API BMW 318i 1992 E36 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1992, Model line: 318i, Model: BMW 318i 1992 E36Pages: 759

Page 7 of 759

Please

read

these

warnings

and

cautions

before

proceeding

with

maintenance

and

repair

work

.

WARNING-

"

Friction

materials

(such

as

brake

pads

or

shorts

or

clutchdiscs)

contain

asbestos

fibers

or

other

friction

materials

.

Do

notcreate

"

See

also

Cautionson

page

viü

dustby

grinding,

sanding,

orby

cleaning

with

compressed

air

.

"

Some

repairs

may

be

beyond

your

capability

.

If

you

lack

the

Avoid

breathing

dust

.

Breathing

any

friction

material

dust

can

lead

skills,

tools

and

equipment,

or

a

suitable

workplace

for

any

proce-

to

serious

diseases

and

may

result

in

death

.

duredescribed

in

this

manual,

we

suggestyou

leave

such

repairs

"

Batteries

give

off

explosive

hydrogen

gas

during

charging

.

to

an

authorized

BMW

dealer

service

department

or

other

quali-

Keep

sparks,

lighted

matches

and

open

flame

away

from

the

top

fied

shop

.

of

the

battery

If

hydrogen

gas

escaping

from

the

cap

vents

is

"Do

not

re-use

any

fasteners

that

are

worn

or

deformed

in

normal

ignited,

it

will

ignite

gas

trapped

in

the

cells

and

cause

the

battery

use

.

Many

fasteners

are

designed

to

be

used

only

once

and

to

explode

.

become

unreliable

and

may

fail

when

used

a

second

time

.

This

"

Connect

and

disconnect

battery

cables,

jumper

cablesora

bat-

includes,

but

is

not

limited

to,

nuts,

bolts,

washers,

self-locking

nuts

or

bolts,

circlips

and

cotterpins

.

Always

replace

these

fasteners

with

new

parts

.

"Do

not

quick-charge

the

battery

(for

boost

starting)

for

longer

"

Never

work

under

a

lifted

car

unless

it

is

solidly

supportedon

than

one

minute

.

Wait

at

least

one

minute

before

boosting

the

bat-

stands

designed

for

the

purpose

.

Do

not

support

a

car

on

cinder

tery

a

second

time

.

blocks,

hollow

tiles

or

other

props

that

may

crumble

under

contin-

uous

load

.

Never

work

under

acar

that

is

supported

solely

by

a

"Do

not

allow

battery

charging

voltage

to

exceed

16

.5

volts

.

If

the

jack

.

Never

work

under

thecar

while

the

engine

is

running

.

battery

beginsproducing

gas

or

boiling

violently,

reduce

the

charg-

ing

rate

.

Boosting

a

sulfated

battery

at

a

high

charging

rate

can

"

If

you

are

going

to

work

under

acar

on

the

ground,

make

sure

cause

an

explosion

.

that

the

ground

is

level

.

Block

the

wheels

to

keep

the

carfrom

roll-

ing

.

Disconnect

the

battery

negative

(-)

terminal

(ground

strap)to

"

The

air-conditioning

system

is

filled

with

chemical

refrigerant,

prevent

others

from

starting

thecar

while

youare

under

it

.

which

is

hazardous

.

TheA/C

system

should

be

servicedonly

by

trained

technicians

using

approved

refrigerant

recovery/recycling

"

Never

run

the

engine

unless

the

work

area

is

well

ventilated

.

equipment,

trained

in

related

safetyprecautions,

and

familiar

with

Carbon

monoxide

kills

.

regulations

governing

the

discharging

and

disposal

of

automotive

"

Finger

rings,

bracelets

and

other

jewelry

shouldbe

removed

so

chemical

refrigerants

.

tery

charger

only

with

the

ignition

switched

off,

to

prevent

sparks

.

Do

not

disconnect

the

battery

while

the

engine

is

running

.

that

theycannot

cause

electrical

shorts,

get

caught

in

running

"

Do

not

expose

any

partof

the

A/Csystem

to

high

temperatures

machinery,

or

be

crushed

by

heavy

parts

.

suchas

open

flame

.

Excessiveheat

will

increase

system

pressure

"

Tie

long

hair

behind

your

head

.

Do

not

wear

a

necktie,

a

scarf,

and

may

cause

the

system

to

burst

.

loose

clothing,

or

a

necklace

when

you

work

near

machine

tools

or

"

Some

aerosol

tire

inflators

are

highly

flammable

.

Be

extremely

running

engines

.

If

your

hair,

clothing,

or

jewelry

were

to

get

caught

cautious

when

repairing

a

tire

that

may

havebeen

inflated

using

in

the

machinery,

severe

injury

could

result

.

an

aerosol

tire

inflator

.

Keep

sparks,

open

flame

or

other

sources

"

Do

not

attempt

to

work

onyourcar

if

you

do

not

feel

well

.

You

of

ignition

away

from

the

tire

repair

area

.

Inflate

and

deflate

the

tire

increase

the

danger

of

injury

toyourself

and

others

if

you

are

tired,

at

least

four

times

before

breaking

the

bead

from

therim

.

Com-

upset

or

have

takenmedication

or

any

other

substance

that

may

Pletely

remove

the

tire

from

the

rim

beforeattempting

any

repair

.

keep

you

from

being

fully

alert

.

"

Illuminate

your

work

areaadequately

but

safety

.

Use

a

portable

safety

light

for

working

inside

or

under

thecar

.

Make

surethe

bulb

is

enclosedbya

wire

cage

.

The

hot

filament

of

an

accidentally

bro-

ken

bulb

can

ignite

spilled

fuel

or

oil

.

"

Catch

draining

fuel,

oil,

orbrake

fluid

in

suitable

containers

.

Do

not

use

food

or

beverage

containers

that

mightmislead

someone

into

drínking

from

them

.

Store

flammable

fluids

away

from

fire

haz-

ards

.

Wipe

up

spills

at

once,

but

do

not

store

the

oily

rags,

which

can

ignite

and

burn

spontaneously

.

"

Always

observe

good

workshop

practices

.

Wear

goggles

when

youoperate

machine

tools

or

work

with

battery

acid

.

Gloves

or

other

protectioeclothing

should

be

worn

whenever

thejob

requires

working

with

harmful

substances

.

"

Greases,

lubricants

and

other

automotive

chemicals

contain

toxic

substances,

many

of

which

are

absorbed

directly

through

the

skin

.

Read

the

manufacturer's

instructions

and

warnings

carefully

.

Use

hand

andeye

protection

.

Avoid

direct

skin

contact

"

Cars

covered

by

this

manual

are

equipped

with

a

supplemental

restraint

system

(SRS),

that

automatically

deploys

an

airbag(s)

in

theevent

of

a

frontal

ímpact

.

The

airbag(s)

is

inflated

byan

explo-

sive

device

.

Handled

improperly

or

without

adequate

safeguards,

can

be

accidently

activated

and

cause

serious

injury

.

"

The

ignition

system

produces

high

voltages

that

can

be

fatal

.

Avoid

contact

with

exposed

terminals

and

use

extreme

care

when

working

ona

car

with

the

engine

running

or

the

ígnition

switched

on

.

