coolant sensor BMW 318i 1992 E36 Service Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1992, Model line: 318i, Model: BMW 318i 1992 E36Pages: 759

Page 450 of 759

640-4

HEATING

AND

AIR

CONDITIONING

Heater

box,

removing

and

installing

The

heater

box,

located

underneath

thecenter

of

the

dash-

board,

houses

theheater

core,

the

A/C

evaporator,

and

asso-

ciated

sensors

and

actuators

.

Removal

of

theheater

box

requires

that

the

A/C

refrigerant

be

discharged

.

CAUTION-

"

Removing

the

heater

box

requires

evacuating

the

AIC

system

.

DO

NOT

attempt

this

procedure

without

proper

tools

and

training

.

"

Any

person

who

services

a

motor

vehicle

air

con-

ditioner

must,

by

law,

be

properly

trained

and

cer-

tified,

and

use

approved

refrigerant

recycling

equipment

.

Technicians

must

complete

an

EPA-

approved

recycling

course

to

be

certified

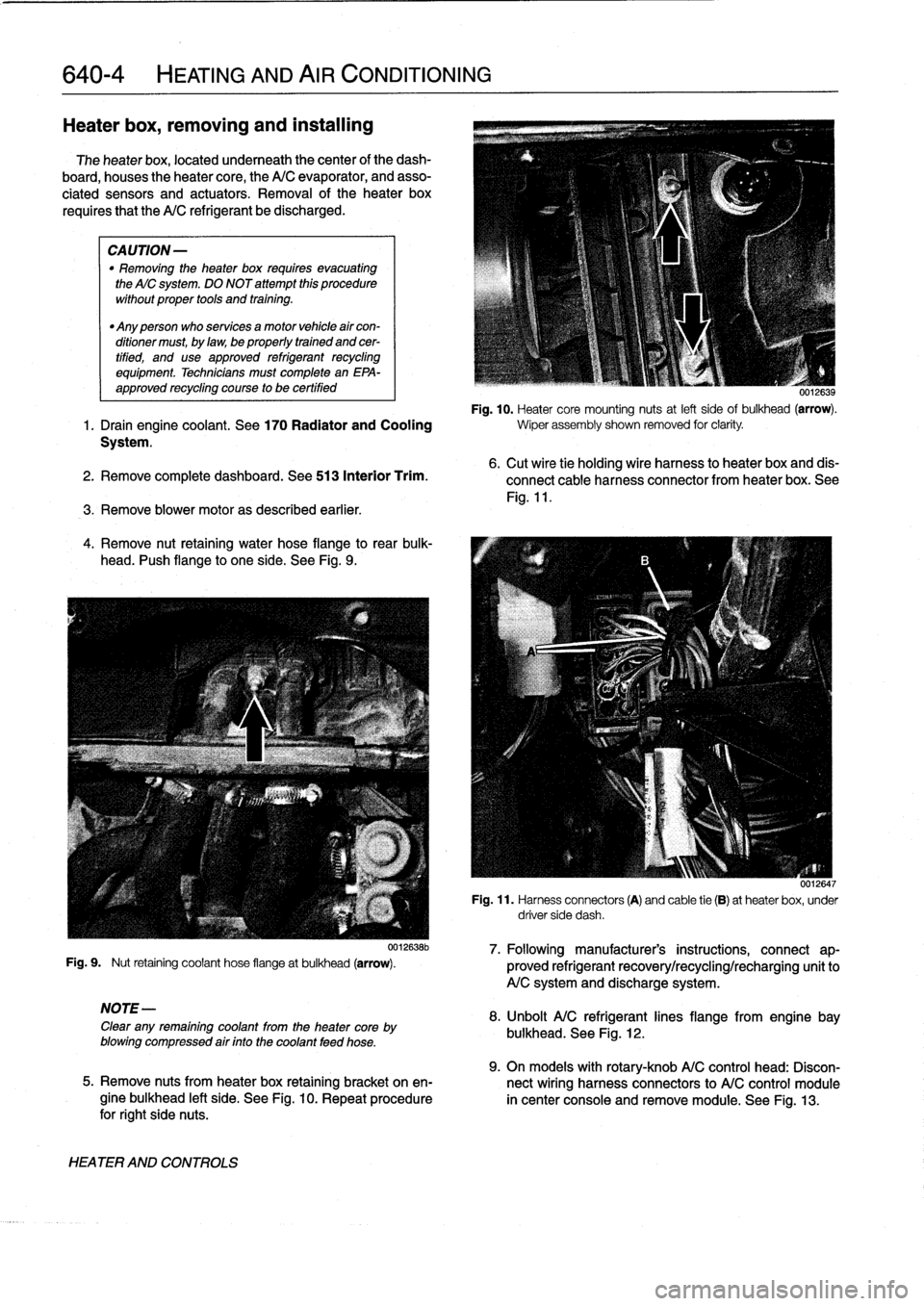

UU12639

Fig

.

10

.

Heater

core

mounting

nuts

at

left

sideof

bulkhead

(arrow)

.

1

.

Drain

engine

coolant

.

See

170

Radiator

and

Cooling

wiper

assembly

shown

removed

for

clarity

.

System

.

2

.

Remove

complete

dashboard

.

See513

Interior

Trim

.

3

.

Remove

blower

motoras

described

earlier

.

4

.

Remove

nut

retaining

water

hose

flange

to

rear

bulk-

head

.

I'ush

flange

to

one

side

.

See

Fig

.

9

.

Fig

.

9

.

Nut

retaining

coolant

hose

flangeat

bulkhead

(arrow)

.

NOTE-

Clear

any

remaining

coolant

from

the

heater

core

by

blowing

compressed

air

finto

the

coolant

feed

hose

.

HEATER

AND

CONTROLS

0012638b

6

.

Cut

wire

tie

holding

wire

harness

to

heater

box

and

dis-

connect

cable

harness

connector

from

heater

box

.

See

Fig

.

11

.

0012647

Fig

.

11

.

Harness

connectors

(A)

and

cable

tie

(B)

at

heaterbox,

under

driver

side

dash

.

7

.

Followingmanufacturer's

instructions,

connect

ap-

proved

refrigerant

recovery/recycling/recharging

unitto

A/C

system

and

discharge

system

.

8

.

Unbolt

A/C

refrigerantlines

flange

from

engine

bay

bulkhead

.

See

Fig

.

12

.

9

.

On

models

with

rotary-knob

A/C

control

head

:

Discon-

5

.

Remove

nuts

from

heater

box

retaining

bracket

on

en-

nect

wiring

harness

connectors

to

A/C

control

module

gine

bulkhead

left

side

.

See

Fig

.

10

.

Repeat

procedure

in

center

console

and

remove

module

.

See

Fig

.

13

.

for

right

side

nuts

.

Page 452 of 759

640-6

HEATING

AND

AIRCONDITIONING

Heater

core,replacing

1.

Drain

engíne

coolant

.

See170

Radiator

and

Cooling

System

.

WARNING

-

Allow

the

cooling

system

to

cool

before

opening

or

drainíng

the

cooling

system

.

2

.

Remove

center

console

.

See

513

Interior

Trim

.

3

.

Remove

Multi-Information

Display

(MID)

module

.

See

620

Instruments

.

4

.

Remove

lower

dash

panel

and

knee

bolster

on

driver

side

.

See

513

Interior

Trim

.

