fenders BMW 318i 1992 E36 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1992, Model line: 318i, Model: BMW 318i 1992 E36Pages: 759

Page 3 of 759

General

Data

and

010

FundamentalsfortheDo-lt-YourselfOwner

Maintenance

020

Maintenance

Program

Engine

Transmission

Suspension,

Steering

and

Brakes

4

Body

100

Engine-General

110

Engine

Removal

and

Installation

113

Cylinder

Head

Removal

and

Installation

116

Cylinder

Head

and

Valvetrain

117

Camshaft

Timing

Chain

119

Lubrication

System

200

Transmission-General

210

Clutch

230

Manual

Transmission

510

Exterior

Trim,

Bumpers

520

Seats

Bo

y

Equipment

512

DoorWTdws

540

nr

t

513

InteriorTrim

541

Convertible

Top

515

Central

Locking

and

Anti-Theft

600

Electrical

System-General

620

Instruments

Electrical

S

stem

610

Electrical

Component

Locations

630

Exterior

Lighting

611

Wipers

and

Washers

640

Heating

and

Air

Conditioning

6

612

Switches

and

Electrical

Accessories

650

Radio

Equipment

and

720

SeatBelts

Accessories

721

Airbag

System

(SRS)

Electrical

Wiring

Diagrams

Foreword

.

...

.

.

.

..................

.

.

.

.....

.

............

.

...

.

.

.

.

.

................

.

.

.

.....

.

......

.

................

.

.

.

.....

v

Warnings

and

Cautions

.....

.

...

.

.

.

.

.

..........

.

...

.

.

.

.

.

......

.

.........

.

.

.

...

.

.

.

......

.

.

.

.

.

............

.

.

.

.

.

.

.vii

Index

..............

.

.

.

.....

.

............

.

...

.

.

.

.

.

........

.

...

.

.

.

.

.

.......

.

......

.

...

.

.

.

.

.

.

.

........

.

.

.

..

back

of

book

300

Suspension,

Steering

and

330

RearSuspension

Brakes-General

331

Final

Drive

310

Front

Suspension

340

Brakes

320

Steering

and

Wheel

Alignment

400

Body-General

411

Doors

410

Fenders,

Engine

Hood

412

Trunk

Lid

120

Ignition

System

121

Battery,Starter,

Alternator

130

Fue¡

Injection

160

Fuel

Tank

and

Fuel

Pump

170

Radiator

and

Cooling

System180

Exhaust

System

240

Automatic

Transmission

250

Gearshift

Linkage

260

Driveshaft

Page 15 of 759

Non-returnable

Parts

FUNDAMENTALS

FOR

THEDO-ITYOURSELF

OWNER

010-

7

Many

independent

repair

shops

make

a

point

of

using

genu-

Original

body

paneis

and

other

large

components

are

identi-

ine

BMW

parts,

even

though

they

may

at

times

be

more

expen-

fied

by

a

label

bearing

the

VINand

two

BMW

roundellogos

.

Re-

sive

.

Theyknow

the

value

of

doing

thejob

right

with

the

right

placement

parts

have

a

similar

label,

bearing

one

BMW

roundel

parts

.

Parts

from

other

sources

can

beas

good,

particularly

if

logo

and

the

letters

DOT-R

.

See

Fig

.

6

.

Parts

or

assemblies

manufactured

by

one

of

BMWs

original

equipment

suppliers,

bearing

the

label

arethe

engine,

transmission,

front

and

rear

but

it

is

often

difficult

to

know

.

bumpers,

front

fenders,

rear

quarter

paneis,

hood,

trunk

lid

and

doors

.

These

labels

shouldnot

be

removed

as

they

will

tear

BMW

is

constantly

updating

and

improving

their

cars,

often

apart

.

making

improvements

during

a

given

model

year

.

BMW

may

recommend

a

newer,

improved

part

as

a

replacement,

and

your

authorized

dealer's

parts

department

will

know

about

it

and

provide

it

.

The

BMW

parts

organization

is

best

equipped

to

deal

with

any

BMW

parts

needs

.

Some

parts

cannot

be

returned

for

credit,

even

if

they

arethe

wrong

parts

forthe

car

.

The

best

example

is

electrical

parts,

which

are

almost

universally

considered

non-returnable

be-

,

..

cause

they

are

so

easily

damaged

internally

.

Buy

electrícal

parts

carefully,

and

beas

sure

as

possible

that

P-

DOT~

R

a

replacement

is

needed,

especially

for

expensive

parts

such

as

electronic

control

units

.

It

may

bewise

to

let

an

authorized

B328FUN

BMW

dealeror

other

qualified

shop

confirm

your

diagnosisbe-

fore

replacing

an

expensive

part

that

cannot

be

retuned

.

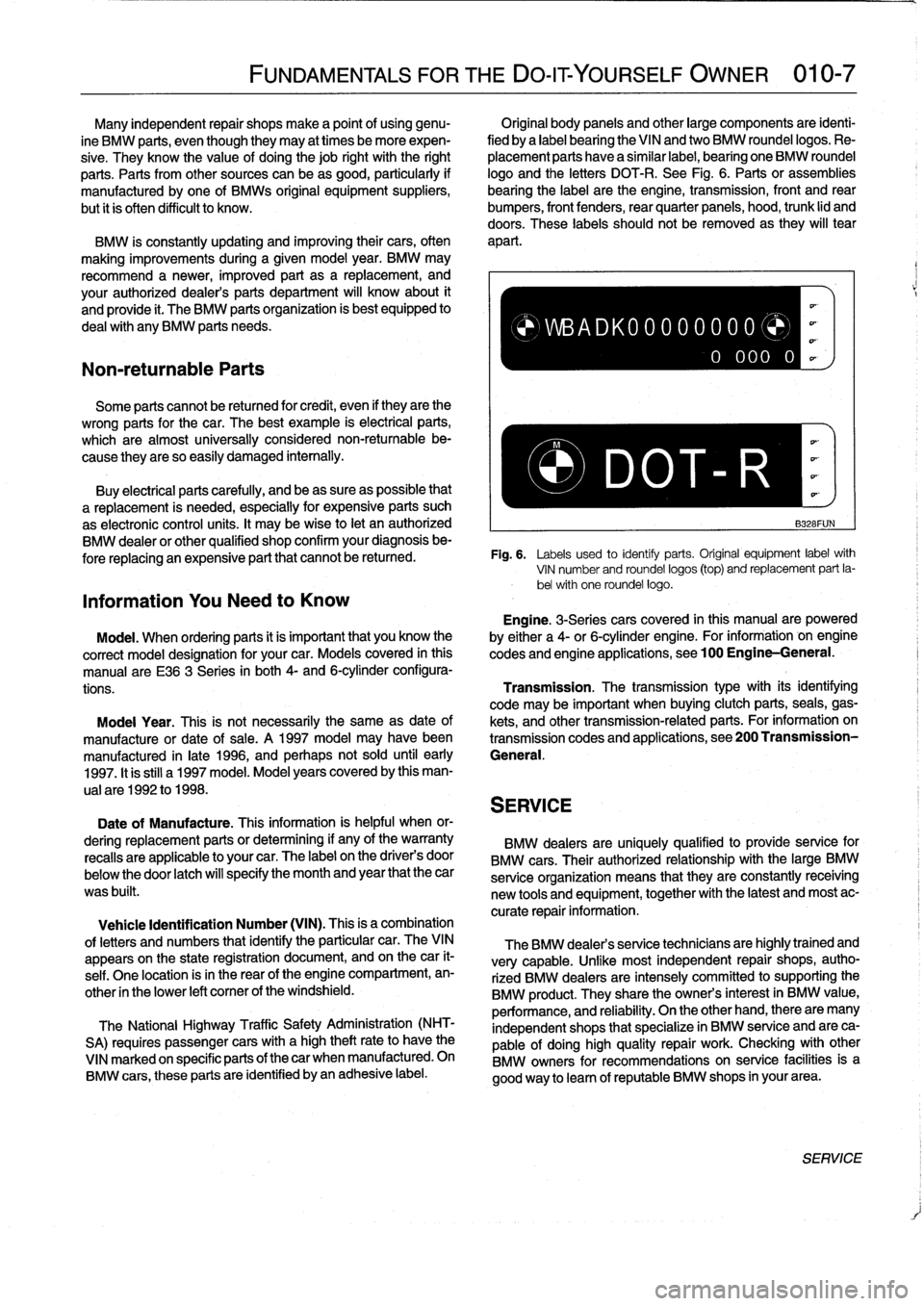

Fig

.