"

Place

jack

stands

only

at

locations

specified

bymanufacturer

.

The

vehicle

lifting

jacksupplied

with

the

vehicle

is

intended

for

tire

changes

only

.

A

heavy

duty

floor

jack

shouldbe

used

to

lift

vehicle

before

installing

jack

stands

.

See

010

Fundamentals

for

theDo-

.

it-Yourself

Owner

.

"

Battery

acid

(electrolyte)

can

cause

severeburns

.

Flush

contact

area

with

water,

seek

medical

attention

.

"

Aerosolcleaners

and

solvents

may

contain

hazardous

ordeadly

vapors

and

are

highly

flammable

.

Use

only

in

a

wellventilated

area

.

Do

not

use

on

hot

surfaces

(engines,

brakes,

etc

.)

.

"

Disconnect

the

battery

negative

(-)

terminal

(Ground

strap)

"

Do

not

remove

coolant

reservoir

or

radiator

cap

with

theengine

whenever

you

work

on

the

fuel

system

orthe

electrical

system

.

Do

hot

.

Danger

of

bums

and

engine

damage

.

not

smoke

or

work

near

heaters

or

other

fire

hazards

.

Keep

an

approved

fire

extinguisher

handy

.

continued

on

next

page

vii

Page 8 of 759

Please

read

these

warnings

and

cautions

before

proceeding

with

maintenance

and

repair

work

.

CAUTION-

"

See

also

Warnings

onpage

vi¡

"

Beforedoing

any

electrical

welding

on

cars

equipped

with

ABS,

disconnect

the

battery

negative

(-)

terminal

(ground

strap)

and

the

"

If

you

lack

the

skills,

tools

and

equipment,

ora

suitable

work-

ABS

control

unit

connector

.

shop

for

any

procedure

described

in

this

manual,

we

suggest

you

leave

such

repairs

to

an

authorized

BMW

dealer

or

other

qualified

"

On

cars

equipped

with

anti-theft

radios,

make

sureyou

know

the

shop

.

correct

radio

activation

code

before

disconnecting

the

battery

or

removing

the

radio

.

lf

the

wrong

code

is

entered

into

the

radio

"

BMW

is

constantly

improving

its

cars

and

sometimes

these

when

power

is

restored,

that

radio

may

lock

up

and

be

renderedchanges,

both

in

parts

and

specifications,

are

made

applicable

to

inoperable,

even

if

the

correct

code

is

thenentered

.

earlier

models

.

Therefore,

part

numbers

listed

in

this

manual

are

for

reference

only

.

Always

check

with

your

authorized

BMW

dealer

"

Always

make

sure

ignition

is

off

before

disconnecting

battery

.

parts

department

for

the

latest

information

.

"

Label

battery

cablesbefore

disconnecting

.

Onsome

models,

"

Before

starting

a

job,

make

certain

that

you

have

all

the

neces-

battery

cablesarenot

color

coded

.

sary

tools

and

parts

on

hand

.

Read

al¡

the

instructions

thoroughly,

do

not

attempt

shortcuts

.

Use

tools

appropriate

to

the

work

and

"

Disconnecting

the

battery

may

erase

fault

code(s)

stored

in

con-

use

only

replacement

parts

meeting

BMW

specifications

.

Make-

trol

module

memory

Using

special

BMW

diagnostíc

equipment,

shift

tools,

parts

and

procedures

will

not

make

good

repairs

.

check

forfault

codes

prior

to

disconnecting

the

battery

cables

.If

the

Check

Engine

light

is

illuminated,

see100

Engine-General

for

"

Use

pneumatic

and

electric

tools

only

to

loosenthreaded

parts

On-Board

Diagnostics

(OBD)

fault

code

information

.

lf

any

other

and

fasteners

.

Never

use

these

tools

to

tighten

fasteners,

espe-

system

faults

have

been

detected

(indicated

by

an

ílluminated

cially

on

light

alloy

parts

.

Always

use

a

torque

wrench

to

tighten

warning

light),

see

an

authorized

BMW

dealer

.

fasteners

to

the

tightening

torque

specification

listed

.

"

If

a

normal

or

rapid

charger

is

used

to

charge

battery,

the

battery

"Be

mindful

of

the

environment

and

ecology

.

Before

you

drain

the

mustbe

disconnected

and

removed

fromthe

vehicle

in

order

to

crankcase,

find

outthe

proper

way

to

dispose

of

the

oil

.

Do

not

avoid

damaging

paint

and

upholstery

pour

oil

onto

the

ground,

down

a

drain,

or

into

a

stream,

pond

orlake

.

Dispose

of

in

accordance

withFederal,

State

and

Local

laws

.

"Do

not

quick-chargethe

battery

(for

boost

starting)

for

longer

than

one

minute

.

Wait

at

least

one

minute

before

boosting

the

bat-

e

If

battery

power

is

lost

or

the

battery

has

been

disconnected,

the

tery

a

second

time

.

powerwindows

must

be

re-initialized

.

Both

one

touch

up/down

and

pinch-protection

will

be

inactive

until

windows

are

re-initial-

"

Connect

and

disconnect

a

battery

charger

only

with

the

battery

ized

.

See

512

Door

Windows

.

charger

switched

off

.

"

The

control

module

for

the

anti-lock

brake

system

(ABS)

cannot

withstand

temperatures

from

a

paint-drying

booth

or

aheat

lamp

in

excess

of

203°F

(95°C)

and

should

not

be

subjected

to

temper-

atures

in

excess

of

185°F

(85°C)

for

more

than

twohours

.

"

Sealed

or

"maintenance

free"

batteries

shouldbeslow-charged

only,

at

anamperage

ratethat

is

approximately

10%

of

the

bat-

tery's

ampere-hour

(Ah)

rating

.

"

Do

not

allow

battery

chargingvoltage

to

exceed

16

.5

volts

.

If

the

battery

begins

producing

gas

or

boiling

violently,

reduce

the

charg-

ing

rate

.

Boosting

a

sulfated

battery

at

a

high

charging

rate

can

cause

an

explosion

.