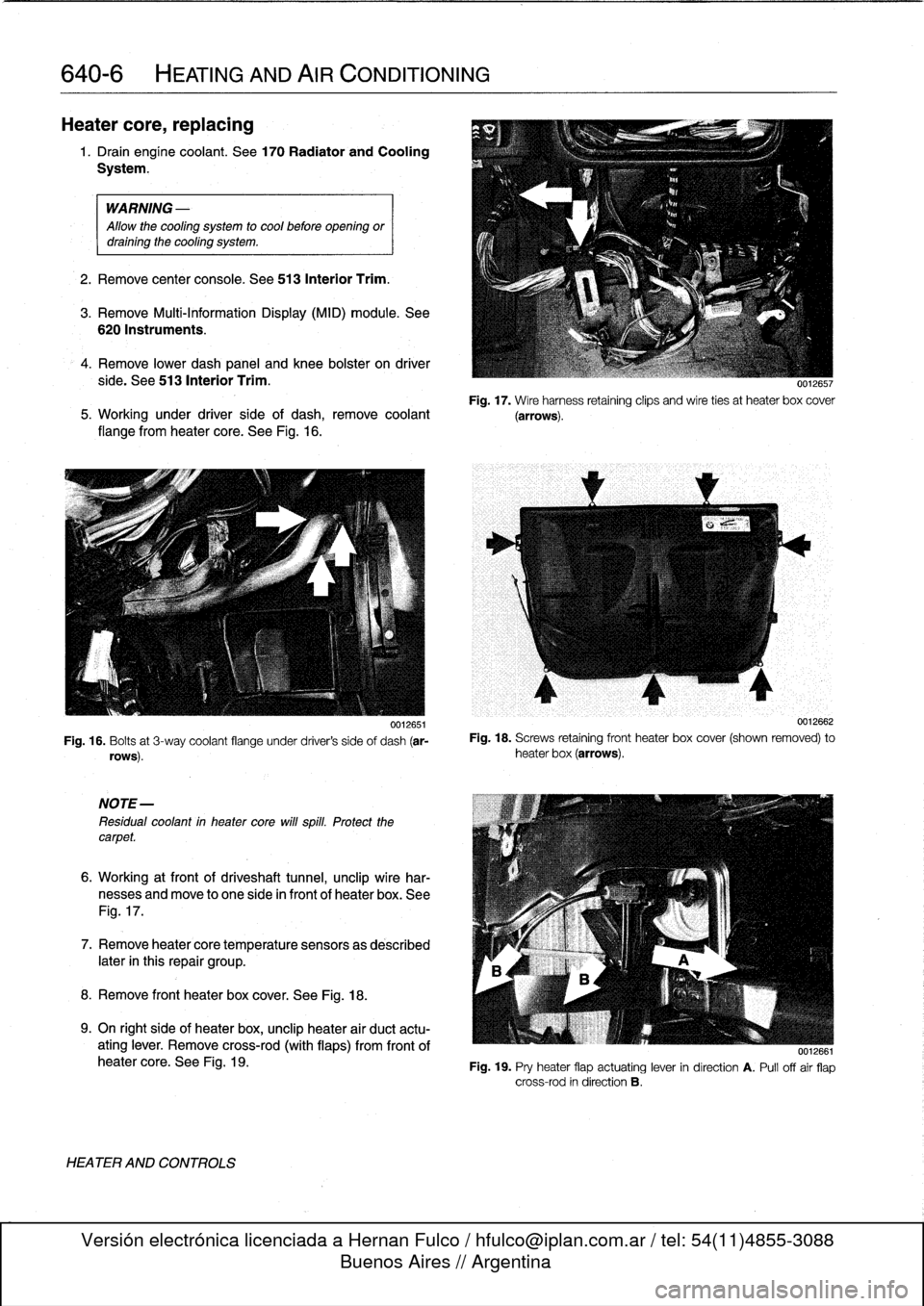

Fig

.

17

.

Wire

harness

retaining

clips

and

wire

ties

at

heater

box

cover

5

.

Working

under

driver

side

of

dash,

remove

coolant

(arrows)

.

flange

from

heater

core

.

See

Fig

.

16

.

0012651

Fig

.

16

.

Bolts

at

3-way

coolant

flange

under

driver's

side

of

dash

(ar-

rows)

.

NOTE-

Residual

coolant

in

heater

core

will

spill

.

Protect

thecarpet

.

6

.

Working

at

front

of

driveshaft

tunnel,

unclip

wire

har-

nesses

and

move

to

one

side

in

front

of

heater

box

.

See

Fig

.

17

.

7

.

Remove

heatercore

temperature

sensorsas

described

later

in

this

repair

group

.

8

.

Remove

front

heater

box

cover

.

See

Fig

.

18

.

9

.

On

right

side

of

heater

box,

unclip

heater

air

duct

actu-

ating

lever

.

Remove

cross-rod

(with

flaps)

from

frontof

heater

core

.

See

Fig

.

19

.

HEATER

AND

CONTROLS

0012662

Fig

.

18

.

Screws

retaining

front

heater

box

cover

(shown

removed)

to

heater

box

(arrows)

.

0012661

Fig

.

19

.

Pry

heater

flap

actuating

lever

in

direction

A

.

Pull

offair

flap

cross-rod

in

direction

B

.

Page 453 of 759

10

.

Pul¡

heater

core

up

and

backward,

away

from

heater

box

.

If

necessary,

remove

left

and

right

reinforcing

bracket

bolts

.

See

Fig

.

20

.

CAUTION-

Replace

coolant

flange

O-rings

and

tighten

fas-

teners

to

specified

torques

.

Tightening

Torques

1

.

Remove

center

console

.

See

513

Interior

trim

.

0012660

Fig

.

20

.

PA

heater

core

upand

towardback

of

car

.

Lower

mounting

bolts

for

steering

column

brace

and

glove

compartment

sup-

port

frame

may

have

to

be

removed

(arrows)

.

11

.

Installation

is

reverse

of

removal

.

Fill

and

bleed

cooling

system

.

See

170

Radiator

and

Cooling

System

.

"

Coolant

flange

to

heater

core

.

..

....

3

Nm

(27

in-lb)

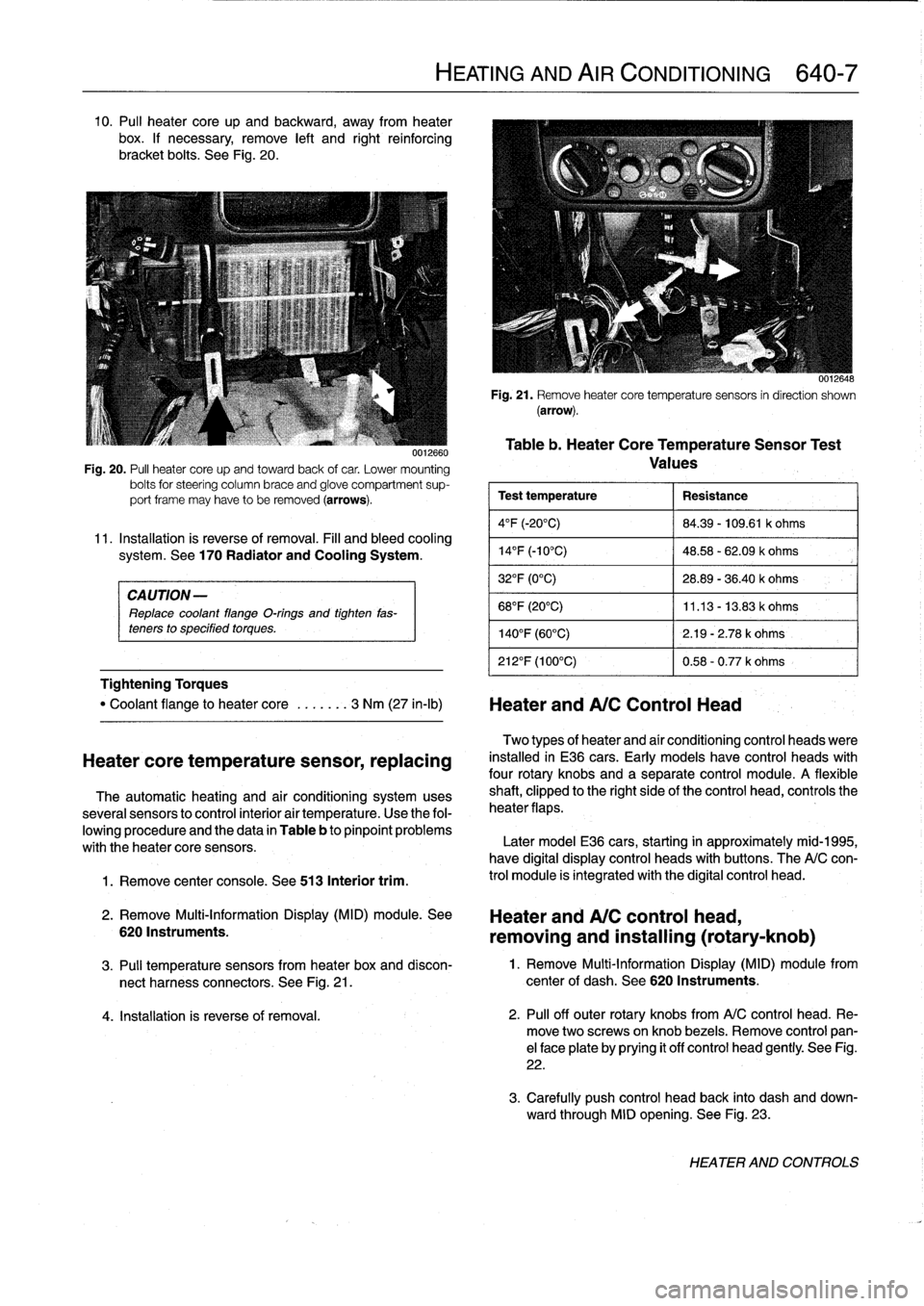

Heater

andA/C

Control

Head

Heatercore

temperature

sensor,

replacing

The

automatic

heating

and

air

conditioning

systemuses

severa¡

sensors

to

control

interior

air

temperature

.