6

.

Labels

used

to

identiy

parts

.

Original

equipment

labelwith

VIN

number

and

roundel

logos

(top)

and

replacement

part

la-

bel

with

one

roundel

logos

Information

You

Need

to

Know

Engine

.

3-Seriescars

covered

in

this

manualare

powered

Model

.

When

ordering

parts

it

is

important

that

you

know

the

by

either

a

4-or

6-cylinder

engine

.

For

information

-

on

engine

correct

model

designation

for

your

car

.

Models

covered

in

this

codes

and

engine

applications,

see100

Engine-General

.

manual

are

E36

3

Series

in

both

4-

and

6-cylinderconfigura-

tions

.

Transmission

.

The

transmissiontype

with

its

identifying

code

may

be

important

when

buying

clutch

parts,

seals,

gas

Moda¡

Year

.

This

is

not

necessarily

the

same

as

date

of

kets,

and

othertransmission-relatedparts

.

For

information

on

manufacture

or

date

of

sale

.

A

1997

model

may

havebeen

transmission

codes

and

applications,

see200

Transmission

manufactured

in

late

1996,

and

perhaps

not

sold

until

early

General

.

1997

.

It

is

still

a1997

model

.

Model

years

covered

by

this

man-

ual

are

1992

to

1998

.

SERVICE

Date

of

Manufacture

.

This

information

is

helpful

when

or-

dering

replacement

parts

or

determining

if

any

of

the

warranty

BMW

dealers

are

uniquely

qualified

to

provide

service

for

recalls

are

applicable

to

your

car

.

The

label

on

the

driver's

door

BMW

cars

.

Their

authorized

relationship

with

the

large

BMW

below

the

door

latch

will

specify

the

month

and

year

that

the

car

serviceorganization

means

that

they

are

constantly

receiving

was

built

.

new

tools

and

equipment,

together

with

the

latest

and

most

ac-

curate

repair

information

.

Vehicle

Identification

Number

(VIN)

.

This

is

a

combination

of

letters

and

numbers

that

identify

the

particular

car

.

TheVIN

appears

on

the

state

registration

document,

and

on

thecar

it-

self

.

One

location

isin

the

rear

of

the

engine

compartment,

en-

other

in

the

lower

left

comer

of

the

windshield

.

The

National

Highway

Traffic

Safety

Administration

(NHT-

SA)

requires

passenger

cars

with

a

high

theftrateto

have

the

VINmarked

on

specific

parts

of

thecar

when

manufactured

.

On

BMW

cars,

these

parts

are

identified

byan

adhesive

label

.

)WBADK00000000

0

000

0

The

BMW

dealers

service

technicians

are

highlytrained

and

very

capable

.

Unfke

most

independent

repair

shops,

autho-

rized

BMW

dealers

are

intensely

committed

tosupporting

the

BMW

product

.

They

share

the

owners

interest

in

BMW

value,

performance,

and

reliability

.

On

the

other

hand,

there

are

many

independent

shops

that

specialize

in

BMW

service

and

are

ca-

pable

of

doing

high

quality

repair

work

.

Checking

with

other

BMW

owners

for

recommendations

on

service

facilitiesis

a

good

way

to

leam

of

reputable

BMW

shops

in

yourarea

.

SERVICE

Page 59 of 759

110

Engine

Removal

and

Installation

GENERAL

.

.

.

.

.......

.

.

.

..........

.

...

110-1

Engine,

removing

and

installing

(4-cylinder

engines)

.

..

.....

..

...........

110-1

ENGINE

REMOVAL

AND

INSTALLATION

110-1

Engine,

removing

and

installing

(6-cylinder

engines)

..

...

...

..

.....

..

....

110-4

GENERAL

Some

special

tools

are

required

for

removal

and

installation

of

the

engine

.

Be

sure

to

have

the

necessary

equipment

on

hand

before

starting

thejob

.

CAUTION-

"

Engine

removal

requires

disconnecting

the

bat-

tery

.

This

may

erase

any

system

fault

code(s)

that

havebeen

stored

in

control

unit

memories

.

Check

forfault

codes

prior

to

disconnecting

the

battery

cables

.

"

If

the

Check

Engine

lightis

illuminated

with

the

engine

running,

see

100

Engine-General

for

On-Board

Diagnostics

(08D)

fault

code

infor-

mation

.

"

If

any

other

system

faults

have

been

detected,

as

indicated

by

an

illuminated

ANTI

LOCK,

SRS

or

AST

warning

light,

see

the

appropriate

repair

group

inthis

manual

or

an

authorized

BMW

dealer

for

more

information

on

fault

codes

.

ENGINE

REMOVALAND

INSTALLATION

Engine,

removing

and

installing

(4-cylinder

engines)

Cover

al¡

painted

surfaces

before

beginning

theremoval

procedure

.

Asan

aid

to

installation,

label

al¡

components,

wires,

and

hoses

before

removing

them

.

Do

not

reuse

gas-

kets,

O-rings

or

seals

during

reassembly

.

WARNING

-

Due

to

risk

of

personal

injury,

be

sure

the

engine

is

cold

before

beginning

the

removalprocedure

.

1.

Disconnect

negative

(-)

cable

from

battery

in

luggage

compartment

.

0011969

CAUTION-

Prior

to

disconnecting

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

viii

.

ENGINE

REMOVAL

AND

INSTALLATION

110-1

2

.

Remove

transmission

from

car

.

See230

Manual

Transmission

or

240

Automatic

Transmission

.

3

.

Remove

enginehood

or

place

hood

in

service

positíon

.

See

410

Fenders,

Engine

Hood

.

NOTE-

tt

is

notnecessary

to

remove

the

engine

hood,

but

it

is

helpful

and

will

make

engine

removal

and

installation

easier

.

4

.

Remove

splash

guard

under

engine,

if

applicable

.

5

.

Unbolt

ignition

coil

assembly

from

bracket

on

strut

tow-er

.

Disconnect

wiring

to

ignition

cofs,

then

place

coil

assembly

on

engine

.

6

.

Disconnect

al¡

cables

and

harness

connectors

at

throt-

tle

housing

.

7

.

Unbolt

andremove

complete

air

cleaner

housing

with

mass

air

flow

sensor,

disconnecting

and

labeling

con-

nectors,

ducting

and

hoses

asnecessary

.

See

Fig

.

1

.