Page 30 of 759

020-

8

MAINTENANCE

PROGRAM

FLUID

AND

LUBRICANT

SPECIFICATIONS

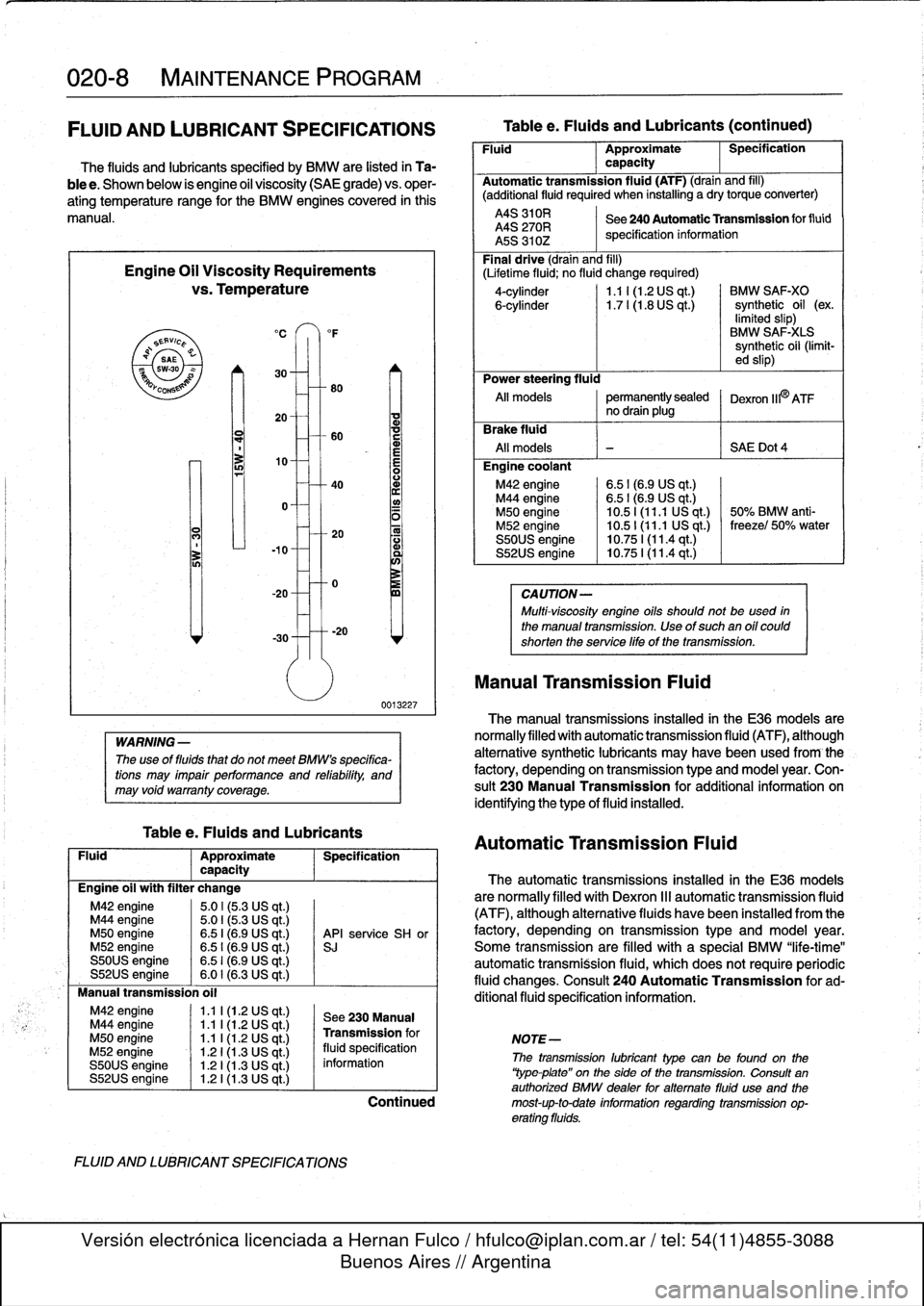

The

fluids

and

lubricante

specified

by

BMW

are

listed

in

Ta-

ble

e

.

Shown

below

is

engine

oil

viscosity

(SAE

grade)

vs

.

oper-

ating

temperature

range

for

the

BMW

enginescovered

in

this

manual

.

Engine

Oil

Viscosity

Requirements

vs

.

Temperature

`S

EAVic

P

Q

SAE

swao

YCO

0

N

M42

engine

1

.1

I

(1

.2

US

qt

.)

M44

engine

1

.1

l(1.2

US

qt

.)

M50

engine

1

.1

1(1.2

US

qt

.)

M52

engine

1

.21(1.3

US

qt

.)

S50US

engine

1

.21(1.3

US

qt

.)

S52US

engine

1

.21(1.3

US

qt

.)

°F

80

-

1o-0

-

30

-----20

WARNING

-

The

use

of

fluids

that

do

not

meet

BMWs

specifica-

tions

may

impair

performance

and

refability,

and

may

void

warranty

coverage

.

Tablee

.

Fluids

and

Lubricants

0013227

Fluid

Approximate

Specification

capacity

Engine

oil

with

filter

change

M42

engine

5

.01

(5

.3

US

qt

.)

M44

engine

5

.0

I

(5

.3

US

qt

.)

M50

engine

6

.5

I

(6.9

US

qt

.)

API

service

SH

or

M52

engine

6

.51

(6.9

US

qt

.)

si

S50US

engine

6

.51

(6.9

US

qt

.)

S52US

engine

6.0

I

(6.3

US

qt

.)

Manual

transmission

oil

FLUID

AND

LUBRICANT

SPECIFICATIONS

See

230Manual

Transmission

for

NOTE-

fluid

specification

Tablee

.

Fluids

and

Lubricants

(continued)

Fluid

Approximate

Specification

capacity

Automatic

transmission

fluid

(ATF)

(drain

and

fill)

(additional

fluid

required

when

installing

a

drytorque

converter)

A4S

310R

See240

AutomaticTransmission

for

fluid

A4S

270R

specification

information

A5S

310Z

Final

drive

(drain

and

fill)

(Lifetime

fluid

;

no

fluid

change

required)

4-cylinder

1

.1

I

(1.2

US

qt

.)

BMW

SAF-XO

6-cylinder

1.7

l(1

.8

US

qt

.)

synthetic

oil

(ex

.

limited

slip)

BMW

SAF-X1-S

synthetic

oil

(limit-

ed

slip)

Power

steering

fluid

Al¡

modeis

permanentlysealed

Dexron

IIPATFno

drain

plug

rake

fluid

All

modeis

-

~

S

AE

Dot4

Engine

coolant

M42

engine

6

.51(6

.9

US

qt

.)

M44

engine

6

.51(6

.9

US

qt

.)

M50

engine

10

.51

(11

.1

US

qt

.)

50%

BMW

anti-

M52

engine

10

.5

1

(11

.1

US

qt

.)

freezel

50%

water

S50US

engine

10

.75

1(11

.4

qt

.)

S52US

engine

10

.75

I

(11

.4

qt

.)

CA

UTION-

Multi-viscosity

engine

oils

should

not

beused

in

the

manual

transmission

.

Use

of

such

an

oil

could

shorten

the

service

life

of

thetransmission

.

Manual

Transmission

Fluid

The

manual

transmissions

installed

in

the

E36

modeis

are

normallyfilled

with

automatic

transmission

fluid

(ATF),

although

alternative

synthetic

lubricants

may

havebeen

used

from

-

the

factory,

depending

on

transmission

type

and

model

year

.

Con-

sult

230

Manual

Transmission

for

additional

information

on

identifying

the

type

of

fluid

installed

.

Automatic

Transmission

Fluid

The

automatic

transmissions

installed

in

the

E36

modeis

are

normally

filled

with

Dexron

111

automatic

transmission

fluid

(ATF),

although

alternative

fluids

havebeen

installed

from

the

factory,

depending

on

transmission

type

and

model

year

.

Some

transmission

are

filled

with

a

special

BMW

"life-time"

automatic

transmission

fluid,

whích

does

not

requireperiodic

fluid

changes

.

Consult

240

Automatic

Transmission

for

ad-

ditional

fluid

specification

information

.

information

1

The

11-

11

lubrican

type

canbefound

on

ti

¡e

`Yype

plate"

on

the

side

of

the

transmission

.