Use

the

fol-

lowing

procedure

and

the

data

in

Table

b

to

pinpoint

problems

with

theheater

core

sensors

.

2

.

Remove

Multi-Information

Display

(MID)

module

.

See

6201nstruments

.

HEATING

AND

AIR

CONDITIONING

640-7

0012648

Fig

.

21

.

Remove

heatercore

temperaturesensors

in

direction

shown

(arrow)

.

Table

b

.

Heater

CoreTemperatureSensor

Test

Values

Test

temperature

Resistance

4°F

(-20°C)

84

.39

-

109

.61

k

ohms

14

°

F

(-10°C)

48

.58

-

62

.09

k

ohms

32°F

(0°C)

28

.89

-

36

.40

k

ohms

68°F

(20°C)

11

.13

-

13

.83

k

ohms

140°F

(60°C)

2

.19

-

2

.78

k

ohms

212°F

(100°C)

0

.58

-

0

.77

k

ohms

Two

types

of

heater

and

aír

conditioning

control

heads

viere

installed

in

E36

cars

.

Early

models

have

control

heads

with

four

rotary

knobs

and

a

separate

control

module

.

A

flexible

shaft,

clipped

to

the

right

sideof

the

control

head,

controls

the

heater

flaps

.

Later

model

E36

cars,

starting

in

approximately

mid-1995,

have

digital

display

control

heads

with

buttons

.

The

A/C

con-

trol

module

is

integrated

with

the

digital

control

head

.

Heater

and

A/C

control

head,

removing

and

installing

(rotary-knob)

3

.

Pul¡

temperature

sensors

from

heater

box

and

discon-

1

.

Remove

Multi-Information

Display

(MID)

module

from

nect

harness

connectors

.

See

Fig

.

21

.

center

of

dash

.

See

620

Instruments

.

4

.

Installation

is

reverse

of

removal

.

2

.

Pul¡

off

outer

rotary

knobs

from

A/C

control

head

.

Re-

move

two

screwsonknob

bezels

.

Remove

control

pan-

el

face

plate

by

prying

it

off

control

head

gently

.

See

Fig

.

22

.

3

.

Carefully

push

control

head

back

into

dash

and

down-

ward

through

MID

opening

.

See

Fig

.

23

.

HEATER

AND

CONTROLS

Page 534 of 759

ELE-50

ELECTRICAL

WIRING

DIAGRAMS

I-

____RIGHT

~LEFT

I

RIGHT

(HEADLAMP

I

LEFT

,HEADLAMP

i

(

)

PARK

I

I

(

)

PARK

i

I

-

LIGHT

I

I

Y

LIGHT

I

LEFT

LEFT

DRIVER'S

CENTRAL

RIGHT

SLIP

I

REAR

I

REAR

I

(

POWER

I(

POWER

I

(

FRONT

CONTROL

I

POWER

I

,POWER

I

(WINDOW

I

(WINDOW

I

(SPEED

I

(MODULE

_

_,

WINDOW

I

_,

WINDOW

I

(

SWITCH

I

(

SWITCH

I

(

SENSOR

I

-

-

j

(WIASC)

SWITCH

SWITCH

``

77''q

(4AD00R)

0

(ATCONSOLE)

4

q

T

1

1I

I

3T

/

19T

/

-323

.328

.

M2

(AT

DOOR/

Z

3

7`

21

011

31

19/x"

318

10441

2

-

RIGHT

I

I

_

1--HEADLIGHT/

III

I

(

)FRONT

(

HIGH

I

IHORN

WASHE

HT

HIGH

SWITCH

TURN

II

,

R

I

(

BEAM

,

"-'

RIGHT

LIGHT

I

,

BEAM

I

,I

LEFT

LIGHT

I

I

(

PUMP

LIGHT_

I_

_

I

(

)

FOG

I

I

I

(

LIGHT

(

)FOG

--

_

I

T

LIGHT

L---

-I

LIGHT

1

2

1

1

1

T

I

INTER-

'

WASHER

I

RIGHT

I

MEDIATE

I

FLUID

I

LOW

IPRESSURE

I

I

LEVEL

I

I

(BEAM

I

-

,SWITCH

II

-

,SWITCH

I

J

-

(LIGHT

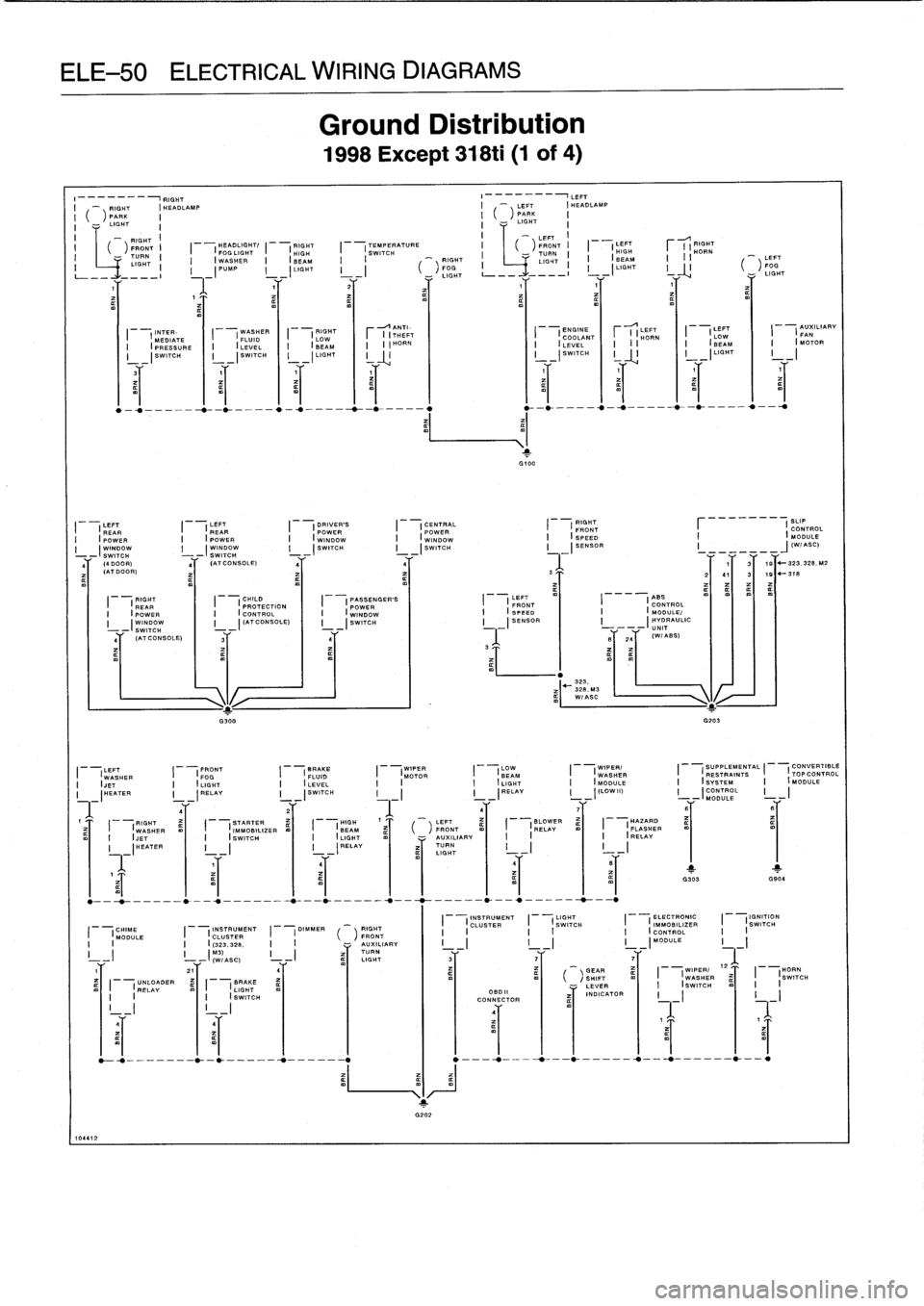

Ground

Distribution

1998Except

318ti

(1

of

4)

~

ANTI-

II

THEFT

I

I'

HORN

I

I

ENGINE

LEFT

I

COOLANTHORN

I

(

LEVEL

I

,

I

I

_I

SWITCH

I

¢t

¢~

LEFT

I

ABS

FRONT

I

CONTROL

I

I

SPEED

I

I

MODULE/

I

_

_I

SENSOR

I

I

HYDRAULIC

UNIT

(ATCONSOLE)

3'f

I

qT

2

(WIASS)