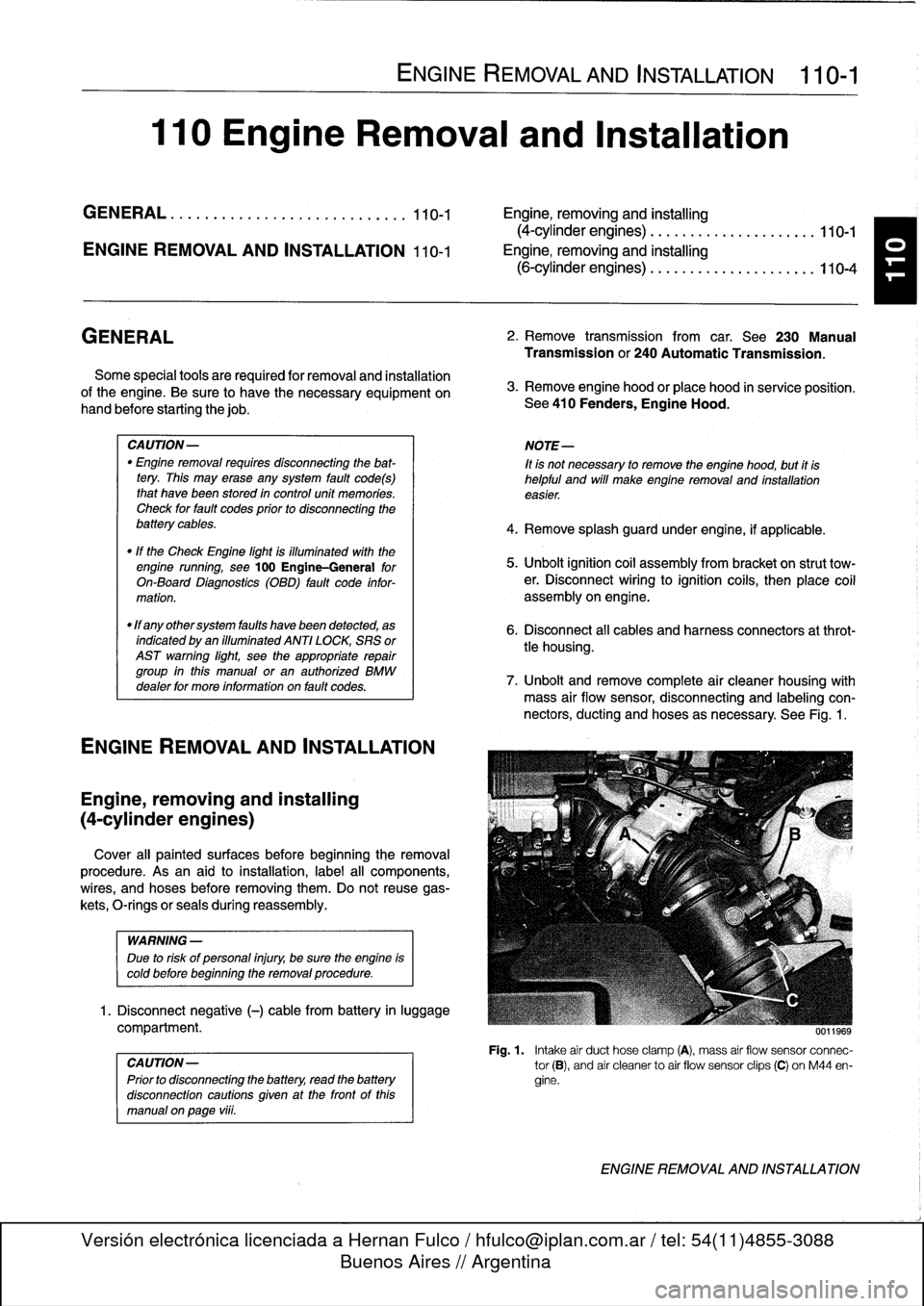

Fig

.

1

.

Intake

air

duct

hose

clamp

(A),

mass

air

flow

sensor

connec-

tor

(B),

and

air

cleanerto

air

flow

sensor

clips

(C)

on

M44

en-

gine

.

ENGINE

REMOVAL

AND

INSTALLATION

Page 62 of 759

110-

4

ENGINE

REMOVAL

AND

INSTALLATION

Engine,

removing

and

installing

(6-cylinder

engines)

Engineremoval

procedures

for

the

various

6-cylinder

en-

gines

arecovered

in

this

section

.

Most

steps

in

theproce-

dures

are

similar

or

the

same

for

al¡

engines

.

Specific

differences

that

apply

are

noted

at

the

beginning

of

each

step

.

Be

sure

to

cover

all

painted

surfaces

before

beginning

the

removal

procedure

.

As

an

aid

to

installation,

label

all

compo-

nents,wires,

and

hoses

before

removing

them

.

Do

not

reuse

gaskets,

O-rings

or

seals

during

reassembly

.

WARNING

-

Due

to

risk

of

personal

injury,

be

sure

the

engine

is

cold

before

beginning

the

removalprocedure

.

1

.

Disconnect

negative

(-)

battery

cable

in

luggage

com-

partment

.

CAUTION-

Prior

to

disconnecting

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manual

onpage

vi¡¡

.

2

.

Remove

engine

hood

or

place

hood

in

service

position

.

See410

Fenders,

Engine

Hood

.

NOTE-

1t

is

not

necessary

to

remove

the

engine

hood,

but

it

is

helpful

and

will

make

engine

removal

and

installation

easier

.

3

.

Remove

splash

guardunder

engine,

if

applicable

.

4

.

Remove

transmission

from

car

.

See

230

Manual

Transmission

or

240Automatic

Transmission

.

5

.

Remove

vacuum

hosefrom

brake

booster

on

bulkhead

.

Cover

hole

in

booster

and

plug

hose

end

.

6

.

Remove

intake

air

plenum

panel

in

rear

of

engine

com-

partment

.

See

640

Heating

and

AirConditioning

.

7

.

Remove

ground

strap

from

timing

case

cover,

if

appli-

cable

.

8

.

Remove

top

enginecovers

and

disconnect

ignition

coil

harness

connectors

.

Working

at

fuel

injectors,

pry

open

small

wire

clipsat

each

injector

.

Remove

main

harness

hold-down

nuts

and

lift

completeharness

away

.

See

Fig

.

7

.