Consult

an

authorized

BMW

dealer

foralternate

fluid

use

and

the

Continued

most-up-to-date

information

regarding

transmission

op-

erating

fluids

.

Page 42 of 759

020-20

MAINTENANCE

PROGRAM

Seat

Belts

Washing

Chassis

Dirt

and

other

abrasive

particles

will

damage

seat

belt

web-

Periodic

washing

of

the

underside

of

the

car,

especially

in

bing

.

If¡t

is

necessary

to

clean

seat

belts,

use

a

mild

soap

solu-

winter,

will

help

prevent

accumulation

of

road

salt

and

rust

.

The

tion

.

Bleach

and

other

strong

cleaning

agents

may

weaken

the

besttime

to

wash

the

underside

is

just

after

the

car

has

been

belt

webbing

and

should

be

avoided

.

driven

in

wet

conditions

.

Spray

the

chassis

with

a

powerful

jet

of

water

.

Commercial

or

self-service

car

washes

may

not

be

best

WARNING-

for

this,

as

they

may

recycle

the

salt-contaminated

water

.

Do

not

clean

the

seat

belt

webbing

using

dry

clean-

ing

or

other

chemicals

.

Allow

wet

belts

to

dry

before

allowing

them

to

retract

.

Speeial

Cleaning

The

condition

of

the

belt

webbing

and

the

function

of

the

re-

tractor

mechanisms

should

be

inspected

.

See720

Seat

Belts

for

seat

belt

inspection

information

.

Exterior

Washing

The

longer

dirt

isleft

on

the

paint,

the

greater

the

risk

of

dam-

aging

the

glossy

finish,

either

by

scratching

or

by

the

chemical

effect

dirt

particles

may

have

on

the

paintedsurface

.

Do

not

wash

the

car

in

direct

sunlight

.

If

the

engine

hood

is

warm,

allow

it

to

cool

.

Beads

of

water

not

only

leavespots

when

dried

rapidly

by

the

sun

or

heat

from

the

engine,

but

also

can

act

as

small

magnifyingglasses

and

burn

spots

into

the

finish

.

Wash

thecar

with

a

mixture

of

lukewarmwater

and

a

car

wash

product

.

Rinse

using

plenty

of

clear

water

.

Wipe

the

body

dry

witha

soft

cloth

towel

or

chamois

to

prevent

water-spotting

.

Waxing

For

a

long-lasting,protective,

and

glossy

finish,

apply

a

hard

wax

after

thecar

has

been

washed

and

dried

.

Use

carnauba

or

synthetic

based

products

.

Waxing

is

not

needed

after

every

washing

.

You

can

tell

when

waxing

is

required

by

looking

at

the

finísh

when

it

is

wet

.

If

the

water

coats

the

paint

in

smooth

sheets

instead

of

forming

beads

that

rol¡

off,

a

new

coat

of

wax

is

needed

.

Wax

shouldnot

be

applied

to

black

trim

pieces,

rub-

ber,or

other

plastic

parts

.

Polishing

Use

paintpolish

only

if

the

finish

assumes

a

dull

lock

after

long

service

.

Polish

can

beused

to

remove

tar

spots

and

tar-

nish,

but

afterwards

a

coat

of

wax

should

be

applied

to

protect

the

clean

finish

.

Do

not

use

abrasive

polish

or

cleaners

on

alu-

minum

trimor

accessories

.

BODYAND

INTERIOR

MAINTENANCE

Cylinder

Head

and

Valvetrain

The

aluminum

cylinder

head

uses

chain-driven

double

overhead

camshafts

and

four

valves

per

cylinder

.

See

Fig

.

1

.

Tha

rvfinriar

hand

nmnlnve

n

ernceflnier

rineinn

fnr

nronter

Tar

spots

canbe

removed

with

a

bugand

tar

remover

.

Never

use

gasoline,

kerosene,

nail

polish

remover,

or

other

unsuitable

solvents

.

Insect

spots

also

respond

to

tar

remover

.

A

bit

of

bak-

ing

soda

dissolved

in

the

wash

water

will

facilitate

their

removal

.

This

method

can

also

beused

to

remove

spotting

from

tree

sap

.

Interior

Care

Dirt

spots

can

usually

be

removed

with

lukewarm

soapy

wa-

ter

or

a

dry

foam

cleaner

.

Use

spot

remover

for

grease

and

o¡I

spots

.

Do

not

pour

the

(quid

directly

on

the

carpetor

fabric,

but

dampen

a

clean

cloth

and

rub

carefully,starting

at

the

edge

of

the

spot

and

working

inward

.

Do

not

use

gasoline,

naptha,

or

other

flammable

substances

.

Leather

Upholstery

and

Trim

Leather

upholstery

and

trim

should

be

periodically

cleaned

using

a

slightly

damp

cotton

or

wool

cloth

.

The

idea

is

to

get

rid

of

the

dirtin

the

creases

and

pores

that

can

cause

brittleness

and

premature

aging

.

On

heavily

soiled

areas,

usea

mild

deter-

gent

(such

as

Woolite®)

or

other

specially

formulated

leather

r

cleaners

.

Use

two

tablespoons

to

one

quart

of

cold

water

.

Dry

the

trim

and

upholstery

completely

using

a

soft

cloth

.

Regular

use

of

agood

quality

leather

conditioner

will

reduce

drying

and

crackingof

the

leather

.

1

.

Camshafts

2

.

Rocker

arms

3

.

Hydraulic

valve

adjusters

(HVA)

4

.