1

T

RIGHT

CHILD

I

I

REAR

I

I

PROTECTION

I

POWER

I

(CONTROL

I

,WINDOW

I

_I

(AT

CONSOLE)

--

SWITCH

G300

II

PASSENGER'S

POWER

I

I

WINDOW

I

_I

SWITCH

I

323,

1-

328,

M3

WIASC

I

I

LEFT

LO

W

I

(BEAM

I

-

(LIGHT

G203

LEFT

FRONT

BRAKE

WIPER

LOW

WIPER,

SUPPLEMENTAL

CONVERTIBLE

IWgSHER

I

FOG

,

FLUID

I

(

MOTOR

I(

BEAM

I

(WASHER

I

(

RESTRAINTS

I

ITOPCONTROL

I

,JET

I

(LIGHT

I

(LEVEL

I

I

,

(LIGHT

I

(MODULE

I

IBYSTEM

I

(MODULE

I

(HEATER__

I_

__IRELAV

I

-(SWITCH

I

I

I

-IRELAV

I

-

I(LOWIU

I

_IMODULEL

-

q

2

_

q

_

l

1

_

I

pIGHT

(STARTER

(HIGH

1

LEFT

(BLOWER

I

IHA2ARD

I

WASHER

I

IMMOBILIZER

m

I

BEAM

(

FRONT

(

RELAY

FLASHER

JET

I

SWITCH

,

,LIGHT

"'

AUXILIARY

II

I

IRELAV

I

-

,HEATER

TURN

I

-

I

I

-IRELAV

dl

IGHT

J

.

G904

INSTRUMENT

LIGHT

ELECTRONIC

IGNITION

CHIME

INSTRUMENT

DIMMER

RIGHT

I

(

CLUSTER

I

(

SWITCH

I

IIMMOaILIZER__

I(

SWITCH

I

I

MODULE

(CLUSTER

I

,

)

FRONT

I

I

I

I

I

CONTROL

I

I

II(323,328,

I

I

AUXILIARY

I

I

I

I

I

MODULE

iII

-

_

-I

I

-

-

-I

ff

TURN

(WIASC)

LIGHT

3T

7T

7

'WIPER/

12

,HORN

I

WASHER

I

--

SWITCH

,SWITCH

I

III

m

I

_I

UNLAY

OADER

I

BRAKE

I

(

REL

m

I

(

LIGHT

I

_I

I

I

SWITCH

I

_I

!

ogoHCONNECTOR

GEAR(

)

SHIFT

LEVER

INDICATOR

AU%ILIARV

I

FAN

I

I

MOTOR

Page 555 of 759

8727

4

FRONT

_TPOWER

ER_DIS_TR_IBUTION

BOX

FHOTIN

OXYOENSE_NSORRE_LA

_Y

I

I

RUNAND

I

GRN/VIO

16

START

I

X,

DD>

6

I

GRNIV10GRN/VIO

BRNIGRNRED/WHT

BLK

YELBLK

BRN/ORG

I

U

E

1185-T86

13D

18,

6A

4Y

BY

6Y

2Y

-

,T,

F

E37017

IL

I

L-

I

--!

!

NORMAL

PRESSURE

SPEEDRELAY

SWITCH

G

ELECTRICAL

WIRING

DIAGRAMS

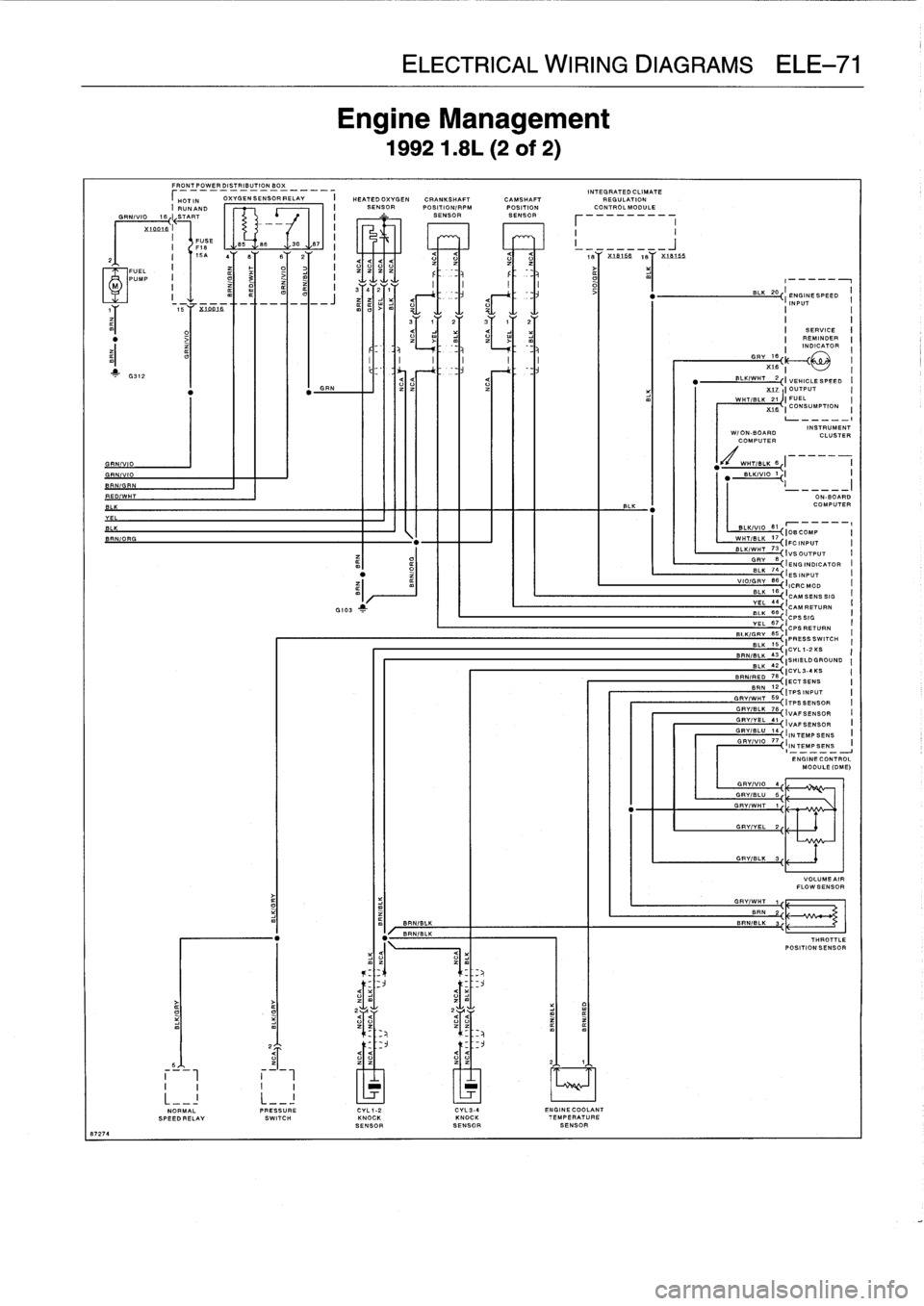

ELE-71

Engine

Management

19921

.8L

(2

of

2)

INTEGRATED

CLIMATE

HEATEDOXYGEN

CRANKSHAFT

CAMSHAFT

REGULATION

SENSOR

POSITION/RPM

POSITION

CONTROLMODULE

SENSOR

SENSOR

I

I

a

<

I

X181

.58

1

X

18185

UV

U

~

22

2

2

2

F

',-

~

F

~

_

_

_

_

vvvv

I

-

tt

i

2

I

I

I

1

I

1

__

r

-

I

.I

r

-

-

I

I

I

1

BLKIWHT

2

"

~~{I

VEHICLE

SPEED

GRN

I

1

1

1

zlzl

1

1

zl

1

1

1

.

.1

1

I

X17

(

OUTPUT

WHT/BLK

21

I

FUEL

%ifi

(CONSUMPTION

BRN/BL

/BL

CYL(-2

CYL3-4

ENGINECOOLANT

KNOCK

KNOCK

TEMPERATURESENSOR

SENSOR

SENSOR

>I

BLK

20

'EN

.IMEBPEE

.