ENGINE

REMOVAL

AND

INSTALLATION

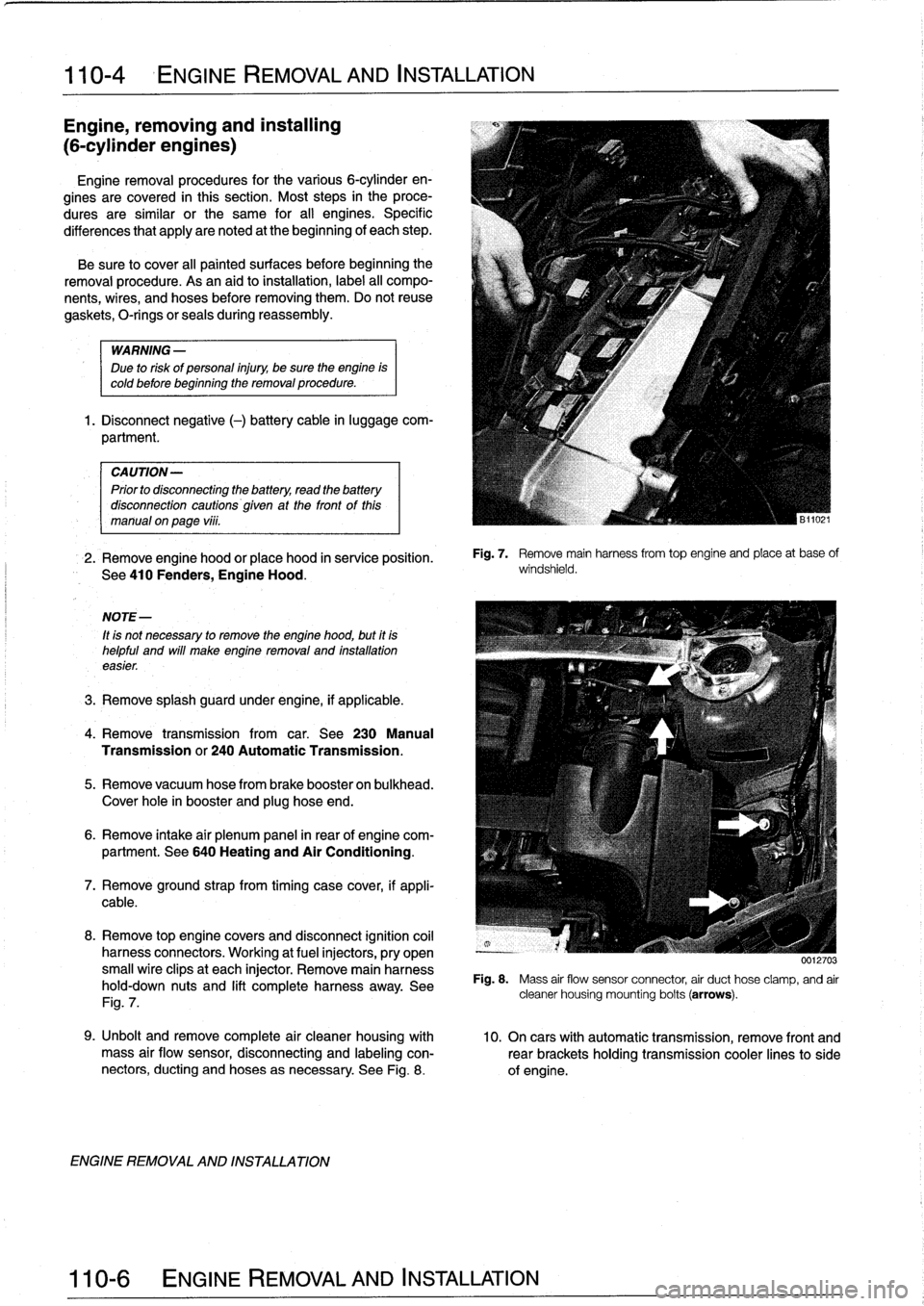

Fig

.

7

.

Remove

mainharnessfrom

top

engine

and

place

at

base

of

windshield

.

0012703

Fig

.

8

.

Mass

air

flow

sensor

connector

air

duct

hose

clamp,

and

air

cleaner

housing

mounting

bolts

(arrows)

.

9

.

Unbolt

andremove

complete

air

cleaner

housing

with

10

.

On

cars

with

automatic

transmission,

remove

front

and

mass

air

flow

sensor,

disconnecting

and

labeling

con-

rearbrackets

holding

transmission

cooler

linesto

side

nectors,

ducting

and

hoses

asnecessary

.

See

Fig

.

8

.

of

engine

.

Page 304 of 759

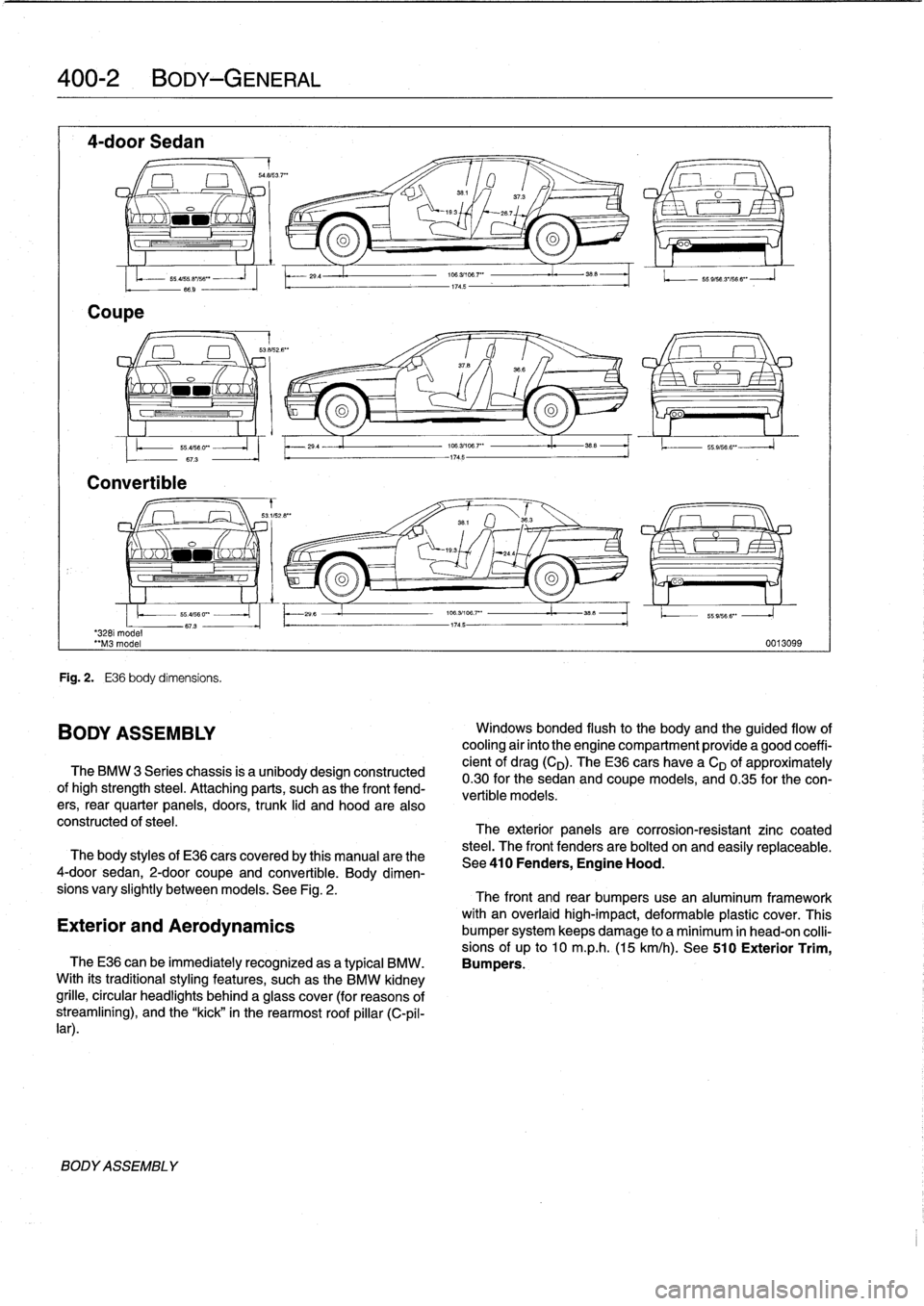

400-2

BODY-GENERAL

4-door

Sedan

Coupe

-

saas3

.7""

351

/

37

.3

O

I

x

`-193

267

o

oa

'3281

model

"M3

model

Convertible

BODYASSEMBLY

55

ass

.e

iss

""

-

66

.9

-

Fig

.

2

.

E36

body

dimensíons

.

BODY

ASSEMBLY

29

.4

29

4

The

BMW

3

Series

chassis

is

a

unibodydesign

constructed

ofhigh

strength

steel

.

Attaching

parts,

suchas

the

front

fend-

ers,

rear

quarter

panels,

doors,

trunk

lid

and

hood

are

also

constructed

of

steel

.

706

.31108

.7"

I

38

.5

174

.5

174

.5

O

oo

196

.3/106

.7'

"

35_5

1.

.

55

.9,566

".

106

.3/196

.7""

i.