Valve

and

conical

valve

spring

Page 194 of 759

160-

1

0

FUEL

TANK

AND

FUEL

PUMP

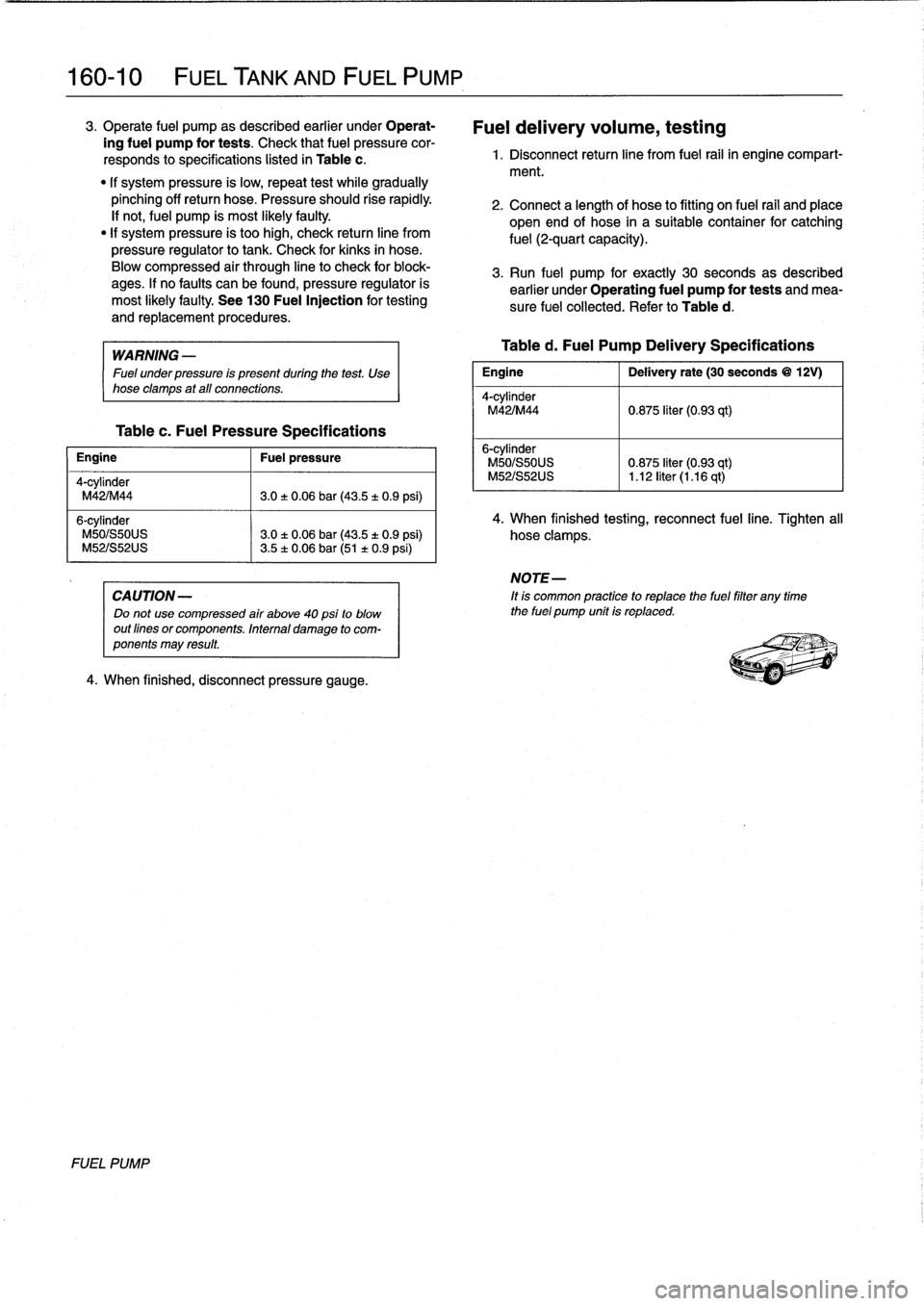

3

.

Operate

fuel

pump

as

described

earlier

under

Operat-

ing

fuel

pump

for

tests

.

Check

that

fuel

pressure

cor-

responds

to

specifications

listed

in

Table

c

.

"

If

system

pressure

is

low,

repeat

test

whilegradually

pinching

off

return

hose

.

Pressure

should

rise

rapidly

.

If

not,fuel

pump

is

most

likely

faulty

.

"

If

system

pressure

is

too

high,

check

return

line

from

pressure

regulator

to

tank

.

Check

for

kinks

in

hose

.

Blow

compressed

air

through

line

to

check

for

block-

ages

.

If

no

faulty

canbe

found,

pressure

regulator

is

most

likely

faulty

.

See

130

Fuel

Injection

for

testing

and

replacementprocedures

.

Table

c

.

Fuel

Pressure

Specifications

Engine

1

Fuel

pressure

4-cylinder

M42/M44

3

.0

:e

0

.06

bar(43

.5

±0

.9

psi)

6-cylinder

M50/S50US

3

.0

:j-

0

.06bar(43

.5

t0

.9

psi)

M52/S52US

3

.5

t

0

.06

bar

(51

t0

.9psi)

CA

UTION-

Do

not

use

compressed

air

above

40

psi

to

blow

out

fines

or

components

.

Interna¡

damage

to

com-

ponents

may

result

.

4

.

When

finished,

disconnect

pressure

gauge

.

FUEL

PUMP

Fuel

delivery

volume,

testing

1

.

Disconnect

return

line

from

fuel

rail

in

engine

compart-

ment

.

2

.

Connect

a

length

of

hose

to

fitting

on

fuel

rail

and

place

open

end

of

hose

in

a

suitable

container

for

catching

fuel

(2-quart

capacity)

.

3

.

Run

fuel

pump

for

exactly

30

seconds

as

described

earlier

under

Operating

fuel

pump

for

tests

and

mea-

sure

fuel

collected

.

Refer

to

Table

d

.

WARNING-

Table

d

.

Fuel

Pump

Delivery

Specifications

Fuel

under

pressure

is

present

duringthe

test

.

Use

I

Engine

Delivery

rate

(30

seconds

@

12V)

hose

clamps

at

all

connections

.

4-cylinder

M42/M44

0

.875

fter

(0

.93

qt)

6-cylinder

M50/S50US

0

.875

fter(0

.93

qt)

M52/S52US

~

1

.12

liter

(1

.16

qt)

4

.

When

finished

testing,

reconnect

fuel

line

.

Tighten

all

hose

clamps

.

NOTE-

It

is

common

practice

to

replace

the

fuel

filter

any

time

the

fuel

pump

unit

is

replaced

.

Page 197 of 759

Cooling

System

Pressure

Test

If

the

engine

overheats

and

no

other

cooling

system

testsindicate

trouble,

the

radiator

may

have

some

pluggedpassag-

A

cooling

system

pressure

test

is

used

to

check

for

internal

es

that

are

restricting

coolant

flow

.

leaks

.

Some

of

the

common

sources

ofinternal

leaks

are

a

faulty

cylinder

head

gasket,

a

cracked

cylinder

head,

or

a

Temperature

Gauge

Quick

Check

cracked

cylinder

block

.