1

INPUT

I

II

SERVICE

II

REMINDER

I

I

INDICATOR

I

GRG~

~

I

X1fi

I

INSTRUMENT

WlON-BOARD

CLUSTER

COMPUTER

Ks

w-HT/B~~

-

"

BLK~VIO

lI

I

i

ON-BOARD

COMPUTER

BLKIVIO

81

r

I

CIOBCOMP

I

WHT/BLK

17

LK/WHT

T3CIFCINPUT

I

B

{IVSOUTPUT

I

ORY

IENGINDICAT0R

I

BLK

74

,

1ESINPUT

I

VIOIGRV

B6

IICRCMOD

I

Y

EL

SLK

1B

I

CAM

SENS

SIG

B

44,

I

CAM8ETURN

BLK

BB

CPS

SIG

yEL

"'

BLK/

I

CPS

RETURN

PRESSSWITCH

-

B

I

BRN/B

ICYLI-2KS

(SHIELD--------

BRN/RED

78

ICYL3-4

K5

IECTSENS

GRYIWHTB

59~ITPSINPUT

ITPSSENSOR

G

I,VAFSENSOR

GRY/YEL

41

(

_

IVAFSENSOR

GRY/SLU

14

~

I

INTEMP

SENS

GRYRYIV

~INTEMPSENS

GRYIVIO

4

GRY/BLU

6

GRY/WHT

1

GRYIYEL

2

GRY/BLK

3

GRY/WHT

1

SRN

2

BRN/BLK

3

ENGINECONTROL

MODULE

(OME)

VOLUMEAIR

FLOW

SENSOR

THROTTLE

POSITION

SENSOR

Page 557 of 759

8727

6

GRN/VIO

BRNIGRN

RED/WHT

RED/WH

T

RED/WHTRED/WHT

REDRED

W/EGS

FRONT

POWER

DISTRIBUTION

BOX

I

OXYGENSENSOR

RELAY

I

HEATED

OXYGEN

CAMSHAFT

CRANKSHAFT

SENSOR

POSITION

POSITION/

SENSORRPMSENSOR

1S)

X199]9

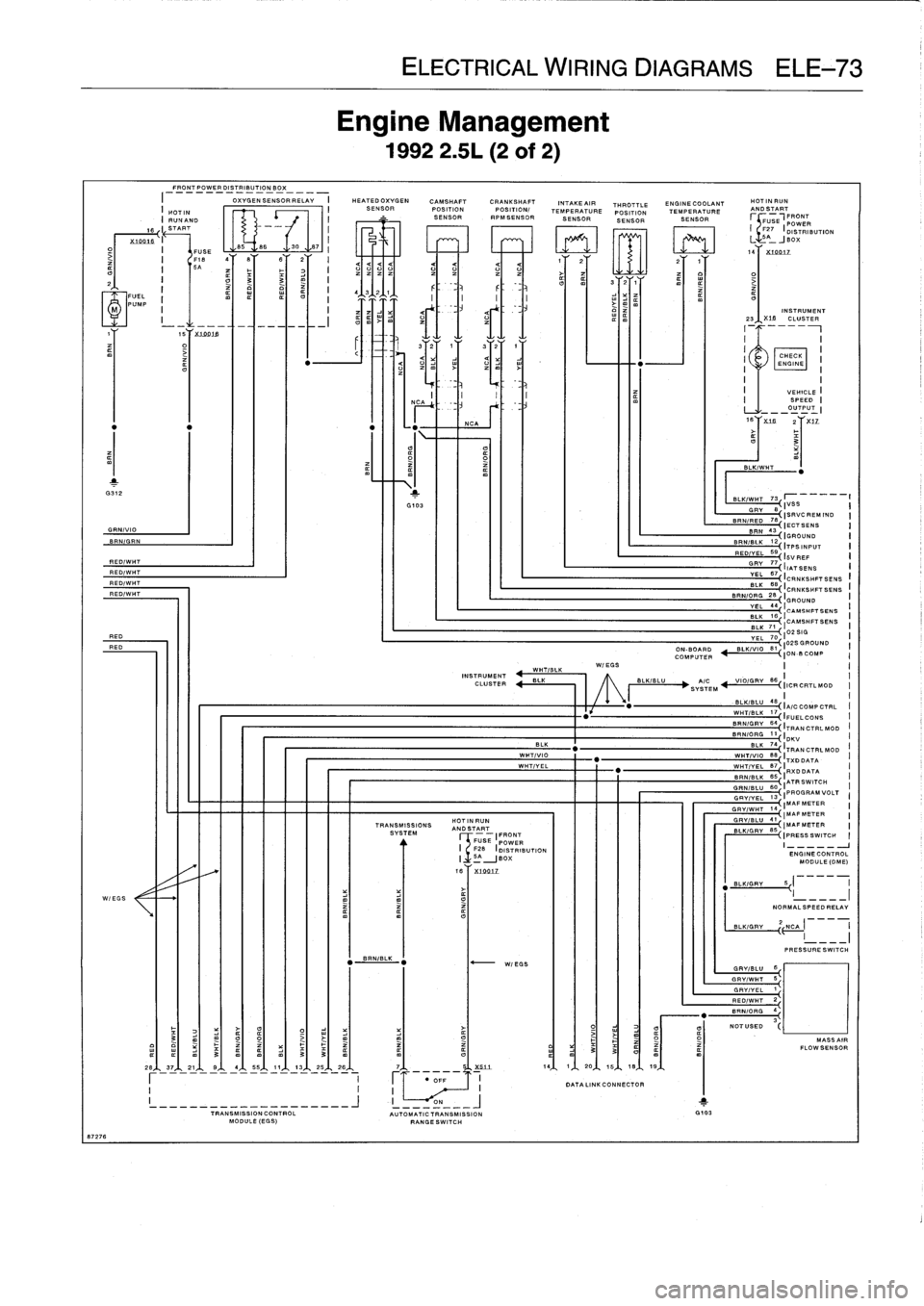

ELECTRICAL

WIRING

DIAGRAMS

ELE-73

Engine

Management

19922

.511-

(2

of

2)

86

v

30

v

87

I

_

W

[~~j

O

TRANSMISSIONS

SYSTEM

----------

---------

--------

-------

TRANSMISSIONTRANSMISSION

TRANSMISSION

CONTROL

AUTOMATIC

TRANSMISSION

MODULE

(EGS)

RANGE

SW

ITCH

HOT

IN

RUNAND

START

(FRONT

FUSE

pOYfER

I

F28

I

DISTRIBUTION

I

-AJBOX

6Y

X]4

017

INTAKEAIR

THROTTLE

ENGINECOOLANT

TEMPERATURE

POSITION

TEMPERATURE

SENSORSENSORSENSOR

O

j

1I

20j1Sj18~

10

DATA

LINK

CONNECTOR

YEL

70

I

ON-BOARD

BLK/VIO

81

1023

GROUNDCOMPUTER

4

ION-BCOMP

A/C

L~

VIO/GRY

86!

I

SYSTEM

IICRCRTLMOD

NOTUSED

HOTINRUNANOSTART

F"~

;/~

FRONT

4/F2SE

POWER

I

F7

(DISTRIBUTION

L~

-

JBOX

INSTRUMENT

23X7

.6

CLUSTER

~/

/

/p~

\

\

/

CHECK

f

\di/

ENGINE

I

BLK/WHT

GRV/BLU

B

GRV/WHT

6

GRV/YEL

1

BLK/WHT

73

r

IVSS

GRY

8

~

ED7a

ISRVCREMINO

BRN/

~JECTSENS

BRN

3

~IGROUND

BR"/81K

12

~1TPSINPUT

RED

/V

EL

59~

ISVREF

DR

IIATSENS

YEL

67

ICRNKSHFTSENS

BL

I

CRNKSHFTSENSBRN

/

RG

28

~

I

GROUND

EL

ICAMSHFTSENS

-

ICAMSHFTSENS

BL

0251G

71,

BLK/BLU

48,

I

IA/C

COMPCTRL

WHT/BLK

17

BRNI

G

R

LCONS

NIG

JV

64

~

ITRAN

CTRL

MOD

BRN/ORG

11,

I

DKV

GRV/BLU

41

-j

'

-~

.AFMETER

I

BLKKIG~y

88

IPRESSSWITCH

I

END

NE

CONTROL

MODULE

(OME)

NOFMALSPEEDRELAY

BLKBLK/GRV

z

N~I

I

I

PRESSURE

S

W

ITCH

(-__----

MASS

AIR

FLOWSENSOR

Page 559 of 759

8727

8

GR

FUEL

PUMP

FRONT

POWER

DISTRIBUTION

BOX

-

-

-

-

-

-

----

-

-

-

-

-

-

I

H

OTIN

OXYGENSENSOR

RELAY

I

HEATEDOXYOEN

I

RUNAND

SENSOR

VII

O

I

k

I

FUSE

I

F18

I

1sA

GRN

EXCEPT

zl¢I

alGBN/~I

31811~

"

BLK

20

ENGINESPEED

--\

INPUT

WHTIBLK

21

FUEL

GIN/VIO

I

mI

QGRN

VIO

BRNGRNRED

WHT

ml

flED/WHTflED/WHT

LT

6117

I

DRY

~~

W1EGS

I

W/EGS

L

IENGINDICATOR

BLK

BLK

.