358

-1745-

55

9/56

3'/56

6"

-

J

0013099

Windows

bonded

flush

to

the

body

and

the

guided

flow

of

cooling

air

into

the

engine

compartment

provide

a

good

coeffi-

cient

of

drag(CD)

.

TheE36

cars

have

a

CD

of

approximately

0

.30for

the

sedan

and

coupe

models,

and

0

.35

for

the

con-

vertible

models

:

The

exterior

panels

are

corrosion-resistant

zinc

coated

steel

.

The

front

fenders

are

bolted

on

and

easily

replaceabie

.

The

body

styles

of

E36

cars

coveredby

this

manual

arethe

See410

Fenders,

Engine

Hood

.

4-door

sedan,

2-door

coupe

and

convertible

.

Body

dimen-

sions

vary

slightly

betweenmodels

.

See

Fig

.

2

.

The

front

and

rear

bumpers

use

an

aluminum

framework

with

an

overlaid

high-impact,

deformable

plastic

cover

.

This

Exterior

and

Aerodynamics

bumper

system

keeps

damage

to

a

minimum

in

head-on

colli-

sions

of

up

to

10

m

.p

.h

.

(15

km/h)

.

See

510

Exterior

Trim,

TheE36

can

be

immediatelyrecognized

asa

typical

BMW

.

Bumpers

.

With

its

traditionalstyling

features,

suchas

the

BMW

kidney

grille,

circular

headlights

behind

a

glass

cover

(for

reasons

of

streamliníng),

and

the

"kick"

in

the

rearmost

roof

pillar

(C-pil-

lar)

.

Page 309 of 759

GENERAL

This

repair

group

covers

replacement

of

the

front

fenders

and

removal

and

installation

of

the

engine

hood

.

NOTE-

The

body

is

painted

at

the

factoryafter

assembly

.

Re-

alignment

of

body

panels

may

expose

unpainted

metal

.

Paint

all

exposed

metal

once

the

work

fs

complete

.

FRONT

FENDERS

Front

fender,

removing

and

installing

1

.

Raise

hood

.

Raise

and

safely

support

front

of

vehicle

.

WARNING

-

"

When

raising

thecar

using

a

floor

jack

or

a

hy-

draulic

lift,

carefully

position

the

jack

pad

to

pre-

vent

damaging

thecar

body

.

A

suitable

liner

(wood,

rubber,

etc

.)

should

be

placed

between

the

jack

and

the

car

to

prevent

body

damage

.

"

Watch

the

jack

closely

.

Make

sure

it

stays

stable

and

does

not

shift

or

tilt

.

As

the

car

is

raised,

the

car

may

roll

slightly

and

the

jack

may

shift

.

2

.

Remove

front

wheel

.

Remove

inner

plastic

liner

from

wheel

well

.

3

.

Remove

front

bumper

.

See510

Exterior

Trim,

Bumpers

.

4

.

Working

atfront

corner

of

fender,

remove

front

grille

panel

bolts

(2

bolts

at

left

and

right)

.

See

Fig

.

1

.

FENDERS,

ENGINE

HOOD

410-1

410

Fenders,

Engine

Hood

GENERAL

...............

.

.

.

.

.

.

.

.

.

.

.

..

410-1

ENGINE

HOOD

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

...

.

.410-3

Hood,

raising

to

service

position

.

.

.

.

.

.

.

.

...

410-3

FRONTFENDERS

........

.

.

.

.

.

.

.

.

.

.

.

.

.410-1

Hood,

removin

and

installin

410-3

Front

Pender,

removing

and

installing

.

.

.

....

410-1

Hood,

aligning

...

.

.

.

.

.

.

.

.....

.

.

.

.

.

.

.

...

410-4

Hood

release

cable

and

latches,

adjusting

...

410-4

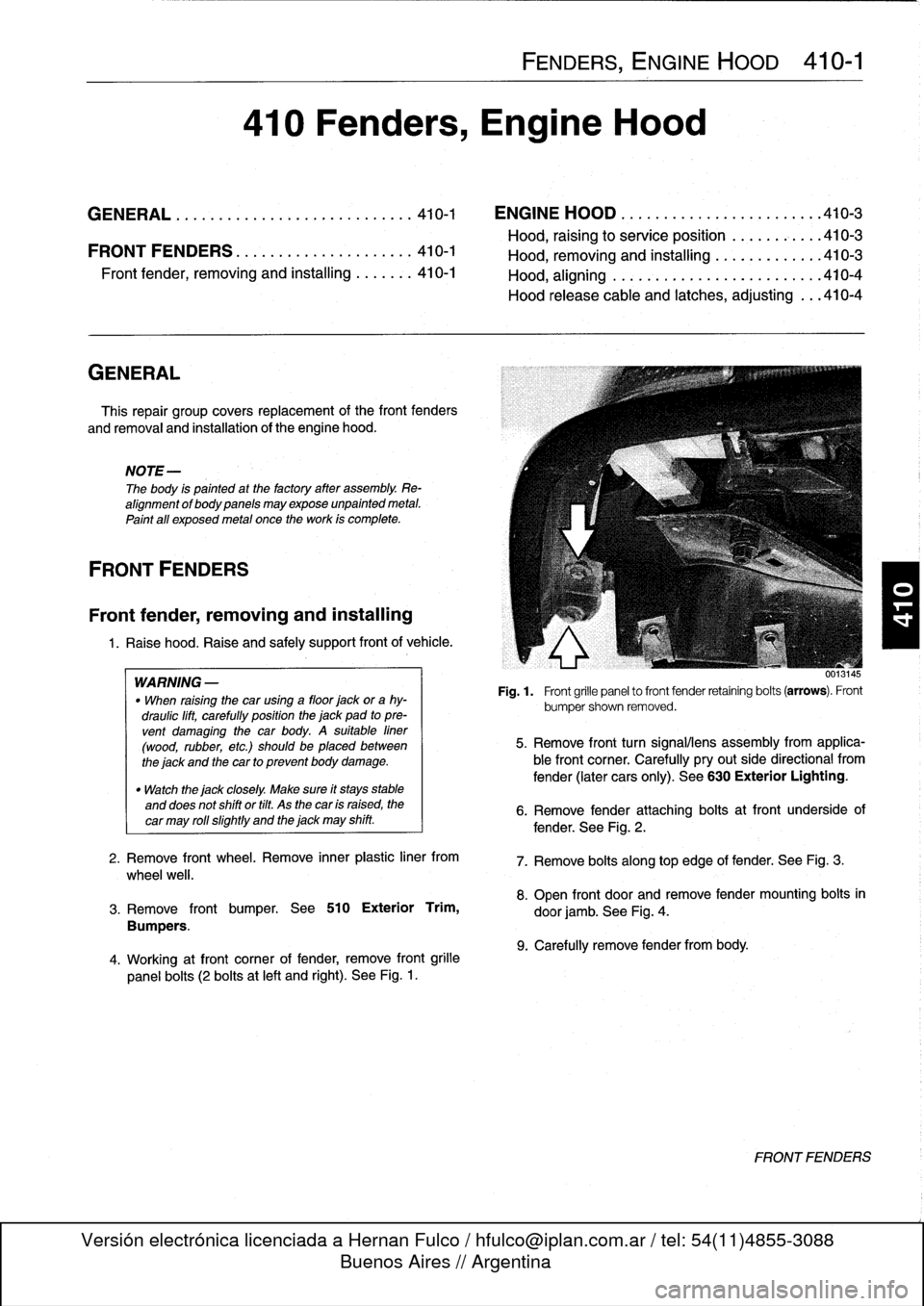

001

.145

Fig

.

1

.

Front

grille

panel

to

front

fender

retaining

bolts

(arrows)

.

