch

541-1

visor

latch

píate

541-1

power

convertible

top

541-2

drive

motor,

replacing

541-7

emergency

operation

541-7

front

latching

mechanism

541-4

lid

541-9

replacing

541-5

visor

latch

541-4

visor

latch

motor541-5

visor

latch

plate

541-4

rollover

protection

system

541-9

Coolant

(Anti-freeze)

See

Maintenance

program

Coolant

pump

See

Cooling

system

Cooling

system

general

information

170-1

cooling

fan,

replacing

170-8

coolant

pump,

replacing

170-10

coolant

pump

and

thermostat170-1

coolant,

draining/filling

170-5

cooling

fans

170-2

cooling

fan,

testing

170-4

cooling

system

service

170-5

cooling

system,

bleeding

(radiator

with

integral

expansion

tank)

170-6

cooling

system

pressure

test

170-3

electric

cooling

fan,

replacing

170-8

radiator,

removing/installing

170-11

Cooling

system

(cont

.)

radiator

and

expansion

tank

170-1

radiator

service

170-11

temperature

gauge

quick

check170-3

thermostat

quick

check

170-3

thermostat,

replacing

170-9

troubleshooting

170-2

warnings

and

cautions

170-2Crankshaft

position/rpm

sensor

See

Ignition

system

Crash

sensor

See

Airbag

system

(SRS)

CV

joint

See

Maintenance

program

See

also

Rear

suspension

Cylinder

head

and

valvetrain

general

information

116-1

camshaft116-7

camshafts,

removing/installing

(M42

engine)

116-1camshafts,

removing/installing

(M44

engine)

116-3

camshafts,

removing/installing

(6-cylinder

engine)

116-4

cylinder

head,

disassembly/assembly

116-1

cylinder

head

and

valvetrain,

reconditioning

116-7

cylinder

head

116-7

hydraulic

cam

followers,

checking

and

replacing

(M42

and

al]

6-cylinder

engines)

116-9

hydraulic

valve

adjusters,

checking

and

replacing

(M44

Engine)

116-8

valve

guides

116-10

valveseats

116-12

valve

springs

116-12

valve

stem

oil

seals

116-11

valves

116-11

valves,

leak

test

116-11

valves,removing/installing

116-6

Cylinder

head

removal

and

installation

general

information

113-1

cylinder

head,

removing/installing

(4-

cylinder

engine)

113-1

cylinder

head

(6-cylinder

engine),

removing/installing

113-10

Dashboard

See

Interior

trim

Deck

lid

See

Trunk

lid

Defogger

See

Heating

Differential

See

Final

drive

DISA

(dual

resonance

intake

system)

See

Fuel

injection

See

also

Engine-general

DME

(digital

motor

electronics)

See

Ignition

system

See

alsoFuel

injection