ELK

74

7

ELK

16

ICRANKRPHI

ICAMPOSSENS

ELK

VEL

44

I

CAMPOS

SENS

WH7/BLK

_

WHT/BLK

17I

FUELCONSSIG

68

87

2Y

GRN

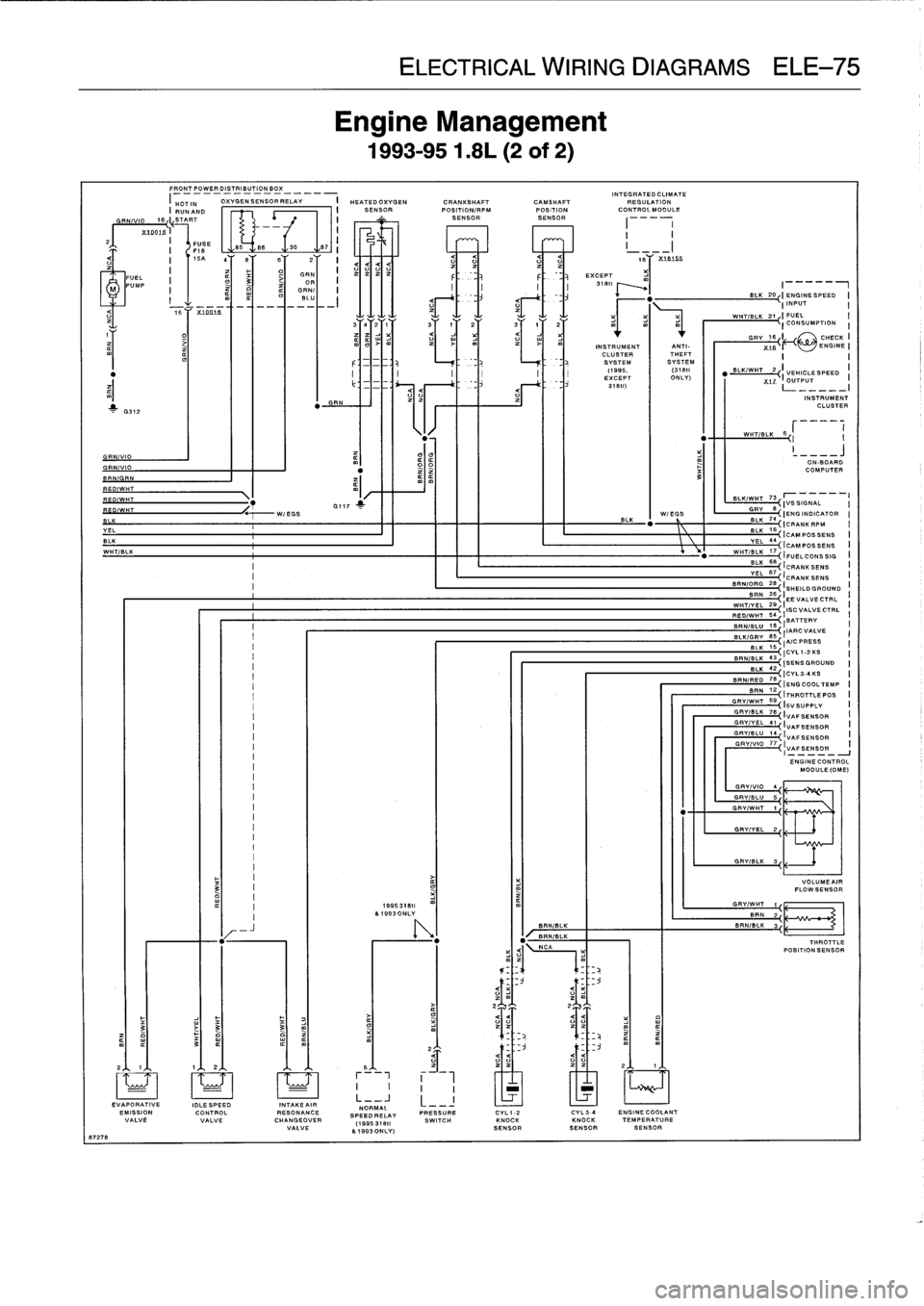

Engine

Management

1993-951

.8L

(2

of

2)

a

ELECTRICAL

WIRING

DIAGRAMS

ELE-75

I

ELK

,

ICRANKSENS

YEL67i

ICRANKSENS

B

R

N/

ORG

28

,I

SHEILO

GROUND

_____SRN

36

I;

EEVALVECTRL

WHT/YEL

2B,

L

ISCVALVECTRL

,ED/W

.I

199531811

m

819930NLY

INTEGRATED

CLIMATE

CRANKSHAFT

CAMSHAFT

REGULATION

POSITION/RPM

POSITION

CON7ROLM000LE

SENSOR

SENSOR

I

~~BRNIBL

gRNIBLCA

INSTRUMENT

CLUSTER

SYSTEM

11995,

EXCEPT

-U)

2,J

1

J

.

1

.l

2A,

A,

I,

i

l

_

I

I

I

I

L__i

EL

LT

VAPORATIVE

IDLESPEED

INTAKEAIR

NORMAL

EMISSION

CONTROL

RESONANCE

SPE

EDR

PRESSURE

CVLl-2

CYL3-4

ENGINECOOLANT

VALVEVALVE

CHANGEOVER

SWITCH

KNOCKKNOCK

TEMPERATURE

VALVE

9930NLY)

(1

9

953

1

BlI811

SENSOR

SENSOR

SENSOR

81

ANTI-

THEFT

SYSTEM

(31811

ONLY)

(CONSUMPTION

I

GR

~

CHECK

ENGINE

I

BATTERY

BRNN/BU

f

"

-

IARCVALVE

BLKIG

RR

e5

(

i

K

15

I

AIC

PRESS

I

CYL

l-2

KS

BRN/BLK

4ISENSGROUND

~ICVL3-4KS

BRNIFEI

78

IENOCOOLTEMP

BR

N

12,;THROTTLEPOS

GRY/WHT

5

9,

I5VSUPPLY

GRVIBLK~

I

VAF

SENSOR

GRY/VEL

<1,

I

VAFSENSOR

GRY

RY/BI

VAFSENSOR

I

GRV/VID

77

{

,

VAFSENSOR

I

GRY

I

VIO

4

GRV/BLU

5

GRY/WHT

1

GRYIYEL

2

GRYISL

GRYIWHT

t

BRN

2

BRNIBLK

3

ENG

ME

CONTROL

MODULE

(OME)