Front

bumpershown

removed

.

5

.

Remove

front

turn

signalliens

assembly

from

applica-

ble

front

corner

.

Carefully

pryout

side

directional

from

fender

(later

cars

only)

.

See

630

Exterior

Lighting

.

6

.

Remove

fender

attaching

bolts

atfront

underside

of

fender

.

See

Fig

.

2

.

7

.

Remove

bolts

along

top

edge

of

fender

:

See

Fig

.

3

.

8

.

Open

front

door

and

remove

fender

mounting

bolts

in

door

jamb

.

See

Fig

.

4

.

9

.

Carefully

remove

fender

from

body

.

FRONTFENDERS

Page 310 of 759

410-2

FENDERS,

ENGINE

HOOD

Fig

.

2

.

Fender

attaching

bolts,

lower

front

(arrows)

.

Fig

.

3

.

Loosen

bolt

A

at

top

offender

.

Remove

bolts

B

.

FRONTFENDERS

0013104

0013105

0013106

Fig

.

4

.

Front

fender

attaching

bolts

as

viewed

through

doorjamb

(ar-

rows)

.

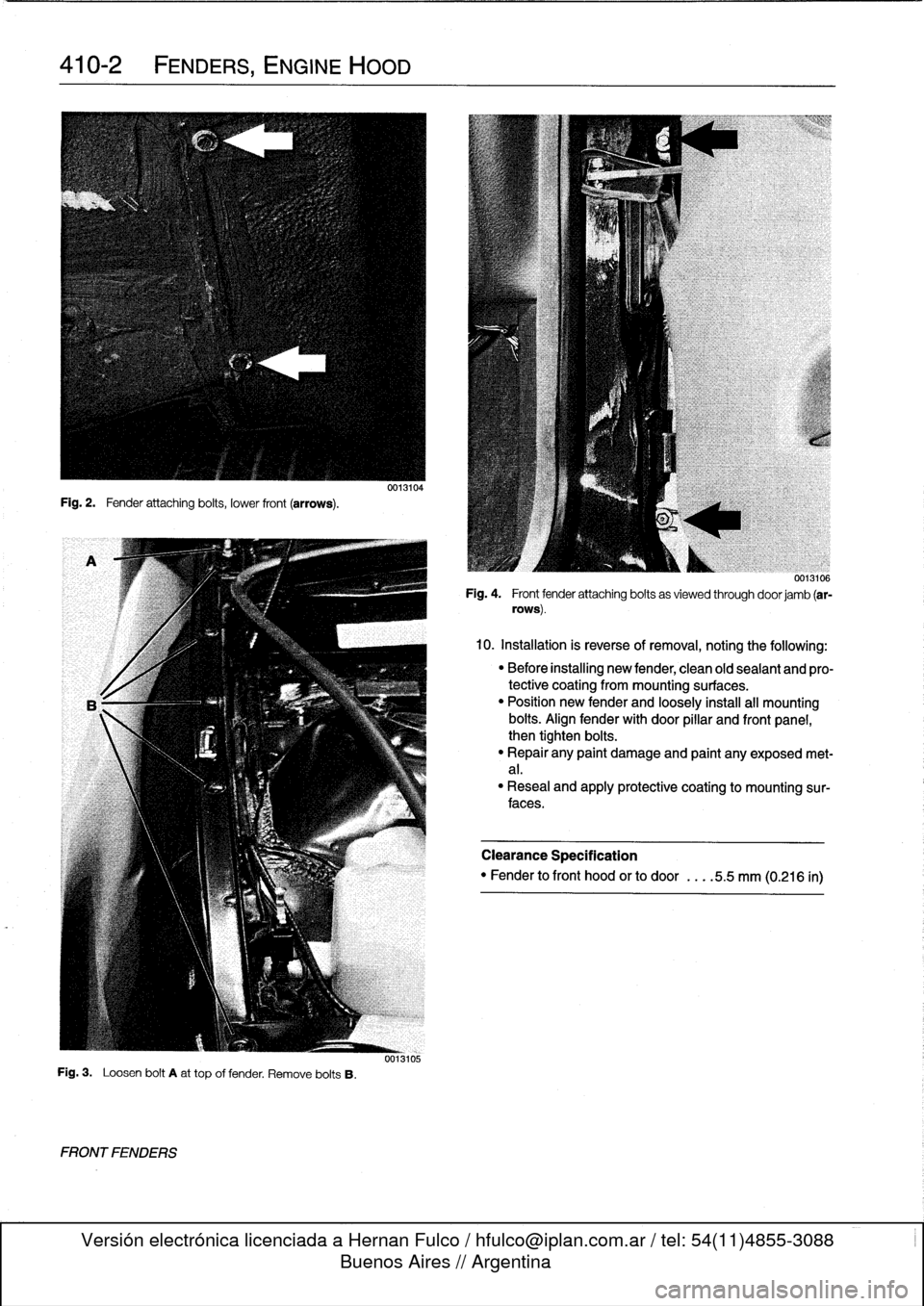

10

.

Installation

is

reverse

of

removal,

noting

the

following

:

"

Before

installing

new

fender,

clean

old

sealant

and

pro-

tective

coating

from

mounting

surfaces

.

"

Position

new

fender

and

loosely

install

all

mounting

bous

.

Align

fender

with

door

pillar

and

front

panel,

then

tighten

bolts

.

"

Repair

any

paint

damage

and

paint

any

exposed

met-

al

.

"

Reseal

and

apply

protective

coating

to

mounting

sur-

faces

.

Clearance

Specification

"

Fender

to

front

hood

or

to

door

.

...

5

.5

mm

(0

.216

ín)