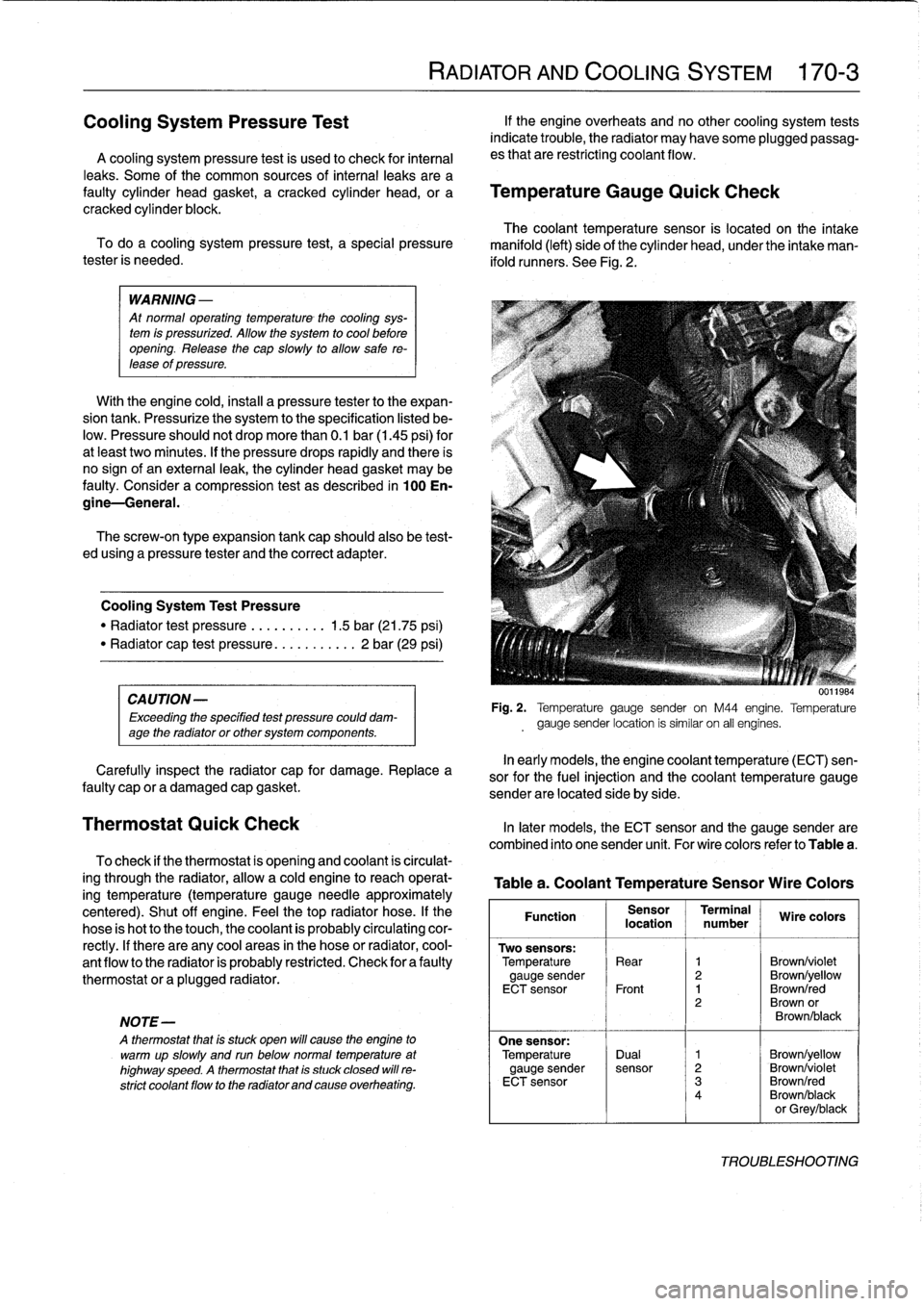

The

coolant

temperature

sensor

is

located

on

the

intake

To

doa

cooling

system

pressure

test,

a

special

pressure

manifold

(left)

side

of

the

cylinder

head,

under

the

intake

man-

tester

is

needed

.

ifold

runners

.

See

Fig

.

2

.

WARNING

-

At

normal

operating

temperature

-

the

cooling

sys-

tem

is

pressurized

.

Allow

the

system

to

cool

before

opening

.

Release

the

cap

slowly

to

allow

sale

re-

tease

of

pressure

.

With

the

engine

cold,instan

a

pressure

tester

to

the

expan-

sion

tank

.

Pressurize

thesystem

to

the

specification

listed

be-

low

.

Pressure

should

not

drop

more

than

0

.1

bar

(1

.45

psi)

for

at

leakt

two

minutes

.

If

the

pressure

drops

rapidly

and

there

is

no

sign

of

an

externa¡

leak,

the

cylinder

head

gasket

may

be

faulty

.

Considera

compression

test

as

described

in

100

En-

gine-General

.

The

screw-on

type

expansion

tank

cap

should

also

be

test-

ed

using

a

pressure

tester

and

the

correct

adapter

.

Cooling

System

Test

Pressure

"

Radiator

test

pressure

.........

.

1

.5

bar

(21

.75

psi)

"

Radiator

cap

test

pressure

..

.

........

2

bar

(29

psi)

CA

UTION-

Exceeding

the

speclfied

test

pressure

could

dam-

age

the

radiatoror

other

system

components

.

Carefully

inspect

the

radiator

cap

for

damage

.

Replace

a

faulty

cap

or

a

damaged

cap

gasket

.

Thermostat

Quick

Check

In

later

models,

the

ECT

sensor

and

the

gauge

sender

are

combined

into

one

sender

unit

.

For

wire

colors

refer

to

Table

a

.

To

check

if

the

thermostat

is

opening

and

coolant

is

circulat-

ing

through

the

radiator,

allow

a

cold

engine

to

reach

operat-

ing

temperature

(temperature

gauge

needieapproximately

centered)

.

Shut

off

engine

.

Feel

the

top

radiator

hose

.

If

the

hose

is

hot

to

the

touch,

the

coolant

is

probably

circulating

cor-

rectly

.

If

there

are

any

cool

areas

in

the

hose

or

radiator,

cool-

ant

flow

to

the

radiator

is

probably

restricted

.

Check

for

a

faulty

thermostat

or

aplugged

radiator

.

NOTE-

A

thermostat

that

is

stuck

open

will

cause

the

engine

to

warmup

slowly

and

run

belownormal

temperature

at

highway

speed

.

A

thermostat

that

is

stuck

closed

will

re-

strict

coolant

flow

to

the

radiator

and

cause

overheating

.

RADIATOR

AND

COOLING

SYSTEM

170-

3

U

.¡ig

.v

Fig

.

2

.

Temperature

gauge

sender

on

M44

engine

.

Temperature

gauge

sender

location

is

similar

on

al]

engines

.

In

early

models,

the

engine

coolant

temperature

(ECT)

sen-

sor

for

the

fuel

injection

and

the

coolant

temperature

gauge

sender

are

located

side

by

side

.

Table

a

.

Coolant

Temperature

Sensor

Wire

Colors

Function

Sensor

Terminal

Wire

colors

location

number

Two

sensors

:

Temperature

Rear

1

Brown/violet

gauge

sender

2

Brown/yellow

ECT

sensor

Front

1

Brown/red

2

Brown

or

Brown/black

One

sensor

:

Temperature

Dual

1

Brown/yellow

gauge

sender

sensor

2

Brown/violet

ECT

sensor

3

Brown/red

4

Brown/black

or

Grey/black

TROUBLESHOOTING

Page 253 of 759

NOTE-

The

traction

control

system

referred

to

as

AST

(all

sea-

son

traction)

may

also

be

referred

to

as

ASC

(Automat-

ic

Stability

Control)

and

ASC+T

(Automatic

Stability

Control+Traction)

.

The

AST

system

improves

traction

by

electronically

apply-

ing

the

rear

brakes

when

therear

drive

wheels

are

spinning

at

a

faster

rate

than

the

front

wheels

.

The

combined

ABS/AST

control

module,

operating

through

the

ABS

hydraulic

control

unit,

modulates

braking

force

at

therear

wheels

.

In

addition,

AST

uses

retarded

ignition

timing

and

an

auxil-iary

engine

throttle

plate

to

reduceengine

torque

and

maintain

vehicle

stability

.

The

auxiliary

throttle

plate

is

held

open

by

spring

pressure

.

The

AST

system

actívates

the

auxiliary

throttie

position

motor

(ADS)

to

cose

the

AST

throttle

as

needed

.

This

reduces

the

volume

of

engine

intake

air

.

Due

to

the

throttle

closing

very

rapidly

during

AST

operationthe

driver

cannot

increase

theengine

power

output

regardless

of

how

far

theaccelerator

pedal

is

pushed

to

the

floor

.