VOLUMEAIR

FLOW

SENSOR

jT

;RT~dl

-

8,

THROTTLE

POSITION

SENSOR

Page 561 of 759

87200

ml

1

G312

GRN/VI

O

BRN/GRN

RED

RED

SPLI_E

--

FRONT

POWER

DISTRIBUTION

BOX

I

OXYGENSENSORRELAY

I

~

RED/WHT

RED/WHT

/I\

RED/WHT

W/OEGS

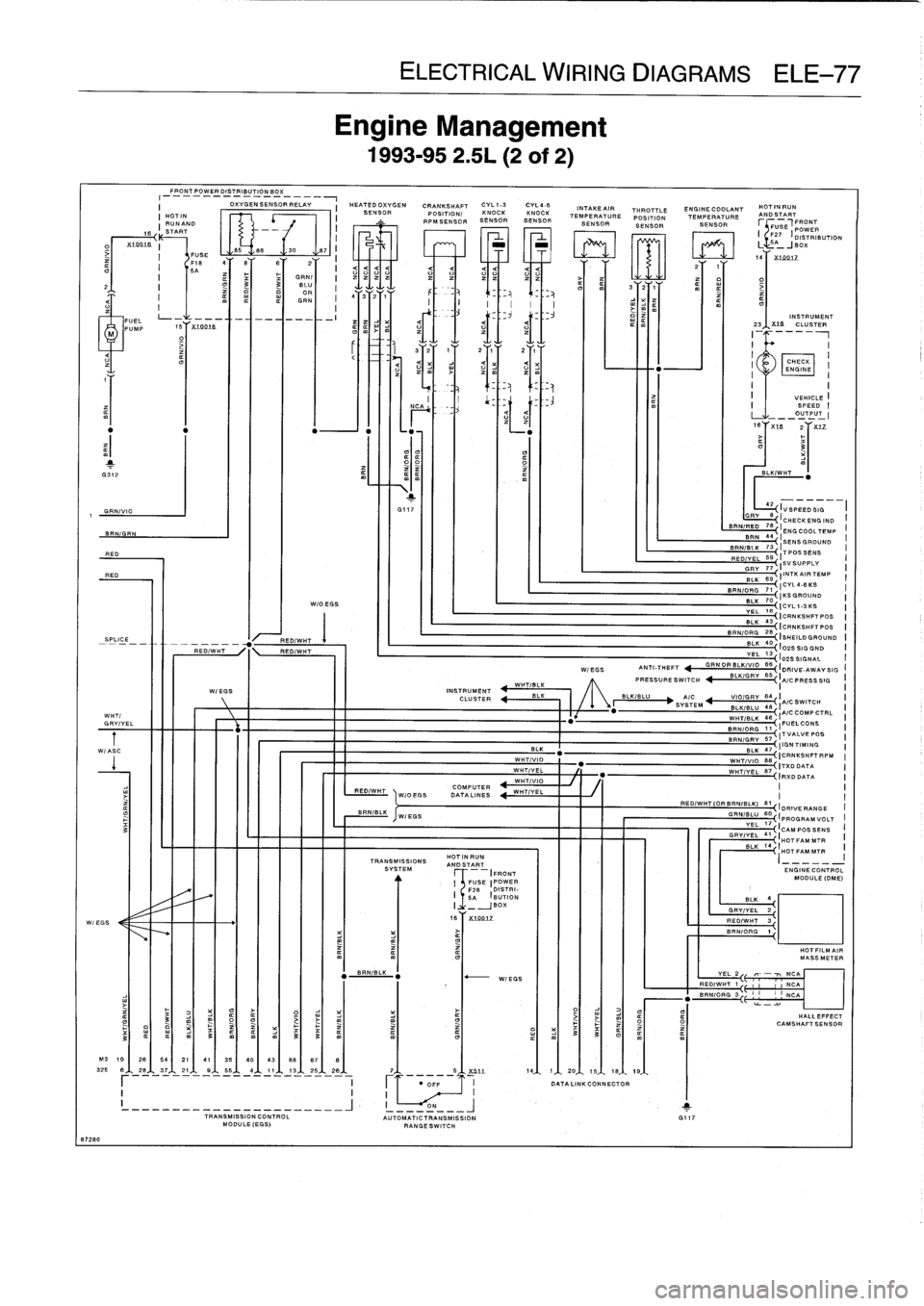

Engine

Management

1993-95

2

.5L

(2

of

2)

ELECTRICAL

WIRING

DIAGRAMS

ELE-77

HEATEDOXVGEN

CRANKSHAFT

CYL1-3

CYL4-6

SENSOR

POSITION(

KNOCK

KNOCK

-

RPM

SENSOR

SENSOR

SENSOR

W/

E..

I

I

I

INSTRUMENT

WHT/BLKCLUSTER

ELK

I

/

BLKK/B~SVBITEM

VIOIGRY

64

I

B

IAICSWITCH

AIC

COMPCTRL

WHT/BLK

46

I

BRNIORG

11

IFUELCONS

BRN/GRV

37

I7

VALVEPOS

BLK

47

I

IGN

TIMING

WHT/VIO

88ICRNKSHFTRPM

W

ITXDDATA

HT/VEL87

H

IR%DDATA

COMP

I

U^

WT/VIO

vc

I

WHT/VEL

0

INTAKE

AIR

THROTTLE

TEMPERATURE

POSITION

SENSORSENSOR

nFffi

BRNIORG

26

ISHEILDGROUND

BLK

40

I02SSIGGND

VEL

13,

102S

SIGNAL

W/EGS

ANTI-THEFT

GRN

ORBLKlV10

66

I

DRIVE-AWAY

SIG

1

I

I

!

~~J

_

______

___------------

TRANSMISSION_

CONTROL

AUTOMATICTRANSMISSION

G117

MODULE

(EGS)

RANGESWITCH

ENGINE

COOLANT

HGTIN

RUN

TEMPERATURE

TEA'

IA

SENSOR

r

,FROOWNER

T

TEA'

EP

I

PD

(DISTRIBUTION

L-J

B0%141

X

1001

INSTRUMENT

23

1

.

CLUSTER

I

II

II

CHECK

I

I

ENGINE

I

I

VEHICLE

II

SPEED

I

OUTPUT

18t'xt6

2Yx1Z

.

BLK/W

HT

GRV

bz

~IVSPEEDSIG

I

~'CHECK

ENGIND

I

BRN/RED

78

I

ENGCOOLTEMP

BRN44,

BRN/BLK

~

I

SENS

GROUND

-<

TPOSSENS

I

REDIYEL

68

'