Page 311 of 759

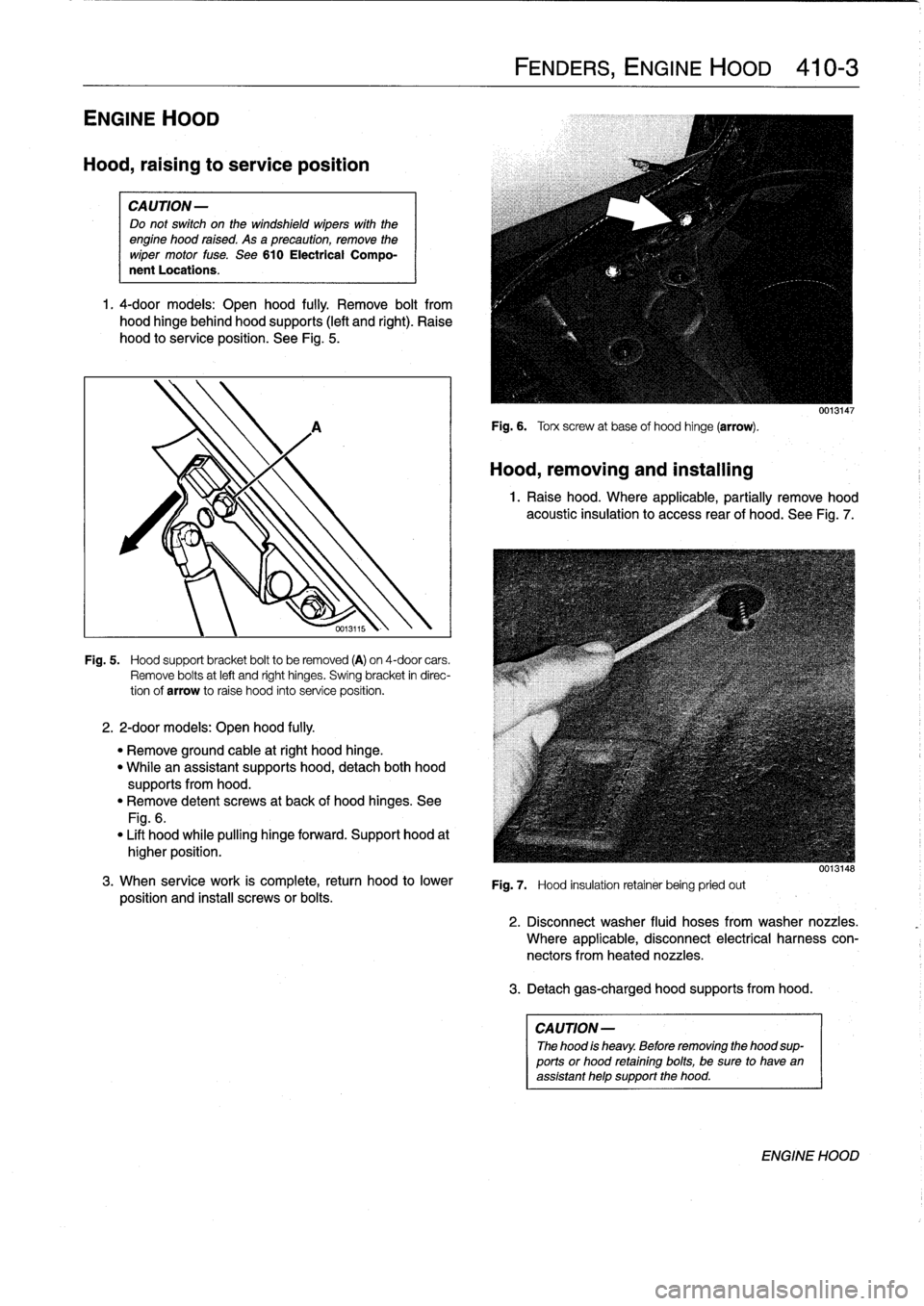

ENGINE

HOOD

Hood,

raising

to

service

position

CA

UTION-

Do

not

switch

on

the

windshield

wipers

wlth

the

engine

hood

raised

.

As

a

precaution,

remove

the

wiper

motor

fuse

.

See

610

Electrical

Compo-

nent

Locations

.

1

.

4-door

models

:

Open

hood

fully

.

Remove

bolt

from

hood

hinge

behind

hood

supports

(left

and

right)

.

Raise

hood

to

service

position

.

See

Fig

.

5

.

2

.

2-door

models

:

Open

hood

fully

.

Fig

.

5

.

Hood

support

bracket

boltto

be

removed

(A)

on

4-door

cars

.

Remove

bolts

at

left

and

right

hinges

.

Swing

bracket

in

direc-

tion

of

arrow

to

raise

hood

into

service

position

.

"

Remove

ground

cable

atright

hood

hinge

.

"

Whilean

assistant

supports

hood,

detach

both

hood

supportsfrom

hood

.

"

Remove

detent

screws

at

back

of

hood

hinges

.

See

Fig

.

6

.

"

Lift

hood

while

pulling

hinge

forward

.

Support

hood

at

higher

position

.

3

.

When

service

work

is

complete,

return

hood

to

lower

position

and

instaf

screws

or

bolts

.

FENDERS,

ENGINE

HOOD

410-

3

Fig

.

6

.

Torx

screw

at

base

of

hood

hinge

(arrow)

.

Hood,

removing

and

installing

0013147

1

.

Raise

hood

.

Where

applicable,

partially

remove

hood

acoustic

insulation

to

access

rear

of

hood

.

See

Fig

.

7

.

Fig

.

7

.

Hood

insulation

retainer

being

pried

out

3

.

Detachgas-charged

hood

supportsfrom

hood

.

CAUTION

-

The

hood

is

heavy

.

Before

removing

the

hood

sup-

ports

or

hood

retainingbolts,

be

sure

to

have

an

assistant

help

support

the

hood

.

0013148

2

.

Disconnect

washer

fluid

hoses

from

washer

nozzles

.

Where

applicable,

disconnect

electrical

harness

con-

nectors

fromheated

nozzles

.

ENGINE

HOOD

Page 312 of 759

410-4

FENDERS,

ENGINE

HOOD

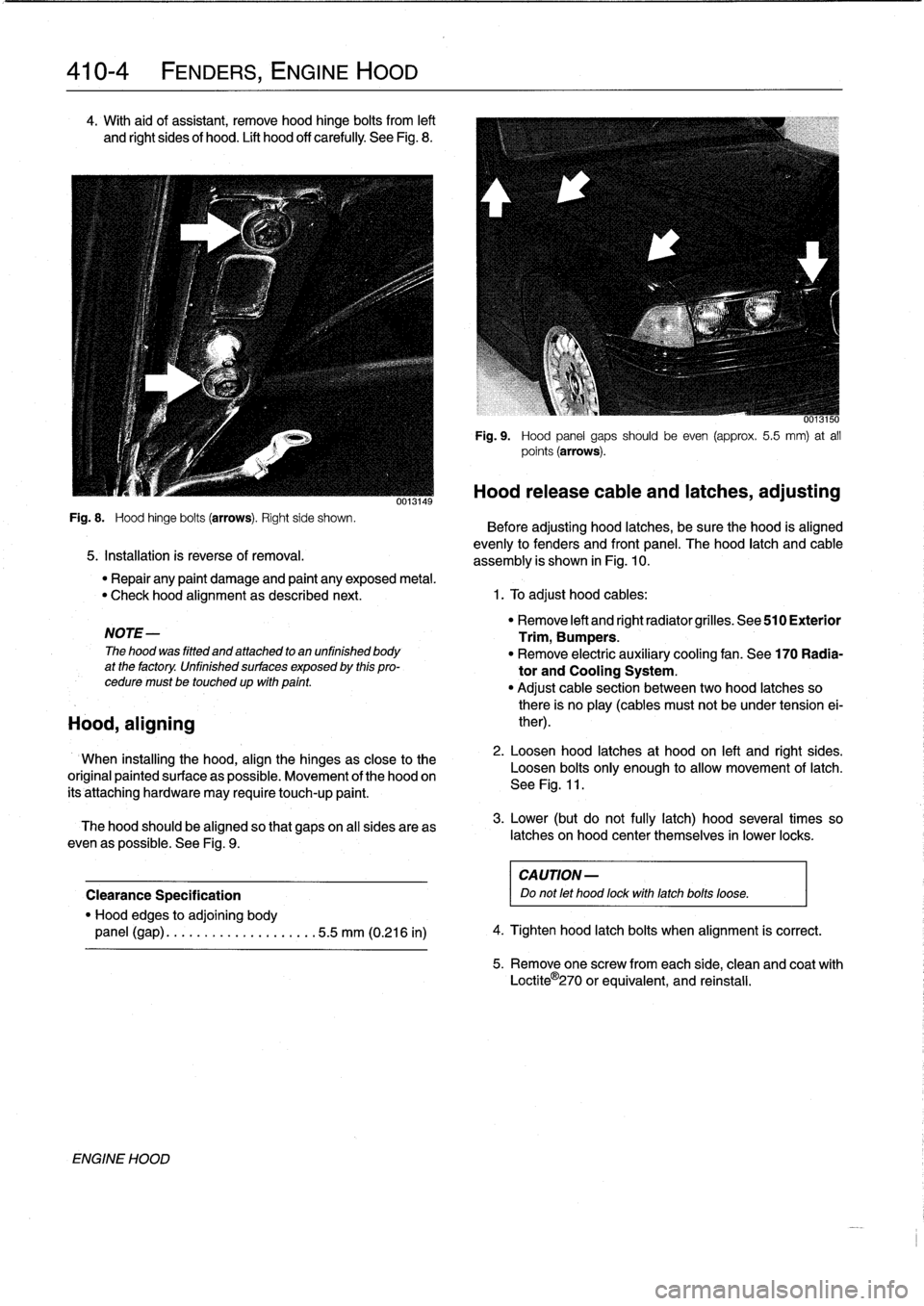

4

.