The

auxiliary

throttle

plate

is

placed

ahead

of

the

conven-

tional

throttle

plate

in

the

throttle

body

.

Traction

control

also

comes

into

operationduringdecelera-

tion

.

Decelerating

on

snowy

or

icy

road

surfaces

can

lead

to

rear

wheel

slip

.

If

a

rear

wheel

startsto

drag

or

lock

up

when

the

throttle

is

closed

rapidly

orduringdownshifting,the

AST

system

can

limit

the

problem

by

advancing

the

ignition

timing

.

A

switch

on

the

center

console

is

used

to

togglethe

AST

on

or

off

.

The

AST

system

is

designed

to

be

maintenance

free

.

There

are

no

adjustments

that

can

be

made

.

Repair

and

trouble-

shooting

of

the

AST

system

requires

special

test

equipment

andknowledgeand

should

be

performed

only

by

an

autho-

rized

BMW

dealer

.

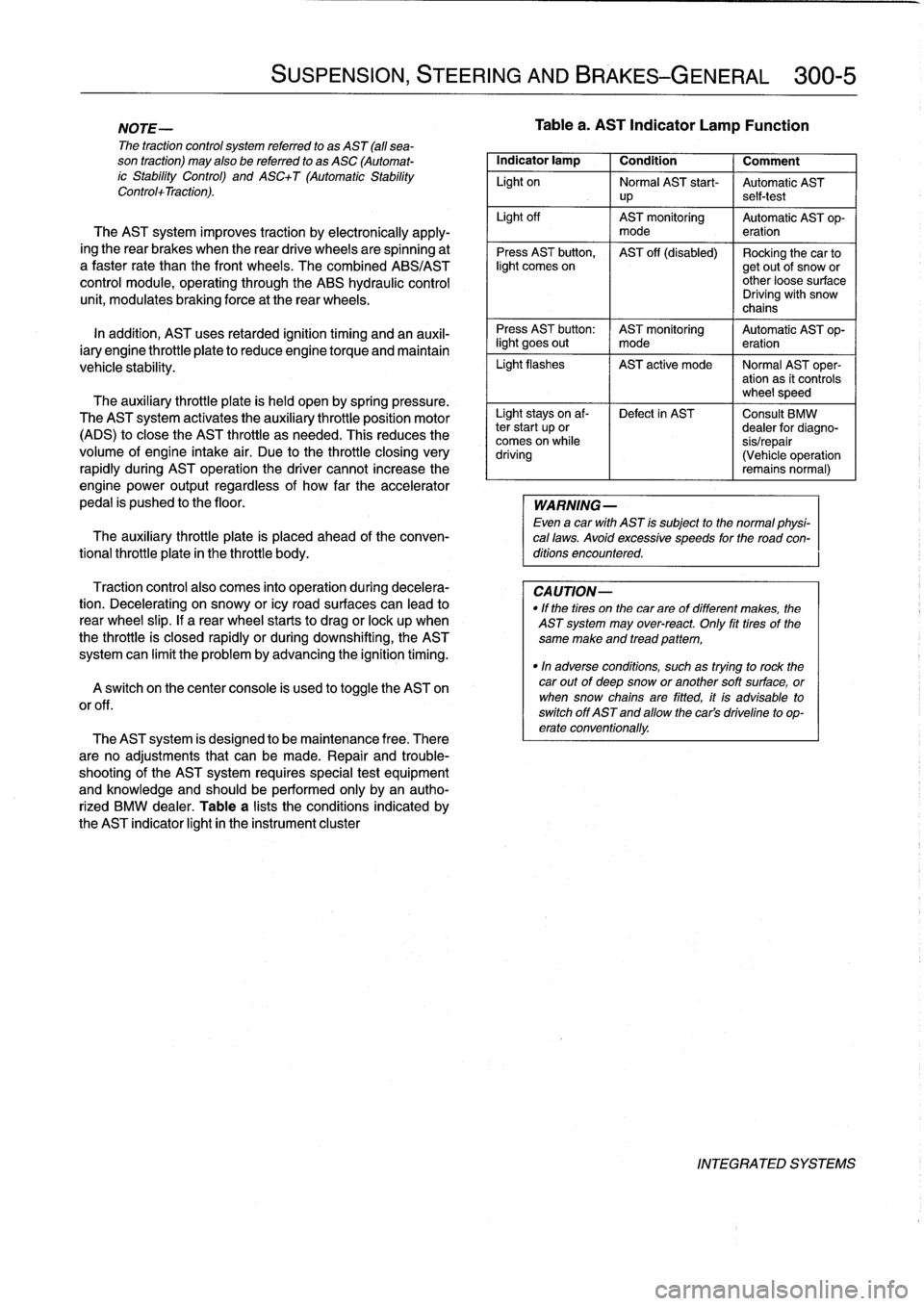

Table

a

lists

theconditions

indicated

by

the

AST

indicator

light

in

the

instrument

cluster

SUSPENSION,

STEERING

AND

BRAKES-GENERAL

300-5

Tablea

.

AST

Indicator

Lamp

Function

Indicator

lamp

1

Condition

1

Comment

Light

on

Normal

AST

start-

Automatic

AST

up

self-test

Light

off

AST

monitoring

Automatic

AST

op-

mode

eration

Press

AST

button,

AST

off

(disabled)

Rocking

the

car

tolight

comes

on

getout

of

snow

or

other

loose

surface

Driving

with

snow

chains

Press

AST

button

:

AST

monitoring

Automatic

AST

op-

light

goes

out

I

mode

eration

Light

flashes

AST

active

mode

I

Normal

AST

oper-

ation

as

it

controls

wheel

speed

Light

stays

on

af-

Defect

in

AST

Consult

BMW

ter

start

up

or

dealer

for

diagno-

comes

on

while

sis/repair

driving

(Vehicle

operation

remains

normal)

WARNING

-

Even

a

car

with

AST

is

subject

to

the

normal

physi-

cal

laws

.

Avoid

excessive

speeds

for

the

road

con-

ditions

encountered

.

CAUTION-

"

If

the

tires

on

the

carare

of

different

makes,

the

AST

system

may

over-react

.

Only

fit

tires

of

the

same

make

and

tread

pattem,

"In

adverse

conditions,

such

as

trying

to

rock

the

car

outof

deep

snow

or

another

soft

surface,

or

when

snow

chainsare

fitted,

it

is

advisable

to

switch

off

AST

and

allow

the

cars

driveline

to

op-

erate

conventionally

.

INTEGRATED

SYSTEMS

Page 293 of 759

When

bleeding

the

brakes,

startat

the

wheel

farthest

from

4

.

Close

bleeder

screw

and

release

brake

pedal

.

Refill

the

master

cylinder

and

progress

in

the

following

order

:

brake

fluid

reservoir

and

proceed

to

rear

left

wheel

.

"

right

rear

brake

5

.

Proceed

with

the

remaining

wheels

using

the

order

list-

"

left

rear

brake

ed

earlier

.

"

rightfront

brake

"

left

front

brake

Pressure

bleeding

brakes

(except

carswith

AST)

1

.

Top

off

brake

fluid

in

reservoir

and

connect

pressure

bleeder

to

reservoir

.