I

I

RV

77LI6VSUPPLV

G

I

INTK

AIR

TEMP

=LK

7~

I

CYL4

-6KS

I

~BRN/ORG

71

I

7

o

j

IKSGROUND

VEL18

I

~~~CVL1-3KS

I

~CRNKSHFTPOS

I

BLK

43,

ICRNKSHFTPOB

PRESSURESWI7CH

BLK/GRY

65

A/C

PRESS

SIG

HALL

EFFECT

CAMSNAFTSENSOR

Page 563 of 759

GRN/VIO

HOT

IN

RUNAND

START

HOT

FILM

AIR

HALLEFFECT

CRANKSHAFT

ELCTRONIC

r

-1FRONT

MASSMETER

CAMSHAFTSENSOR

POSITION/RPM

IMMOBILIZERCONTROL

I

(POWER

r

-

-

1

1

1

SENSOR

MODULE

(EWS11)

FUSE

I

FSSE

F

IDIS7RIBUTION

I

iDA

ISA

(BOX

I

I

(199fi)

(1997)

I

is

Y

iBy

$

1D01B

I

D

-

22

OXYGENSENSOR

(BEHIND

CATALYTIC

CONVERTER)

88648

FUEL

PUMP

SPLICE

BLK

-----

.--_

.-------

OXYGENSENSOR

(FRONT

OFCATALYTIC

CONVERTER)

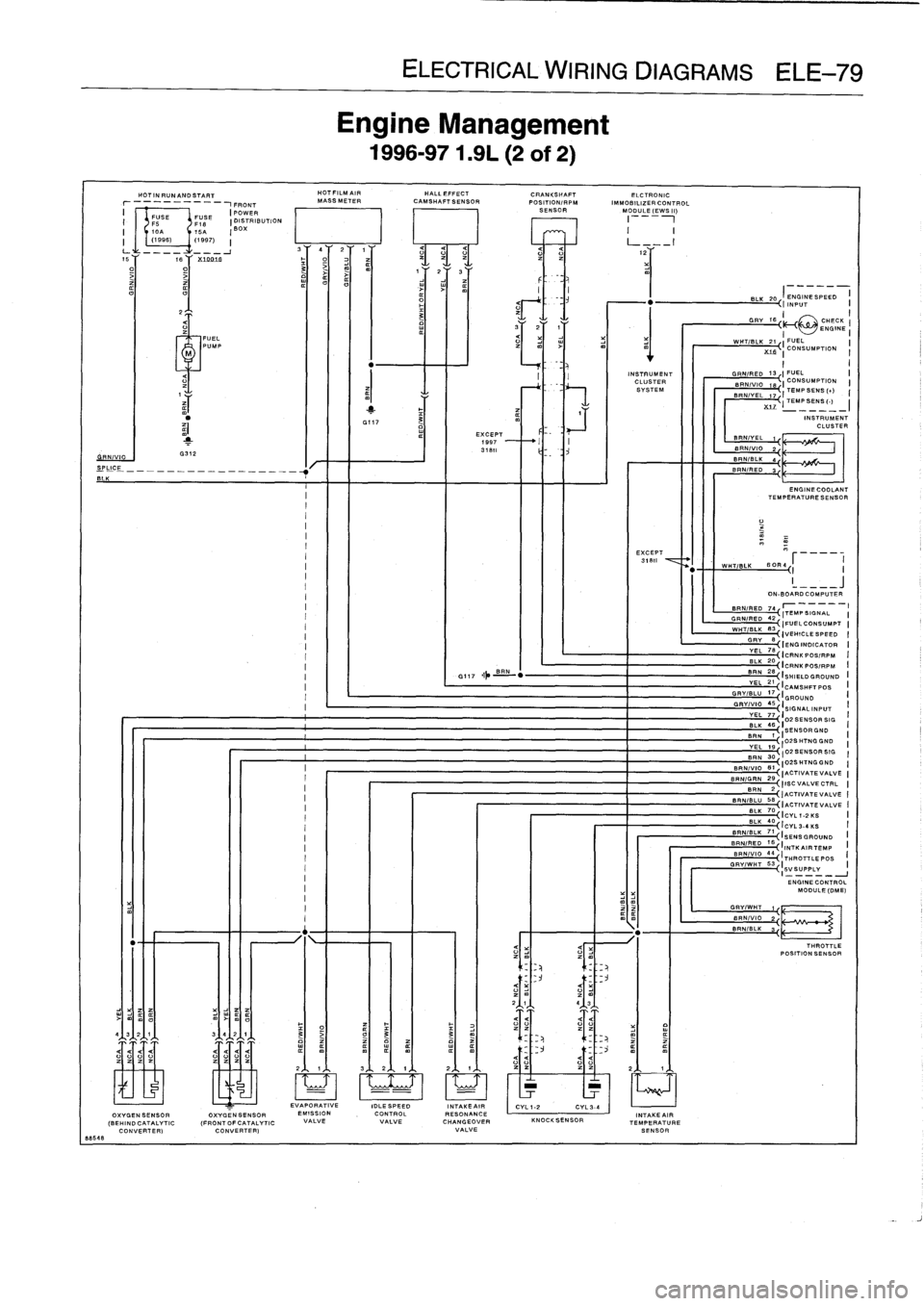

Engine

Management

1996-971

.91-(2

of

2)

EVAPORATIVE

IDLESPEED

EMISSION

CONTROL

VALVEVALVE

ELECTRICAL

WIRING

DIAGRAMS

ELE-79

EXCEPT

1997

318

ti

INSTRUMENT

CLUSTER

SYSTEM

EXCEPT

31811

INTAKEAIR

I

CYL1-2

CYL3-4

RESONANCE

INTAKEAIR

CHANGEOVERKNOCKSENSORTEMPERATURE

VALVE

SENSOR

BLK

IENGINESPEED

I

-

2

k

I

INPUT

I

GRG=1fi~

CHECK

ENGINE

I

WHT/BLK

21

I

FUEL

X

t

fi

'C

CONSUMPTION

I

~GRN/RED

13

3

I

FUEL

I

CONSUMPTION

SRN/VI

jg

TEMPSENS

(L)

BRN/V=L

17{iTEMPSENS(-)

INSTRUMENT

CLUSTER

ENGINECOOLANT

TEMPERATURESENSOR

WW=TIBLK

BOR4

(I

I

__J

ON-BOARD

COMPUTER

BRN/RED

74,

r

_

----

I

~ITEMPSIGNAL

I

-

~GRN/RED

42

J

~IFUELCONSUMPT

I

WHT/BLK

83

~~

I

VEHICLE

SPEED

I

GRV

S,

IENGINDICATOR

I

VEL

78

-

-~{ICRNKPOS/RPM

_ILL

-(ICRNKPOSIRPM

BRN

(SHIELD

GROUND

YEL

I21

CAMSHFTPOS

GRV/BLU

17

'GROUND

GRV/V

-

10

4S

`

VEL77,

:SIGNAL

8-{

I02

SENSOR

SIG

B-

:

..

.SORGND

OISHTNGGND

VEL

19

I

B

3D~I023ENSORBIG

02SHTNGGND

BRN/VIO

B7

I

{

ACTIVATEVALVE

-

-

~BRNIG

RN29

J

I

~

I

ISC

VALVE

CTRL

BRN

2

BRNIBLU~JACTIVATE

VALVE

BIACTIVATEVALVE

-

BILK

70

'

~

BLK

40

;CVL

1-2KS

-~{

I

CYL

3-6

KS

BRN/BLK

711

SENSGROUND

BRN/RED

~

IINTKAIRTEMP

BRN/VIO

44

I

I

~

W

L~~~

THROTTLEPOS

GRVRY/

-

W

I

SVSUPPLY

I

ENGINECONTROL

MODULE

(DME)

THROTTLE

POSITION

SENSOR

Page 565 of 759

![BMW 318i 1992 E36 Service Manual

SO

OXYGEN

OXYGEN

OXYGEN

OXYGEN

CAMSHAFT

DUALTEMPERATURE

SECONDAIR

PUMP

RELAY

VALVE

ID

SECOND

CARBON

EXHAUST

UST

SENSOR

SENSOR]

SENSOR

SENSOR]

POSITION

BMW 318i 1992 E36 Service Manual

SO

OXYGEN

OXYGEN

OXYGEN

OXYGEN

CAMSHAFT

DUALTEMPERATURE

SECONDAIR

PUMP

RELAY

VALVE

ID

SECOND

CARBON

EXHAUST

UST

SENSOR

SENSOR]

SENSOR

SENSOR]

POSITION](/img/1/2800/w960_2800-564.png)

SO

OXYGEN

OXYGEN

OXYGEN

OXYGEN

CAMSHAFT

DUALTEMPERATURE

SECONDAIR

PUMP

RELAY

VALVE

ID

SECOND

CARBON

EXHAUST

UST

SENSOR

SENSOR]

SENSOR

SENSOR]

POSITION

SENSOR

INTAKE

AIR

(RUNNING

AIRPUMP

CANISTER

FLAP

(INFRONTOF

(IN

FRONTOF

(BEHIND

(BEHIND

SENSOR

TEMPERATURE

(COOLANT

CONVERTER)

CONVERTER)

CONVERTER)

CONVERTER)

(CYLINDER

ID)

TEMPERATURE)

LOSSES)

VALVEVALVEVALVE

SENSOR

68894

(1997

ONLY)

ELECTRICAL

WIRING

DIAGRAMS

ELE-81

Engine

Management

1996-97

2

.81L

(2

of

2)

II

````

``

aa

a

a

.

.U

~lal

f

2f

COMPUTER

DATA

LINES

(1997

0NLY)

~t

11~

EXCEPT1996M3

TRANSMISSION

CONTROL

~-

-

MODULE(EGS)

MASS

METE

R

-

-

MASSMETER

6117

1

1

L,2)13)l

2s,t,54,1,95,1,as,t,

60,1,

99,L

-

14,L,

2~

1

18~17~

19~

.~

_

CRANKSHAFT

I

DATA

LINK

CONNECTOR

POSITION/

1

I

RPM

i

-----------~

SENSOR

BRN/VIO

18

~

I

~BRN/YE~L

~17_~

1

I

~

O

RN/RENN~

I

I

X17

I

I

.

WHT/BLK

21

I

I

-

GRrr,~I

I

XL6

I-_-J

INSTRUMENT

CLUSTER

I

I

IGRY

20-

ICHECKENGINO

I

INSTRU-

IFUELCONS

MENT

GRN/RED

46

I

FUELCONS

CLUSTER

SRWRED

10

I

ENGCOOLTEMP

GRV/BRN

39

I

GRY

14

(GROUND

NCA

S1

IINTKAIRTEMP

(GROUND

BLK64,

(GROUND

VEL

65

ICAMS

HAFTPOS

BR

N

43

~ICAMSHAFTPOS

B

ISENSO

YES,

RSIGNAL

I

8

I02S

SIG

GNO

1

-,

I02SHTGGND

I

YEL

~ISENSORSIGNAL

I

BLK

71

1

025

SIG

GNO

I

B

1

02SHTGGND

I

SRN

55

I

02S

H

TG

GND

I

BLK70,

I

02551GGND

I

BRN

255,SENSORSIGNAL

I

B~1025HTGGND

I

Y~102SSIGGND

I

-~

SENSORSIGNAL

1

GflV/V=0

BIGEXHSTFLAP

I

GRN/BLU

61,

I

IACTIVATEVALVE

I

BRN/WHT

62

VEL/BLU

50

IACTIVATEVALVE

I

BRN/GRN

35

IRUNNINGLOSS

1

IACTIVATEVALVE

I

BLK

85

ICANLOW

I

VEL

86

CANHIGH

I

BLK/BLU

74

AIC

-~IACTVA/C

COMP

I

VIO/GRY

19

SYSTEM

A/C

ON

BIG

I

BLK

36

I

CRNKSHFTRPM

I

GRN/BLU

60,

I

PROGRAMVOLT

I

WHT/VIO/VEL

88

I

TxDYEL

6

I

SILK

7~

1

HOTFAM

MTR

HOTFAMMTR

BRN/0=

1

(GROUND

YEL

4

<

IVOLTSUPPLY

.LK

'ISENSORSIGNAL

.BRN/B=

K

400

(1

GROUND

VEL/RED

11

IFUELTNKPRES

REDIGRN

00

~IVOLTSUPPLV

BLK

12ITHROTPOSSIG

BRN

42

GROUND

ENGINECONTROL

MODULE

(DME)

NCA

J

]

-k

0

1

I

RE

~

/GRN

3,

GRV/WHT

1

YEL/RED

3

BRN/BLK

2

THROTTLE

POSITION

SENSOR

FUELTANK

l

ml

mlml

PRESSURESENSOR

¢I

¢I

ml

>I

t7

B

¢I3I

m

O

3m

¢I

>I

m