With

aid

of

assistant,

remove

hood

hinge

bolts

from

left

and

Rght

sides

of

hood

.

Lift

hood

off

carefully

See

Fig

.

8

.

Fig

.

8

.

Hood

hinge

bolts

(arrows)

.

Right

side

shown

.

5

.

Installation

is

reverse

of

removal

.

NOTE-

The

hood

was

fitted

and

attached

to

an

unfinished

body

at

the

factory

.

Unfinished

surfaces

exposed

by

this

pro-

cedure

must

betouchedup

wfth

pafnt

.

Hood,

aligning

ENGINE

HOOD

0013149

6013150

Fig

.

9

.

Hood

panel

gaps

should

be

even

(approx

.

5

.5

mm)

at

all

points

(arrows)

.

Hood

release

cable

and

latches,

adjusting

Before

adjusting

hood

latches,

be

sure

the

hood

is

aligned

evenly

to

fenders

and

front

panel

.

The

hood

latch

and

cable

assembly

is

shown

in

Fig

.

10

.

"

Repair

any

paint

damage

and

paint

any

exposed

metal

.

"

Check

hood

alignment

as

described

next

.

1

.

To

adjust

hood

cables

:

When

installing

the

hood,

align

the

hinges

as

close

to

the

original

paintedsurface

as

possible

.

Movement

of

the

hood

on

its'attaching

hardware

may

require

touch-up

paint

.

The

hood

should

be

aligned

so

that

gapson

all

sides

areas

even

as

possible

.

See

Fig

.

9

.

Clearance

Specification

"

Hood

edges

to

adjoining

body

panel

(gap)

........

..

..

..

.....

.5

.5

mm

(0.216

in)

"

Remove

left

and

right

radiator

grilles

.

See

510

Exterior

Trim,

Bumpers

.

"

Remove

electric

auxíliary

cooling

fan

.

See

170

Radia-

tor

and

Cooling

System

.

"

Adjust

cable

section

between

two

hood

latches

so

there

is

no

play

(cables

must

not

be

under

tension

ei-

ther)

.

2

.

Loosen

hood

latches

at

hood

on

left

and

right

sides

.

Loosen

bolts

only

enough

to

allow

movement

of

latch

.

See

Fig

.

11

.

3

.

Lower

(but

do

not

fully

latch)

hood

severa¡

times

so

latches

on

hood

center

themselves

in

lower

locks

.

CA

UTION-

Do

not

let

hood

fockwith

latchbolts

loose

.

4

.

Tighten

hood

latch

bolts

when

alignment

is

correct

.

5

.

Remove

one

screw

fromeach

side,

clean

and

coat

with

Loctite

O

270

or

equivalent,

and

reinstall

.

Page 313 of 759

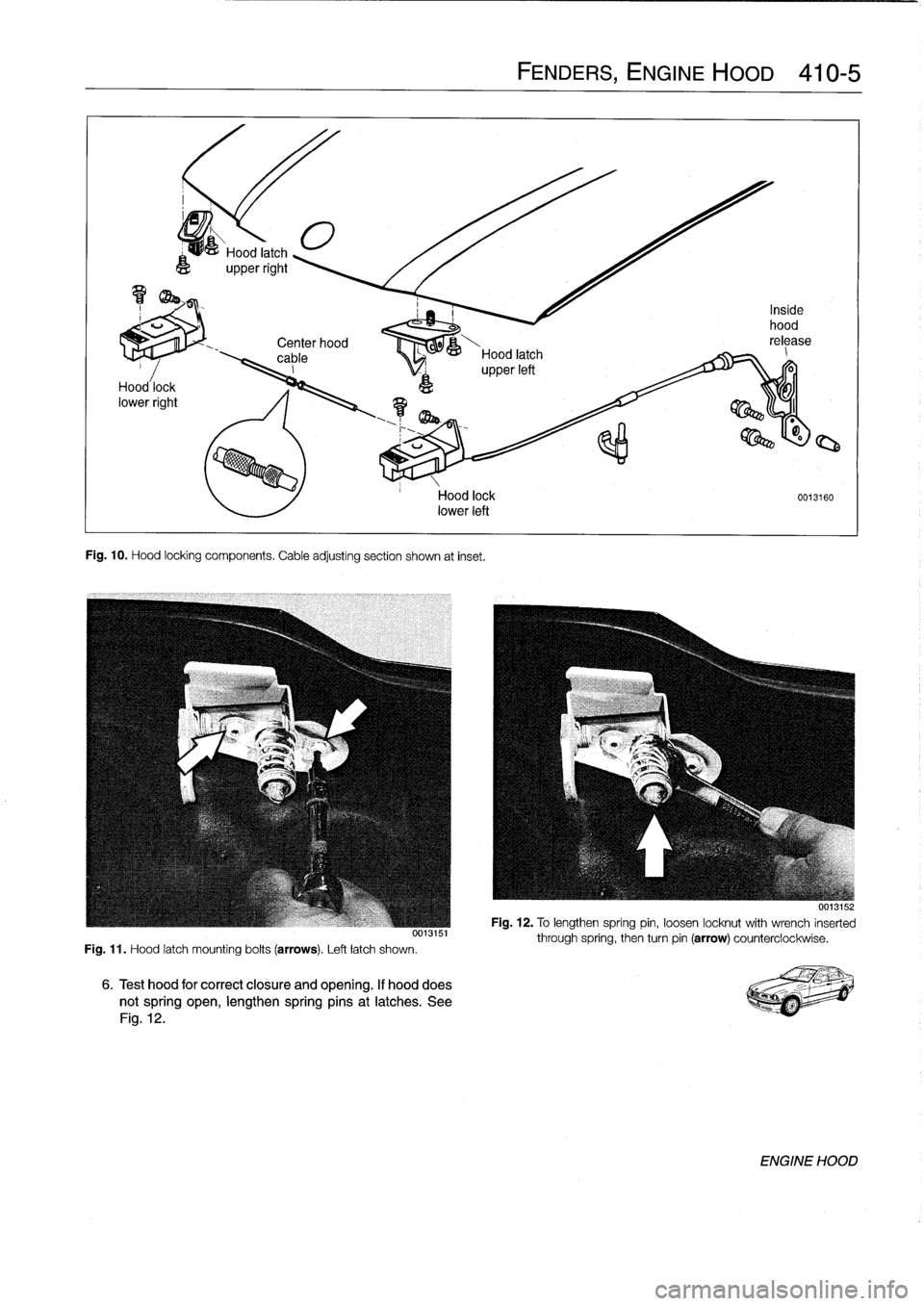

Center

hood

,

00--&---

cable

Hood

latch

_

I

upperleft

Fig

.

10

.

Hood

locking

components

.

Cable

adjusting

section

shown

at

inset

.

Fig

.

11

.

Hood

latch

mounting

bolts

(arrows)

.

Left

latch

shown

.

Hood

lock

0013160

lower

left

6

.

Test

hood

for

correct

closure

and

opening

.

If

hooddoes

notspring

open,

lengthen

springpins

at

latches

.

See

Fig

.

12

.

FENDERS,

ENGINE

HOOD

410-5

001aio

Fig

.

12

.

To

lengthen

spring

pin,

loosen

locknut

with

wrench

inserted

through

spring,

then

turn

pin

(arrow)

counterclockwise

.

ENGINE

HOOD