Connect

bleeder

hose

and

bottle

to

right

rearcaliper

bleeder

screw

.

Pressurize

system

to

approximately

1

bar

(14

.5

psi)

.

BRAKES

340-

3

Tightening

Torques

"

Bleeder

screws

:

7

mm

screw

..........

..

.

.

.

.

......

5

Nm

(4

ft-Ib)

9

mm

screw

..........

..

.

..

.......

6

Nm

(5

ft-Ib)

BRAKE

PADS,

CALIPERS,

AND

ROTORS

CAUTION-

TheE36

front

brake

caliper

is

shown

in

Fig

.

2

.

The

rear

Do

not

exceed

a

pressure

of

2

bar

(29

psi)

when

brake

caliper

is

shown

in

Fig

.

7

.

pressure

bleeding

the

brake

system

.

Excessive

pressure

will

damage

the

brake

fluid

reservoir

.

Brake

pads

canbe

replaced

without

disconnecting

the

brake

fluid

hose

from

the

caliper

or

having

to

bleed

the

brakes

.

2

.

Have

a

helperhold

brake

pedal

down

.

The

rotors

can

be

replaced

without

disassembling

the

wheel

huband

bearing

.

Always

machine

or

replace

rotors

in

parts

.

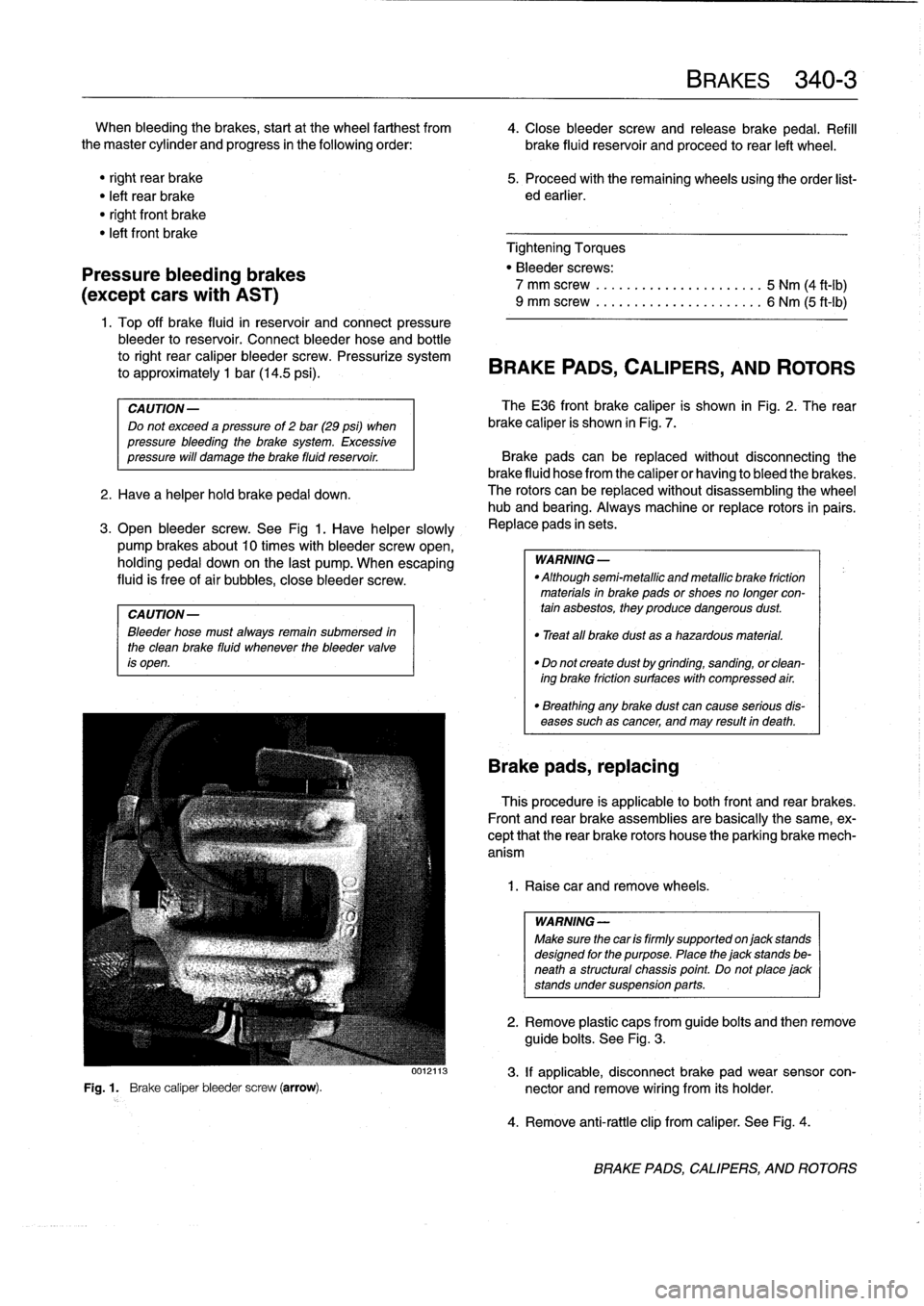

3

.

Open

bleeder

screw

.

See

Fig

1

.

Have

helper

slowly

,

Replace

pads

in

sets

.

pump

brakes

about10

times

with

bleeder

screw

open,

holding

pedal

down

on

the

last

pump

.

When

escaping

WARNING-

fluid

is

free

of

air

bubbles,

close

bleeder

screw

.

"

Althoughsemi-metallicandmetallicbrake

friction

materials

in

brake

pads

or

shoes

no

longer

con

CAUTION-

tain

asbestos,

they

produce

dangerous

dust

.

Bleeder

hose

must

alwaysremain

submersed

in

"

Treat

all

brake

dust

asa

hazardous

material

.

the

clean

brake

fluid

whenever

the

bleeder

valve

is

open

.

"

Do

not

create

dust

by

grinding,

sanding,

orclean-

ing

brake

friction

surfaces

with

compressed

air

.

"

Breathing

any

brake

dust

can

cause

serious

dis-

eases

such

as

cancer,

and

may

result

in

death

.

Brake

pads,

replacing

This

procedure

is

applicable

lo

both

front

and

rear

brakes

.

Front

and

rear

brake

assemblies

are

basically

the

same,

ex-

cept

that

the

rear

brake

rotors

house

the

parking

brake

mech-

anism

1

.

Raise

car

andremove

wheels

.

WARNING

-

Make

sure

thecar

is

firmly

supported

onjack

stands

designed

for

the

purpose

.

Place

the

jack

stands

be-

neath

a

structural

chassis

point

.

Do

not

place

jack

stands

undersuspension

parts

.

2

.

Remove

plastic

caps

from

guide

bolts

and

then

remove

guide

bolts

.

See

Fig

.

3

.

0012113

3

.

If

applicable,

disconnect

brake

pad

wear

sensor

con-

Fig

.

1

.

Brake

caliper

bleeder

screw

(arrow)

.

nector

and

remove

wiring

from

its

holder

.

4

.

Remove

anti-rattle

clip

from

caliper

.

See

Fig

.

4

.

BRAKE

PADS,

CALIPERS,

AND

ROTORS